Page 1

Installation Guide

TM

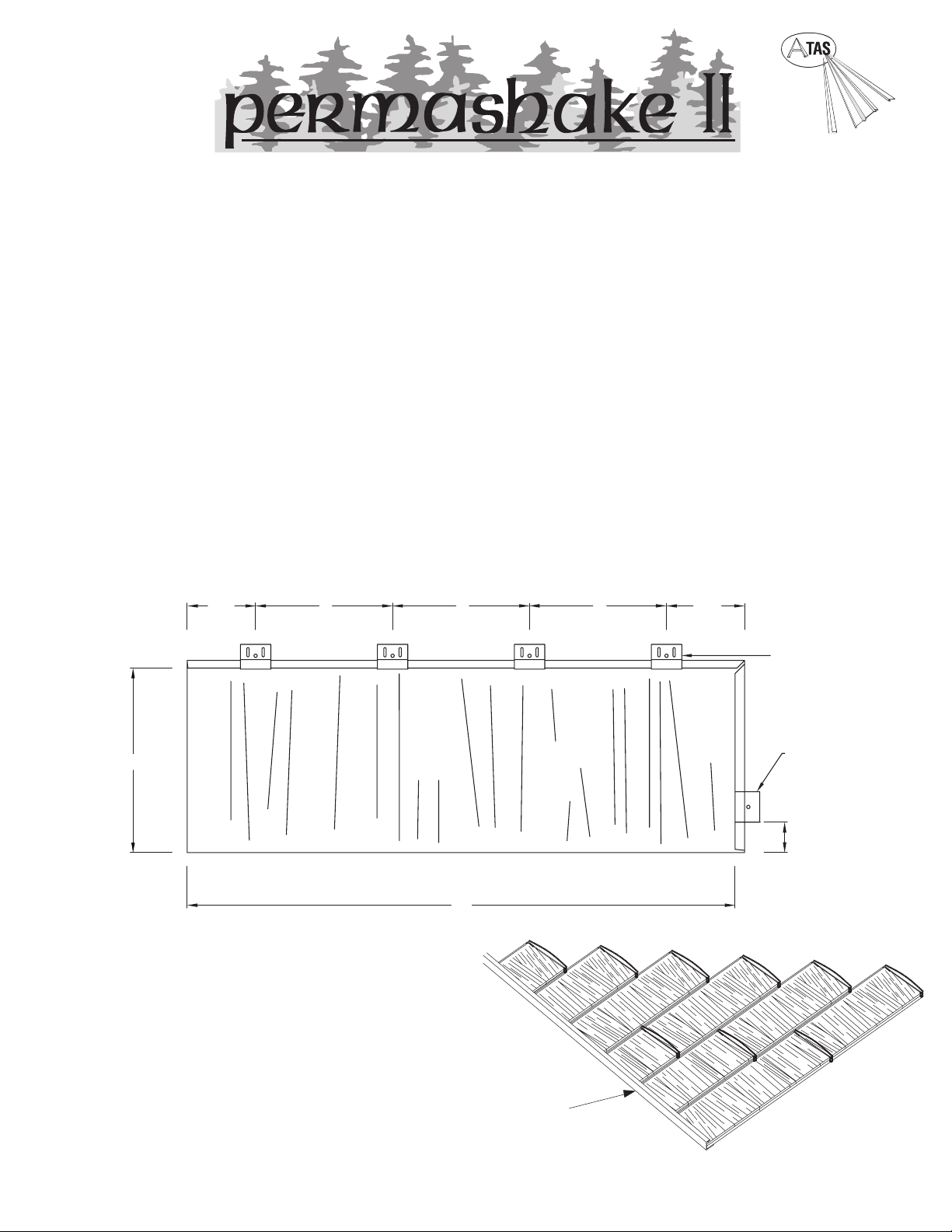

CHANNEL TRIM

TOP CLIPS

SIDE CLIP

4 ½”

9”

9” 9” 4 ½”

12”

36”

2”

ATAS International, Inc.

www.atas.com/permashakeII

484.221.6375

Review and understand complete guide before beginning

installation. This guide has been prepared as suggested

details to particular design conditions. Each condition has

certain limitations to performance, aesthetics or economics.

Professionals qualified to assess this information for a

specific project should determine that the selection and

installation are made to their requirements.

ATAS cannot assume any responsibility for the actual

selection, use and/or installation of materials. The panels,

flashings and trim shown in the guide, illustrated over a

solid and plumb substrate, assume that the structure has

been designed and prepared in accordance with local

building codes. Care should be taken during installation

not to damage panels and finish. May void product

warranty.

Published panel width dimensions are to be considered as

nominal dimensions. Variations in overall coverage may

occur at installation due to typical manipulation of panels

during attachment to the roof assembly.

