Page 1

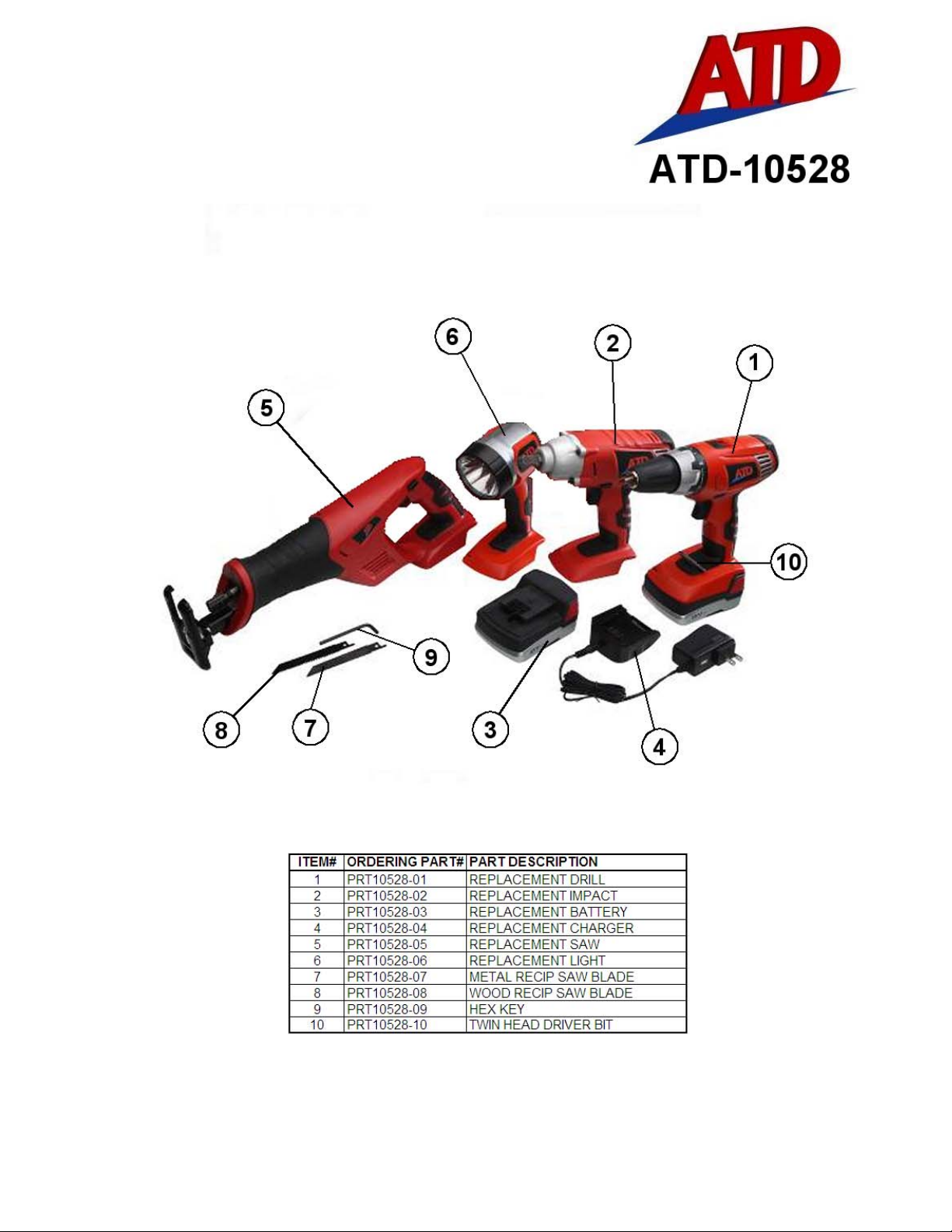

ATD-10528

4PC 18V LITHIUM ION CORDLESS COMBO KIT

Instruction Manual

1

Page 2

Cordless Drill

PRT10528-01

Please read this MANUAL carefully before using the tool.

