.

_·\<

•: :·;, '

- -

...

_. ,-.

.. -......

..-..

..

--

~;

-~;.:~:r :.:

·_

.

.:_

SM144

MONOCHROME

MONITOR

FIELD

SERVICE

MANUAL

~

ATARI

:-

'

!CONTENTS I

SPECIFICATIONS

.........................................................................

2

SAFETY

PRECAUTIONS

...........................................................

3

TIMING

CHART

.............................................................................

4

HOW

TO REMOVE REAR CABINET FOR SERVICE

......

5

CONTROLS LOCATION

.............................................................

6

CIRCUIT DESCRIPTION

............................................................

7

DESCRIPTION OF

SIGNAL

CABLE .

.......

....................

...

.......

8

GEOMETRIC DISTORTION

......................................................

9

SERVICE

ADJUSTMENTS

.....................................................

10

ALIGNMENT

LOCATIONS

.......................................................

11

DESCRIPTION OF

ALIGNMENT

LOCATIONS

...............

12

TROUBLESHOOTING GUIDE

...........................................

13-17

BLOCK

DIAGRAM

......................................................................

18

TRANSISTOR &

IC

BASING

.................................................

19

·~.

--------

.......

: rSPECIFICATIONS I

1.

CATHODE

RAY

TUBE

14"

diagonal,

goo

defelection

Face plate: Antiglare treatment

Flat Square Tube

2.

SIGNAL

CONNECTOR

Input signals are applied through a

13

pin

"Din"

connector. The machting connector is a

13

pin

"Din"

female connector. (Refer to Fig.

3)

2-1

VIDEO INPUT

Amplitude

Signal

Polarity

Rise & Fall Time

2·2 VERTICAL

Amplitude

Blanking time

Vert. Frequency

2-3

HORIZONTAL

: 1 Vp-p TTL MIN

: Positive

: 10nS max.

:

5.0Vp-p ± 0.25V

: 0.70mS max.

: 71.2Hz

Amplitude : 5.0Vp-p ± 0.25V

Blanking time : 4mS max.

Horiz. Frequency : 35.7KHz

2-4

SOUND INPUT SIGNAL

Sound : Mono phone

Amplitude : 1Vp-p

Impedance : 47Kohm

2-5

VIDEO OUTPUT

Video Bandwidth

Rise

& Fall Time

2-6

SOUND AMPLIFIER

: 32MHz.

:

20nS max.

Frequency Response :

100Hz-15KHz(±

3d

B)

Output Power : Max 0.5W

Audio Distortion : Max, 10%

3.

POWER

SUPPLY

3-1

Power Rating

3-2

AC

Ripple

3-3

Consumption

:

AC 90-136V, 60Hz

AC

198-265V, 50Hz

: Less than 1

OOmV

:

35

watt max.

VOLTAGE CHART

.................................................................

20-21

PRINTED CIRCUIT BOARD

...................................................

22

EXPLODED

VIEW

........................................................................

23

AUDIO

CIRCUIT

.........................................................................

24

POWER CIRCUIT

FOR

220-240V

VERSION

............

25·26

POWER CIRCUIT FOR 120V VERSION

.....................

27-28

VIDEO

MAIN

AMP

CIRCUIT

..........................................

29·30

VIDEO PRE-AMP &

BLANKING

CIRCUIT

..................

31-32

HORIZONTAL DEFLECTION CIRCUIT

.......................

33-34

VERTICAL

DEFLECTION CIRCUIT

...............................

35-36

CIRCUIT

DIAGRAM

.......................... ; .................................

37-38

PACKING

DIAGRAM

.................................................................

39

REPLACEMENT

PARTS LIST

.........................................

40·43

4.

DISPLAY

AREA

Active Video Area

5.

CENTERING

Horizontal

Vertical

6.

GEOMETRY

Refer to Fig. 4

7.

LINEARITY

Adjacent character

Total character

8.

RESOLUTION/FOCUS

MAX

9.

EXTERNAL

CONTROLS

:

235mmx14

7mm

(9.25" X 5.79")

: ± 4 mm (0.16'').

: + 4mm (0.16").

- 6mm (0.24").

: 10%

:10%

:640

X 400

Brightness, Contrast, Volume(Sound), H-size,

Vsize, H-position, V-position.

Push-On (Power Switch)

10.

ENVIRONMENT

Operating Temperature

Storage Temperature

Relative Humidity

Altitude

11.

WEIGHT

(NET)

12.

DIMENSIONS

:

10

to

41°C

: 0

to

+60°C

: 5 to 80%

(noncondensing)

:

3000m (9800ft.)

: 7.9Kg(17.421bs)

:

328(W) X 318(D)

X

347(H)

mm

(12.89(W)

X 12.52(D)

x 13.66(H) inch)

3-3

DC

Output Power

: 55V ± 0.5V,

33V

± 0.5V

14V

±0.5V,

12V ± 0.5V

-2-

. . . . .

..

··

-·

··-

--~·

...

..

___ ..

".. .-

...

-··- .

r-·-·

[SAFETY PRECAUTIONS!

CAUTION: No work should

be

attempted on

an

exposed monitor chassis by anyone not familiar with

servicing procedures and precautions.

1.

SAFETY

PROCEDURES

should be developed by

habit so that when the technician is rushed

with

repair work,

he

automatically takes precautions.

2.

A GOOD PRACTICE, when working on any unit,

is

to

first ground the chassis and to use only one

hand when testing circuitry. This

will avoid the

possibility of carelessly putting one hand on the

chassis or the ground

and

the other on

an

electrical connection which could cause a severe elec·

trical shock.

3.

Extreme care should

be

used in HANDLING THE

PICTURE TUBE. Rough handling may cause

it

to

implode due to atmospheric pressure.

Do

not nick

or

scratch glass or subject

it

to

any undue

pressure in removal or installation. When

handl·

ing, safety goggles and heavy golves should be

{j

worm

for protection. Discharge the picture tube

by shorting the anode connection to the chassis

ground (not cabinet or other mounting parts).

When discharging, go from the ground

to

the

anode or use a self insulated piece

of

wire. When

servicing or repairing the monitor,

if

the CRT is

replaced

by

a type

of

tube other than that

specified under the GoldStar Part Number

as

original equipment in this service manual, avoid

prolonged exposure at close range

to

unshield·

ed

areas of the cathode

ray

tube. Possible danger

of

personal injury from unnecessary exposure

to

X-ray radiation may result.

4.

AN ISOLATION TRANSFORMER should always

be used during the servicing

of a unit

whose

chassis is connected to one side

of

the power

line. Use a transformer

of

adequate power rating

as

this

protects the serviceman from accidents

resulting

in

personal injury from electrical shocks.

f"-

. It will also protect the chassis and

its

com-

'

.•

ponents from being damaged by accidental

shorts

of

the circuitry that may be inadvertently

introduced during the service operation.