Permashake II panels are simulated wood shakes

manufactured from 29 gauge steel with a Kynar 500® PVDF

or Hylar 5000® PVDF nish. They are available in 6 colors.

Panel coverage is 12” x 36”. Minimum recommended roof

pitch is 4:12.

There are twelve (12) Permashake II panels packaged per

carton. Approximately thirty-four (34) panels equal a square.

Panels are always installed left to right and should have a

minimum of four (4) top anchor clips and one (1) side anchor

clip.

PANEL INSTALLATION - In environments where ice and

water may dam, apply self-adhered roong underlayment in

accordance with local building codes. Then apply appropriate

underlayment over balance of roof. Snap a vertical and

horizontal line to square up the plane with the eave. Start

at the bottom left hand corner of the roof plane with a full

length panel. Install shingles in a left to right manner from

eave to ridge. See right for stagger method of installation.

Fasten panels to solid substrate with galvanized steel clips.

Manufacturer recommends the use of exterior grade #10-16 x

1 ½” wafer head screws.

STAGGER METHOD

Each course 12” to the left of the lower course.

Page 2

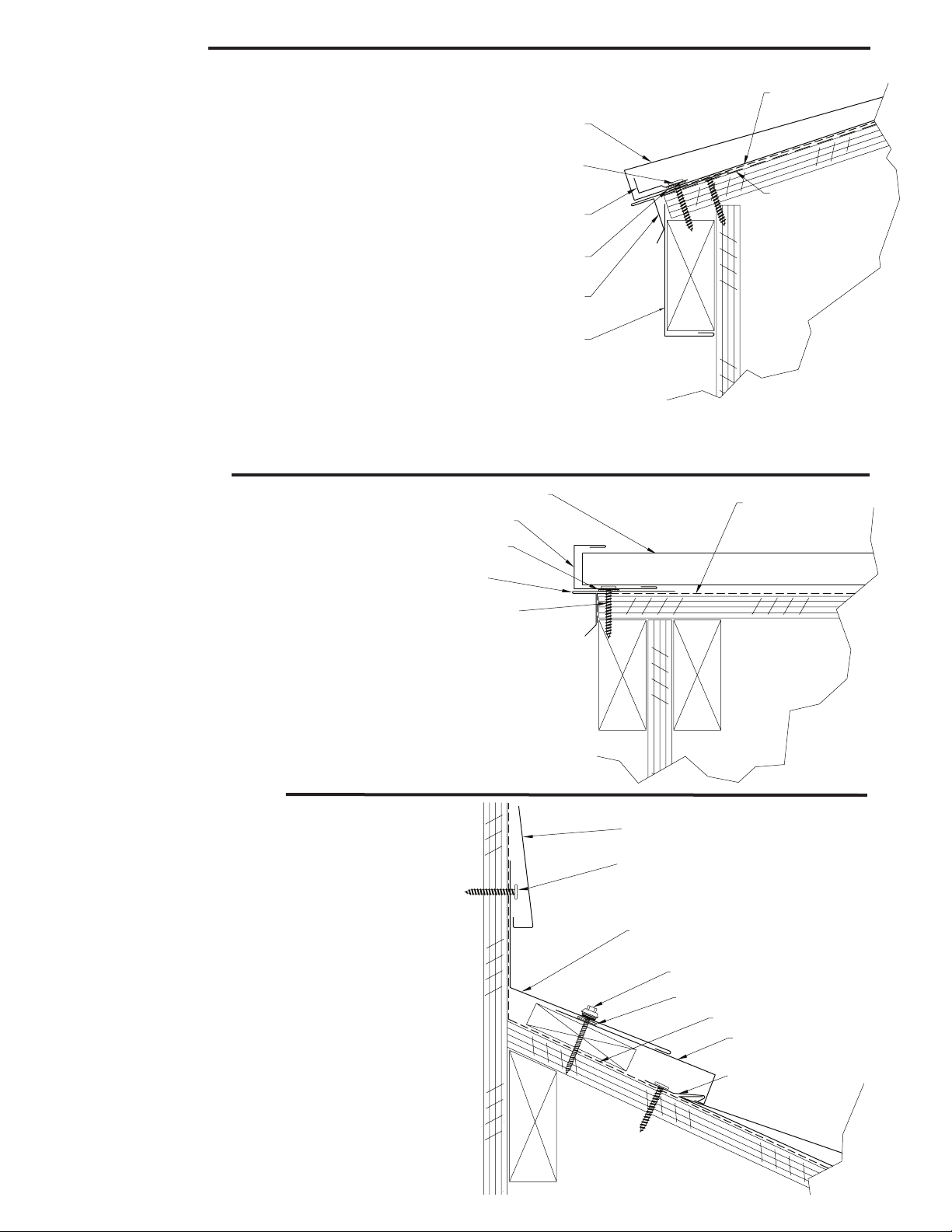

Eave Detail

WALL COVERING

BUTYL TAPE

ANCHOR CLIP

PERMASHAKE II PANEL

UNDERLAYMENT

2" HEX HEAD SCREW

HEADWALL TRIM

APPROPRIATE FASTENER

SELF-ADHERED

ROOFING

UNDERLAYMENT

FASCIA

DRIP EDGE

BUTYL TAPE

1 ½" WAFER HEAD SCREW

STARTER CLEAT

PERMASHAKE II PANEL

UNDERLAYMENT

UNDERLAYMENT

1 ½" WAFER

HEAD SCREW

DRIP EDGE

BUTYL TAPE

PERMASHAKE II PANEL

CHANNEL TRIM

1. When applying a re-roof application, cut back existing

shingles and drip edge as required to apply appropriate

underlaments.

2. Apply self-adhered roofing underlayment on roof deck

areas where ice & water damming can occur. Extend this

underlayment over fascia board. Install drip edge as tight as

possible against the fascia trim. Space fasteners at maximum

of 12” o.c. Overlap eave trim pieces a minimum of 3”.

3. Lay full width of underlayment (roofing felt or equivalent)

on top of the drip edge. Apply butyl tape on top of drip edge

and fasten starter cleat through butyl tape and eave trim into

substrate with front face up as shown at right.

4. Install panel only after the gable closure is installed (see

below). Install by sliding lower flanged edge between starter

cleat and drip edge. Square the panel in the J channel at the

gable edge and fasten with clips and exterior grade #10-16 x

1 ½” wafer head screws.

Gable Detail

1. Install drip edge over underlayment. Overlap on

