Page 1

ATD-10515

14" Cut-off Saw with Laser Guide

Operation and Safety Instructions

07/12

Page 2

Table of contents

EGAPNOITCES

I. Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

II. General safety rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

III. Specific safety rules for the cut-off saw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

IV. Electrical information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

V. Know your cut-off saw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

VI. Assembly and adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

VII. Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

VIII. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . .

IX. Replacement parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

. . . . . . . . . . . . .6

I. Technical data

14" CUT-OFF SAW WITH LASER LINE

A 51 ,zH 06 ,V 021:ROTOM

2/1 2:REWOPESROH

)daol on( MPR 0083:DEEPS ROTOM

)mc 5.53( "41:CSID GNITTUC

)mc 5.2( "1:ROBRA

SWIVELLING VISE CLAMP: 0–45˚ right, 0–45˚ left

MAXIMUM CUTTING DIAMETER: 4" (10 cm)

LASER WAVELENGTH: 640–660 nm

LASER OUTPOWER: ≤5 mW

43 lb(19.5kg):THGIEWTEN

detarepo-yrettab ,III ssalC:ELUDOM RESAL

2

Page 3

Safety is a combination of common sense, staying alert, and knowing how your cut-off saw

works.

1. READ and become familiar with this entire instruction manual. Learn the tool’s

applications, limitations, and possible hazards.

2. AVOID DANGEROUS CONDITIONS. DO NOT use power tools in wet or damp areas or

expose them to rain. Keep work area well-lit.

3. DO NOT use power tools in the presence of flammable liquids or gases.

4. ALWAYS keep your work area clean, uncluttered, and well-lit. DO NOT work on floor

surfaces that are slippery from sawdust or wax.

5. KEEP BYSTANDERS AT A SAFE DISTANCE FROM the work area, especially when tool

is operating. NEVER allow children or pets near the tool.

6. DO NOT FORCE THE TOOL to do a job for which it was not designed to perform.

7. DRESS FOR SAFETY. DO NOT wear loose clothing, gloves, neckties, or jewellery

(rings, watches, etc.) when operating tool. Inappropriate clothing and items can get

caught in moving parts and draw you in. ALWAYS wear non-slip footwear and tie back

long hair.

8. WEAR AFACE MASK OR DUST MASK as the sawing operation produces dust.

9. ALWAYS remove the power cord plug from the electrical outlet when making

adjustments, changing parts, cleaning or working on the tool.

10. KEEP GUARDS IN PLACE AND IN WORKING ORDER.

11. AVOID ACCIDENTAL START-UPS. Make sure that the power switch is in the OFF

position before plugging in the power cord.

12. REMOVE ADJUSTMENT TOOLS. ALWAYS MAKE SURE all adjustment tools are

removed from the cut-off saw before turning it on .

13. NEVER LEAVE A RUNNING TOOL UNATTENDED. Turn the power switch to OFF.

DO NOT leave tool until it has come to a complete stop.

14. NEVER STAND ON THE TOOL. Serious injury could result if the tool tips or is

accidentally hit. DO NOT store anything above or near the tool.

15.DO NOT OVERREACH. Keep proper footing and balance at all times. Wear oil-resistant,

rubber-soled footwear. Ensure the floor is not subjected to accumulation of oil, scrap, and

other debris.

16.MAINTAIN TOOLS PROPERLY. ALWAYS keep tools clean and in good working order.

Follow instructions for lubricating and changing accessories.

WARNING: TO AVOID MISTAKES THAT COULD CAUSE SERIOUS INJURY, DO NOT

PLUG IN THE CUT-OFF SAW UNTIL THE FOLLOWING STEPS HAVE BEEN READ AND

UNDERSTOOD.

SAVE THESE SAFETY INSTRUCTIONS

II. General safety rules

3

Page 4

SAVE THESE SAFETY INSTRUCTIONS

II. General safety rules ... continued

4

17.CHECK FOR DAMAGED PARTS. Check moving parts for alignment, jamming, breakage,

improper mounting, or any other conditions that may affect the tool's operation. Any part

that is damaged should be properly repaired or replaced before use.

18.MAKE WORKSHOP CHILDPROOF. Use padlocks, master switches, and always remove

starter keys.

19.DO NOT operate tool if you are under the influence of drugs, alcohol or medication that

could affect your ability to use the tool properly.

20.WHEN SERVICING USE ONLY IDENTICAL REPLACEMENT PARTS. Double insulation

does not take the place of normal safety precautions when operating this tool.

LASER SAFETY

The laser light beam used in this system is Class III with a maximum ≤5 mW and

640–660 nm wavelength.

WARNING:

DO NOT STARE DIRECTLY AT THE LASER BEAM! A HAZARD MAY EXIST

IF YOU DELIBERATELYSTARE INTO THE BEAM.

PLEASE OBSERVE ALLSAFETY RULES ASFOLLOWS:

• THE LASER SHALL BE USED AND MAINTAINED IN ACCORDANCE WITH THE

MANUFACTURER'S INSTRUCTIONS.

• NEVER AIM THE BEAM AT ANY PERSON OR AN OBJECT OTHER THAN THE

WORKPIECE.

• DO NOT PROJECT THE LASER BEAM INTO THE EYES OF OTHERS.

