Page 1

Based on a powerful built-in microcomputer, the compact 366 is the most

versatile and cost-effective counter ATC has ever built. No industrial counter has

ever achieved a higher level of reliability and ruggedness than the 366. It has

no moving parts in its electronic logic circuits, only plug-in circuit boards which

are computer-tested for reliability and assembled virtually without hand wiring.

Its few mechanical components have been selected for reliable service; long

life relays with heavy-duty contacts and rotary set point selector switches with

extremely low wear characteristics.

CONTACT BOUNCE AND NOISE IMMUNITY: No industrial counter of-

fers greater immunity to noise and contact bounce than the 366. Most

noise encountered in typical industrial environments is blocked by such

design features as full-wave bridges and a transformer power supply... so

effectively that the 366 does not have to be shielded. Furthermore the

366’s microcomputer employs redundant sampling logic to detect and

reject any noise pulse that manages to penetrate its defenses. Through

the same powerful technique, the microcomputer also detects and rejects

even severe contact bounce. As a result, the 366 maintains absolute count

accuracy and is virtually immune to false starts and reset, even in difficult

industrial environments.

COMPUTATION: Through its internal microcomputer, the 366 keeps

track of the set point throughout the count cycle. Whenever there is

a change in set point, even during a cycle, it instantly recomputes the

remaining count and accurately determines the number of counts

before count-out. This unique capability is especially valuable in the count-

down modes as it allows you to shorten or lengthen a cycle

without loss of accuracy.

PROGRAMMABLE DISPLAY: The 366’s three-digit cycle progress display

will count UP to or DOWN from the set point, depending on the position

of an internal jumper. After count-out, the display will either STOP or GO.

In the UP & GO program, the display counts up to the set point and

continues to count after count-out; in the DOWN & GO mode, it counts

down to the set point, then begins to count up (from zero) after count-out.

WIDE RANGE: Each 366 Long-Ranger covers the overall span of 1 to

99,900 counts in three switch-selected ranges of 1 to 999, 10 to 9990

or 12 to 99,900. It can be optimized within any selected range simply by

removing appropriate selector knobs (e.g. with the counter in the 1 to

999 range, you can obtain a tamper-proof span of 1 to 99 by setting the

left selector at 0 and removing the knob.) To the right of the three-digit

display, a counting bar ( ) blinks on each time a pulse is received.

At left, a marker ( )turns on when the delayed relay is energized at

count-out.

SELF-DIAGNOSTICS: A built-in diagnostic program lets you verify—

without using any test instrument--that the counter’s functional circuits

are operating properly. Just follow the instructions on the flip-up card,

using the counter’s own display for the test readout. If all self-test

displays are correct, any malfunction is almost certainly due to

external circuits or to the relays, not the counter.

COMPACT, PLUG-IN AND DUST-TIGHT: Packaged in a 72mm2 DIN housing,

the 366 occupies 40% less panel space than most other industrial coun-

ters. It is a true plug-in counter that can be replaced in seconds without

disturbing housing or wiring. The 366 is also fully gasketed and O ring

sealed to be dust and water-tight whether panel or surface-mounted.

POSITIVE RESET TIME AND PULSE LENGTH: Digitally clocked by the

microcomputer, the 366’s reset time is consistently of the same duration,

regardless of variations in line voltage, power supply or cycle length.

When the 366 operates in repeat-cycle mode, the output pulse is also

digitally clocked so that both the time of occurrence and its duration are

consistent from cycle to cycle.

