Page 1

ATD8198 MADE IN MEXICO BASIC HEAVY DUTY REEL

BASIC HEAVY DUTY REEL SYSTEM;

Suitable for Oil Hose ½” or Grease Hose up to 50 feet

OWNERS MANUAL

RETAIN THIS MANUAL FOR FUTURE REFERENCE TO IMPORTANT WARNINGS AND

OPERATING AND MAINTENANCE INSTRUCTIONS.

PROPER USE AND MAINTENANCE OF THIS EQUIPMENT IS THE RESPONSIBILITY OF THE

OWNER AND/OR OPERATOR.

DO NOT USE THIS EQUIPMENT UNLESS YOU HAVE CAREFULLY READ AND

UNDERSTAND THE INSTRUCTIONS AND WARNINGS IN THIS MANUAL.

! WARNING !

NEVER exceed the stated maximum working pressure of the pump or of the lowest rated component in your

system.

NEVER modify any part of this equipment.

NEVER use combustible gas with this equipment.

NEVER attempt repairs while the system is under pressure.

NEVER attempt to disassemble the equipment while the system is under pressure.

ALWAYS tighten fluid connections before using this equipment

ALWAYS read/follow the fluid manufacturer’s recommendations regarding fluid compatibility.

ALWAYS read/follow the fluid manufacturer’s recommendations regarding the use of protective clothing and

equipment.

REGULARLY check all equipment and repair/replace worn or damaged parts immediately.

FAILURE TO HEED THESE WARNINGS INCLUDING OVERPRESSURIZING,

ALTERING PARTS, USE OF INCOMPATIBLE FLUIDS, MISUSE, OR USE OF

DAMAGED/WORN PARTS MAY RESULT IN EQUIPMENT DAMAGE, PROPERTY

DAMAGE, FIRE, EXPLOSION AND/OR SERIOUS PERSONAL INJURY.

SAFETY INSTRUCTIONS

Extreme caution should be used when operating this equipment as it generates very high fluid pressure. Leaks

from loose or ruptured components or material from dispensing valve can inject fluid through the skin causing

serious bodily injury and possible need for amputation. Always wear protection to prevent material splashing

onto skin or into eyes.

IMPORTANT: GET EMERGENCY MEDICAL CARE IMMEDIATELY IF ANY FLUID APPEARS TO

PENETRATE THE SKIN! INFORM PHYSICIAN OF EXACTLY WHAT WAS INJECTED. PLEASE DO

NOT TREAT THIS INJURY AS A SIMPLE CUT.

