Page 1

ULTRASONIC PRECISION THICKNESS GAGES

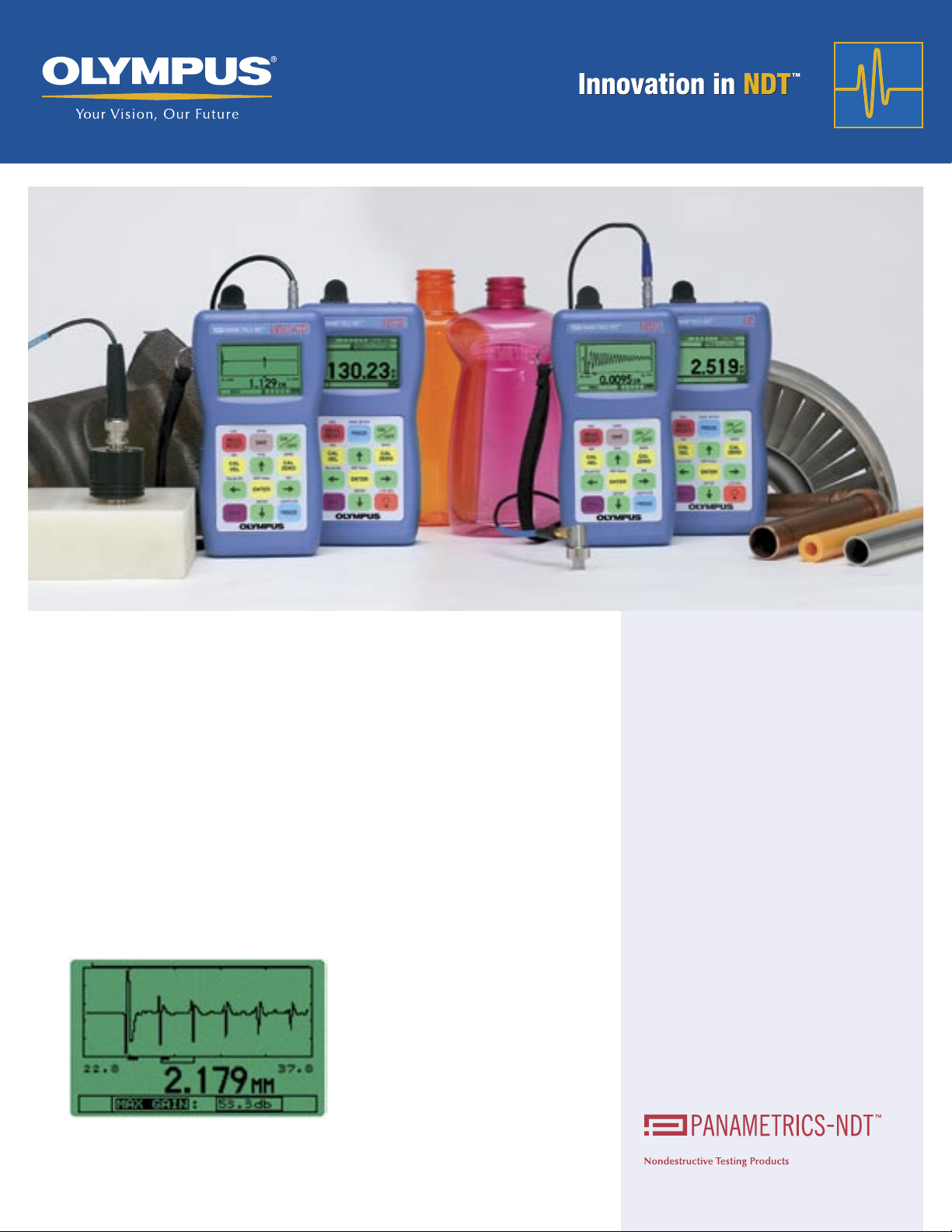

The Panametrics-NDT™ Series 35

ultrasonic precision thickness gages

provide easy-to-use and cost-effective

solutions in applications where the

opposite side of the test material is

difficult or impossible to reach. These

rugged, pocket-sized gages make stable,

repeatable thickness measurements on

most materials of varied shapes and sizes.