PRODUCT SPECIFICATIONS

Rated Voltage 18V DC

No-load Speed 0~350 / 0~1200Rpm

Chuck ½’’ Jacob Single Sleeve Chuck

Max Torque 22N.M (16.2 lb.ft)

Torque Setting 19+1

Charge Time 3~5 hours

2

Page 3

Product Features

1

2

3

4

Operation

Only use tool bits which can be securely fastened in the chuck and for which the drill has been design ed.

1. Drilling

Check whether the drill bit is correctly inserted and tightly fastened before you start the machine. Use prop erl y

sharpened drill bits. Use screwdriver bit s that are not overly wo rn. At the start of ea ch drilling operation select a

lower speed. For large holes drill with a smaller drill bit first and then enlarge the hole using a large r drill bit.

2. Drilling in Wood

For drilling in wood use a wood drill-bit. Protect or fasten the work-piece in a suitable holder . Mark the po sitions

of the holes to be drilled with a sharp tool or a nail. Do not apply ex cessive pressure against the work-piece with

the drill.

3. Drilling in Metal

For drilling in metal use a steel drill-bit. Always provide sufficient cooling with suitable non-flammable coolants.

Protect or fasten the work-piece with a suitable holder. The work-piece should lie flat on the work bench. Mark

the positions of the holes to be drilled with a center-punch. Do not apply excessive pressure against the

work-piece with the drill. Allow the drill to operate at its normal operating speed.

Important! When beginning to drill, select a lower speed to avoid the bit slipping away from the desired hole

location. If the hole is deep, the drill bit may become jammed in the hole. In this event a high torque could

damage the drill bit or the drill. If the bit becomes jammed, hold the drill firmly and immediately release the

On/Off trigger . Switch to counter-clockwise rot ation, and use a low rotation speed to remove the jammed d rill bit

more easily.

5

1. LED work light

2. Variable speed trigger

3. Bit holder

4. Battery

5. High/low gear slide switch

6. Forward/Reverse switch

7. Soft grip handle

8. Battery lock button

7

8

3

Page 4

4. Drilling in Plastic

For drilling in plastic use a steel drill bit and follow the same instructions as for drilling in wood.

5. Drilling in Stone, Brick, Masonry

For drilling in walls, stone, masonry etc. use a masonry-bit. Do not put too much pressure on the machine.

Follow the same instructions as for drilling in metal.

6. Using the drill as a screwdriver

Before using the machine check whether the screwdriver bit is inse rted correctly . A void over-tightening screws,

otherwise the screw head may be damaged or stripping of the threads may occur.

7. Screw insertion

Set the direction of rotation of the drill to the clockwise direction. Insert the screwdriver bit into the slot in the

head of the screw. Hold th e screw bit pe rpendicular to the head of the screw, otherwise the screw or the screw

head may be damaged. Press the screw bit against the screw with a constant pressure while driving in the

screw. When the screw is completely screwed in, hold the drill firmly and release the On/Off trigger, otherwise

the screw or the screw head may be damaged. If the On/Off trigger is not released immediately, high torque

could also damage the drill bit or the drill.

8. Screw removal

Set the direction of rotation of the drill to the counter-clockwise direction. Insert the screw-bit into the slot in the

head of the screw. Hold the screwdriver bit perpendicular to the head of the screw, otherwise the screw or the

screw head may be damaged. Press the screw bit against the screw with a constant pressure while removing

the screw.

4

Page 5

Cordless Impact Wrench

PRT10528-02

PRODUCT SPECIFICATIONS

Rated Voltage 18V DC

Impact Power 0~3000 Ipm

No-load Speed 0~2000 Rpm

Anvil Size ½”

Rate Torque 230 N.M (169.7 ft.lb)

Max Torque 280 N.M (206.6 ft.lb)

Charge Time 3~5 hours

5

Page 6

Product Features

3

6

1

4

2

5

Assembly

Selecting Correct Socket

Always use the correct size socket for bolts and nut s.

1. LED work light

2. Variable speed trigger

3. Battery

4. Forward/Reverse switch

5. Soft grip handle

6. Battery lock button

An incorrect size socket will result in inaccurate and inconsistent

fastening torque and /or damage to the bolt or nut.