top of drip edge at the eave.

2. Apply butyl tape along drip edge as shown to

the right. Lay the channel trim along the gable

edge. Overlap channel at a minimum of 2” to 4”

working upward from the eave. Fasten channel as

shown at right.

3. Align the first shingle into the J channel and

snap a line across the roof plane. (See panel

installation section)

Headwall Detail

1. Install metal shingles up to the headwall. Shim the last

row of panels if necessary as shown at right.

2. Lay headwall trim over the shingles while insuring that the

vertical section is flush against the headwall. Use double

sided butyl tape between the panel and trim assemblies.

3. Fasten through butyl tape and shingle into solid substrate.

Use #10 x 2” long gimlet point screw with 5/16” cast zinc

color matched hex washer head and EPDM washer at 24” o.c.

4. Apply wall covering over the headwall trim as required, or

install wall paneling.

1

2

Exterior grade #10-16 x 1 ½” wafer head screw

#10 x 2” long gimlet point screw with 5/16” cast zinc color matched hex washer head and EPDM washer

Page 3

Hip & Ridge Detail

CUT AND FOLD PANEL EDGE

IN VALLEY TO CLOSE END.

POP RIVET

SELF-ADHERED ROOFING

UNDERLAYMENT

VALLEY PAN

UNDERLAYMENT

ANCHOR CLIP

1 ½" WAFER HEAD SCREW

PERMASHAKE II PANEL

RIDGE CAP BENT TO

REQUIRED ANGLE AND TWO

INTERLOCKING TABS BENT UP

FOR CLIP ATTACHMENT.

(HIP CAP SIMILAR)

LOCATE CLIPS HERE

SHORT RIDGE

CAP PIECES

CHANNEL TRIM

PERMASHAKE II PANEL

PREVAILING WIND

DIRECTION

LAP

START APPLYING

RIDGE CAP SHINGLE

AT THIS END

SHORT HIP CAP PIECES

PANELS CUT

TO MEET AT

HIP LINE

HIP LINE

UNDERLAYMEN

T

Hip and ridge applications are handled in

the same manner.

1. Install roof panels to meet at hip or

ridge. (Depending on roof geometry

and run of roof, the top panel may have

to be cut along the length of panel.)

2. Lay a 6” strip of closure tape across

panels at hip/ridge line.

3. Lay cap on roof and secure the cap

with clips and screws, (2) per piece.

Ridge caps can accommodate standard

ridge venting products. Refer to venting

manufacturer's instructions and local

building code requirements.

Note: For hip applications, fasten the caps

with clips at the high point on the shingle

in order to avoid dimpling, and make sure

the clip and screw penetrates the cap

through the closure into the solid

substrate.

Valley Detail

1. Install self-adhered roofing underlayment

18” up both sides of the valley line.

2. Install the valley pan and clip fasten

through the substrate at 24” o.c.