5.

BEFORE

RETURNING A SERVICED

UNIT, the ser·

vice technician must thoroughly test the

unit

to

be certain that

it

is completely safe

to

operate

without

danger of electrical shock.

DO

NOT

USE

A LINE ISOLATION TRANSFORMER WHEN MAK·

lNG THIS

TEST.

-3-

/

GROUND

lEAD

OF

MfTER

TO

AN'I'

EARTH

GROUND

SUCM

AS

A COLD WATER

PIPE

t!>QO

Q~otM

tO

WATT

RESISTOR

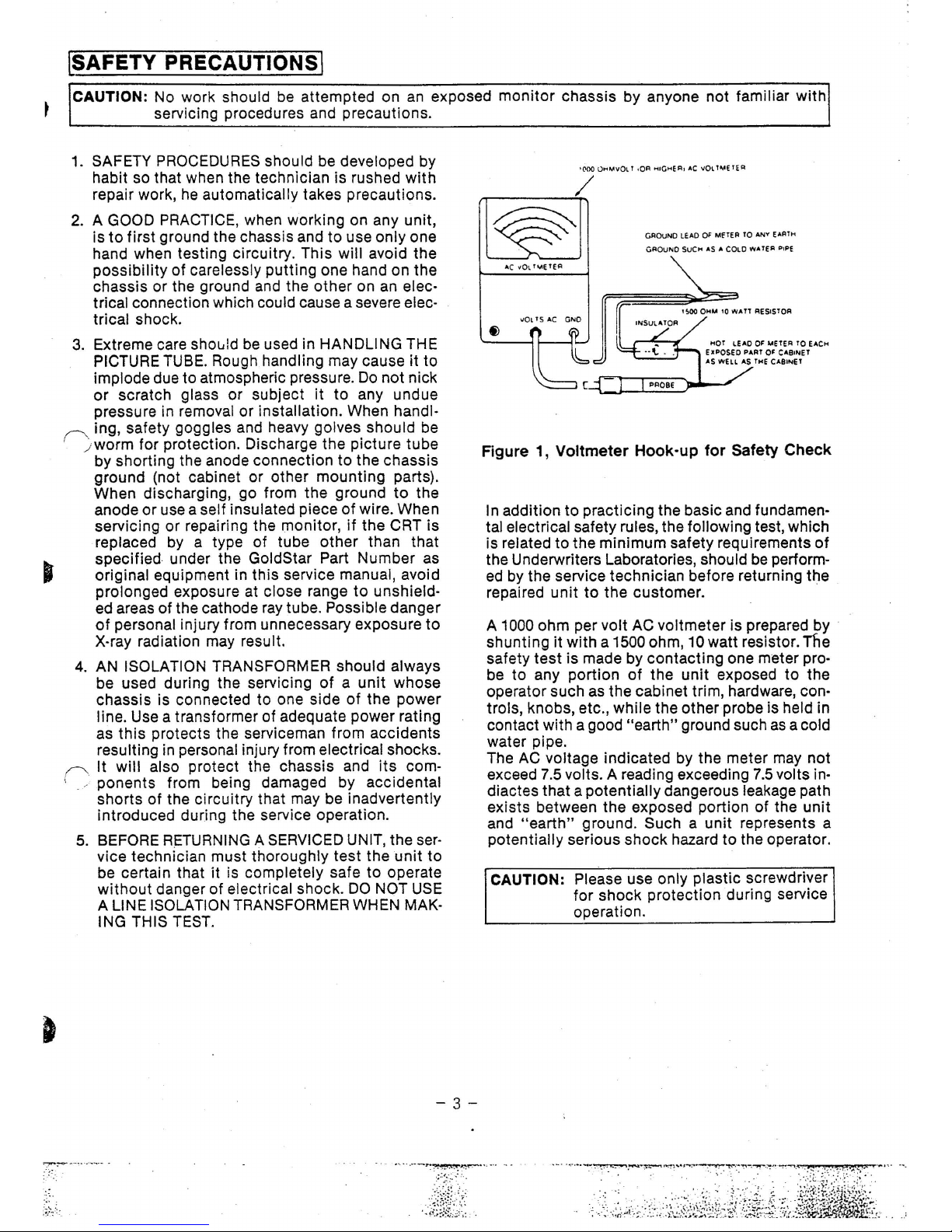

Figure 1, Voltmeter Hook-up for Safety Check

In addition

to

practicing the basic and fundamen·

tal electrical safety rules, the following test, which

is related

to

the minimum safety requirements

of

the Underwriters Laboratories, should

be

perform-

ed

by the service technician before returning the

repaired

unit

to

the customer.

A

1000

ohm per volt

AC

voltmeter is prepared by

shunting it with a

1500 ohm,

10

watt resistor. Tfie

safety test is made by contacting one meter pro-

be

to

any portion

of

the unit exposed

to

the

operator such as the cabinet trim, hardware,

con-

trols, knobs, etc., while the other probe is held in

contact with a good

"earth" ground such

as

a cold

water pipe.

The

AC

voltage indicated by the meter

may

not

exceed

7.5

volts. A reading exceeding

7.5

volts indiactes that a potentially dangerous leakage path

exists between the exposed portion

of

the

unit

and

"earth"

ground. Such a unit represents a

potentially serious shock hazard to the operator.

CAUTION: Please use only plastic screwdriver

for shock protection during service

operation.

·····.-

--~~,..,r:--·········

IFEATURESj

• 2000 characters (displays 25rows x

80

columns)

•

32

MHz bandwidth, high class

• Accepts separate

TIL

signal such as vertical sync and Horizontal sync,

TIL

Video.

