Page 1

OPERATING INSTRUCTIONS

MANUEL D'INSTRUCTIONS

MANUAL DE INSTRUCCIONES

3.300.849

IMPORTANT OPERATING INSTRUCTIONS

SA VE THESE INSTRUCTIONS

MODEL

ATD

37155

Page 2

2

INSTRUCTION MANU AL FOR WIRE WELDING MA CHINES

IMPORTANT:

READ THIS MANUAL CAREFULLY BEFORE

INSTALLING, USING, OR SERVICING THE WELDING

MACHINE, PAYING SPECIAL ATTENTION TO SAFETY

RULES. CONTACT YOUR DISTRIBUTOR IF YOU DO

NOT FULLY UNDERSTAND THESE INSTRUCTIONS.

1 INSTALLATION

This machine must be used for welding only.It m ust not be

used to defrost pipes.

It is also essential to pay special attention to the chapter

on SAFETY PRECAUTIONS.

The symbols next to certain paragraphs indicate points

requiring extra attention, practical advice or simple information.

This manual must be stored carefully in a place familiar to

everyone involved in using the machine. It must be consulted whenever doubts arise and be kept for the entire

life-span of the machine; it will also be used for ordering

replacement parts.

1.1 PLACEMENT

Unpack the machine and place it in an adequately ventilated area, dust-free if possible, taking care not to block

the air intake and outlet from the cooling slots.

CAUTION: REDUCED AIR CIRCULATION causes overheating and could damage internal parts.

Keep at least 500 mm of free space around the machine.

Never place any filter ing device over the air intake points

of this welding machine.

The warranty shall become void if any type of filtering

device is used.

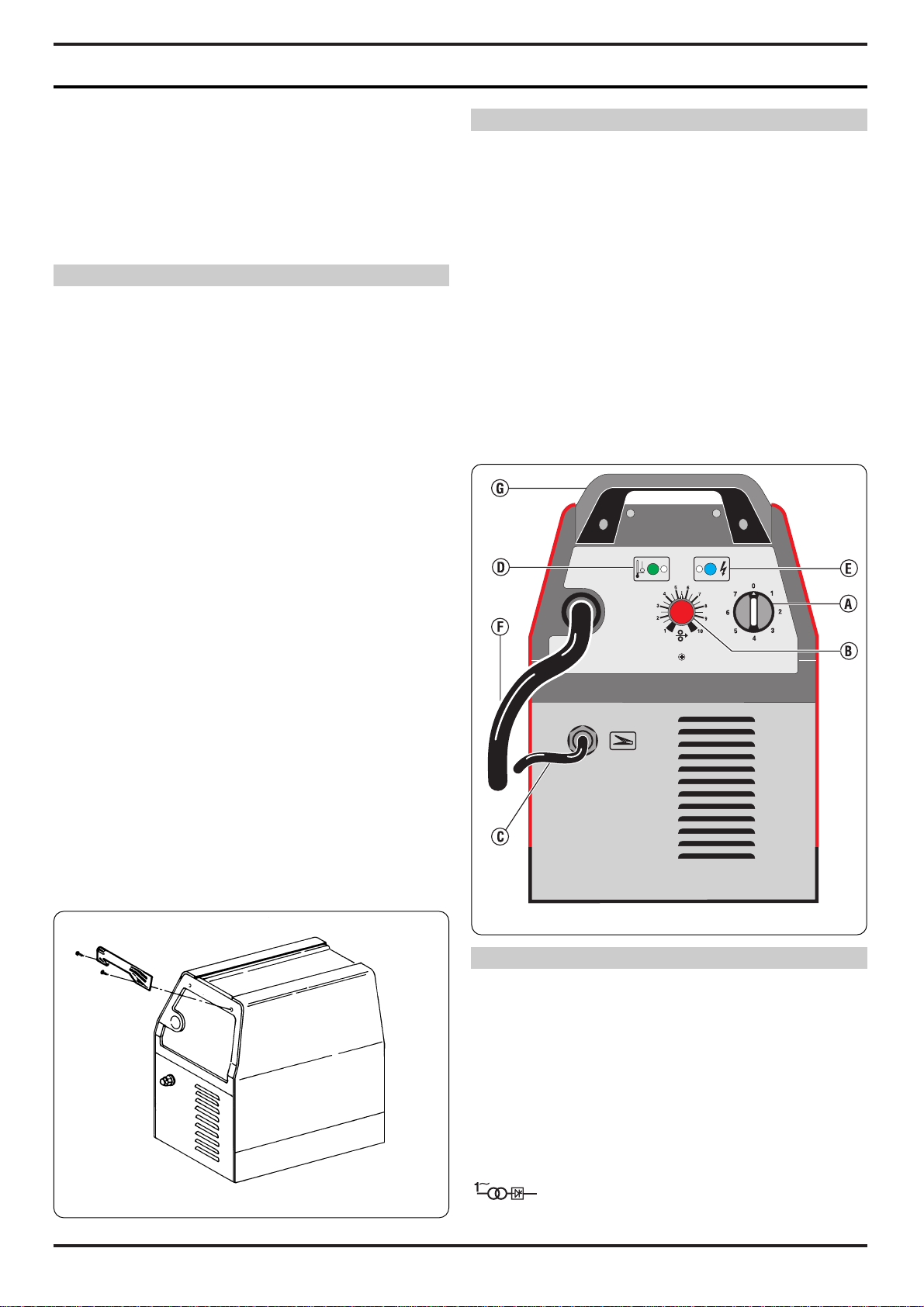

Mount the parts supplied with the machine as shown in

the figure 1.

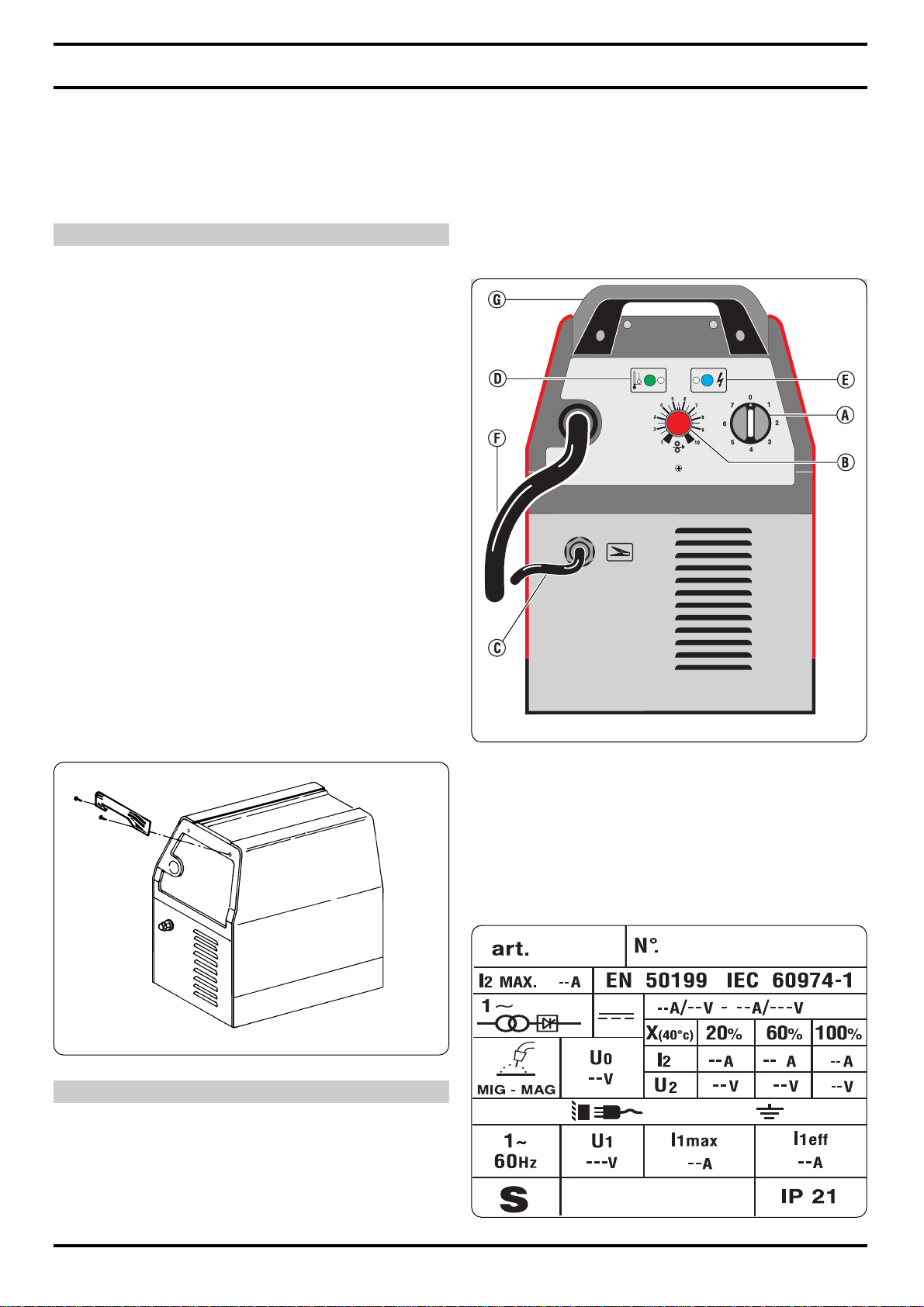

2 DESCRIPTION OF THE MACHINE

A) Switch

Turns the machine on and off, and also regulates the

welding voltage range.

B) Setting knob

This knob serves to adjust the welding wire speed.

C) Earth cable

D) Yellow LED

Lights only when the thermostat is tripped and

interrupts the machine operation.

E) Green LED

Indicates that the machine is turned on.

F) Welding torch

G) Handle

Must not be used to lift the machine.

3 GENERAL DESCRIPTIONS

3.1 SPECIFICATIONS

This welding machine allows welding of soft steel, stainless steel and aluminium.

3.2 EXPLANATION OF TECHNICAL SPECIFICATIONS

Fig. 1

Fig. 2

Page 3

3

N° Serial number which must be stated when

asking for information or servicing related to

this machine.

IEC 60974-1 The welding machine is manufactured according

EN 50199 to these international standards.

Single-phase Transformer - Rectifier

MIG/MAG. Suitable for continuous wire welding

I2 max Unconventional welding current.

The value represents the maximum level that

can be obtained in welding.

Uo Secondary no-load voltage.

