Page 1

R

INT

V

+

–

V

+

–

Battery 2302/2306

R

OUT

2302

2306, 2306-PJ

• Ultrafast response to transient

load currents

• Choice of single- or dual-

channel supplies

• Optimized for development

and testing of battery-powered

devices

• Variable output resistance

for simulating battery response

(U.S. Patent No. 6,204,647)

• Pulse peak, average, and

baseline current measurements

• 100nA DC current sensitivity

• Current step measure function

• Sink up to 3A

• Open sense lead detection

• Built-in digital voltmeter

SERVICES AVAILABLE

2302-3Y-EW 1-year factory warranty extended to 3 years

from date of shipment

2306-3Y-EW 1-year factory warranty extended to 3 years

from date of shipment

2306-PJ-3Y-EW 1-year factory warranty extended to 3 years

from date of shipment

C/2302-3Y-ISO 3 (ISO-17025 accredited) calibrations within 3

years of purchase for Model 2302*

C/2306-3Y-ISO 3 (ISO-17025 accredited) calibrations within 3

years of purchase for Models 2306, 2306-P*

*Not available in all countries

Battery Simulator

Battery/Charger Simulators

The single-channel Model 2302 Battery

Simulator and dual-channel Model 2306 Battery/

Charger Simulator were designed specifically for

development and test applications of portable,

battery-operated products, such as cellular and

cordless telephones, mobile radios, and pagers.

These precision power supplies have ultrafast

transient response so they can have output

characteristics identical to actual batteries.

These supplies employ a unique variable output

resistance so the voltage output can emulate a

battery’s response (U.S. Patent No. 6,204,647).

They provide stable voltage outputs, even when

a device-under-test (DUT) makes the rapid transition from the standby (low current) state to the

RF transmission (high current) state. In addition,

they can monitor DUT power consumption by

meas uring both DC currents and pulse load currents. The Model 2302’s and the Model 2306’s

battery-simulator channel can be programmed

to operate like a discharged rechargeable battery, sinking current from a separate charger or from the

Model 2306’s charger- simulator channel.

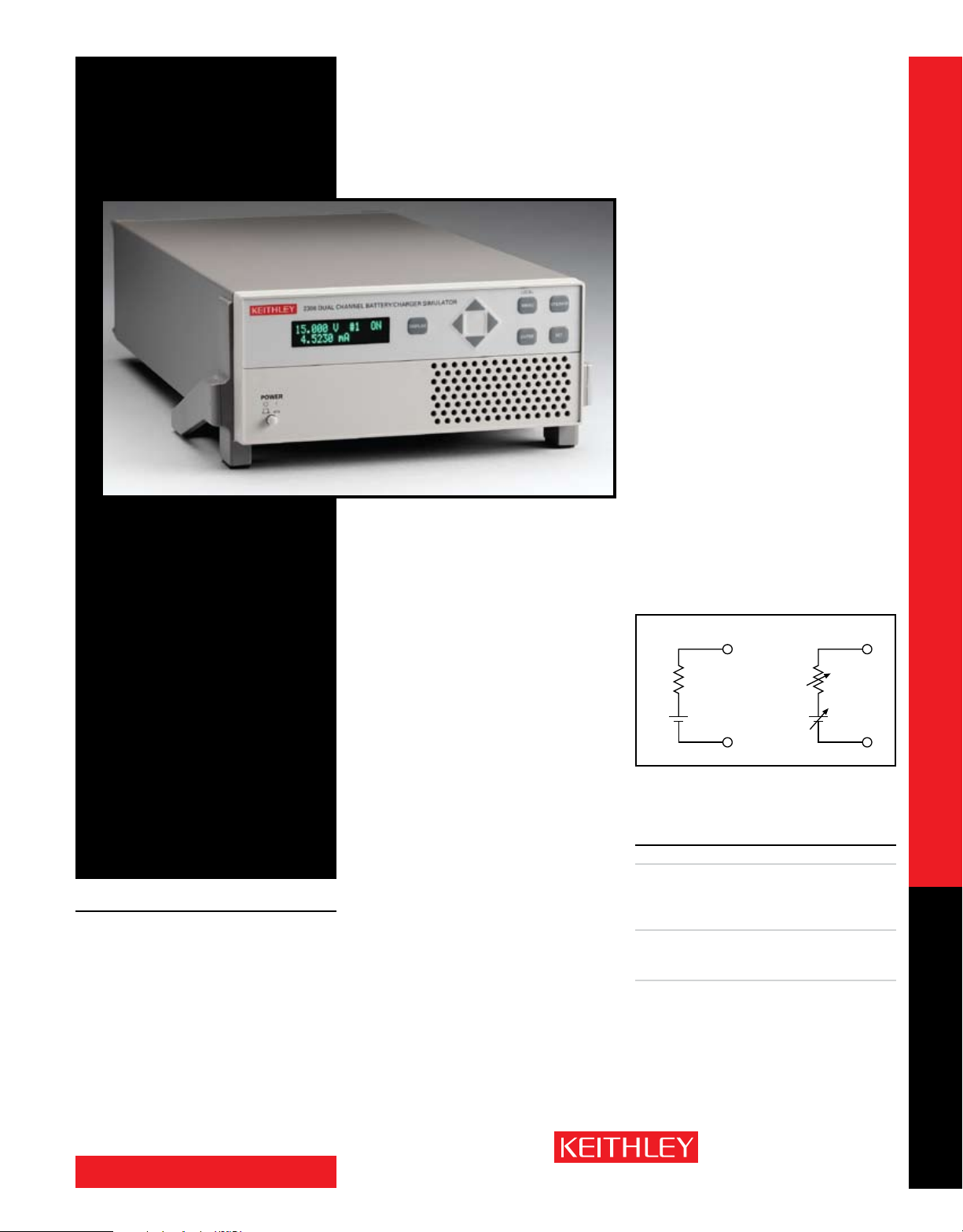

Maximize Test Throughput with Accurate Battery Simulation

The battery-output channels of the Models 2302 and 2306 are designed to simulate the output