Installing or Removing Socket

Always be sure that the tool is switched off and the battery pack is

removed before installing or removing the socket.

To install the socket, push it onto the anvil of the tool until it locks

into place. To remove the socket, simply pull it off.

Operation

Loosening nuts and bolt s

Install socket as shown above. Place impact wrench and socket over nut or bolt making sure you have the

correct size and type of socket needed. Be sure impact wrench and socket are square with the nut or bolt.

Switch impact into the counter-clockwise direction and pull the variable speed trigger switch until nut or bolt is

removed. For stubborn nuts or bolts, a loosening agent may be needed p rio r to removing.

Tightening nuts and bolts

Start your nut or bolt by hand to ensu re that you are not cross threading it. Be cert ain all threads are cl ean an d

free of defects before tightening. After hand starting your nut or bolt, place impact wrench and socket over nut

or bolt making sure you have the correct size and type of socket needed. Be sure impact wrench and socket

are square with the nut or bolt. Switch impact into the clockwise direction and pull the variable speed trigger

switch until nut or bolt is tightened.

6

Page 7

Cordless Reciprocating Saw

PRT10528-05

Technical Data

Rated Voltage DC 18V

No-load Speed 0-2800/min

Stroke length 22mm (0.87’’)

Charging Time 3-5 hours

Product Features

1

6

1. Adjustable pivoting blade shoe

2. Soft touch front handle

3. Variable speed trigger switch

4. Battery

5. Battery lock button

6. Soft grip handle

7. Lock-off switch

2

3

4 5

7

Page 8

ASSEMBLY

WARNING:

Always remove battery pack from your saw when you are assembling parts, making adjustments,

assembling or removing blades, cleaning, or when not in use. Removing battery pack will prevent

accidental starting that could cause serious personal injury.

Inserting/Removing Battery Pack

TO INSERT:

1. To insert the battery pack by sliding battery pack into the body of the tool. Insert the battery pack until

the battery latches lock.

TO REMOVE:

1. To remove the battery pack, press in both battery latches and slide the battery pack off of the tool.

2. Make sure the latches on each side of the battery pack slip into place and battery pack is

secured to saw before beginning operation.

TO INSTALL SAW BLADE (Fig. 4)

1. Remove battery pack first.

WARNING:

Failure to remove battery pack from saw could

result in accidental starting causing possible

serious personal injury.

2. Loosen the blade clamp screw enough to

permit the saw blade to be inserted between

blade clamp and saw bar, by the blade wrench.

Note: it is never necessary to remove the blade

clamp screw from the blade clamp when

installing or removing blade.

3. Align the hole in the shank of the blade and blade clamp with the pin in the saw bar, and then seat both

on the pin in the saw bar.

Note: The wrench hole is used for wrench to

install the blade.

4. Tighten blade clamp screw securely.

5. Remove blade wrench and store it.

6. Replace battery pack.

Note: there may be times when the blade clamp

sticks to the saw bar and will not loosen enough

to allow blades to be installed or removed. If this

happens, loosen the blade clamp screw with the

blade wrench, then tap lightly on the end of the

blade wrench with a mallet. (Fig. 5)

