Page 1

Product Data

Power Amplifier — Type 2706

USES:

❍

To drive the Vibration Exciter Type 4809

❍

To drive the Mini-Shaker Type 4810 safely to full

rating

❍

General purpose power amplifier, supplying for

example 75 W into a 3Ω loudspeaker for

reverberation measurem ents

The Power Amplifier Type 2706 has

been designed to drive small vibration

exciters, particularly the Brüel&Kjær

Vibration Exciter Type 4809. It can

also be use d to driv e the Min i- Shak er

Type 4810 to full rating. For this application, the maximum output current sh ould be l imited to 1.8 A .

The po wer amplifie r has a flat frequency re s po nse from 10Hz to 2 0 kH z

(±0.5 dB). The power output capability is 7 5 VA into a 3Ω exciter o r res istive load and the maximum voltage

gain is 40 dB. This enables the power

amplifier to be used in acoustical

measurement set-ups, even when

third-octav e narrow band noise i s em ployed.

The us e of a tran sform erless p ower

output stage and high negative feedback results in very low harm onic distortion. A balanced preamplifier and

rugged solid-state design results in a

stable instrument which can tolerate

temperature fluctuations and supply

line variations.

FEATURES:

❍

75 VA power output capability

❍

Switcha ble 5 A or 1. 8 A max. curren t limiting

❍

40 dB voltage gain

❍

Built-in attenuator and cont inuously variable gain

control

❍

Low distortion over wide frequen cy range

❍

Built-in protection against shor t-circuit and excess

heat sink temperature

❍

Front panel indicator light showing clipped output

