Page 1

Fuel Tank

Adapter

Operating Instructions & Parts Manual

Model

ATD-7470

This is the safety alert symbol. It is used to alert you to potential personal injury hazards.

!

Obey all safety messages that follow this symbol to avoid possible injury or death.

Capacity

80 lbs.

! ADVERTENCIA

• Leer, comprender, y seguir las instrucciónes antes

de utilizar el aparato.

• El manual de instrucciónes y la información de

seguridad deben estar comunicado en lengua del

operador antes del uso.

• No seguir estas indicaciónes puede causar daños

personales o materiales.

ATD Tools Inc.

160 Enterprise Drive, Wentzville MO 63385

! DANGER

Risk of Explosion! Use of this product requires special skills and knowledge pertaining to grounding and bonding of the

components.

Use ONLY on METAL FUEL TANKS!

Printed in China

ATD7470-M0 -04/08

Page 2

SAFETY and GENERAL INFORMATION

Save these instructions.

device before using. The owner and operator of this equipment shall have an understanding of it and safe operating

procedures before attempting to use. The owner and operator shall be aware that use of this product requires special skills and knowledge pertaining to bonding and grounding of personnel and components. Instructions and safety

information shall be conveyed in the operator's native language before use of this product is authorized. If any doubt

exists as to the safe and proper use of this device, remove from service immediately.

Inspect before each use. Do not use if broken, bent, cracked, or damaged parts (including labels) are noted. Any

Fuel Tank Adapter that appears damaged in any way, operates abnormally or is missing parts, shall be removed

from service immediately. If you suspect that the product was subjected to a shock load (a load dropped suddenly,

unexpectedly upon it), immediately discontinue use until it has been checked by a factory authorized service center

(contact distributor or manufacturer for list of authorized service centers). It is recommended that an annual inspection

be done by qualied personnel. Labels and owner’s manuals are available from manufacturer.

For your safety read, understand, and follow the information provided with and on this

PRODUCT DESCRIPTION

This Fuel Tank Adapter is designed for fuel tank removal and fuel tank installation. This Fuel Tank Adapter must

ONLY be secured to ATD transmission jack model ATD-7430, ATD-7431. It is designed for use with passenger

cars and light trucks only. The Fuel Tank Adapter should only be used on METAL FUEL TANKS!

SPECIFICATIONS

Model Capacity

ATD-7470 80 lb. 40 gal. 32" x 15-3/8" x 9-1/4" 49 lb.

Risk of Explosion! Use of this product requires special skills and knowledge pertaining to grounding and

!

bonding of the components.