X The duty-cycle expresses the percentage of

10 minutes during which the welding machine

can operate at a determined current level

without overheating: e.g. X=60% at I2=100 A.

This means that the welding machine can

weld with a current I2 = 100A for 6 minutes out

of 10, i.e. 60%.

I2 Welding current

U2 Secondary voltage with welding current I

U1 Nominal supply voltage at the rated frequency.

I1 max. This is the maximum value of the absorbed

current.

I1 eff. This is the maximum value of the actual absor-

bed current.

Ip 21 Grade of protection of the case.

Grade 1 as a second number means that this

unit is not fit for working in the rain.

S Fit for working in high-risk areas.

3.3 DESCRIPTION OF PROTECTION

This device is protected by a normally closed thermostat

on the power transformer.

When the thermostat is tripped the machine stops welding, while the motor-driven fan continues to run and the

yellow LED lights.

After it has been tripped, wait a few minutes to allow the

generator to cool down.

4 INSTALLATION

The machine must be installed by skilled personnel. All

connections must be made in compliance with current regulations and in full respect of safety laws.

Make sure that the wire diameter corresponds to the one

indicated on the roller, and mount the wire reel.Make sure

that the welding wire passes through the groove in the

small roller 7.

Before connecting the power cable 23, make sure that the

power voltage corresponds to that of the welding machine ,

then: a) for permanent connection to the power mains

without a plug, you must insert a main switch

having a suitable capacity in compliance with the

rated specifications.

b) for a plug-socket connection, use a plug having

a suitable capacity in compliance with the rated

specifications.In this case the plug must be used

to completely disconnect the machine from the

mains, after setting the switch 47 to “O” (off).

The yellow-green wire must be connected to the earth terminal.Connect the earth clamp 37 to the part to be welded.

The welding circuit must not be deliberately placed in

direct or indirect contact with the protection wire except in

the workpiece.

If the workpiece is deliberately grounded using the protection wire, the connection must be as direct as possible,

using a wire at least as large as the welding current return

wire, and connected to the workpiece at the same point as

the return wire, using the return wire clamp or a second

grounding clamp placed next to it.

All precautions must be taken to avoid stray welding currents.

Turn the machine on using the switch 47.

Remove the tapered gas tip 44 by turning it clockwise.

Unscrew the contact tip 43.

Do not press the torch trigger until you have read the

instructions carefully.

It is important to make sure the machine is turned off

whenever changing the wire reel and wire roller, to prevent

the wire feed motor from starting accidentally.

Press the torch trigger 39 and release it only when the

welding wire comes out.

Welding wire can cause puncture wounds.

Never aim the torch at parts of the body, other people or

metals when loading the welding wire.

Screw the contact tip 43 back on, making sure that the

hole diameter corresponds to the wire used.

Slide the tapered gas welding tip 44 on, always turning

clockwise.

4.1 CONNECTING THE GAS HOSE

l The gas cylinder must be equipped with a pressure

reducer and flow meter.

l If the cylinder is placed on the cylinder holder of the

machine, it must be held in place by the chain provided

and be of an appropriate size to avoid jeopardizing the

stability of the machine.

l Connect the gas hose leaving the back of the machine

to the pressure reducer only after the cylinder is in place.

l Open the gas cylinder and set the flow meter to approx-

imately 8-10 lt./min.

CAUTION:Make sure the gas used is compatible with the

material to be welded.

4.2 GENERAL NOTES

Before using this welding machine, carefully read the regulations CEI 26/9 or CENELEC HD 407 and CEI 26/11 or

CENELEC HD 433. Also make sure that the insulation on

cables, torch and earth cable is intact.

5 WELDING

5.1 WELDING MILD STEEL

5.1.1 With gas protection.

Either 75% ARGON + 25% CO2 or 100% CO2 may be

used for welding mild steel.

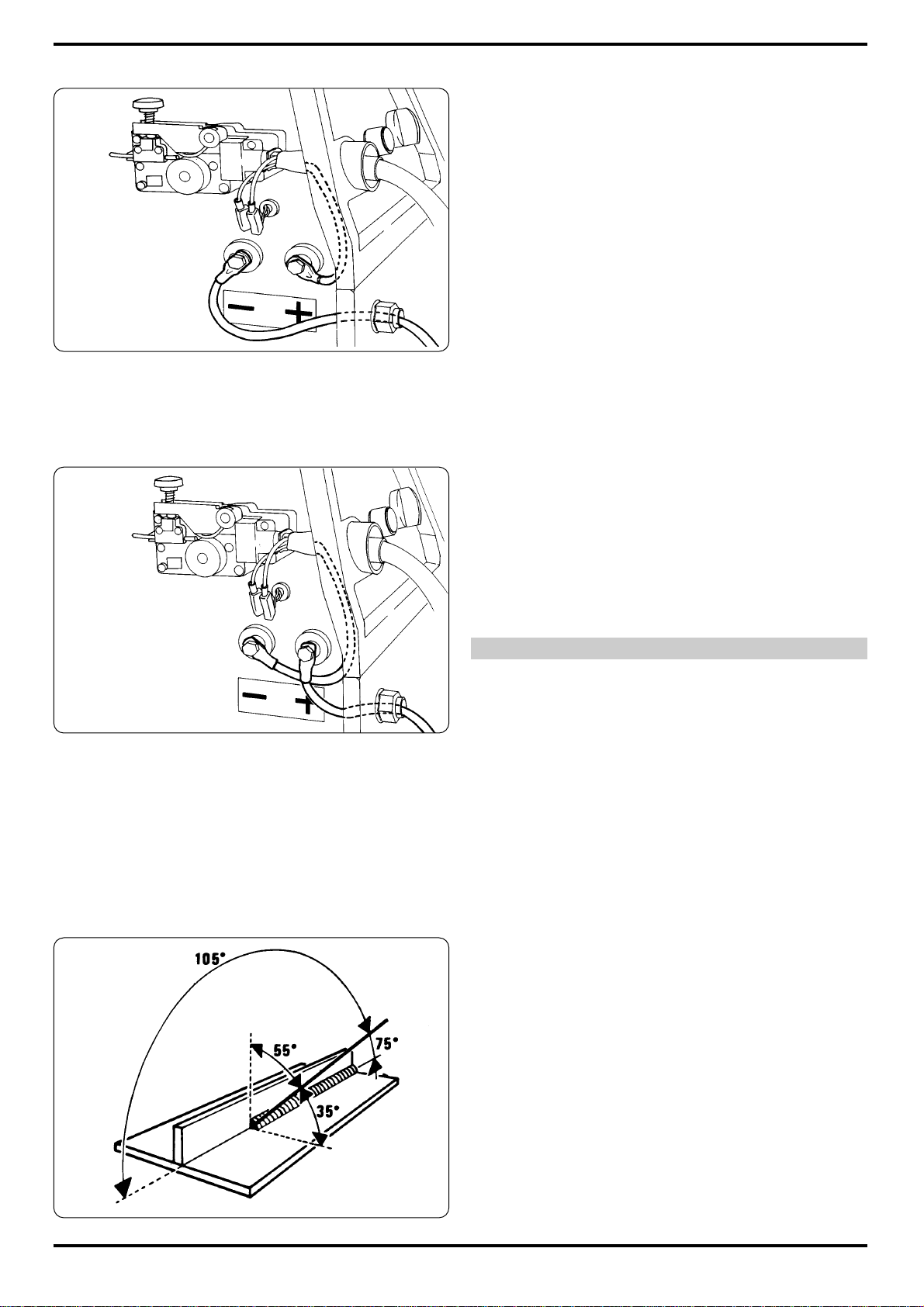

Connect the cables as shown in the figure 3.

Select the welding current by means of the rotary switchl

47.

Move the torch near the welding point and press the trigger 39.

Adjust the potentiometerl knob 2 until the welding is done

with a constant, continuous noise.

If the speed is too fast, the wire tends to stick to the piece

and cause the torch to skip; if the speed is too low, the

wire melts in spaced drops or the arc does not remain lit.

Page 4

4

When you have finished w elding, turn off the machine and

close the gas cylinder.

For the correct welding angle see figure 5.

5.1.2 Without gas protection.

Connect the cables as shown in the figure 4.

Use only diam. 0.9 flux cored wire that complies with the

standard AWS AS .20 E71 TII or E71 TGS, suitab le for use

without gaseous protection.

Connect the earth cable clamp to the workpiece.

After connecting the cables, follo w the instructions given in

paragraph 5.1.1.

NOTE: For compact, well-protected welds always work

from left to right and from top to bottom.

Remove all waste after each welding operation.

For the correct welding angle see figure 5.

5.2 WELDING ALUMINIUM

The welding machine must be prepared as for welding

mild steel with gas protection, but with the following differences:

- 100% ARGON as the protection gas for welding.

- A wire having a composition suited to the base material

to be welded.

For welding ALLUMAN: 3÷5% silicon wire

- For welding ANTICORODAL: 3÷5% silicon wire

- For welding PERALUMAN: 5% magnesium wire

- For welding ERGAL: 5% magnesium wire

Use grinding wheels and brushes specifically designed for

aluminium, and never use them on other materials.

REMEMBER that cleanliness is quality!

The wire reels must be stored in nylon bags with dehumidifying packets.

For the correct welding angle see figure 5.

5.3 WELDING STAINLESS STEEL

The welding machine must be prepared as for welding

mild steel with gas protection, but with the following differences:

- Reel of stainless steel wire compatible with the composition of the material to be welded.

- Cylinder containing 98% ARGON + 2% 02 (recommended composition)

The recommended torch angle and welding direction are

shown in figure 5.

6 MAINTENANCE AND CHECKS

6.1 GENERAL NOTES

l Turn off the welding machine and unplug the power cord

from the socket before each checking and maintenance

operation.

l Moving parts can cause serious lesions

l Keep away from moving parts.

l INCANDESCENT SURFA CES can cause serious burns.

l Let the unit cool before servicing.

l Periodically remove any dust or foreign matter that may

have deposited on the transf ormer or diodes;to do so, use

a jet of clean, dry air.

l When replacing the wire roller, make sure the groove is

aligned with the wire and corresponds to the diameter of

the wire used.

l Always keep the interior of the gas nozzle clean to avoid

metal bridges created by welding dross between the gas

nozzle and the contact tip.Make sure the outlet hole of the

contact tip has not expanded excessively; if so, replace.

l Strictly avoid striking the torch or allowing it to suffer vio-

lent impact.

