Page 1

Section 1

Introduction and Specification

The TEKTRONIX 1730-Series is an 8-1/2-inch wide by 5-1/4-inch high

waveform monitor, weighing approximately 8 pounds. The 1730 (System M,

NTSC) and the 1731 (System I, B, etc., PAL, PAL-M), and the 1735 (dual-standard) versions can be powered from an ac source or, with the addition of a field

upgrade kit (1700F10), 12 Vdc. The CRT occupies approximately two-thirds of

the front-panel area, with the control panel taking up the remainder of the space.

Operation is controlled by a microprocessor that polls the front-panel switches

and remote ground closures. Front-panel switches are of the momentary touch

type with lighted functional indicators. Most of the switches are also used to

select special functions, which are accessed by holding the switches in until the

microprocessor recognizes the request.

The signal is displayed on a bright CRT capable of displaying one line per frame.

It is of the mesh type, for better geometry, and uses an internal graticule to

reduce parallax. Variable graticule scale illumination provides even lighting to

improve measurement accuracy and the quality of waveform pictures. Option 74

provides a P4 (white) phosphor tube.

The Channel A and B Composite Video Inputs and the External Reference

Signal Input are high impedance bridging loop-throughs, in order to protect the

integrity of the signal paths. The input switching allows for the display of either

Channel A or Channel B Input or both inputs. Synchronization can be either

internal or external, with the further choices of using remote sync or 90 or 100

Hz synchronization, from a VTR, where the application warrants.

The 1730-Series offers a choice of three basic sweep rates: 2 Field, 2 Line, and

1 Line, each of which can be magnified to provide three additional sweep rates:

1 ms (2 Line), 0.2 ms (1 Line), and X25 (2 Field) which provides for viewing the

complete vertical interval. In addition, there is full frame line selection that can

be displayed as 1 line, 2 lines, or 15 lines. A bright-up pulse, for picture

monitors, that corresponds to the intensified region on the CRT display, is

available through a rear-panel bnc connector.

The vertical signal processing provides a choice of fast or slow dc restoration, or

an unclamped display. The input signal can be unfiltered (Flat) or either Low

Pass or Chrominance filtered. There is also a combination of Flat and Low Pass

filtering available when a 2 Line or 2 Field sweep rate is employed; the display

consists of one line or field low pass filtered while the second is unfiltered.

Vertical amplitudes can be displayed in a calibrated gain mode, which corresponds directly with the graticule vertical scales, magnified 5 times, or can be set

to a specific amplitude by using the Variable GAIN control.

1–1

Page 2

1730–Series Introduction

An RGB or YRGB Parade display, for camera setup, is accommodated with a

shortened sweep. The input of the camera signal and an enable are through the

rear-panel REMOTE jack. The choice of 3-step (RGB) or 4-step (YRGB) is

made by changing the position of an internal jumper.

The 1730-Series has a unique Store and Recall function built in that allows for

the storing of up to four front-panel setups that can be recalled by pressing the

appropriate recall button, or a ground closure through the rear-panel REMOTE

connector. In addition, four factory-programmed measurement setups can be

accessed, by external ground closures input through the REMOTE connector.

An auxiliary output, to control a companion 1720-Series Vectorscope, is

provided through a rear-panel connector. The auxiliary output contains a bus for

two-way communications between the waveform monitor and vectorscope

microprocessors and a strobe to provide line select unblanking for the Vectorscope.

Typical Configurations

The 1730-Series Waveform Monitor is designed for operation either alone or

with a 1720-Series Vectorscope. Line select and measurement recall for this

waveform monitor are also used by the vectorscope. Because of these capabilities, and the available 90 or 100 Hz triggering, the 1730-Series Waveform

Monitor is ideally suited to operate in a VCR bridge. With its factory-preset

measurement routines, that can be accessed through the rear-panel REMOTE

connector and the Store/Recall functions, it is possible to have one-button

measurements of key parameters, including various vectorscope measurements.