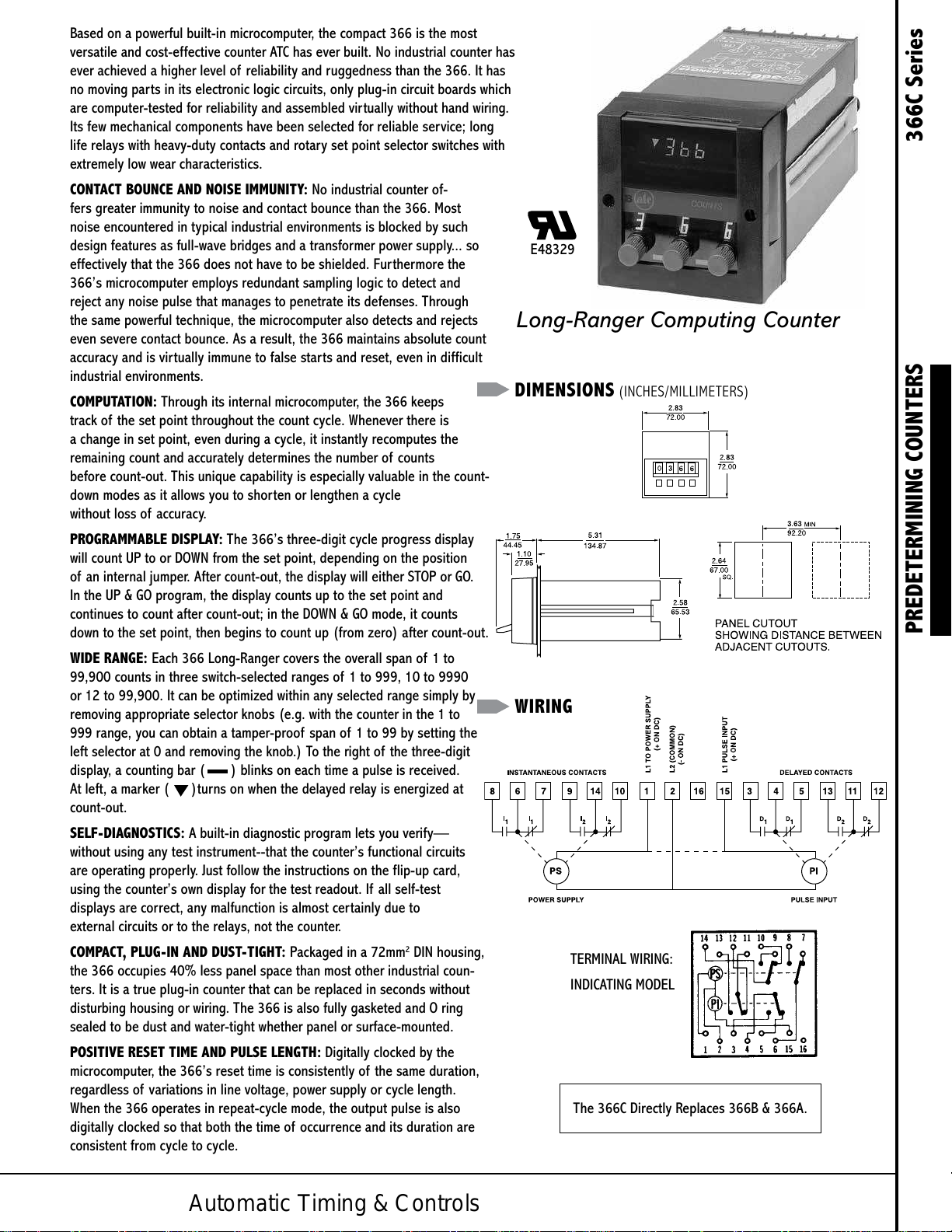

E48329

Long-Ranger Computing Counter

DIMENSIONS (INCHES/MILLIMETERS)

PREDETERMINING COUNTERS 366C Series

WIRING

TERMINAL WIRING:

INDICATING MODEL

The 366C Directly Replaces 366B & 366A.