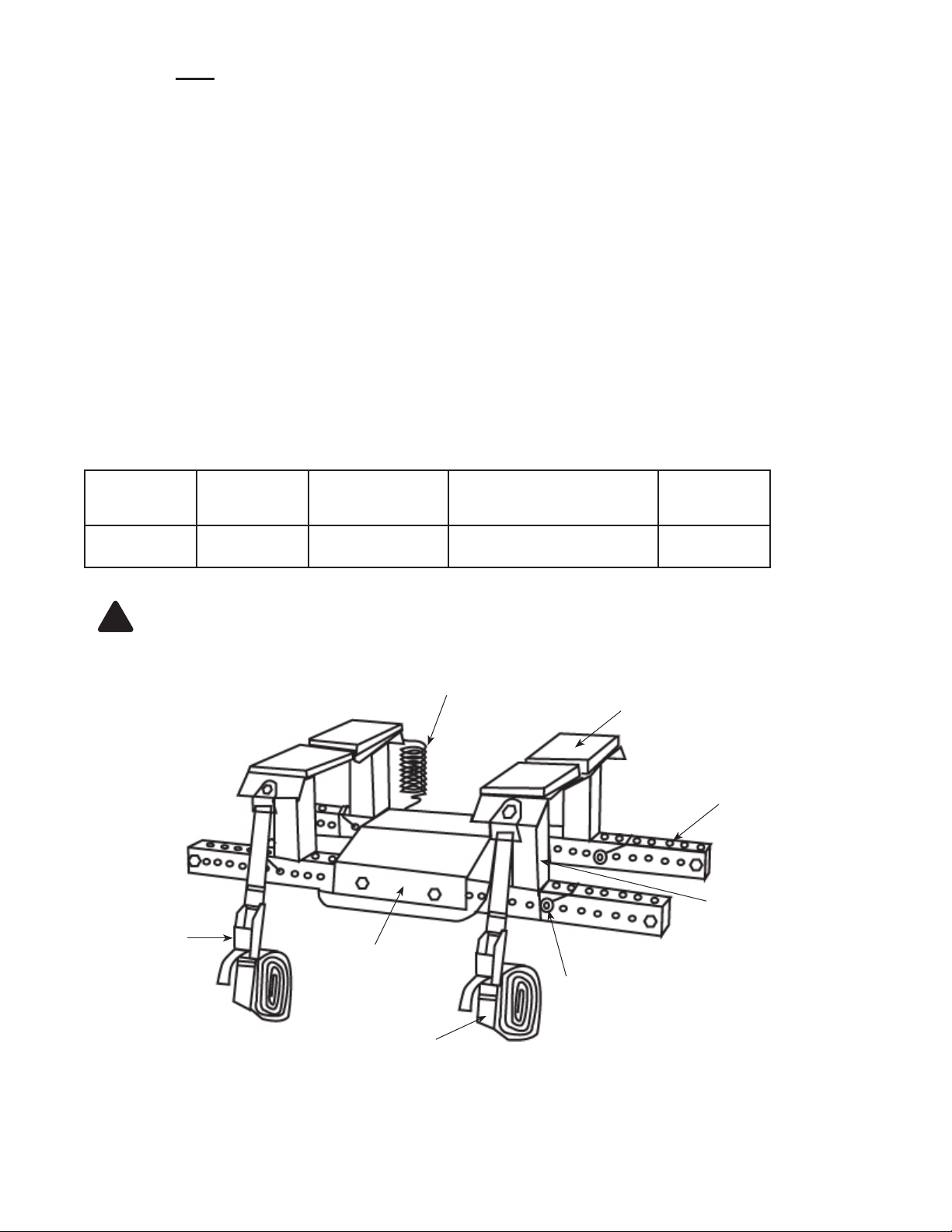

Ratchet

Max. Fuel Tank

Size

Use ONLY on METAL FUEL TANKS!

Bonding Cable

Base Plate

Product Size

( L x W x H)