In addition to the VCR bridge and the typical Master Control monitoring

applications, this monitor can be used in camera chains. It has a choice of RGB

or YRGB Parade display that can easily be selected by changing one internal

jumper setting. The Parade signal and enable are input through the rear-panel

REMOTE connector.

A number of operating conditions can be altered by changing internal jumpers,

using some of the factory-preset combinations, or setting up and saving the front

panel with the Store/Recall function. Using these methods most of the current

528A operational modes can be accommodated. There is a difference in how the

remote control operates — the 1730-Series uses ground closures, not positive

voltage as the 528A did.

1–2

Page 3

Options

1730–Series Introduction

CRT Options

Power Cord Options

Accessories

Standard Accessories

The standard instrument is shipped with a P31 (green) phosphor CRT installed.

Option 74 instruments are shipped with a P4 (white) phosphor CRT installed.

Any of the power cord options described in Section 7 can be ordered for the

1730-Series. If no power cord option is ordered, instruments are shipped with a

North American 125 V power cord and one replacement fuse.

The following accessories are shipped with the 1730-Series. Part numbers for

these accessories are located at the end of the Replaceable Mechanical Parts list.

1 1730-Series Instruction Manual

1 Power Cord, with selected power plug option

1 Replacement Cartridge Fuse (correct rating for the power

plug option)

3 Replacement Scale Illumination Bulbs (Tektronix Part

No. 150-0168-00 or ANSI #73)

Optional Accessories

There are a number of accessories that can be used with a 1730-Series Waveform

Monitor. The following is a list of the most common accessory items for this

series of waveform monitors. 1700F items are Field Upgrade Kits that are

installed by the customer; instructions are included in all Field Upgrade Kits.

Viewing Hood (016-0475-00)

Front Panel Cover (200-3897-01)

1700F00, Plain Cabinet (painted silver-grey)

1700F02, Portable Cabinet (painted silver-grey)

1700F05, Side-by-Side Rack Adapter

1700F06, Blank Half-Rack Width Panel

1700F10, DC Power Converter

1–3

Page 4

1730–Series Introduction

Safety Information

Specification

The 1730-Series is intended to operate from an ac power source that will not

apply more than 250 V rms between the supply conductors or between either

supply conductor and ground. A protective ground connection by way of the

grounding conductor is essential for safe operation (except for those instruments

that are operated from a battery supply).

The 1730-Series was tested for compliance in a cabinet. To ensure continued

compliance, the instrument will need to be enclosed in a cabinet that is equivalent to the Factory Upgrade Kits that are listed as Optional Accessories for the

1730-Series. A drawing of the 1700F00 plain cabinet is contained in the

Installation Instructions (Section 3).

In the specification tables that follow, some items are identified as performance

requirements. These can be verified by performing the Performance Check

Procedure in Section 5. Not all performance requirements have a measureable

tolerance, and therefore do not have a performance check step; however, they are

either verified by indirect means, through other portions of the procedure, or are

design criteria that do not need to be tested for individual instruments.

Whenever there is a verifiable performance requirement, in the specification

table, there will also be a reference to identify the location, in the Performance

Check Procedure, of the appropriate performance verification procedure.

The supplemental Information designation in the tables indicates that this is

information that either amplifies a performance requirement or is special

information that is of importance. Unlike performance requirements, there is no

need, and often no way to check these items to any specific tolerance.

