Page 1

ATAS INTERNATIONAL, INC.

SPECIFICATION DATA SHEET

1. PRODUCT NAME

InSpire

TM

SOLAR COLLECTOR

BWS390, BWS392

2. MANUFACTURER

ATAS INTERNATIONAL, INC.

Website: www.atas.com

Email: info@atas.com

Corporate Headquarters:

Allentown, PA 18106

Phone: (610) 395-8445

Fax: (610) 395-9342

Western Facility:

Mesa, AZ 85204

Phone: (480) 558-7210

Fax: (480) 558-7217

Southern Facility:

Maryville, TN 37801

Phone: (800) 468-1441

3. PRODUCT DESCRIPTION

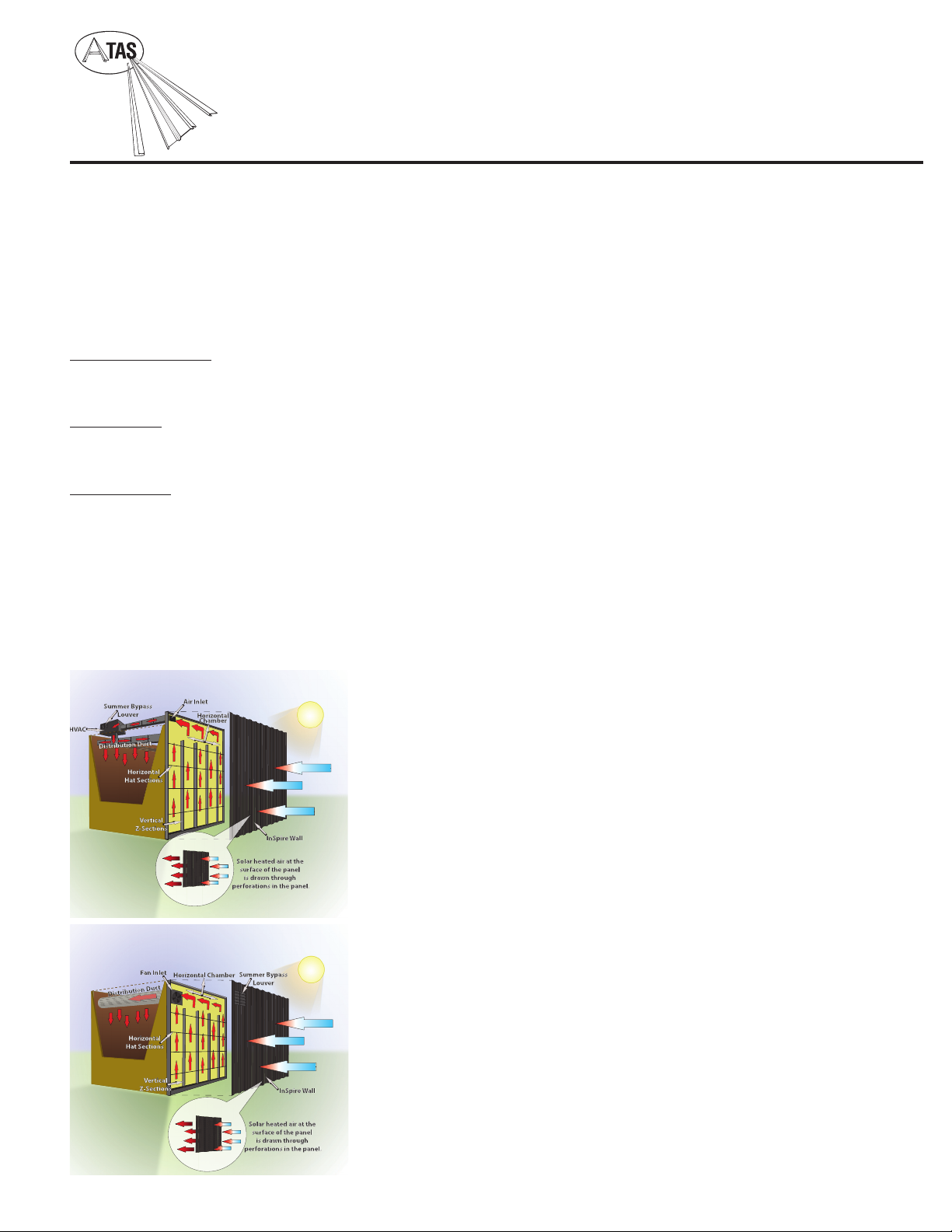

Basic Uses:

The InSpire solar collector is a metal

wall system used to collect and distribute

solar-heated, outside air for ventilation or

processes, such as drying. The concept

is simple:

Integrated with HVAC

Stand Alone Destratication

· Perforated collector panels are installed

several inches from an appropriate wall,

creating an air cavity.

