Page 1

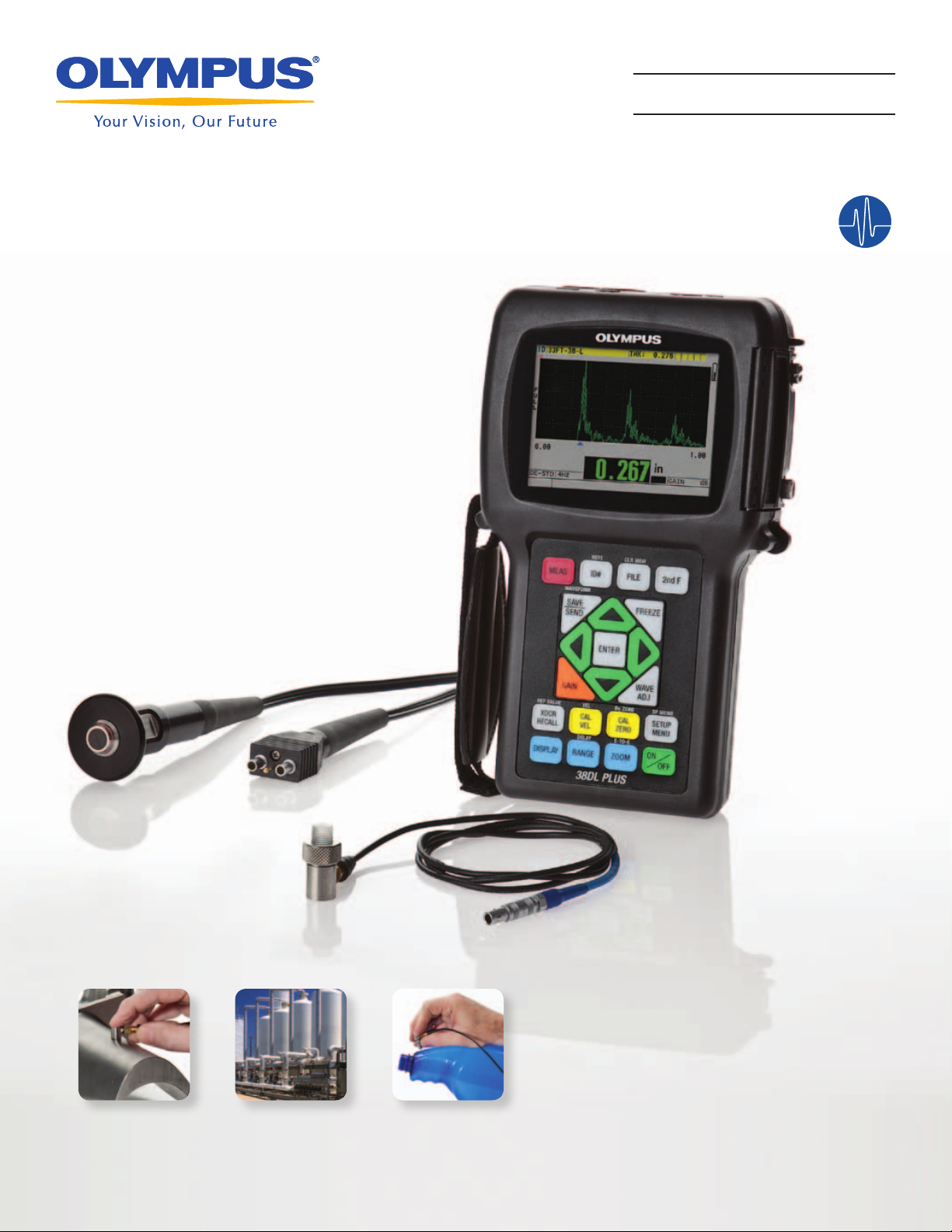

ULTRASONIC THICKNESS GAGE

38DL PLUS

• Dual and Single Element

Transducers

• Rugged, designed for IP67

• Thickness range from 0.08 mm

(0.003 in.) to 635 mm (25 in.)