• ALWAYS ENSURE THE LASER BEAM IS AIMED AT A WORKPIECE WITHOUT

REFLECTIVE SURFACES AS THE LASER BEAM COULD BE PROJECTED INTO

YOUR EYES OR THE EYES OF OTHERS.

ALWAYS WEAR EYE PROTECTION.

A cut-off saw can throw foreign objects into your eyes which

could cause permanent eye damage.

ALWAYS wear safety goggles (not glasses). Ordinary eyeglasses

have only impact-resistant lenses...they ARE NOT safety

goggles.

WARNING: DUST GENERATED FROM CERTAIN MATERIALS CAN BE HAZARDOUS TO

YOUR HEALTH. ALWAYS OPERATE THE CUT-OFF SAW IN A WELL-VENTILATED AREA.

USE DUST COLLECTION SYSTEMS WHENEVER POSSIBLE. USE A FACE MASK OR

DUST MASK WHEN OPERATING THE CUT-OFF SAW.

Page 5

1. If you are not thoroughly familiar with the operation of a cut-off saw, obtain advice from a

supervisor, instructor, or other qualified person.

2. ALWAYS WEAR SAFETY GOGGLES. Wear hearing protection during periods of

extended operation.

3. REPLACE CRACKED METAL CUTTING DISC IMMEDIATELY. Handle disc carefully and

inspect for cracks before each use. Tighten spindle bolt enough to hold the disc firmly.

Use only the disc flanges provided with your cut-off saw.

4. DO NOT stand in front of the cut-off saw when starting it. To start the saw, stand to one

side and turn ON. Wait until the cut-off saw comes to full speed. There is always the

possibility that a piece from a damaged disc may be thrown off when coming to full

speed.

5. ONLY USE abrasive cut-off discs rated at 4100 RPM or higher.

6. NEVER USE ACIRCULAR SAW BLADE or tooth-type blade in the cut-off saw.

7. DO NOT CUT wood with this cut-off saw.

8. DO NOT USE THE CUT-OFF SAW with the upper or lower blade guard removed.

9. ALWAYS CLAMP THE WORKPIECE with the vise clamp assembly when cutting.

10. CAUTION! Flying sparks will occur when cutting. Sparks can cause personal injury and

ignite flammable materials.

11. DO NOT TOUCH the workpiece after cutting. It is hot and could burn the skin.

12. RELEASE TRIGGER SWITCH AND ALLOW THE CUTTING DISC TO COME TO A

COMPLETE STOP BEFORE REMOVING ANYTHING FROM THE CUT-OFF SAW

TABLE.

13. KEEP HANDS AWAY from rotating parts.

14. AVOID DANGEROUS CONDITIONS. Do not use the cut-off saw in wet or damp areas, or

expose to rain. Use the cut-off saw in a well-ventilated area. FOR INDOOR USE ONLY.

WARNING: DO NOT OPERATE YOUR CUT-OFF SAW UNTIL IT IS COMPLETELY

ASSEMBLED AND INSTALLED ACCORDING TO THE INSTRUCTIONS.

SAVE THESE SAFETY INSTRUCTIONS

III. Specific safety rules for the cut-off saw

5

Page 6

SAVE THESE SAFETY INSTRUCTIONS

IV. Electrical information

GROUNDING INSTRUCTIONS

IN THE EVENT OF AMALFUNCTION OR BREAKDOWN, grounding provides the path of

least resistance for electric current to reduce the risk of electric shock. This tool is equipped

with an electric cord that has an equipment grounding conductor and a grounding plug. The

plug MUST be plugged into a matching outlet that is properly installed and grounded in

accordance with ALL local codes and ordinances.

DO NOT MODIFY THE PLUG PROVIDED. If it will not fit in the outlet, have the proper outlet

installed by a qualified electrician.

IMPROPER CONNECTION of the equipment grounding

conductor can result in risk of electric shock. The conductor

with the green insulation (with or without yellow stripes) is the

equipment grounding conductor. If repair or replacement of the

electric cord or plug is necessary, DO NOT connect the

equipment grounding conductor to a live terminal.

CHECK with a licensed electrician or service person if you do

not completely understand the grounding instructions, or if you

are not sure if the tool is properly grounded.

USE 3-WIRE EXTENSION CORDS that have 3-prong plugs and 3-prong outlets that accept

the tool's plug as shown in Fig. A. Repair or replace damaged or worn cord immediately.

CAUTION: IN ALL CASES, MAKE CERTAIN THE OUTLET IN QUESTION IS PROPERLY

GROUNDED. IF YOU ARE NOT SURE IF IT IS, HAVE A CERTIFIED ELECTRICIAN CHECK

THE OUTLET.

6

WARNING: THIS CUT-OFF SAW IS FOR INDOOR USE ONLY. DO NOT EXPOSE TO

RAIN OR USE IN DAMP LOCATIONS.

Fig. A

1

3

2

1 - 3-prong plug

2 - Properly grounded outlet

3 - Grounding prong

Page 7

GUIDELINES FOR USING EXTENSION CORDS

Make sure your extension cord is in good condition. When using an extension cord, be sure

to use one heavy enough to carry the current your product will draw. An undersized cord will

cause a drop in line voltage resulting in loss of power and overheating. The table below

shows the correct size to use according to cord length and nameplate ampere rating. If in

doubt, use the next heavier gauge. The smaller the gauge number, the heavier the cord.