response of a battery. This capability, combined with their fast transient response, makes it possible

to power the device during testing in exactly the

same way as a battery will power the device

during actual use. The output resistance of the

Model 2302’s and the Model 2306’s battery channel can be programmed (with 10mΩ resolution)

over the range from 0Ω to 1Ω so that the output resistance can be set to the same level as the

output resistance of the battery that powers the

device. See Figure 1.

Portable wireless devices make great demands

on their battery power sources. The battery must

source load currents that can jump virtually

instantaneously from a standby current level

(100–300mA) to a full-power RF transmission

current level (1–3A). In other words, the load

current on the battery can increase rapidly by

a factor of 700–1000%. As a result, the battery

voltage drops by an amount equal to the value

of the current change multiplied by the battery’s

internal resistance. The Models 2302 and 2306

power supplies enable test systems to duplicate

this voltage drop by programming their output

resistance to be equivalent to that of the battery

that will power the device. This allows wireless device manufacturers to test their products

under the same power conditions that they will

encounter in actual use. (See Figure 2.)

Figure 1. Simplified schematic of a battery

and the 2302/2306.

ACCESSORIES AVAILABLE

CABLES

7007-1 Shielded IEEE-488 Cable, 1m (3.3 f t)

7007-2 Shielded IEEE-488 Cable, 2m (6.6 f t)

SC-182 Low-Inductance Coax ial Cable (42nH/f t)

RACK MOUNT KITS

4288-1 Single Fi xed Rack Mount Kit

4288-2 Dual Fi xed Rack Mount Kit

IEEE-488 INTERFACES

KPCI- 488LPA IEEE- 488 Interface/Control ler for the PCI Bus

KPXI-488 IEEE- 488 Interface Board for the PXI Bus

KUSB- 488A IEEE- 488 USB-to- GPIB Interface Adapter

Fast transient response power supplies

1.888.KEITHLEY

www.keithley.com

(U.S. only)

A GREATER MEASURE OF CONFIDENCE

SPECIALIZED POWER SUPPLIES

Page 2

High current level

Trigger level

Average current level

High

Time

Low current level

Low Time

Average Time

(out to 60s with long integration)

2302

Battery Simulator

2306, 2306-PJ

Ordering Information

2302 Battery Simulator

2306 Dual-Channel Battery/

2306-PJ Dual-Channel Battery/

Accessories Supplied

User and service manuals,

CS-846 output connectors

mating terminal

Conventional Power Supplies

and Wireless Device Testing

During production testing, supplying

power to a device that undergoes large,

instantaneous load current changes can be

extremely difficult. Changes like this force

a conventional power supply’s output voltage to fall instantaneously. When the power

supply’s control circuitry senses the error

Fast transient response power supplies

condition (the difference in voltage between

the programmed level and the actual

level), it attempts to correct or restore the

voltage to the programmed level. During

this time, the voltage will fall or droop

substantially, with the amount of the droop

depending on the size of the load current

change. The recovery time depends on the

transient response of the power supply’s

control loop. Conventional power supplies

have transient voltage drops of >1V when

confronted with load current changes of

up to 1000%, and take up to a millisecond

to recover to the programmed voltage. For

portable devices such as cellular phones

that operate at full power for only short

intervals, the full power event is over before

the conventional power supply can recover.

For example, a cellular phone designed to

the GSM cellular phone standard transmits

and receives information in 576µs pulses. If

the power supply used to test these types of

phones cannot recover quickly enough, the

performance of the phone during testing

will be compromised by the power supply.

If the power supply voltage drops below the

threshold of the phone’s low battery detection circuitry for long enough, then the

phone will turn off during testing, giving a

false indication of a failed device.

1.888.KEITHLEY

SPECIALIZED POWER SUPPLIES

www.keithley.com

Charger Simulator

Charger Simulator

with 500mA Range

(U.S. only)

