Page 1

Truck Ramps

Operating Instructions & Parts Manual

Model Number

Atd-7320

Atd-7321

Capacity per pair

20 Ton

20 Ton

Atd Tools Inc.

160 Enterprise Drive, Wentzville MO 63385

Printed in China

ATD7320-M0 01/07

Page 2

Save these instructions. For your safety, read, understand and follow the information contained within. The owner

and operator shall have an understanding of this product and safe operating procedures before attempting to use

this product. Instructions and Safety information shall be conveyed in the operators native language before use of

this product is authorized. Make certain that the operator thoroughly understands the inherent dangers associated

with the use and misuse of the product. If any doubt exists as to the safe and proper use of this product as outlined

in this factory authorized manual, remove from service. Inspect before each use. Do not use if there are broken,

bent, cracked or otherwise damaged parts (including labels). If the ramp operates abnormally, discontinue use until

inspected by an Atd Tools authorized service center. Owners and operators of this equipment shall be aware that the

use of this equipment may require special training and knowledge. It is recommended that an annual inspection be

done by qualified personnel and that any missing or damaged decals, warning / safety labels or signs be replaced

with factory authorized replacements only. Any truck ramp that appears to be damaged in structure shall be removed

from service and destroyed immediately.

PRODUCT DESCRIPTION

Atd Tools Truck Ramps are designed to safely support rated capacity vehicles for extended periods. Truck ramps

are not to be used to simultaneously support both ends or one side of a vehicle. Heavy gauge steel frame helps

prevent distortion and twisting. These ramps comply with applicable ASME / ANSI Standards to ensure safety,

strength and stability.

IMPORTANT: RATED CAPACITY IS PER PAIR ONLY! TRUCK RAMPS MUST BE USED IN PAIR AND USE

ONLY ONE PAIR PER VEHICLE.

DO NOT USE FOR ANY PURPOSE OTHER THAN THOSE USES OUTLINED ABOVE!

