Page 1

ATD-8699

MASTER BALL JOINT SET

WARNING: TO HELP PREVENT PERSONAL INJURY

z Always wear ANSI approved goggles when using this product. Normal use of this product is likely to expose the

user to dust and/or microscopic particles containing chemicals known to the State of California to cause cancer,

birth defects or other reproductive harm. Always wear appropriates safety equipment and clothing when using this

product.

z Study, understand, and follow all instructions provided with this product.

z Before repairing vehicle, block the wheels to prevent the vehicle from moving.

z Check the final alignment of the C-frame press and all tooling with components before exerting pressure to remove

or replace a ball joint.

OPERATING INSTRUCTIONS

Brake Anchor Pin Remo val and Installation

1. Remove all lock ring retainers from the brake anchor pins.

2. Position the C-frame press over the brake spider as shown in Figure 1.

3. Tighten the forci ng screw until the anchor pin is r emove d.

U-Joint Assembly and Disassembly

The basic C-frame press is used to service the U-Joints on most cars and light trucks.

The U-Joints can be serviced either on or off the v ehicle.

Disassembly

1. Remove any external and/or internal lock rings.

Page 2

2. Position the C-frame press around the drive shaft yoke, and tighten the forcing screw until the first bearing is

removed.

3. Reposition the C-frame and remove the second bearing.

Assembly

1. Clean all dirt and oil from the yoke area.

2. Align the replacement bearing and C-frame press as straight as possible over the yoke. Press the replacement

bearing into the yoke, and reassemble the external / internal lock ring.

3. Reposition the C-frame press and secon d repl acement b earing as str aight as possibl e over t he yoke, and pr ess the

bearing into the yoke. Reassemble the external / internal lock ring.

Ball Joint Re moval and Installation

This tool set is designed for use on all cars and li ght truck s that ha ve press-fit typ e ball join ts wi thout th e need to r emove

the control arm from the vehicle.

NOTE: Some cars and light trucks may have the upper ball joint spot-welded to the control arm. The weld must

be cut before attempting to remove the ball joint.