1–4

Page 5

1730–Series Introduction

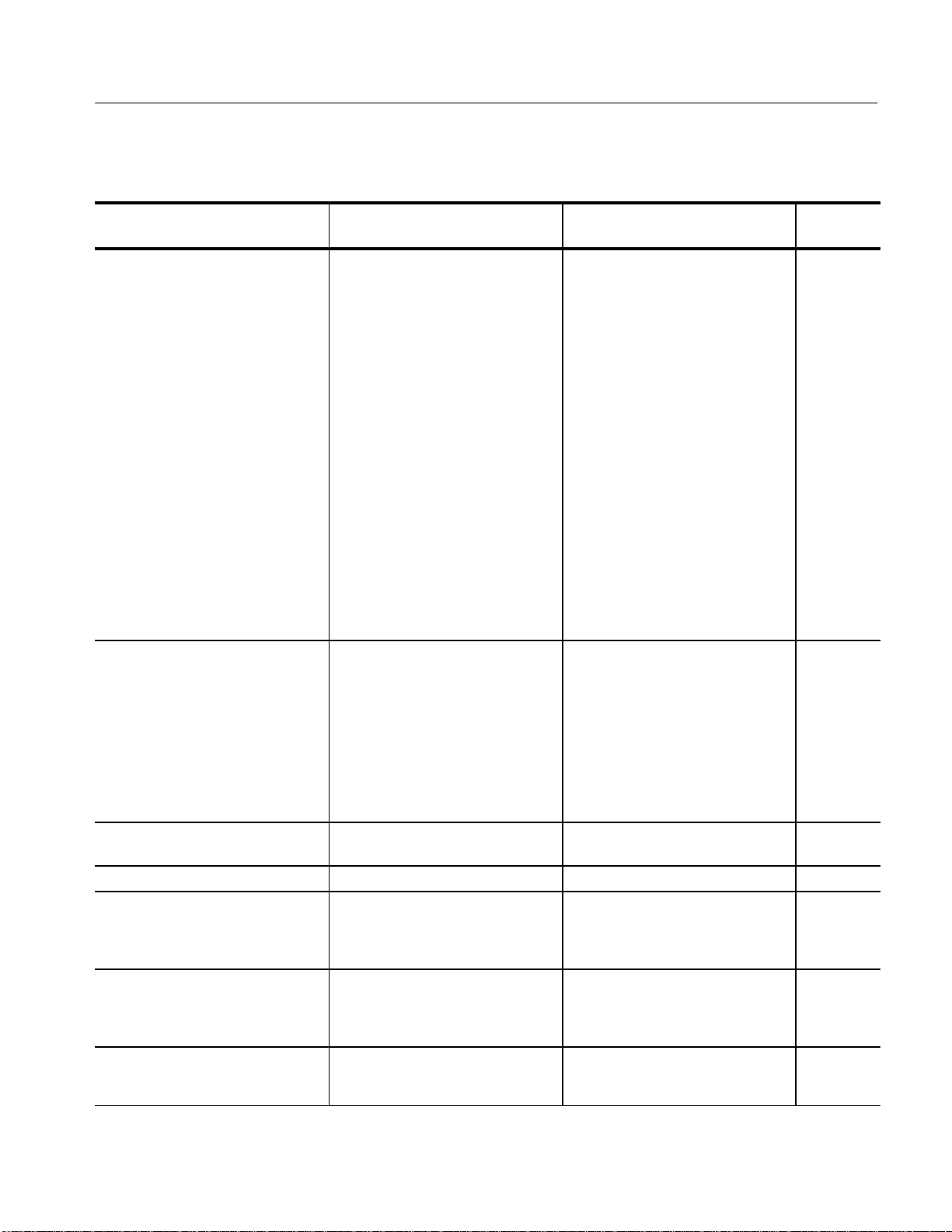

T able 1–1: Vertical Deflection System

Characteristic Requirement Supplemental Information

Frequency response

Flat

Flat: 50 kHz to 6 MHz within 2% of

response at 50 kHz.

Flat (X5): 50 kHz to 6 MHz within 5%

of response at 50 kHz.

Specifications apply for full screen

height video input signal, with variable

GAIN off.

Step

Number

13

Low-pass filter

Chroma filter

Transient response Preshoot: ≤1%

Field rate tilt ≤1% Field rate square wave or vertical

Line rate tilt ≤1% 25 ms bar 15

Overscan Less than 2% variation in baseline of

Differential gain Displayed differential gain is ≤1% with

Deflection factor 140 IRE (1.0 V) within 1% with 1 V

1730: At least 30 dB attenuation at

3.58 MHz

1735: 4.00 MHz

1731: 4.43 MHz

NTSC and PAL-M: Nominal bandwidth

1 MHz. Attenuation at 7.2 MHz 20 dB

or greater. Response at 3.58 MHz

does not vary between FLAT and

CHROMA by more than 1%.