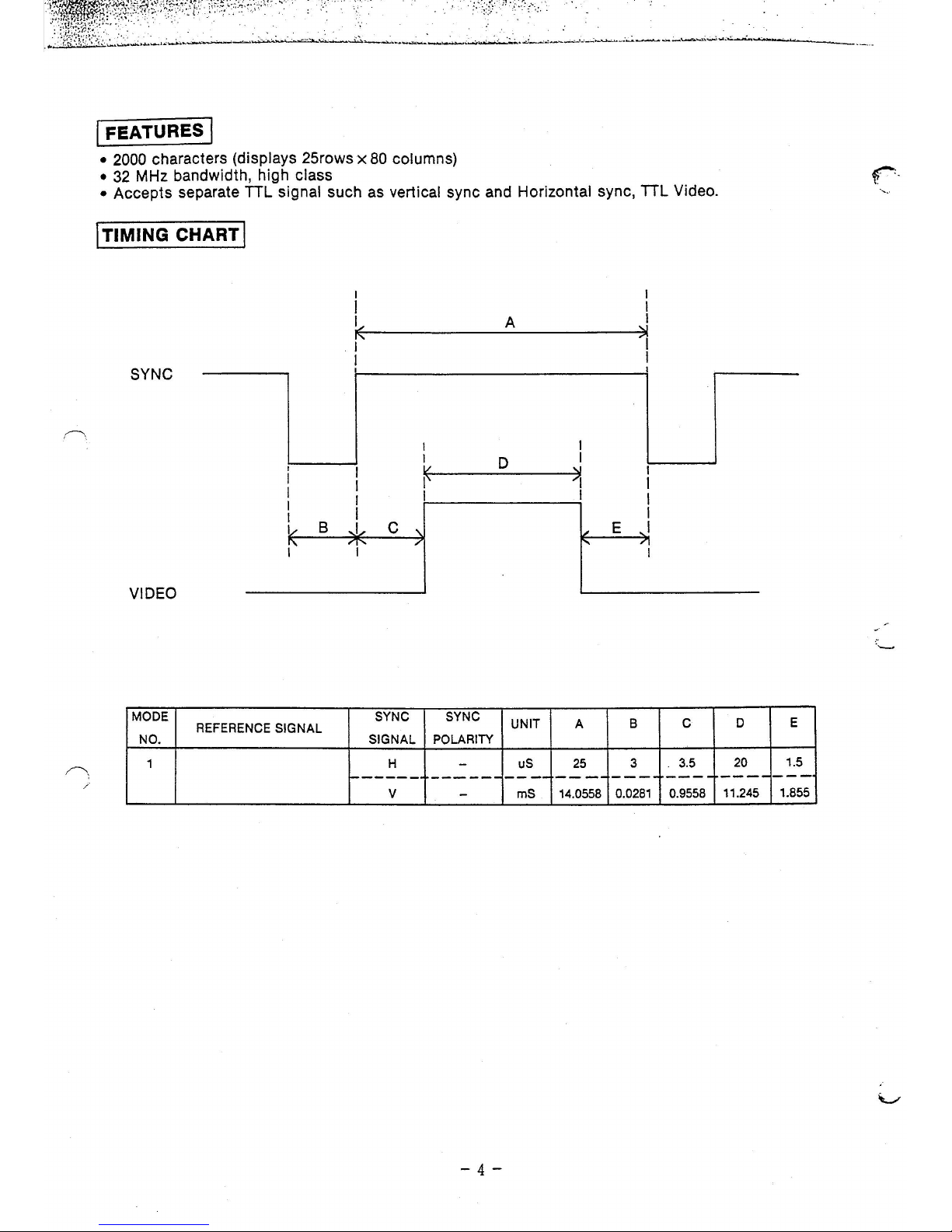

1 TIMING CHART I

SYNC

I

I

I

I

I

I

I

I

I

I

1/

B

,J,

c

'

I'

-'1"-

7

I

VIDEO

MODE SYNC

REFERENCE

SIGNAL

NO. SIGNAL

1 H

1------

v

A

I

I

D

~

I

SYNC

UNIT

POLARITY

-

uS

------

----

-

mS

-4-

I

I

1..-

A

25

---

14.0558

E

8

3

I

/1

I

----

0.0281

c

3.5

---

0.9558

D

E

20

1.5

----

---

11.245 1.855

I HOW TO REMOVE REAR CABINET FOR SERVICE I

t • Unscrew the Four screws maked

®shown

in Figure 2

JJ~~

ATARI

0

looodO

Figure

2

®

- 5. -

.

~-·:~: ~~-·~~~~~~~

..

_:·~~

·--

~-7'

:

....

-·······

......

--·-· . .. ···- · .

....

..

--~-

-

.............. ------·-

..

l

~:~-----~'!.

-·?i;·.:

-

·_

·' -...

--:-

--·?~:-:\~~~~~~~~~

.

·.·._

...

. ·._

.·

. >

..

.

...

.

. : : ·- ' . . :

~

...

. • -;

•,

-.:

~

..

~

I

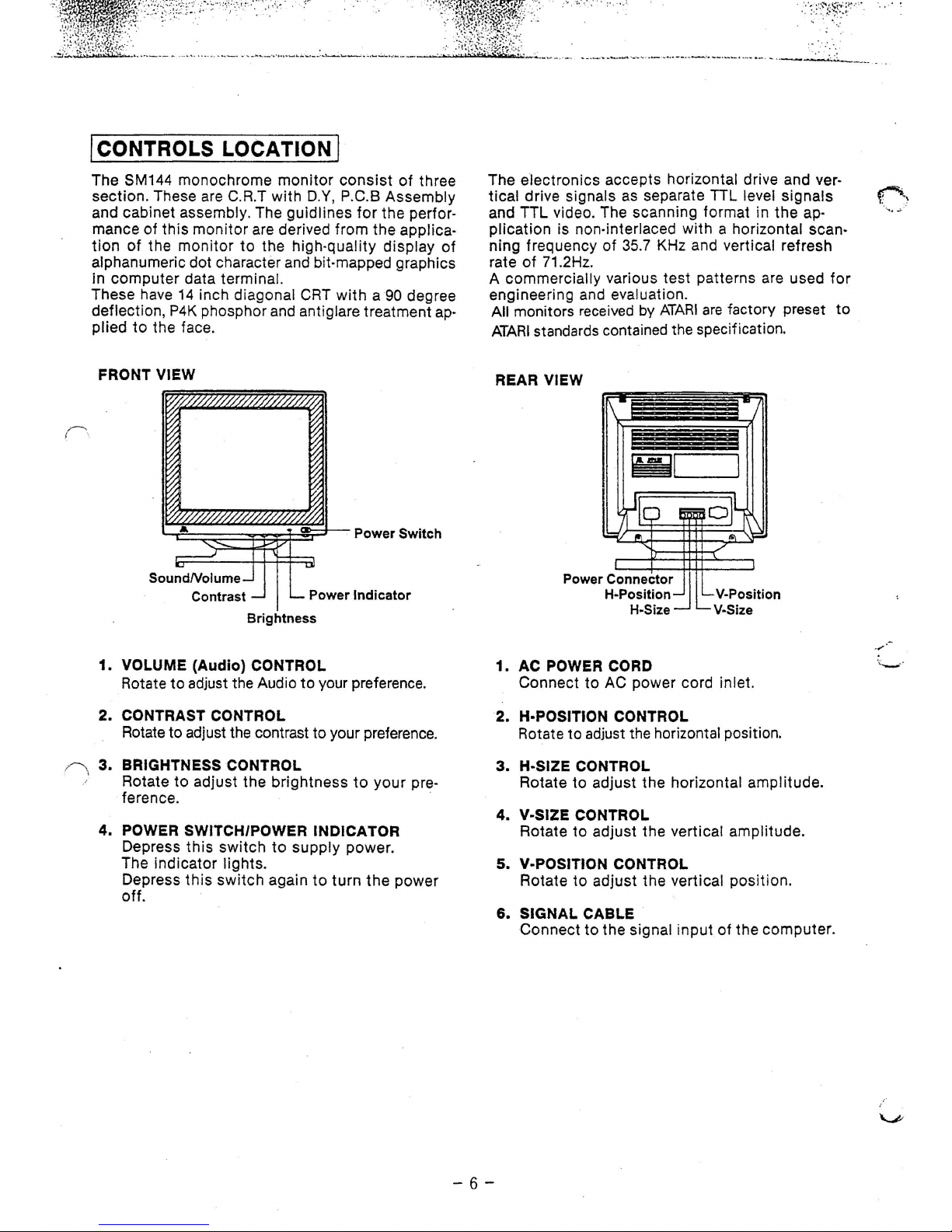

coNTROLs

LOCATION I

The SM144 monochrome

monitor

consist

of

three

section. These are

C.R.T

with

D.Y, P.C.B Assembly

and cabinet

assembly. The guidlines

for

the perfor-

mance of this monitor are derived from the

applica-

tion

of

the

monitor

to

the high-quality display

of

alphanumeric dot character

and

bit-mapped graphics

in computer data

terminal.