Automatic Timing & Controls

Page 2

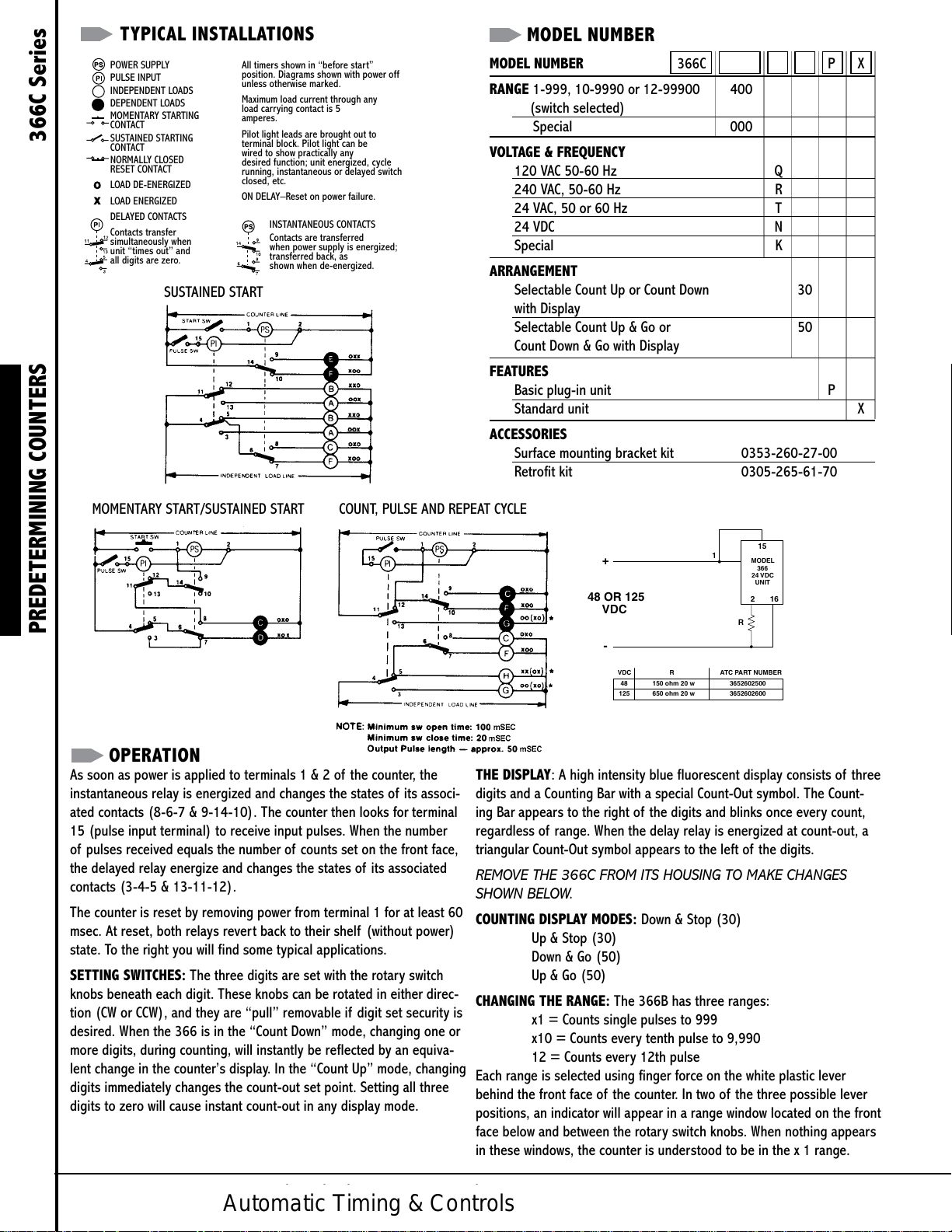

TYPICAL INSTALLATIONS

48 OR 125

NUMBER

MODEL NUMBER

POWER SUPPLY

PULSE INPUT

INDEPENDENT LOADS

DEPENDENT LOADS

MOMENTARY STARTING

CONTACT

SUSTAINED STARTING

CONTACT

NORMALLY CLOSED

RESET CONTACT

LOAD DE-ENERGIZED

LOAD ENERGIZED

DELAYED CONTACTS

Contacts transfer

simultaneously when

unit “times out” and

all digits are zero.

SUSTAINED START

All timers shown in “before star t”

position. Diagrams shown with power off

unless otherwise marked.

Maximum load current through any

load carrying contact is 5

amperes.

Pilot light leads are brought out to

terminal block. Pilot light can be

wired to show practically any

desired function; unit energized, cycle

running, instantaneous or delayed switch

closed, etc.

ON DELAY–Reset on power failure.

INSTANTANEOUS CONTACTS

Contacts are transferred

when power supply is energized;

transferred back, as

shown when de-energized.

MODEL NUMBER 366C P X

RANGE 1-999, 10-9990 or 12-99900 400

(switch selected)

Special 000

VOLTAGE & FREQUENCY

120 VAC 50-60 Hz Q

240 VAC, 50-60 Hz R

24 VAC, 50 or 60 Hz T

24 VDC N

Special K

ARRANGEMENT

Selectable Count Up or Count Down 30

with Display

Selectable Count Up & Go or 50

Count Down & Go with Display

FEATURES

Basic plug-in unit P

Standard unit X

ACCESSORIES

Surface mounting bracket kit 0353-260-27-00

Retrofit kit 0305-265-61-70

MOMENTARY START/SUSTAINED START COUNT, PULSE AND REPEAT CYCLE

PREDETERMINING COUNTERS 366C Series

OPERATION

As soon as power is applied to terminals 1 & 2 of the counter, the

instantaneous relay is energized and changes the states of its associ-

ated contacts (8-6-7 & 9-14-10). The counter then looks for terminal

15 (pulse input terminal) to receive input pulses. When the number

of pulses received equals the number of counts set on the front face,

the delayed relay energize and changes the states of its associated

contacts (3-4-5 & 13-11-12).

The counter is reset by removing power from terminal 1 for at least 60

msec. At reset, both relays rever t back to their shelf (without power)

state. To the right you will find some typical applications.

SETTING SWITCHES: The three digits are set with the rotary switch

knobs beneath each digit. These knobs can be rotated in either direc-

tion (CW or CCW), and they are “pull” removable if digit set security is

desired. When the 366 is in the “Count Down” mode, changing one or

more digits, during counting, will instantly be reflected by an equiva-

lent change in the counter’s display. In the “Count Up” mode, changing

digits immediately changes the count-out set point. Setting all three

digits to zero will cause instant count-out in any display mode.

15

1

+

VDC

-

VDC RATC PART

48 150 ohm 20 w

650 ohm 20 w

MODEL

24 VDC

R

3652602500

3652602600125

366

UNIT

162

THE DISPLAY: A high intensity blue fluorescent display consists of three

digits and a Counting Bar with a special Count-Out symbol. The Count-

ing Bar appears to the right of the digits and blinks once every count,

regardless of range. When the delay relay is energized at count-out, a

triangular Count-Out symbol appears to the left of the digits.

