Page 1

Up-turned edge

Alignment mark

Alignment Point

Alignment

Point

Locking Ta b

Down-turned Edge

Pre-Punched

fastening holes

Locking Ta b

Connecting Area

15-3/4”

Expanded

Polystyrene

Backer Board

Installation Guide

Valley @

Dormer Area

Eave Line

8-3/8”

22-1/4”

Strike square horizontal chalk line

at shingle course as a “benchmark”

to work at opposite side of valley.

Horizontal chalk line

for first course

CastleTop is a diamond shaped at metal shingle. These shingles have a unique

locking feature that allow for easy installation. The overlapping shingles have a

turned down edge on the lower front and a turned up edge on the upper front.

The panel is 15 ¾” square, net coverage is 13 ⁄” x 13 ⁄”. There are approximately

78 shingles per 100 square feet. The CastleTop shingle is packed 39 shingles

per carton, which equates to approximately half of a square.

Review and understand

complete guide before

beginning installation.

This guide has been prepared

as suggested details to

particular design conditions.

Each condition has cer tain

limitations to per formance, aesthetics

or economics. Professionals qualified to assess the

information regarding suitability for a specific project

should determine that the selection and installation

are made to their requirements. ATAS cannot assume

any responsibility for the actual selection and/or

installation of materials. The panels, flashings and trim

shown in this guide, illustrated over solid and plumb

substrate, assume that the structure has been

designed and prepared in accordance with local

building codes.

Published panel width dimensions are to be considered as nominal dimensions. Overall panel

width dimensions may vary during installation due to adjustments to accommodate as built roof

conditions.

Shingle Layout

It is recommended to apply

waterproof membrane, such as

ATA-Shield**, at eave, gable, and

valley. Place ATA-Guard*

underlayment up from the eave.

For re-roof applications, remove

the extended roof material and old

drip edge. After Starter Trim is

installed (see page 2), snap a

horizontal chalk line at 8 ⁄” from

the edge after squaring up eave.

Snap vertical lines at 11 ⁄” o.c.

Line-up shingle corners with chalk

lines to assure square alignment of

the shingles. To aid in squaring of

shingle, make sure alignment

points meet at the alignment mark

of the lower course. Shingles are

secured with three fasteners per

shingle.

Helpful hint: to square-up the

shingle, line up the top hole with the

vertical line.