These have

14

inch diagonal

CRT

with

a 90 degree

deflection,

P4K

phosphor

and

antiglare treatment

ap-

plied

to

the face.

FRONT

VIEW

Power

Indicator

Brightness

1.

VOLUME (Audio) CONTROL

Rotate

to

adjust the Audio

to

your preference.

2. CONTRAST

CONTROL

Rotate to adjust the contrast to your preference.

3.

BRIGHTNESS CONTROL

Rotate

to

adjust the brightness

to

your

pre-

ference.

4. POWER

SWITCH/POWER INDICATOR

Depress this

switch

to

supply power.

The indicator

lights.

Depress

this

switch

again

to

turn

the

power

off.

. ..

....

. :

.

:':'

:·.~:t!;~~~:

..

~::·_

' . •.

The electronics accepts horizontal drive and vertical

drive signals

as

separate

TIL

level signals

and TTL video. The scanning format in the ap-

plication is non-interlaced

with

a horizontal scan-

ning frequency

of

35.7

KHz and vertical refresh

rate

of

71.2Hz.

A

commercially various test patterns are used

for

engineering and evaluation.

All monitors received

by

ATARI

are

factory preset

to

ATARI

standards contained the specification.

REAR

VIEW

Power Connector

H•Position

H-Size

1. AC POWER CORD

Connect

to

AC power cord inlet.

2. H·POSITION CONTROL

Rotate

to

adjust the horizontal position.

3.

H·SIZE CONTROL

Rotate

to

adjust the horizontal amplitude.

4.

V·SIZE CONTROL

Rotate

to

adjust the vertical amplitude.

5. V·POSITION CONTROL

Rotate

to

adjust the vertical position.

6.

SIGNAL CABLE

Connect

to

the signal

input

of

the computer.

-6-

· . . ·

.....

~

_

,.,

'\ .

.._

.. ·

I CIRCUIT DESCRIPTION I

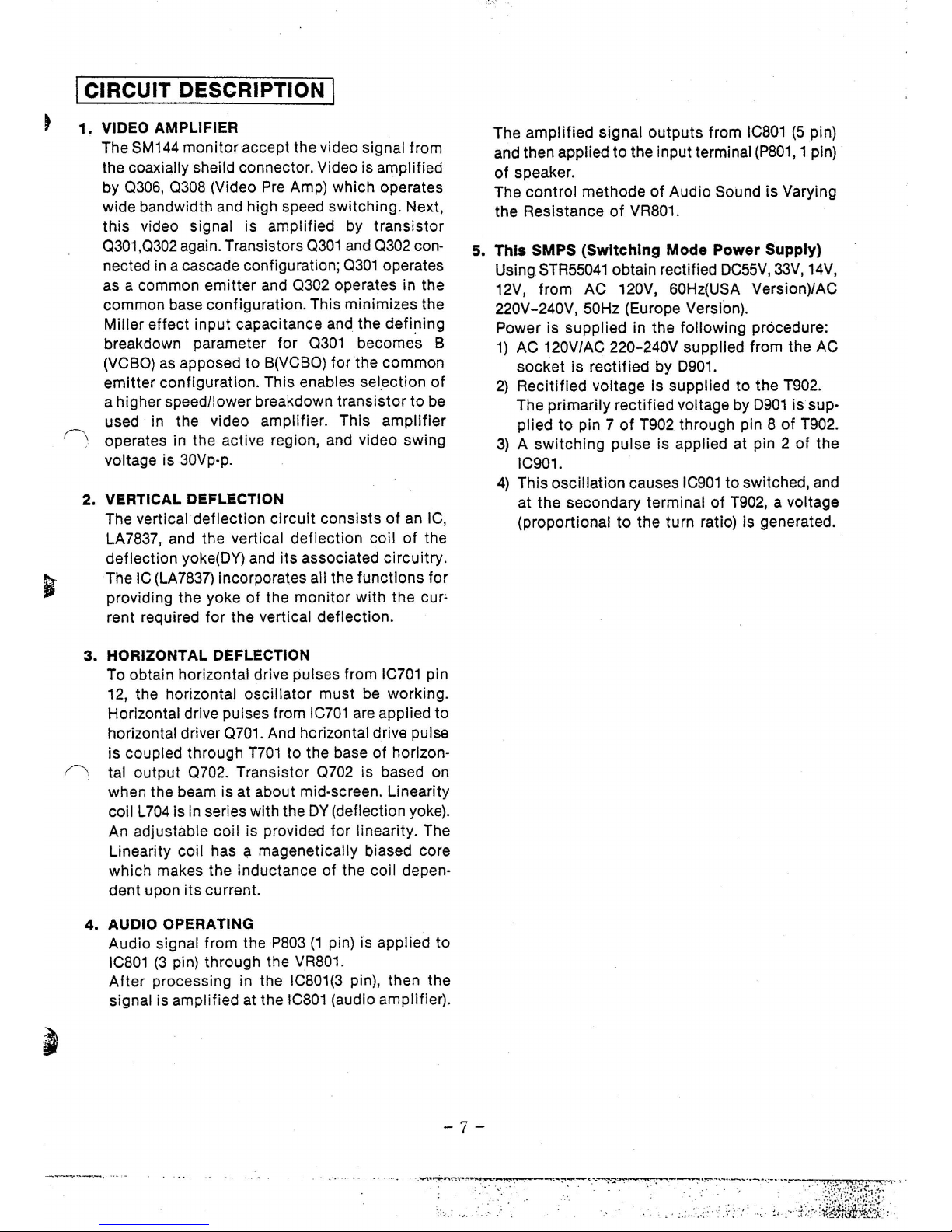

1.