Net Weight

Support Pad

Arm

Support Stand

Safety Nylon Strap

Figure 1 - Fuel Tank Adapter Components

2

Safety Snap Pin

Page 3

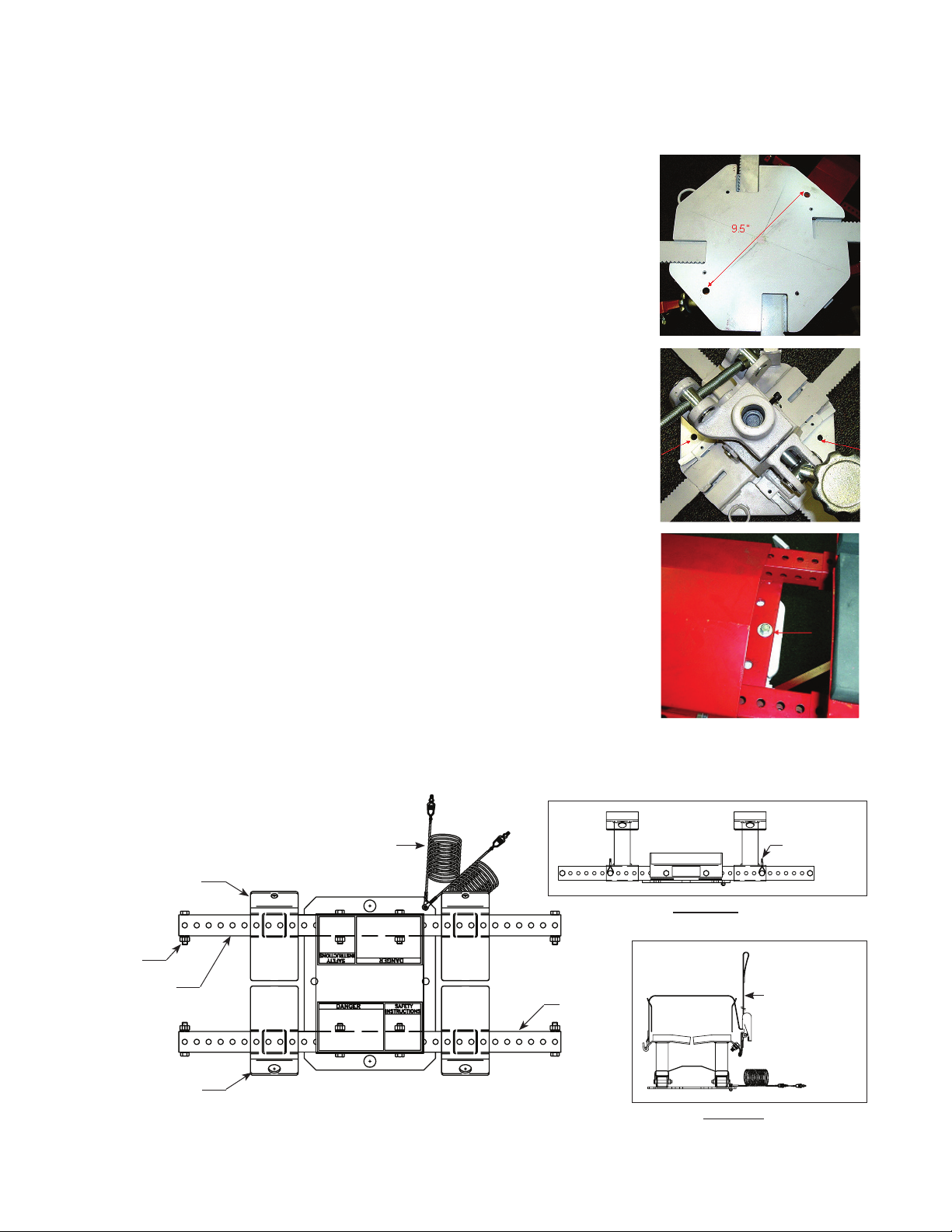

INSTALLATION (refer Figure 1 thru 5)

Note: Below instruction is illustrating the use of fuel tank adapter conjunction with Model ATD-7430, ATD-7431.

Estimated Time: 30 minutes

Tools required: Drill, 7/16" drill bit, 17mm & 19mm wrenches.

1. Remove saddle from the transmission jack.

2. Drill two

7

/16” size holes on the saddle. Ensure the holes are 9

1/2" apart

and, should be located equally away from the saddle edges about 1”

(Refer gures 2 & 3 for location of holes).

Note: The integrity of your transmission jack should not be affected by

these two holes as long as the instructions are followed. ATDll warrant

its transmission jack original warranty for this specic fuel tank adapter

installation.

3. Secure the fuel tank adapter to the saddle with two 3/8”-24x1

1/2" bolts,

at washers, lock washers and nuts provided (Figure 4).

(Refer to Figure 5 for below procedures)

4. Slide support stand (1) over one end of the two arms (2). Repeat

procedure on other end of same arm; Slide support stand (3) over one

end of the other arm. Repeat procedure on other end of same arm.

5. Secure each support stand by inserting snap pin (4) through the aligned

holes on arm, snapping the latch over the end of pin as shown.

6. Insert the 3/8"-16 x 2 1/2" Bolt (5) through the last set of holes in arm and

secure in place with washers, lockwasher and nut provided. Repeat for

other three sides.

7. Secure both bonding cables (6) to the top side of frame base with

1

/4"-20x1" bolt and nut provided.

Note: Remove paint from top and bottom of plate around the

1

/4" diameter

hole.

8. Bolt safety nylon strap (7) to support stand (3). Secure with 1/2"-13x1"

bolt, washer, lockwasher and nut provided. Repeat procedure on other

support stand.