6.2 REPAIRING THE WELDING MACHINE

Experience has shown that many accidents are caused by

repairs performed incorrectly. That is why it is just as

important to check a repaired welding machine carefully

and completely as it is for a new welding machine.

In addition, this protects the manufacturer from being held

liable for defects when the true fault lies elsewhere.

Fig. 5

Fig. 3

Fig. 4

Page 5

5

6.2.1 Instructions for performing repairs

l After rewinding the transformer or inductance, the weld-

ing machine must pass the applied voltage tests as indicated in table 2 of paragraph 6.1.3 of the standard EN

60974.1 (CEI 26.13). Compliance must be verified as

specified in 6.1.3.

l If no rewinding has been done, a welding machine that

has been cleaned and/or revised must pass an applied

voltage test with test voltage values equal to 50% of the

values given in table 2 of paragraph 6.1.3. Compliance

must be verified as specified in 6.1.3.

l After rewinding and/or replacing parts, the no-load volt-

age must not exceed the values given in paragraph 10.1

of EN 60974.1.

l If the repairs have not been performed by the manufac-

turer, repaired welding machines in which some components have been replaced or altered must be marked in

such a way that the person who perfor med the repairs is

clearly identifiable.

l After making repairs, take care to re-order the wiring so

that there is certain insulation between the primar y side

and the secondary side of the machine. Prevent the wires

from coming into contact with moving parts or parts that

heat up during operation. Replace all clamps as on the

original machine to prevent a connection from occurring

between the primary and secondary side if a conductor

accidentally breaks or disconnects.

6.3 TROUBLESHOOTING GUIDE

7 SAFETY PRECAUTIONS

7.1 FIRE

l Avoid causing fire because of sparks,

slag, hot metal or pieces.

l Make sure that suitable fire-fighting equip-

ment is available close to welding area.

l Remove all flammable and combustible material from

the welding area and its surrounding (32 ft minimum).

l Do not weld containers of combustible or flammable

material, even when empty. These must be carefully

cleaned before being welded.

l Allow the welded material to cool down before touching it or

putting it in contact with combustible or flammable material.

l Do not weld parts with hollow spaces, containing flam-

mables.

l Do not work under conditions with high concentrations of

combustible vapours, gases, or flammable dust.

l Always check the work area half an hour after welding

so as to make sure that no fire has started.

l Do not keep any combustible material such as lighters or

matches in your pockets.

7.2 BURNS

l Wear fire-proof clothing all over your body in order to pro-

tect your skin against burns caused by ultraviolet radiation

given off by the arc, and from weld metal spar ks and slag.

l Wear protective clothing-gauntlet gloves designed for

use in welding, hat and high safety-toe shoes.Button shirt

collar and pocket flaps, and wear cuff-less trousers to

avoid entry of sparks and slag.

l Wear helmet with safety goggles and glasses with side

shields underneath, appropriate filter lenses or plates (protected by clear cover glass).This is a MUST for welding to

protect the eyes from radiant energy and flying metal.

Replace cover glass when broken, pitted, or spattered.

l Avoid oil or greasy clothing. A spark may ignite them.

Hot metal such as electrode stubs and workpieces should

never be handled without gloves.

l First-aid facilities and a qualified first-aid person should

be available for each shift unless medical facilities are

close by for immediate treatment of flash b urns of the eyes

and skin burns.

l Ear plugs should be worn when working on overhead or

in a confined space.A hard hat should be worn when others work overhead.

l Flammable hair preparations should not be used by per-

sons intending to weld or cut.

7.3 FUMES

Welding operations give off harmful fumes and

metal dusts which may be hazardous to your

health, therefore:

l Work in a well-ventilated area.

l Keep your head out of fumes.

l In closed areas, use suitable exhaust fans.

l If ventilation is not enough, use breathing sets approved

for this procedure.

l Clean the material to be welded of any solvents or halo-

gen degreasers giving rise to toxic gases. Some clorine

solvents may decompose with the radiation emitted by the

arc, and create phosgene gas.

l Do not weld plated metals or those containing lead,

ROUBLE

The welding machine supplies limited

current

Welding with a lot

of metal spatter

The wire jams or

entangles between

the drive rolls and

the torch infeed wire

guide

No wire feed or irregular wire feed

Porosity in the welding seam

PROBABLE CAUSE

Line fuse blown

Burnt out diode or diodes

Burnt out electronic board

Loosened torch or earth

connections or any other

electrical power connections

Voltage adjustment switch

has a loose contact

Improper adjustment of

welding parameters

Insufficient grounding

Contact tip with wrong diameter

Misalignment of the drive

roll groove

Obstructed or clogged

liner

Drive roll with too large a

groove

Obstructed or clogged

liner

Wire holding roller not

completely tightened

Clogged contact tip

Insufficient shielding gas

Excess oxidation of the

edges to be welded

Gas nozzle partially or

completely clogged by

spatter

REMEDY

Replace line fuse

Replace

Replace

Tighten all connections

Replace the switch

Select the correct parameters through the weldingvoltage switch and the

wire-speed adjustment

potentiometer

Check grounding connections

Replace

Realign

Remove and clean

Replace the drive roll

Remove and clean

Tighten all the way

Replace

Increase gas delivery

Thoroughly clean the

edges with a metal brush

Remove and clean or

replace being careful not

to clog the gas outlets

Page 6

6

graphite, cadmium, zink, chrome, mercury or beryllium,

unless you have the proper breathing set.

l The electric arc creates ozone. A long exposure to high

concentrations may cause headaches, nasal, throat and

eye irritation as well as serious congestions and chest

pains.

IMPORTANT: DO NOT USE OXYGEN FOR VENTILATION.

l Gas leaks in a confined space should be avoided.

Leaked gas in large quantities can change oxygen concentration dangerously. Do not bring gas cylinders into a

confined space.

l DO NOT WELD where solvent vapors can be drawn into

the welding atmosphere or where the radiant energy can

penetrate to atmospheres containing even minute

amounts of trichloroethylene or perchloroethylene.

7.4 EXPLOSIONS

Do not weld above or near containers under pressure.

l Do not weld in environments containing explo-

sive dusts, gases or vapours.

This welding machine uses inert gases such as CO2,

ARGON, or a mixture of ARGON + CO2 for the protection

of the arc, thus you should take special precautions:

A) CYLINDERS

l Do not directly connect cylinder to the machine gas hose

without a pressure regulator.

l Handle or use pressure cylinders in conformity with the

existing rules.

l Do not use leaking or damaged cylinders.

l Do not use cylinders which are not well secured.

l Do not carry cylinders without the protection of the

installed valve.

l Do not use cylinders whose content has not been clear-

ly identified.

l Never lubricate cylinder valves with oil or grease.

l Do not put the cylinder in electrical contact with the arc.

l Do not expose cylinders to excessive heat, sparks,

molten slags or flame.

l Do not tamper with the cylinder valves.

l Do not try to loosen tight valves by means of hammers,

keys, or any other object.

l NEVER DEFACE or alter name, number, or other mark-

ings on a cylinder.It is illegal and hazardous.

l Do not lift cylinders off the ground by their valves or

caps, or by chains, slings or magnets.

l Never tr y to mix any gases in a cylinder.

l Never refill any cylinder.

l Cylinder fittings should never be modified or exchanged.

B) PRESSURE REGULATORS

l Keep pressure regulators in good condition. Damaged

regulators may cause damages or accidents, they should

only be repaired by skilled personnel.

l Do not use regulators for gases other than those for

which they are manufactured.

l Never use a leaking or damaged regulator.

l Never lubricate regulators with oil or grease.

C) HOSES

l Replace hoses which appear damaged.

l Keep hoses unwound in order to avoid bending.

l Keep the excess hose wound and out of the working

area in order to avoid any damage.

7.5 RADIATIONS

Ultra-violet radiation created by the arc may damage your eyes and bur n your skin. Therefore:

l Wear proper clothing and helmet.

l Do not use contact lenses!! The intense heat coming

from the arc may cause them to stick to the cornea.

l Use masks with grade DIN 10 or DIN 11 safety lenses at

the least.

l Protect people in the surrounding welding area.

Remember: the arc may dazzle or damage the eyes. It is

considered dangerous up to a distance of 15 meters (50

feet). Never look at the arc with the naked eye.

l Prepare the welding area so as to reduce reflection and

transmission of ultra-violet radiation. Paint walls and

exposed surfaces in black to reduce reflection, install

sheathings or curtains to reduce ultra-violet transmissions.

l Replace mask lenses whenever damaged or broken.

7.6 ELECTRIC SHOCK

Electric shock can kill.

All electric shocks are potentially fatal.

l Do not touch live parts.

l Insulate yourself from the piece to be cut and from the

ground by wearing insulated gloves and clothing.

l Keep gar ments (gloves, shoes, hats, clothing) and body

dry.

l Do not work in humid or wet areas.

l Avoid touching the piece to be welded.

l Should you work close to or in a dangerous area, use all

possible precautions.

l If you should feel even the slightest electric shock sen-

sation, stop welding immediately. Do not use the machine

until the problem is identified and solved.

l Always fit an automatic wall switch with adequate po wer,

possibly close to the machine, allowing you to immediately switch the machine off in case of an emergency.

l Frequently inspect the power supply cable.

l Disconnect power supply cable from mains before

replacing cables or before removing unit covers.

l Do not use the unit without protection covers.

l Always replace any damaged parts of the unit, with orig-

inal material.

l Never disconnect unit safety devices.

l Make sure that the power supply line is equipped with an

efficient earth plug.

l Make sure that the work bench and the workpiece are

connected to an efficient earth plug.

l Any maintenance should only be carried out by qualified

personnel aware of the risks due to dangerous voltages

necessary for the operation of the unit.

7.7 PACE MAKER

l Magnetic fields from high currents can affect pacemak-

er operation. Persons wearing electronic life support

equipment (pacemaker) should consult their doctor before

going near arc welding, gouging or spot welding operations.

7.8 CAUTION! WELDING WIRE CAN CAUSE PUNCTU

Page 7

7

RE WOUNDS.

l Do not press gun trigger until instructed to do so.

l Do not point gun toward any part of the body, other peo-

ple, or any metal when threading welding wire.

7.9. MOVING PARTS CAN CAUSE INJURY.

Moving parts, such as fans, can cut fingers and hands and

catch loose clothing.

l Keep all doors, panels, covers, and guards closed and

securely in place.

l Have only qualified people remove guards or covers for

maintenance and troubleshooting as necessary.

l Keep hands, hair, loose clothing, and tools away from

moving parts.

l Reinstall panels or guards and close doors when ser-

vicing is finished and before starting the machine.

