Page 1

ATD-5007

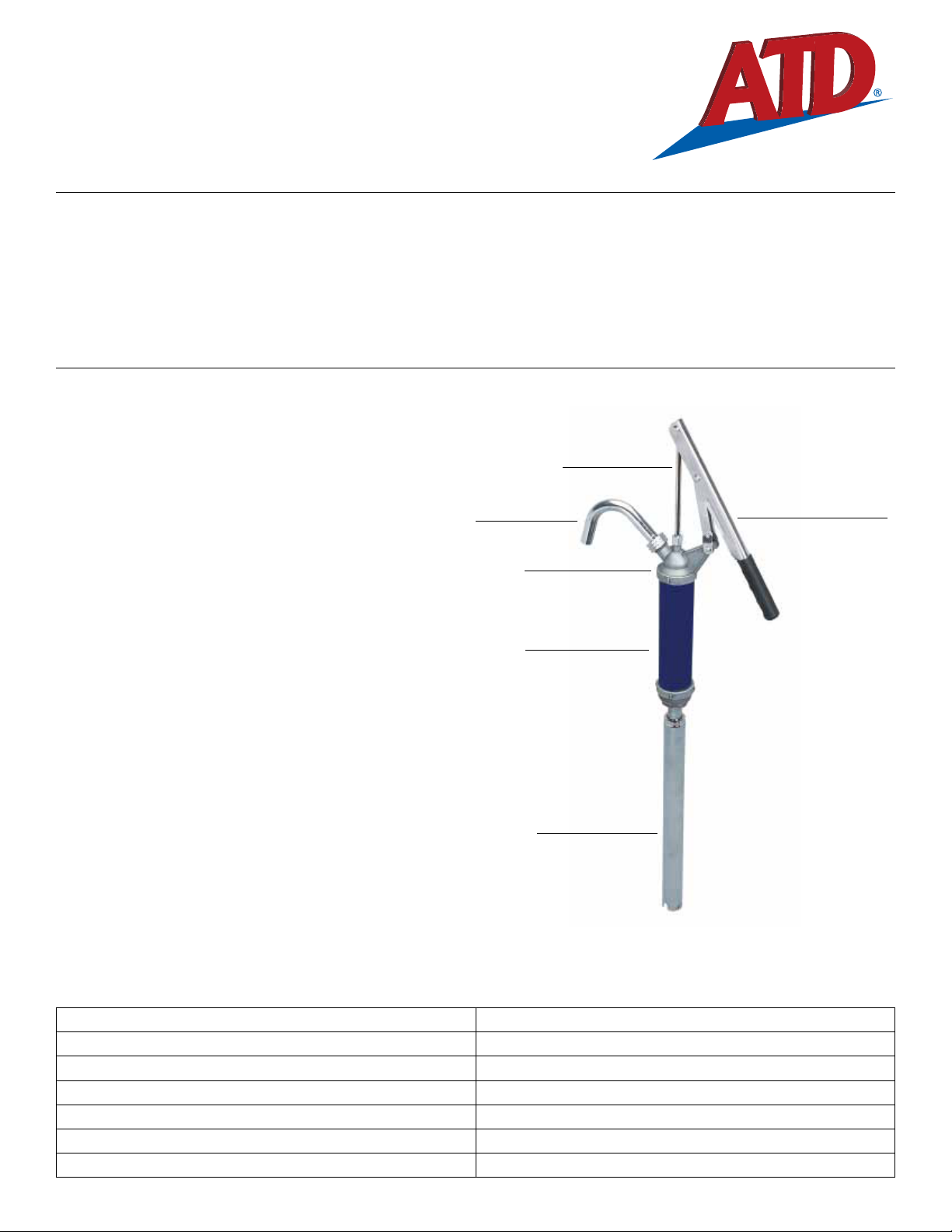

Lever Action Barrel Pump

LBP/04/BU

DESCRIPTION

• Oil Pump for use with oil based uids, heating oils,

motor oils, heavy & light oils, Diesel & Kerosene

• Premium powder coated steel pump body with

ribbed section aluminum die cast pump head for

maximum strength

• Built-in 1.1/2” & 2” bung for use on drums with either

openings

• Wear resistant Brass piston rings tted onto zinc die

cast piston

• Non return seal is NBR rubber.