Battery/Charger Simulators

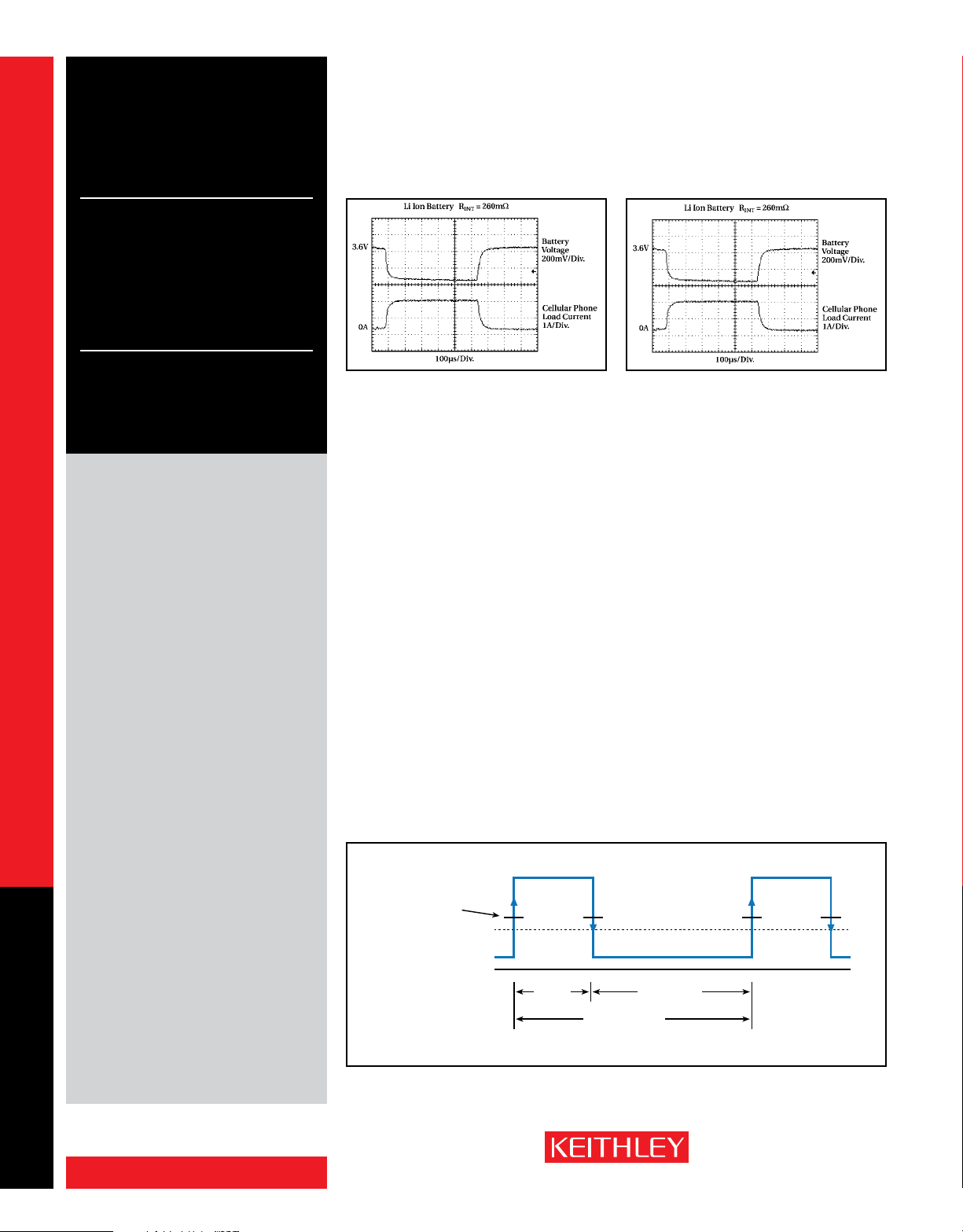

Figure 2. Comparison of the voltage outputs of a lithium-ion battery (with an internal resistance of

260mΩ) and the Model 2306’s battery channel (programmed with an output resistance of 260mΩ )

when powering a cellular telephone as it makes the transition from standby mode to transmit mode.

In response to large load changes, the Model

2302 and the battery channel of the Model 2306

have transient voltage droops of less than 100mV

and transient recovery times of less than 60µs,

even when the test leads between the power

supply and the DUT are long. This fast transient

response, combined with the supplies’ variable output resistance, allows engineers to test

their portable products under the most realistic

operating conditions and eliminate false failures

due to conventional power supplies with slow

response times. (See the sidebar titled “Conventional Power Supplies and Wireless Device

Testing.”) These supplies also eliminate the large

stabilizing capacitors needed at the DUT to compensate for the large droop that occurs when

testing with conventional power supplies. By

varying the output resistance, which can be done

while the output is turned on, test engineers can

simulate the operation of different battery types,

as well as batteries nearing the end of their

useful lives.

The Models 2302 and 2306 ensure maximum

production throughput when testing portable

Figure 3. Built-in pulse current measurement functions allow test engineers to measure peak,

average, and baseline load currents.

A GREATER MEASURE OF CONFIDENCE

devices by minimizing false failures, minimizing

the number of test setups by performing multiple tests with the same power supply, and minimizing test fixture complexity by eliminating the

need for voltage-stabilizing capacitors.

Measure Load Currents for

Power Consumption Verification

or Analysis

As manufacturers of portable devices strive to

extend their products’ battery life, measuring

load currents accurately has become increasingly

essential in both design and production test in

order to ensure the product meets its demanding

specifications. Comprehensive testing of these

devices requires measuring peak currents, average currents, and baseline currents in various

operation modes. When testing these devices,

these measurements are complicated by the pulsating nature of load currents, such as the transmit and receive load currents of digital cellular

phones. The Models 2302 and 2306 can measure

the peak and average currents of pulses as short

as 60µs and as long as 833ms. (See Figure 3.)

Page 3

I

1

I

2

I

3

I

4

I

5

I

6

I

7

I

8

Trigger Levels

Load Currents

R

+

–

Battery Channel Charger Channel

V

battery

V

charger

> V

battery

Battery

Terminals

Charger

Terminals

+

–

II

DVM

+

–

+

–

V

OUT

V

IN

–5V to +30V DC

RI Sense

R

OUT

+

–

2302

Battery Simulator

2306, 2306-PJ

Battery/Charger Simulators

Measure Long-Period Waveform Currents

For pulse trains with periods longer than 850ms, the Models 2302 and

2306 offer a unique, long integration current measurement mode. This

mode can provide an average measurement of a current waveform from

850ms up to 60 seconds long.

