Page 1

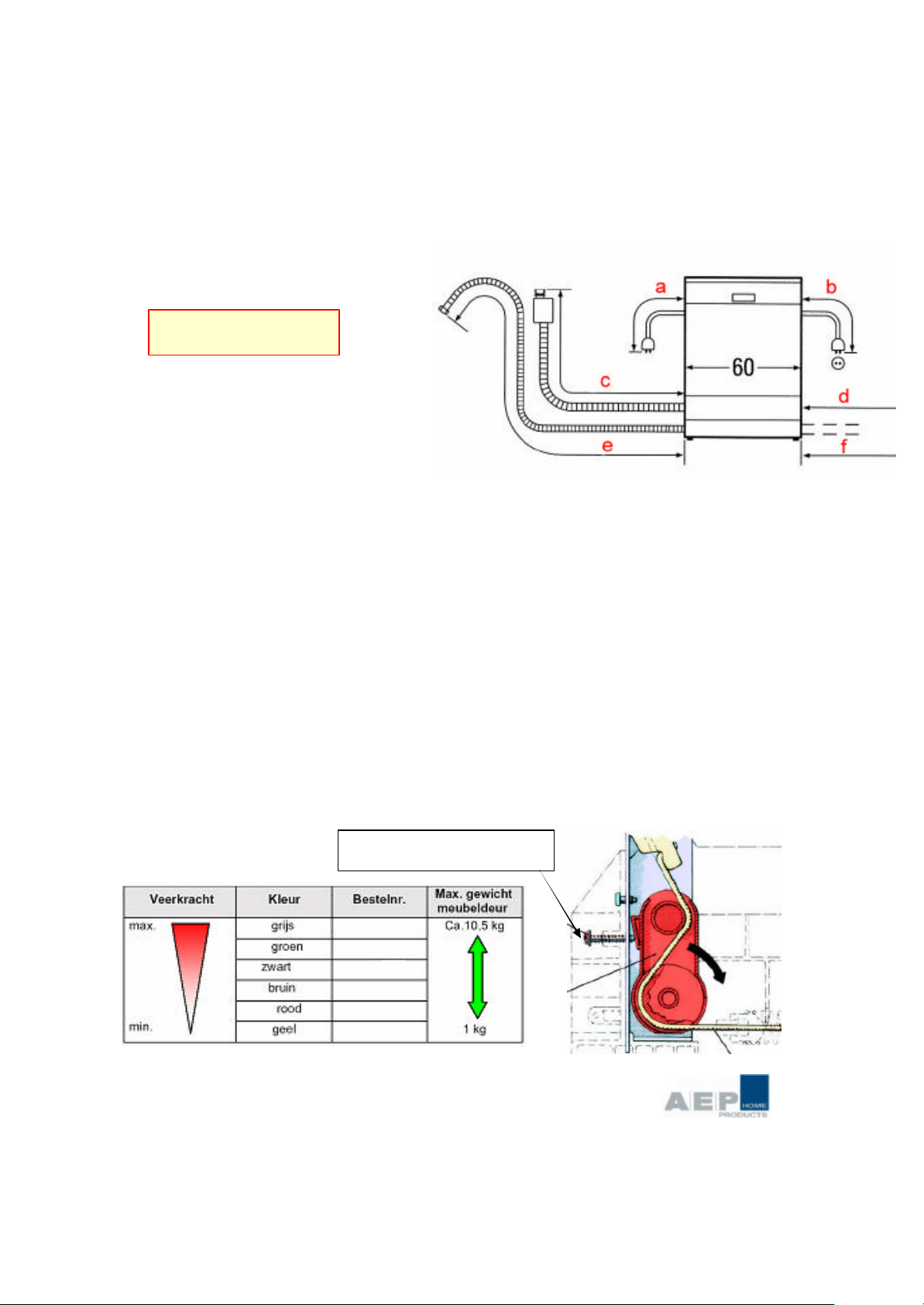

ATAG VA3..

VA9011ZT / XT

VA(9)6211Q /R/S/T

Page 2

Maximum heigth 90 cm

Enclosed separately

General information

The machine may be connected to a hot water tap upto 60 °C.

For cleaner and dryer results however, it is advised to connect the machine to a

cold water tap

with extension 80 cm

va =1,3 m

v b=1,6 m

v c =1,4 m (3,6 m with extension set)

v d =1,2 m (3,4 m with extension set)

v e =1,6 m (3,6 m with extension set)

v f =1,2 m (3,2 m with extension set)

Water connection:

v The water connection is ¾”

v Minimal water pressure 0,5 bar (to be tested with a bucket, minimal 8 l/min)

v Maximum water pressure 10 bar

Warmwater recognition:

If during hot rinsing the temperature of the incoming water is higher than 45°C , the

temperature of the hot rinsing is increased to 72°C.

The heat exchanger is not being filled during the drying process.