Make sure your extension cord is properly wired and in good condition. Always replace a

damaged extension cord or have it repaired by a qualified person before using it. Protect your

extension cords from sharp objects, excessive heat and damp or wet areas.

Use a separate electrical circuit for your tools. This circuit should not be less than a #12 wire

and should be protected with a 15 Atime-delayed fuse. Before connecting the motor to the

power line, make sure the switch is in the OFF position and the electric current is rated the

same as the current stamped on the motor nameplate. Running at a lower voltage will

damage the motor.

WARNING: THIS CUT-OFF SAW MUST BE GROUNDED WHILE IN USE TO PROTECT

THE OPERATOR FROM ELECTRICAL SHOCK.

SAVE THESE SAFETY INSTRUCTIONS

IV. Electrical information ... continued

7

Minimum Gauge for Extension Cords (AWG)

(when using 120 V only)

Ampere Rating Total Length of Cord in Feet (metres)

More Than Not More Than 25' (7.6 m) 50' (15 m) 100' (30.4 m) 150' (45.7 m)

0 6 18 16 16 14

6 10 18161412

10 12 16 16 14 12

12 16 14 12 Not Recommended

Page 8

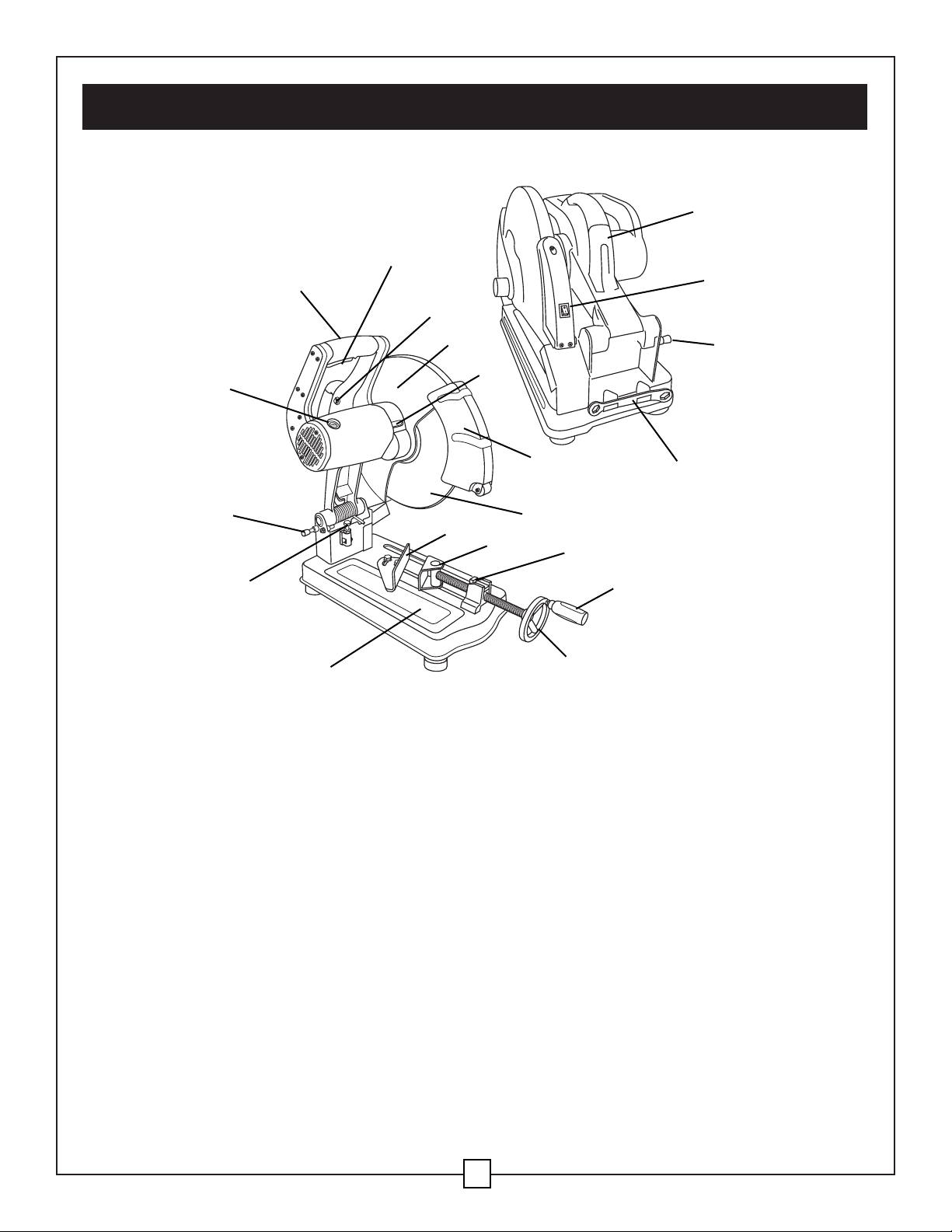

V. Know your cut-off saw

8

A D-handle

B Trigger switch

C Reset switch

D Upper blade guard

E Arbor lock

F Lower blade guard

G 14" metal cutting disc

H Angle plate

I Vise pressure plate

J Quick-release latch