3. Measure required panel to length to come

within 3” of center of valley.

4. Cut and fold panel on diagonal to create a

solid end and fasten with stainless steel color

matched pop rivet to hold in place.

5. Lay shingles onto the valley pan

maintaining at least 3” clearance from the

valley’s center and fasten with clips outside

the valley pan.

1

Exterior grade #10-16 x 1 ½” wafer head screw

2

#10 x 2” long gimlet point screw with 5/16” cast zinc color matched hex washer head and EPDM washer

Page 4

Shed Ridge Detail

WALL COVERING

SELF-ADHERED ROOFING

UNDERLAYMENT

PERMASHAKE II PANEL

SIDEWALL CAP

STEP FLASHING

APPROPRIATE FASTENER

UNDERLAYMENT

2" HEX HEAD SCREW

SHED RIDGE

PERMASHAKE II PANEL

1 ½" WAFER HEAD SCREW

ANCHOR CLIP

SHIM

Sidewall Detail

1. Install metal shingles up to the shed ridge peak.

Shim panels if necessary as shown at left.

2. Place double sided butyl tape just inside hem of

Shed Ridge Trim. Fit trim to peak. Fasten through tape

and shingle into solid substrate. Use #10 x 2” long

gimlet point screw with ⁄” cast zinc hex washer head

and EPDM washer at 24” o.c.

3. Fasten Shed Ridge Peak Trim to fascia with #10 x 2”

long gimlet point screw with ⁄” cast zinc color

matched hex washer head and EPDM washer at 24” o.c.

1. Install self-adhered roofing underlayment along roof plane

and up sidewall.

2. Install step flashing tight against the sidewall.

3. Install the panel up to the wall. Fasten the panel clip as close

to the wall as possible without penetrating the step flashing.

4. Install the sidewall flashing and fasten in place.

5. If the wall treatment is siding, it should lay over the sidewall

trim. If brick or stucco, a reglet should be used with counter

flashing to seal. Be sure to seal reglet.

Note: Step flashing is designed to drain at the eave. The panel

that is attached to the eave at the gable end should be notched

to allow water to drain out.

Note Regarding Trim Details

The application of flashing and trim requires a detailed approach. Consideration should be given to the roof’s geometry and the course it creates for water runoff. Location of gutters and the use of snow retention systems should also be considered. Proper planning regarding the sequence of material overlap is critical.

Sealants, such as butyl tape and tripolymers, should be used at overlapping trim edges, in conjunction with exposed fasteners and to seal flashings. All fasteners

should be properly tightened and not over driven or at an angle. Fasteners that are too loose can “back out” over time. An over driven fastener may cause a

depression in the material, which becomes a collection point for standing water.

Basic Equipment Required:

Tie-off ropes, safety harness, long level, ladders,

scaffolding with approved planking, extension cords

with approved ground plugs and electrical services.

Additional Tools:

Metal folding tool, hammer, chalk line, measuring tape,

metal cutting tools - nibblers, drills, hacksaw, utility knife,

pop-rivet gun, caulking guns, layout and combination

square, C clamps, sheet metal shears (including RH, LH,

straight and overhand). Power driven screw gun with

proper bits, depth-setting nosepiece, variable speed.

Choose the correct equipment and tools to do the

job in a safe manner. Wear safety gear and follow

OHSA requirements.

1

Exterior grade #10-16 x 1 ½” wafer head screw 2 #10 x 2” long gimlet point screw with 5/16” cast zinc color matched hex washer head and EPDM washer

©2011 ATAS International, Inc. All rights reserved. PermashakeTM II is a trademark of ATAS International, Inc. ATAS reserves the right to modify, eliminate and/or change its products without prior notification. ATAS cannot assume any

responsibility for the actual selec tion, use and/or installation of materials. The structure should be designed and prepared in accordance with local building codes. Warr anty no t valid without registr ation. LRD0511 LAT089

Tools and Rules:

1. Never cut the panels with an abrasive cut-off wheel or torch, as this will damage the finish.

Follow these simple rules:

2. Do not weld the trim or panels.

3. Remove any small burrs left by cutting, screwing or drilling.

4. Remove protective masking immediately after trim and panels are installed.

5. Caution should be taken when handling the panels to prevent damage.

6. Use appropriate screws for the type of underlayment and long enough to fully penetrate and secure the panel.

7. The stored materials should be kept dry.

8. Do not cut on finished roof. Remove all drill spirals, chips and dust immediately.

9. Seal neoprene closures and soft cell foam by applying appropriate sealant to both surfaces.

10. Put appropriate sealant/butyl tape between overlapping trims.

11. Overlap trims in a manner not to impede the flow of water.

Loading...

Loading...