7.10 NOISE

These power source alone do not produce noise

levels exceeding 80 dB. The welding procedure,

however, may produce noise levels in excess of

80 dB. in which case the machine operator must take the

necessary safety precautions as prescribed by the national safety regulation.

Page 8

8

2 DESCRIPTION DE LA MACHINE

A) Interrupteur.

Il sert pour mettre en marche ou arrêter la machine

ainsi que pour régler les valeurs de la tension de soudure.

B) Bouton de réglage.

A l’aide de ce bouton, il est possible de régler la vites-

se du fil de soudure.

C) Câble de masse.

D) Led jaune.

Elle s’allume uniquement lorsque le thermostat inter-

rompt le fonctionnement du poste à souder.

E) Led verte.

Elle indique la mise en marche de la machine.

F) Torche de soudure.

G) Poignée.

Elle ne doit pas être utilisée pour le levage.

3. DESCRIPTIONS GENERALES

3.1 SPECIFICATIONS

Ce poste à souder permet la soudure d’acier doux, acier

inoxydable et aluminium.

3.2. EXPLICATION DES DONNEES TECHNIQUES

N° Numéro de matricule qui doit toujours être

indiqué pour toute demande relative à ce

poste à souder.

IEC 60974-1 Le poste à souder est constr uit selon ces

EN 50199 normes internationales

Transformateur - Redresseur monophasé

MIG/MAG. Indiqué pour la soudure à fil continu.

IMPORTANT:

A VANT D’INSTALLER, EMPLO YER, OU BIEN COMMENCER TOUT ENTRETIEN AU POSTE A SOUDER, IL

FAUT LIRE LE CONTENU DE CE MANUEL EN FAISANT

PARTICULIERE ATTENTION AUX NORMES DE SECURITE. CONTACTEZ VOTRE DISTRIBUTEUR SI VOUS

N’AVEZ PAS COMPLETEMENT COMPRIS CES

INSTRUCTIONS.

1. INTRODUCTION

Cette machine ne doit être employée que pour des opérations de soudure et ne doit pas être utilisée pour décongeler les tuyaux.Il est cependant indispensab le de donner

toute l’attention possible au chapitre concernant les PRECAUTIONS DE SECURITE.

Les symboles placés à proximité des paragraphes auxquels se réfèrent ont le but de mettre en évidence des

situations d’attention maximum, des conseils pratiques ou

bien quelques simples renseignements.

Ce manuel doit être gardé avec soin, dans un lieu connu

par les différentes personnes intéressées. Il devra être

consulté chaque fois qu’on a des doutes;il devra suivre la

vie opérationnelle de la machine et sera utilisé pour émettre les commandes d’achat des pièces de rechange.

1.1 MISE EN PLACE

Enlever la machine de son emballage et la placer dans un

endroit ayant une ventilation appropriée, si possible sans

poussières, en faisant attention à ne pas obturer l’entrée

et la sortie de l’air dans les grilles de refroidissement.

ATTENTION: UNE CIRCULATION REDUITE DE L’AIR

cause la surchauffe et de possibles endommagements

des parties intérieures.

Laisser au moins 500 mm d’espace libre tout autour de la

machine.

Ne placer aucun dispositif de filtration sur les passages

d’entrée de l’air de ce poste à souder.

La garantie devient nulle lorsqu’on utilise un dispositif de

filtration de n’importe quel type.

Monter les pièces fournies avec la machine comme indiqué en figure 1.

MANUEL D’INSTRUCTIONS POUR POSTES A SOUDER A FIL

Fig. 1

Fig. 2

Page 9

9

la tension de réseau correspond à celle du poste à souder.

En suite:a) En cas de branchement permanent au

système d’alimentation sans fiche, il faut prév oir

un interrupteur général de capacité adéquate

par rapport aux données de la plaque.

b) En cas de branchement avec fiche, utiliser

une fiche de capacité adéquate par rapport aux

données de la plaque.Dans ce cas la fiche doit

être utilisée pour débrancher complètement la

machine du réseau, après avoir positionné

l’interrupteur 47 sur «O».

Le conducteur vert/jaune doit être raccordé à la borne de

terre. Raccorder la borne du câble de masse 37 à la pièce

à souder.

Le circuit de soudure ne doit pas être placé délibérément au

contact direct ou indirect avec le conducteur de protection,

sauf dans la pièce à souder.

Si la pièce à usiner est raccordée délibérément à la terre à

travers le conducteur de protection, le raccordement doit

être le plus direct possible et exécuté au moyen d’un conducteur de section au moins égale à celle du conducteur de

retour du courant de soudure et raccordé à la pièce à usiner en utilisant la borne du conducteur de retour ou bien

une deuxième borne de masse placée immédiatement à

proximité.Toute précaution possible doit être prise afin

d’éviter des courants errants de soudure.

Mettre la machine en marche à l’aide de l’interrupteur 47.

Extraire la buse gaz conique 44 en la tournant en sens

horaire.Dévisser la buse porte-courant 43.

Ne pas appuyer sur le bouton de la torche av ant d’av oir

lu soigneusement le mode d’emploi.

Il est important de s’assurer que la machine est arrêtée

chaque fois qu’on remplace la bobine du fil et le rouleau

entraîne-fil afin d’éviter que le motoréducteur démarre accidentellement.

Appuyer sur le bouton de la torche 39 et le laisser uniquement à la sortie du fil.

Le fil de soudure peut causer des blessures perforées.

Ne pas pointer la torche vers des parties du corps, d’autres

gens ou biens des métaux lors du montage du fil de soudure.

Revisser la buse porte-courant 43 en s’assurant que le

diamètre du trou est égal au fil employé.

Introduire la buse gaz conique de soudure 44 en la tournant

toujours en sens horaire.

4.1 RACCORDEMENT DU TUYAU DU GAZ

l La bouteille de gaz doit être équipée d’un détendeur de

pression et d’un débitmètre.

l Si la bouteille est positionnée sur la plate-forme de la

machine, elle doit être fixée à l’aide de la chaîne prévue et

avoir des dimensions telles à ne pas compromettre la stabilité de la machine.

l Positionner tout d’abord la bouteille et en suite exécuter le

raccordement du tuyau du gaz sortant de la partie arrière

de la machine au détendeur de pression.

l Ouvr ir la bouteille de gaz et régler le débitmètre à 8/10

litres/min. environ.

ATTENTION: Contrôler que le gaz employé est compatible

avec le matériel à souder.

I2 max Courant de soudure non conventionnel.

Le valeur représent la limite maximale pouvant

être obtenue en soudure.

Uo Tension à vide secondaire.

X Le facteur de marche exprime le pourcentage

de 10 minutes au cours desquelles le poste à

souder peut travailler avec un courant fixé

sans provoquer des surchauffages.

Par exemple: X = 60% a I2 = 100 A.

Cela signifie que le poste à souder peut

souder avec un courant I2 = 100A pendant 6

minutes sur 10, c’est-à-dire 60%.

I2 Courant de soudage.

U2 T ension secondaire a vec cour ant de soudage I2.

U1 Tension nominale d’alimentation à la fréquence

décrite.

I1 max. C'est la valeur maximale du courant absorbé.

I1 eff. C'est la valeur maximale du courant

effectif absorbé.

IP21 Degré de protection de la carcasse.

Degré 1 comme deuxième chiffre signifie que

cet appareil ne peut pas être utilisé

sous la pluie.

S Indiqué pour travailler dans des locaux

soumis à un risque accru.

3.3. DESCRIPTION DE LA PROTECTION

Cette machine est protégée par un thermostat normalement fermé positionné sur le transformateur de puissance.

Lors de l’entrée en fonction du thermostat, la machine

cesse de souder tandis que le ventilateur à moteur continue

à fonctionner et la led jaune s’allume.

Après l’entrée en fonction, attendre quelques minutes de

façon à permettre le refroidissement du générateur.

4 MISE EN OEUVRE

L’installation de la machine doit être exécutée par personnel

expert.Tous les raccordements doivent être exécutés selon

les normes en vigueur et dans le respect total de la réglementation en matière de prévention des accidents.

Contrôler que le diamètre du fil correspond au diamètre

indiqué sur le rouleau et monter la bobine du fil. S’assurer

que le fil de soudure passe à l’intérieur de la gorge du rouleau 7.

Avant de r accorder le cordon d’alimentation 23, s’assurer que

Page 10

10

avec la norme AWS AS.20 E71 TII ou bien E71 TGS, apte

à l’emploi sans protection de gaz.

Raccorder la pince du câble de masse à la pièce à souder.

Après avoir raccordé les câbles suivre les mêmes instructions décrites au paragraphe 5.1.1.

N.B. Afin d’obtenir des soudures raccordées et bien

protégées, procéder toujours de gauche à droite et du haut

vers le bas.

A la fin de chaque soudure, enlever les déchets.

Pour la correcte inclinaison de soudure, voir figure 5.

5.2 SOUDURE DE L’ALUMINIUM

Le poste à souder doit être prédisposé comme pour la soudure de l’acier doux avec protection de gaz, en appliquant

les variations suivantes:

- ARGON 100 % en tant que gaz de protection pour la soudure.

- Un fil d’apport de composition adéquate au matériel

de base à souder.

- Pour souder ALUMAN fil 35 % silicium.

- Pour souder ANTICORODAL fil 35 % silicium.

- Pour souder PERALUMAN fil 5% magnésium.

- Pour souder ERGAL fil 5 % magnésium.

Utiliser des meules et des brosseuses spécifiques pour l’aluminium sans jamais les utiliser sur d’autres matériels.

SE RAPPELER que propreté veut dire qualité!

Les bobines de fil doivent être gardées à l’intérieur de

sachets en nylon avec un déshumidificateur.

Pour la correcte inclinaison de soudure, voir figure 5.

5.3 SOUDURE DE L’ACIER INOXYDABLE

Le poste à souder doit être prédisposé comme pour la soudure de l’acier doux avec protection de gaz, en appliquant

les variations suivantes:

- Bobine de fil d’acier inoxydable compatible avec la composition de l’acier à souder.

- Bouteille contenant de l’ARGON 98 % + O2 2% (composition conseillée).

L’inclinaison de la torche et la direction de soudure conseillées sont illustrées dans la figure 5.

6 ENTRETIEN ET CONTROLES

L’entretien doit être exécuté par personnel qualifié.