VIDEO AMPLIFIER

The SM144

monitor

accept

the video signal from

the coaxially sheild connector. Video is amplified

by 0306, 0308 (Video

Pre

Amp)

which

operates

wide bandwidth and high speed switching. Next,

th

is video signal is amplified by

transistor

0301,0302 again. Transistors 0301 and 0302 connected in a cascade configuration; 0301 operates

as a common

emitter

and

0302

operates in the

common base configuration. This minimizes the

Miller

effect

input

capacitance and the

defi~ing

breakdown parameter for 0301 becomes B

(VCBO)

as

apposed

to

B(VCBO) for

the

common

emitter

configuration. This enables sel_

ection

of

a higher speed/lower breakdown

transistor

to

be

used in the video

amplifier

. This

amplifier

r---\ operates in the active region, and video swing

voltage is 30Vp-p.

2. VERTICAL DEFLECTION

The vertical

deflection

circuit

consists

of

an IC,

LA7837, and

the

vertical

deflection

coil

of

the

deflection

yoke(OY) and

its

associated

circuitry.

The IC {LA7837) incorporates all the

functions

for

providing the yoke

of

the

monitor

with the

cur~

rent required

for

the

vertical

deflection.

3.

HORIZONTAL DEFLECTION

To obtain horizontal drive pulses from

IC701

pin

12, the horizontal

oscillator

must

be working.

Horizontal drive pulses from

IC701

are applied

to

horizontal driver 0701. And horizontal drive pulse

is

coupled through

T701

to

the base

of

horizon-

0 tal

output

0702. Transistor

0702

is based on

when the beam is at about mid-screen. Linearity

coil L704 is in series with the

OY

(deflection yoke).

An adjustable

coil

is provided for linearity. The

Linearity coil has a magenetically biased core

which

makes

the

inductance

of

the coil depen·

dent

upon

its

current.

4. AUDIO OPERATING

Audio

signal from the

P803

(1

pin) is applied

to

IC801

(3

pin) through the VR801.

After

processing in the IC801(3 pin), then the

signal is amplified at the

IC801

(audio amplifier).

The

amplified

signal

outputs

from

IC801

(5

pin)

and then applied

to

the input terminal

(P801,

1 pin)

of

speaker.

The

control

methode

of

Audio Sound

is

Varying

the Resistance

of

VR801.

5. This SMPS (Switching Mode Power Supply)

Using

STR55041

obtain rectified

OC55V,

33V,

14V,

12V,

from

AC 120V, 60Hz(USA Version)/AC

220V-240V, 50Hz (Europe Version).

Power is supplied in the following procedure:

1)

AC 120V/AC 220-240V supplied from the AC

socket

is

rectified

by 0901.

2)

Recitified

voltage is supplied

to

the T902.

The

primarily

rectified

voltage by

0901

is sup-

plied

to

pin 7

of

T902 through pin 8

of

T902.

3) A switching

pulse is applied at pin 2

of

the

IC901.

4)

This oscillation causes

IC901

to

switched, and

at

the

secondary terminal

of

T902, a voltage

(proportional

to

the

turn ratio) is generated.

-7-

·":'··

..

-~

·:""""'·~

..

...

.

....,...

....

. -

.........

~.

~

..

.

. ';.;

..

:::

.:

~

.

:;·:

.. : :; :··

+

;

.-

>

;l{~~i

t£:·,

..

·-;*~~~

~~w~

~~

~~07F;~xn'<

4

r:r:

·

')'':..

~---··,

·.-·

·· ...

··

· ·

~-:-:

_.

~_~_·:

·_

··:.·

:·

.·_

:_·_,

_::

·.

~._:

..

·

.~

;_:_~,

_

;·

_

.

__

.~

:·.::::_

~-~:

·

_F

_

..

~:~·-·_·./·~_

:·

~,-.:_

.·

:.

~_:;_=,·

_~

_:_:~_-

_

:_·

_.::.~_~

..

~

.•

.

~

.::,

__

:_~--

.

--~_~

..

·_:_:

._ ..

~_,:

·-"'.

_

......

·.··

•.~

::_

.. -._.

·_;

__

:~_

.. ·_.:_·

.• : __

··.··

·· ·

·:

__

.·_._-.· _·

_·._.·.

_· .

_.

- _· :'_:

_·

.. .;-_· ·

.......

-:\·

· -

;·

_2

.mf-:?5;~~12

~t::·

.. ·,.·

:::

.

.:.~"--

-

·.;.-..

-·

.

._:-...;;........:...;...

__

,..:...:.

~.......:..;..--

--

... _ .. --.