Page 2

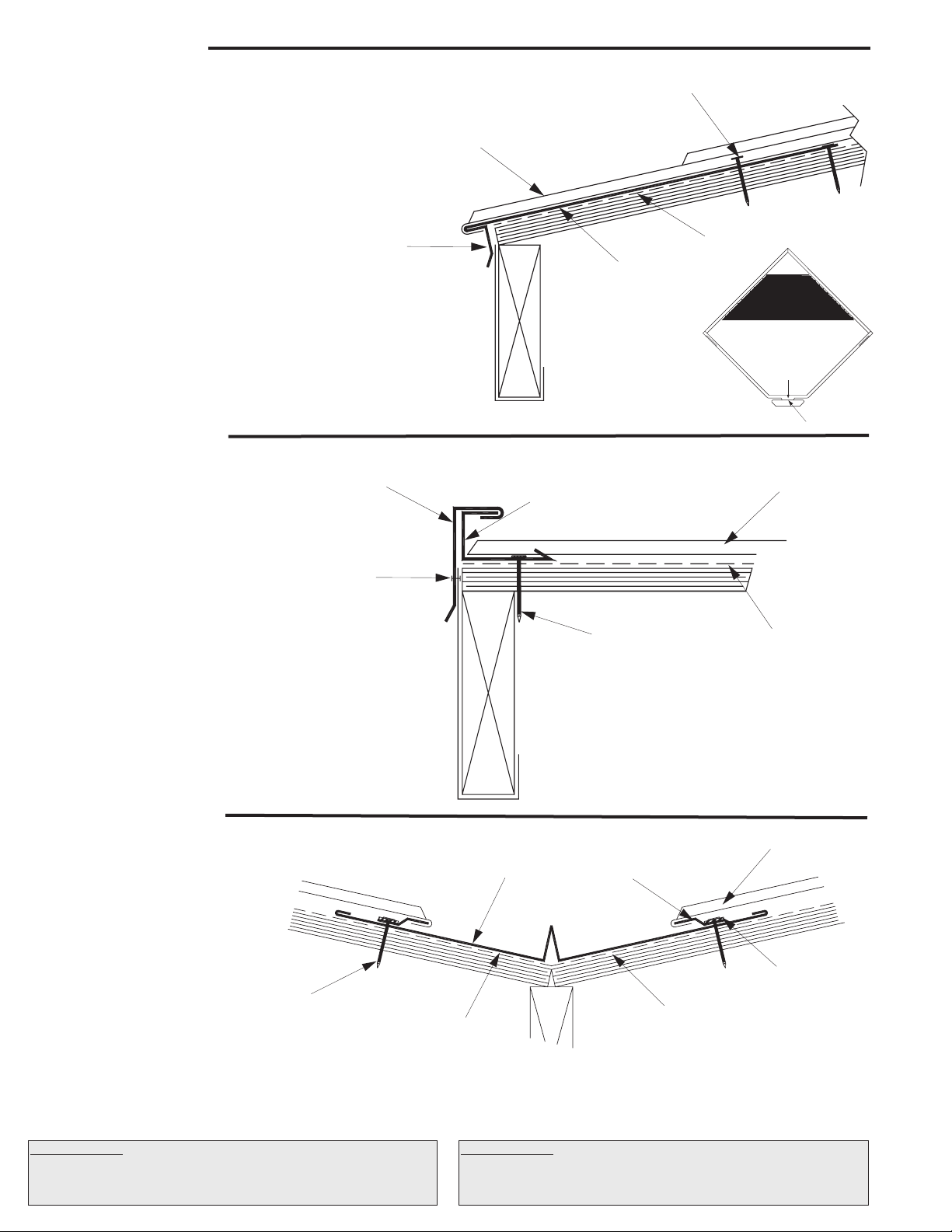

Eave Detail

ATA-Guard*

Castle Top Shingle

2” Ring Shank

Grommetted Nail

HCA112

Drip Edge/

Starter Trim

ATA-Shield**

ATA-Guard*

Castle Top Shingle

2” Ring Shank

Grommetted Nail

Approriate

Fastener

HCA201

Gable Trim Cap

HCA200 Channel Trim

Butyl Ta pe

ATA -Guard*

Castle Top Shingle

2” Ring Shank

Grommetted Nail

HCA800

Valley Pan

HCA975

Joggle Cleat

ATA -Shield**

Remove foam backer from

lower part of shingle

first row only

Bend Line

Cut Line

1. When applying in a re-roof application, cut back

existing shingles and drip edge to be flush with the

eave and gable lines. Apply ATA-Shield at eave.

2. Install Drip Edge/Starter Trim. Place lap joint of

starter trim at center of shingles to hide seam.

Fasteners should be located under the center of each

shingle.

3. Apply ATA-Guard to entire roof.

4. Remove the foam backer from lower half of the first

row of shingles to assure a flat seal onto the starter

trim.

5. Cut lower part of locking edge from shingle (see

detail); bend the remaining tab inward under edge of

starter trim to avoid wind uplift. Fasteners must

penetrate solid substrate.

Gable Detail

1. Install Channel Trim on gable edge, fasten into

the substrate 12” o.c.

2. Insert cut edge of shingles into channel trim.

3. Hook Gable trim over channel, fasten with

appropriate fastners.

Valley Detail

1. Install ATA-Shield** 18” up both side of

the valley line.

2. Install the valley with the joggle cleat

maintaining a 3” clearance from valley’s

center. Place butyl tape between joggle

cleat and pan. Fasten through tape into

the substrate 6” o.c. max.

3. Overlap valley pans by a minimum of

6”.Apply butyl tape/caulk between all

valley metals.

4. Cut backer foam 1” from cut edge of

shingle and turn shingle under as shown.

5. Hook shingles onto the joggle cleat and lay in the valley pan and fasten.

Maintain square line-up of shingles.

Underlayments: ATA-Guard* is a polyolefin based, 100% asphalt free,

high strength reinforced roofing underlayment for use beneath

metal roofing on steep slope applications. 1000 sq. ft. per roll at 48”

wide.

Underlayments: ATA-Shield** is the recommended self adhesive

underlayment for eaves, sidewall and any critical areas exposed to ice

damming and extensive water run off. Available in 65’-8” x 39 ⁄” rolls

(200 sq. ft. per roll).