K Vise handle

L Vise wheel

M Saw table

N Depth stop bolt

O Wheel lock lever

P Carbon brush cap

Q Carrying handle

R Laser switch

S Wrench

A

B

e

F

R

J

H

I

G

K

O

S

M

O

N

P

C

D

E

Q

L

Page 9

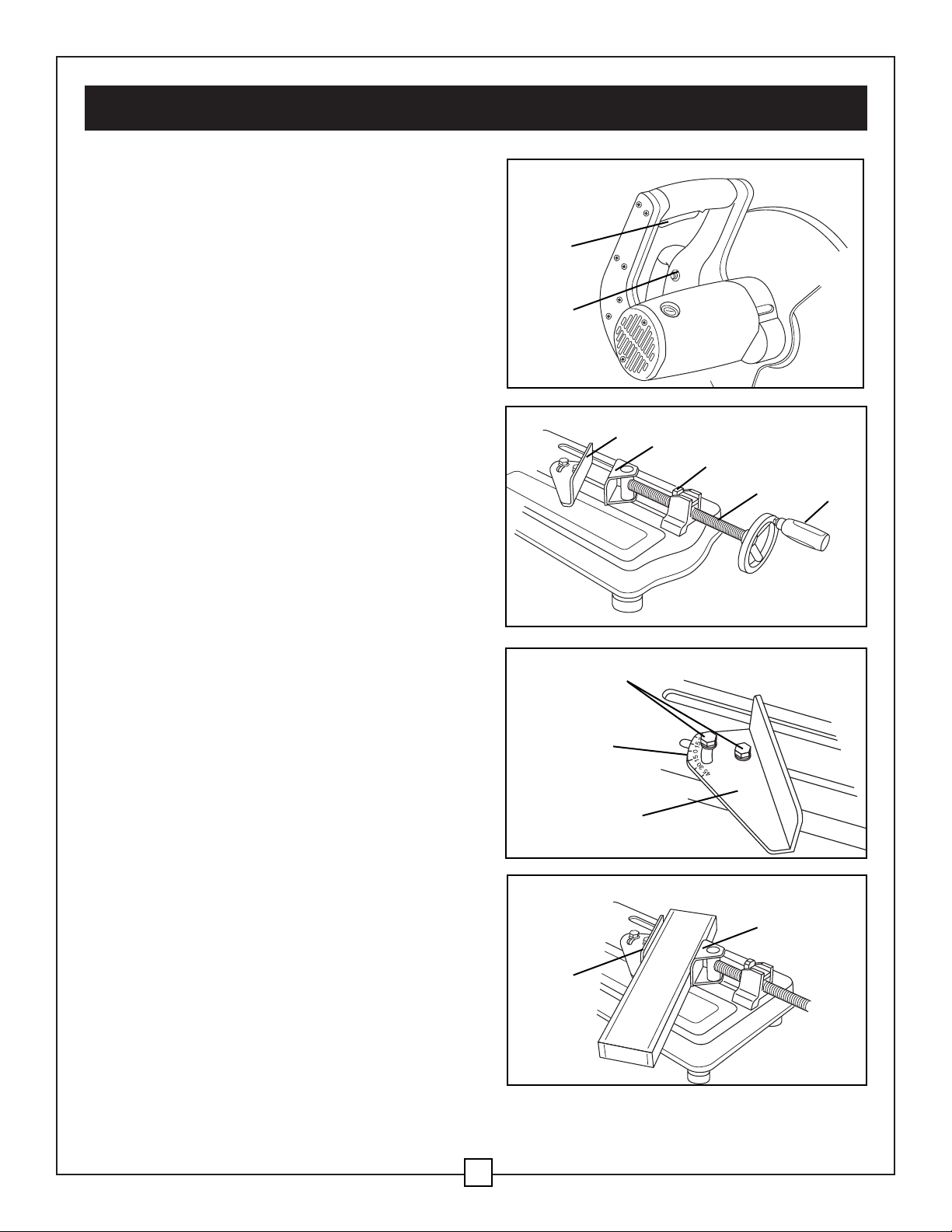

VI. Assembly and adjustments

Unpacking (Fig. 1)

1. Remove the cut-off saw (1) from the carton

by lifting it by the carrying handle.

2. Place the cut-off saw on a secure surface

and examine it carefully. Ensure that you

have:

• 14" cut-off saw assembly (1)

• Vise clamp handle (2)

• Threaded bolt and nut (3)

• Blade wrench (4)

Although this cut-off saw requires minimal

assembly, it does, however, require adjustments

to operate properly. For your safety, make all

adjustments prior to plugging in the cut-off saw.

Vise clamp assembly (Fig. 2)

1. Insert the bolt (1) through the vise clamp

handle (2).

2. Tighten the nut (3) on the bolt.

3. Insert the assembled handle into the

opening (4) on the vise wheel and turn

handle clockwise to secure to the wheel.

Raise/lower the saw (Fig. 3)

1. Pull out the wheel lock lever (1) and use the

handle to raise or lower the cut-off saw.

2. Push in the wheel lock lever (1) to lock the

cut-off saw in the raised or lowered position.

WARNING: IF ANY PART IS MISSING OR DAMAGED, DO NOT PLUG IN THE CUT-

OFF SAW UNTIL THE MISSING OR DAMAGED PART IS REPLACED.