·.:_;~

__

--~-

_-- -

.....:..:..

~~~

--

-

-.

-~---

- ·

~-

I DESCRIPTION OF SIGNAL CABLE I

1.

13

PIN CONNECTOR (MALE)

TO

THE COMPUTER

PIN

SIGNAL

NAME

PIN SIGNAL NAME

4

1

1

Audio

8

GND

2

Not used 9

H-sync

8

5

3

Not used

10

Not used

4 GND

11

Video

12

9

5

Not used 12

V-sync

6

Not used

13

GND

7 Not used

13

2. 6 PIN CONNECTOR

ON

THE P.C.B

3. 3

PIN CONNECTOR

ON

THE P.C.B

P401

P803

1 2 3 4 5 6

2

3

000000

0 0 0

I I

J

1

PIN SIGNAL NAME

PIN

SIGNAL

NAME

1

GND

1

AUDIO

2

VIDEO

2

Not

used

3

GND

3

GND

4

H-sync

5

V-sync

6

GND

Figure

3.

Signal

Connector

Pin

Assignments

-8-

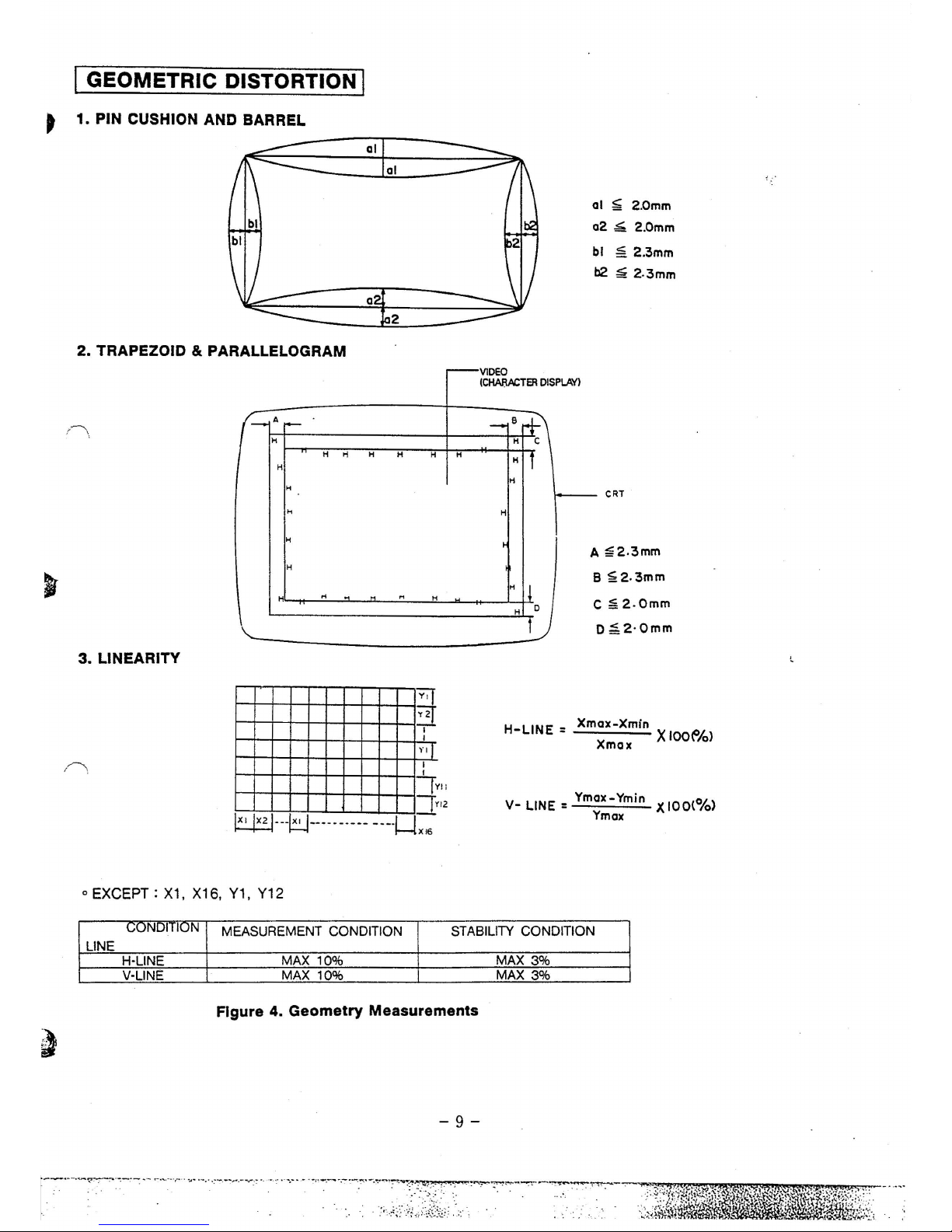

I GEOMETRIC DISTORTION I

~

1. PIN CUSHION AND BARREL

--------~--------

2. TRAPEZOID & PARALLELOGRAM

al ~ 2.0mm

a2

~

2.0mm

bl ~ 2.3mm

b2 ~ 2.3mm

~VIDEO

t

\.

(-:-

.

H

H

H

H H

H

H

H

H

H

H

M

...

...

3. LINEARITY

Y.J

~

I

I

Yll

I

I

ly

JY

~

---

~---- ·

-···-

-·-·1-!X16

o EXCEPT:

X1, X16,

Y1,

Y12

H

!i

12

ICHAI'IACTER

DISPLAY)

-e+~

H

c

H f

H

H

~

H

!!

H

D

1

1----

CRT

A

~2.3mm

B

~2.3mm

C ~

2.0mm

0~2·0mm

H-LINE

: Xmax-Xmin

----

X

IOO(%>

X max

V-

LINE:

Ymax-Ymin X

100(%)

Ymax

CONDITION

MEASUREMENT CONDITION STABILITY CONDITION

LINE

H·LINE

MAX

10%

MAX

3%

V·LINE

MAX

10%

MAX

3%

Figure 4. Geometry Measurements

-9-

·w·f•"'~'-t<3-lf.:'·~i',-

· •' ,

•.

,,..,,~

-

· · ·'

·

-~~zttwJ.~rt!.~t -:

:'

.~:

·~~)~~~~'f:

-

.

:

~~:

-

.

:'

-..

--..:. ~

~~2~·

::

..

:

:~~~:-·

. -· ...... •••

..

. . ··•

~·

-·r•

·-·-

..... :.

·

'-'--~-

~---·· ·~···--··--

•

· •

~--

·--·-..:i,;•

:-:

;::_~:;,{:;i

·'--·

--

-··

•• • • •"• ·-

-·-

-··

·· ,;_,_.,.

____

.._

...

- ·

w£!..o-.::

.....

- ....

..

_-l.-

•---·-~·

~

·

.... · ·-

I SERVICE ADJUSTMENTS I

NOTE:

ALL GEOMETRY MEASUREMENTS SHOULD

BE

PERFORMED

AT

THE DISPLAY ADJUSTEDT0230

mm WIDE AND

165

mm HEIGHT AFTER WARMING

UP

THE MONITOR

FOR

30

MINUTES.

1. H-HOLD ADJUSTMENT

1-1.

Set the H-position VR702

to

the mechanical

center position.

1·2.

Display white over the entire screen.

1-3.

Turn the H-hold

VR701

until

the picture is

almost-stable.

2.

HORIZONTAL

AND

VERTICAL CENTERING

ADJUSTMENT

2-1.

Adjust centering magnet (on

the

DY)

that the

(-

. picture to

be

mechanical center.

2-2.

Display the cross hatch pattern screen.

2-3.

Adjust H-position VR702

until

the picture is

positioned at the center

of

screen.

2-4.

Adjust V-position

VR605

until the picture is posi-

tioned at the center of screen.

3.

HORIZONTAL

AND

VERTICAL SIZE

ADJUSTMENT

NOTE:

Before

attemping

adjustment,

adjust

brightness volume to be

30