• Color Transflective VGA Display

920-212C-EN

Page 2

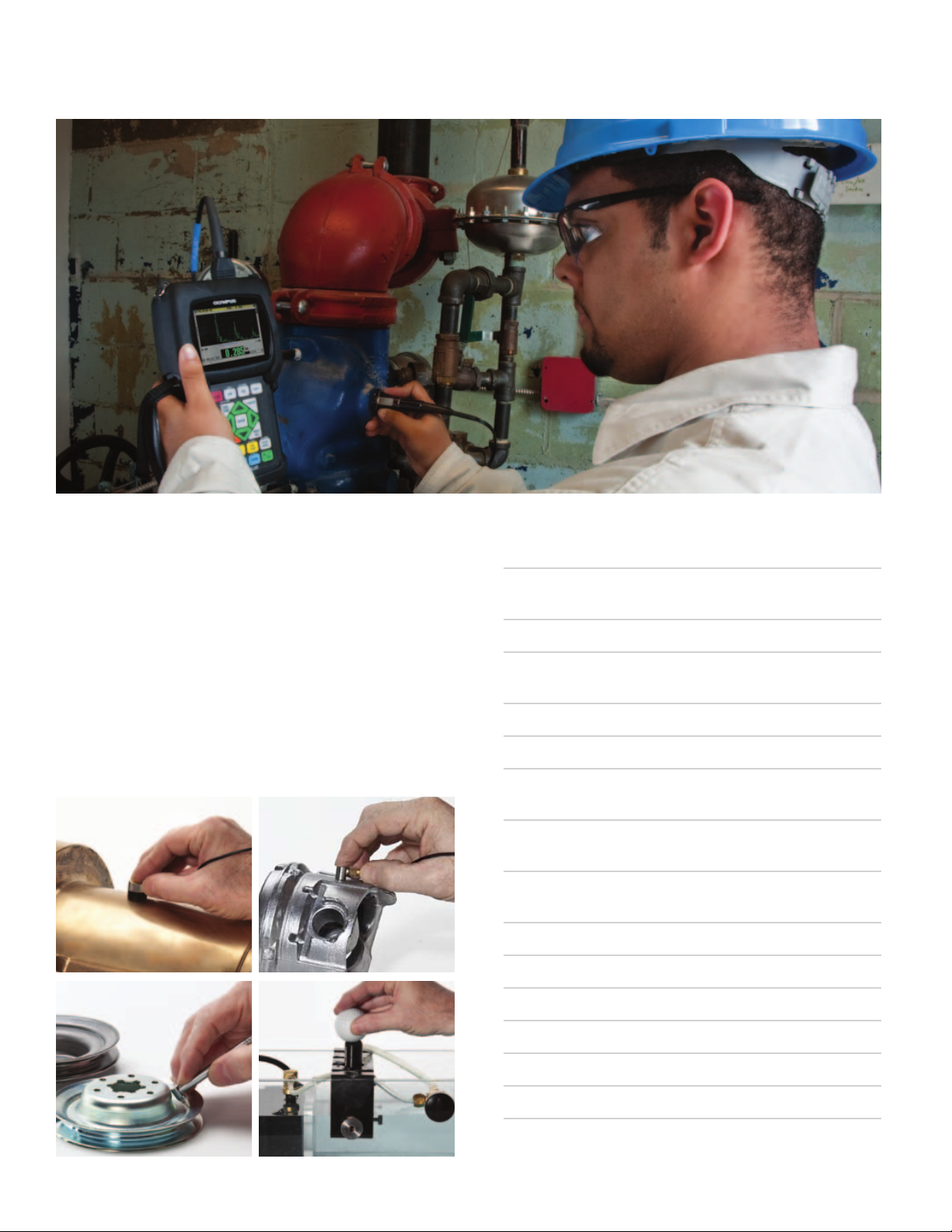

38DL PLUS Ultrasonic Thickness Gage:

Advanced Features, Simple Operation, Rugged, Reliable

The 38DL PLUS is an innovative instrument that signals a new era

in ultrasonic thickness gaging. Ideally suited for almost every ultrasonic thickness application, this handheld thickness gage is fully

compatible with a full line of dual and single element transducers.