Page 3

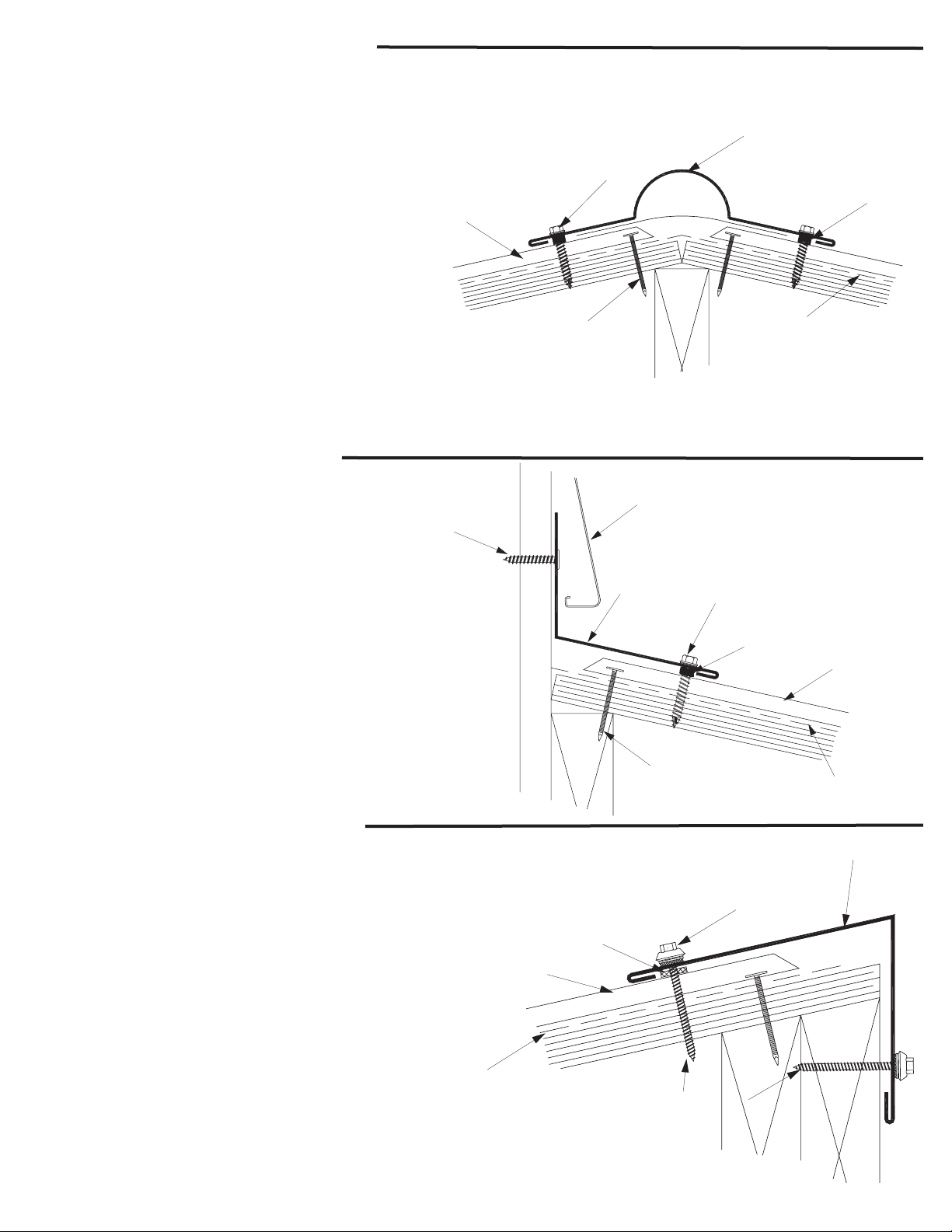

Hip & Ridge Detail

ATA -Guard*

Castle Top Shingle

2” Ring Shank

Grommetted Nail

2” x 5/16” Painted

Gasketed Screw

HCA303

Ridge/Hip Cap

Soft Cell Closure Ta pe

ATA -Guard*

Castle Top Shingle

2” Ring Shank

Grommetted Nail

2” x 5/16” Painted

Gasketed Screw

HCA500

Headwall

Tr im

Approriate

Fastener

Soft Cell Closure Ta pe

Wall Tr eatment

ATA -Guard*

Castle Top Shingle

2” Ring Shank

Grommetted Nail

HCA342

Shed Ridge

Cap

Soft Cell

Closure Ta pe

2” x 5/16” Painted

Gasketed Screw

Hip and ridge applications are handled

in the same manner.

1. Install Castle Top roof shingles to meet at hip/ridge.

2. Apply expandable sealant tape to ridge cap; place

just behind returned edge of cap.

3. Secure the cap with 2” x ⁄” painted gasketed

screws on each side of ridge at approximately 2’-0” o.c.

Make sure the screw penetrates soft cell closure

between metals.

