Page 1

L-PB

L-PW

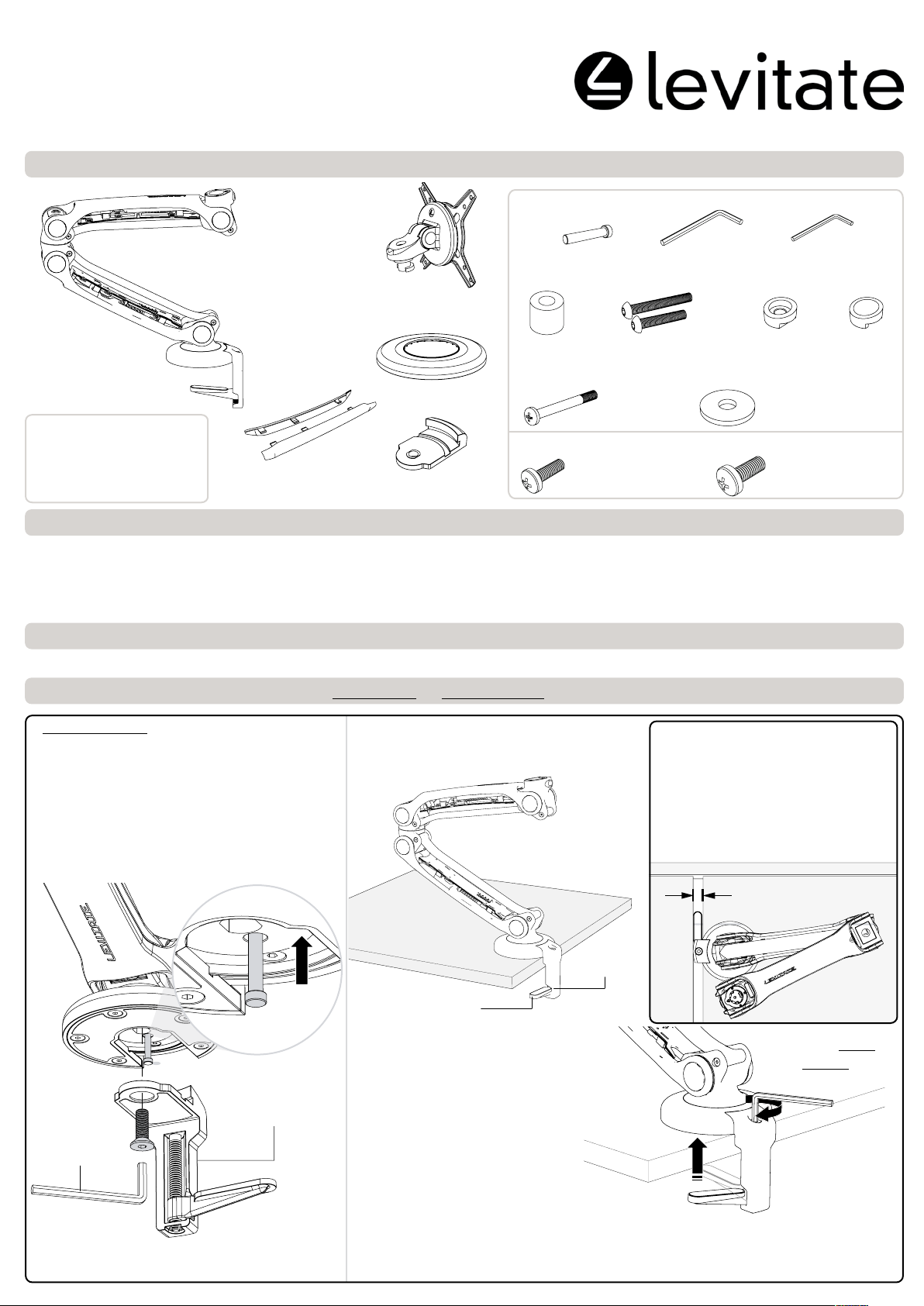

Component Checklist

Installation Instructions

Desk | Single

Hardware (BAG A)

Arm Assembly

(with pre-assembled Desk Clamp)

Mounting

Head

Bush (x4)

Cover Plate

Tools Required:

Phillips Head Screwdriver

Power drill

5

8mm (

/16”) drill bit

IMPORTANT INFORMATION

! IMPORTANT - Install Levitate Single Monitor Arm as per Installation Instructions

! This product supports a maximum weight of 9kg (19.5lbs).

! This product supports VESA mounting hole congurations 75 x 75mm and 100 x 100mm.

! The manufacturer accepts no responsibility for incorrect installation.