Weight accessory panels

88001054

88001114

88007087

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

- 1

-

Page 3

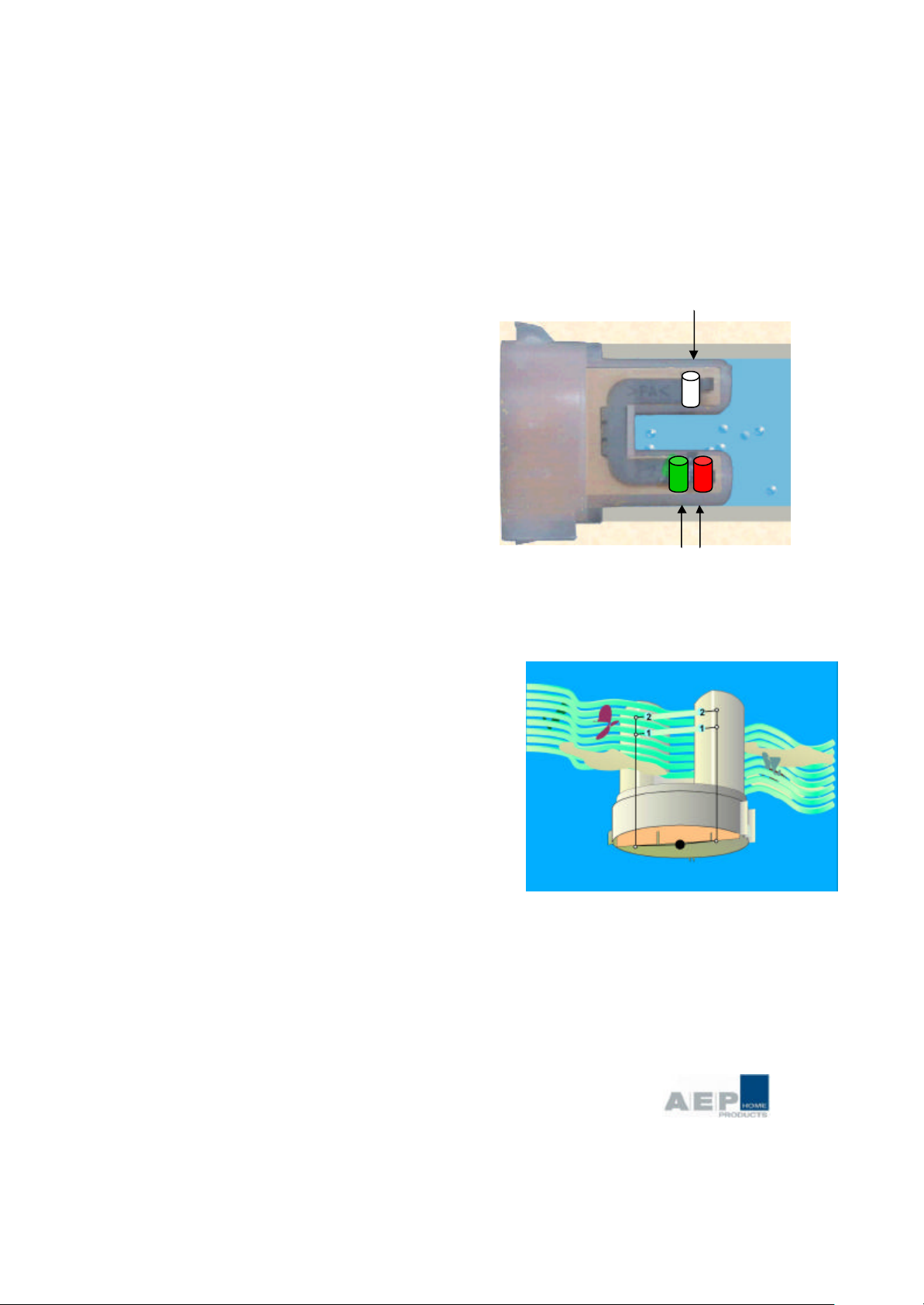

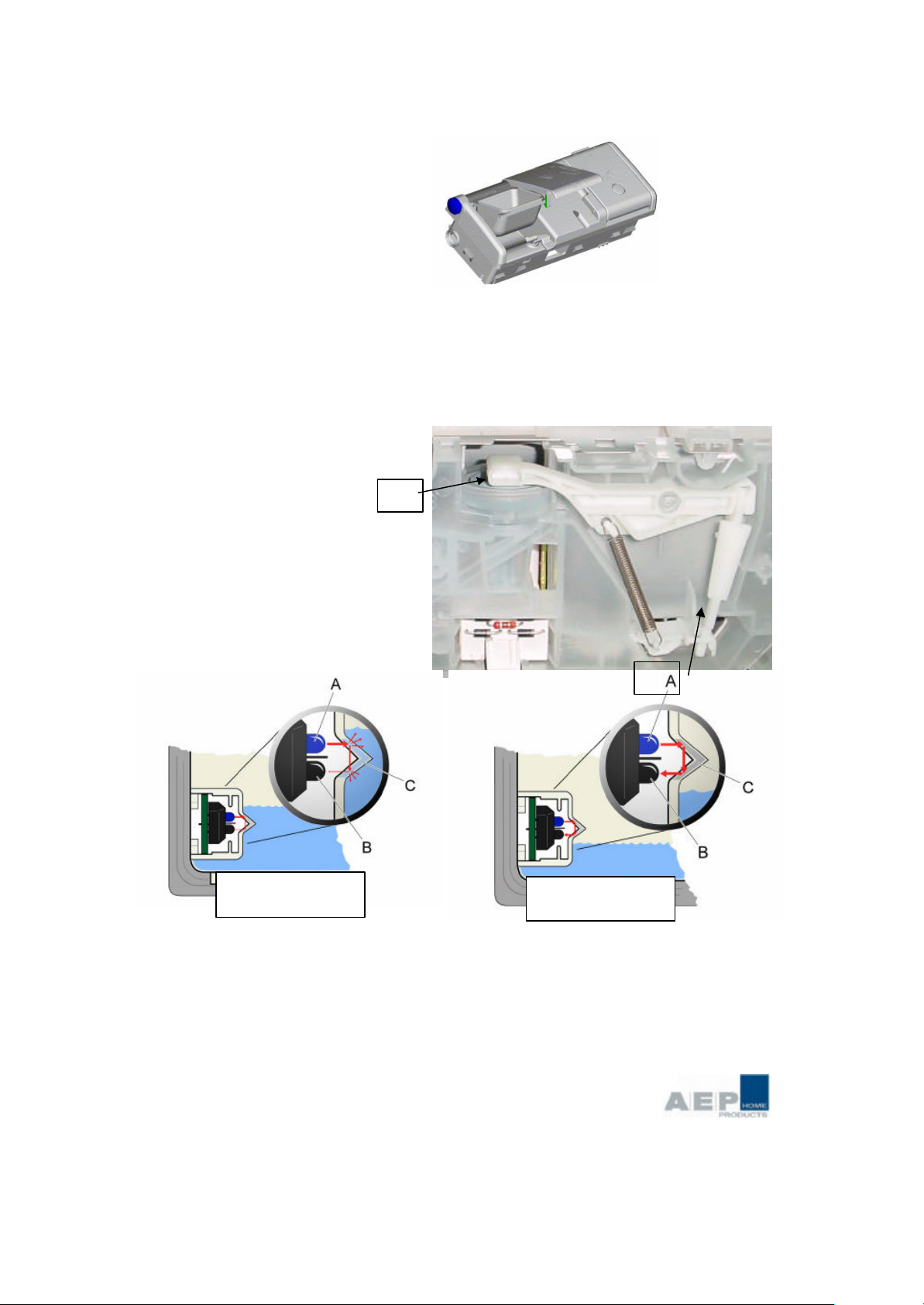

Aquasensor II

By means of the Aqua sensor it is decided whether or not the rinsing

water will be used for the next rinsing cycle.

The Aqua sensor II has two LED’s

v Red LED (measures turbidity)

v Green LED (measures soil remains)

Because of this, more soiling (like tea or

spinach) will be recognized.

The calibrating process uses water, reason not to calibrate every washing cycle.

During the first 3 washing cycles an extra 400 ml water is being used for

calibrating the Aqua sensor.

The calibrating process is repeated every 20th

washing cycle.

Receiver

Transmitters

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

- 2

-

Page 4

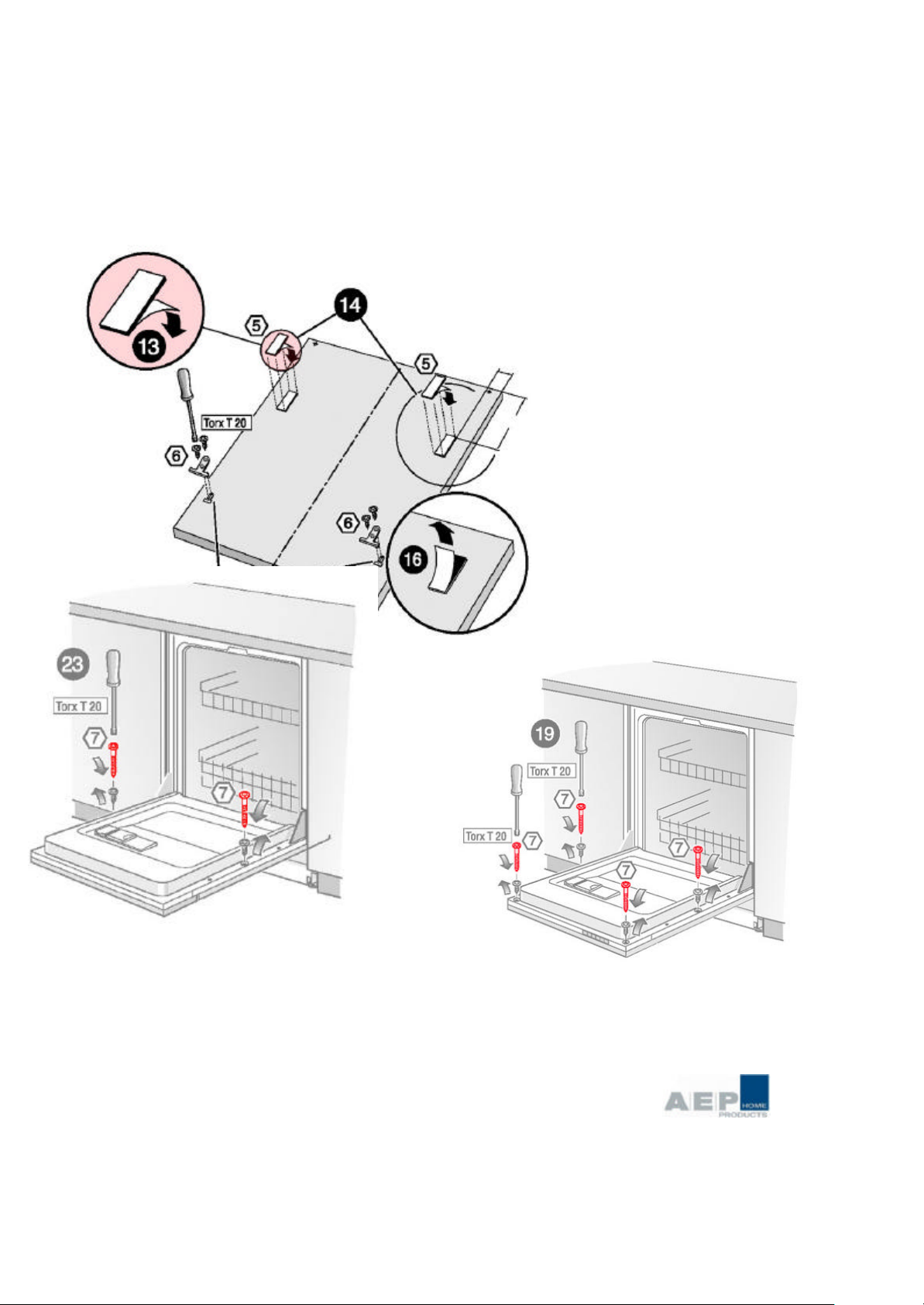

Panel mounting ( new )