• Comes complete with curved metal spout & telescopic

suction tube for use on 15 gallon (50 litres) – 55 gallons

(205 litre) barrels

Discharge

Spout

Aluminum Die

Cast Head

Barrel

Plunger Rod

Lever Handle

with

Rubber Grip

Telescopic

Suction Tube

SPECIFICATIONS

Mechanism Lever Action

Discharge Rate Up to 300 ml (10 oz. / stroke)

Wetted Components Steel, Aluminum, Zinc, Brass, NBR

Bung 1.1/2” & 2” threads

Pump Inlet 3/4” NPT

Fits 15-55 Gal (50-205 Litre) barrels

Max. temperature 60°C (140°F )

1

Page 2

PUMP CONSTITUENTS

ITEM NO. PART DESCRIPTION QUANTITY

1

2

3

4

PRODUCT DETAIL

Pump Assembly (Pump Head with Suction Tube & Plunger Rod) 1

Steel Spout with Nut 1

Lever Handle 1

Suction Tube 1

PACKAGING

INNER

PACKAGING

MASTER CARTON

Quantity Quantity Length Width Height CBM Net Weight

01 10 53 cm 35 cm 35 cm 0.064 25 Kg

Power Cord

Warning

Country of

Origin

Product

Warranty

Date Code

/ Factory

Product Warnings:

Code:

N/A India 12 Months N/A N/A

• Recommended use for dispensing oil based

heating oils, motor oils, heavy & light oils, Diesel

& Kerosene.

• Do NOT use this pump with water based

solvents, acids, antifreeze, gasoline etc.

• The pump is constructed using plated steel

components. It should never be used to transfer

that may cause the pump to rust

DISCLAIMER

Imperial dimensions shown as equivalent to Metric sizes are approximate, and vice versa.

2

Page 3

SERVICE INSTRUCTIONS

LEVER ACTION BARREL PUMP

Description

Lever Action Barrel Pump is a hand operated heavy duty

pump designed to transfer oil based fluids (lubricants),

heating oil, motor oil, heavy & light oils, transmission oils

and other non-corrosive liquids.

Fits : 15 gallons (50 litres) to 55 gallons (205 litres ) barrels.

Delivery : 300 ml (10 ounce) of fluid per stroke

The pump comes complete with self adjusting telescopic

suction tube, curved metal spout, and 1.1/2” & 2” bung

nut.

Assembly & Operation

1. Screw the Suction tube assembly into the bung nut.

Tighten the connection securely to eliminate any air leaks

Note : Apply thread sealent to the threads of the tube

assembly before attaching it to the bung nut. Do not use

undue force when tightening

Plunger Rod

Compression Nut

Delivery

Spout

Spout Nut

Pivot Pin &

Retainer Clip

Lever Handle

Rubber Grip

Connecting Link

Pump Head

Pump Body

Bung Nut

2. Screw the delivery spout nut (part of the spout) onto

the pump head. Tighten securely to eliminate possibility

of leakage.

Note : Ensure rubber gasket is positioned properly in

spout nut before attaching the spout.

3. Extend the telescopic suction pipe little longer than the

height of the drum.

Note : The telescopic suction tube will automatically

adjust to the proper position.

4. Screw the pump into the drum’s bung. Tighten the

pump assembly securely by grasping the pump body

and rotating.

Note : Do not tighten the barrel by holding the lever

handle.

5. Pull the plunger rod of piston sub assembly up and

attach the lever handle to the piston rod using the

pivot pin and retainer clip.

Note : Ensure

that the retainer clip is bent properly so as

to eliminate possibility of pivot pin coming out while

using the pump.

Now the pump is ready, start the pump by moving the

lever with several quick strokes.

Suction Tube Assembly

If the pump fails to operate, it may be nece

ssary to prime.

Prime The Pump

Turn the delivery spout upward.

Pour a few drops of the fluid being dispensed into the spout

Start the pump by moving the lever with several quick strokes.

If the pump still fails to start:

Remove the pump from the drum and ensure the Suction tube

is extended enough to reach the bottom of the drum

Pump Suitable for use with oil based fluids, heating

oils, motor oils, diesel oil, kerosene, heavy & light oils

Warning : The pump is constructed using plated steel components. It should never be used to transfer fluids that

may cause the pump to rust. Never use this pump with water based fluids, solvents, acid, antifreeze.

Certain fluids have a tendancy to build a coating on the surface when dry, it is recommended to leave the lever

handle in upright position when not in use

3

Loading...

Loading...