4.2 NOTES GENERALES

Avant d’utiliser ce poste à souder, lire soigneusement les

normes CEI 26/9 ou bien CENELEC HD 407 et CEI 26/11

ou bien CENELEC HD 433.En outre vérifier l’intégrité de l’isolement des câbles, de la torche et du câble masse.

5 SOUDURE

5.1 SOUDURE DE L’ACIER DOUX.

5.1.1 Avec protection de gaz.

Pour les soudures d’acier doux on peut utiliser de l’ARGON

75% + CO2 25% ou bien CO2 100%.

Raccorder les câbles comme d’après la figure 3.

Choisir la tension de soudure au moyen du bouton du commutateur rotatif 47.

Se rapprocher au point de soudure et appuyer sur le bouton de la torche 39.

Tourner le bouton du potentiomètre 2 jusqu’à obtenir une

soudure avec un bruit constant et continu.

Avec une vitesse trop élevée le fil tend à trébucher en faisant rebondir la torche; avec une vitesse trop réduite le fil

fond à gouttes irrégulières ou bien l’arc ne demeure pas

allumé.

Après avoir exécuté la soudure, arrêter la machine et fermer la bouteille de gaz.

Pour la correcte inclinaison de soudure, voir figure 5.

5.1.2 Sans protection de gaz.

Raccorder les câbles comme d’après la figure 4.

On ne doit utiliser que du fil avec âme 0,9 en confor mité

Fig. 4

Fig. 5

Fig. 3

Page 11

11

6.1 NOTES GENERALES

l Arrêter le poste à souder et retirer la fiche d’alimentation

de la prise avant d’effectuer toute opération de contrôle et

entretien.

l Les parties en mouvement peuvent causer des lésions

graves.

l Se tenir éloigné des parties en mouvement.

LES SURFACES INCANDESCENTES peuvent causer des

brûlures graves.

l Laisser refroidir avant de procéder a l’entretien.

l Enlever périodiquement la poussière ou les matières

étrangères qui se sont déposées éventuellement sur le

transformateur ou sur les diodes;pour ce faire utiliser un jet

d’air sec et propre.

l Lors du remontage du rouleau entraîne-fil, veiller à ce que

la gorge soit alignée au fil et que corresponde au diamètre

du fil employé.

l Maintenir toujours propre l’intérieur de la buse du gaz de

façon à éviter des ponts métalliques constitués de jets de

soudure entre la buse du gaz et la buse porte-courant.

S’assurer que le trou de sortie de la buse porte-courant ne

s’est pas trop élargi; dans le cas contraire procéder à son

remplacement.

l Eviter absolument de frapper la torche ou de lui provoquer

des chocs violents.

6.2 DEPANNAGES DES POSTES A SOUDER

L’expérience a montré que beaucoup d’accidents mor tels

sont causés par des dépannages non exécutés selon les

règles de l’art. C’est pour cette raison qu’un contrôle complet et soigné sur un poste à souder dépanné est autant

important que le contrôle sur un poste à souder neuf.

De cette manière les producteurs sont également protégés

de l’accusation d’être responsables de défauts lorsque la

faute est à imputer à d’autres.

6.2.1 Prescriptions à suivre pour les dépannages

l Après le réenroulement du transformateur ou des induc-

tances, le poste à souder doit passer les essais de tension

appliquée comme d’après le tableau 2 de 6.1.3. de la

norme EN 60974.1 (CEI 26.13).La conformité doit être vérifiée comme spécifié au point 6.1.3.

l Si aucun réenroulement n’a été effectué, un poste à soud-

er nettoyé et/ou révisé doit passer un essai de tension

appliquée avec les v aleurs de la tension d’essai à 50 % des

valeurs données dans le tableau 2 de 6.1.3. La conformité

doit être vérifiée comme spécifié au point 6.1.3.

l Après le réenroulement et/ou le remplacement de pièces,

la tension à vide ne doit pas dépasser les valeurs exposées

au point 10.1 de EN 60974.1.

l Si les dépannages ne sont pas exécutés par le produc-

teur, les postes à souder où on a remplacé ou modifié

quelques composants doivent être marqués de façon à

identifier l’auteur du dépannage.

l Après l’exécution d’un dépannage, veiller à ranger le

câblage de façon à avoir un isolement sûr entre le côté primaire et le côté secondaire de la machine.

l Eviter que les fils puissent venir en contact avec les par-

ties en mouvement ou les parties se chauffant pendant le

fonctionnement. Remonter tous les colliers comme sur la

machine d’origine de façon à éviter que, si par hasard un

conducteur se casse ou se débranche, se puisse vérifier un

raccordement entre le primaire et le secondaire.

6.3 PANNES D’EMPLOI

7 PRECAUTIONS GENERALES.

7.1 Feu.

l Eviter que le feu ne se déclare par suite

d’étincelles et de scories chaudes ou de

corps incandescents.

l S’assurer que des dispositifs appropriés contre l’incen-

die soient disponibles près de la zone de soudage.

l Enlever de la zone de soudure et de la zone environ-

nante (10 mètres au moins) les matériaux inflammables et

les combustibles.

l Ne pas effectuer de soudure sur les récipients de com-

bustible et de lubrifiant, même s’ils sont vides. Ces récipients doivent être attentivement nettoyés avant d’être

soudés.

l Laisser refroidir le matériau soudé avant de le toucher

ou de le mettre en contact avec des matériaux combusti-

INCONVENIENT

Le débit de courant

est limité

Soudage avec plusieurs giclées de

métal

Le fil n’avance pas

ou avance irrégulièrement

Le fil se bloque et

s’entortille entre les

rouleaux et le guidefil d’entrée dans la

torche

Porosité dans le

cordon de soudure

CAUSE PROBABLE

Le fusible de la ligne est

grillé

Diode ou diodes grillées

Circuit de contrôle grillé

Connexions de la torche ou

de la masse ou toute autre

connexion desserrées

Le contact au commutateur de régulation du courant de soudage est faible

Réglage erroné des

paramètres de soudage

Connexions de masse

insuffisantes

Rouleau d’entraînement

du fil doté d’une gorge

trop large

Gaine obstruée ou bouchée

Rouleau presse-fil non

serré à fond

Friction du porte-bobine

trop serré

Buse gaz obstruée

Buse gaz d’un diamètre

erroné

La gorge du rouleau n’est

pas correctement alignée

La canette n’est pas en

position

Gaine obstruée ou bouchée

Insuffisance du gaz de

protection

Bords à souder excessivement oxydés

Buse gaz partiellement ou

totalement obstruée par

les glicées

REMEDE

Remplacer le fusible.

Remplacer

Remplacer

Serrer toutes les

conexions

Remplacer le commutateur

Rechercher les paramètres

exacts en agissant sur le

po- tentiomètre de la tension de soudage et sur le

potentio- mètre de la vitesse du fil

Contrôler l’efficacité des

connexions

Remplacer le rouleau

L’extraire et la nettoyer

Le serrer à fond

Desserrerle en agissant

sur le réglage

La remplacer

La remplacer

L’aligner

L’approcher le plus possible

du rouleau qui entraîne le fil

L’extraire et la nettoyer

Augmenter le débit de gaz

Nettoyer soigneusement

avec une brosse métallique

les bords à souder

La démonter et la nettoyer

ou bien la remplacer en

ayant soin de ne pas

obstruer les orifices de

sortie des gaz

Page 12

12

bles ou inflammables.

l Ne pas effectuer de soudure sur des pièces qui possè-

dent des insterstices pouvant contenir des matériaux

inflammables.

l Ne pas travailler dans un milieu contenant des concen-

trations élevées de vapeurs combustibles, des gaz ou des

poussières inflammables.

l Contrôler toujours la zone de travail une demi-heure

après la soudure pour s’assurer qu’il n’y ait pas un début

d’incendie.

l Ne pas garder dans les poches des matériaux combu-

stibles comme des briquets ou des allumettes.

7.2 Brûlures.

l Pour protéger la peau contre les brûlures provoquées

par les radiations ultraviolettes émises par l’arc, contre les

étincelles et les scories de métal fondu, utiliser des vêtements ignifuges qui recouvrent toutes les parties exposées du corps.

l Revêtir des vêtements/gants utilisés par les soudeurs,

une casquette et des bottillons avec la pointe de sécurité.

Boutonner le col de la chemise et les pattes des poches

et utiliser des pantalons sans revers pour éviter que les

étincelles et les scories ne pénètrent dans ces revers.

l Mettre un casque avec une vitre de protection à l’extérieur

et des verres filtrants à l’intérieur. Il s’agit d’une précaution

IMPERATIVE pour les opérations de soudage pour protéger

les yeux des radiations et des métaux volatils. Remplacer la

vitre de protection si cassée, grêlée ou tachetée.

l Eviter les vêtements graisseux ou sales de graisse. Une

étincelle pourrait les enflammer.

l Utiliser toujours des gants pour saisir les parties métal-

liques incandescentes, telles que des morceaux d’électrode ou des pièces à usiner.

l Des instruments pour une urgence et une personne

qualifiée devraient toujours être disponibles pour chaque

brigade de travail à moins que des structures sanitaires ne

se trouvent dans les environs pour un traitement immédiat

et éventuel de brûlures aux yeux, dérivant de flambées,

ou de brûlures de la peau.

l Des bouchons pour les oreilles devraient être utilisés lor-

squ’on travaille au plafond ou dans un espace réduit. Un

bonnet solide doit être coiffé lorsque d’autres personnes

travaillent dans la zone située au dessus.

l Les personnes qui doivent souder ou découper ne doivent

pas utiliser des produits inflammables pour les cheveux.

7.3 Fumées.

Les opérations de soudage produisent des

fumées et des poussières métalliques nocives à

la santé. Il faut donc:

l Trav ailler dans des locaux munis d’une v entilation appro-

priée.

l Garder la tête hors des fumées.

l Utiliser, dans des locaux fermés, des aspirateurs appro-

priés.

l Utiliser des respirateurs agréés si la ventilation n’est pas

adéquate.

l Nettoyer le matériau à souder si l’on note la présence de

solvants ou de dégraissants halogènes qui donnent origine à des gaz toxiques. Durant le soudage quelques solvants chlorinés peuvent se décomposer en présence de

radiations émises par l’arc et engendrer des gaz phosgènes.

l Ne pas souder des métaux recouverts ou contenant du

plomb, de la graphite , du cadmium, du zinc, du chrome, du

mercure ou du béryllium si l’on ne dispose pas d’un respirateur approprié.

l L’arc électrique produit de l’ozone. Une exposition pro-

longée dans des milieux avec de hautes concentrations

d’ozone peut provoquer des maux de tête , de l’irritation au

nez, à la gorge et aux yeux, de graves congestions et des

douleurs de poitrine.