The versatile 38DL PLUS can be used in applications ranging from

wall thinning measurements of internally corroded pipes with dual

element probes to very precise thickness measurements of thin or

multilayer materials with single element transducers.

The 38DL PLUS comes standard with many powerful but easyto-use measurement features and a host of application-specific

software options. Its sealed case is designed to meet IP67 requirements to withstand the rigors of very wet or dusty environments.

The color transflective VGA display provides superior readability

from bright sunlight to complete darkness. It features a simple,

ergonomic keypad that can be operated with the left or right hand

for easy access to all functions.

Key Features

■■ Dual■and■single■element■transducer■compatibility

■■ Wide■thickness■range:■0.08■mm■(0.003■in.)■to■635■mm■(25■in.)■

depending■on■material■and■transducer■selection

■■ Corrosion■thickness■gaging■with■dual■element■transducers

■■ THRU-COAT®■and■Echo-to-Echo■measurements■on■painted■and■

coated■surfaces

■■ Internal■Oxide/Scale■software■option

■■ Standard■resolution■of■0.01■mm■or■0.001■in.■for■all■transducers

■■ High■Resolution■software■option■of■0.001■mm■or■0.0001■in.■with■

single■element■transducers■2.25■MHz■to■30■MHz

■■ Multilayer■software■option■for■measurements■of■up■to■four■layers■■

simultaneously

■■ High■Penetration■software■option■for■attenuating■materials■such■as■■

fiberglass,■rubber■and■thick■casting

■■ Thickness,■Velocity,■and■time-of-flight■measurements

Ultrasonic thickness measurements are accurate, reliable, and repeatable. Instant readings can

be achieved from one side of a material, making it unnecessary to cut up or destroy the part.

2

■■ Differential■mode■and■Reduction■Rate■mode

■■ Time-based■B-scan■mode;■10,000■reviewable■readings■per■scan

■■ Olympus■High■Dynamic■Gain■technology■with■digital■filters

■■ V-Path■Builder■for■custom■V-path■compensation

■■ Designed■for■EN15317

www.olympus-ims.com

Page 3

What Makes This Thickness Gage Different From Others?

The 38DL PLUS is designed to meet the challenges of demanding

applications and built to withstand tough conditions in the field

and on the production floor. Whether you work in very wet or

dusty conditions, cold or hot climates, or bright or dark areas, the

38DL PLUS can handle any inspection job. Need an instrument

tough enough to tolerate shocks, drops, and rough handling?

The 38DL PLUS with its protective rubber boot and designed for

IP67 rating is your answer.

Built for Tough Environments

• Compact, weighs only 0.814 kg (1.80 lb)

• Rugged, designed for IP67

• Explosive Atmosphere: Safe operation as defined by Class I,

Division 2, Group D, as found in the National Fire Protection

Association Code (NFPA 70), Article 500, and tested using

MIL-STD-810F, Method 511.4, Procedure I.

• Shock tested using MIL-STD-810F, Method 516.5, Procedure I,

6 cycles each axis, 15 g, 11 msec Half sine.

• Vibration tested using MIL-STD-810F, Method 514.5, Procedure I,

Annex C, Figure 6, general exposure: 1 hour each axis.

• Wide operating temperature range

• Protective rubber boot with gage stand

• Color transflective VGA display with indoor and outdoor color

settings for superior clarity

Designed for Easy Operation

• Simple keypad for right hand/left hand operation

• Easy operator interface with direct access to all functions

• Internal and External MicroSD memory card storage

• USB and RS-232 communication ports

• Alphanumeric data logger with 475,000 thickness readings

or 20,000 waveforms

• VGA output to connect to computer or monitor

• Default/Custom dual element transducer setups

• Default/Custom single element transducer setups

• Password protected function allows locking of instrument

features

Outdoor display setting, A-scan mode

Indoor display setting, B-scan mode

38DL PLUS with standard protective rubber boot

3

Page 4

Thickness Measurements on Internally Corroded Metals

• Automatic Probe Recognition for

standard D79X series dual element

transducers

• Ten custom dual element transducer

setups

• Optimized default gain during

calibration for dual element transducer

• V-Path Builder for custom V-path

compensation

• Calibration Doubling when echo

doubling may occur during calibration

• THRU-COAT® and Echo-to-Echo

measurements on painted and coated

surfaces

• High temperature measurements; up to

500 °C (932 °F)