9

Fig. 1

Fig. 2

1

4

2

3

4

3

2

1

Fig. 3

1

Page 10

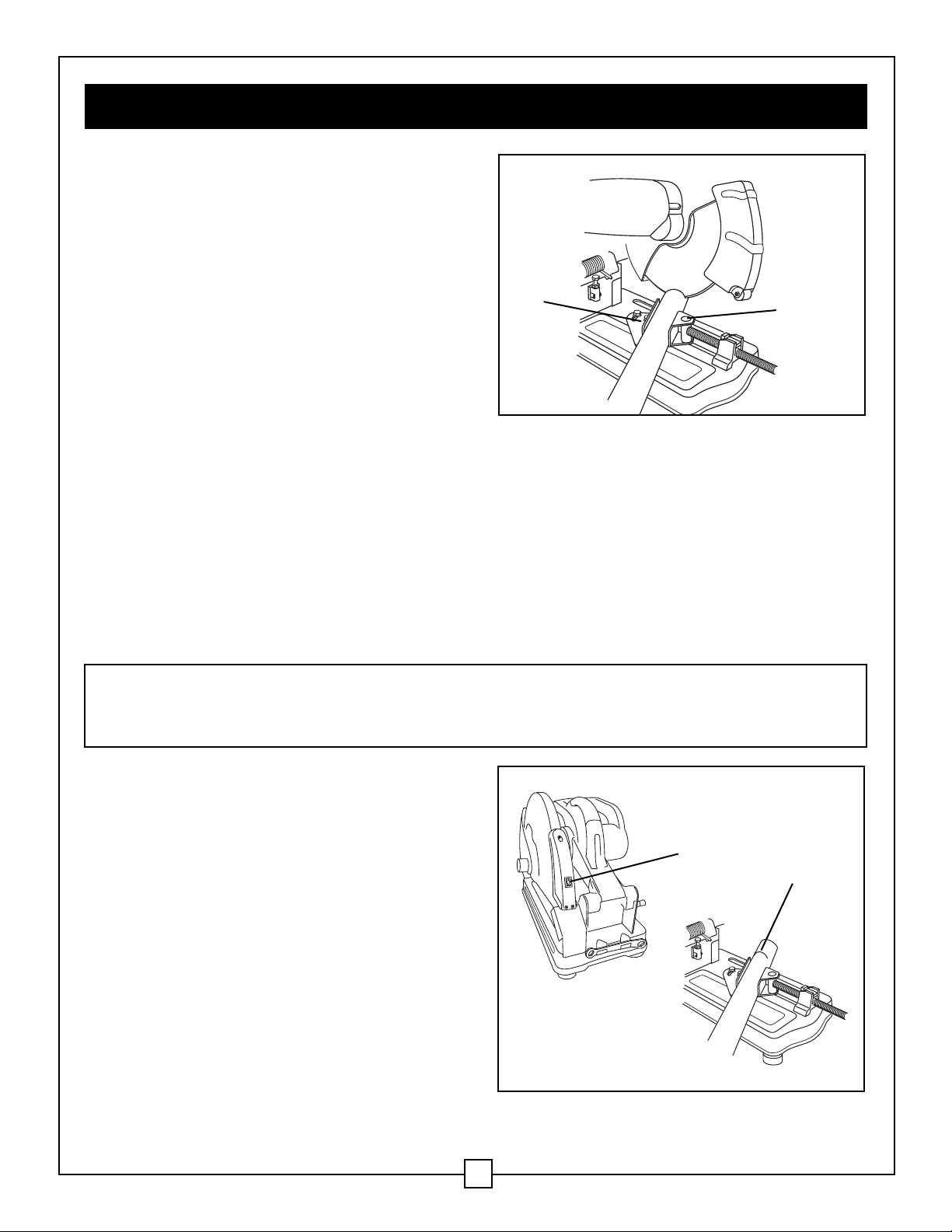

ON/OFF trigger switch (Fig. 4)

To start the cut-off saw, squeeze the trigger

switch (1). To stop the cut-off saw, release the

trigger switch.

Reset switch (Fig. 4)

If the cut-off saw does not start when the trigger

switch is depressed, press the reset switch (2).

Squeeze the trigger switch to start.

Swivelling vise clamp assembly with

quick-release latch (Fig. 5)

Always secure the workpiece between the angle

plate and the vise pressure plate when cutting.

1. Place the workpiece between the angle

plate (1) and the vise pressure plate (2).

2. Push the vise screw (3) toward the angle

plate and turn the vise wheel (4) clockwise to

secure. To release, turn the wheel counterclockwise two turns, raise the quick-release

latch (5) and pull the vise screw towards you.

Angle plate (Fig. 6 and 7)

The angle plate can be moved forward,

backward, or rotated for angle cutting.

1. To set a cutting angle, loosen the two bolts (1)

and rotate the angle plate (3) up to 45˚ right

or 45˚ left. Align the index (2) with the red line

on the saw table. Retighten the bolts.

2. Always centre the workpiece over the table

slot-web to maximize cutting depths. Move the

vise pressure plate (4) toward the angle

plate (3). Tighten angle plate bolts (2) and

vise pressure plate (4).

3. To move the angle plate (3), remove the two

bolts (1) and washers. Move the angle plate to

the desired position and align the angle plate

with the threaded holes on the saw base.

Insert the two bolts and washers and tighten

to secure the angle plate to the table.