REMOVE THE 366C FROM ITS HOUSING TO MAKE CHANGES

SHOWN BELOW.

COUNTING DISPLAY MODES: Down & Stop (30)

Up & Stop (30)

Down & Go (50)

Up & Go (50)

CHANGING THE RANGE: The 366B has three ranges:

x1 = Counts single pulses to 999

x10 = Counts every tenth pulse to 9,990

12 = Counts every 12th pulse

Each range is selected using finger force on the white plastic lever

behind the front face of the counter. In two of the three possible lever

positions, an indicator will appear in a range window located on the front

face below and between the rotary switch knobs. When nothing appears

in these windows, the counter is understood to be in the x 1 range.

Automatic Timing & Controls

Automatic Timing & Controls

Page 3

SPECIFICATIONS

MODELS Display model only for operation at 120, 240 or

24 VAC; and 24 VDC. Unit counts on break

(i.e. when count input switch opens). Unit operates

in on delay mode only.

RANGE Switch-selectable ranges of 1 to 999, 10 to

9990, and 12 to 99900.

REPEAT 100% (+0 count on all ranges)

ACCURACY

RESET TIME Clocked at 40 mSEC

COUNT INPUT AC

Max. count rate 1000/MIN

(symmetrical input)

Min. pulse on time 20 mSEC

Min. pulse off time 30 mSEC

DC

Max. count rate 2000/MIN

(symmetrical input)

Min. Pulse on time 15 mSEC

Min. Pulse off time 15 mSEC

Bounce Immunity 5 mSEC

(max. bounce open time)

Pulse Contact 10 mA at line voltage

Requirement

COUNT Single Cycle interval or delayed

CONTROL MODES Repeat Cycle pulse (occurrence and

duration 50 mSEC clocked)

DISPLAY Cycle Progress 3-digit display, 0.3 inch, high-

intensity, blue programmable

modes: DOWN & STOP, DOWN &

GO, UP & STOP or UP & GO.

Count-Out display; energized at

count-out

Counting Bar display; blinks on when count

switch is closed, when pulse is

received

HOUSING 72mm2 DIN size; plug-in design; fully gasketed,

dust and water-tight in panel mounted installations.

NEMA 4 when mounted per installation instructions.

TERMINALS 16 screw terminals accessible at rear;

integral wiring diagram.

COUNT INPUT Voltage Model

120 VAC Model Turn On 60V 3.5 mA (nom.)

Turn Off 30V 2.4 mA (nom.)

10 mA max. current at 120V

240 VAC Model Turn On 120V 3.5 mA (nom.)

Turn Off 60V 2.4 mA (nom.)

10 mA max. current at 240V

24 VAC Model Turn On 12V 9.5mA (nom.)

Turn Off 4V 3.8 mA (nom.)

30 mA max. current at 24V

24 VDC Model Turn On 15 VDC 2.5 mA (nom.)

Turn Off 3 VDC .5 mA (nom.)

5 mA max. current at 24V

LOAD RELAY Number one instantaneous and one

delayed

Type DPDT, Form C

Operate Time 13 ms, max.

Release Time Time 10 ms, max.

Contact Ratings 7A at 120, 240 or 24 VAC, 1/6

HP. 3A at 24 VDC, 1.5A at 48

VDC, 0.5A at 125 VDC.

LIFE 100 million operations

(no load)

POWER 120V 95 to 132V, 50/60 Hz

inrush–0.3A

running–0.06A at 120 VAC

240V 190 to 264V, 50/60 Hz

inrush–0.15A

running–0.03A at 240 VAC

24 VAC 19.2 - 26.4 VAC, 50 or 60 Hz

Inrush–1 A

Running–0.25 A at 24 VAC

24 VDC 19.2 - 26.4 VDC, 5% ripple

Running - .120 A at 24 VDC

TEMPERATURE 32 to 122°F (0 to 50°C)

RATING

MOUNTING Standard hardware is provided for

front-of-panel mounting.

Optional Surface-mounting brackets

with front-facing terminals

NEMA 12 molded case (1 counter)

NEMA 1 steel case (2 counters)

WEIGHT NET: AC - 1 lb., 6oz. DC - 10 oz.

SHIPPING: AC - 2 lbs., DC - 1 lb., 4 oz.

PREDETERMINING COUNTERS 366C Series

Powered by TCPDF (www.tcpdf.org)Powered by TCPDF (www.tcpdf.org)Powered by TCPDF (www.tcpdf.org)

Powered by TCPDF (www.tcpdf.org)Powered by TCPDF (www.tcpdf.org)

Automatic Timing & Controls

Loading...

Loading...