Removal

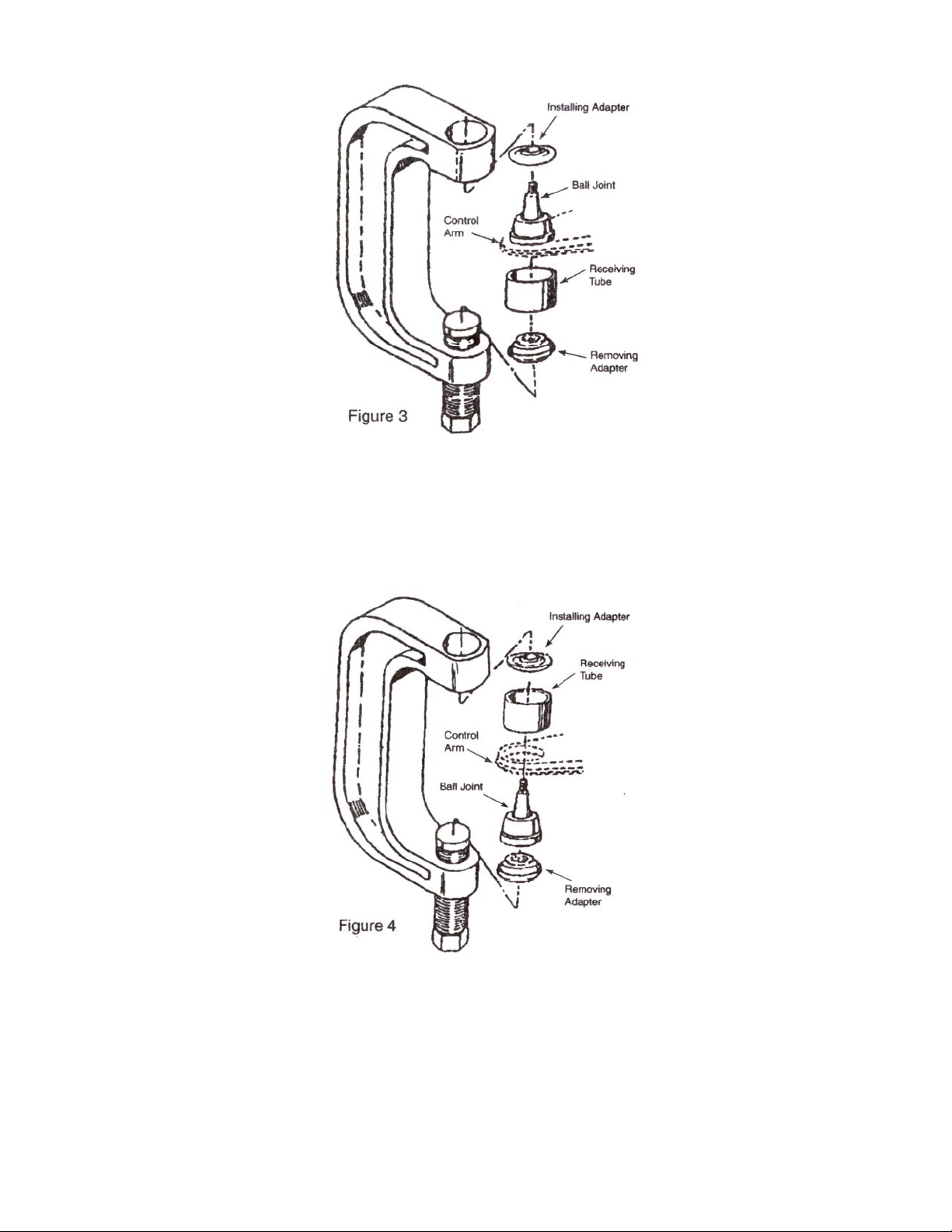

1. Assemble the ball joint pr es s over the control arm as shown in Figure 3. Select the correct size receiving tube (Item

6, 7, or 8), and position it under the vehicle ball joi nt refer to Figure 3.

2. Tighten the forcing screw until the receiving tube contacts the control arm. Check the alignment of all tooling and

components, and continue tightening the forcing screw until the ball joint is removed.

Page 3

Installation

1. Clean the control arm and coat the I.D. with a suitable lubricant.

2. Insert the replacement ball joint as straight as possible into the vehicle control arm.

3. Assemble the ball joint press component as shown in Figure 4. Position the receiving tube, and tighten the forcing

screw. Check the alignment of all tooling and components, and continue tightening the forcing screw until the ball

joint is firmly seated.

Page 4

ATD-8699

APPLICATION CHART

R=Remove I=Install

Ball

Joint

Upper/

Lower

Vehicle

DODGE / CHRYSLER / PLYMOUTH

1987-97 Dakota 2WD

Lower

Lower

Lower

Upper

Lower

Upper

Lower

Lower

Upper

Upper

Lower 1993-04 Grand Cherokee 4WD

Upper 1993-04 Grand Cherokee 4WD

Lower

Upper

1972-93 1/2-, 3/4-ton 2WD Pickup

1974-93 1/2-ton 2WD Ramcharger

1979-97 1/2-, 3/4-, 1-ton 2WD Van

1972-93 3/4-, 1-ton 2WD Pickup

1979-97 1-ton 2WD Van

1984-96 Caravan, Voyager,

Town & Country

1994-97 1/2-, 3/4-, 1-ton 2WD

Pickup(IFS)

1994-97 1/2-, 3/4-, 1-ton 2WD

Pickup(IFS)

1994-97 1-ton solid axle, 2WD;

3/4-, 1-ton Dana 60 axle, 4WD

1994-97 1-ton solid axle, 2WD;

3/4-, 1-ton Dana 60 axle, 4WD

1994-2006 1/2-, 3/4-ton Dana 44

axle,

4WD;