VII. Operation

10

Fig. 4

Fig. 5

Fig. 6

Fig. 7

1

2

1

2

5

3

4

2

1

3

3

4

Page 11

VII. Operation

...

continued

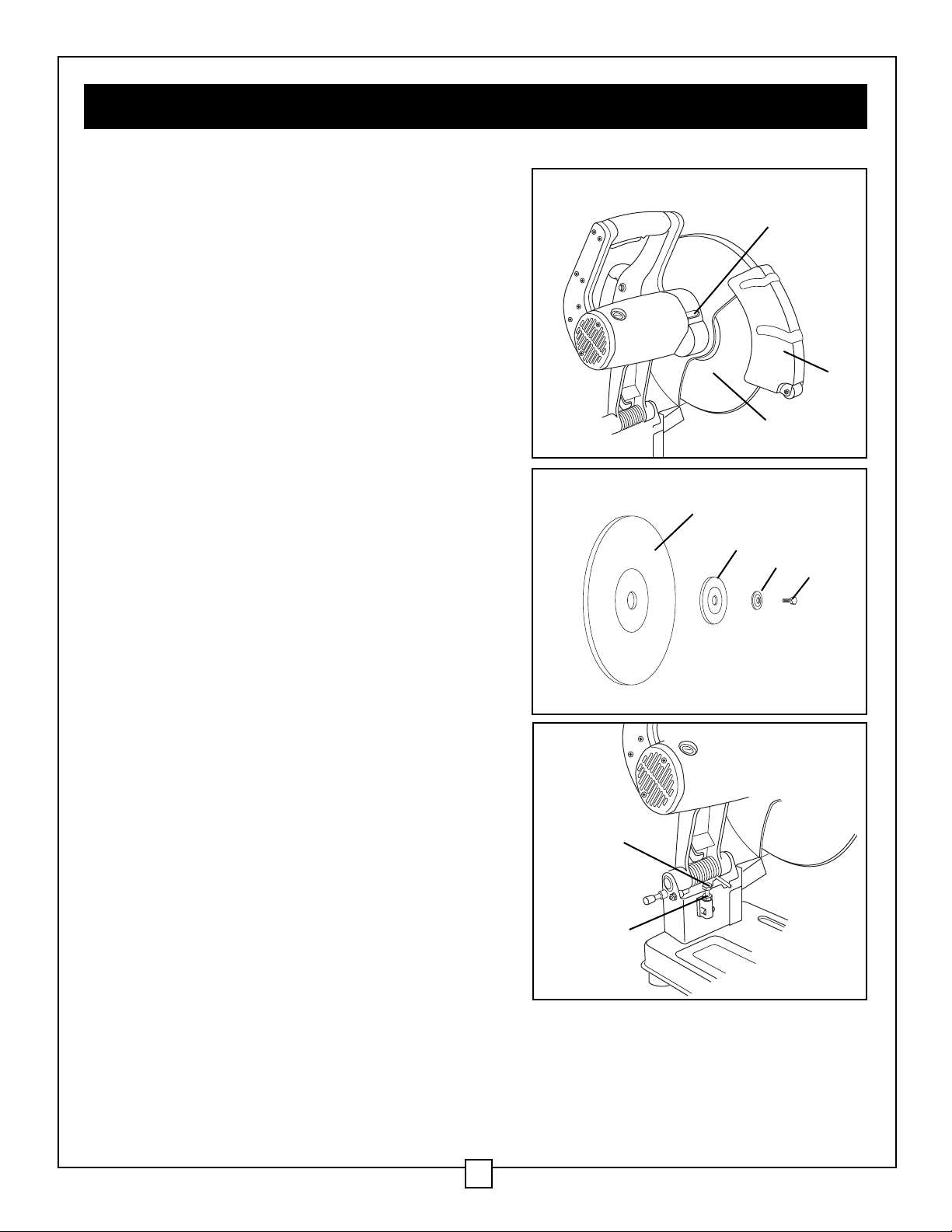

Installation and removal of metal cutting disc

(Fig. 8 and 9)

1. Unplug the cut-off saw.

2. Push the arbor lock lever (1) towards the metal

cutting disc (2) and slowly turn the disc (either

direction) until the disc locks. (Fig. 8)

3. Push back the lower blade guard (3) and loosen

the hex bolt (6) in the centre of the disc using

the wrench. Remove the bolt (6), washer (5),

flange (4), and disc (2). (Fig. 9).

4. To install a new metal cutting disc, reverse the

process in step 3. Do not overtighten the bolt.

5. Make sure all guards are in place and the disc

rotates freely.

6. Adjust the depth stop bolt (Fig. 10). Return the

wrench to the storage slot.

7. Plug in the cut-off saw.

8. Run the cut-off saw and check to make sure the

disc is in good condition. Always stand to one

side when turning on the cut-off saw. When

testing a new disc, run the the cut-off saw for

3 minutes. When testing an existing disc, run the

cut-off saw for 1 minute.

Adjusting the cutting depth (Fig. 10)

The diameter of the metal cutting disc decreases

with use. The depth stop bolt should be adjusted

periodically to prevent the disc from cutting the

work surface below the cut-off saw table.

1. Loosen the lock nut (1).

2. Turn the stop bolt (2) to set the downward travel

of the disc.

3. Lower the saw to check the depth.

4. Repeat steps 2 and 3 until the downward travel

of the disc is at the desired level.

5. Tighten the lock nut (1) to secure the cutting

depth assembly.