signal

Clipping

5 A

1.8 A

Peak

Current

Limiters

Description

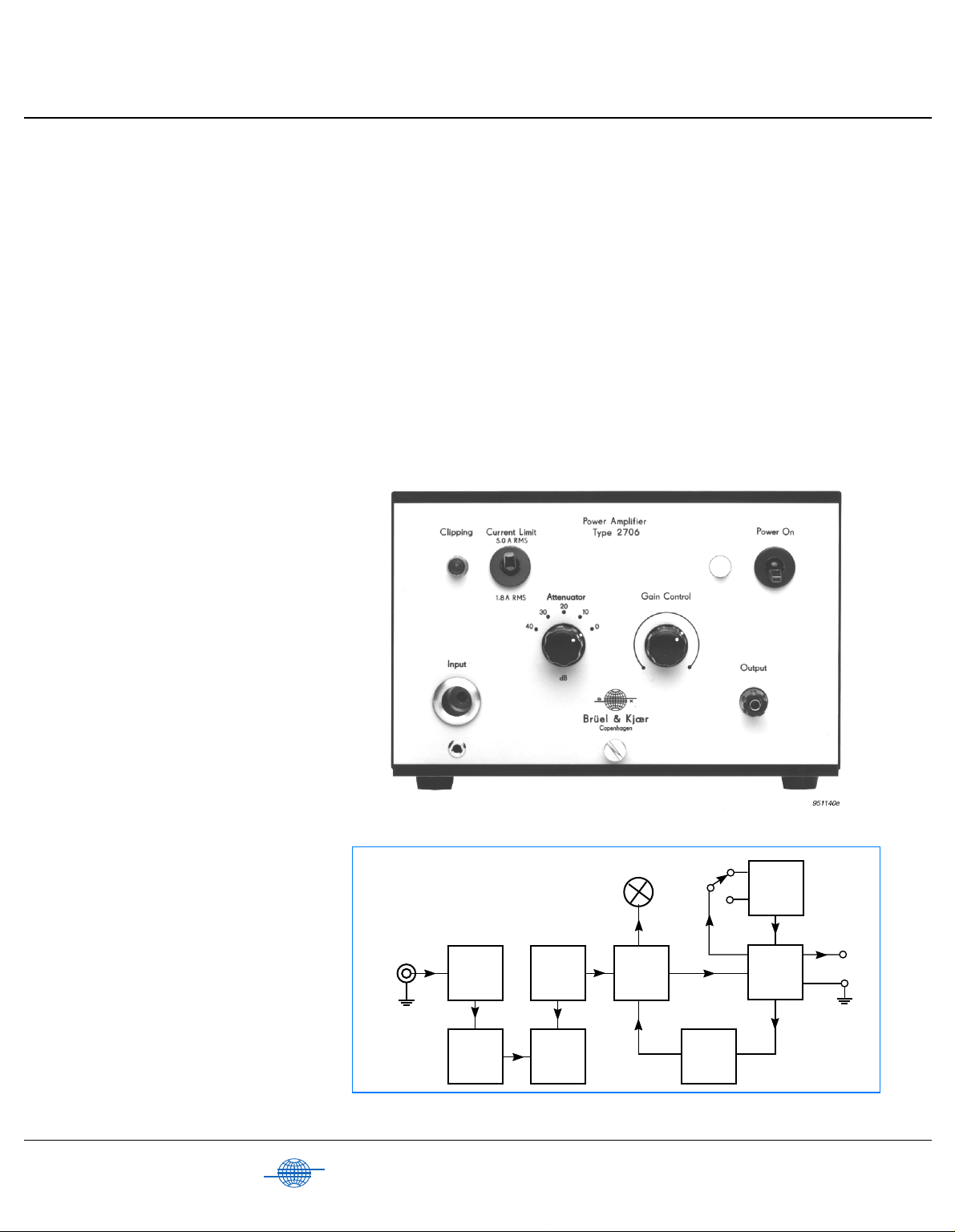

The block diagram for the various circuit functions is shown in Fig. 1.

The input circuitry includes an attenuator for attenuation of the input

signal in 10 dB steps from 0 to 40 dB.

This is followed by a continuously

Brüel & Kjær

B

Input

Fig.1 Block diagram of Power Amplifie r Type 2706

K

Input

Attenuator

Gain

Control

10 µF

Coupling

Capacitor

Preamplifier

Driver

Power

Amplifier

Tempera-

ture

Sensor

272084/2e

Page 2

variable gain control and a preamplifier. The preamplifier is capacitively

coupled to the driver stage, which is

equipped with a clipping detector. Excessive signal levels at the input will

saturate the amplifier and cause clipping of the output waveform. This

will trigger the clipping detector,

which then lights the yellow clipping

warning light on the front panel. The

instrument remains in operation during clipping.

The power stage employs an output

current limiter, which limits the instantaneous positive and negative

peaks of the output current . The power output stage is protected by a temperature sensing device. Abnormal

load conditions, high ambient temperatures or an output short-circuit

could resul t in outpu t transi sto r temperatures well in excess of design

limits. To prevent any subsequent

damage, the temperature protective

circuitry blocks the amplifier input

signal. When the heat-sink temperature reverts to the normal level the

power amplifier will automaticially

regain operation.