Integrated Fully integrated

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

- 3

-

Page 5

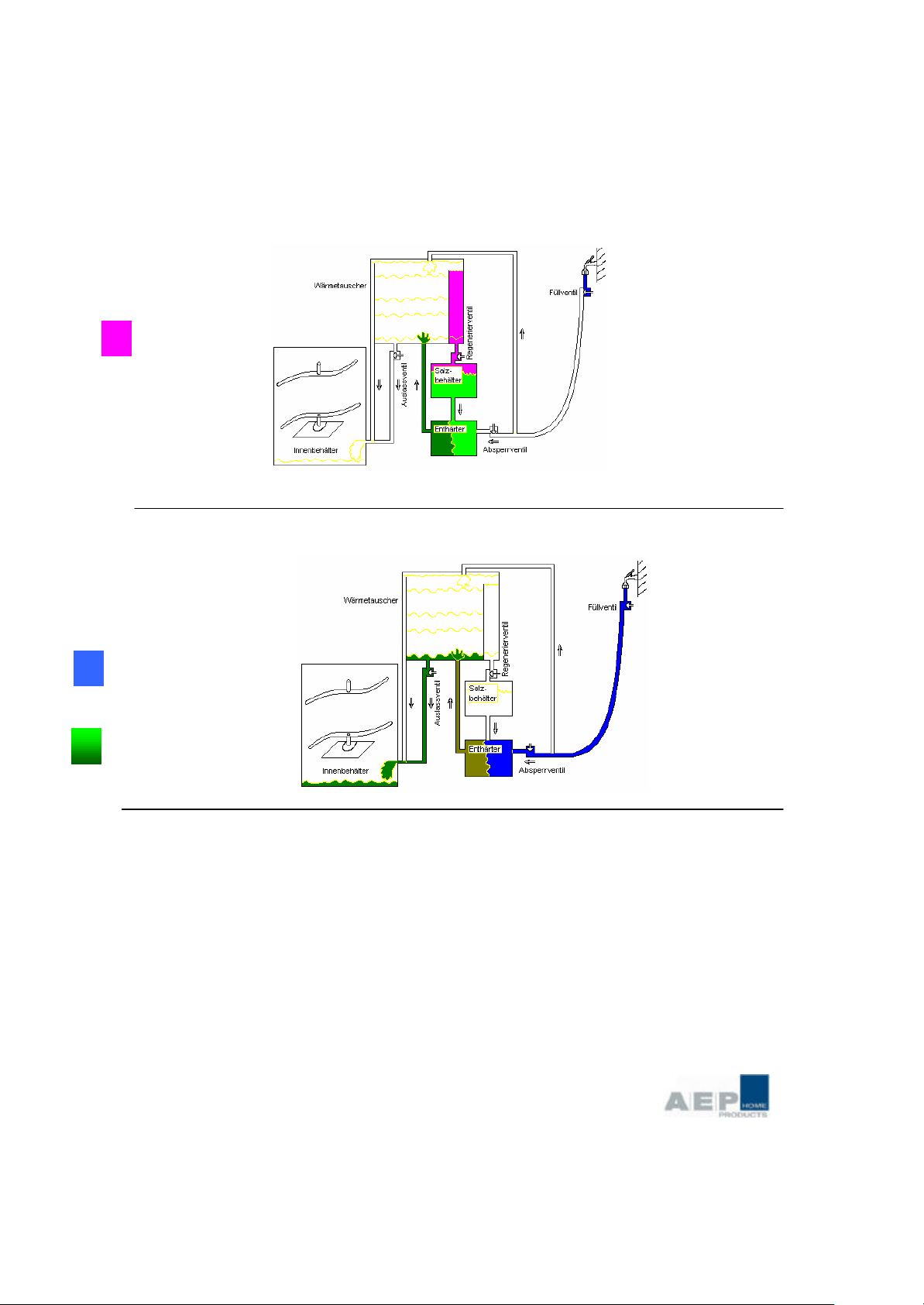

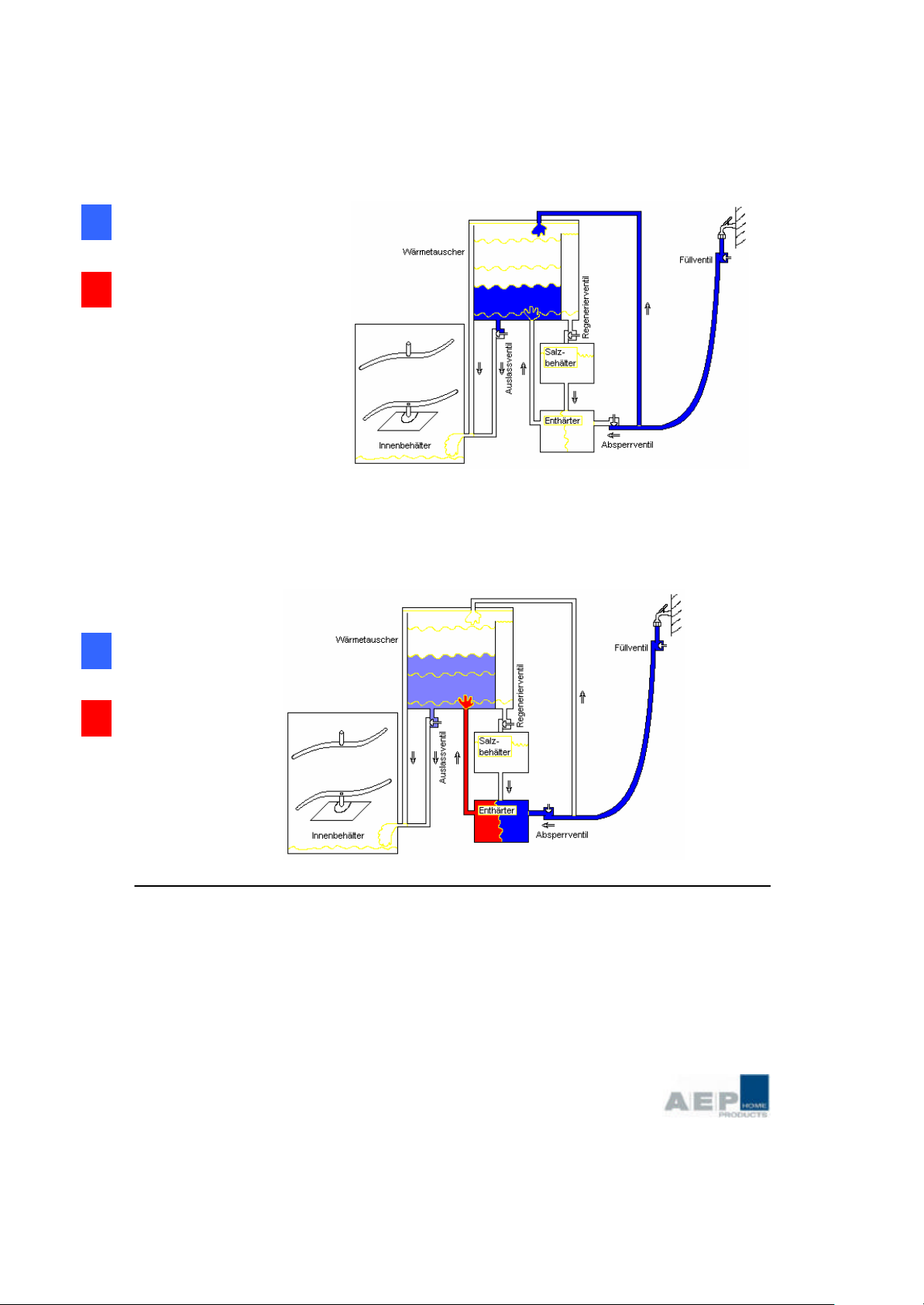

Regenerating the water softener

Regeneration water

Flushing the softener

Hard water

Reg. Water

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

- 4

-

Page 6

Filling with non-softened water.

Hard water

Soft water

Filling with softened water.

Hard water

Soft water

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

- 5

-

Page 7

Load recognition

How it is determined whether or not water has to be added because of toppled

crockery.