11

Fig. 8

Fig. 9

Fig. 10

2

4

5

6

1

1

2

2

3

Page 12

VII. Operation

...

continued

12

Cutting workpiece (Fig. 11)

1. Set the angle plate (1) to the desired cutting

angle.

2. Make sure the workpiece lies flat on the cutoff saw table.

3. Use the vise (2) to secure the workpiece to

the table.

4. Squeeze the trigger switch.

5. After the motor reaches full speed, lower the

disc into the centre of the workpiece.

6. Using a smooth, firm, and gentle downward

motion, make a clean cut through the

workpiece. Do not allow the disc to bump or jump when making contact with the

workpiece; this may damage both the workpiece and the disc.

7. Keep consistent pressure when coming to the bottom of the cut to avoid forming a heavy

burr and overheating the workpiece.

8. Raise the disc completely from the workpiece before releasing the trigger switch and allow

the motor to stop before removing the workpiece.

Note: A long workpiece should be supported on both ends with blocks of a non-flammable

material so that the workpiece is level with the cut-off saw table.

Using the laser line (Fig. 12)

1. Secure the workpiece in the vise clamp.

2. Turn the laser switch (1) to the ON position.

3. Check the location of the laser line on the

workpiece. Move the workpiece (2), if

needed.

Fig. 11

1

2

1

2

Fig. 12

WARNING: DO NOT STARE DIRECTLY AT THE LASER BEAM! A HAZARD MAY EXIST

IF YOU DELIBERATELY STARE INTO THE BEAM, PLEASE OBSERVE ALL SAFETY

RULES.

Page 13

VIII. Maintenance

13

Brush inspection and replacement

Replace both carbon brushes when either has less than 1/4" of carbon remaining. To inspect

or replace, unplug the cut-off saw, remove the carbon brush cap on the side of the motor

housing, and pull out the brush (Note: the cap is spring-loaded). Repeat the steps on the

other side. To reassemble, reverse the procedure.

Replace the laser module batteries (Fig. 13)

1. Remove the 3 screws that secure the laser

module cover to the housing. Remove the cover,

taking care not to damage the wires connected to

the laser switch.

2. Remove the 2 screws (1) that secure the battery

cover to the battery case. Remove the battery

cover.

3. Replace both "AAA" batteries (2).

Lubrication

ATD

tools are properly lubricated at the factory and are ready to use. When necessary,

lubricate only those parts that pivot or move with a dry silicone spray. Lubricating

motor bearings and other internal parts should be done only by qualified service technicians.

General maintenance

Before each use, inspect the guards, switches, power cord, and extension cord. Check for

loose screws, jamming, improper mounting, broken parts, and any other condition that may

affect the safe operation of the cut-off saw. If an unusual operating noise or vibration occurs,

turn the cut-off saw OFF and immediately correct the problem before using the cut-off saw

again.

Cleaning

Clean dust and debris from vents, tabletop, and vise screw. Use a dry, clean rag to clean all

areas of the cut-off saw. Never use solvents or other harsh chemicals for cleaning as they

are harmful to plastic and other insulated parts. Petroleum-based products, brake fluid,

thinners and ammonia detergents will also permanently damage the cut-off saw.

WARNING: TO AVOID INJURY FROM UNEXPECTED START-UP OR ELECTRICAL

SHOCK, UNPLUG THE POWER CORD BEFORE ATTEMPTING INSPECTION OR

MAINTENANCE. DO NOT USE A DAMAGED CUT-OFF SAW.

WARNING: NEVER USE FLAMMABLE OR COMBUSTIBLE SOLVENTS AROUND THIS

CUT-OFF SAW. WHEN SERVICING, USE ONLY IDENTICAL ATD REPLACEMENT PARTS.

USE OF ANY OTHER PARTS MAY CREATE A HAZARD OR CAUSE PRODUCT FAILURE.

Fig. 13

1

2

Page 14

IX. Replacement parts

WARNING: ALL ELECTRICAL OR MECHANICAL REPAIRS SHOULD BE ATTEMPTED

ONLY BY A QUALIFIED SERVICE TECHNICIAN. USE ONLY IDENTICAL REPLACEMENT

PARTS. ANY OTHER PARTS MAY CREATE A HAZARD.

14

Page 15

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

PRT10515-01

PRT10515-02

PRT10515-03

PRT10515-04

PRT10515-05

PRT10515-06

PRT10515-07

PRT10515-08

PRT10515-09

PRT10515-10

PRT10515-11

PRT10515-12

PRT10515-13

PRT10515-14

PRT10515-15

PRT10515-16

PRT10515-17

PRT10515-18

PRT10515-19

PRT10515-20

PRT10515-21

PRT10515-22

PRT10515-23

PRT10515-24

PRT10515-25

PRT10515-26

PRT10515-27

PRT10515-28

PRT10515-29

PRT10515-30

PRT10515-31

PRT10515-32

PRT10515-33

PRT10515-34

PRT10515-35

PRT10515-36

PRT10515-37

PRT10515-38

PRT10515-39

PRT10515-40

PRT10515-41

PRT10515-42

PRT10515-43

PRT10515-44

PRT10515-45

PRT10515-46

PRT10515-47

PRT10515-48

PRT10515-49

PRT10515-50

PRT10515-51

PRT10515-52

IX. Replacement parts

POWER CORD

POWER CORD SHEATH

SCREW

CARRY HANDLE (L)