PAL: Nominal bandwidth 1 MHz.

Attenuation at 8.9 MHz 20 dB or

greater. Response at 4.43 MHz does

not vary between FLAT and CHROMA

by more than 1%.

Pulse-to-Bar Ratio: X1: 0.99:1 to

1.01:1X5: 0.98:1 to 1.02:1

Overshoot: X1: 2% or less X5: 4%

or less

Ringing: X1: 2% or less X5: 4% or

less

100 IRE (700 mV) 12.5T (20T)

modulated pulse as it is positioned

over the middle 80% of the screen.

10% to 90% APL changes.

input.

Response at 15 kHz does not vary

between FLA T and LPASS by more

than 1%

Upper and lower –3 dB points are

approximately ±350 kHz from

3.579545 MHz. 15 to 35 C operating

temperature.

Upper and lower –3 dB points are

approximately ±350 kHz from

4.433619 MHz. 15 to 35 C operating

temperature.

Specifications apply for full screen

height video input signal, with variable

GAIN off.

window

Chroma filter must be selected.

Baseline at 50 IRE and displayed

subcarrier adjusted to 100 IRE with

VAR gain.

1 V full scale. 20-30 °C, Flat response

selected. Vertical gain temperature

coefficient is –0.3%/10 °C.

17

18

15, 16

15

15

9

1–5

Page 6

1730–Series Introduction

T able 1–1: Vertical Deflection System (Cont.)

Characteristic

X5 gain accuracy ±5% 1 V input signal 9

X5 gain registration ≤1 major div. of vertical shift from

baseline.

Variable gain range Input signals between 0.8 V and 2 V

can be adjusted to 140 IRE (1.0 V)

display. 160 mV and 400 mV for X5

gain.

Position range 1 V signal can be positioned so that

peak white and sync tip can be placed

at blanking level, with the DC RESTORER on, regardless of gain

setting.

Maximum absolute input level ±5 VDC + peak AC Displays in excess of 200 IRE

DC input impedance Greater than 15 kW (unterminated)

Return Loss (75 W) video inputs

(CH-A, CH-B)

Crosstalk between channels Greater than 50 dB of isolation

Loop through isolation Greater than 80 dB of isolation

PIX MON frequency response 50 kHz to 6 MHz, within 3% of

PIX MON differential gain (50% APL) Within 1% with a 140 IRE (1.0 V) unit

PIX MON differential phase (50%

APL)

PIX MON DC level on output 0.5 V or less into 75 W. load No input signal 11

PIX MON intensification (bright-up) During line select only. Active video of

PIX MON output impedance 75 W. (nominal)

PIX MON return loss (75 W) ≤30 dB, 50 kHz to 6 MHz With instrument turned on 19

Input to PIX MON output gain ratio 1:1 ±5% at 15 kHz 11

≥40 dB from 50 kHz to 6 MHz A and B channels, loop-through

response at 50 kHz

display

Within 1° with a 140 IRE (1.0 V) unit

display

Supplemental InformationRequirement

Unmagnified to magnified display 9

Applies to calibrated gain positions

only

(1.428 V) may cause frequency

response aberrations.

terminated in 75W. Input in use or not

in use, instrument power on or off, all

deflection factor settings.

between channels. Measured at F

between Channel A, Channel B, and

EXT REF.

between loop-throughs. Measured at

FSC between Channel A, Channel B,

and EXT REF.

Terminated in 75 W 14

selected lines has a DC offset of

approximately 180 mV .

SC

Step

Number

9

9

19

1–6

Page 7

1730–Series Introduction

T able 1–2: DC Restoration

Characteristic Requirement Supplemental Information

DC restorer clamp time Back porch

Frequency response at 60 Hz Slow: 20% or less

Fast: 90% or greater

Blanking level shift with 10% to 90%

APL change

Blanking level shift due to presence or

absence of burst

APL changes from 50% to either 10%

or 90% will cause blanking level shift

of 1 IRE unit (7.14 mV) or less.

