Page 1

AT 8000 Series fast installation guide

Installation steps:

Step 1: Check components

Welcome to AT 8000 Series

Tire Pressure Monitoring

System (TPMS). This Fast

installation Guide is intended

to give you a fast overview of

the key steps required to

install your AT 8000 Serial

TPMS. For more detailed

information, please refer to the

8000 Serial TPMS Installation

Guide.

Step 5: Installing one sensor into wheel

Please get help from professional tire shops if necessary.

1. Remove the wheel

from vehicle,

Deflate, and

separate rim and

tire.

2. Fix sensor on rim.

3. Assemble rim and

tire, inflate to

typical pressures.

4. Balance wheel and

install to vehicle.

5. Use receiver to

search ID of this

wheel again, and

assign this ID to

the position

respect to this tire

installation. Make

sure that the

sensor inside tire

was keeping work

well.

Steps 6: Continue to install all other sensors with

the same procedure.

Install all tires to the right positions of vehicle. Using

receiver to search and assign all IDs to correct

position respect to tire installation.

Steps 7: Setup pressure and temperature

thresholds according to tire type.

Step 2: Check identification number

Each sensor should be

assigned a unique

identification number

(ID), which was marked

on the top of sensor.

Step 3: Enable and Test

sensors before installing

To enable a sensor, it is

only needed to pull out

the jumper attached on

sensor. After successfully

enabled, sensor will start

to measure environment air pressure and temperature and send them to

receiver.

Step 4: Set up the receiver

Plug the attached power cord into Receiver and insert the other terminal

to the cigarette electrical socket of vehicle. You can adjust parameters

of receiver according to your requirement.

Only the first two and last four digitals of ID will show on panel

of receiver, for example, if ID is 34125678, only345678 will be

shown.

Do not mix up each tire’s ID, or the detected tire parameter

may not be correct!

It is easy to identify each tier’s ID by changing its pressure

(slightly deflate) and monitor the receiver for checking this

pressure variation and tire position.

Check all recorded tire IDs by press Key 1. Each single press on

Key 1 can call one tire parameters out, including temperature,

pressure, and identification code. Continually press on Key 1 can

read tire parameters one by one.

Key1 Key2 Key3 Key4

Typical torque of new valve nut is 3~5 N-m(30~50 kgf-cm).

In order to guarantee sealing, be sure that the rubber rings are

properly positioned between rim and valve.