Step 1. Check Components

Check you have received all parts against the Component Checklist and Hardware.

Step 2. Fasten Base to Work Surface - Choose DESK CLAMP OR BOLT THROUGH option (PTO...)

Cable Covers

(x2 sets)

Base Plate

Display Mounting Screws (BAG B)

Spacer

Brake

Pin (x1)

45mm/60mm

Bolts (x1 each)

Security

Screw (x1)

M4 x 12mm (x4)

M4 x 16mm (x4)

5mm Allen

Key (x1)

2mm Allen

Key (x1)

Security

Washer (x1)

Bolt Through

Washers (x3)

M5 x 12mm (x4)

M5 x 16mm (x4)

Head

Cap (x1)

A - DESK CLAMP

The default base setup allows 360° of

rotation of the Lower Arm around the base. If

you want to limit the Lower Arm rotation to

180° go to A1, if not skip to A2.

A1. OPTIONAL 180° ROTATION

To limit the Lower Arm rotation to 180° insert

the Brake Pin underneath the Desk Clamp.

PUSH

Insert

Brake Pin

Desk Clamp

5mm Allen

Key

A2. Position Arm Assembly on the work

surface so that the Desk Clamp hangs over

the edge.

Desk

Clamp

Clamp Pad

A3. Using the 5mm Allen Key, close the

Desk Clamp to grip the work surface.

Tighten very rmly.

The Clamp Pad will automatically

rotate under the work surface

when tightened.

TOP LOADING ATTACHMENT

TIP: When sliding the Desk Clamp

between two work surfaces, ensure

that the Clamp Pad is fully open

and parallel with the edge of the

work surface.

Min. gap=18mm

TIGHTEN VERY

(clockwise)

(0.71”)

Work Surface

(top view)

FIRMLY

Remove and re-install the Desk Clamp, using

the 5mm Allen Key supplied. Then go to A2.

NOTE: The unique top loading Desk Clamp allows product installation/removal

without having to gain access to the underside of the work surface.

A4. Desk Clamp is now installed, please skip to Step 3 (PTO>>>).