SPECIFICATIONS

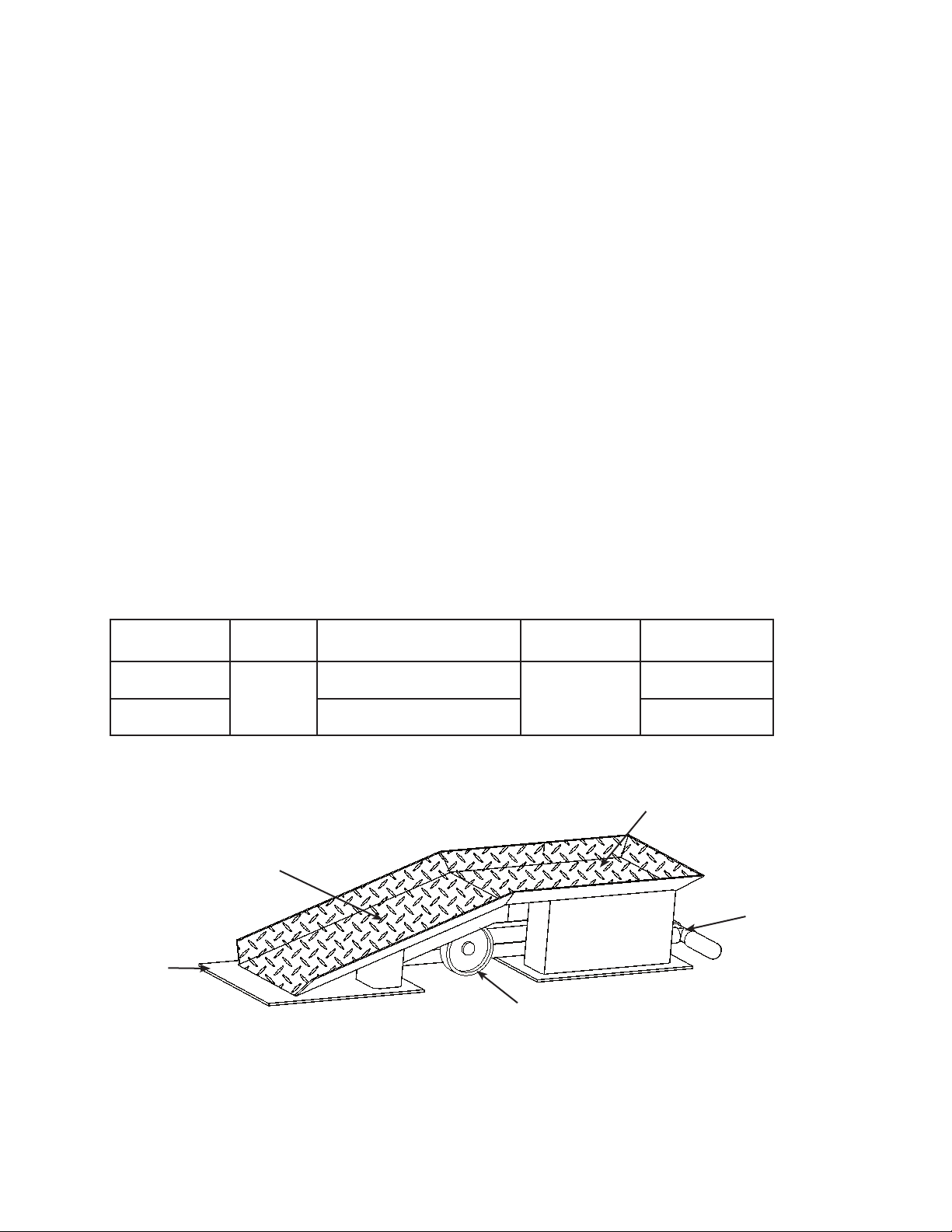

Model Capacity Product Size (L x W x H) Handle Length

Atd-7320

Atd-7321 45 5/8" x 18 1/4" x 9 1/4" 15 1/2"

Ramp Slope

Base

20 Ton

45 5/8" x 13 1/2" x 9 1/4"

Max. Vehicle Tire

Width

10 3/4"

33 3/4"

Support Platform

Handle

Wheel

Figure 1 - Truck Ramp Components

2

Page 3

BEFORE USE

1. Verify that the product and the application are

compatible.

2. Before using this product, read the operator's manual

completely and familiarize yourself thoroughly with

the product and the hazards associated with its

improper use.

3. Inspect before each use. Do not use if bent, broken

or cracked components are noted.

4. Ensure that all parts move freely.

! WARNING

• Study, understand, and follow all instructions

provided before attempting to use this equipment.

• Rated capacity is per pair! Do not exceed rated

capacity.

• Use only on hard, level surfaces capable of

sustaining rated capacity loads.

• Center load between the sides of the ramp.

• Use as a matched pair to support one end of a

vehicle. One pair per vehicle only.

• Ramps are not to be used to simultaneously

support both ends or one side of a vehicle.

• Do not use other lifting equipment in conjunction

with the ramps.

• Ensure other persons are clear from the vehicle

path and the ramps.

• Never accelerate or brake suddenly. Proceed

slowly and cautiously.

• Do not disconnect brakes, engine, transmission

components, drive train, drive shaft, universal

joints, or wheels while the vehicle is on the ramps.

• No alterations shall be made to this device

• Failure to heed these markings may result in

personal injury and/or property damage.

OPERATION

Lifting

1. Center the two ramps against the tires of vehicle.

2. Ensure that the wheels to be driven on the ramps

are positioned straight forward in alignment with the

ramps.

3. After positioning the truck ramps, keep the handle

in lowest position in order to lower the base to

surface. The rubber padded base will prevent ramps

movement while vehicle is being driven onto or off

the ramps.

Note: Must keep the handle in lowest position in order

to lower the base to contact with the floor/surface.

4. Another person, standing clear from vehicle path,

should observe and guide the vehicle operator

when ascending and descending the ramps.

