Page 1

ATD-5830

3/16” AIR RIVETER INSTRUCTION MANUAL

Safety Precautions

• Do not use the tool outside of the design intent.

• Never modify the tool for any other purpose, or for its use.

• Normal use of this product is likely to expose the user to dust and /or microscopic

particles containing chemicals known to the State of California to cause cancer, birth

defects or other reproductive harm. Always wear appropriate safety equipment and

clothing when using this product. Study, understand and follow all instructions

provided with this product.

• Always wear ANSI approved goggles when using this product.

• Always select the correct accessories of the correct size and design for the job that

you are attempting to perform.

• Always work in a clean, safe, well-lit, organized and adequately equipped area.

• Do not begin repairs without assurance that vehicle is in secure position and will not

move during repair.

Important:

Read these instructions carefully before installing, ope rating, serv icing or repairing this tool.

Keep these instructions in a safe accessible place.

Unpacking:

When unpacking this unit, check the parts diagram and part number listing to make sure all

parts are included. If any parts are missing or damaged please call your distributor.

Product Information:

• Powerful durable, high speed production tool

• Quick release air valve permits cylinder to return quickly for high speed assembly

• Performs well at any angle

• Gets into hard-to-reach areas

• Provides quick, quiet and comfortable operation preventing user fatigue

• Includes 3/16”(4.8mm), 5/32”(4mm), 1/8”(3.2mm) & 3/32”(2.4mm) nosepieces

operations: Prevents overloading for long life.

Page 2

Specifications:

Rivet Capacity: 3/16”

Overall Length: 10-5/8”(270mm)

Net Weight: 3lbs(1.41kg)

Stroke: 1/2”(14mm)

Motor: 1/2h p

Air Inlet Thread NPT: 1/4”

Air Hose I.D. Size: 3/8”(10mm)