· Sunlight heats the solar collector surface.

· Fans create a negative pressure and draw

warmed air through the perforations

into the plenum.

· Heated air is distributed into the building

through the existing HVAC system or separate,

perforated ducts. The wall system should be

considered whenever outside air is being

heated. Energy savings depend on several

project-specic factors and can be predicted

by computer modeling. Factors that inuence

system eectiveness include the ventilation

requirement of building, length of heating

season, utility rates for heating and the

available wall area facing south, southeast or

southwest.

There are six ways to save energy:

· Solar energy is captured by the collector.

· When the fan is running, building heat loss

through the main wall is recaptured

in the plenum.

· The air space creates an insulating eect on

the building inner wall.

· In industrial buildings, solar heated air

distributed through perforated ducts

destraties and utilizes hot air trapped

at the ceiling.

· With lower ceiling temperatures in industrial

buildings, less energy is lost through ceiling

exhaust systems.

· Solar collector panels shield the inner wall

from direct sunlight during the summer season.

Typically, each square foot of solar collector

contributes 1.0 to 2.0 therms of energy per

year. Annual heating costs are usually reduced

by $1.50 to $5.50 per square foot of collector,

depending on the type of fuel replaced.

Ideal applications include:

· Industrial buildings

· Hospitals and other institutional buildings

· Schools and gymnasiums

· Arenas

· Laboratories

· Maintenance facilities

· Government and military buildings

· Warehouses

· Theaters and conference centers

· Restaurants

· Other commercial buildings

Major system components may include:

· Wall panels

· Standos and canopy components

· Fans, controls, dampers and ducting

· Trim and closures

Composition and Materials:

InSpire cladding is available in .032” aluminum

and .027” pre-weathered zinc.

Sizes and Proles:

InSpire cladding incorporates 1 ¼” high ribs.

Aluminum panels are 41 ¼” wide with 39 ⁄”

coverage, and zinc panels are

33 ⁄” wide with 31 ½” coverage.

The panels can be specied in two

orientations as illustrated. Panel lengths

are cut to customer specications up to 40’

maximum. Proles contain proprietary lanced

perforations for air intake.

The airow rate through each square foot of

collector panel is tailored to meet specic

project objectives:

· 1 to 3 cfm/ sq ft for high temperature gain

· 3 to 6 cfm/ sq ft for standard operation

· 6 to 10 cfm/ sq ft for high eciency

Color and Finish:

A choice of 30 stock colors is available in

KYNAR 500® PVDF or HYLAR® 5000 PVDF

based nishes for collector panels and accent

components. (Request color chart or chips).

Four darker colors, which absorb solar energy

more eciently, are recommended for

collector panels. A Dark Bronze anodized nish

is also available. Zinc panels have a dark, preweathered nish.

Limitation:

InSpire solar collector panels heat fresh air

during the day time and are not designed

to replace conventional space heating

system. InSpire must be installed over noncombustible wall material. Consult re codes

for use in multi-story applications.

4. TECHNICAL DATA

Applicable Standards

Solar Collector System

The technology for perforated solar air

heating systems was developed through

extensive testing at The National Renewable

Energy Laboratory of the U.S. Department of

Energy, and in Canada at the CANMET Energy

Diversication Research Laboratory, an agency

of Natural Resources Canada. Detailed project

performance monitoring has been conducted

under the auspices of CANMET to validate

computer feasibility software.

