Page 1

Multi-Channel Hipot Tester

MODEL 19020 SERIES

Key Features :

■ 10 channels in one design

■ 10 sets of sync output and measurement

■ AC/DC/IR 3 in 1 EST test

■ Master/Slave link - 10 units max.

■ Programmable V-output and limits

■ OSC (Open/Short Check)

■ Flashover detection

■ 5kVAC & 6kV DC hipot test

■ 1MΩ~50GΩ insulation resistance test

■ Standard RS232 / Handler interface

■ Optional GPIB interface

■ Large LCD panel

■ Key lock function

■ CE Mark

MULTICHANNEL HIPOT TESTER

MODEL 19020 SERIES

High Eciency Hipot Test Solution

Hipot test is one of the major test items in electrical

safety test. All electrical components and products

including transformers, capacitors, power supplies,

chargers and home appliances all require Hipot

test.

Wi th more tha n 2 5 ye ars of ex pe ri en ce in

de vel o p i ng t h e i n st ru me nts fo r t es t an d

measurement, Chroma creates the 19020 multichannel Hipot tester with a brand new architecture.

It can measure the Hipot leakage current of all

channels at the same time and conduct tests on

100 DUTs maximum simultaneously.

There is no need to purchase various Hipot testers

to save the production line space. I ts one time

multi -c hannel tes t can increase the eff iciency

of e le ctrica l re gul atory test . It i mpr ov es t he

productivity and reduces the risk of test for the

products that require Hipot test only.

Chrom a 190 20 also has powe rful func tion s in

Fla shover detection and Open/S hort Check . It

contains several international patents and is the

best tool for electrical regulatory Hipot test as not

only reliable quality can be obtained, but highly

ecient test platform can also be created.

World's First Sync Hipot Test

(Patent Registered)

Chroma 19020 has equipped wit h the world 's

firs t sync Hi pot test functio n that on e single

unit can perform 10 channels sync output and

measurements simultaneously. Maximum 10 units

(master & slave) can be controlled to have 100

channels in total. They can be grouped for output

to avoid creating voltage dierence due to adjacent

tests as well as to improve the productivity.

Applications

Chroma 19020 can be applied to various electrical

products for time consuming tests such as quality

assurance sampling test and production line test.