• Boiler tube and Internal Oxide

measurements (optional) with M2017

or M2091 single element transducers

• EMAT transducer (E110-SB) for

no-couplant measurements of boiler

tubes with external oxide/scale buildup

One of the major applications of the 38DL PLUS is measuring the remaining thickness of

pipes, tubes, tanks, pressure vessels, hulls, and other structures affected by corrosion or

erosion. Dual element transducers are most commonly used for these applications.

Thru-Coat

®

Technology

uses a single back-wall

echo to measure true

metal thickness. You

can display the metal

and coating thicknesses,

each adjusted for their

correct material sound

velocities. There is no

need to remove paint

and coatings from

surfaces. THRU-COAT

measurements use the D7906-SM,

D7906-RM, and D7908 dual element

transducers.

®

Temperature

Compensation

variations in material temperature affect

sound velocity and

accuracy of thickness

measurements. The

temperature compensation feature allows you

to manually enter the

calibration block’s temperature and the current

(high) temperature at

the measurement points. The 38DL PLUS

automatically displays the temperaturecorrected thickness.

Optional Oxide/

Scale Measurement

uses advanced algorithms to measure the

thickness of oxide/

scale buildups inside

boiler tubes. The gage

simultaneously displays

the metal thickness of

the boiler tube and the

thickness of the oxide

layer. Knowing the

thickness of the oxide/

scale helps predict tube life. We recommend using M2017 or M2091 transducers

in this application.

4

www.olympus-ims.com

Page 5

V-Path Builder

This new and patented feature allows you to build a custom

V-Path compensation curve for almost any dual element transducer. These curves can be saved and recalled along with custom

setups for most dual element transducers. You simply calibrate

and enter the known thickness with a minimum of 3 and up to

10 calibration points, and the instrument will create the V-path.

Automatic Probe Recognition

All standard dual element transducers (see chart below) feature

Automatic Probe Recognition, which automatically recalls a

default V-path correction for each specific transducer.

Dual Element Transducers with Automatic Probe Recognition for Corrosion Gaging Applications

Transducer

D790 U8450002

D790-SM U8450009 Straight LCMD-316-5B† U8800353

D790-RL U8450007 90° LCLD-316-5G† U8800330

D790-SL U8450008 Straight LCLD-316-5H U8800331

D791 U8450010 5.0 90°

D791-RM U8450011 5.0 90°

D792 U8450012

D793 U8450013 90° Potted —

D794 U8450014

D795 U8450015 90° Potted

D797 U8450016

D797-SM U8450017 Straight LCMD-316-5D U8800355

D7226 U8454013

D798-LF U8450019

D798 U8450018

D798-SM U8450020 Straight LCMD-316-5J U8800357

D799 U8450021 5.0 90°

MTD705 U8620225 5.0 90°

D7906-SM

D7906-RM

D7908

††

††

††

Item

Number

U8450005

U8450025 90° LCMD-316-5N U8800647

U8450006 7.5 90°

Freq.

(MHz)

5.0

10

5.0

2.0

7.5 90°

7.5

5.0

Connector

Straight

Straight

Straight

90°

90°

Straight

Tip Dia.

mm (in.)

11.00

(0.434)

11.00

(0.434)

11.00

(0.434)

7.20

(0.283)

7.20

(0.283)

22.90

(0.900)

8.90

(0.350)

7.20

(0.283)

11.00

(0.434)

5.10

(0.200)

11.00

(0.434)

7.20

(0.283)

Range (Steel)*

mm (in.)