Avg. Air Consumption: 4cfm

Air Pressure: 90-120psi

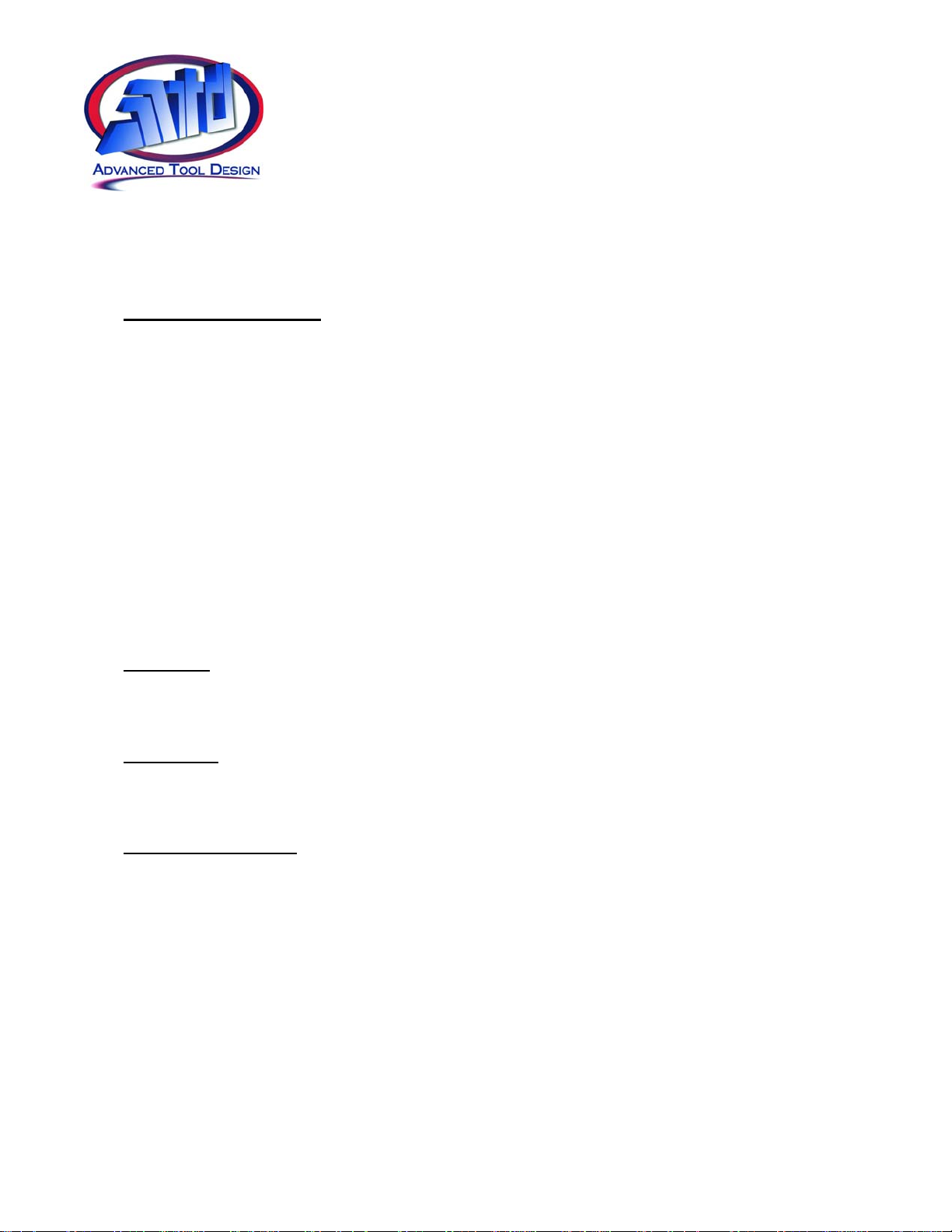

Maintenance/Adding Oil for Hydraulic Riveter

1. Turn off air supply

2. Use spanner wrench to dismantle the riveter head (fig. 1).

3. Use spanner wrench to open bottom cover of the riveter (fig. 2).

4. Remove piston from cylinder (fig. 3).

5. Clean inside of the cylinder and lubricate cover seal (fig. 4).

6. Lubricate the intake with oil until full (fig. 5).

7. Clean piston stem and add grease on the inner wall of the cylinder and the ring.

8. Reassemble (fig.6).

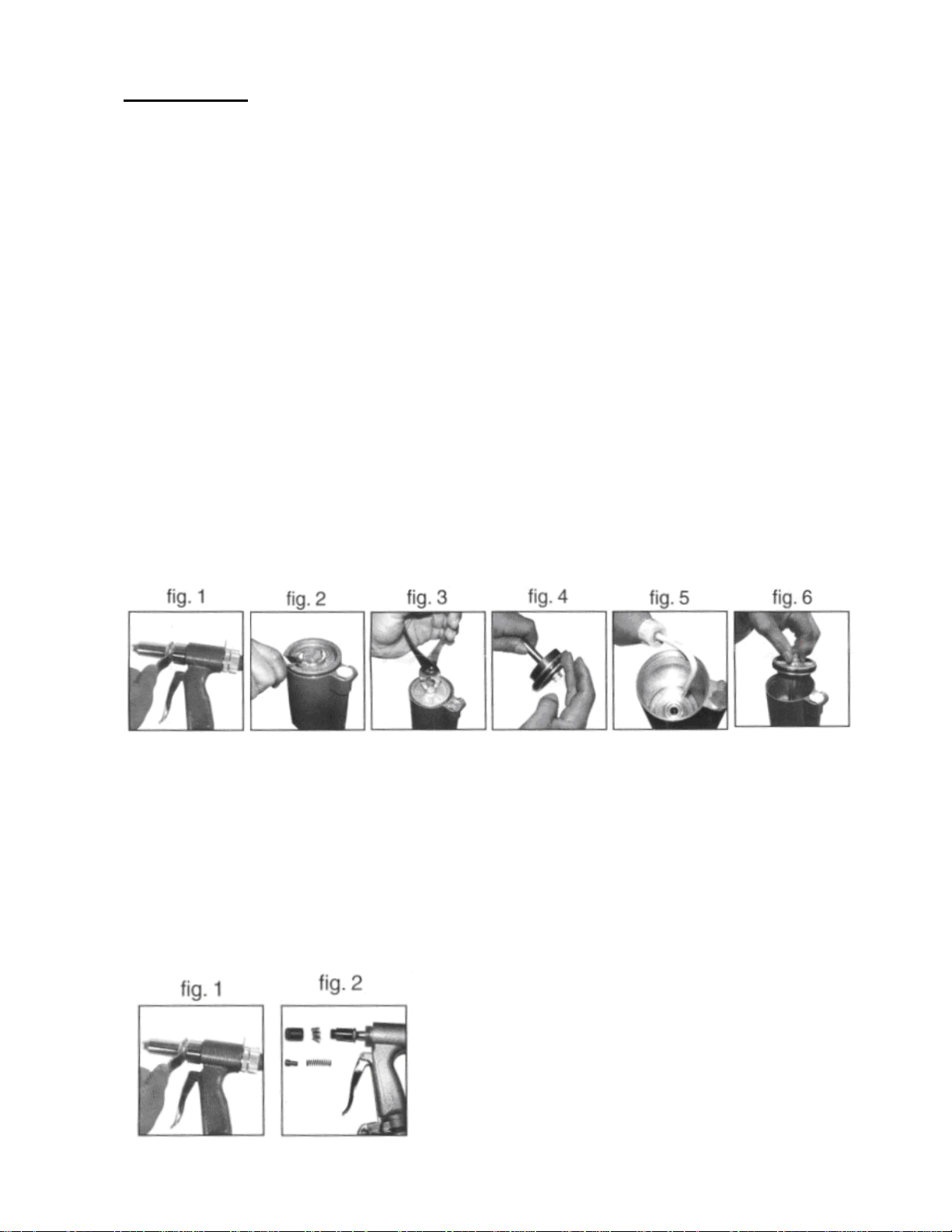

Cleaning/Maintenance for the Head of Riveter

1. Turn off air supply. Assur e all pressure is released prior to disassembly.

2. Use spanner wrench to dismantle the riveter head (fig.1).

3. Use spanner wrench to disassemble (fig. 2).

4. Clean all inner/assembly parts of the riveter head with a brush.

5. Reassemble the inner/assembly parts.

6. Oil the parts and reassemble riveter head completely.

Page 3

Page 4

Loading...

Loading...