Page 2

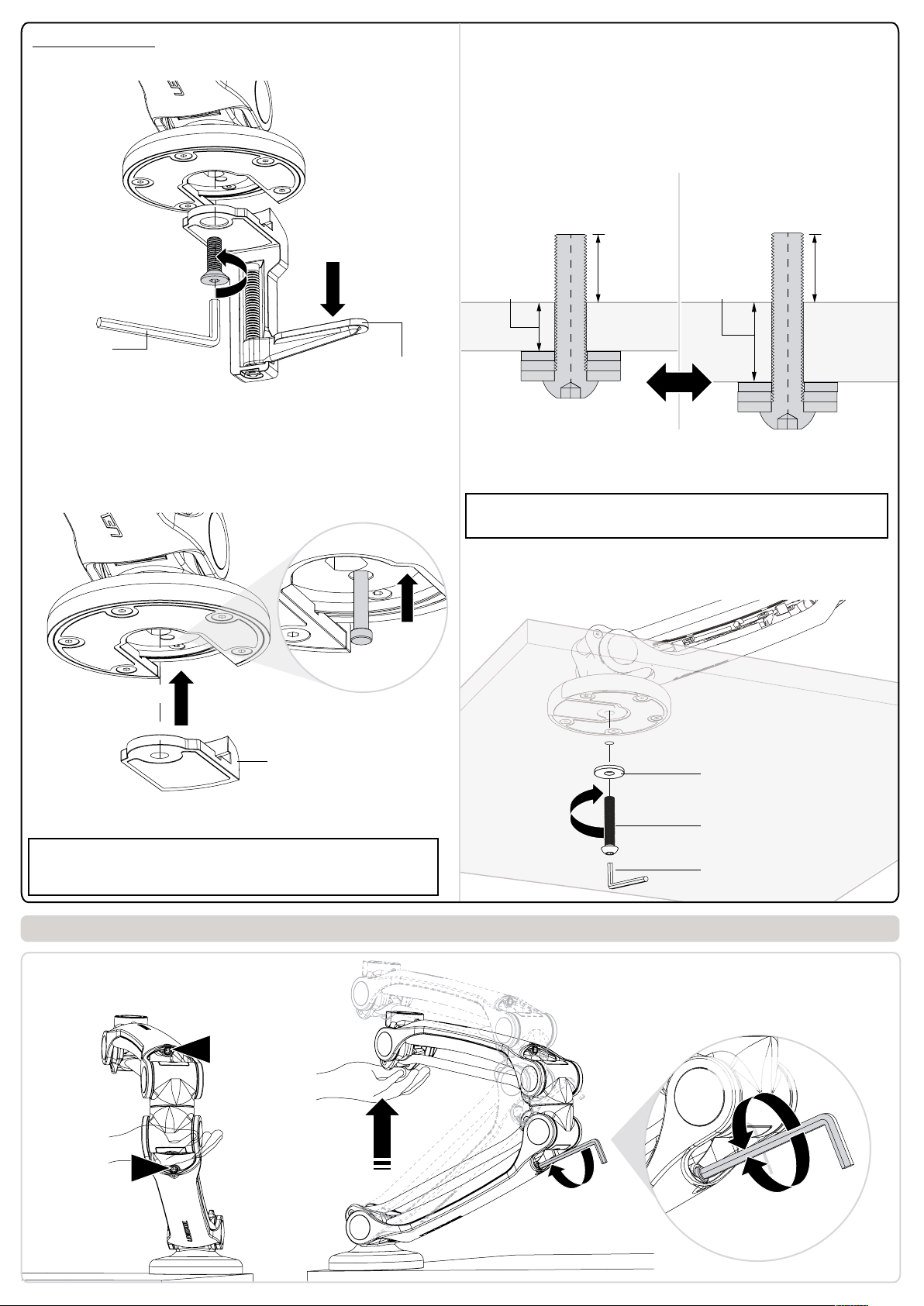

B - BOLT THROUGH

B1. Remove the Desk Clamp using the 5mm Allen Key supplied.

B4. Drill an 8mm (

5

/16”) hole through the work surface where you

want the centre of the base to be.

NOTE: The hole should be at least 55mm (2.17”) from any work

surface edge to allow for the diameter of the base.

B5. Select the appropriate length bolt, 45mm or 60mm

depending on the work surface thickness.

SHORT (45mm) suits work

surface thickness between

14-28mm

(0.5”-1.1”).

LONG (60mm) suits work

surface thickness between

29-43mm (1.1”-1.7”).

REMOVE

PUSH

(anti-clockwise)

5mm

Allen Key

Desk Clamp

The default base setup allows 360° of rotation of the Lower Arm

around the base. If you want to limit the Lower Arm rotation to

180° go to B2, if not skip to B3.

B2. OPTIONAL 180° ROTATION

To limit the Lower Arm rotation to 180° insert the Brake Pin (as

shown below). Then go to B3.

PUSH

Insert

Brake Pin

Max.

28mm (1.1”)

Min.

14mm (0.5”)

Max.

25mm (1”)

Min.

17mm (0.7”)

Max.

43mm (1.7”)

Min.

29mm (1.1”)

Max.

25mm (1”)

Min.

17mm (0.7”)

OR

Use 1,2, or 3 Bolt Through Washers to provide a thread length of

17mm minimum to 25mm maximum (0.7”-1”) protruding above

the work surface.

TIP: For work surfaces thicker than 43mm

can be purchased from hardware stores.

B6. Align the centre of the base over the pre-drilled hole.

Using the hardware selected in B5 fasten the base to the work

surface.

(1.7”), longer M8 bolts

Base Plate

B3. Install the Base Plate to replace the Desk Clamp

(no screw required).

TIP: To correctly insert the Brake Pin, so that the head of the Brake

Pin is ush, the base and Lower Arm must be aligned as shown

above.

Step 3. Tighten Tension Bolts

1. Lift and support the weight of the Upper

and Lower Arms.

Upper Arm

Tension Bolt

Lower Arm

Tension Bolt

TIGHTEN

FIRMLY

(clockwise)

Bolt Through

Washer

45mm or

60mm Bolt

5mm Allen Key

2. Using the 5mm Allen Key supplied, tighten

the Upper and Lower Arm Tension Bolts until

the Arm Assembly supports its own weight.

LESS TENSION

(anti-clockwise)

MORE TENSION

(clockwise)

Page 3

Step 4. Attach Mounting Head to Monitor

1. Select appropriate Display Mounting Screws from hardware ‘BAG B’ to suit the

monitor, and fasten the Mounting Head to the back of the monitor.

Back of Monitor

TOP OF

MONITOR

Display Mounting

Mounting Head

Mounting Hole

2. Push the Cover Plate over the

Mounting Head.

Press rmly around the inside edge

until you hear a ‘CLICK’.

Screws (x4)

Recessed Mounting Holes or

Display with a Curved R ear P ane l

Display Mounting

Screws (x4)

Spacer Bush (x4)

Mounting Hole

If the Mounting Holes are recessed into the

back of the monitor, or the monitor has

a curved rear panel, use the Spacer Bushes

supplied to pack the Mounting Holes.