Measure Low Currents Accurately

The Models 2302 and 2306 are based on Keithley’s expertise in low current

measurement technologies, so they’re well-suited for making fast, accurate

measurements of sleep and standby mode currents. With 100nA resolution

and 0.2% basic accuracy, they provide the precision needed to monitor the

low sleep mode currents of both today’s battery-operated products and

tomorrow’s.

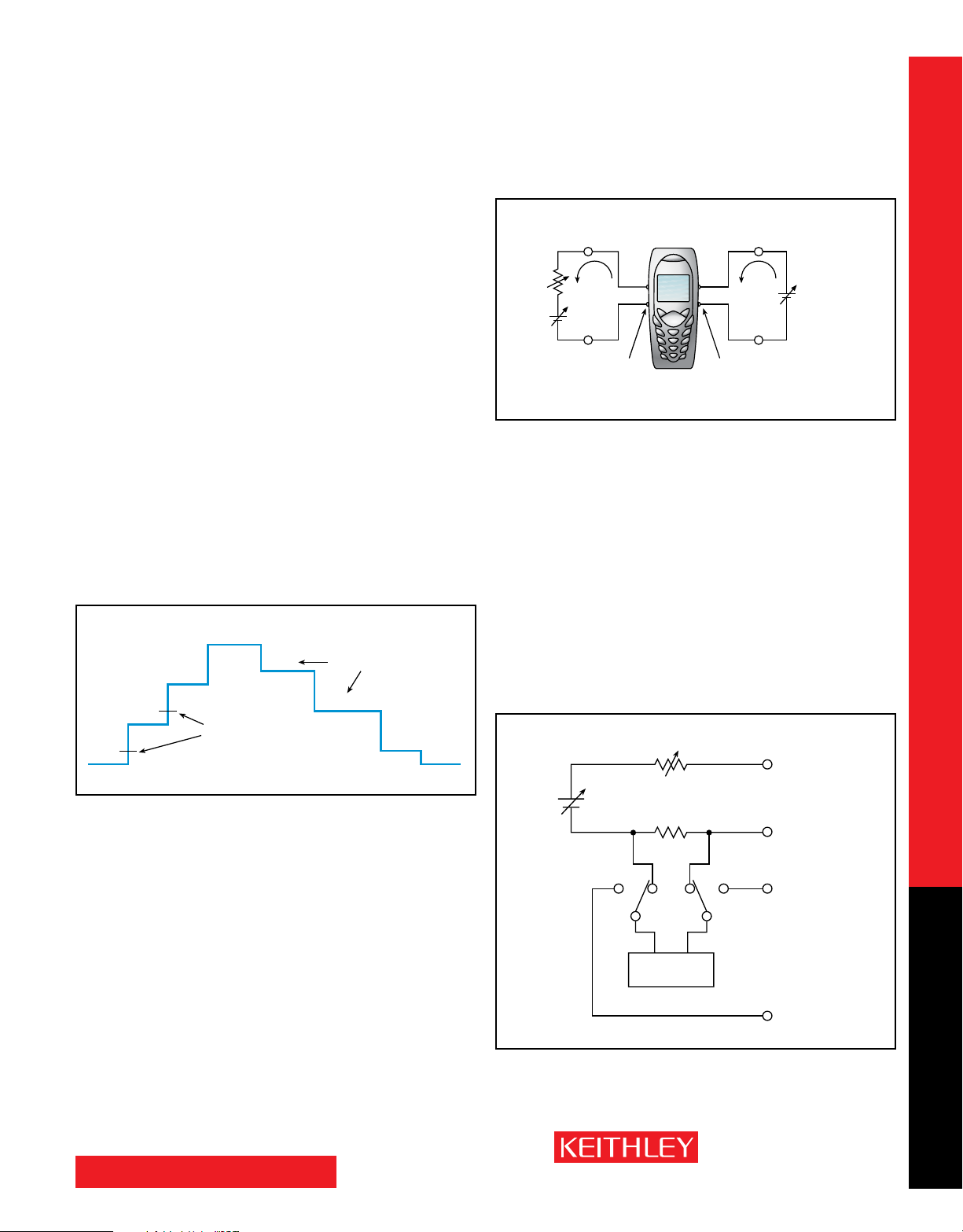

Verify Load Currents in All Operating States

The Models 2302 and 2306 employ a unique pulse current step function

for measuring the load current at each level of a device’s operational

states. (See Figure 4.) For example, if a cellular phone is ramped up and

down through as many as 20 discrete power consumption states, the

Models 2302 and 2306 can measure the load currents in synchronization

with the current steps. This capability allows a test engineer to verify

performance at each operational state and simultaneously acquire power

consumption information. The fast current measure capability is another

way the Models 2302 and 2306 power supplies save test time and production costs.

Figure 5. For charger control circuit testing applications, the Model

2306 and 2306-PJ can provide the functions of both a charger-simulating source and a discharged battery simulator.

the output voltage does not change from the programmed level, which

could cause production devices to be improperly calibrated, the user can

set high and low limits around the desired voltage level.

Independent Digital Voltmeter Inputs

Many programmable power supplies offer output readback capabilities, but

the Model 2302 and 2306 also offer DVM inputs. Both instruments allow

measuring signals from –5V to +30V DC anywhere in the test system with

the same rated accuracy as the voltage readback. The Model 2306 has two

sets of DVM inputs; the Model 2302 has one. The DVMs and the power

sources can operate simultaneously. For many applications, these built-in

DVMs eliminate the expense and space required to add a separate voltage

measurement instrument.