8

Page 9

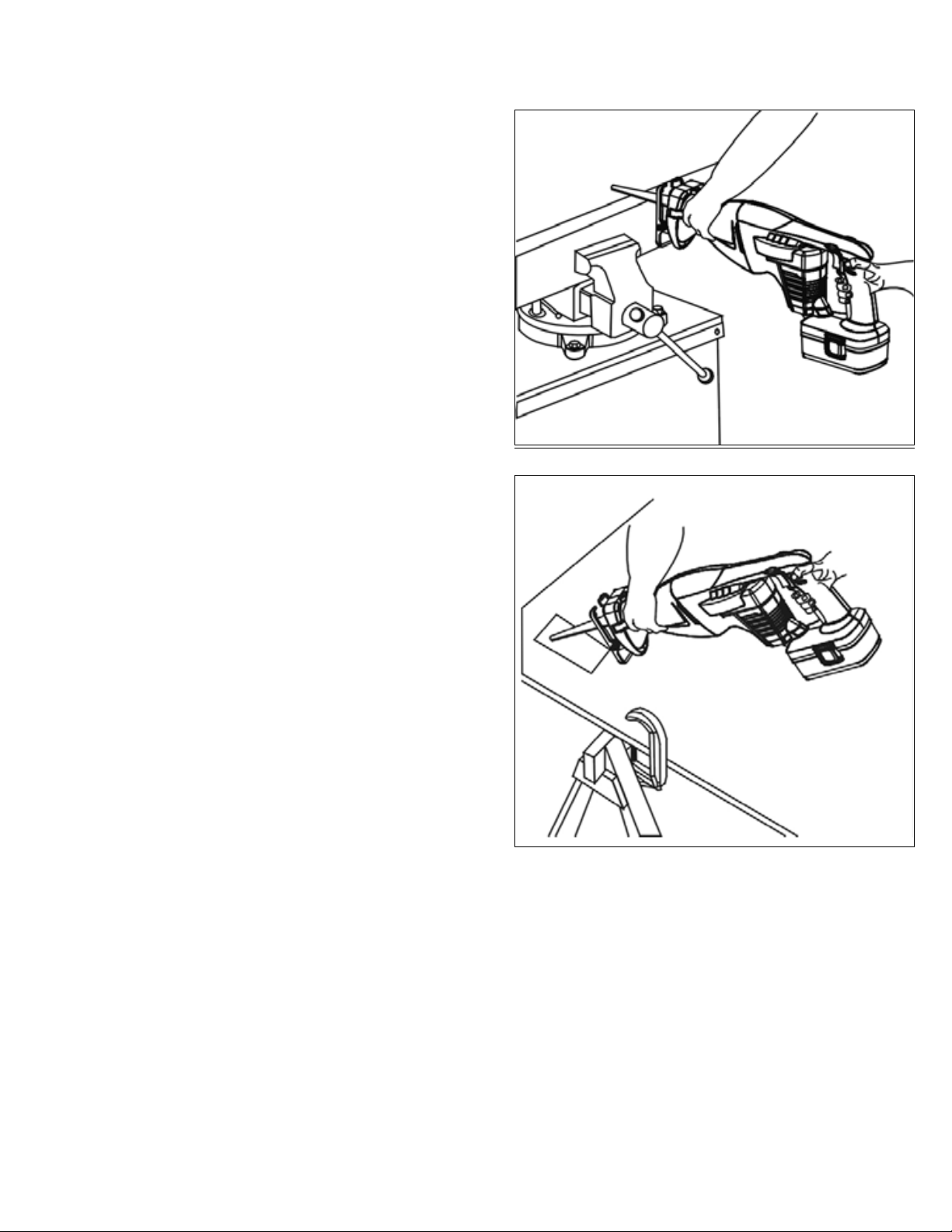

GENERAL CUTTING (Fig. 6)

Hold your saw firmly in front of and clearly

away from you. Make sure saw blade is clear of

any foreign material. Be sure material to be cut

is held firmly. Small work pieces should be

securely clamped in a vise or with clamps to the

work bench or table. Mark the line of cut clearly.

Depress the lock-off button, then pull switch

trigger to start the cutting action.

Place the base assembly against the work piece.

Then move the blade into the work piece. Do not

force. Use only enough pressure to keep the

saw cutting. Let the blade and saw do the work.

Use of excessive pressure that causes bending

or twisting of the blade may result in broken

blades.

PLUNGE CUTTING (Fig. 7)

Mark the line of cut clearly. Choose a convenient

starting point inside the area to be cut out and

place the tip of the blade over that point. Rest

front edge of base (shoe) on work and hold

firmly in position. Depress the lock-off button,

then pull switch trigger to start the cutting action.

WARNING:

Make sure blade does not touch work until motor

reaches full speed, since this could cause loss

of control resulting in serious injury. With saw

blade at full cutting speed, slowly tilt saw

down-ward until tip of blade starts cutting work.