Note: Make sure to fasten the caps to the high point on

the shingle in order to avoid dimpling, and make sure the

screw penetrates the cap through the expandable

sealant tape into the solid substrate. Ridge caps can

accommodate standard ridge venting products. Refer to

venting manufacturer’s instructions and local building

code requirements.

Headwall Detail

1. Install the shingles up to the headwall.

2. Depending on wall treatment, cut reglet in wall.

3. Apply soft cell closure tape to the headwall trim just

behind returned hem of headwall.

4. Lay headwall trim over shingles while insuring that the

perpendicular section is flush to the wall.

5. Secure the headwall with 2” x ⁄” painted gasketed

screws at approximately 2’-0” o.c. Make sure the screw

penetrates soft cell closure between metals.

6. Install counterflashing or wall treatment over headwall.

Shed Ridge Detail

1. Install metal shingle up to the roof peak.

2. Apply soft cell closure tape on the inside of the shed ridge

cap just above the hem.

3. Lay shed ridge trim over shingles while insuring that the

cap is tight against the peak.

4. Secure shed ridge cap with 2” x ⁄” painted gasketed

screws at 24” o.c., making sure to fasten through tape and

shingle into solid substrate.

Page 4

Sidewall Detail

Approriate

Fastener

Wall Treatment

HCA410

Sidewall Trim

HCA200

Channel Trim

Castle Top

Shingle

Blocking

ATA -Guard*

Trim Boards

Wood Substrate

1” Screw (Shown)

or 2” Screw Shank

Grommetted Nail

1. Install ATA-Shield** along roof plane and up

sidewall.

2. Install channel trim; fasten into the substrate 12”

o.c.

3. Place panel into channel, fasten.

4. Apply soft cell closure tape in channel.

5. Install sidewall trim. Secure to the exterior wall.

6. Install wall treatment or counterflashing.

Note Regarding Trim Details

The application of flashing and trim requires a detailed approach. Consideration should be given to the roof ’s geometry and course it creates for

water run-off. Location of gutters and the use of snow retention systems should also be considered. Proper planning regarding the sequence of

material overlap is critical. Sealants, such as butyl tapes and tripolymers, should be used at overlapping trim edges, in conjunction with exposed

fasteners, and to seal flashings. All fasteners should be properly tightened and not overdriven at an angle. Fasteners that are too loose can “back out”

over time. An overdriven fastener may cause a depression in the material, which becomes a collection point for standing water.

Pipe Detail

Step 1

Cut on the proper pipe

diameter marked on the

flashing.

Pipe drawings provided by Triangle Fasteners

Tools and Rules:

Basic Equipment Required:

Tie-off ropes, safety harness, long level, ladders, scaffolding with

approved planking, extension cords with approved ground plugs

and services.

Additional Tools:

Metal folding tool, hammer, chalk line, measuring tape, metal

cutting tools - nibblers, drills, hacksaw, utility knife, pop-rivet

gun, caulking guns, layout and combination square, C clamps,

sheet metal shears (including RH, LH, straight and overhand).

Power driven screw gun with proper bits, depth-setting

nosepiece, variable speed.

Choose the correct equipment and tools to do the job in a

safe manner. Wear safety gear and follow OHSA

requirements.

Position over pipe and slide

For further information or assistance, contact our Product Support at 800.468.1441

Step 2

down the pipe.

Corporate Office - Allentown, PA 18106 www.atas.com (610.395.8445)

©2012 ATAS International, Inc. and Accel Roofing Products. All rights reserved. CastleTop® is a registered trademark of ATAS International, Inc.

Apply polyurethane sealant

to the bottom of the base.

1. Never cut the panels with an abrasive cut-off wheel or torch, as this will damage

the finish.

2. Do not weld the trim or panels.

3. Remove any small burrs left by cutting, screwing or drilling.

4. Remove protective masking immediately after trim and panels are installed.

5. Caution should be taken when unloading the panels to prevent damage.

6. Use appropriate screws for the type of underlayment and long enough to fully

penetrate and secure the panel.

7. The stored materials should be kept dry.

8. Do not cut on finished roof. Remove all drill spirals, chips and dust immediately.

9. Seal neoprene closures and soft cell foam by applying appropriate sealant to

both surfaces.

10. Put appropriate sealant/butyl tape between overlapping trims.

11. Overlap trims in a manner not to impede the flow of water.

Step 3

Mold the flexible base to the

Follow these simple rules:

Step 4

panel contours.

Step 5

Fasten with ¼” x

1 ⁄” drilling

fastener every 1½”

around the base.

ATAS International, Inc.

LRD0412 LAT230

Loading...

Loading...