• Power cord

• Capacitor

• Resistance

• Switch

• Connector

• Transformer

• Charger

• Adapter

AC

in

DC

out

Page 2

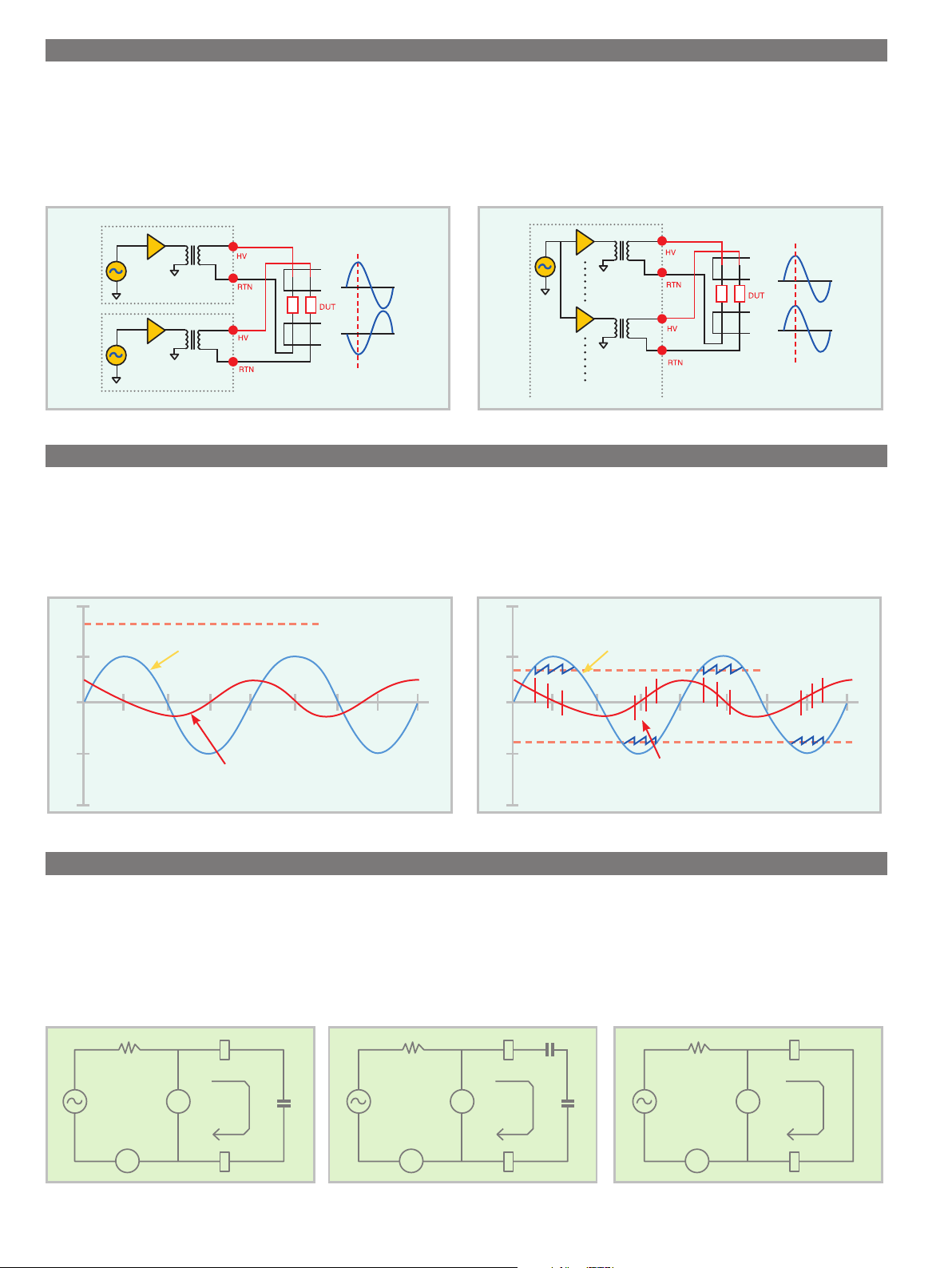

SYNCHRONOUS HI-POT TEST

The issue frequently encountered when testing multiple DUTs for Hipot is unable to synchronize the voltage output. When planning for production line or

automation, minimized facility and optimized space are often utilized in the plant; therefore, the distance between two DUTs is usually very short. Taking the

output voltage 5kVac for example, when the output of Hipot tester is not synchronized, the two DUTs may create a discharge of high voltage dierence (up

to14kV peak-peak) and cause the xture to be damaged and erroneous judgment. Chroma 19020 synchronizes the output signal so there is no high voltage

dierence on the adjacent two ends that not only can extend the life of production equipment but also reduce the occurrence of misjudgment.

~0kV

Figure 1 : Unsynchronized Output

~14kV p-p

10 Channel Output

Figure 2 : Synchronized Output

FLASHOVER DETECTION

Same as other Chroma EST Series, 19020 has Flashover detection function. Flashover is the electrical discharge generated by high electric eld inside or on the

surface of insulation material that makes the DUT to lose its insulation characteristic and form a transient or discontinuous discharge. It can cause a carbonized

conductive path or damage the product under test. Flashover cannot be detected by monitoring leakage current only. The change rates of test voltage or

leakage current are monitored to detect ashover as its detection is one of the most indispensable test items for electrical safety test.