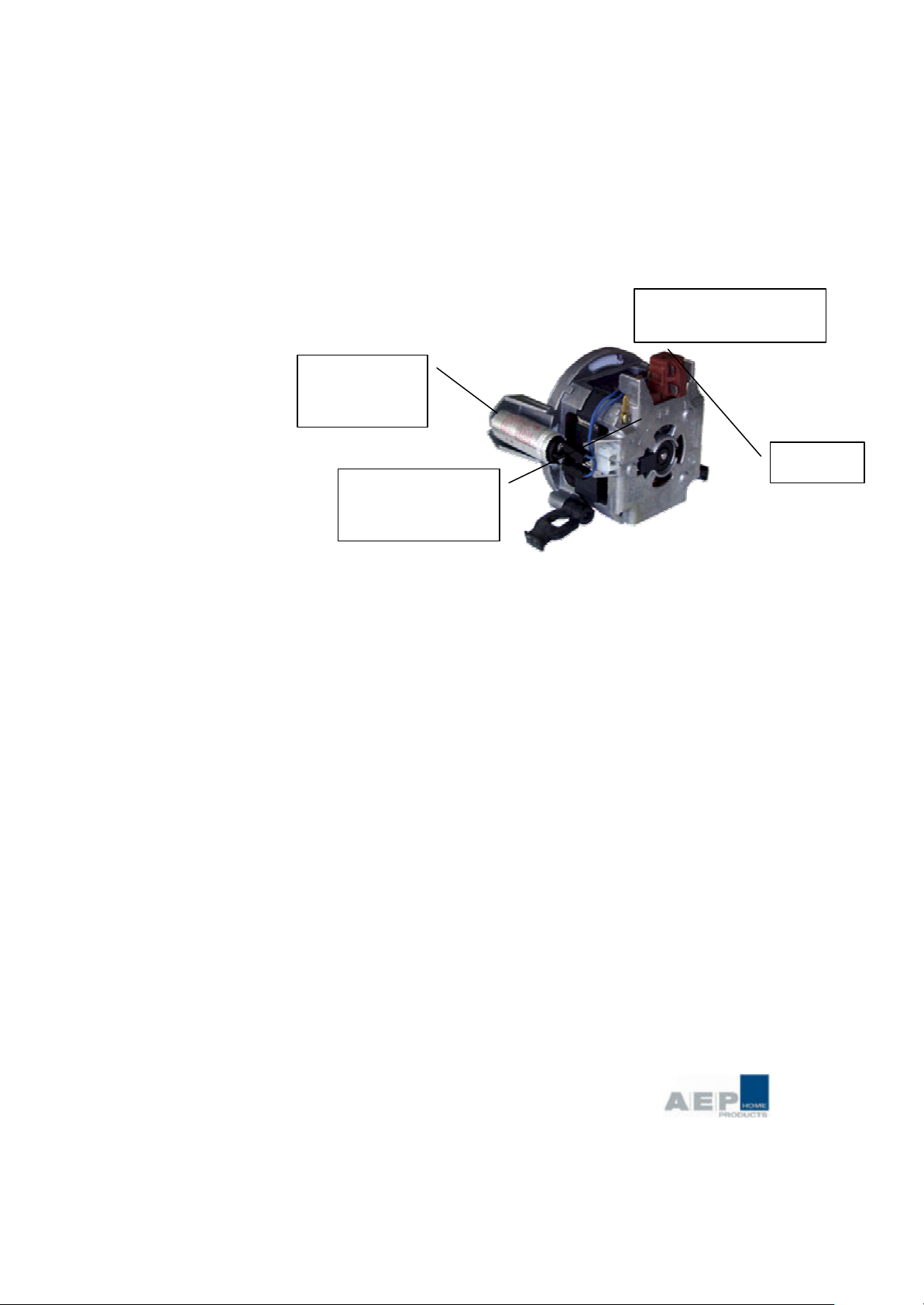

Circulation pump

with tacho and sycasym control

Capacitor

Tachogenerator

Single phase AC motor

Tacho generator

Motor RPM is measured by means of a tacho generator.

Speed control is applied by means of electronic phase shifting.

v Load recognition

At the first wetting of the dishes, some water will stay behind, for instance in a

toppled dish or plate, so under circumstances the machine begins washing in

short supply of water.

If so, the pump may catch air, starting to run irregularly while making more noise.

The tacho generator recognizes this irregular running and extra water is supplied.

v At the first test 200 ml

v At the second test another 200 ml

v At the third test another 500 ml

Max. 900 ml of extra water supply is possible.

This means that not 2,8 l but 3,7 l of water is being used for washing.

PTC

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

- 6

-

Page 8

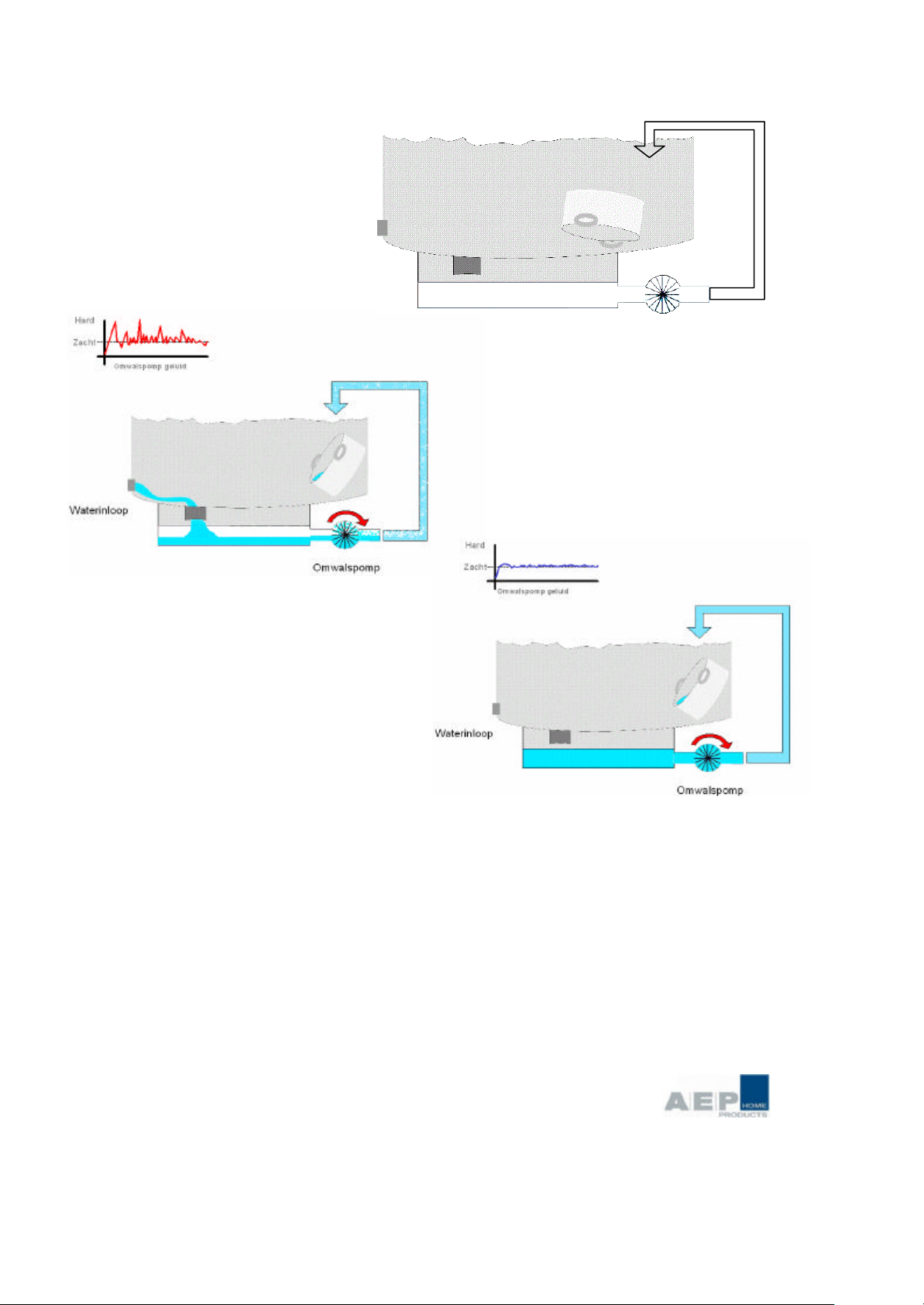

Load recognition

Tacho recognizes shortage of

water because of irregular running.

After levelling the machine runs

quietly again

Motor RPM is measured by means of a tacho generator.

Speed control is applied by means of electronic phase shifting.

• Load recognition.

• RPM reduction d uring soft programs

• RPM reduction at rinsing change (shifting from upper basket washing to

lower basket washing )

• Different RPM for upper basket washing relative to lower basket washing

( 2200 / 2800 1/min)