1 IRE unit (7.14 mV) or less shift from

no color burst to presence of color

burst.

Attenuation of 60 Hz on input signal 12

Step

Number

12

12

T able 1–3: Calibrator

Characteristic Requirement Supplemental Information

Frequency 100 kHz ±100 Hz Synchronizes in 2H and 1H sweeps. Crystal controlled. Timing

accuracy is 10 µs, ±0.01 µs. Can be used as 10 µs and 1 µs timing

calibrator.

Amplitude 140 IRE (1 V) within 1% 10

Position Top of waveform must be between 80 IRE (0.86 V) and 120 IRE

(1.14 V) on graticule when backporch is positioned to 0 IRE (0.300 V)

line, with DC RESTORER on.

T able 1–4: Horizontal Deflection System

Characteristic Requirement Supplemental Information

Sweep Sweep occurs in all horizontal mode

settings with or without synchronization.

2FLD sweep repetition rate Equal to frame rate of applied video or

external sync

2FLD sweep magnification Approximately X25

Step

Number

3

Step

Number

5

1–7

Page 8

1730–Series Introduction

T able 1–4: Horizontal Deflection System (Cont.)

Characteristic

1LINE sweep repetition rate Equal to line rate of applied video or

external sync

2LINE sweep repetition rate Equal to half line rate of applied video

or external sync

Sweep length 2LINE and 2FLD sweep length is

Timing accuracy All timing and linearity specifications

10 µs/div. (2LINE) sweep accuracy Within 2% 6

5 µs/div . (1LINE) sweep accuracy Within 2% 6

0.2 µs/div. (1LINE + MAG) sweep

accuracy

Integral linearity Within 1% Measured between the 10 ms and

Sweep magnifier registration Magnification occurs about center of

HORIZONT AL position Any portion of a synchronized video

Within 2% 6

sweep can be positioned on screen in

all sweep modes.

Supplemental InformationRequirement

nominally 12.5 divisions.

exclude the first and last major

divisions of the unmagnified display.

Timing can be adjusted ±5% with

front-panel H CAL.

110 ms points on the 10 ms/division

sweep. Calibrator transitions fall

exactly on graticule marks.

screen

Step

Number

6

1–8

Page 9

T able 1–4: Horizontal Deflection System (Cont.)

Characteristic

LINE SELECT Displays the selected line in 1LINE.

Displays the selected line first in

2LINE. Intensifies selected line in

2FLD. In 15LINE, displays overlayed

lines in 1 or 2LINE, intensifies the

selected 15 lines in 2FLD. A small 15

is added to the bottom of the CRT

readout in 15LINE mode.

Readout NTSC:

Supplemental InformationRequirement

Field 1: Lines 1 to 263

Field 2: Lines 1 to 262

All: Lines 1 to 262

PAL

Field 1: Lines 1 to 313

Field 2: Lines 314 to 625

All: Lines 1 to 312

1730–Series Introduction

Step

Number

PAL-M

Field 1: Lines 1 to 263

Field 2: Lines 264 to 525

All: Lines 1 to 262

T able 1–5: Synchronization

Characteristic Requirement Supplemental Information

Input requirements, internal reference

NTSC and PAL–M

Composite video or black burst with

sync amplitudes 40 IRE ±6 dB

PAL

External reference Sync amplitude between 143 mV and

External reference, DC input impedance (unterminated)

Return loss (75 ) At least 40 dB from 50 kHz to 6 MHz Loop-through terminated in 75 ,

Absolute maximum input voltage ±12 VDC plus peak AC

Composite video or black burst with

sync amplitudes 300 mV ±6 dB

4 V will synchronize sweeps

Greater than 15 k

instrument power on or off

Step

Number

4

4

4

19

1–9

Page 10

1730–Series Introduction

T able 1–5: Synchronization (Cont.)