IMPORTANT: NE PAS UTILISER DE L’OXYGENE POUR

LA VENTILATION.

l Eviter des pertes de gaz dans des espaces réduits.Des

pertes de gaz impor tantes peuvent modifier, de manière

dangereuse, la concentration d’oxygène .Ne jamais placer

des bouteilles de gaz dans des espaces réduits.

NE JAMAIS SOUDER ou découper dans les locaux où

des vapeurs de solvant peuvent être mêlées à l’atmosphère de soudage ou de découpe ou bien lorsque l’énergie radiante peut pénétrer dans des atmosphères qui

contiennent du trichloréthylène ou du perchloréthylène.

7.4 Explosions.

l Ne pas effectuer des soudures au dessus ou à

proximité de récipients sous pression.

l Ne pas souder dans un milieu contenant des

poussières, gaz ou vapeurs explosifs.

l Ce poste à souder utilise des gaz inertes comme le

CO2, l’ARGON ou des mélanges de ARGON + C02 pour

la protection de l’arc; il faut donc faire très attention a:

A) BOUTEILLES.

l Ne jamais relier directement la bouteille au tube de gaz

de l’appareil sans utiliser un régulateur de pression.

l Manipuler ou utiliser des bouteilles sous pression

conformément aux normes en vigueur.

l Ne pas utiliser des bouteilles qui perdent ou qui sont

physiquement endommagées.

l Ne pas utiliser des bouteilles qui ne soient pas bien

fixées.

l Ne pas transporter des bouteilles sans la protection de

la soupape montée.

l Ne jamais utiliser des bouteilles dont le contenu n’a pas

été clairement identifié.

l Ne jamais lubrifier les soupapes de la bouteille avec de

l’huile ou de la graisse.

l Ne jamais mettre en contact électrique la bouteille avec

l’arc.

l Ne jamais exposer les bouteilles à une chaleur excessiv e,

à des étincelles, à des scories fondues ou à des flammes.

l Ne jamais agir sur les soupapes de la bouteille.

l Ne pas essayer de débloquer avec des mar teaux, des

clés ou autres systèmes les soupapes bloquées.

l NE JAMAIS EFFACER et ne jamais modifier le nom, le

numéro ou autres marques figurant sur la bouteille. Cela

est illégal et dangereux.

l Ne jamais soulever les bouteilles du sol en les prenant

par la valve ou par le bouchon ou en utilisant des chaînes,

des élingues ou des aimants.

l Ne jamais essayer de mélanger des gaz à l’intérieur de

la bouteille.

l Ne jamais recharger les bouteilles.

l Ne jamais modifier ou changer les raccords des bouteilles.

B) REGULATEURS DE PRESSION.

Page 13

13

l Maintenir les régulateurs de pression en parfait état.Des

régulateurs endommagés peuvent provoquer des

inconvénients ou causer des accidents. Ils doivent être

réparés uniquement par un personnel qualifié.

l Ne pas utiliser des régulateurs pour des gaz différents

de ceux pour lesquels ils ont été fabriqués.

l Ne jamais utiliser un régulateur qui perd ou qui apparaît

physiquement endommagé.

l Ne jamais lubrifier un régulateur avec de l’huile ou de la

graisse.

C) TUBES.

l Remplacer les tubes qui semblent détériorés.

l Tendre les tubes pour éviter les plis.

l Enrouler le tube excédent et le garder hors de la zone

de travail pour éviter des endommagements éventuels.

7.5 Radiations.

Les radiations ultraviolettes émises par l’arc peuvent blesser les yeux et brûler la peau.

l Revêtir des vêtements et des masques de pro-

tection appropriés.

l Ne jamais utiliser des lentilles!! En raison de la chaleur

intense qui émane de l’arc elles pourraient se coller à la

cornée.

l Utiliser des masques avec des verres dont le degré de

protection minimal est de DIN 10 ou DIN 11.

l Faire protéger les personnes qui se trouvent dans la

zone de soudage.

Rappel: L’arc peut éblouir ou blesser les yeux. Il doit être

considéré dangereux jusqu’à une distance de 15 mètres.

Ne regarder jamais l’arc à l’oeil nu.

l Préparer la zone de soudage de manière à réduire la

réflexion et la transmission des radiations ultraviolettes:

peindre en noir les parois et les surfaces exposées pour

réduire la réflexion, installer des écrans protectifs ou des

rideaux pour atténuer les transmissions ultraviolettes.

l Remplacer les verres du masque lorsqu’ils sont endom-

magés ou cassés.

7.6 Choc électrique.

Le choc électrique peut provoquer la mort.

Tous les chocs électriques sont potentiellement

mortels.

l Ne jamais toucher les organes sous tension.

l S’isoler de la pièce que l’on doit couper et du sol en met-

tant des gants et des vêtements isolants.

l Faire en sorte que les vêtements (gants, chaussures,

bonnet, habits) et le corps soient secs.

l Ne pas travailler dans des milieux humides ou mouillés.

l Eviter de s’appuyer sur la pièce à souder.

l Prendre toutes les précautions nécessaires si l’on doit

travailler à proximité d’une zone à risque ou dans cette

même zone.

l Interrompre immédiatement les opérations de soudage

si l’on ressent la moindre sensation de décharge électrique.

l Ne pas utiliser l’appareil jusqu’à ce que l’inconvénient

n’ait pas été localisé et supprimé.

l Prévoir un interrupteur automatique mural, d’une portée

appropriée, si possible à proximité de l’appareil pour pouvoir l’éteindre immédiatement en cas d’urgence.

l Examiner fréquemment le cordon d’alimentation.

l Débrancher le cordon d’alimentation avant d’intervenir

sur les câbles ou avant d’ouvrir la machine.

l Ne jamais utiliser la machine sans les couvercles de

protection.

l Remplacer toujours avec des pièces de rechange origi-

nales les éléments endommagés de la machine.

l Ne jamais exclure les sécurités de la machine.

l S’assurer que la ligne d’alimentation soit munie d’une

prise de terre fiable.

l S’assurer que le banc de travail et la pièce à souder

soient reliés à une prise de terre fiable.

l L’entretien éventuel doit être effectué uniquement par un

personnel expert, conscient des risques qui dérivent des

tensions nécessaires au fonctionnement de l’appareillage.

7.7 Pacemaker.

l Les champs magnétiques dus à des courants élevés

peuvent agir sur le fonctionnement du pacemaker. Les

personnes auxquelles un appareillage électronique vital a

été appliqué doivent consulter un médecin avant de s’approcher des opérations de soudage à l’arc, de découpe ou

de soudage par points.

7.8 Attention! Le fil de soudage peut causer des blessures profondes.

l Ne jamais appuyer sur le bouton de la torche avant d’a-

voir lu attentivement le mode d’emploi.

l Ne jamais orienter la torche en direction de par ties du

corps, d’autres personnes ou de métaux quand on monte

le fil de soudage.

7.9 Les parties en mouvement peuvent provoquer

des accidents.

Les parties mobiles, comme le ventilateur, peuv ent couper

les doigts et les mains et happer les vêtements.

l Bien fermer toutes les portes, les revêtements et les pro-

tections.

l Pour l’entretien ou des contrôles, les protections et les

revêtements peuvent être enlevées mais exclusivement

par le personnel qualifié.

l Ne jamais approcher les mains, les cheveux, des vête-

ments larges ou des outils aux parties en mouvement.

l Remonter les revêtements et les protections et fermer

les portes, une fois l’intervention terminée et avant de

mettre la machine en marche.

7.10 Bruit.

Le niveau sonore de ces soudeuses ne dépasse

pas 80dB. Le procédé de soudage peut produire

des bruits dépassant cette limite. Les utilisateurs

devront donc prendre les précautions prévues par la loi.

Page 14

14

D) Led de color amarillo.

Se enciende sólo cuando el termostato

interrumpe el funcionamiento de la soldadora.

E) Led de color verde.

Señala el encendido de la máquina.

F) Antorcha de soldadura

G) Manecilla

No deberá ser utilizada para el levantamiento de

la máquina.

3 DESCRIPCIONES GENERALES

3.1 ESPECIFICACIONES

Esta soldadora permite la soldadura de acero suave, acero

inoxidable y aluminio.

3.2 EXPLICACION DE LOS DATOS TECNICOS

N° Número de matrícula que siempre hay que citar

para cualquier petición relacionada con la soldadora.

IMPORTANTE:

ANTES DE LA INSTALACION, DEL USO O DE CUALQUIER MANTENIMIENTO A LA SOLDADORA, LEER EL

CONTENIDO DE ESTE MANUAL PONIENDO PARTICULAR ATENCION A LAS NORMAS DE SEGURIDAD, CONT A CTEN AL DISTRIBUIDOR SI NO HAN ENTENDIDO POR

COMPLETO ESTAS INSTRUCCIONES.

1 PRELIMINARES

Este aparato debe ser utilizado exclusivamente para operaciones de soldadura. No debe ser usado para descongelar

tubos.Es además indispensable, tener en la máxima consideración el capítulo que concierne a las PRECAUCIONES

DE SEGURIDAD.Los símbolos colocados en la proximidad

de los párrafos a los cuales se refieren, evidencian situaciones de máxima atención, consejos prácticos o simples informaciones.El presente manual debe ser conservado con cuidado, en un sitio conocido por los interesados. Deberá ser

consultado cada vez que surjan dudas, deberá seguir toda la

vida operativa de la máquina y será empleado para el pedido de las partes de repuesto.

1.1 COLOCACION

Sacar la máquina del embalaje y colocarla en un local adecuadamente ventilado, posiblemente sin polvo, teniendo cuidado de no obstruir la entrada y la salida del aire de los orificios de enfriamiento.

ATENCION: UN REDUCIDO FLUJO DE AIRE provocaría

recalentamiento y posibles daños en las partes internas

Mantener por lo menos 500 mm.de espacio libre, alrededor

del aparato

No colocar ningún dispositivo de filtrado en los pasos de

entrada de aire de esta soldadora.

La garantía será anulada en el caso de que se utilizace cualquier tipo de dispositivo de filtrado.