Accurate thickness measurements are

displayed in large numerals on the backlit

LCD or can be viewed along with the live

waveform in the optional A-scan Mode.

NEW: LIVE A-SCAN (WAVEFORM)

AND ADJUST MODE

These full-featured gages include many

standard solution-oriented measurement

capabilities: Application Auto-Recall

to select and recall any of the stored

standard or custom transducer setups in

gage memory, Reduction Rate to track

the percentage of wall thinning, and

Velocity or Time of Flight Measurements

to directly measure material sound

velocity, as well as many other practical

measurement features.

35, 35DL, 35HP

& 35DL-HP

Precision Thickness Gages

Four models are available: 35 and 35DL

for measurements on metals, plastics, glass,

and other thin materials; and 35HP and

35DL-HP for sound attenuating materials

such as cast metals, thick rubber, fiberglass,

and composites. The 35DL and 35DL-HP

add a versatile file-based alphanumeric

data logger with incremental, sequential,

and 2-D grid file formats.

Operator can view thickness and waveform with the

optional A-scan mode

920-103

Page 2

To thick materials ...

Measure depth to steel / ply cords in rubber conveyor

belts or tires.

Cylinder bores and many other cast metal parts or

sound-attenuating materials can be measured with

the 35HP gages.

35HP and 35DL-HP

Models 35HP and 35DL-HP are used

in sound-attenuating materials

With a very low ultrasonic frequency bandwidth and a special

pulser-receiver, the HP gages are specifically designed to optimize

ultrasound penetration when measuring thick, highly sound attenuating or sound scattering materials. Typically these materials cannot be

measured with most other ultrasonic thickness gages.

The 35HP gages are excellent tools to measure fiberglass or composite parts, from aerospace structures

to boat hulls and storage tanks that require thickness

control.

applications

- most thick or sound-attenuating

materials

- thick cast metal parts

- thick rubber tires, belts

- fiberglass boat hulls, storage tanks

- composite panels

- resolution of 0.01 mm or 0.001”

Why HP gages?

For more than three decades, PanametricsNDT thickness gage engineers have developed

the HP (High Penetration) series specifically

for very sound-attenuating or thick materials.

Not only can these gages use transducers as

low as 0.5 MHz but their electronics (pulserreceiver) are highly optimized to process

signals at these low frequencies. The result

is that the Panametrics-NDT gages have

earned a reputation for superior performance

in measuring thick rubber, fiberglass,

composites, and other tough materials.

Page 3

From thin materials...

The Model 35 with a delay line transducer or immersion bubbler makes accurate thickness measurements

on both convex and concave surfaces of turbine

blades.

Micrometers won’t work in this classic application.

Instead, the Model 35 with a M208 transducer makes

a thickness measurement up to a calibrated accuracy

of 0.001 mm (or 0.0001 inch) without breaking the

glass.

35 and 35DL

Models 35 and 35DL are used in the

majority of applications

The 35 and 35DL can use transducers ranging from 2.25 to 30 MHz,

which means that these versatile gages can solve the majority of

thickness gaging applications, from very thin to very thick. In general,

transducers with higher frequencies and smaller diameters allow

measurements of thinner or curved parts and enhance the accuracy

of the measurement.

Plastic or metal tubes and pipes of various diameters

can easily be measured ultrasonically with contact

type transducers. Small diameters may require immersion type measurements.

applications

- most materials, from thin to thick

- plastic bottles, tubes, pipes, sheets as

thin as 0.08 mm (or 0.003 inch)

- metal containers, steel coils, machined

parts as thin as 0.10 mm (or 0.004 inch)

- cylinder bores, turbine blades

- glass bulbs, bottles

- thin fiberglass, rubber, ceramics, and

composite materials

- curved areas or containers with

small radii

- resolution up to 0.001 mm or 0.0001”

Page 4

From simple thickness measurements...

More than 40 years of experience has

made Panametrics-NDT ultrasonic

thickness gages the most advanced

and best known in the world. The new

pocket-sized 35 gages are no exception.