Fast transient response power supplies

Figure 4. These power supplies can obtain a load current profile

synchronized to the transitions of a DUT as it is stepped through its

operating states.

Simulate a Discharged Battery for Charger Testing

The Models 2302 and 2306 can sink up to 3A continuously, just like

an electronic load. This allows these supplies to simulate a discharged

rechargeable battery for use in testing the performance of battery chargers

or battery charger control circuitry.

The Model 2306 Battery/Charger Simulator combines the functionality of

both the charging current source (the charger channel) and the current

sinking to simulate the recharging of a discharged battery (the battery

channel) in a single enclosure. (See Figure 5.)

Open-Sense Lead Detection

The Model 2302 and 2306 have an automatic open–sense lead detection

capability, which indicates if there is a broken remote sense lead or an

open connection from a remote sense lead to the test fixture. To ensure

1.888.KEITHLEY

www.keithley.com

(U.S. only)

Figure 6. Model 2302 and Model 2306 Battery Channel Block Diagram.

The Model 2306 charger channel is identical except it does not have

the variable output resistance.

SPECIALIZED POWER SUPPLIES

A GREATER MEASURE OF CONFIDENCE

Page 4

2302

Battery Simulator

2306, 2306-PJ

Battery/Charger Simulators

Big Functionality in a Small Package

For high volume production environments where floor and test rack space

are at a premium, the Model 2306 packs two power supplies into one

half-rack enclosure. In addition to power control, both the Model 2302

and 2306 provide extensive measurement capabilities in the same halfrack case. The front panel of each unit displays the user’s choice of either

the output voltage and output current, the average, peak, and baseline

pulse current levels, long integration currents, or DC DVM meas urements.

A minimum of front panel buttons ensures that operation is simple and

straight-forward.

For additional control requirements, the Models 2302 and 2306 each have

four digital relay control outputs and a 5V DC output to power a relay coil.

GENERAL

ISOLATION (l ow–ea rth): 22V DC max. For Models 2306 and 2306-PJ, do not exceed 60V DC

between any t wo terminals of eit her connector.

PROGRAMMING: IEEE-488.2 (SCPI).

USER-DEFINABLE POWER-UP STATES: 5 (4 for Model 2306-PJ).

REA R PANEL CONNECTORS: Two (one for Model 2302) 8-position quick disconnect termi-

nal block for output (4), sense (2), and DVM (2).

TEMPERATURE COEFFICIENT (outside 23°C ±5°C): Derate accuracy specification by (0.1 ×

specification)/°C.

OPERATING TEMPER ATURE: 0° to 50°C (Derate to 70%). 0° to 35°C (Full power).

STORAGE TEMPERATURE: –20° to 70°C.

HU MIDI TY: <80% @ 35°C non-condensing.

DISPLAY T YPE: 2-line × 16-character VFD.

REMOTE DISPLAY/KE YPAD OPTION: Disables standard front panel.

DIMENSIONS: 89mm high × 213mm wide × 411mm deep (3

NE T W EIGH T: 3.2kg (7.1 lbs).

SHIPPING WEIGHT: 5.4kg (12 lbs).

INPUT POWER: 100–120V AC/220–240V AC, 50 or 60Hz (auto detected at power-up).

POWER CONSUMPTION: 150VA max.

EMC: 2302, 2306: Conforms w ith European Union Directive 89/336/EEC, EN 55011, EN

50082-1, EN 61000-3-2 and 61000 -3-3, FCC part 15 class B. 2306-PJ: Conforms with

European Union Directive 89/336/EEC.

SAFETY: 2302, 2306: Conforms with European Union Directive 73/23/EEC, EN 61010-1.

2306-PJ: Conforms with European Union Directive 73/23/EEC.

1

⁄2 in × 83⁄8 in × 163⁄16 in).

Fast transient response power supplies

Figure 7. Model 2306 Rear Panel showing 8-position power output

connectors, RJ-45 remote display connector, DB-9 relay output connector, IEEE-488 connector, and power input socket.

1.888.KEITHLEY

SPECIALIZED POWER SUPPLIES

www.keithley.com

(U.S. only)

A GREATER MEASURE OF CONFIDENCE

Page 5

2302

Battery Simulator

2306, 2306-PJ

Battery/Charger Simulators

Output #1 (Battery)

DC VOLTAGE OUTPUT (2 Years, 23°C ± 5°C)

OUTPUT VOLTAGE: 0 to +15V DC.

OUTPUT ACCURACY: ±(0.05% + 3mV).

PROGRAMMING RESOLUTION: 1 mV.

REA DBACK ACCU RACY

REA DBACK R ESOLUTION: 1mV.

OUTPUT VOLTAGE SETTLING TI ME: 5ms to within stated accuracy.

LOAD R EGULATION: 0.01% + 2mV.

LINE REGUL ATION: 0.5mV.

2

STABILITY

MEASUREMENT TIME CHOICES: 0.01 to 10PLC

AVERAGE READINGS: 1 to 10.

REA DING TIME

TRANSIENT RESPONSE: High Bandwidth Low Bandwidth

Transient Recovery Time

Transient Voltage Drop <75mV3 or <100mV4 <250mV3 or <400mV

REMOTE SENSE: 1V max. drop in each lead. Add 2mV to the voltage load regulation specification for

: 0.01% + 0.5mV.

each 1V change in the negative output lead due to load current change. Remote sense required.

Integrity of connection continually monitored. If compromised, output will turn off automatically

once settable window (±0 to ±8V) around normal voltage exceeded.

VARIABLE OUTPUT IMPEDANCE

RANGE: 0 to 1.00Ω in 0.01Ω steps. Value can be changed with output on.