1.00 to 500.00

(0.040 to 20.000)

1.00 to 500.00

(0.040 to 20.000)

1.00 to 500.00

(0.040 to 20.000)

0.50 to 25.00

(0.020 to 1.000)

0.75 to 50.00

(0.030 to 2.000)

3.80 to 635.00

(0.150 to 25.000)

0.71 to 100.00

(0.028 to 4.000)

0.71 to 100.00

(0.028 to 4.000)

1.00 to 500.00

(0.040 to 20.000)

1.00 to 19.00

(0.040 to 0.750)

1.00 to 50.00

(0.040 to 2.000)

1.00 to 37.00

(0.040 to 1.500)

Temp. Range**

°C (°F)

–20 to 500

(–5 to 932)

–20 to 500

(–5 to 932)

–20 to 400

(–5 to 752)

0 to 50

(32 to 122)

0 to 50

(32 to 122)

–20 to 400

(–5 to 752)

–20 to 150

(–5 to 300)

–20 to 150

(–5 to 300)

–20 to 150

(–5 to 300)

0 to 50

(32 to 122)

0 to 50

(32 to 122)

0 to 50

(32 to 122)

Cable

Potted —

Potted —

LCMD-316-5C U8800354

Potted

Potted

Potted —

Potted —

Potted —

Potted —

LCLPD-78-5 U8800332

LCMD-316-5L U8800358

Potted —

Item

Number

—

—

—

Single Element Transducers for Corrosion Gaging Applications

For a complete list of single element transducers, please consult your local representative or consult our web site www.olympus-ims.com.

Transducer

V260-SM U8411019

V260-RM U8411018 90° LCM-74-4 U8800348

V260-45 U8411017 45° LCM-74-4 U8800348

M2017 U8415002 20 90°

M2091 U8415018 20 90°

E110-SB U8471001 — Straight

* Dependent on material, transducer type, surface conditions, and temperature. Full range may require Gain Adjust.

** Maximum temperature with intermittent contact only

†

Stainless steel cable available; consult Olympus NDT for details.

††

Transducers used with THRU-COAT® technology

Item

Number

Freq.

(MHz)

15

Connector

Straight

Tip Dia.

mm (in.)

2.00

(0.080)

6.35

(0.250)

6.35

(0.250)

28.50

(1.250)

Range (Steel)*

mm (in.)

0.50 to 10.00

(0.020 to 0.400)

Steel 0.50 to 12.00

(0.020 to 0.500)

Oxide 0.25 to 1.25

(0.010 to 0.050)

Steel 0.50 to 12.00

(0.020 to 0.500)

Oxide 0.15 to 1.25

(0.006 to 0.050)

2.00 to 125.00

(0.080 to 5.000)

Temp. Range**

°C (°F)

0 to 50

(32 to 122)

0 to 50

(32 to 122)

0 to 50

(32 to 122)

0 to 80

(32 to 176)

Cable

LCM-74-4 U8800348

LCM-74-4 U8800348

LCM-74-4 U8800348

LCB-74-4 and

1/2XA/E110

Item

Number

U8800320

U8767104

5

Page 6

Thickness Measurements on Plastics, Metals, Composites,

Glass, Rubber, Ceramics

When using single element transducers, you can make accurate

thickness measurements on metals, plastics, composites, glass,

ceramics, and other materials. These transducers are available in

a wide range of frequencies, diameters, and connector styles. The

High Resolution software option allows you to make very precise

measurements at a resolution of 0.0001 in. or 0.001 mm.

• Standard resolution of 0.01 mm (0.001 in.) for all transducers

• High Resolution software option can display measurements up

to 0.001 mm (0.0001 in.) for single element transducers from

2.25 MHz to 30 MHz

• High Penetration software option for measurements on

attenuating materials such as fiberglass, rubber, and thick

castings

• Multilayer software option for individual thickness

measurements of up to four layers simultaneously

• Thickness, Velocity, or time-of-flight measurements

• Application Auto-Recall with default and custom setups to

simplify thickness measurements

High Penetration Software Option

This option allows you to use low frequency single element transducers (as low as 0.5 MHz) to measure thick or sound attenuating

materials such as rubber, fiberglass, castings, and composites.

Measure the thickness of many materials including plastic, metal, rubber, glass, ceramic,

and composites.

Multilayer Software Option

This software option calculates and simultaneously displays thickness measurements of up to four individual layers. It also displays

total thickness of selected layers. Typical applications include

thickness of barrier layers in plastic fuel tanks, bottle preforms,

and soft contact lenses.