Characteristic

Remote sync

Amplitude

Sweep trigger polarity

90/100 Hz triggering amplitude 2.0 to 5.0 V square wave

90/100 Hz triggering frequency NTSC: 90 Hz ±15%

2.0 to 5.0 V square wave, or 4.0 V

comp sync

PAL: 100 Hz ±15%

Supplemental InformationRequirement

Input and enabled through rear-panel

REMOTE connector. Input Impedance

1 M. 30/60 Hz (25/50 Hz) square

wave will sync 2FLD Sweep. Remote

sync bypasses the sync stripper and

field ID circuits.

Internal jumper selects polarity.

Normal: Negative-going edge line

sync, positive edge of field sync.

Inverted: Positive-going edge line

sync, negative edge of field sync.

Step

Number

9

T able 1–6: RGB/YRGB Mode

Characteristic Requirement Supplemental Information

RGB/YRGB Will display either a 3-step or 4-step RGB/

YRGB parade or overlay display.

Staircase amplitude A 10 V input will result in a horizontal display

of 9 divisions ±1.4 major divisions.

Sweep repitition rate Field or line rate of displayed video or external

sync signal as selected by front-panel

HORIZONT AL controls.

Control RGB/YRGB mode and parade/overlay

Magnifier Approx. X25 for 2FLD, and X10 in 1 or 2LINE.

Sweep length 3-step: 3.4 — 4.1 divs

4-step: 2.5 — 3.1 divs

Internal jumper is used to change from 3-step

to 4-step capability . Factory set to 3-step.

Internal adjustment offsets any incoming

signal DC component between ±12 V . Input

impedance 1 M shunted by approx. 3 pF.

Field or line rate, if enabled from the REMOTE

connector.

selected by applying ground (TTL low) at the

RGB enable pin on the rear-panel REMOTE

connector. RGB components may be

overlayed with normal sweep length by not

activating RGB enable.

Field or line rate sweeps. A 1FLD sweep is

selected by grounding the 1FLD/1LINE pin of

the rear-panel REMOTE connector.

Step

Number

7

7

7

7

1–10

Page 11

1730–Series Introduction

T able 1–7: CRT Display

Characteristic Requirement Supplemental Information

CRT viewing area 80 X 100 mm

Horizontal = 12.5 div

Vertical = 170 IRE units (1.19 V)

Accelerating potential Nominally 13.75 kV

Trace rotation range Greater than ±1° from horizontal Total adjustment range is typically 8°

Graticule Internal, variable illumination

T able 1–8: Power Source

Characteristic Requirement Supplemental Information

Mains voltage range 90 – 250 V Continuous range from 90 to 250 VAC

Mains frequency 50 or 60 Hz

Power consumption 56 VA (35 Watts)

T able 1–9: Environmental Characteristics

Characteristic Requirement

Operating temperature 0 to 50 °C (+32 to 122 °F)

Storage temperature –40 to 75 °C (–40 to 158 °F)

Operating altitude To 15,000 feet (4572 meters)

Storage altitude To 50,000 feet (15,240 meters)

Vibration 5 minutes at 5 - 15 Hz with 0.060 inch displacement. 5 minutes at

15 - 25 Hz with 0.040 inch displacement. 5 minutes at 25 - 55 Hz

with 0.020 inch displacement. Military Specification:

Mil-T-28800D, Paragraph 1.2.2, Class 3.

Mechanical shock Non operating: 50 g’s 1/2 sine, 11 ms duration, 3 shocks per

surface (18 total).

Transportation Qualified under NST A Test Procedure 1A, Category II (24 inch

drop).

Humidity Will operate at 95% relative humidity for up to five days. Do not

operate with visible moisture on the circuit boards.