5. Never accelerate or apply brakes suddenly. Proceed

slowly and cautiously.

6. Once the vehicle reaches the top of the ramps,

apply brakes only to prevent over-travel.

7. Place the vehicle in neutral. Release brakes; vehicle

should not move.

8. Turn the engine off, set parking brake. Place vehicle in

park (or in reverse gear for manual transmission).

9. Get out of the vehicle and securely chock the

remaining wheels on the ground.

10.Be sure that both tires are properly positioned on

the ramp’s support platform.

11.Using caution in positioning your body clear of

danger, shake vehicle sideways and endways to be

sure that vehicle and ramps are stable.

12.Check that ramps have not become damaged or

bent during loading.

Lowering

! WARNING

Be sure all tools and personnel are clear before

lowering load.

1. Another person, standing clear from vehicle path

should observe and guide the vehicle operator.

2. Proceed slowly and cautiously, never apply brakes

suddenly.

3. After lowering the vehicle, pull the ram handle up to

dolly the truck ramp.

MAINTENANCE

Periodically inspect the Truck Ramps. To help prevent

rust, wipe clean after each use. If rust appears, sand

affected area and cover with suitable utility paint. Store

the Truck Ramps in a clean, dry area.

3

Page 4

REPLACEMENT PARTS

Not all components of the Truck Ramp are replacement items, but are illustrated as a convenient reference of parts

location. When ordering parts, give part number and parts description. Call or write for current pricing: Atd Tools

Inc. 160 Enterprise Drive, Wentzville, MO 63385. Tel: (636) 327-9050 Fax: (636) 327-9044

Item ATD7320 Part# ATD7321 Part# Description Qty

1 93200-01 93200-01 Handle Assembly 1

2 93200-02 93200-02 Wheel Assembly, 5 1/8" 2

3 93200-03 93200-03 Handle Grip 2

- ATD7320-L0 ATD7321-L0 Label 1

- ATD7320-M0 ATD7320-M0 Manual 1

1

3

2

Figure 2 - Truck Ramp Parts Illustration

ONE YEAR LIMITED WARRANTY

For a period of one (1) year from date of purchase, ATD Tools Inc. will repair or replace, at its option, without

charge, any of its products which fails due to a defect in material or workmanship under normal usage. This limited

warranty is a consumer's exclusive remedy.

Performance of any obligation under this warranty may be obtained by returning the warranted product,

freight prepaid, to ATD Tools Inc. Warranty Service Department,160 Enterprise Drive, Wentzville, MO 63385.

Except where such limitations and exclusions are specifically prohibited by applicable law, (1) THE

CONSUMER'S SOLE AND EXCLUSIVE REMEDY SHALL BE THE REPAIR OR REPLACEMENT OF DEFECTIVE

PRODUCTS AS DESCRIBED ABOVE. (2) ATD Tools Inc. SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL

OR INCIDENTAL DAMAGE OR LOSS WHATSOEVER. (3) ANY IMPLIED WARRANTIES, INCLUDING WITHOUT

LIMITATION THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE, SHALL BE LIMITED TO ONE YEAR, OTHERWISE THE REPAIR, REPLACEMENT OR REFUND AS

PROVIDED UNDER THIS EXPRESS LIMITED WARRANTY IS THE EXCLUSIVE REMEDY OF THE CONSUMER,

AND IS PROVIDED IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED. (4) ANY MODIFICATION,

ALTERATION, ABUSE, UNAUTHORIZED SERVICE OR ORNAMENTAL DESIGN VOIDS THIS WARRANTY AND

IS NOT COVERED BY THIS WARRANTY.

Some states do not allow limitations on how long an implied warranty lasts, so the above limitation may not

apply to you. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the

above limitation or exclusion may not apply to you. This warranty gives you specific legal rights, and you may also

have other rights which vary from state to state.

Atd Tools Inc.

160 Enterprise Drive, Wentzville MO 63385

636-327-9050

4

Loading...

Loading...