These practical gages offer more

measurement features and applicationsolving capabilities than their renowned

predecessors. All the more reasons for

you to consider the 35 gages for your

precision thickness gage application.

35 SERIES FEATURES

• Velocity and Reduction Rate

measurements are standard on all

models

• Wide thickness range from 0.0030”

to 25.0” (0.08 mm to 635.0 mm)

depending on instrument and material

• Uses contact, delay line, and

immersion transducers

• Application Auto-Recall with default

and custom setups

• Hand-held; weighs only 8.5 oz.

(0.24 kg)

• Min/Max Mode

• Hi-Low alarm

• English and metric display (inches/mm)

• Multi-language user interface

• Long battery life

Velocity measurement mode with direct Velocity

readout

MATERIAL SOUND VELOCITY

MEASUREMENTS

All 35 models have the capability

to make material sound velocity

measurements. This standard feature

is useful in applications where the

speed of the sound within the material

can be correlated to other properties.

Typical applications include cast metals

to monitor the degree of nodularity,

and composites/fiberglass to monitor

variations in density. Olympus NDT offers

a digital caliper for automatic transfer of

measurement thickness.

APPLICATION AUTO-RECALL

SIMPLIFIES GAGING

Application Auto-Recall simplifies making

thickness measurements. Select any of

the stored transducers and the 35 gages

recall all relevant internal transducer

parameters.

Stored Standard Setups

Standard setups include most commonly

used transducers.

Stored Custom Setups

Just in case your special application

problem cannot be solved with a

Standard Setup, these gages can create,

store, and recall as many as 20 Custom

Setups (10 with the 35 and 35HP).

You can measure critical thickness metal thinning

caused by bending.

REDUCTION RATE

MEASUREMENTS

Differential Mode and Reduction Rate

Mode are standard features on all models.

Differential Mode shows the thickness

variation from a pre-set thickness value.

Reduction Rate calculates and displays

the percent of thickness reduction after

a material thinning process. A typical

application is automotive sheet steel that

is bent and formed to make car body

panels.

Material thinning is displayed as a percentage.

Page 5

to difficult applications...

Thickness and waveform of a very thin (0.004 inch

or 0.10 mm) sheet of steel.

NOW YOU CAN SEE THE

LIVE WAVEFORM AND MAKE

ADJUSTMENTS

An optional Live Waveform Mode on

all models permits the user to view the

ultrasound waveform (or A-scan) directly

on the gage’s display to make sure the

thickness reading is correct. The Adjust

Mode feature facilitates transducer setup

adjustments to maximize measurement

performance for challenging applications.

• High pixel density LCD renders sharp

trace of live waveform

• Permits real-time verification of

thickness readings

• Helps solve many difficult applications

• A Range, Delay, or Zoom allow

enlarging and centering to any section

of the waveform

• Permits adjustments of transducer

setup parameters

• Stores waveforms in data logger and

transfers to PC

35PCSCOPE

Optional 35PCSCOPE interface

software permits the instant display of

live ultrasonic waveforms and thickness

readings directly on your computer

screen. This is helpful when setup

parameters require closer examination.

Why ultrasonics?

Ultrasonic measurements are accurate, reliable, and

repeatable. Instant digital readings can be achieved by

transmitting sound into just one side of a material, making

it unnecessary to cut or destroy parts where the opposite

side is difficult to reach and where micrometers or other

inspection tools cannot do the job.

An optional protective rubber

boot protects the gage.

Page 6

and data collection and management...

DATA COLLECTION FOR FAST AND

RELIABLE DOCUMENTATION

Internal Data Logger

The powerful 35DL and 35DL-HP internal

data loggers allows you to store, recall,

and transmit 8000 thickness readings

along with their Identifi cation Codes.

With the optional live wave form mode

these gages can also store 350 wave

forms with thickness readings. All stored

information can be transmitted from

these units to your computer for statistical

analysis.

Alphanumeric Identifi cation Codes

You can assign an eight character fi le

name and up to ten alphanumeric

ID numbers to each stored thickness

measurement. Each thickness reading

is fully documented with parameter

information such as material sound

velocity, transducer data, and

measurement mode.

