Page 1

FEATURES

♦ Limits torque applied with reduced-friction release mechanism.

♦ Can be used with confidence in all automotive, aircraft, marine

and industrial applications.

♦ Lock ring prevents accidental change of torque setting.

♦ Pliable handgrip of soft Thermoplastic rubber protects painted

surfaces and simplifies use with greasy hands. Resistant to

mechanical damage and impervious to automotive fluids such

as gasoline, oil, kerosene, etc.

♦ Ratchet action requires only 10 degrees handle travel.

♦ Extra str

♦ May be used continually at maximum torque capacity.

♦ Wrench cannot be damaged by normal handling or dropping

♦ Mechanism protected from routine contamination.

♦ Finished with tough, durable chromium-nickel plating.

♦ All parts corrosion proofed.

♦ Wrench made of highest quality CR-MOLY steel.

ength ratchet design for long life.

from workbench.

SUGGESTIONS

Proper use of this professional torque wrench will give you

complete satisfaction in its performance and reliability. Following

are some helpful tips:

1. Greater torque accuracy is assured by gripping it properly.

Grasp the GRIP, not the SHAFT, and pull smoothly.

2. Each torque wrench is lubricated before leaving the factory. If it

has not been used for some time, it should be operated several

times to re-distribute the lubricant within the working

mechanism.

3. Never attempt to turn the GRIP when the LOCK RING is in the

"LOCK" position.

4. Never set for higher or lower torque values than those indicated

on your wrench.

5. For greater accuracy, clean all thread surf

burrs on the fasteners being used.

6. WARNING- Never use your torque wrench to apply more

torque than its rated capacity.

7. It is not necessary to return this wrench to its lowest calibrated

value after use unless it is to be stored for an extended period

of time.

DO NOT OVERTORQUE

aces and remove any

This torque wrench is certified to be calibrated prior to

shipment to accuracy of +/-4% in the right hand direction on

readings 20% to 100% of capacity. On readings below 20% of

capacity, the accuracy is +/- two scale increments

LIMITED WARRANTY

If within 90 days from the date of purchase, this wrench fails

due to defects in materials or workmanship, we will repair

and recalibrate it free of charge. After 90 days and until one

year from the date of purchase we will repair any defect in

material or workmanship in the torque wrench free of charge.

This warranty does not include recalibration.

PROOF OF PURCHASE MUST BE INCLUDED WITH EACH

REQUEST FOR WARRANTY SERVICE.

For warranty service send the wrench to:

.

In the U.S.A.

Angle Repair & Calibration

175 Angle Drive

Beckley, WV 25801

www.anglerepair.com

CERTIFICATION

REPAIR AND CALIBRATION SERVICE

All torque wrenches should have periodic accuracy checks

and recalibration as required. This should be done at least

once a year or every 5000 torque application cycles,

whichever comes first.

Recalibration is also recommended after any abnormal

handling. For service send the wrench to one of the

Warranty Centers listed above of contact our Customer

Service department at (800)866-5287 for a list of additional

Approved Repair Centers.

REVISED/PRINTED IN USA APR 2014 FORM 6000M-90

972-864-6762

In Canada

ATG Torque Repair

7631 Bath Road

Mississauga, ON L4T3T1

1-866-691-6212

ATD-112

INDUSTRIAL DUTY

MICRO-ADJUSTING

TORQUE WRENCH

OPERATING INSTRUCTIONS

1. STUDY THIS BOOKLET CAREFULLY

BEFORE ATTEMPTING TO OPERATE THIS

WRENCH.

2. NEVER APPLY MORE TORQUE THAN THE

MAXIMUM SCALE SETTING.

3. This Torque Wrench is designed for manual

tightening of threaded fasteners only. DO

NOT USE IT AS A NUT-BREAKER OR FOR

ANY OTHER PURPOSE.

4. Over torqued or defective fasteners and

sockets may suddenly break. Ratchets on

plain drives that are improperly engages,

worn out, damaged or over torqued, may

slip or break. TO PREVENT INJURY, KEEP

PROPER FOOTING AND BALANCE AT ALL

TIMES.

PLACES FROM WHICH YOU MAY FALL OR

SLIP OR AROUND ROTATING MACHINERY.