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

- 7

-

Page 9

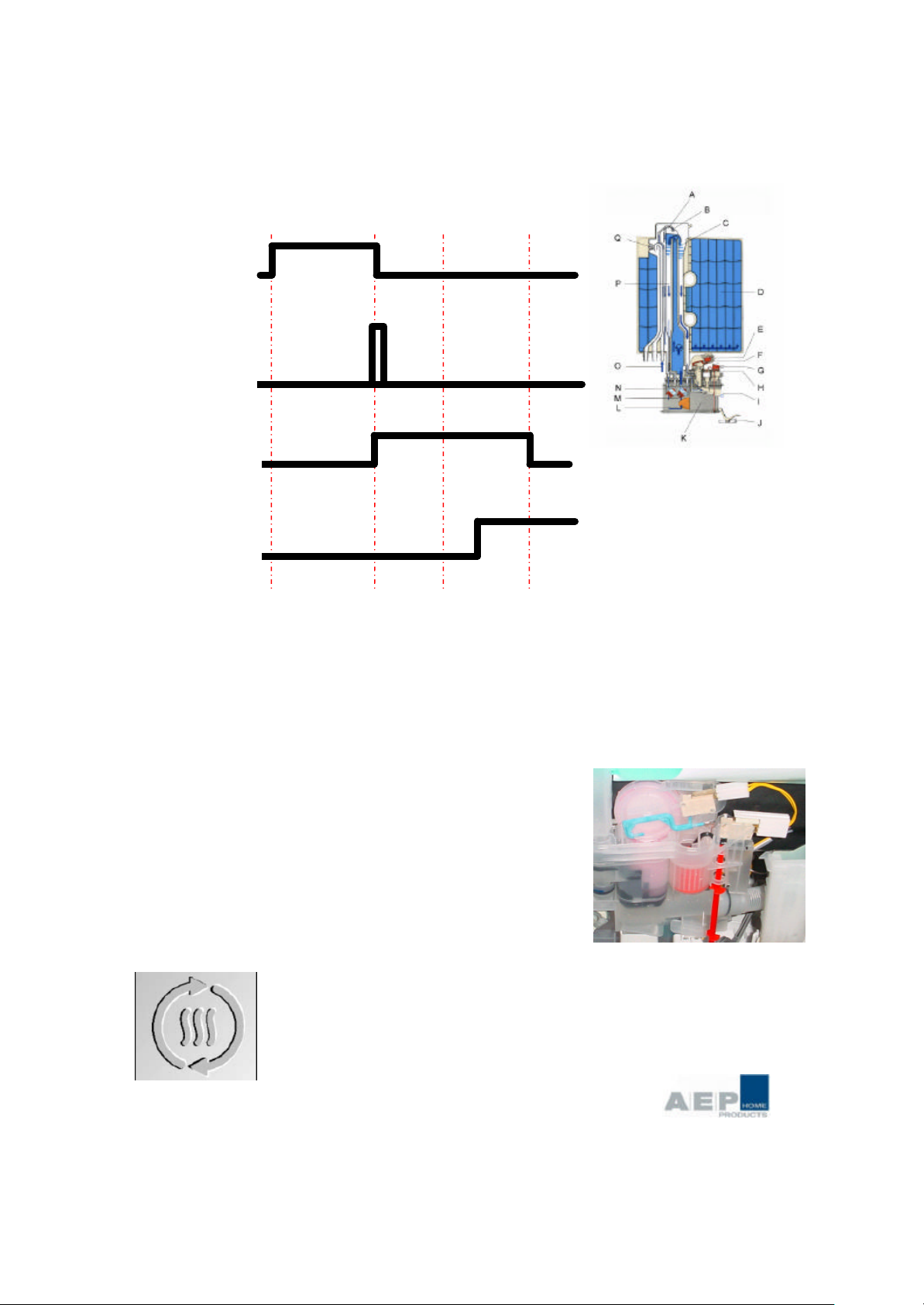

Inlet valve

Outlet valve

F1

After

this, water

supplement

depends on

the

tacho

generator

(load recognition

) Circulation

Filling water

pump

If tap is closed:

In case level F1 is not reached after 3½ minutes, the control will stay in this

position. On the display the message appears: ´Check water supply´.

As soon as the tap is opened, the machine will continue running the program .

In case of clogged level chamber or faulty F1

In case of faulty F1 the filling process develops as

follows

v Machine continues filling

v Safety level will be reached

v Machine idles

v After some time the inlet valve will be closed and

the programme continues

This symbol on the inner door indicates that the machine is equipped

with a heat exchanger.

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

- 8

-

Page 10

B A

Soap dispenser

Function:

At the first pulse the soap dispenser is opened. Lever A is put in the position which

facilitates – at the next pulses – the operation of lever B (each pulse lasting 20 seconds).

Depending on the chosen amount of

rinsing aid, this lever B is being

activated (2 ml per pulse )

Setting Pulses

0 0

1 2

2 3

3 4

4 5

5 6

6 7

Tank total 120 ml

Top control. Only for ST and TT

Sufficient

The soap dispensers in the other models are controlled by means of an actuator. This

actuator is being controlled for two minutes continuously . That is why these dispensers

are not interchangeable !