10

Gap Discharge Voltage

Test Voltage Waveform

10

Test Voltage Waveform

Gap Discharge Voltage

0

180 360

Leakage Current (normal capacitive)

-10

Figure 3 : Normal Leakage Current Waveform

0

180 360

Leakage Current (abnornmal with ashover)

-10

Figure 4 : Leakage Current Waveform when Flashover occurred

OPEN / SHORT CHECK (OSC)

OSC function can check if there is any Open (bad connection) or Short (DUT short circuited) occurred during test. If a DUT is open circuit during test, the unit

might be misjudged as a good one. If a DUT has short circuit, OSC function can lter it out to diminish the damage to xture and save the test cost.

In general, products under Hi-pot test have capacitance (CX). CX could be tens of pF to several μF in normal condition. When the circuit connection is

interrupted, a small capacitance (Cc in Figure 6) will be formed on the broken interface that is usually lower than 10pF. It makes the entire capacitance of the

product lower than normal value. The capacitance of a product may be higher than normal when the product is short-circuited or near short circuit. Thus the

high/low limit of capacitance variation can be used to identify the short circuit problem.

Hi

V

s

V

µA

Lo

C

x

V

s

µA

Hi

V

Lo

C

c

C

x

V

s

V

µA

Hi

Lo

Figure 5 : Normal Connection Figure 6 : Connection Open Figure 7 : Connection Short

Page 3

APPLICATION

P

S

C

10

Chroma 19020 can be applied to test various electrical parts and

products. The multi-channel Hipot tester can test multiple DUTs at

once. The applications include:

• Automation of power cord and related cable material

• Automation of capacitor and resistance

• Insulation test of switch and connector

• One time test for transformer with multiple pins or multiple units

• Production planning for charger and adapter

With 190201 3-CH scanner, 19020 can finish 3 Hipot tests at once.

Taking a two winding transformer as an example, the following three

Hipot tests can be done at one time within a DUT loading time.

1. Primary to Secondary Hipot test.

2. Primary to Core Hipot test

3. Secondary to Core Hipot test.

This application can be applied to transformer, power adapt er,

common mode choke and so forth.

For different test solutions, Chroma has accessories and fixtures

available for use. Please contact local service for further information.

Figure 8 : A190201 with 3 way scanning

PANEL DESCRIPTION

1011

1 2

12 13 14 15 16 17 18 19 20

3 4

6

987

5

1. Power Switch

2. LCD Display

3. Function Keys

4. Cursor and Enter Keys

5. PASS/FAIL LED Indicator

6. Danger LED indicator

7. Test Key

8. Main Index

9. System Key

10. STOP Key

11. START Key

12. GPIB Interface (optional)

13. RS232 Interface

14. Internal Communication Interface

15. Master/Slave selector

16. Interlock

17. Handler Interface

18. Internal Control Interface

19. Fuse and Earth Terminal

20. AC Input

21. HV Output Module

22. High Voltage Terminal

23. Return/Low Terminal

212223

Page 4

SPECIFICATIONS

Model 19020 19020-4 19021 19022

Mode AC/DC/IR AC/DC/IR AC DC/IR

Channel 10 4 10 10

Withstanding Voltage Test

Output Voltage AC:0.05kV-5kV ; DC:0.05kV-6kV AC:0.05kV-6kV DC:0.05kV-8kV

Load Regulation 2% of setting + 0.1% of full scale

Voltage Resolution 2V

Voltage Accuracy 2% of setting + 0.1% of full scale

Cuto Current AC : 0.01 ~ 10mA, DC : 0.001 ~ 5mA

Current Resolution AC : 1μA, DC : 0.1μA

Current Accuracy 1% of setting +0.5% of full scale

Output Frequency 50Hz / 60Hz

Flashover Detection AC : 1mA ~ 15mA, DC : 1mA ~ 5mA , step 0.1mA

Test Time 0.03 ~ 999.9 sec, continue

Ramp Time 0.1 ~ 999.9 sec, o

Fall Time 0.1 ~ 999.9 sec, o

Dwell Time 0.1 ~ 999.9 sec, o

Waveform Sine wave

Insulation Resistance Test(19020&19022 series only)