Statistic report showing Minimum and Maximum

values

On-board Statistics Calculator

The Models 35DL and 35DL-HP internal

data loggers feature an on-board

statistical calculator to generate reports

that can be transmitted directly to your

printer.

Statistic report showing Hi/Low Alarms, Mean,

Median and Standard Deviation

This printed measurement report contains measurement, ID

and other parameters.

GAGEVIEW

The optional GageView Interface Program,

a Windows-based application, collects,

creates, prints, and manages data from the

35DL and 35DL-HP.

• Datasets and Surveys creation

• Stored data editing

• Viewing Dataset and Survey fi le

information including thickness

readings, gage setup values, and

transducer setup values

A color coded grid easily

fl ags out-of-tolerance

thickness conditions.

• Downloading and uploading thickness

surveys to and from the gages

• Exporting Surveys to spreadsheets and

other programs

• Collecting snapshot screens

• Printing reports such as Thickness,

Setup Table, Statistics, and Color Grid

• Upgrading operating software

Page 7

...we have a thickness gage for you

OTHER CHALLENGES – OTHER

CHOICES

Olympus NDT offers a full range of

ultrasonic thickness gages designed to

meet your most demanding application

requirements. The Models 25DL PLUS

and 25HP PLUS are advanced precision

thickness gages that feature a large 4 x

3.3 inch LCD with full waveform range

and delay control. These gages also

feature a more advanced alphanumeric

fi le-based data logger and a direct access

keypad for easy control over measurement parameters.

Visit the Application section of

panametrics-ndt.com to to learn more

about our ultrasonic solutions.

Multi-layered materials

The 25MULTI PLUS calculates and

simultaneously displays as many as four

separate measurements. The Summation

Mode accurately displays the total thickness of selected layers.

On-line applications

The 25MX PLUS takes multipoint and

single thickness measurements on a wide

variety of materials. Connected to the

optional MX-8 multiplexer, the 25MX

PLUS can collect and display thickness

measurements from as many as eight

transducers.

Hall Effect thickness gage

The Magna-Mike® 8500 thickness gage

makes measurements when a magnetic

probe is held on one side of the test

material and a small steel target ball is

placed on the opposite side.

Flaw detection

Olympus NDT offers the EPOCH series

of portable ultrasonic fl aw detectors that

are widely used to detect and characterize hidden internal defects in engineering

materials such as metals, plastics and

composites.

A FULL LINE OF TRANSDUCERS

AND ACCESSORIES

Olympus NDT offers a complete

selection of transducers, cables,

couplants, calibration test blocks, and

other accessories to meet the most

demanding thickness measurement

applications. Our high quality

Panametrics-NDT Microscan transducers

are available in many frequencies,

element diameter sizes, and connector

styles.

• Contact, delay line, and immersion

thickness gage transducers

• Transducer cables

• Couplants

• Calibration test blocks

Ask for our comprehensive 8-page

brochure on thickness gage transducers

and accessories!

Olympus NDT is represented by welltrained, experienced applications and

sales engineers located in all major

industrial regions around the world.

These professionals are available to

assist the customer in selecting the best

and most cost-effective solution for a

particular application. Visit our website

panametrics-ndt.com to locate the nearest

representative in your area.

Page 8

35, 35DL, 35HP and 35DL-HP SPECIFICATIONS*

MEASUREMENTS

Mode 1: Time interval between excitation

pulse and first back wall echo, using

contact transducers.

Mode 2: Time interval between the first

interface echo after the excitation pulse

and the first backwall echo, using delay

line or immersion transducers.

Mode 3: Time interval between

successive back wall echoes following

the first interface echo after the excitation

pulse, using delay line and immersion

transducers.

Measurement Types: Thickness, Velocity,

or Time of Flight

Thickness Measurement Range*:

0.003 - 25 inches (0.08 - 635 mm)

*Thickness range depends on model, material,

transducer, surface condition, and setup

selected.