1–11

Page 12

1730–Series Introduction

T able 1–10: Certifications and Compliances

Category Standards or Description

EC Declaration of Conformity –

1

EMC

Meets intent of Directive 89/336/EEC for Electromagnetic Compatibility. Compliance was

demonstrated to the following specifications as listed in the Official Journal of the European Union:

EN 50081-1 Emissions:

EN 55022 Class B Radiated and Conducted Emissions

EN 50082-1 Immunity:

IEC 801-2 Electrostatic Discharge Immunity

IEC 801-3 RF Electromagnetic Field Immunity

IEC 801-4 Electrical Fast Transient/Burst Immunity

1

High-quality shielded cables must be used to ensure compliance to the above listed

standards.

This product complies when installed into any of the following Tektronix instrument

enclosures:

1700F00 Standard Cabinet

1700F02 Portable Cabinet

1700F05 Rack Adapter

Australia/New Zealand

Complies with EMC provision of Radiocommunications Act per the following standard(s):

Declaration of Conformity – EMC

AN/NZS 2064.1/2 Industrial, Scientific, and Medical Equipment: 1992

AN/NZS 3548 Information T echnology Equipment: 1995

FCC Compliance Emissions comply with FCC Code of Federal Regulations 47, Part 15, Subpart B, Class A Limits.

Installation (Overvoltage)

Category

Terminals on this product may have different installation (overvoltage) category designations. The

installation categories are:

CA T III Distribution-level mains (usually permanently connected). Equipment at this level is

typically in a fixed industrial location.

CA T II Local-level mains (wall sockets). Equipment at this level includes appliances, portable

tools, and similar products. Equipment is usually cord-connected.

CA T I Secondary (signal level) or battery operated circuits of electronic equipment.

Pollution Degree A measure of the contaminates that could occur in the environment around and within a product.

Typically the internal environment inside a product is considered to be the same as the external.

Products should be used only in the environment for which they are rated.

Pollution Degree 1 No pollution or only dry, nonconductive pollution occurs. Products in

this category are generally encapsulated, hermetically sealed, or

located in clean rooms.

Pollution Degree 2 Normally only dry, nonconductive pollution occurs. Occasionally a

temporary conductivity that is caused by condensation must be

expected. This location is a typical office/home environment.

Temporary condensation occurs only when the product is out of

service.

Pollution Degree 3 Conductive pollution, or dry, nonconductive pollution that becomes

conductive due to condensation. These are sheltered locations where

neither temperature nor humidity is controlled. The area is protected

from direct sunshine, rain, or direct wind.

1–12

Page 13

1730–Series Introduction

T able 1–10: Certifications and Compliances (Cont.)

Category Standards or Description

Pollution Degree 4 Pollution that generates persistent conductivity through conductive

dust, rain, or snow. Typical outdoor locations.

Safety Standards

U.S. Nationally Recognized

Testing Laboratory Listing

Canadian Certification CAN/CSA C22.2 No. 231 CSA safety requirements for electrical and electronic measuring and

European Union Compliance Low Voltage Directive 73/23/EEC, amended by 93/69/EEC

Additional Compliance IEC61010-1 Safety requirements for electrical equipment for measurement,

Safety Certification Compliance

T emperature, operating +5 to +40_ C

Altitude (maximum operating) 2000 meters

Equipment Type Test and measuring

Safety Class Class 1 (as defined in IEC 1010-1, Annex H) – grounded product

Overvoltage Category Overvoltage Category II (as defined in IEC 1010-1, Annex J)

Pollution Degree Pollution Degree 2 (as defined in IEC 1010-1). Note: Rated for indoor use only.

UL1244 Standard for electrical and electronic measuring and test equipment.

test equipment.

EN 61010-1 Safety requirements for electrical equipment for measurement,

control, and laboratory use.

control, and laboratory use.

T able 1–11: Physical Characteristics

Characteristic Requirement

Dimensions Height: 5 1/4 inches (133.4 millimeters)

Width: 8 1/2 inches (215.9 millimeters)

Depth: 18 1/8 inches (460.4 millimeters)

Weight Net: 8.5 pounds (3.8 kilograms)

1–13

Page 14

1730–Series Introduction

1–14

Page 15

Operating Instructions

Page 16

Loading...

Loading...