5. This wrench will not prevent you from

applying more torque than set, it is not a

torque limiting tool. Learn how different

amounts of torque “feel”, so you will reduce

the possibility of damage and/or injury due

to accidental over torquing.

6. APPLY FORCE TO THE GRIP ONLY. DO

NOT USE “CHEATER BARS” (A Piece of

pipe placed over the hand grip for more

leverage).

7. There are no user-serviceable components

inside the wrench. Disassembling the

wrench or making any adjustments will

result in the lo

the warranty.

DO NOT USE THE WRENCH IN

ss of accuracy, and will void

Page 2

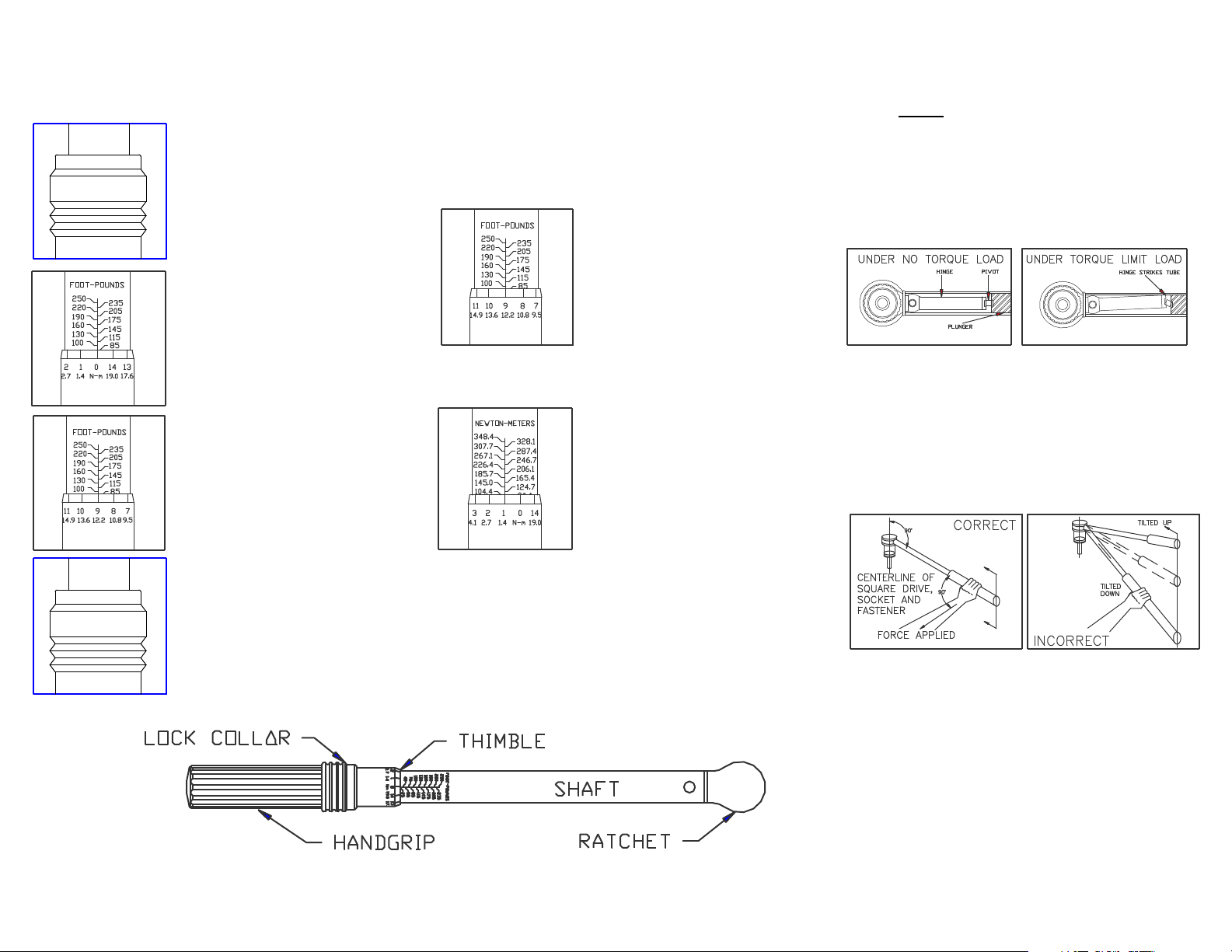

ADJUSTING YOUR MICROMETER TORQUE

WRENCH

CAUTION-Do not turn the GRIP with the LOCK RING in the lock

position. Damage to the adjusting mechanism may occur.