9. The assembly is now ready to use.

Fig. 2

Fig. 3

Fig. 4

Support Stand (3)

Bolt (5)

Arm (2)

Support Stand (1)

Bonding Cable (6)

Figure 5 - Assembly instruction

(4) Snap Pin

Front View

(2) Arm

Side View

(7) Safety Strap

3

Page 4

BEFORE USE

1. Verify that the product and the application are compatible.

2. Before using this product, read this fuel tank adapter manual, the transmission jack manual, and the vehicle

service manual completely. Familiarize yourself thoroughly with the product, its components, and recognize the

potential hazards associated with its use.

3. Locate and place a Class B re extinguisher near the working area.

4. Afx the fuel tank adapter to transmission jack properly before removing or installing the fuel tank.

5. Bond the Fuel Tank Adapter to the transmission jack and to the fuel tank while grounding the transmission jack

to earth before removing or installing the fuel tank. Operator must be bonded to both the jack and tank! If

unsure how to provide proper grounding and bonding of personnel and equipment STOP, discontinue use, and

seek the advice of qualied personnel.

6. Replace worn or damaged parts and assemblies with factory authorized replacement parts only.

7. Inspect before each use. Do not use if bent, broken or cracked components are noted.

! DANGER

NO SMOKING!

• NEVER use fuel tank handler near open ame,

heat sources or spark inducing environments.

• ALWAYS have a Class B re extinguisher

available.

• Drain ALL fuel from the vehicle fuel tank into

an approved and grounded fuel storage tank.

NEVER drain or store fuel in an open container,

near open ames, heat sources, or spark

inducing environments.

• If the fuel tank is damaged during servicing,

STOP and discard the fuel tank.

• Use ONLY on METAL FUEL TANKS! Do not

use on plastic fuel tanks!

• FAILURE TO HEED THESE WARNINGS

COULD RESULT IN DEATH, PERSONAL

INJURY, AND/OR PROPERTY DAMAGE!

! WARNING

• Study, understand, and follow all instructions

provided with and on this device before use.

• Do not exceed rated capacity.

• Use the Fuel Tank Adapter only with ATD

transmission jack models:

ATD-7430, ATD-7430

• ALWAYS bond the fuel tank to the

jack and bond the transmission jack to the earth

using the two bonding cables provided.

• ALWAYS center fuel tank on the four support

pads.

• ALWAYS secure fuel tank to fuel tank adapter

using the provided safety nylon straps.

• The fuel tank and the Fuel Tank Adapter must be

completely lowered (transmission jack ram fully

retracted) before transporting.

• Do not use adapters or accessories that are not

provided initially. Only accessories supplied by

the manufacturer can be used.

• Do not modify this device.

• Failure to heed these markings may result in

personal injury and/or property damage.

!

WARNING

!

• The paint on this product contains lead, a

chemical known in the State of California to cause

cancer, birth defects and other reproductive harm.

• Do not ingest paint chips and keep product

away from children.

• Wash hands after each use.

transmission

Operator must be bonded to both the jack and tank! If unsure how to provide proper bonding of

!

personnel and equipment STOP, discontinue use, and seek the advice of qualied personnel.

BEFORE USE

1. Verify that the product and the application are compatible, if in doubt call ATD Tech. Service.

2. Before using this product, read the operator's manual completely and familiarize yourself thoroughly with the

product and the hazards associated with its improper use.