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

- 9

-

Empty

Page 11

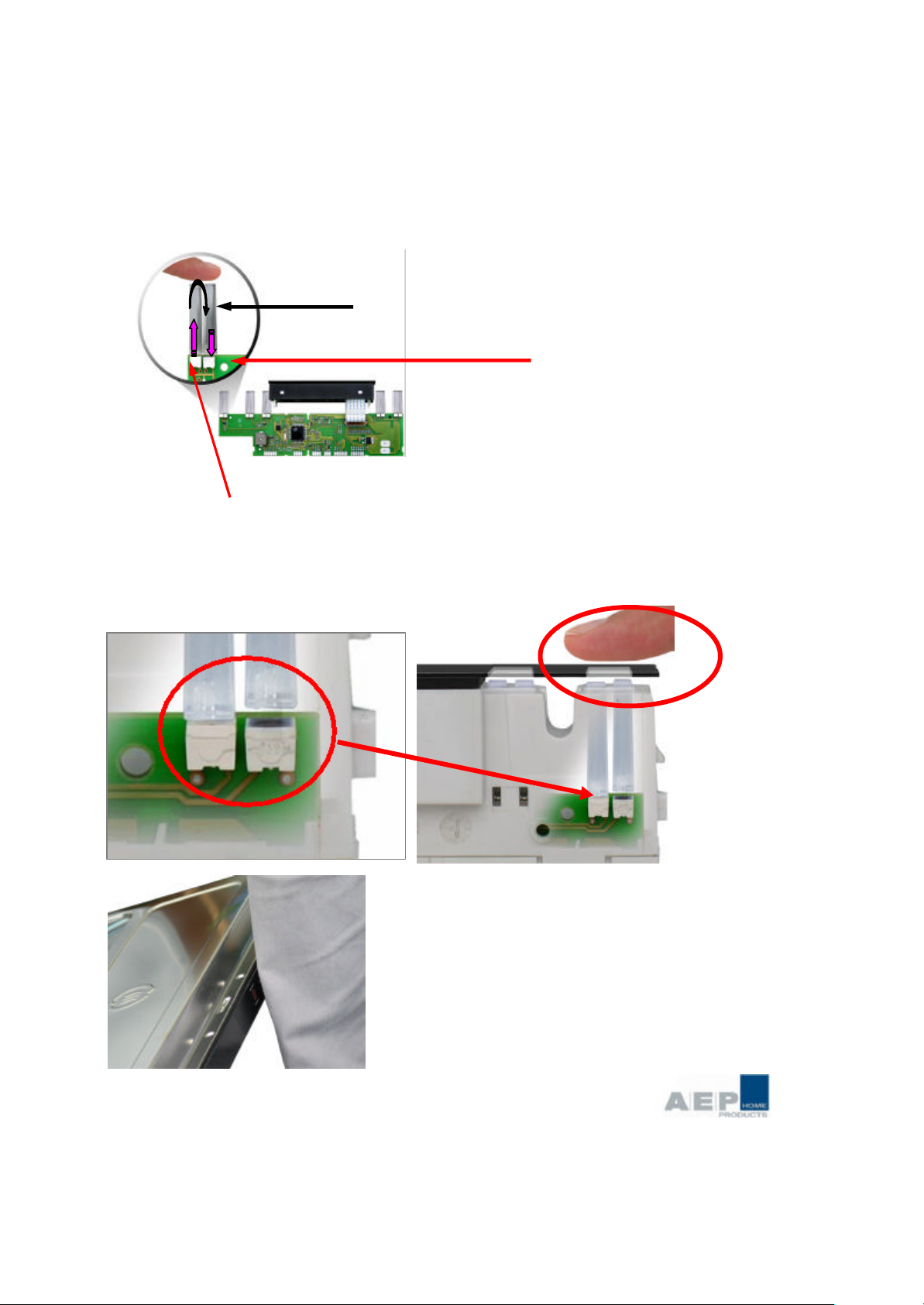

Operation

Touch control with IR technology

Lightconductor

IR -receiver

IR-transmitter-LED

Common problems with IR sensors

Too much distance between sensor and panel

Sensor comes loose

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

10 -

Page 12

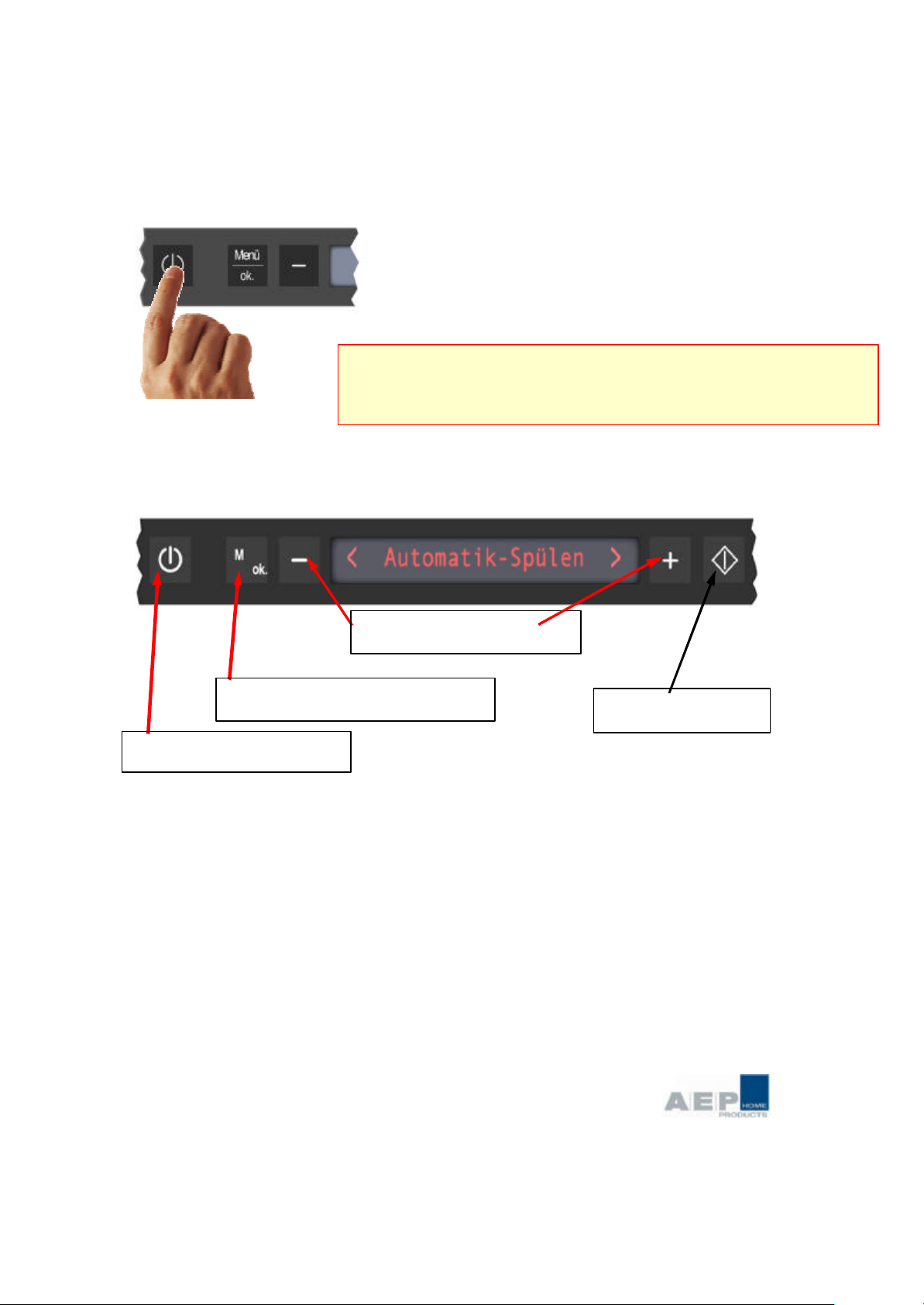

Sensors react after ~1 seconds

Stand

-

by button

Option

-

/ store button

Push touch control button at least 1 second .