Montar las piezas suministradas con la maquina según la

figura 1.

2 DESCRIPCION DEL APARATO

A) Interruptor

Enciende y apaga la máquina y regula también

las gamas de la tensión de soldadura.

B) Perilla de regulación.

Con esta perilla se regula la velocidad del hilo de

soldadura.

C) Cable de tierra

MANUAL DE INSTRUCCIONES PARA SOLDADORAS DE HILO

Fig. 1

Fig. 2

Page 15

15

IEC 60974-1 La soldadora se ha construido según estas

EN 50199 normas internacionales

Transformador - Rectificador Monofàsico

MIG/MAG. Adapto para soldadura de hilo continuo.

I2 max. Ccorriente de soldadura no convencional.

El valor representa el límite máximo que se

puede obtener en soldadura.

Uo Tensión en vacío secundaria

X El factor de servicio expresa el porcentaje de 10

minutos durante los cuales la soldadora puede

trabajar a una determinada corriente sin produ-

cir recalentamiento:

ejemplo x = 60% a I2 = 100 A.

Esto quiere decir que la soldadora puede soldar

con una corriente I2 = 250A por 6 de 10 minutos

es decir el 60%.

I2 Corriente para soldar.

U2 Tensión secundaria con corriente para soldar I.

U1 T ensión nominal de alimentación con la frecuen-

cia descrita.

I1 max. Es el máximo valor de la corriente absorbida.

I1 efec. Es el máximo valor de la corriente efectiva

absorbida considerando el factor de servicio.

IP 21 Grado de protección del armazón externo.

Grado 1 como segunda cifra significa que esta

máquina no se puede usar bajo la lluvia.

S Idónea para trabajar en ambientes altamente

peligrosos.

3.3 DESCRIPCION DE LA PROTECCION

Este aparato está protegido por un termostato normalmente

cerrado colocado en el transformador de potencia.

Cuando el termostato interviene, la máquina cesa de soldar,

mientras tanto el motoventilador continua a funcionar y el led

amarillo se enciende.

Después de la intervención, esperar algunos minutos para

que pueda enfriarse el generador.

4 PUESTA EN FUNCIONAMIENTO

La instalación de la máquina debe ser efectuada por personal experto.Todas las conexiones deberán ser conformes a

la normas vigentes y realizadas en el pleno respeto de la ley

antiaccidentes.

Controlar que el diametro del hilo corresponde al diametro

mencionado sobre el rodillo y montar la bobina del hilo.

Asegurarse que el hilo de soldadura pase dentro de la garganta del rodillo 7.

Antes de conectar el cable de alimentacion 23 asegurarse

que la tensión de red corresponde a la de soldadura, por

consiguiente: a) En el caso de una conexión permanente a

la red de alimentación sin enchufe, habría

que predisponer un interruptor general de

capacidad adecuada que corresponda a

las características nominales.

b) En el caso de una conexión con enchufe,

utilizar uno de capacidad adecuada que

corresponda a las características

nominales.

En este caso el enchufe debe ser usado

para desconectar completamente la

máquina de la red, después de haber

colocado en “O” el interruptor 47.

El conductor amarillo/verde, debe estar conectado a un terminal de tierra. Conectar el borne del cable de tierra 37 a la

pieza por soldar.

El circuito de soldadura no debe ser situado deliberadamen-

te en contacto directo o indirecto con el conductor de protección si no en la pieza por soldar.

Si la pieza en elaboración se conectase deliberadamente a

tierra mediante el conductor de protección, la conexión

deberá ser lo más directa posible y efectuada con un conductor de sección por lo menos igual a la del conductor

de retroceso de la corriente de soldadura y conectado a la

pieza en elaboración en el mismo punto del conductor de

retroceso utilizando el borne del conductor de tierra situado

inmediatamente cercano.

Deben ser tomadas todas las precauciones posibles para

evitar corrientes vagabundas de soldadura.

Encender la máquina mediante el interruptor 47.

Extraer la tobera de gas cónica 44 girándola en el sentido de

las agujas del reloj.

Destornillar la tobera portacorr iente 43.

No presionar el pulsador de la antorcha antes de haber

leído las instrucciones de uso atentamente.

Es importante asegurarse de que la máquina esté apagada

cada vez que se sustituye la bobina del hilo y el rodillo tira hilo

para evitar que el motorreductor se ponga en marcha accidentalmente.

Presionar el pulsador de la antorcha 39 y soltarlo sólo cuando sale el hilo.

El hilo de soldadura puede causar heridas perforadas.

No dirigir la antorcha hacia partes del cuerpo, otras personas

o metales cuando se monta el hilo de soldadura.

Volver a atornillar la tobera por tacorriente 43 asegurándose

de que el diámetro del orificio sea igual al hilo utilizado.

Insertar la tobera gas cónica de soldadura 44 girándola siempre en el sentido de las agujas del reloj.

4.1 CONEXION DEL TUBO DE GAS

l La bombona de gas debe ser dotada de un reductor de

presión y de un flujómetro.

l Si la bombona estuviese colocada en la plataforma porta

bombona de la máquina, deberá estar sujeta con la cadena

correspondiente y ser de dimensiones tales que no comprometan la estabilidad de la máquina.

l Sólo después de haber colocado la bombona, conectar el

tubo de gas que sale de la parte posterior de la máquina al

reductor de presión.

l Abrir la bombona del gas y regular el flujómetro a aproxi-

madamente 8/10 l./min.

ATENCION: Controlar que el gas usado sea compatible con

el material por soldar.

4.2 NOTAS GENERALES

Antes del uso de esta soldadora leer atentamente las normas CEI 26/9 o también CENELEC HD 407 y CEI 26/11 o

también CENELEC HD 433. Además verificar la integridad

del aislamiento de los cables, sea de la antorcha como del

cable de tierra.

5 SOLDADURA

5.1 SOLDADURA DEL ACERO SUAVE

5.1.1 Con protección de gas

Para las soldaduras de acero suave, se puede utilizar

ARGON 75% + CO2 25% o incluso CO2 100%.

Conectar los cables como se indica en la figura 3.

Elegir la corriente de soldadura mediante la empuñadura del

conmutador giratorio 47.

Page 16

16

- Para soldar ANTICORODAL hilo 3 + 5% silicio.

- Para soldadura PERALUMAN hilo 5% magnesio.

- Para soldadura ERGAL hilo 5% magnesio.

Utilizar muelas y cepillos metálicos especificas para el aluminio sin usarlos jamás con otros materiales.

RECUERDEN que la limpieza es calidad

Las bobinas de hilo deben ser conservadas dentro de bolsas

de nilón con un deshumidificador.

Para la adecuada inclinación de soldadura ver la figura 5.

5.3 SOLDADURA DEL ACERO INOXIDABLE

La soldadora debe ser predispuesta como para la soldadura

del acero suave con protección de gas aplicando las siguientes variantes:

- Bobina de hilo de acero inoxidable compatible con la composición del acero por soldar.

- Bombona que contiene ARGON 98% + O2 2% (composición aconsejada).

La inclinación de la antorcha y la dirección de soldadura

aconsejadas se muestran en la figura 5.

6. MANTENIMIENTO Y CONTROLES

El mantenimiento debe ser efectuada por personal cualificado.

6.1 NOTAS GENERALES

l Apagar la soldadora y desenchufar de la corriente antes de

cada operación de control y mantenimiento.

l La partes en movimiento pueden causar graves lesiones.

l Mantenerse lejos de las partes en movimiento.

l LAS SUPERFICIES INCANDESCENTES pueden causar

graves quemaduras.

l Dejar enfriar antes de proceder al mantenimiento.

l Eliminar periódicamente el polvo o los materiales extraños

que eventualmente se hubieran depositado en el transformador o en los diodos;para esto , usar un chorro de aire seco

y limpio.

l Al volver a montar el rodillo tirahilo, tengan cuidado de que

el canal esté alineada con el hilo y que corresponda al diámetro del hilo usado.

l Mantener constantemente limpio el interior de la tobera

del gas para evitar la for mación de puentes metálicos constituidos por salpicaduras de soldadura entre la tobera de gas

y la tobera portacorriente. Asegurarse de que el orificio de

salida de la tobera portacorriente no se haya ensanchado

excesivamente, en caso contrario sustituirlo.

l Evitar absolutamente golpear la antorcha o que sufra gol-

pes violentos.

Acercarse al punto de soldadura y presionar el pulsador de

la antorcha 39.

Mover la empuñadura del potenciómetro 2 hasta obtener una

soldadura con un ruido constante y continuo.

Con la velocidad demasiado elevada, el hilo tiende a tropezar con la pieza haciendo rebotar la antorcha; con una velocidad demasiado baja el hilo se funde a gotas intermitentes

o el arco no permanece encendido.

Acabada la soldadura, apagar la máquina y cerrar la bombona del gas.

Para la inclinación adecuada de soldadura ver la figura 5.

5.1.2 Sin protección de gas

Conectar los cables como se indica en la figura 4.

Si se utilizase sólo hilo animado 0,9, responderán a la norma

AWS AS.20 E71 TII o E71 TGS, adapto al utilizo sin protección gaseosa.

Conectar la pinza del cable de tierra a la pieza por soldar.

Después de haber conectado los cables seguir las mismas

instrucciones ilustradas en el párrafo 5.1.1.

NOTA: para obtener soldaduras empalmadas y bien protegidas siempre de derecha a izquierda y de arriba hacia abajo.

Para la inclinación adecuada de soldadura ver la figura 5.

5.2 SOLDADURA DEL ALUMINIO

La soldadora debe ser predispuesta como para la soldadura

del acero suave con protección de gas, aplicando las

siguientes variantes:

- ARGON 100% como gas de protección para la soldadura.

- Un cordón de soldadura de composición adecuada al material base por soldar.

- Para soldar ALLUMAN hilo 3 + 5% silicio.

Fig. 5

Fig. 3

Fig. 4

Page 17

17

7 PRECAUCIONES GENERALES

7.1 Fuego

l Hay que evitar que se produzcan fuegos o

chispas o residuos calientes o trozos incandescentes.

l Asegurarse que apropiados dispositivos

anti-incendios se encuentren a disposición cerca de la zona

de soldadura.

l Eliminar de la zona de soldadura todo material inflamable

y combustible (mínimo 10 mtr.de distancia).

l No realizar soldaduras en envases de conbustibles y lubri-

cantes, aunque éstos se encuentren vacios.Dichos envases

deben estar perfectamente limpios antes de soldarlos.

l Dejar enfriar el material soldado antes de tocarlo o de poner-

lo a contacto con otro material combustible o inflamable.

l No realizar soldaduras en detalles con intersticios que con-

tengan material inflamable.

l No trabajar en ambientes con alta concentración de vapo-

res combustibles, gas o polvos inflamables.

l Controlar siempre la zona de trabajo, media hora después,

para asegurarse que no existan principios de incendios.

l No conser var en las carteras material combustible como

por ejemplo, encendedores o fósforos.