DC CURRENT (2 Years, 23°C ± 5°C)

OUTPUT CURRENT (2302):

0–4V: 5A max.

= 60W/(V

>4V: I

MAX

CONTINUOUS AVERAGE OUTPUT CURRENT (2306, 2306-PJ):

Channel #2 (Charger) OFF:

I = 50W/(V

Channel #2 (Charger) ON:

I = (50W – Power consumed by channel #2)/(V

The power consumed by channel #2 is calculated as:

Channel #2 sourcing current:

Power consumed = (V

Channel #2 sinking current:

Power consumed = 5 × (sink current)

Peak currents can be a maximum of 5A provided the average current is w ithin the above limits.

CONTINUOUS AVERAGE SINK CURRENT:

Channel #2 (Charger) OFF:

0–5V: 3A max.

5–15V: Derate 0.2A per volt above 5V. Compliance setting controls sinking.

Channel #2 (Charger) ON:

Available current = (50W – Power consumed by channel #2)/5; 3A max. (0–5V).

Derate 0.2A per volt above 5V.

SOURCE COMPLIANCE ACCURACY: ±(0.16% + 5mA)

PROGRAMMED SOURCE COMPLIANCE RESOLUTION: 1.25mA.

READBACK ACCURACY

5mA Range: ±(0.2% + 1µA) (2302 and 2306).

500mA Range: ±(0.2% + 20µA) (2306-PJ only).

READBACK RESOLUTION: 5A Range: 100µA.

5mA Range: 0.1µA (2302 and 2306).

500mA Range: 10µA (2306-PJ only).

LOAD REGULATION: 0.01% + 1mA.

LINE REGULATION: 0.5mA.

4

STABILITY

MEASUREMENT TIME CHOICES: 0.01 to 10PLC

AVERAGE READINGS: 1 to 10.

REA DING TIME

: 0.01% + 50µA.

1

: ±(0.05% + 3mV).

7

1, 8, 9

: 31ms, typical.

13

<40µs3 or <60µs4 <80µs3 or <100µs

+6) (not intended to be operated in parallel).

OUT

channel 1 + 6V); 5A max.

SET

channel 2 + 6V) × (current supplied)

SET

1

: 5A Range: ±(0.2% + 200µA).

7

1, 8, 9

: 31ms, typical.

, in 0.01PLC steps.

channel 1 + 6V); 5A max.

SET

5

.

, in 0.01PLC steps.

4

4

PULSE CURRENT MEASUREMENT OPERATION

TRIGGER LEV EL:

5A CURRENT R ANGE

5A Range: 5mA to 5A, in 5mA steps.

1A Range: 1mA to 1A , in 1mA steps.

100mA R ange: 0.1mA to 100m A, in 100µA steps.

500mA CURRENT R ANGE (2306-PJ)

500mA Range: 0.5mA to 500mA, in 0.5mA steps.

100mA R ange: 0.1mA to 100m A, in 100µA steps.

10mA Ra nge: 100µA to 10mA , in 100µA steps.

TRIGGER DELAY: 0 to 100ms, in 10µs steps.

INTERNAL TRIGGER DELAY: 15µs.

HIGH/LOW/AVERAGE MODE:

Measurement Aperture Settings: 33.3µs to 833ms, in 33.3µs steps.

Average Readings: 1 to 100.

PULSE CURRENT MEASUREMENT ACCURACY

Aperture

<100 µs 0.2% + 900 µA + 2 mA 0.2% + 90 µA + 2 mA

100 µs – 200 µs 0.2% + 900 µA + 1.5 mA 0.2% + 90 µA + 1.5 mA

200 µs – 500 µs 0.2% + 900 µA + 1 mA 0.2% + 90 µA + 1 mA

500 µs – <1 PLC 0.2% + 600 µA + 0.8 mA 0.2% + 60 µA + 0.8 mA

12

1 PLC

>1 PLC 0.2% + 400 µA + 100 µA 0.2% + 40 µA + 100 µA

5A Range 500mA Range (2306-PJ)

0.2% + 400 µA + 0 mA 0.2% + 40 µA + 0 mA

11

(2 Years, 23°C ±5°C):

±(% reading + offset + rms noise

Accuracy

10

)

BURST MODE CURRENT MEASUREMENT

MEASUREMENT APERTURE: 33.3µs.

CONVERSION RATE: 3650/second, typical.

INTERNAL TRIGGER DELAY: 15µs.

NUMBER OF SAMPLES: 1 to 5000.

TRANSFER SAMPLES ACROSS IEEE BUS IN BINARY MODE: 4800 bytes/s, typical.

LONG INTEGRATION MODE CURRENT MEASUREMENT

2302, 2306: Available on 5A range only.

2306-PJ: Available on 5A and 500mA current ranges.

MEASUREMENT TIME

6

: 850ms (840ms) to 60 seconds in 1ms steps.

DIGITAL VOLTMETER INPUT (2 Years, 23°C ± 5°C)

INPUT VOLTAGE RANGE: –5 to +30V DC.

INPUT IMPEDANCE: 2MΩ typical.

MAXIMUM VOLTAGE (either input terminal) WITH RESPECT TO OUTPUT LOW: –5V, +30V.

READING ACCURACY

READING RESOLUTION: 1mV.

CONNECTOR: HI and LO input pair part of Output #1’s terminal block.

MEASUREMENT TIME CHOICES: 0.01 to 10PLC

AVERAGE READINGS: 1 to 10.