Material Velocity Range:

0.02000 - 0.7362 inch/μs

(0.5080 - 18.699 mm/μs)

Resolution (keypad selectable):

LOW: 0.01” (0.1 mm)

STANDARD: 0.001” (0.01 mm)

HIGH: 0.0001” (0.001 mm) (35 & 35DL)

Time of Flight Measurement Range:

0.0 - 109.5 µs

Time of Flight Resolution:

Fixed at 000.01 µs

Measurement Update Rate:

4, 8, 16, or Max Hz (16-20 Hz depending

on application and measurement mode)

Transducer Frequency Range:

2.25 - 30 MHz (35 & 35DL)

0.5 - 5.0 MHz (35HP & 35DL-HP)

Min/Max Mode: Displays current

thickness, minimum or maximum

thickness depending on setting.

Display Hold/Blank: Displays blanks after

last reading or holds reading.

Alarm Mode: Programmable Hi-Low

alarm set points with audible and visual

indicators

Differential Mode: Displays thickness

difference between actual measurement

and reference value.

Reduction Rate Mode: Displays thickness

and percent difference between actual

measurement and reference value.

Application Auto-Recall: Automatically

adjusts internal parameters for various

default and custom transducer setups.

# of Default # of Custom

35 21 10

35DL 21 20

35HP 17 10

35DL-HP 17 20

Other Standard Features: Calibration

Lock Mode, Internal Diagnostic Test

Mode, Metric/English Units, On-board

Statistics (35DL and 35DL-HP only)

POWER SUPPLY

Battery: 3 AA alkaline or NiMH batteries

Operating Time: 150 hours typical battery

life; 30 hours continuous with backlight

on

Low Battery Indicator: Continuously

indicates battery status.

Battery Saver: Auto Power Off/

Continuous On

AC Power Supply: Optional

GENERAL

Environmental IP-65 compliant:

Splash-proof, impact-resistant case.

Sealed, color-coded keypad with tactile

and audible feedback.

Operating Temperature Range:

-10°C to +50°C (+14°F to 122°F)

Size: 3.31” W x 6.0” L x 1.50” H

(84 x 152 x 84 mm)

Weight: 8.5 oz. (0.24 kg)

Custom Language Utility: Allows

translation of display text in many

languages.

35DL & 35DL-HP

INTERNAL DATA LOGGER

Data Logger: The 35DL & 35DL-HP

identify, store, recall, clear, and transmit

thickness readings and transducer setup

information via the USB port or optional

RS-232.

Max. # of Stored Values: Over 8,000 or

350 waveforms with thickness readings

(with Waveform Option)

Stored Data Documentation: Each saved

thickness reading is fully documented

with measurement status flags and a

setup number that identifies parameters

such as velocity, transducer, etc.

File Name Length: 8 alphanumeric

characters

Identification Codes: 10 character

alphanumeric Identification Code system

identifies or locates stored data

4 File Templates: Incremental, Sequential

and 2D Grid. Manual files from PC.

STANDARD INCLUSIONS

Wrist Strap, 3 AA Batteries, Test Block,

Transducer Cable, Couplant, Carrying

Case, Instruction Manual, Two-Year

Limited Warranty

OPTIONAL ACCESSORIES

35/WF Live Waveform

Gageview Interface Program

35DL/RS232 RS-232 output

35DLHP/RS232 RS-232 output

35PCScope PCScope Program

USB/ADP-115 AC-115 Power Supply

USB/ADP-230 AC-230 Power Supply

MG2/RPC Protective Rubber Boot

35/DLRETRO Upgrade 35 to 35DL

35HP/DLRETRO Upgrade 35HP to

35DL-HP

Printed 8/2005

© 2005 Olympus NDT, All Rights Reserved.

*All specifications are subject to change without notice.

Panametrics, Panametrics-NDT and the Panametrics-NDT logo are trademarks of Panametrics Inc.

Other company or product names mentioned in this document may be trademarks or registered

trademarks of their respective companies.

Olympus NDT

48 Woerd Ave. Waltham, MA U.S.A.

TEL 781-419-3900 • 800 225-8330 in North America

e-mail: pana@olympusNDT.com

www.panametrics-ndt.com

Loading...

Loading...