After blade penetrates work, tilt saw until blade

is perpendicular to the work.

9

Page 10

METAL CUTTING (Fig. 8)

Metals such as sheet steel, pipe, steel rods ,

aluminum, brass and copper may be cut with

your saw. Be careful not to twist or bend the saw

blade. Do not force. We recommend cutting oil

when cutting most soft metals and steel. Cutting

oil will also keep blades cool, increase cutting

action, and prolong blade life. Never use

gasoline since normal sparking of motor could

ignite fumes. Clamp the work firmly and cut

close to the clamping point to eliminate any

vibration of the work being cut. When cutting

conduit pipe or angle iron, clamp work in a vise if

possible and cut close to the vise. To cut thin

sheet material, "sandwich" the material between

hardboard or plywood and clamp the layers to

eliminate vibration and material tearing.

WARNING

To reduce the risk of injury, be sure the blade always extends beyond the shoe and work piece

throughout the stroke. Blades may shatter if they impact the work-Piece or shoe.

WARNING

To reduce the risk of injury, Keep hands away from the blades and other moving part, always wear safety

goggles or Glasses with side shields. Use only specifically recommended.

10

Page 11

Cordless Light

PRT10528-06

1. Rotatable 90°head

2. On/off switch

3. Soft grip handle

4. Battery

5. Battery lock button

2

3

5

Rated Voltage DC 18V

LED Light power 1W

Charging Time 3-5 hours

Battery 1300mAh

Tool Operation

The ON/OFF Switch

Turn cordless flash light ON by depressing the switch. To turn the tool OFF, release the switch.

Remove Battery Pack

Press the battery-lock button and pull downward.

Function Description

The cordless light has a 90 degree changeable head suitable for multi-angle work. Do not use this

light in damp or wet areas.. Do not look it directly into light as it is very bright and will cause damage

to your eyes.

Technical Data

11

Page 12

Charger

PRT10528-04

_____________________

Technical Data

Model HP2270380B

Rated Input Voltage AC 100-120V, 60Hz

Rated Input Power Max 0.25A

Rated Output Voltage DC 22.7V

Rated Output Current 380mA

Charging Time 3-5hours

Protection Class II

Indoor operation only

Battery

PRT10528-03

__________________

12

Page 13

Operation

To Charge the Battery

1. Connect the charger cord to the charger base

2. Firmly insert battery pack onto charger base

3. Plug the battery charger (adapter) to power source (100-120V / 60Hz).

4. The Red LED light on the charger base will come on when the unit is plugged in and has power.

5. When the battery is full charged, the Red and Green light will be lighted on.

The proper charging time is 3-5 hrs.

Unplug charger after charging is complete and whenever it is not in use.

Working status Battery Red Green

Plug connected into the socket Not Insert On On

Insert On Off

Under charging Insert On Off

Fully charged Insert On On

CAUTION: Use only the provided battery charger for charging the battery. First place the rechargeable

battery into the charging slot in the charger and then plug the charger into your 120V AC supply, such as a

wall outlet. Charging starts automatically.

Remove the battery from the charge after it’s fully charged (After about 5 hours). Always disconnect the

charger from the main power before you remove the battery from the charger.

z The charger and battery may become warm to touch while charging. This is a normal condition, and

does not indicate a problem.

z Use the charger at normal room temperatures whenever possible. To prevent overheating, do not

cover the charger and do not charge the battery in direct sunlight or near heat sources.

z If the battery does not charge properly:

1) Check current at power outlet by plugging in a lamp or other appliance.

2) If charging problems persist, have the complete drill checked by an electrician or a power tool

technician.

To Attach Battery Pack

z Align the raised portion on the battery pack with the grooves in the handle of the tool, and then insert

the battery pack in to the tool as shown in Fig

z Make sure that the latch on the battery pack snaps into place and the battery pack is secured to the

tool before beginning operation.

13

Page 14

To Detach Battery Pack

z Depress both battery-release buttons located on the side of the battery pack to release

the battery pack.

z Slide the battery pack back to remove it from the tool.