REA DING TIME

1

: ±(0.05% + 3mV).

1, 8, 9

: 31ms, typical.

7

, in 0.01PLC steps.

Model 2302, 2306, 2306-PJ specifications

1.888.KEITHLEY

www.keithley.com

(U.S. only)

SPECIALIZED POWER SUPPLIES

A GREATER MEASURE OF CONFIDENCE

Page 6

2302

Battery Simulator

2306, 2306-PJ

Battery/Charger Simulators

OUTPUT #2 (CHARGER)

DC VOLTAGE OUTPUT (2 Years, 23°C ± 5°C)

OUTPUT VOLTAGE: 0 to +15V DC.

OUTPUT ACCURACY: ±(0.05% + 10mV).

PROGRAMMING RESOLUTION: 10mV.

READBACK ACCURACY

READBACK RESOLUTION: 1mV.

OUTPUT VOLTAGE SETTLING TIME: 5ms to within stated accuracy.

LOAD REGULATION: 0.01% + 2mV.

LINE REGULATION: 0.5mV.

2

STABILITY

MEASUREMENT TIME CHOICES: 0.01 to 10PLC

AVERAGE READINGS: 1 to 10.

REA DING TIME

TRANSIENT RESPONSE: High Bandwidth Low Bandwidth

Transient Recovery Time

Transient Voltage Drop <120mV3 or <150mV4 <160mV3 or <200mV

REMOTE SENSE: 1V max. drop in each lead. Add 2mV to the voltage load regulation specification for

Side Text

: 0.01% + 0.5mV.

each 1V change in the negative output lead due to load current change. Remote sense required.

Integrity of connection continually monitored. If compromised, output will turn off automatically

once settable window (±0 to ±8V) around normal voltage exceeded.

DC CURRENT (2 Years, 23°C ± 5°C)

CONTINUOUS AVERAGE OUTPUT CURRENT:

Channel #1 (Battery) OFF:

I = 50W/(V

Channel #1 (Battery) ON:

I = (50W – Power consumed by channel #1)/(V

Model 2302, 2306, 2306-PJ specifications

The power consumed by channel #1 is calculated as:

Channel #1 sourcing current:

Power consumed = (V

Channel #1 sinking current:

Power consumed = 5 × (sink current)

Peak currents can be a maximum of 5A provided the average current is w ithin the above limits.

CONTINUOUS AVERAGE SINK CURRENT:

Channel #1 (Battery) OFF:

0–5V: 3A max.

5–15V: Derate 0.2A per volt above 5V. Compliance setting controls sinking.

Channel #1 (Battery) ON:

Available current = (50W – Power consumed by channel #1)/5; 3A max. (0–5V).

Derate 0.2A per volt above 5V.

SOURCE COMPLIANCE ACCURACY: ±(0.16% + 5mA)

PROGRAMMED SOURCE COMPLIANCE RESOLUTION: 1.25mA.

READBACK ACCURACY

5mA Range: ±(0.2% + 1µA).

READBACK RESOLUTION: 5A Range: 100µA.

5mA Range: 0.1µA.

LOAD REGULATION: 0.01% + 1mA.

LINE REGULATION: 0.5mA.

4

STABILITY

MEASUREMENT TIME CHOICES: 0.01 to 10PLC

AVERAGE READINGS: 1 to 10.

REA DING TIME

: 0.01% + 50µA.

1

: ±(0.05% + 3mV).

1, 8, 9

: 31ms, typical.

13

<50µs3 or <80µs4 <60µs3 or <100µs

channel 2 + 6V); 5A max.

SET

channel 1 + 6V) × (current supplied)

SET

1

: 5A Range: ±(0.2% + 200µA).

1, 8, 9

: 31ms, typical.

7

, in 0.01PLC steps.

channel 2 + 6V); 5A max.

SET

5

.

7

, in 0.01PLC steps.

PULSE CURRENT MEASUREMENT OPERATION

TRIGGER LEVEL: 5mA to 5A, in 5mA steps.

TRIGGER DELAY: 0 to 100ms, in 10µs steps.

INTERNAL TRIGGER DELAY: 15µs.

HIGH/LOW/AVERAGE MODE:

Measurement Aperture Settings: 33.3µs to 833ms, in 33.3µs steps.

Average Readings: 1 to 100.

PULSE CURRENT MEASUREMENT ACCURACY

Aperture

<100 µs 0.2% + 900 µA + 2 mA

100 µs – 200 µs 0.2% + 900 µA + 1.5 mA

200 µs – 500 µs 0.2% + 900 µA + 1 mA

500 µs – <1 PLC 0.2% + 600 µA + 0.8 mA

12

4

4

1 PLC

>1 PLC 0.2% + 400 µA + 100 µA

±(% reading + offset + rms noise10)

11

(2 Years, 23°C ±5°C):

Accuracy

0.2% + 400 µA + 0 mA

BURST MODE CURRENT MEASUREMENT

MEASUREMENT APERTURE: 33.3µs.

CONVERSION RATE: 2040/second, typical.

INTERNAL TRIGGER DELAY: 15µs.

NUMBER OF SAMPLES: 1 to 5000.

TRANSFER SAMPLES ACROSS IEEE BUS IN BINARY MODE: 4800 bytes/s, typical.

LONG INTEGRATION MODE CURRENT MEASUREMENT

MEASUREMENT TIME6: 850ms (840ms) to 60 seconds in 1ms steps.

DIGITAL VOLTMETER INPUT (2 Years, 23°C ± 5°C)

INPUT VOLTAGE RANGE: –5 to +30V DC.