Collector Cladding

KYNAR 500® PVDF or HYLAR® 5000 PVDF based

nishes tested by paint supplier for:

Dry Film Thickness: ASTM D 1005,

ASTM D 1400, ASTM D 4138 or ASTM D 5796

Specular Gloss: ASTM D 523

Page 2

Pencil Hardness: ASTM D 3363

7 ⁄”

39 ⁄” Coverage

41¼” Overall

1¼”

7 ⁄”

39 ⁄” Coverage

41¼” Overall

1¼”

BWS390

BWS392

Exposed Side

Exposed Side

T-Bend Flexibility: ASTM D 4145

Mandrel Bend Flexibility: ASTM D 522

Impact Resistance: ASTM D 2794

Adhesion: ASTM D 3359

Water Immersion Resistance:

ASTM D870

Abrasion Resistance: ASTM D 968

Acid Resistance: ASTM D 1308

Acid Rain Resistance (Kesternich):

ASTM G 87 or DIN 50018

Salt Spray: ASTM B 117

Cyclic Salt Spray: ASTM D 5894 and

ASTM D 5487

Humidity Resistance: ASTM D 2247

Accelerated Weathering: ASTM D 822

and ASTM G 23, ASTM G 151 or

ASTM G 153

Color Retention, Florida Exposure:

ASTM D 2244

Chalking Resistance: ASTM D 4214

Cleveland Condensing Cabinet:

ASTM D 4585

Cure test, MEK resistance: ASTMD 5402

Alkali resistance, sodium hydroxide:

ASTM D 1308 Procedure 7.2

Flame Spread Rating: ASTM E 84

Organic coatings meet requirements of

AAMA 2605 when applied to aluminum

Panel testing/ratings:

Aluminum: ASTM B 209

Zinc: EN988

Coil Coating: ASTM A 755

Field Tested and Approved

Load Tables available upon request.

Environmental Considerations

The InSpire solar collector is a renewable

energy system that benets the environment

by:

- Supplying 1 to 2 therms of energy per square

foot of collector per year

- Collecting solar energy at a typical eciency

of over 60%

- Reducing annual CO2 production by

40 to 60 pounds per square foot of collector

- Utilizing metal components that contain

recycled material and are recyclable at the end

of their life cycle.

Projects with InSpire technology may qualify

for LEED® credits in renewable energy,

optimizing energy performance and other

areas.

5. Installation

InSpire cladding is generally installed 4

to 8 inches from the main wall and can

be installed over or around existing wall

openings. Installation manuals and project

specic installation drawings are available.

Contact ATAS technical service advisors for

more information. If required, additional air

distribution equipment is installed using

standard practices.

6. Availability & Cost

Availability:

The InSpire system is available through

product distributors. A complete line of

related components and trim accessories

is available to complete the wall system. In

addition, a complete line of rainware and

perimeter roof edge trims can be supplied

by ATAS to complement the wall system. Flat

sheet and/or coil stock is available in matching

color for fabrication of related components by

the installing contractor.

Cost:

Cladding cost is comparable to a brick wall.

Contact product distributors for current

pricing on system components. Many state

and federal incentives are available. The typical

payback is 3 to 8 years, sometimes 1 year or

less.

7. Warranty

Products coated with a uoropolymer, KYNAR

500® PVDF or HYLAR® 5000 PVDF nish carry a

limited warranty against chalking and fading.

8. Maintenance

InSpire collector panels are virtually

maintenance free. Surface residue may

be easily removed by conventional

cleaning methods. For painted products,

minor scratches should be touched up

with a matching paint, available from

the manufacturer. The balance of system

components contain no liquids or moving

parts, except for intake fans and dampers,

which require normal maintenance.

9. Technical Services

Complete technical information and literature

are available from ATAS International. System

design specications depend on individual

project requirements, such as the amount of

ventilation air required and the available wall

area. The ATAS technical sta may assist by

performing feasibility studies to determine

potential energy savings and dene air

collection and distribution requirements for

specic projects. ATAS will assist with design

ideas and shop drawings.

10. Filing Systems

- www.atas.com/inspire

- Additional product information is available

from the manufacturer upon request.

M

InSpire

is a trademark of ATAS International, Inc.

KYNAR 500® is a registered trademark of Arkema.

HYLAR 5000® is a registered trademark of Solvay Solexis, Inc.

© 2011 ATAS International, Inc. LRD0611 LAT746

Loading...

Loading...