1972-93 1/2-, 3/4-, 1-ton 4WD &

Ramcharger

1994-2006 1/2-, 3/4-ton Dana 44

axle,

4WD

1972-93 1/2-, 3/4-, 1-ton 4WD &

Ramcharger

1994-01 Dodge Ram 4WD 1/2- Ton

Pickup

1994-01 Dodge Ram 4WD 1/2- Ton

Pickup

ATD-8699

PRT8697-13

PRT8697-14

PRT8697-03

PRT8697-06

PRT8697-12

PRT8697-07

PRT8697-10

PRT8697-09

PRT8697-11

PRT8697-02

PRT8697-04

PRT8697-08

PRT8697-05

PRT8697-01

PRT8696-03

PRT8696-06

PRT8696-10

I R RI

I R

R

I

I

I I

R I

I I

I R R I R I

I R R I R I

I R I

I R I R

I R I R

I R I R

I R I R

Page 5

R=Remove I=Install

Ball

Joint

Upper/

Lower

Vehicle

PRT8697-13

PRT8697-14

PRT8697-03

PRT8697-06

PRT8697-12

JEEP

1993-97 2WD Grand Cherokee

1993-95 4WD Grand Cherokee,

Upper

Lower

Upper

Lower

Upper

Lower

Grand Wagoneer

1987-98 4WD Wrangler

1984-95 4WD Wagoneer,

Comanche, Cherokee

1993-97 2WD Grand Cherokee,

1990-97 2WD Cherokee,

Wagoneer,

Comanche

1993-95 4WD Grand Cherokee,

Grand Wagoneer

1990-98 4WD Wrangler

1990-95 2WD & 4WD Wagoneer,

Comanche, Cherokee

1984-97 2WD Cherokee,

Wagoneer,

Comanche

1984-89 2WD Cherokee,

Wagoneer,

Comanche

1987-89 4WD Wrangler

1984-89 4WD Wagoneer,

Comanche,

Cherokee

1984-92 full size 4WD Grand

Wagoneer

1972-88 4WD Truck, CJ, full size

Cherokee, Wagoneer

1984-92 full size 4WD Grand

Wagoneer

1972-88 4WD Truck, CJ, full size

Cherokee, Wagoneer

I I R I R

I I R I R

I R I R

I I R I R

I R I

I R I

ATD-8699

PRT8697-07

PRT8697-10

PRT8697-09

PRT8697-11

PRT8697-02

PRT8697-04

PRT8697-08

PRT8697-05

PRT8697-01

PRT8696-03

PRT8696-06

PRT8696-10

Page 6

R=Remove I=Install

ATD-8699

Ball

Joint

Upper/

Lower

Vehicle

FORD

Lower 1986-97 Aero

1989-90 2WD Bronco Ⅱ

Upper

Upper

Lower

Lower

Lower 1997 1/2-ton Pickup, 2WD & 4WD R I

Upper

Lower 1987-96 1/2-ton 2WD Pickup

1991-94 2WD Explorer

1989-97 2WD Ranger

1987-88 2WD Bronco Ⅱ

1983-88 2WD Ranger

1989-90 2WD Bronco Ⅱ

1991-94 2WD Explorer

1989-97 2WD Ranger

1987-88 2WD Bronco Ⅱ

1983-88 2WD Ranger

1987-96 1/2-ton 2WD Pickup

1987-97 3/4-, 1-ton 2WD Pickup

1981-86 1/2-ton 2WD Pickup

PRT8697-13

PRT8697-14

PRT8697-03

PRT8697-06

PRT8697-12

PRT8697-07

PRT8697-10

PRT8697-09

PRT8697-11

PRT8697-02

PRT8697-04

PRT8697-08

PRT8697-05

PRT8697-01

PRT8696-03

PRT8696-06

PRT8696-10

I

I I

I

I

I R R I

I

I R R I

1980 4WD Bronco Ⅱ w/Dana 28

Upper

Lower

Lower 1987-97 3/4-, 1-ton 2WD R I

Upper 1992-97 1/2-,3/4-, 1-ton 2WD Van

Lower 1992-97 3/4-, 1-ton 2WD Van

Lower 1992-97 1/2-ton 2WD Van

Upper

1984-89 4WD Bronco Ⅱ

1991-94 4WD Explorer w/Dana 28

1991-97 4WD Ranger w/Dana 28

1983-89 4WD Ranger

1981-86 1/2-ton 2WD Pickup

1980-95 4WD Bronco

1981 1-ton (3800 axle) 4WD

1980-96 1/2-, 3/4-ton 4WD

1990 4WD Bronco Ⅱ w/Dana 35

1991-93 4WD Explorer w/Dana 35

1990-93 4WD Ranger w/Dana 35

1990 4WD Bronco Ⅱ w/Dana 28

I

I R I

I I

I R R RI I

I I R I

I

I

Lower

1984-89 4WD Bronco Ⅱ

1990-97 4WD Explorer w/Dana 28

1990-97 4WD Ranger w/Dana 28

1983-89 4WD Ranger

I

Page 7

R=Remove I=Install

Ball

Joint

Upper/

Lower

Vehicle

FORD

1990 4WD Bronco Ⅱ w/Dana 35

Lower

Upper

Upper

Lower

Lower 1996-97 1-ton 4WD w/solid axle R I

Lower 1990-95 3/4-, 1-ton 4WD spindle R I

1991-93 4WD Explorer w/Dana 35

1990-93 4WD Ranger w/Dana 35

1980-96 4WD Bronco

1992-97 1-ton 4WD

1980-96 1/2-, 3/4-, 1- ton 4WD (IFS)

1993-94 4WD Explorer w/Dana 35

1993-97 4WD Ranger w/Dana 35

1993-94 4WD Explorer w/Dana 35

1993-97 4WD Ranger w/Dana 35

GM

Lower

Lower

Lower

Lower 1985-97 Astro, Safari van

Lower 1973-95 1/2-, 3/4-ton 2WD G Van

Lower 1996-97 1/2-, 3/4-, 1-ton 4x4

Lower

1982-97 2WD S-10 Blazer, Jimmy,

& Pickup

1993-97 2WD 1/2-, 3/4-, 1-ton Pickup ,

Suburban

1996-97 1/2-, 3/4-ton 2WD G Van

1989-92 2WD 1/2-, 3/4-, 1-ton Pickup ,

Suburban

1996-2006 4WD 1/2-, 3/4-ton

Pickups, Suburban, Yukon, Tahoe

HONDA

Lower 1999-2004 Odyssey Vans

ATD-8699

PRT8697-13

PRT8697-14

PRT8697-03

PRT8697-06

PRT8697-12

PRT8697-07

PRT8697-10

PRT8697-09

PRT8697-11

PRT8697-02

PRT8697-04

PRT8697-08

PRT8697-05

PRT8697-01

PRT8696-03

PRT8696-06

PRT8696-10

I

I R I

I

I

I I

I I

I I R

I

I

I I R

I I

RI

R R I I

Page 8

Loading...

Loading...