CAUTION: When placing battery pack in your cordless impact wrench, be sure raised rib on battery pack

aligns with groove in wrench’s battery port and latches snap in place properly. Improper assembly of

battery pack can cause damage to internal components.

BATTERY PROTECTION

The circuitry protects the battery pack from extreme temperature, over discharge, and over-charge. To

protect the battery from damage and prolong its life, the battery pack circuitry will turn off the battery pack

if it becomes overloaded or if the temperature becomes too high during use. Both red and green LED light

will turn on when the battery fully charged.

General Safety Rules

WARNING

Read all safety warnings and all instructions. Fail to follow all warnings and instructions may result in

electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference

The term “power tool” in the warnings refers to your electrically operated (corded) power tool or battery

operated (cordless) power tool.

1) Work area

a) Keep work area clean and well lit. Cluttered and dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the presence of flammable

liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes.

c) Keep children and bystanders away while operating a power tool. Distractions can inhibit

accidents.

14

Page 15

2) Electrical safety

a) Power tool plugs must match the outlet. Never modify the plug in any other way. Do not use

any adapter plugs with electrically grounded power tools. Unmodified plugs and matching

outlets will reduce risk of electric shock.

b) Avoid body contact with electrically grounded surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock if your body is grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a power tool will increase

the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled cords

increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension cord suitable for outdoor use which

reduces the risk of electric shock.

f) If operating a power tool in a damp location is unavoidable, use a residual current device

(RCD) protected supply which reduces the risk of e l ectric shock.

3) Personal safety

a) Stay alert, watch what you are doing and use common sense when operating a power tool.

Do not use a power tool while you are tired or under the influence of drugs, alcohol or

medication. A moment of inattention while operating power tools may result in serious personal

injury.

b) Use safety equipment. Always wear eye protection. Safety equipment such as dust mask,

non-skid safety shoes, hard hat, or hearing protection used for appropriate conditions will reduce

personal injuries.

c) Avoid accidental starting. Ensure the s witch is in the off position before plugging in. Carrying

power tools with your finger on the switch or plugging in power tools that have the switch on invites

accidents.

d) Remove any adjusting key or wrench before turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at all times. This enables better control of

the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewelry or long hair can be caught in moving parts.

g) If devices are provided for the connection of dust extraction and collection facilities, ensure

these are connected and properly used.

4) Power tool use and care

a) Do not force the power tool. Use the correct power tool for your application. The correct power

tool will do the job better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch loses its function. Any power tool that cannot be controlled

with the switch is dangerous and must be repaired.

15

Page 16

c) Disconnect the plug from the power source before making any adjustments, changing

accessories, or storing power tools. Such preventive safety measures reduce the risk of st arting the

power tool accidentally.

d) Make sure the stored, idle power tools are out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power tool. Power tools are

dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving p arts, breakage of part s and

any other condition that may affect the power tools operation. If damaged, have the power tool

repaired before using it. Many accidents are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are

less likely to bind and are easier to control;

g) Use the power tool, accessories and tool bits etc., in accordance with these instructions and in

the manner intended for the particular type of power tool, taking into account the working

conditions and the work to be performed. Use of the power tool for operations different from

intended could result in a hazardous situation.

5) Battery use and care

a) Recharge only with the charger specified by the manufacturer. One charger is suitable for only

one type of battery pack.

b) Use power tools only with specifically designated battery p acks. Use any other battery pa cks may

create a risk of injury and fire.

c) When battery pack is not in use, keep it away from other metal objects, like paperclips, coins,

keys, nails, screws or other small metal objects, which can make a connection from one

terminal to another. Shorting the battery terminals together with ot her metal obj ects may cau se burns

or a fire.

d) Under abusive conditions, liquid may be ejected from the battery; avoid contact. If contact

accidentally occurs, flush with water. If liquid contacts eyes additionally, seek medical help as

soon as possible. Liquid ejected from the battery may cause irritation or burns.

6) Service

a) Have your power tool serviced by a qualified repair person using only identical replacement

parts. This will ensure that the power tool is safe.

16

Page 17

17

Loading...

Loading...