2. Rotate GRIP until the "0" on the

3. Continue rotating the GRIP if the

PULL TO U

PULL TO U

1. To UNLOCK, hold Handle GRIP

with one hand and pull down

LOCKING COLLAR in direction

of arrow.

THIMBLE SCALE reaches the

primary number of the desired

torque value on the SHAFT MAIN

SCALE.

desired torque value is between

the primary numbers on the MAIN

SCALE. Add the secondary

number on the THIMBLE SCALE

to the primary number on the

MAIN SCALE to achieve the

desired torque value.

4. To lock wrench, release

LOCK RING.

EXAMPLES OF TORQUE SETTINGS

NOTE: Many models have both American Standard and Metric

scales on the same wrench.

The MAIN SCALE American Standard graduations are on the

front of the SHAFT and the THIMBLE SCALE graduations are

closest to the beveled edge. The MAIN SCALE Metric

graduations are on the reverse side of the SHAFT and the

THIMBLE SCALE Metric graduations are below the American

Standard graduations.

EXAMPLE - STANDARD

For a torque setting of 94 foot pounds,

rotate GRIP until the "0" on the

THIMBLE SCALE is aligned with the

"90" on the "FT.LB." MAIN SCALE.

Continue rotating GRIP clockwise until

the "4" on the THIMBLE SCALE is

aligned with the center line on the

"FT.LB." MAIN SCALE. The wrench is

now set at 94 foot pounds. Put the

LOCK RING in the lock position before

using.

EXAMPLE - METRIC

For a torque setting of 105.8 Newton

meters rotate the GRIP until the "0" on

the THIMBLE SCALE is aligned with the

104.4 on the "N.m" MAIN SCALE.

Continue rotating the GRIP clockwise

until the 1.4 on the Metric THIMBLE

SCALE is aligned with the center line of

the "N.m" MAIN SCALE.

The wrench is now set at 105.8 N.m

(104.4 +1.4=105.8). Put the LOCK

RING in the lock position be fore using.

HOW TO APPLY TORQUE

1. This Micrometer Adjustable Torque Wrench is designed so that

when force is properly applied to the handgrip, an audible signal

and/or impulse feel will indicate that the desired torque has been

attained. DO NOT-pull beyond this point.

CAUTION: The audible signal and/or impulse feel is an indicator

that the proper torque has been attained. Over torquing beyond

these signals could cause fastener failure.

Additionally, when wrench is set at low end of the torque range, the

degree of signal and impulse will be less than when set at the high

end of the range. Therefore, care must be taken at low end of scale

to hear signal or feel impulse.

2. To properly apply torque, attach socket securely on torque

wrench square drive and position socke t on th e fastener so that

tilting will not occur. Grasp the center of hand grip and apply a

force perpendicular (90 degrees ) to the torque wrench body and

perpendicular (90 degrees) to the center line of the square drive,

socket, and fastener.

NOTE: The common center line of the square drive, socket and

fastener must be maintained while applying a steadily increasing

force as shown in Figure in order to insure accurate torque readings

via an audible signal or impulse feel.

WARNING: Do not tilt torque wrench handle during torquing

operation. Tilting of torque wrench handle can result in inaccurate

torque and/or over-torq uing damage.

2. Turn the fastener down with a smooth and even force applied

to the handle of the torque wrench (as described in fig.). As

turning resistance increases pull more slowly. To assure

accuracy, the fastener must be in motion when the torque

measurement is made.

WARNING: USE OF NON-AXIAL EXTENSIONS THAT CHANGE

THE EFFECTIVE LENGTH OF THE TORQUE WRENCH SUCH

AS CROWFOOT ATTACHMENTS OR UNIVERSAL JOINTS WIL L

CHANGE THE TORQUE BEING APPLIED. DO NOT USE UNTIL

YOU KNOW THE CONSEQUENCES.

Loading...

Loading...