3. Inspect before each use. Do not use if bent, broken or cracked components are noted.

4. Ensure that all parts move freely.

4

Page 5

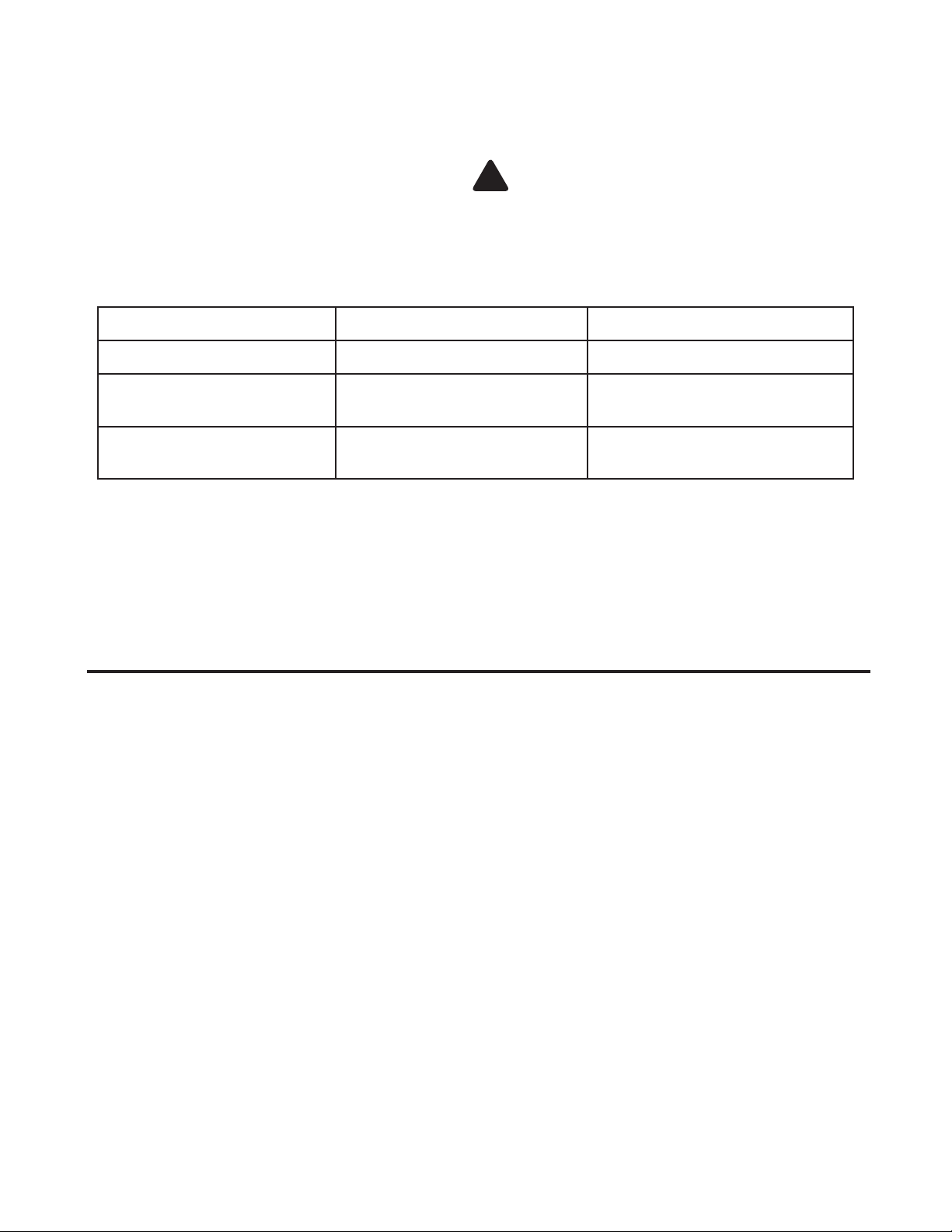

OPERATION

Removal of Fuel Tank (Refer to Figure 6)

1. Read and follow the fuel tank removal/installation procedures as stated in the vehicle service manual.

2. Drain the existing fuel into an approved and grounded fuel storage tank.

3. Raise the transmission jack to directly underneath the designated fuel tank, refer to your transmission jack owner/

operator’s manual for instructions on how to raise and lower the transmission jack.

Operator must be bonded to both the jack and tank! If unsure how to provide proper bonding of

!

personnel and equipment STOP, discontinue use, and seek the advice of qualied personnel.

4. Clip one bonding cable to the fuel tank.

5. Clip the other bonding cable to the transmission jack.

6. Ground the transmission jack to earth.

7. Center the fuel tank on all four of the Fuel Tank Adapter padded supports. For adjustment,:

a.

Open the latch of the safety snap pin and remove.

b. Slide the support stand to the desired location.

c. Re-insert safety snap pins through the holes in both the support stand and arm. Close the latch of snap pin.

d. Adjust the opposite support stand to match the previously repositioned support stand.

e.