Outer

Surface

HDPE

Layer

0.1658 in.

EVOH

Barrier

0.0044 in.

Inside

Surface

0.0781 in.

HDPE

Layer

Total

Thickness

0.2483 in.

Many cast metal parts or sound-attenuating materials can be measured with the

High Penetration software option.

The 38DL PLUS can make accurate measurements of up to four individual layers

simultaneously.

6

The High Resolution software option allows thickness measurements of up to 0.001 mm

(0.0001 in.) resolution.

www.olympus-ims.com

Page 7

Data Logger and PC Interface

The 38DL PLUS has a full-featured internal bidirectional alphanumeric data logger that is designed to easily collect and transfer

thickness readings and waveform data.

• Internal memory of 475,000 thickness readings or 20,000

waveforms with thickness readings

• 32 Character File name

• 20 Character ID# (TML#)

• 9 file formats:

Incremental, Sequential, Sequential with custom point, 2-D

Grid, 2-D Grid with custom point, 3-D Grid, 3-D custom,

Boiler, and Manual

• The ability to store up to 4 comments (notes) per ID# (TML)

• Stores comments (notes) at an ID# or to a Range of ID#’s

• Internal and External MicroSD memory cards

• File copy with the ability to copy files between Internal/

External MicroSD memory cards

• Standard USB and RS-232 communication

• Two-way transfer of both single and dual element transducer

setups

• Onboard statistical report

• Onboard DB Grid View with three programmable colors

• GageView™ interface program can communicate with the

38DL PLUS using the USB, RS-232 ports, and can read and

write to a MicroSD memory card.

• Direct export of internal files to MicroSD memory card in

Excel compatible CSV (comma-separated values) format

Charger

USB or

RS-232

MicroSD Card

VGA Connectors

USB Connector

Probe Connectors

When viewed on your PC a color coded grid easily flags out-of-tolerance thickness conditions.

Measurement reports

can easily be generated

and printed containing

measurements, ID, and

other parameters.

Onboard DB Grid View with three programmable colors

GageView

™

• The GageView interface program, a Windows-based

application, collects, creates, prints, and manages data from

the 38DL PLUS.

• Creates datasets and surveys

• Stored data editing

• View dataset and survey files; including thickness readings,

gage setup values, and transducer setup values

• Download and upload thickness surveys to and from the gages

• Export surveys to spreadsheets and other programs

• Collecting snapshot screens

• Printing reports such as Thickness, Setup Table, Statistics, and

Color Grid

• Upgrading operating software

• Download and upload single and dual element transducer

setup files

• B-scan review

7

Page 8

38DL PLUS Specifications*

Measurements

Dual element transducer

measurement mode

THRU-COAT® measurement

Thru-Paint Echo-to-Echo

Single element transducer

measurement modes

Thickness range

Material velocity range 0.508 mm/μs to 13.998 mm/μs (0.020 in./μs to 0.551 in./μs)

Resolution (selectable)

Transducer frequency range

Time interval from a precision delay after the excitation pulse to the first echo

Measurement of true metal and coating thicknesses with a single back-wall echo

(with D7906-SM and D7908 transducers)

Time interval between two successive back-wall echoes to eliminate paint or

coating thickness

Mode 1: Time interval between the excitation pulse and the first back-wall echo

Mode 2: Time interval between the delay line echo and the first back-wall echo

(with delay or immersion transducers)

Mode 3: Time interval between successive back-wall echoes following the first

interface echo after the excitation pulse (with delay line or immersion

transducers)

Oxide: optional

Multilayer mode: optional

0.080 mm to 635.00 mm (0.003 in. to 25.000 in.) depending on material,

transducer surface conditions, temperature, and selected configuration

Low: 0.1 mm (0.01 in.)

Standard: 0.01 mm (0.001 in.)

High Resolution (optional): 0.001 mm (0.0001 in.)