Main switch after ~2 seconds

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

11 -

Selector buttons

Start button

Page 13

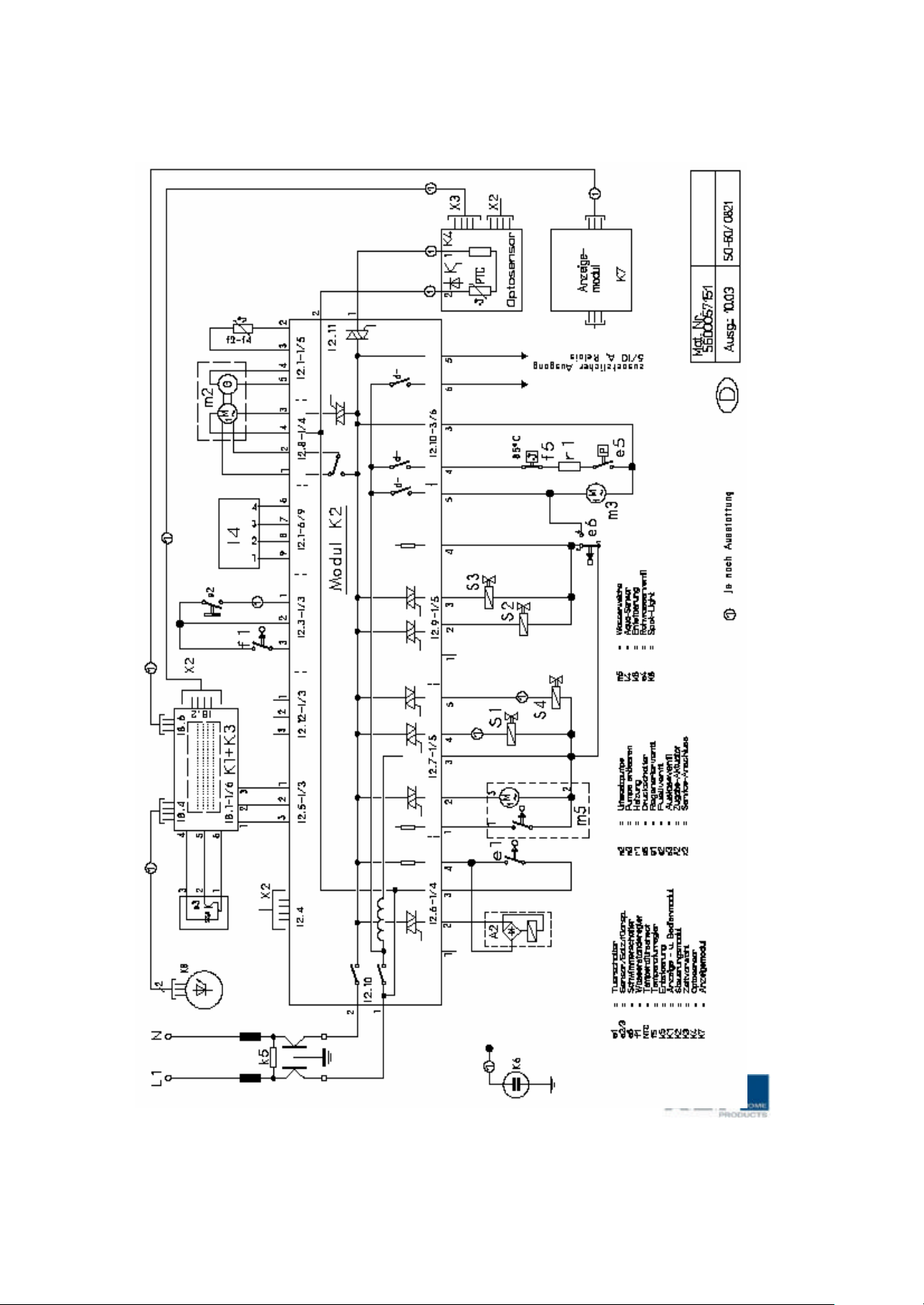

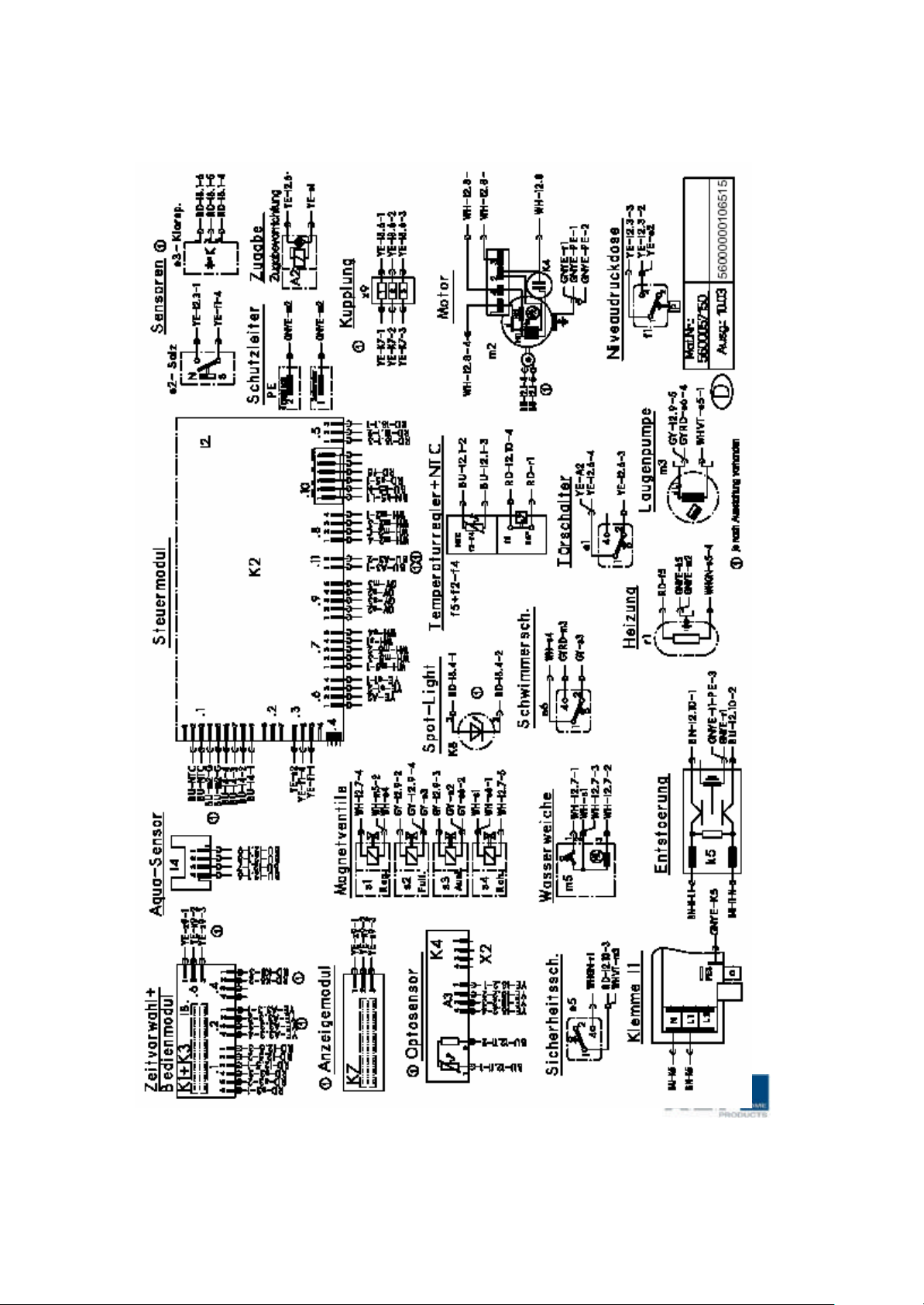

A control soap dispenser B

water

renewal

VA(9)6211TT

C regeneration valve D Aquamix valve

F inlet valve G outlet valve

H circulation pump I Opto sensor

J drainage valve K sicasym relay

L+M mains relay N heating relay

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

12 -

Page 14

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

13 -

Page 15

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

14 -

Page 16

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

15 -

Page 17

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

16 -

Page 18

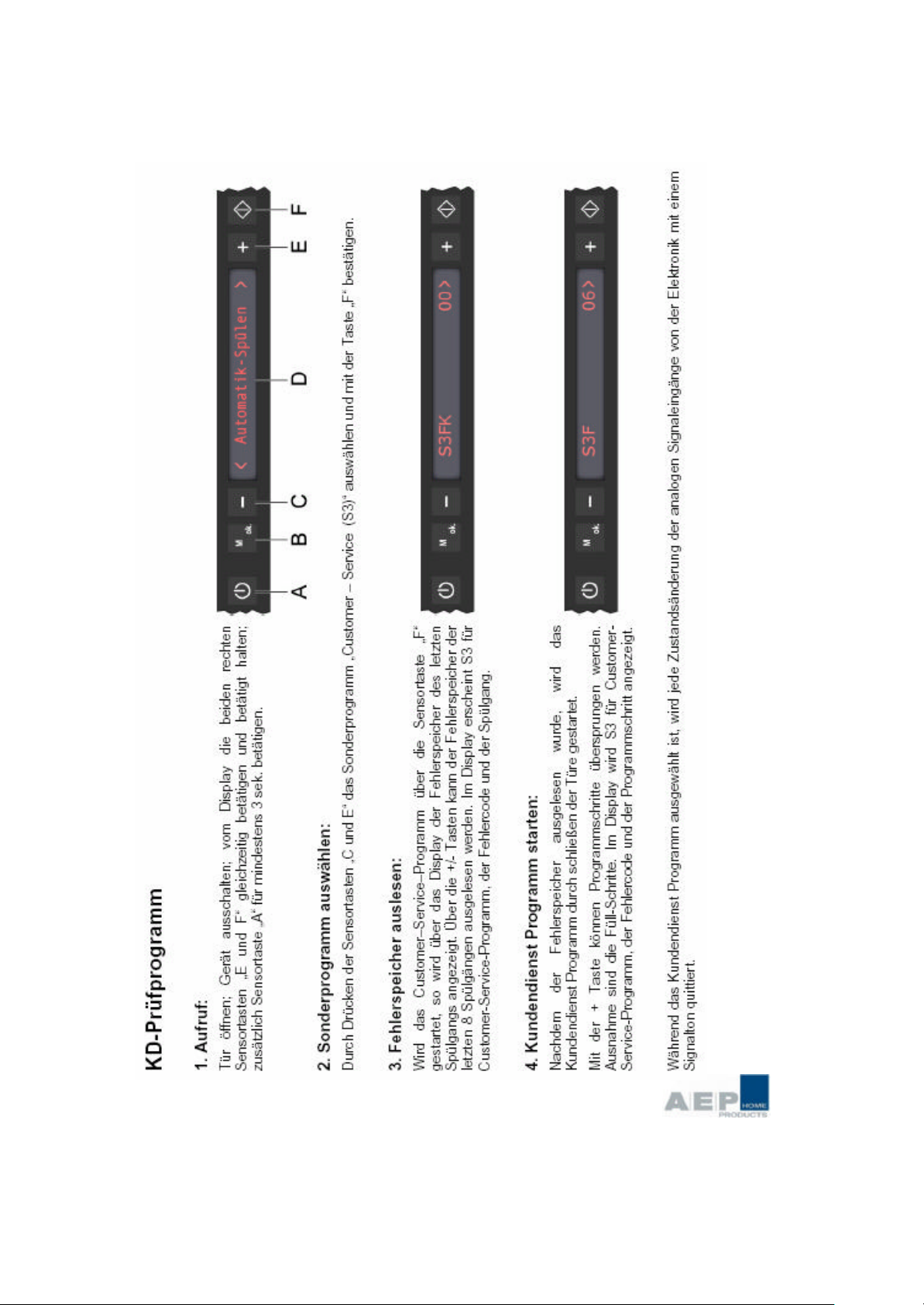

Activ

ating

special

programs

service department

Options for the

1: Open door and switch off machine.

2: Push and hold the buttons E + F.

3: After this, push button A for at least 3 seconds.

4 Select program using +/- buttons.

5: Button F activates chosen program.

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

17 -

Page 19

Special programs

Functi onal test display

By pushing B C E and F all pixels of the display will lighten up.

Special programs

Factory test program

Test program as used in factory,

not relevant for service department.

Special programs

Factory test program

Test program as used in factory,

not relevant for service department.

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

18 -

Page 20

function.

Special programs

Factory test program

Test program as used in factory,

not relevant for service department.

Special programs

Showroom program

Showroom program

Various items are being displayed without activating any

Special programs

Error reset

Resetting all errors in memory of the machine.

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

19 -

Page 21

2: Luxury soap dispenser on top of machine

Special programs

Selection of soap dispenser

Possible choices soap dispenser.

1: Normal soap dispenser

Special programs

Selection water softener

Optional selection of using the water softener.

Once chosen for not using the water softener, this option

will not longer appear in the option menu.

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

20 -

Page 22

Does not apply for our models.

Special program s

Selection Opto sensor

Special pr ograms

Reset of the Opto sensor

After changing an Opto sensor, calibrating is necessary.

Use this program.

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

21 -

Page 23

3

2

The test program

After activating the test program, at first

all

errors

are

Reading of errors

1

being showed that occurred during the last 8 runs.

S3 = test program

Error K en H occurred during the last run (00)

00 = last run 01 = the run before last, etc.

The test program

The test program starts after closing the door.