Ascertain that the load is centered with respect to

8. Place the safety nylon straps around the fuel tank, and hook them to the holes on the on support pads (refer to

Figure 6 and Figure 5 side view).

9. Securely tighten using the ratchet.

Note: To loosen the strap, pull the safety latch on the ratchet downward and rotate handle 180 degrees. When the

strap has been fully opened, the strap may be pulled through the ratchet to take up excess slack.

10. Ascertain that the hooks stay in place while tightening with the ratchet.

11. Remove fuel tank according to the vehicle service manual.

12. Lower the transmission jack to its lowest position before transporting the fuel tank.

the transmission jack.

Figure 6

5

Page 6

MAINTENANCE

Inspections should be made before each use of the Fuel Tank Adapter, checking for abnormal conditions.

1. It is important to keep the product clean.

2. Periodically wipe the product with an oily cloth.

3. Inspect the product annually.

Storage

Store the fuel tank adapter in a clean, dry area when not in use.

Paint contains lead!

!

DO NOT sand or grind painted surface!

TROUBLESHOOTING

Symptom Possible Causes Corrective Action

A vertical arm will not reposition Bent parts Contact Customer Service

The fuel tank does not maintain

steadiness while on the adapter

The adapter is shaky or feels

loose

Loose support pad Contact Customer Service

Components are worn or loose

Check, replace, and tighten

components and fasteners

ONE YEAR LIMITED WARRANTY

For a period of one (1) year from date of purchase, ATD Tools Inc. will repair or replace, at its option, without

charge, any of its products which fails due to a defect in material or workmanship under normal usage. This limited

warranty is a consumer's exclusive remedy.

Performance of any obligation under this warranty may be obtained by returning the warranted product,

freight prepaid, to ATD Tools Inc. Warranty Service Department, 160 Enterprise Drive, Wentzville, MO 63385.

Except where such limitations and exclusions are specically prohibited by applicable law, (1) THE

CONSUMER'S SOLE AND EXCLUSIVE REMEDY SHALL BE THE REPAIR OR REPLACEMENT OF DEFECTIVE

PRODUCTS AS DESCRIBED ABOVE. (2) ATD Tools Inc. SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL

OR INCIDENTAL DAMAGE OR LOSS WHATSOEVER. (3) ANY IMPLIED WARRANTIES, INCLUDING WITHOUT

LIMITATION THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE, SHALL BE LIMITED TO ONE YEAR, OTHERWISE THE REPAIR, REPLACEMENT OR REFUND AS

PROVIDED UNDER THIS EXPRESS LIMITED WARRANTY IS THE EXCLUSIVE REMEDY OF THE CONSUMER,

AND IS PROVIDED IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED. (4) ANY MODIFICATION,

ALTERATION, ABUSE, UNAUTHORIZED SERVICE OR ORNAMENTAL DESIGN VOIDS THIS WARRANTY AND

IS NOT COVERED BY THIS WARRANTY.

Some states do not allow limitations on how long an implied warranty lasts, so the above limitation may not

apply to you. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the

above limitation or exclusion may not apply to you. This warranty gives you specic legal rights, and you may also

have other rights which vary from state to state.

6

Page 7

Replacement Parts List for ATD-7470

REPLACEMENT PARTS

Not all components of the Fuel Tank Adapter are replacement items, but are illustrated as a convenient reference

of parts location. When ordering parts, give part number and parts description. Call or write for current pricing: ATD

Tools Inc. 160 Enterprise Drive, Wentzville, MO 63385. Tel:(636)327-9050 Fax:(636)327-9044

Item Part# Description Qty.

1 247552 Safety Snap Pin 4

2 247554 Bonding Cable Assembly 2

3 247576 Foam Pad/ Foot Assembly (1" Hole) 2

4 247578 Safety Tension Strap 2

5 247754 Foam Pad/ Foot Assembly (1/2" Hole) 2

6 247760 Hardware Kit 1

7 ATD7470-L0 Label 1

8 ATD7470-M0 Manual 1

3

5

1

4

2

Figure 7 - Replacement Parts Illustration for ATD-7470

ATD Tools Inc.

160 Enterprise Drive,

Wentzville MO 63385

636-327-9050

7

Loading...

Loading...