Standard: 2.0 MHz to 30 MHz (–3 dB)

High Penetration (optional): 0.50 MHz to 30 MHz (–3 dB)

General

Operating temperature range –10 °C to 50 °C (14 °F to 122 °F)

Keypad Sealed, color-coded keypad with tactile and audible feedback

Case

Dimensions (W x H x D) Overall: 125 mm x 211 mm x 46 mm (4.92 in. x 8.31 in. x 1.82 in.)

Weight 0.814 kg (1.80 lb)

Power supply AC/DC adaptor, 24 V; lithium-ion battery 23.760 Wh; or 4 AA auxiliary batteries

Battery life, lithium-ion

Standards Designed for EN15317

Impact-resistant and water-resistant, gasketed case with sealed connectors.

Designed for IP67.

Operating time: minimum 12.6 h, 14 h typical, 14.7 h maximum

Fast charge: 2 h to 3 h

Display

Color transflective VGA display Liquid crystal display, display area 56.16 mm x 74.88 mm (2.2 in. x 2.95 in.)

Rectification Full wave, RF, half-wave positive, or half-wave negative

Inputs/Outputs

USB 1.0 client

RS-232 Yes

Memory card Maximum capacity: 2 GB External MicroSD memory card

Video output VGA output standard

Internal Data logger

Data logger

Capacity

File names, IDs, and comments

File structures Nine standard or custom application-specific file structures

Reports

The 38DL PLUS identifies, stores, recalls, clears, and transmits thickness

readings, waveform images, and gage configuration information through the

standard RS-232 serial port or USB port.

475,000 thickness measurements or 20,000 waveforms with thickness

measurements

32-character file names and 20-character alphanumeric location codes with four

comments per location

On-gage reporting of summary with statistics, Min./Max. with locations, Min.

review, file comparison, and alarm report

Standard Package

• 38DL PLUS digital ultrasonic thickness

gage, AC or battery operation, 50 Hz to

60Hz

• Kits available with standard dual

element transducers

• Charger/AC adaptor (100 VAC, 115 VAC,

230 VAC)

• Internal data logger

• GageView interface program

• Test block and couplant

• USB cable

• Rubber protective boot with gage stand

and neck strap

• User’s manual

• Two-year limited warranty

• Measurement features: THRU-COAT®,

Thru-Paint Echo-to-Echo, EMAT

compatibility, Min./Max. mode, two

alarm modes, differential mode, B-scan,

Application Auto-Recall, temperature

compensation, Average/Min. mode

Software Options

38DLP-OXIDE (U8147014): Code-activated

Internal Oxide measurement software

38DLP-HR (U8147015): Code-activated High

Resolution measurement software

38DLP-MM (U8147016): Code-activated

Multilayer measurement software

38DLP-HP (U8147017): Code-activated High

Penetration (low frequency) measurement

software

Optional Accessories

38DLP/EW (U8778348): Three-year warranty

1/2XA/E110 (U8767104): Filter adaptor for

E110-SB EMAT transducer

38-9F6 (U8840167): RS-232 cable

38-C-USB-IP67 (U8800998): USB cable for

IP67 sealed operation

38DLP/RFS (U8780288): Foot switch, factory

installed

HPV/C (U8780124): Digital caliper for

thickness input for velocity measurements

38DLP-V-CC (U8840172): Cable for digital

caliper

38DLP/BCW/NC (U8780289): Bar code

reader

EPLTC-C-VGA-6 (U8840035): VGA output

cable

MICROSD-ADP-2GB (U8779307):

2 GB External MicroSD memory card

www.olympus-ims.com

info@olympusNDT.com

48 Woerd Avenue, Waltham, MA 02453, USA, Tel.: (1) 781-419-3900

12569 Gulf Freeway, Houston, TX 77034, USA, Tel.: (1) 281-922-9300

505, boul. du Parc-Technologique, Québec (Québec) G1P 4S9, Tel.: (1) 418-872-1155

1109 78 Ave, Edmonton (Alberta) T6P 1L8

38DL_Plus_EN_201005• Printed in the USA • Copyright © 2010 by Olympus NDT.

*All specifications are subject to change without notice.

All brands are trademarks or registered trademarks of their respective owners and third party entities.

is ISO 9001 certified.

Loading...

Loading...