SPRING WASHER

CARRY HANDLE (R)

SCREW

FLAT WASHER

SCREW

SCREW

LEFT SIDE PANEL

SWITCH TRIGGER

NUT

SWITCH,HY18

D-HANDLE (UP)

CIRCUIT BREAKER

RIGHT SIDE PANEL

SCREW

FLAT WASHER

SCREW

STRAIN RELIEF

WIRE NIP

SCREW

D-HANDLE (DOWN)

SCREW

BRUSH CAP

BRUSH HOLDER

SPRING

CARBON BRUSH

SCREW

ARM

WIRE BUSH

GEAR WASHER

SCREW

STATOR ASSEMBLY

FLAT WASHER

SPRING WASHER

SCREW

BEARING

ROTOR ASSEMBLY

FAN BEARING

FAN RING

LOCK PIN

LOCK PIN KNOB

SPRING

GEAR BOX

BEARING, 6000

C-RING

BIG GEAR

SLEEVE

KEY

SHAFT

1

1

4

1

22

1

4

52

4

2

1

1

3

1

1

1

1

6

3

3

1

1

1

1

4

2

2

2

2

2

1

1

1

1

1

2

2

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

PRT10515-53

PRT10515-54

PRT10515-55

PRT10515-56

PRT10515-57

PRT10515-58

PRT10515-59

PRT10515-60

PRT10515-61

PRT10515-62

PRT10515-63

PRT10515-64

PRT10515-65

PRT10515-66

PRT10515-67

PRT10515-68

PRT10515-69

PRT10515-70

PRT10515-71

PRT10515-72

PRT10515-73

PRT10515-74

PRT10515-75

PRT10515-76

PRT10515-77

PRT10515-78

PRT10515-79

PRT10515-80

PRT10515-81

PRT10515-82

PRT10515-83

PRT10515-84

PRT10515-85

PRT10515-86

PRT10515-87

PRT10515-88

PRT10515-89

PRT10515-90

PRT10515-91

PRT10515-92

PRT10515-93

PRT10515-94

PRT10515-95

PRT10515-96

PRT10515-97

PRT10515-98

PRT10515-99

PRT10515-100

PRT10515-101

PRT10515-102

PRT10515-103

PRT10515-104

PRT10515-105

...

continued

BEARING,6004

C-RING

GEAR BOX COVER

INNER FLANGE

BLADE SLEEVE

SCREW

SPRING WASHER

FLAT WASHER

LASER COVER

LASER SWITCH

SCREW

BATTERY COVER

BATTERY SPRING 3

BATTERY

SCREW

BATTERY SPRING 1

BATTERY BOX

SCREW

LASER BASE

BATTERY SPRING 2

LASER

LASER PRESS BOARD

LASER JOINTER

JOINTER BASE

LASER GUARD

BLADE

OUTER FLANGE

SPACER WASHER

BLADE SCREW

SCREW

UPPER GUARD

GUARD STOP

LOCKNUT

LOCKNUT

LOWER GUARD

GUIDE WHEEL

BIG WASHER

HINGE

SPRING

SCREW

SCREW

SCREW

HINGE CAP

SCREW

DEPTH PLATE

DEPTH BOLT

WRENCH

WRENCH STORAGE CLIP

NUT

PIN CAP

C-RING

O-RING

NUT

ytQnoitpircseD.oNytQnoitpircseDPart no. Part no..oN

1

1

1

1

1

3

7

5

1

1

6

1

1

2

2

1

1

2

1

1

1

1

1

1

1

1

1

1

1

4

1

1

1

1

1

1

1

1

1

1

1

3

1

5

1

1

1

2

2

1

1

1

1

15

Page 16

IX. Replacement parts

...

ATD-10515 14" Cut-off Saw with Laser Guide

continued

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

Part no.

PRT10515-106

PRT10515-107

PRT10515-108

PRT10515-109

PRT10515-110

PRT10515-111

PRT10515-112

PRT10515-113

PRT10515-114

PRT10515-115

PRT10515-116

PRT10515-117

PRT10515-118

PRT10515-119

PRT10515-120

PRT10515-121

PRT10515-122

PRT10515-123

PIN 1

PIN 2

SCREW

NUT

DEPTH STOP BASE

BIG SPRING

ROTATION AXIS

C-RING

BASE

NUT

SPARK GUARD

FOOT CUSHION BASE

FOOT CUSHION

FLAT WASHER

FOOT CUSHION ASSEMBLY

HEX BOLT

SPRING WASHER

FENCE

Part no.

1

1

2

1

1

1

1

2

1

3

1

4

4

7

1

2

2

1

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

PRT10515-124

PRT10515-125

PRT10515-126

PRT10515-127

PRT10515-128

PRT10515-129

PRT10515-130

PRT10515-131

PRT10515-132

PRT10515-133

PRT10515-134

PRT10515-135

PRT10515-136

PRT10515-137

PRT10515-138

PRT10515-139

C-RING

PIN

CLAMP

LOCKNUT

SCREW

SPRING PIN

BOLT

SPRING WASHER

FLAT WASHER

NUT

NUT BASE

SPRING PIN

WHEEL

NUT

HANDLE

BOLT

noitpircseD

ytQ.oNytQnoitpircseD.oN

1

1

1

1

1

1

2

2

3

1

1

1

1

1

1

1

16

Loading...

Loading...