Page 2

Page 3

Page 4

Page 5

Page 6

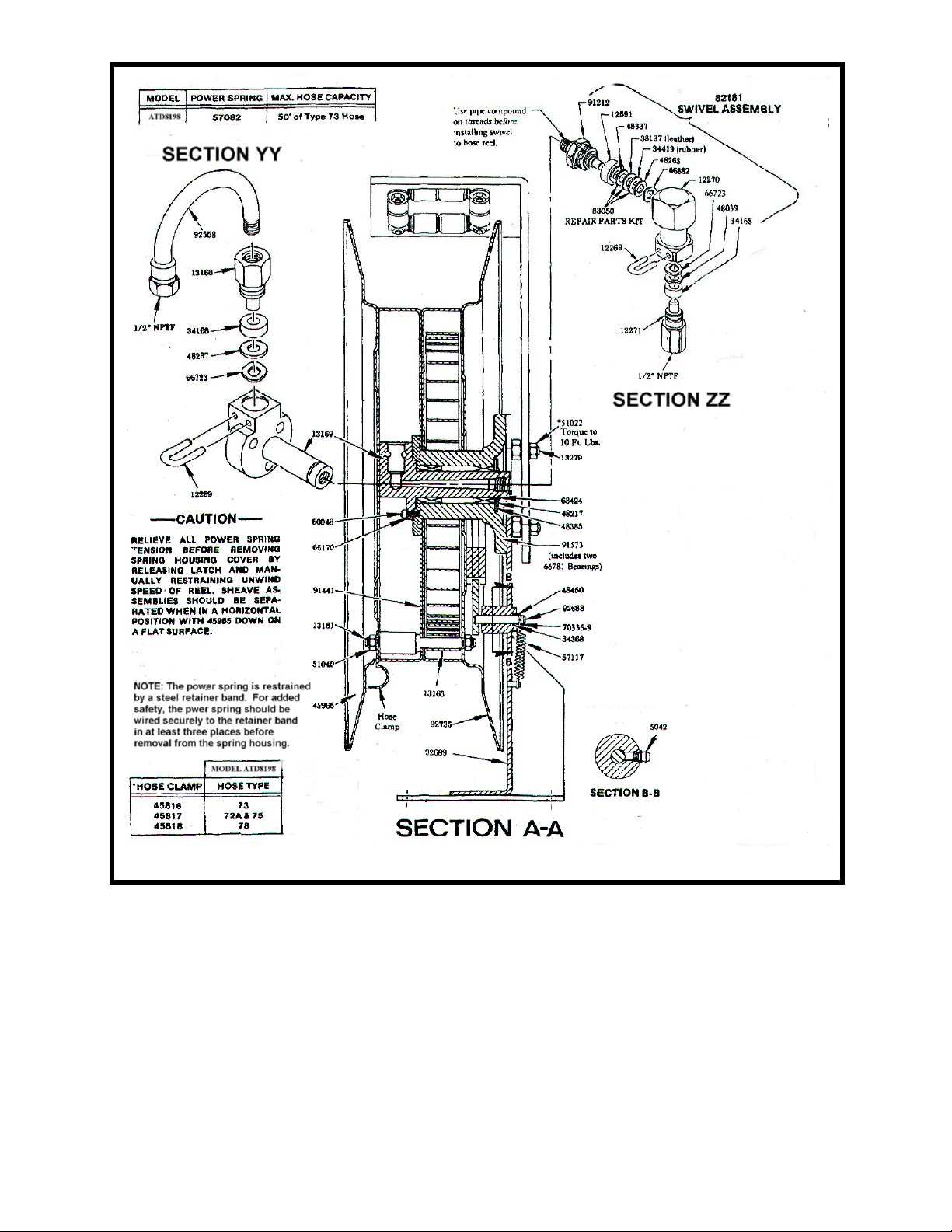

Warning: Use Extreme Caution when working on the Reel Spring. Consider the spring very dangerous.

Caution Note: Relieve all power spring tension before removing spring house cover by releasing latch and

manually restraining unwind speed of reel. Sheave assemblies should be separated when in a horizontal

position with 45965 down on a flat surface.

Caution Note: The power spring is restrained by a steel retainer band. For added safety the power spring

should be wire securely to the retainer band in at least three (3) places before removal from the spring

housing.

Note: Use Pipe Compound on Threads before installing swivel on Hose Reel.

Page 7

ATD8198 SERVICE PARTS LISTING AND DESCRIPTION

PART QTY DESCRIPTION | PART QTY DESCRIPTION

5042 1 LUBE FITTING | 48385 4 SHIM WASHER

12269 2 KEEPER | 48450 1 WASHER

12270 1 SWIVEL BODY | 50048 3 SCREW

12271 1 ADAPTER | 50079 1 SCREW

12591 1 RETAINER | 50757 4 BOLT

13160 1 ADAPTER(12271ME) | 51022 3 NUT

13161 3 STUD | 51040 6 NUT

13162 1 SPRING PIN | 51412 4 NUT

13163 3 SPACER | 57117 1 SPRING

13169 1 SHAFT | 66170 3 LOCKWASHER

13272 8 ROLLER | 66723 2 SPRING WASHER

13273 2 PIN | 66781 2 BEARING

13274 2 PIN | 66882 1 SPRING WASHER

13275 2 SPACER | 68424 1 RETAINING RING

13279 3 STUD | 70336-9 1 COTTER PIN

34168 2 PACKING | 82181 1 SWIVEL ASSEMBLY

34368 2 O-RING | 82860 1 ROLLER OUTLET ASSEMBLY

34419 1 PACKING (RUBBER)THICK | 91212 1 SWIVEL STUD

38137 1 PACKING (LEATHER)REPLACED BY 34419ME THICK | 91441 1 SPRING HOUSING

45965 1 SHEAVE HALF | 91573 1 ARBOR

48039 1 WASHER | 92558 1 TUBE & ADAPTER

48217 1 WASHER | 92668 1 PAWL

48237 1 WASHER(35039ME) | 92689 1 SUPPORT ASSEMBLY

48263 1 WASHER | 92735 1 SHEAVE

48337 1 WASHER | 360209 1 ROLLER SUPPORT ARM

Repair Kit for Soft Parts: 83050ME; consisting of: 48337ME(Metal Washer),

34419ME(1)(Rubber Packing) or(34419ME-THIN 2PCS RUBBER PACKING); 48263ME(Thin

Metal Washer); 66882ME Wave Spring Washer; Note: Item 38137ME (Leather Washer) has been

replaced by 34419ME (Rubber Washer)

Page 8

REF: Threading Hose onto Reels: Please note pictorial below:

Loading...

Loading...