± 8FL in Full

white pattern, at

this

time contrast volume

is maximum.

3·1.

Adjustment

of

horizontal size.

3·1·1. Display cross hatch pattern screen.

3·1·2. Adjust the H-size VR704

until

the picture

size become 230 mm.

3-2.

Adjustments

of

Vertical Size

3-2-1.

Display cross hatch pattern screen.

3·2·2. Adjust the V-size VR603

until

the picture

size becomes 165 mm.

4.

VERTICAL

LINEARITY & HORIZONTAL

LINEARITY

ADJUSTMENT

4-1.

Display the cross hatch pattern screen.

4-2.

Adjust

VR604

(V-Lin,

Volume)

to

the best condi-

tion.

4-3.

Check

the vertical linearity when the nonlinearity

is

within

10%

on

all

signal

with

cross hatch pat-

tern.

4-4.

Adjust

L704

(H-Lin

Coil)

to

the best condition.

4-5.

Check

the Horizontal linearity when the nonlin-

earity

is

within 10%

on

all

signal

with

cross hatch

pattern.

5.

DISTORTION ADJUSTMENT

5·1.

Display the cross hatch pattern screen.

5-2.

Adjust clic:tortion magnet

(on

the

DY)

to

meet

Fig. 4

G~ometry

measurements.

5-3.

Adjust side pincnshion or Barrel co,;

tml

v~lume

(VR707)

to meet Fig. 4 Geomertry measurements.

6.

BRIGHTNESS AND CONTRAST

Set

the Sub-Brightness control

VR705

to

disappear

of

the backraster; when external brightness control

knob is positioned at the maximum.

Thereafter, set external contrast volume

to

max posi-

tion and control internal contrast volume

(VR710)

to

30FL at center screen.

The contrast control is used

to

vary the data

brightness level

as

dicated by ambient lighting

conditions.

7.

FOCUS ADJUSTMENT

Adjust the focus control volume

(VR301)

for best over

all focus

of

test

pattern (Display

with

all

"H"

character). Usually the center and corners

of

the

screen do not focus at the same setting and a

com·

promise must be made.

-:-10-

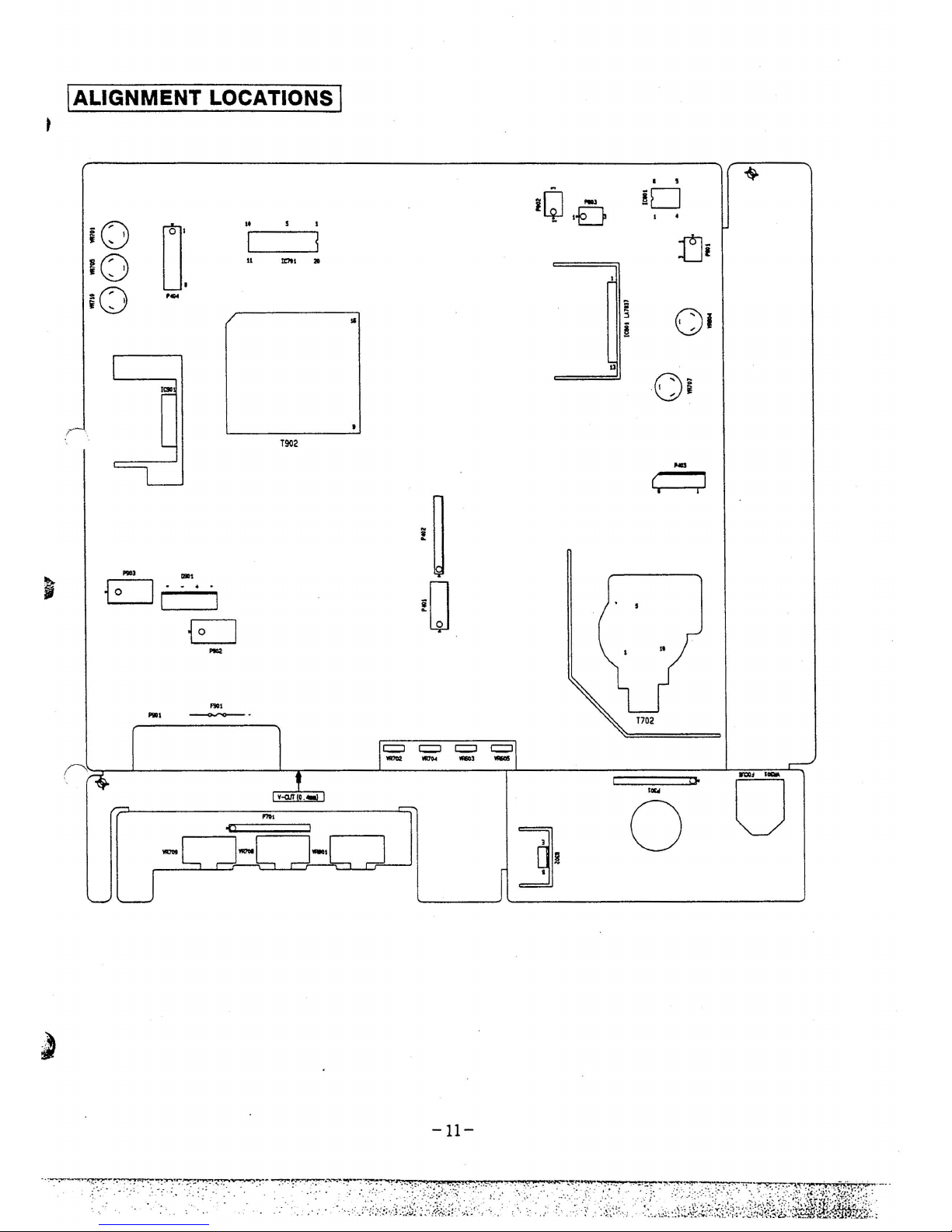

!ALIGNMENT LOCATIONS I

I s

'$-

i[J

-

ftD

-

1-D

I

•

i()

0:

"

s

I

I

l

t]i

;()

II

11:?11

..

I

·o

....

~

- I

i "

Ql

/

:l

II

ft

ll

~

()i

r

I

L-

T902

'---L_

...

(

I

•

I

-

..

1

~~

EJ,·

..

·D

I

s

EJ

-

1

"

...

I

....

T702

1

rr=J

r=J

r=J

;I

"""'

..,..

_,

,._.;

r

~

•

RC:I

11QM.

.....

0

v-arr o.-.1

0

~

,...........

,,

..

r

]}

~[

l--f

]-·[

J

~U

~

-ll-

·

--=----~

~

~

-~

"="~~~~--~ __,_:

~·~

----~~-·-

·

:.~

.7-r:.~'-~.

=-:./.-

.

..

·.·

~.-·-

.:~

.1;:

~ -'

·

__

:_~:.

·

.·.

·

·.-·~·~.

- -.··

--

_:.

.

..

~:7

: ·

·~·

.·

·

~·:-

~.

~

1\7T?}:

y\:::-

..

\''::

~~-~-:-:-.:

-.:~~-

:/I.

~·;:,

t-\,~~

i~~~

t--~s--·

-

' .. · .·

•··

·

:{.,;o;·

:~~~~

i::i(

{

j;

',;l;)

;$ttJl•.i~~\~

m;

t.i

&::.;

...

·.,.

':

·:~~~--

·-n~

~;~r~

~:~-~~~~;:

t~:\~l::

::_· - -~·.

:

_·.

.

,.

. .

.. _ -.:..

. · .•

b'-

...

_.

:.·.~~-J~

~-

.....

~i~~~-i.:.,

·.:.:

~

-·

.

....

::

...

::

~...,..;.

·

..;,;.

·

_-..:.

- -~.:.:;;·~

:-

;._

__

I DESCRIPTION OF ALIGNMENT LOCATIONS I

1. Main P .C.B

Marking

Description

Marking

Description Marking Description

VR701

H-Hold

VR

IC701

H-Deflection IC

P403

From D.Y(Deflectior

VR705 Sub-Bright

VR

IC601

V-Deflection IC

Yoke)

VR710 Sub-Contrast

VR

IC801

Audio AMP IC

P802

To

Control Volume

VR604 V-Linearity

VR

0901

Bridge Diode

P.C.B(P701)

VR707 Side Pincusition

VR

IC901

SMPS

Control

P803

From Signal Cable

VR702

EXT

H-Position

VR

Switching IC

P801

To Speaker

VR704

EXT

H-Size

VR

P901

AC Socket

VR603

EXT

V-Size

VR

P903/904

To Power Switch

VR605

EXT

V-Position

VR

P401

From Signal Cable

T902 Power Trans

P402

To CRT Socket

T702

F.B.T(Fiy Back Trans)

P.C.B

(P301)

F901

Fuse

P404

To Control Volume

P.C.B

(P701)

2. Control Volume P.C.B

Martc:lng

Description

VR709

EXT Brightness

VR

VR708

EXT Contrast VA

VR801

EXT Sound

VR

P701

From Main P.C.B

P404 & P802

3. CRT Socket P.C.B

Martc:lng

Description

VR301

Focus

VR

0302

Video

AMP Out

P301

From Main P.C.B

P402

-12-

I TROUBLESHOOTING.GUIDE I

Problem 1.

NO

POWER

(Cause)

Trouble in the power circuit

IC901,

0901

and

its

external elements are faulty.

( \

NO

POWER

YES

TROUBLE

IN

PRIMARY

OTHER

COMPONENTS

NO

NO

NO

NO

NO

NO

-13-

TROUBLE

IN

POWER

CORO

TROUBLE

IN

FUSE

F90

1. 1.6A/2SOV

TROUBLE

IN

0901

TROUBLE

IN

IC901

STRS5041

TROUBLE

IN

0901

TROUBLE

IN

SMPS

SECONDARY

B

LINE

SHORT

SSV

. 33V.

14V.

12V

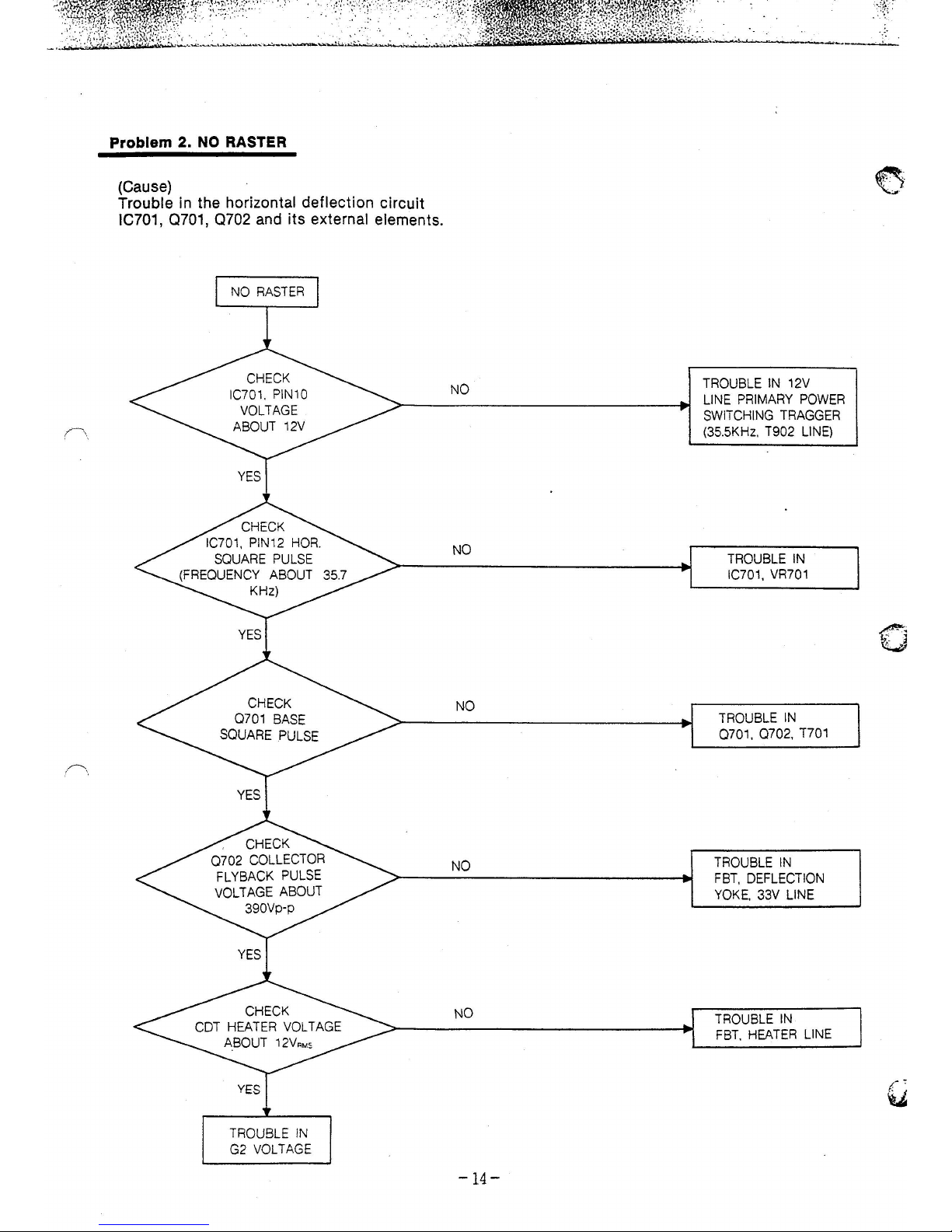

Problem 2.

NO

RASTER

(Cause)

Trouble in the horizontal deflection circuit

IC701, 0701, 0702

and

its external elements.

NO

RASTER

YES

TROUBLE

IN

G2

VOLTAGE

NO

NO

NO

NO

NO

-14-

TROUBLE

IN

12V

LINE

PRIMARY

POWER

SWITCHING

TRAGGER

(35.5KHz.

T902

LINE)

TROUBLE

IN

IC701,

VR701

TROUBLE

IN

0701. 0702.

T701

TROUBLE

IN

FBT,

DEFLECTION

YOKE.

33V

LINE

TROUBLE

IN

FBT.

HEATER

LINE

Problem 3.

NO

IMPROPER HORIZONTAL

OR

VERTICAL SYNCHRONIZATION

(Cause)

1)

Defective horizontal sync.

IC701

and its applied parts are faults·.

2)

Defective vertical sync.

This is due to a failure

of

the vertical oscillator.

(IC701

and its applied parts), or applied parts of the IC601.

NO

CHECK

THE LINE

OF

BETWEEN

PIN

401

AND IC701

PIN

1

CHECK

IC701

NO

AND

12V

LINE

TROUBLE

IN

HOR.

TROUBLE

IN

OTHER COM-

PONETS

OR

VER.

SYNC

YES

-15-

NO

TROUBLE

IN

SIGNAL CABLE

PIN

401

TROUBLE

IN

0601

TROUBLE

IN

IC701 AND

12V

LINE

Loading...

Loading...