S3 = Test program

F = Error F occurred during the test program

06 = Acti ve test step

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

22 -

Page 24

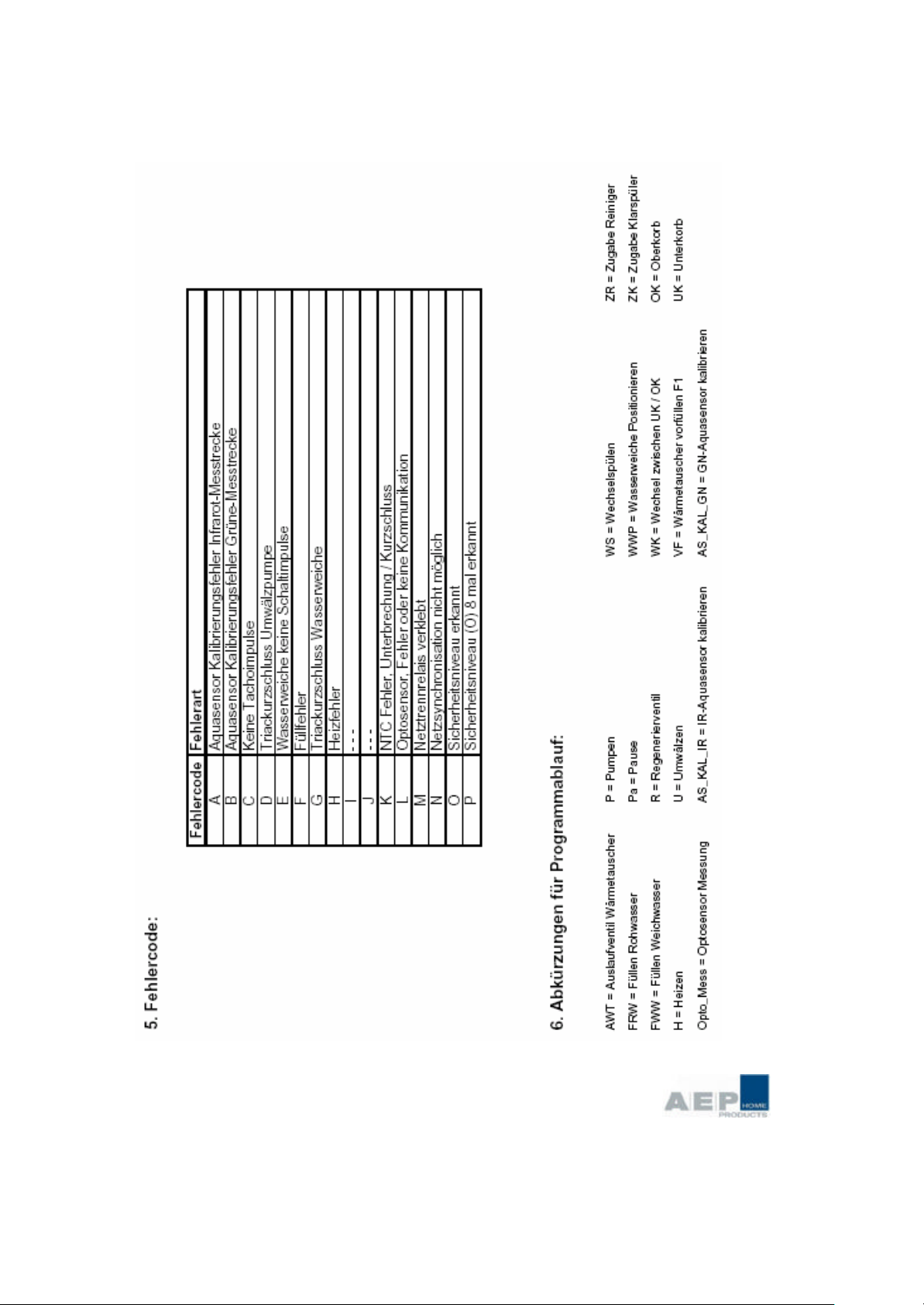

Error codes

A Aqua sensor calibrating error red sensor

B Aqua sensor calibrating error green sensor

C No tacho pulse

D Circulation pump short circuit

E No pulse from water hardness sensor

F Filling error

G Triac water hardness sensor short circuit

H Heating error

I - - -

J - - -

K NTC error, interrupted / short circuit

L Opto sensor, error or no communication ( does not apply)

M Relay power supply stuck

N Net synchronisation not possible

O Safety level activated

P Safety level (O) 8 x recognized

Sequence test program VA(9)6211TT

0 Pumping 30

1 Opto sensor PTC switched on 2

2 Filling soft water - Aqua sensor - Opto sensor 1 litre

3 Pause - Aqua sensor (red) 2

4 Filling hard water - Aqua sensor (red) 1 litre

5 Pause - Aqua sensor (red) 2

6 Filling hard water - Aqua sensor (red) tot F1

7 Pause 2

8 Aqua sensor (green) 60

9 Outlet valve heat exchanger 60

10 Regeneration valve 10

11 Control soap dispenser 90

12 - 17 water renewal positioning BK / OK

18 Circulation pump (relay sub coil sicasym)10 + 20 OK

19 Water renewal positioning BK

20 Circulating 20 BK

21 Circulating + heating 250 max. 67 °C Rinsing

22 Pumping 5

23 Circulating 5

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

23 -

Page 25

Front panel

Light spot being projected on

floor

LED

Light

conductor

Light spot

Floor

24 Pumping 5

25 Circulating 5

26 Pumping 5

27 Circulating 5

28 Supply of rinsing aid 90

29 Filling soft water + outlet valve 1 litre

30 - 36 pumping 5 Circulating 5

37 Opto sensor measurement 2 2

38 Opto sensor PTC switched on 2

39 Pumping 30

00 END

Inf o light

The modelS VA6211TT and VA9211TT feature an info light

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

24 -

Page 26

the

customer

Options for

Time saving program:

Running the time saving program the Aqua sensor is only activated during rinsing

in between. Therefore, in addition to increasing the washing temperature, no prerinsing is applied .

Drying:

1: Energy saving drying:

Drying time is being decreased and temperature of rinsing aid is lowered to

55 °C

2: Standard drying:

3: Extra drying:

Temperature of rinsing aid is increased with 3 °C

Selecting amount of rinsing aid: only in combination with top soap dispenser.

Electronically switchable between 0 and 6.

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

25 -

Page 27

When selecting ´automatic´ the Opto sensor determines the regeneration. The

following settings can be selected by hand:

Selecting language

Selecting sign al:

Sound can be selected in seven increasing levels (standard programs without

using Aqua sensor or Opto sensor etc.).

v 0 = OFF

v 1 – 6 increasing sound levels

After finishing 5 x , then 5 times every 10 minutes.

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

26 -

Page 28

Triac

inlet

Triac

regeneration

Triac

water

renewal

Triac

outlet

Triac

actuator

Electronics

VA9011ZT

valve

valve

valve

motor

soap dispenser

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

27 -

Page 29

Relay

circu

lation

Relay

outlet

Rela

y heater

Rela

y starter

Buzzer

100 kHz transformer

motor

pomp

circulation motor

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

28 -

Page 30

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

29 -

Page 31

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

30 -

Page 32

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

31 -

Page 33

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

32 -

Page 34

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

33 -

Page 35

B = Triac

regeneration valve

A = Triac

hard

water

valve

F = Triac

outlet valve

G = Triac

so

ap dispenser

actuator

C = Triac Water

renewal

motor

E = Triac motor

slot

Electronics

VA9011XT

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

34 -

Page 36

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

35 -

Page 37

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

36 -

Page 38

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

37 -

Page 39

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

38 -

Page 40

100 kHz

Rela

y

starter

Electronics

Rela

y drainage

VA(9)6211QT

transformer

pump

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

39 -

circulation motor

Relay heating

Page 41

Triac

inlet

Triac

regeneration

Triac water

renewal

Triac

outlet

Triac

so

ap

Triac

circulation

dispenser actuator

motor

motor

valve

valve

valve

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

40 -

Page 42

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

41 -

Page 43

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

42 -

Page 44

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

43 -

Page 45

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

44 -

Page 46

B = Triac

inlet valve

H = Triac

regen

eration valve

A = Triac water

renewal

motor

F = Triac

outlet valve

G = Triac

soap dispenser

actuator

C = Triac hard

water

valve

E = --

Electronics

VA(9)6211ST

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

45 -

Page 47

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

46 -

Page 48

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

47 -

Page 49

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

48 -

Page 50

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

49 -

Page 51

Triac

inlet

Triac

regeneration

Rela

y circu

lation

Triac

upper basket

Triac

soap

Triac

outlet

Rela

y

Rela

y heating

50 Hz

Transistor

Electronics

VA311F

drainage

pump

valve

valve

motor

transformer

power supply

valve

dispenser

actuator

actuator

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

50 -

Page 52

Triac

inlet

Triac

regeneration

Rela

y circulation

Triac

upper basket

Triac

soap

Triac

outlet

Rela

y

50 Hz

Transistor

Buzze

r

Electronics

VA301I

drainage

pump

Relay heating

valve

valve

motor

actuator

transformer

power supply

valve

dispenser

actuator

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

51 -

Page 53

Total failure of the machine may be caused by a poor solder joint on the printed

circuit board, especially near the transistor power supply.

Not fitting the red jumper may affect the program sequence.

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

52 -

Page 54

Product information

VA 3.. VA9011XT..ZT..VA..VA(9)6211Q..R..S..T

MPr 28112005

53 -

Loading...

Loading...