PUSHPUSH

Cover Plate

Back of Monitor

Step 5. Attach Monitor onto Arm Assembly (How do I remove the Monitor? See nal page for help)

1. Align and locate the Mounting Head onto the Quick Release

coupling.

Mounting Head

Quick Release

Coupling

2. Once the Mounting Head is in position, press in the WHITE

outer button to lock in place. Listen for ‘CLICK’.

NOTE: To unlock and remove the monitor, refer to instructions

on the nal page.

PUSH

TO LOCK

Press in WHITE

outer button

4. Choose SECURITY SCREW OR HEAD CAP option.

SECURITY SCREW

Security

Security

DO NOT

OVERTIGHTEN

TIP: When inserting the Security Washer ensure that the

thicker side is towards the monitor, so that it follows the

contour of the Mounting Head.

HEAD CAP

MORE TENSION

(clockwise)

3. If necessary adjust the swivel tension to increase head

stability. Use the 2mm Allen Key supplied.

2mm Allen

Key

MORE TENSION

(clockwise)

LESS TENSION

(anti-clockwise)

PUSH

Head Cap

TIP: When inserting the Head Cap ensure that the thicker

side is towards the monitor, so that it follows the contour of

the Mounting Head.

Page 4

Step 6. Adjust Spring Assistance

Upper Arm

Upper Arm

Tension Bolt

Lower Arm

Tension Bolt

Lower Arm

TIP: FOR MULTIPLE INSTALLATIONS ONLY.

When tensioning the Upper and Lower Arms take

note of the Visual Gauge on each arm.

This will help when installing multiple Levitate

products supporting the same weight monitors.

Starting with the Lower Arm, tighten the Tension Bolt until the arm comfortably holds its

position wherever it is moved.

Once satised, repeat the process for the Upper Arm.

MORE TENSION

(clockwise)

TIP: DO NOT OVER TENSION.

Both arms should move freely, and support

the weight of the monitor in any position.

LESS

TENSION

(anti-clockwise)

Visual Gauge

Step 7. Cable Management (How do I remove Cable Covers? See nal page for help)

1. Position the Arm Assembly for MAXIMUM

REACH OR COMPACT use depending on your

monitor requirements.

MAXIMUM REACH COMPACT

2. Route cables along the length of the Arm

Assembly and connect to the monitor.

TIP: Leave enough slack in the cables to

allow full movement at the joints.

TIP: If cable plugs are too big to t through

the joints, route the cables on the outside.

3. Push cables under retaining clips on the Upper and Lower

Arms to hold the cables in position.

OR

4. Install Cable Covers on both sides of the Upper and Lower

Arms.

PUSH

A

B

TIP: If necessary gently ex clips

A and C to hold the cable.

C

NOTE: The Cable Covers are dierent for left and right sides.

PUSH

Page 5

Step 8. Monitor Orientation

1. Rotate the monitor to Portrait or Landscape position

depending on user requirements.

NOTE: The monitor will only rotate 90° clockwise from

the starting position (when facing the screen).

2. Tilt the monitor up or down to suit the user.

TIP: Depending on the weight of the monitor, make

adjustments to the tilt tension using the 5mm Allen

Key if necessary.

5mm Allen

Key

MORE TENSION

(clockwise)

LESS TENSION

(anti-clockwise)

Upward/

Downward Tilt

Portrait/

Landscape

Rotation

INSTALLATION COMPLETE - Refer to the User Operator Guide for user adjustments

Page 6

How to remove the Monitor

1. If you inserted the Security Screw in Step 5, remove it

using a Phillips head screwdriver.

REMOVE

(anti-clockwise)

2. If you tightened the swivel tension in Step 5, loosen the

screw (do not remove) using the 2mm Allen Key supplied.

2mm Allen

Key

3. Unlock the Quick Release coupling (as shown below), and lift

the Monitor away from the Arm Assembly.

LIFT

Mounting Head

Quick Release

Coupling

TO UNLOCK

Press in BLACK

inner button

NOTE: When you press in the black inner button, the white outer

button will pop out to indicate the lock has been disengaged.

LESS TENSION

(anti-clockwise)

How to remove Cable Covers

1. Using a paper clip or a ball point pen press in the

three tabs holding the Cable Cover in place.

A

B

TIP: Access the tabs through the three

pinholes nearest the Cable Cover you

want to remove (e.g. A,B,C).

2. Pull the Cable Cover away from the Arm. Repeat this

process for each Cable Cover.

C

REMOVE

No portion of this document or any artwork contained herein should be reproduced in any way without the express written consent of Atdec Pty

Ltd.

Loading...

Loading...