INPUT IMPEDANCE: 2MΩ typical.

MAXIMUM VOLTAGE (either input terminal) WITH RESPECT TO OUTPUT LOW: –5V, +30V.

READING ACCURACY

READING RESOLUTION: 1mV.

CONNECTOR: HI and LO input pair part of Output #2’s terminal block.

MEASUREMENT TIME CHOICES: 0.01 to 10PLC

AVERAGE READINGS: 1 to 10.

REA DING TIME

AC LINE LEA KAGE CURRENT: 450µ A @ 110VAC, typ.; 60 0µA @ 220V, typ.

RELAY CONTROL PORT: 4- channel, each capable of 100m A sink, 24V max. Total port sink capac-

ity (all 4 combined) is 250mA max. Accepts DB-9 male plug.

1 PLC = 1.00.

2 Following 15 mi nute warm-up, t he change in o utput over 8 hours under ambient t emperature, constant load,

and li ne operating conditio ns.

3 Remote sense, at output termi nals, 0.5A to 5A t ypical.

4 Remote sense, with 4.5m (15 ft) of 16 gaug e (1.31mm

test env ironment, 1.5A load change (0.15A to 1.65A).

5 Minimum cu rrent in const ant current mode is 6mA .

6 60Hz (50Hz).

7 PLC = Power Lin e Cycle. 1PLC = 16.7ms for 60Hz operat ion, 20ms for 50 Hz operation.

8 Display off.

9 Speed includes measurement a nd binary d ata transf er out of GPIB.

10 Typical values, peak-t o-peak nois e equals 6 ti mes rms noise .

11 Based on settled sig nal: 100µs pul se trigger d elay.

12 Als o applies to oth er aperture s that are in teger multiples of 1PLC.

13 Recover y to withi n 20mV of previous level.

1

: ±(0.05% + 3mV).

1, 8, 9

: 31ms, typical.

7

, in 0.01PLC steps.

2

) wire and 1Ω resist ance in each le ad to simulate typical

1.888.KEITHLEY

1.888.KEITHLEY

SPECIALIZED POWER SUPPLIES

SPECIALIZED POWER SUPPLIES

www.keithley.com

www.keithley.com

(U.S. only)

(U.S. only)

A GREATER MEASURE OF CONFIDENCE

A GREATER MEASURE OF CONFIDENCE

Page 7

1.888.KEITHLEY

www.keithley.com

(U.S. only)

SPECIALIZED POWER SUPPLIES

A GREATER MEASURE OF CONFIDENCE

Page 8

All Keithley trademar ks and t rade names are the property of Keithley Instruments, Inc.

All other trademark s and trade names are the pro perty of their respective companie s.

Specifications are subject to change without notice.

A GREATER MEASURE OF CONFIDENCE

KEITHLEY INSTRUMENTS, INC. ■ 28775 AURORA ROAD ■ CLEVELAND, OHIO 44139-1891 ■ 440-248-0400 ■ Fax: 440-248-6168 ■ 1-888-KEITHLEY ■ www.keithley.com

BELGIUM

Sint-Pieters-Leeuw

Ph: 02-3630040

Fax: 02-3630064

info@keithley.nl

www.keithley.nl

CHINA

Beijing

Ph : 8610 - 82 255010

Fax: 8610-82255018

china@keithley.com

www.keithley.com.cn

FINLAND

Espoo

Ph: 358-40-7600-880

Fax: 44-118-929-7509

finland@keithley.com

www.keithley.com

FRANCE

Saint-Aubin

Ph: 01-64532020

Fa x: 01- 60117726

info@keithley.fr

www.keithley.fr

GERMANY

Germering

Ph: 089-84930740

Fax: 089-84930734

info@keithley.de

www.keithley.de

INDIA

Bangalore

Ph: 080-26771071, -72, -73

Fax: 080-26771076

support_india@keithley.com

www.keithley.com

ITALY

Peschiera Borromeo (Mi)

Ph: 02-5538421

Fax: 02-55384228

info@keithley.it

www.keithley.it

JAPAN

Tok yo

Ph: 81-3-5733-7555

Fax: 81-3-5733-7556

info.jp@keithley.com

www.keithley.jp

SWEDEN

Stenungsund

Ph: 08-50904600

Fax: 08-6552610

sweden@keithley.com

www.keithley.com

KOREA

Seoul

Ph: 82-2-574-7778

Fax: 82-2-574-7838

keithley@keithley.co.kr

www.keithley.co.kr

SWITZERLAND

Zürich

Ph: 044-8219444

Fax: 044-8203081

info@keithley.ch

www.keithley.ch

MALAYSIA

Penang

Ph: 60-4-643-9679

Fax: 60-4-643-3794

chan_patrick@keithley.com

www.keithley.com

TAIWAN

Hsinchu

Ph: 886-3-572-9077

Fax: 886-3-572-9031

info_tw@keithley.com

www.keithley.com.tw

NETHERLANDS

Gorinchem

Ph: 0183-635333

Fax: 0183-630821

info@keithley.nl

www.keithley.nl

UNITED KINGDOM

Theale

Ph: 0118-9297500

Fax: 0118-9297519

info@keithley.co.uk

www.keithley.co.uk

SINGAPORE

Singapore

Ph: 65-6747-9077

Fax: 65-6747-2991

koh_william@keithley.com

www.keithley.com.sg

SPECIALIZED POWER SUPPLIES

© Copyright 2009 Keithley Instruments, Inc. Printed in the U.S.A. No. 2118 60909.2KCG

30%

Loading...

Loading...