Output Voltage DC : 0.05 ~ 1kV

Voltage Resolution 2V

Voltage Accuracy 2% of setting + 0.1% of full range

IR Range 1MΩ ~ 50GΩ

1MΩ ~ 1GΩ : ± 3% of reading + 0.1% of full range

Resistance Accuracy

≥ 500V

1GΩ ~ 10GΩ : ± 7% of reading + 0.2% of full range

10GΩ ~ 50GΩ : ± 10% of reading + 1% of full range

≤ 500V 1MΩ ~ 1GΩ : ± 3% of reading + (0.2*500/Vs)% of full scale

Test Time 0.3 ~ 999.9 sec, continue

Memory Storage

Save/Recall 30 instrument setups with up to 10 test steps can be stored into and recalled from the internal memory

Secure Protection Function

Fast Output Cut-o 0.4ms after NG happen

Panel Operation Lock Present password

Interlock YES

GO/NG Judgment Window

Indication, Alarm GO : Short sound, Green LED, NG : Long sound, Red LED

Data Hold Least tests data memories

Memory Storage 30 instrument setups with up to 10 test steps

Interface

RS232 & Handler (Standard), GPIB (Optional)

CANBUS & data control interface are used for Max. 10 units of master & slaves connection

General

18 to 28℃ (64 to 82℉), 70% RH.

Operation Environment

Maximum relative humidity 80% for temperature up to 31℃ (88℉)

Decreasing linearly to 50% relative humidity at 40℃(104℉)

Power Consumption Standby : < 250W ; With rated load : <1000W

Power Requirements AC 100V~240V, 47~66 Hz

Weight Approx.40 kg

All specifications are subject to change without notice. Please visit our website for the most up to date specifications.

19022-4

DC/IR

4

ORDERING INFORMATION

19020: Multi-Channel Hipot Tester

19020-4: Multi-Channel Hipot Tester (4CH)

19021: Multi-Channel Hipot Tester (AC)

Developed and Manufactured by :

CHROMA ATE INC.

致茂電子股份有限公司

HEADQUARTERS

No. 66, Hwa-Ya 1st Rd.,

Hwa-Ya Technology Park,

Kuei-Shan Hsiang,33383

Taoyuan County, Taiwan

Tel: +886-3-327-9999

Fax: +886-3-327-8898

http://www.chromaate.com

E-mail: info@chromaate.com

CHINA

CHROMA ELECTRONICS

(SHENZHEN) CO., LTD.

8F, No.4, Nanyou Tian An

Industrial Estate, Shenzhen,

China PC: 518052

Tel: +86-755-2664-4598

Fax: +86-755-2641-9620

19022: Multi-Channel Hipot Tester (DC/IR)

19022-4: Multi-Channel Hipot Tester (DC/IR/4CH)

A190508: GPIB Interface

JAPAN

CHROMA JAPAN CORP.

472 Nippa-cho, Kouhoku-ku,

Yokohama-shi, Kanagawa,

223-0057 Japan

http://www.chroma.co.jp

E-mail:info@chromaate.com

U.S.A.

CHROMA SYSTEMS

SOLUTIONS, INC.

25612 Commercentre Drive,

Lake Forest, CA 92630-8830

Tel: +1-949-600-6400

Fax: +1-949-600-6401

Toll Free: +1-866-600-6050

http://www.chromausa.com

E-mail: sales@chromausa.com

A190200: 19" Rack Mounting Kit for 19020 Series

A190201: 3-CH Scanner

*HV cable is optional for customized requirement.

Distributed by:

EUROPE

CHROMA ATE EUROPE B.V.

Morsestraat 32, 6716 AH Ede,

The Netherlands

Tel: +31-318-648282

Fax: +31-318-648288

http://www.chromaeu.com

E-mail: sales@chromaeu.com

Worldwide Distribution and Service Network

19020-201108-2000

Loading...

Loading...