Accelerometer

4384

Charge Amplifier

Force Transducer

8200

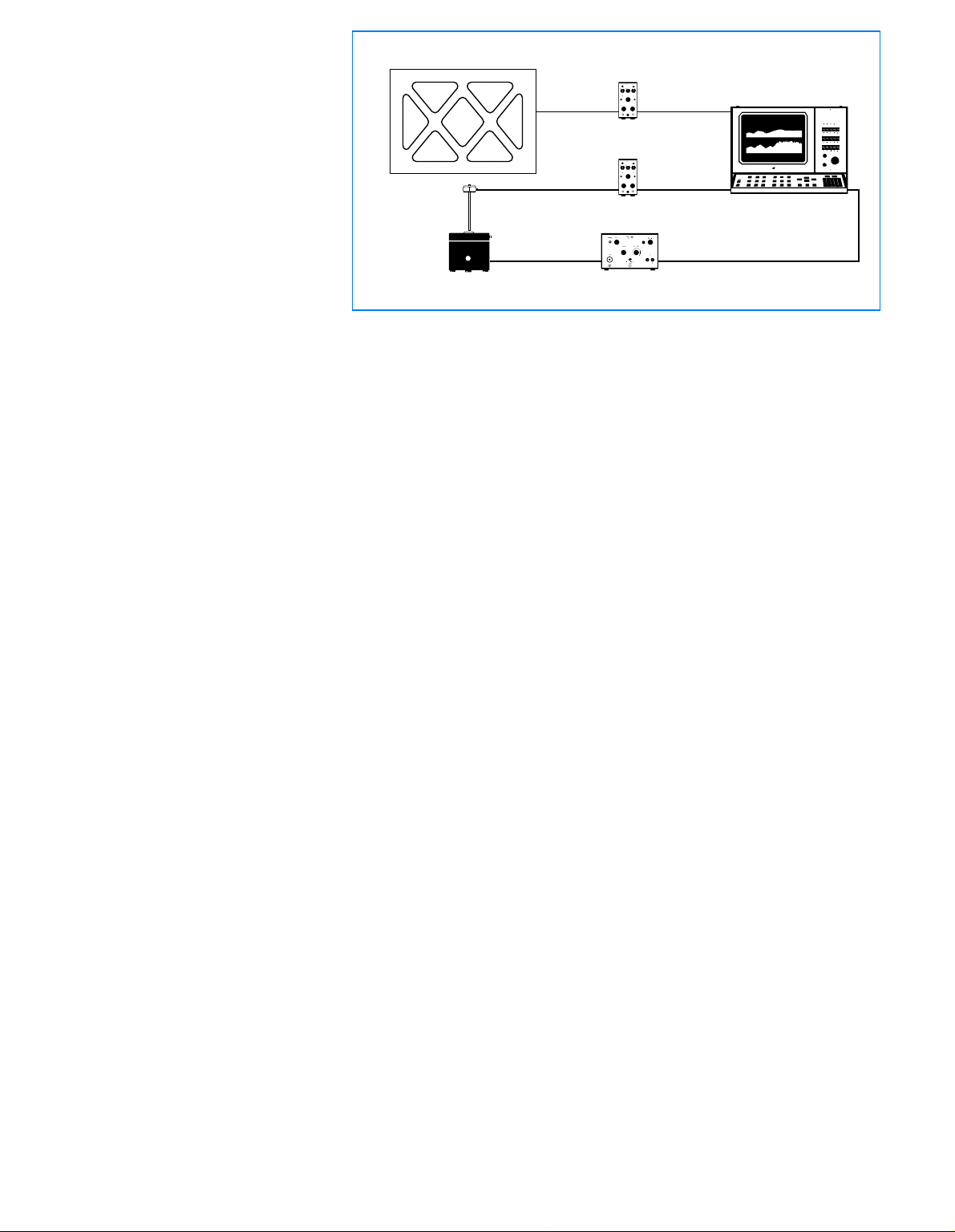

Fig.2 Typical frequency response test set-up

Charge Amplifier

Power Amplifier

Example Of Set-Up

A typi cal fr e qu e nc y re sp o n se test setup for vibration testing is shown in

Fig. 2.

An input forcing signal is taken

directly from the Signal Analyzer

Type 2032 and is fed to the power

2635

2635

2706

Dual Channel Signal

2032

850792/1e

amplifier which drives the Vibration

Exciter Type 4809. The signal analyzer measures the input forcing signal and the structural response

signal and uses them to produce a

representation of frequency response

function of the structure under test.

2

Page 3

Specifications 2706

POWER OUTPUT CAPABILITY:

75 VA into 3Ω exciter or resistive load

CURRENT LIMITING:

Switchable,

Max. 5 A for Vibration Exiter Type 4809

Max. 1.8 A for Mini-S haker Type 4810

FREQUENCY RESPONSE:

10 Hz to 20kHz (±0.5 d B)

2 Hz to 50 kHz (±3dB)

HARMONIC DISTORTION:

< 0.2% (20 Hz to 10 kHz)

< 0.5% (20 Hz to 20 kHz)

at full outp ut capacity

INPUT IMPEDANCE:

Ω

15 k

OUTPUT IMPEDANCE:

<0.04Ω (10Hz to 5kHz)

<0.08Ω (5 kH z to 20 kHz )

PROTECTION:

Short circui t

Excessive heat sink temperatu re

Input overload

DC STABILITY:

< 25 mV drift for ±5% supply line variation

< 25 mV drift for ambient temperature vari ations

between 10 and 40°C (50 and 104°F)

HUM AND NOISE:

<5mV RMS

MAX. VOLTAGE GA IN AT 1 KH Z:

40 dB (±1dB)

ATT EN UATOR :

0 to 40 dB in 10 dB s teps

GAIN CONTROL:

0 to –× dB logari thmic

POWER REQUIREMENTS:

110, 115, 127, 220 and 240 V AC (±5%, 50 to

60 Hz)

Approximately 1 40 VA

Complies with safety class 1 of IEC 348

COMPLIANCE WITH STANDARDS:

CE-mark i ndicates comp liance w ith: EMC Directive a nd Low Voltage Directive.

Safety

EMC Emiss ion

EMC Immunity

Temperature

Humidity

IEC 348: Safety Requirements for Electronic Appara tus

EN 50081– 1: Gener ic emissi on standard. Part 1: Residenti al, comme rcial and

light industr y.

EN 50081 – 2: G eneric emiss ion standard. Par t 2: Ind ustrial environm ent.

CISPR22 : Limits and methods o f radio disturb ance character istics of

information technology equipment. Class B L imits.

FCC Rules, Part 15: Complies with the li mits for a Class B digital device.

EN 50082–1: Generi c immu nity s tand ard . Par t 1: Res iden tial, c omm erci al and

light industr y.

EN 50082 – 2 : Generic immunity standard . Part 2: Ind ustrial envir onment.

Note 1:

The above is guaranteed us ing a cces sori es li sted in t his Pr odu ct Dat a

sheet only.

Note 2:

RF disturbances above 3MHz may result in demodulation and overload

conditions.

IEC68 – 2 – 1 & IE C 68 – 2 – 2: Environmental Testing. Col d and Dry Heat.

Operating Temperature: +5 to +40°C (41 to 104°F)

Storage Temperature: –25 to + 70°C (–13 to 158°F)

IEC68 – 2 – 3: Da mp Heat 90% RH (non-conden sing at 4 0°C (104°F))

DIMENSIONS:

Height:

133 m m (5.2 i n)

Width:

210mm (8.3in)

Depth:

240 mm (9.5 i n)

(KK 0042 Cabi net, 6/12 of 19 in rack module)

WEIGHT:

6kg (13.2lb)

Ordering Information

Type 2706

following accessories:

JP 01 01 Standard Coa xial Plug

3×VF 0010 2 A, 250 V F use, time-lag

2×VF 0013 1 A, 250 V F use, time-lag

Power Amplifier includes the

Mains Cable

Brüel &Kjær reserves the right to change specificatio ns and accessories without noti ce

3

Page 4

Brüel & Kjær

B

K

WORLD HEADQUARTERS:

DK-2850 Naerum · Denmark · Telephone: +45 45 80 05 00 · Fax: +45 45 80 14 05 · Internet: http://www.bk.dk · e-mail: info@bk.dk

Australia (02 ) 9450-2066 · Austria 00 43-1-865 74 00 · Belgium 016/44 92 25 · Brazil (011) 246-8166 · Canada: (514) 695-8225 · China 10 6841 9625 / 10 6843 7426

Czech Republic 02-67 021100 · Finland 90-229 3021 · France (01) 69 90 69 00 · Germany 0610 3/908-5 · Holland (0)30 6039994 · Hong Kong 254 8 7486

Hungary (1) 215 83 05 · Italy ( 02) 57 60 41 41 · Japan 03 -3779-8671 · Republic of Korea (02) 3473-0 605 · Norway 66 9 0 4410 · Polan d (0-22) 40 93 92 · Portug al (1) 47 114 53

Singapore (65) 275-8816 · Slovak Republic 07-37 6181 · Spain (91) 36810 00 · Sweden (08) 71127 30 · Switzerland 01/94 0 09 09 · Taiwan (02) 713 9303

United Kingdom and Ireland (0181) 954-236 6 · USA 1 - 800 - 332 - 2040

Local representatives and service organisations worldwide

BP0227 –14

96/05

Loading...

Loading...