Valve nut

Page 2

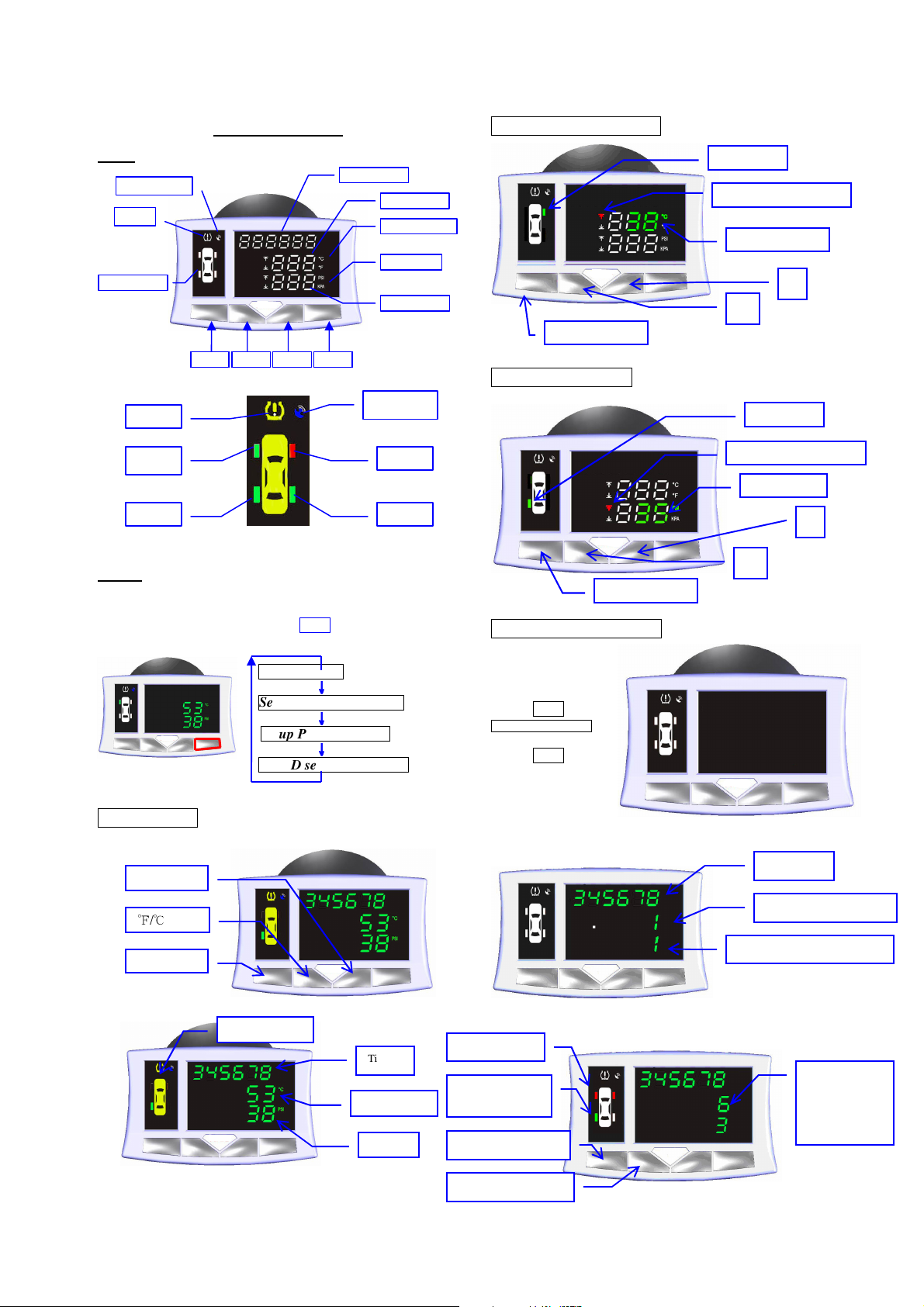

Receiver Setting

Key 1 Key 2 Key 4

N

umeric row 1

N

umeric row 2

N

umeric row 3

Status displayer

Temperature unit

Pressure unit

Alarm

Receive Status

Key 3

Alarm

Tire 1

Tire 4

RF Symbol

Tire 2

Tire 3

℉/℃

Select

tire

Temperature

Pressure

Select tuning item

+

-

Setting tire

High/Low limit indication

Temperature limit

PSI/KPA

Setting tire

High/Low limit indication

Pressure limit

-

+

Select

tuning item

2

1

Panel

Modes

In order to integrate friendly operation interface and powerful parameter

adjusting function, AT8000 contains four major operation modes, and it

is easy to switch between them by press Key 4 over 0.5 second:

Working mode

Key functions:

Display

Working mode

Setup Temperature limits

Setup Pressure limits

Tire ID search and assign

Graphic display

↓↓↓↓

↓↓↓↓

↓↓↓↓

Tire ID

Setup Temperature limits

Setup Pressure limits

Tire ID search and assign

Step 1:

ID search mode by:

1. Press Key 4 into

Tire ID search and assign

mode.

2. Press Key 1

confirm to search.

Switch into

Step 2:

Step 3:

ID assigned Tire

Selected Tire for

assigning

Press to assign ID

Select Tire to assign ID

Waiting for ID search

Assign searched ID to exact position

2

1

2

1

Selected ID

One ID had been searched

First received ID was selected

Select ID from

ID buffer.

The third of six

ID.

Page 3

FCC Notice:

Notice : The changes or modifications not expressly approved by the party responsible

for compliance could void the user’s aut hority to operate the equipment.

IMPORTANT NOTE: To comply with the FCC RF exposure compliance requirements, no change

to the antenna or the device is permitted. Any change to the antenna or the

device could result in the device exceeding the RF exposure requirements

and void user’s authority to operate the device.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) this device may not cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause undesired operation.

910805

2

Loading...

Loading...