7.2 Quemaduras

l Proteger la piel de las quemaduras causadas por las radiacio-

nes ultravioletas emitidas por el arco , de las chispas y de los residuos de metal fundido utilizando prendas de vestir ignífugas que

cubren toda la superficie del cuerpo expuesto al peligro.

l Ponerse ropa/guantes de protección para soldador , gorro y

zapatos subidos con punta de seguridad.Abrocharse el cuello de la camisa y los cierres de los bolsillos y usar pantalones sin bastilla para evitar la entrada de chispas y residuos.

l Ponerse el casco con vidrio de protección hacia el exterior

y lentes con filtro al interior. Esto es PRIMORDIAL en las

operaciones de soldadura con el objetivo de defender los

ojos de la energía radiante y de los metales que circulan.Si

el vidrio de protección está roto,tiene protuberancias o man-

6.2 REPARACIONES DE LAS SOLDADORAS

La experiencia ha demostrado que muchos accidentes mortales tienen origen en reparaciones no efectuadas según

normas.P or este motiv o, un atento y completo control en una

soldadora reparada es tan importante como el efectuado en

una soldadora nueva.

Además de esta forma los productores podrán ser protegidos contra el ser considerados responsables de defectos,

cuando la culpa sea de otros.

6.2.1 Prescripciones por seguir para las reparaciones

l A continuación del rebobinado del transformador o de las

inductancias, la soldadora deberá superar las pruebas de

tensión aplicada según cuanto indicado en la tabla 2 de 6.1.3

de la norma EN 60974.1 (CEI 26.13).La conformidad deberá

ser verificada como se especifica en 6.1.3.

l Si no se hubiese efectuado ningún rebobinado, una solda-

dora que haya sido limpiada y/o revisada, deberá superar

una prueba de tensión aplicada con valores de las tensiones

de prueba equivalentes al 50% de los valores dados en la

tabla 2 de 6.1.3.La conformidad deberá ser verificada como

se especifica en 6.1.3.

l A continuación del rebobinado y/o la sustitución de partes,

la tensión en vacío no deberá superar los valores mostr ados

en 10.1 de EN 60974.1.

l Si las reparaciones no fuesen realizadas por el productor,

las soldadoras reparadas en las que se hayan sustituido o

modificado algunos componentes, deberán ser marcadas de

forma que pueda ser identificado quien ha llevado a cabo la

reparación.

l Después de haber efectuado una reparación, tengan cui-

dado al volver a ordenar los cables, de forma que exista un

aislamiento seguro entre el lado primario y el secundario

de la máquina. Evitar que los hilos puedan entrar en contacto con partes en movimiento o partes que se recalientan

durante el funcionamiento.Volver a montar las abrazaderas

como en la máquina original para evitar que si accidentalmente se rompiese o desconectase un conductor, se produzca una conexión entre el primario y el secundario.

6.3 ANOMALIAS DE USO

INCONVENIENTE

El alambre no avanza o avanza irregularmente

El alambre se bloca

o se enrolla entre

los rollos y la conducción de alambre

de entrada a la

antorcha

Cordón para soldar

poroso

CAUSA PROBABLE

Rollo para el alambre con

ranura demasiado larga

Vaina obturada o tapada

Rollo aprete-alambre mal

apretado

Fricción del aspó porta

bobina demasiado apretada

Boquilla porta corriente

opturada

Boquilla porta corriente con

diametro equivocado

Equivocada alineacion de la

ranura del rollo

Si el carrete va fuera de

posición

Vaina obturada o tapada

Insuficiencia del gas de

protección

Bordes excesivamente oxidados para soldarlos

Boquilla gas totalmente o

parcialmente tapada con

restos de soldadura

AJUSTE

Cambiar el rollo

Desenrollarla y proceder a

limpiarla

Apretarlo a fondo

Soltar la fricción a través de

la regulación

Cambiarla

Cambiarla

Alinearlo

Hay que acercarlo lo más

posible al rodillo de arrastre

del cable

Desenrollarla y limpiarla

Aumentar la capacidad del

gas

Limpiar perfectamente los

bordes con un cepillo de

metal

Desmontarlo y proceder a

limpiarlo o cambiarlo poniendo atención a no tapar los

foros de salida del gas

INCONVENIENTE

La distribución de la

corriente aparece

limitada

Soldadura con

muchas protecciones de metal

CAUSA PROBABLE

Fusible de línea quemado

Diodo o diodos quemados

Esqueda electrónica quemada

Conexiones de la antorcha

o de la masa o de cualquier

otra conexión eléctrica de

potencia disminuida

Si el conmutador de regulación de la tensión presenta

un contacto inseguro

Regulación equivocada de

los parámetros para soldar

Coneción insuficiente de la

masa

AJUSTE

Cambiar fusible

Cambiarlos

Cambiarla

Apretar todas las conexiones

Cambiar el conmutador

Buscar los parámetros

justos controlando el potenciómetro de la tensión para

soldar y el potenciómetro

que regula la velocidad del

alambre.

Controlar la eficiencia de las

conexiones

Page 18

18

chas, hay que cambiarlo.

l Evitar el uso de ropa pegajosa y grasienta.Una chispa

podría incendiarla.

l Las partes metálicas incandescentes como por ejemplo

pedazos de electrodos y pedazos sobre los cuales se trabaja, hay que cogerlos siempre con guantes.

l Un servicio de primeros auxilios y una persona cualificada

tendría que estar presente en cada uno de los turnos a no

ser que se encuentren estructuras sanitarias en los alrededores que se puedan utilizar en caso de un tratamiento

urgente debido a llamaradas que quemen los ojos y la piel.

l Cuando la pieza con la cual hay que trabajar se encuentra

sobre la cabeza se deben usar tampones en las orejas.Se

debe usar un gorro resistente cuando otros trabajan en una

zona cercana.

l Las personas que tienen que soldar o cortar no deben usar

productos inflamables para los cabellos.

7.3 Humos

Las operaciones de soldadura producen humos y

polvos metálicos nocivos que pueden hacer daño a

la salud, por lo tanto:

l Hay que trabajar en espacios que tengan una adecuada

ventilación.

l Tener la cabeza fuera de los humos.

l En los ambientes cerrados hay que utilizar adecuados

aspiradores.

l Si la ventilación no es apropiada se deben usar respirado-

res autorizados.

l Limpiar el material que hay que soldar en el caso se

encuentren presentes disolventes o material halógeno para

desengrasar ya que éstos producen gases tóxicos.Durante

el proceso de soldadura, algunos disolventes al cloro, se

pueden descomponer debido a la presencia de las radiaciones que produce el arco y generar gases fosgenos.

l No soldar metales revestidos o que contengan plomo,gra-

fito,cadmio ,zinc, cromo , mercurio o berilio si no se dispone de

un adecuado respirador.

l El arco eléctrico genera ozono.Una prolongada permanen-

cia en ambientes a alta concentración de ozono puede causar dolores de cabeza, irritación a la nariz, a la garganta, a

los ojos y grave congestión y dolor al pecho.

IMPORTANTE:NO USAR O XIGENO PARA LA VENTILACION.

l Hay que evitar las pérdidas de gas en espacios reducidos;

una pérdida de gas grande puede modificar peligrosamente

la concentración de oxígeno.No hay que colocar las bombonas en espacios reducidos.

NO SOLDAR o cortar en lugares donde los vapores de los

diluentes puedan ser atraidos a la atmósfera de soldadura o

de corte o en caso que la energia radiante pueda penetrar en

el interior de atmósferas que contengan pequeñas cantidades de tricloroetileno o percloroetileno.

7.4 Explosiones

l No realizar soldaduras sobre o cerca de recipien-

tes a presión.

l No soldar en ambientes que contengan polvo, gas

o vapores explosivos.

l Esta soldadora utiliza gas inerte como CO2, ARGON o

mezcla de Argón + CO2 para la protección del arco, por lo

tanto es necesario poner la máxima atención a:

A) bombonas

l No conectar directamente la bombona al tubo a gas de la

máquina sin haber utilizado un regulador de presión.

l Manejar y utilizar bombonas a presión autorizadas por la

normativa vigente.

l No utilizar bombonas que pierdan o que físicamente estén

dañadas.

l No utilizar bombonas que no estén bien fijas.

l No trasladar bombonas sin la protección de la válvula montada.

l NO hay que usar bombonas cuyo contenido no ha sido

identificado claramente.

l No hay que lubrificar nunca las válvulas de las bombonas

con aceite o grasa.

l No poner en contacto eléctrico la bombona con el arco.

l No exponer la bombona a excesiv o calor , chispas, residuos

fundidos o llamas.

l No hurgar dentro de las válvulas de las bombonas.

l No tratar de abrir con martillos, llaves u otros sistemas las

válvulas bloqueadas.

l NO borrar ni alterar nunca el nombre, el número u otras

señales de la bombona. Es ilegal y peligroso.

l No levantar las bombonas tomándolas por la válvula o por

la tapa, o usando cadenas, amarras o calamita.

l No tratar de mezclar nunca ningún gas al interior de la

bombona.

l No cargar jamás las bombonas.

l Las conexiones de las bombonas no se deben cambiar ni

modificar nunca.

B) REGULADORES DE PRESIóN

l Mantener en buenas condiciones los reguladores de presión.

l Los reguladores estropeados pueden causar daños o acci-

dentes; Dichos reguladores tienen que ser reparados solo

por personal especializado.

l No utilizar reguladores para gas diverso de aquel para lo

cual fueron fabricados.

l No usar nunca un regulador que pierde o que se ve que fisi-

camente está dañado.

l No lubricar nunca un regulador con aceite o grasa.

C) TUBOS

l Cambiar los tubos que se ve que están dañados.

l Mantener los tubos extendidos para evitar pliegues.

l Mantener enrollado fuera de la zona de trabajo el tubo en

exceso, de manera de prevenir eventuales daños.

7.5 Radiaciones

Las radiaciones ultravioletas producidas por el arco