Asyst Falcon™ 300mm Loadport

Technical Manual

n

with Installation Instructions

e

r

l

mi

i

a

r

y

P

Tool Picture

Rev. Ax9 Date: 9/12/2008

P/N: 2000-6698-05

Copyright © 2008

Asyst Technologies, Inc.,

All rights reserved.

Disclaimers

This manual may not be reproduced, either wholly or in part, for any reason whatsoever, without prior written permission

from Asyst Technologies, Inc. (“Asyst”). Material contained in this manual is provided for informational purposes and is

subject to change without notice.

If this manual is marked “Preliminary” or “Draft,” then Asyst has not yet released a final version of the manual and the

manual is likely to be incomplete and will be revised. Contact Asyst at the address below to obtain a final copy of the

manual.

Manual Information

PCN: Unreleased

Part Number: 2000-6698-05

Date: 9/12/2008

Release: Ax9

Asyst Technologies, Inc.

46897 Bayside Parkway

Fremont, California 94538

Telephone: (510) 661-5000

FAX: (510) 661-5166

Technical Support: 1-800-342-SMIF

Falcon Technical Manual

Disclaimers

Trademarks

Asyst and the Asyst logo(s) are registered trademarks ® of Asyst Technologies, Inc.

ADVAN-TAG and Falcon are trademarks

All other product and company names mentioned herein may be trademarks and/or service marks of their respective

owners.

Equipment Modification

Any change, alteration, or modification to this equipment, as well as use of this equipment in a manner inconsistent with its

intended use will void this equipment’s warranty and may render this equipment unsafe for use or unfit for its intended

purposes.

Training and Languages

User training for equipment operation and maintenance is conducted in English. Translators are available on an as needed

basis. English versions of the manuals and other technical materials are provided and reviewed during the training. Please

contact the Asyst Training department or http://www.asyst.com for the training schedule and signup requirements.

Warranty

For warranty information, see Asyst’s Standard Terms and Conditions.

TM

of Asyst Technologies, Inc.

Draft Ax9 2000-6698-05 Page iii

Falcon Technical Manual

Reader Comments

Reader Comments

We welcome your comments regarding this manual. Your comments and suggestions

help us to improve our publications.

Please send comments and suggestions to:

Asyst Technologies, Inc.

Technical Publications Manager

46897 Bayside Parkway

Fremont CA 94538

Or fax: Attention—Tech Pubs Manager at 1-510-661-5185

Or email: TechPubs@asyst.com

Include the following:

Name:

Company:

Contact Phone # (in case we have questions):

Email:

Document Information (Name of document, Part Number, Revision):

Location of comment (page number or other reference):

Comments: (The more specific the comments, the more useful they are to us.)

Thank you for helping to improve the manuals and to maintain accuracy.

Page iv 2000-6698-05 Draf t Ax9

Acronym List

AGV Automated Guided Vehicle

APHD Active Pod Hold Down

ASCII American Standard Coding for Information Interchange

CAN Control Area Network

DSP Digital Signal Processor

EMI Electromagnetic Interference

EMO Emergency (Machine) Off

ESD Electrostatic Discharge

FIMS Front-opening Interface Mechanical Standard

FOUP Front Opening Unified Pod

K-Plate Kinematic Plate (also referred to as FOUP Advance Plate)

MGV Manually Guided Vehicle

OEM Original Equipment Manufacturer

OHS Overhead Hoist Shuttle

OHT Overhead Transport or Overhead Hoist Transport

PCB Printed Circuit Board

PN or P/N Part Number

RFID Radio Frequency IDentification

SEMI Semiconductor Equipment and Materials International

SMIF Standard Mechanical Interface

Draft Ax9 2000-6698-05 Page v

Falcon Technical Manual

Acronym List

Page vi 2000-6698-05 Draft Ax9

Revision History

This section gives an overview of the change history for the document.

Date Author Version Revision Information

11/15/2007 Catherine Day Ax1 Created using 2000-2414-05 Rev. C as a base.

1/10/2008 Catherine Day Ax2WIP WIP - Compiled for Mike F. Reference Only

3/21/2008 Catherine Day Ax2 Compiled for training class. Huge gaps in Installation,

Overview, Interfaces and Comm SW which we will attempt to

fill during training week 3/24-28.

3/28/2008 Catherine Day Ax3WIP WIP - Compiled for Tou Vang. Reference Only

04/08/2008 Catherine Day Ax3 Added redlines from Training class. Updated some images with

Beta images. Added verifications steps after Service procedures.

Added 100-240VAC Option. Added removal of FOUP Advance

under cover to affected Service procedures. Fleshed out

Overview Chapter.

04/18/2008 Catherine Day Ax4 Added redlines and new input from Tou Vang, Mike

Fahkrabadhi, Selby Sondergaard, Chi Yeh, Gary Durham, Grant

Imper, Pranav Desai. Updated more images.

04/24/2008 Catherine Day Ax5 Added redlines and new input from Tou Vang, Mike

Fahkrabadhi, Selby Sondergaard, Matt Hoang. Updated more

images.

5/30/2008 Catherine Day Ax6 Added Content from Tou Vang, Mike Fahkrabadhi and drawings

7/11/2008 Catherine Day Ax7 Expanded Software upgrade procedure and made it part of the

Service Chapter. Added input from John Green and Pranav

Desai. Made changes to all chapters and appendices.

Incorporated Beta 9 Software release notes, in many case

replacing existing content with info from the release notes.

Changed multiple illustrations. Updated all Assembly drawings

and PCB drawings.

Draft Ax9 2000-6698-05 Page vii

Falcon Technical Manual

Revision History

Date Author Version Revision Information

9/3/2008 Catherine Day Ax8 Added input from John Greene, Duc Le, Bob Carlson, and

Pranav Desai. Made changes to all chapters and appendices.

Incorporated Beta 10 Software release notes. Updated all

Assembly drawings and PCB drawings.

9/22/2008 Catherine Day Ax9 FINAL DRAFT -Removed information duplicated in the

Software Communications Manual and just reference that

document.

Added Remove and Replace instructions for the E84 and AC

Power Options. Edited all service procedures to show new front

panel removal. Updated all Assembly drawings and PCB

drawings.

Added customer cable routing for the E84 and AC Option to the

Installation Appendix. Added Details about the Vertical Brake.

Added comments/corrections from Chris Lueders, John Greene,

Duc Le, Bob Carlson and Tou Vang. Added Specifications from

Engineering and Matt Hoang.

Page viii 2000-6698-05 Draft Ax9

Falcon Technical Manual

Table of Contents

Disclaimers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

Manual Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

Trademarks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

Equipment Modification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

Training and Languages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

Reader Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iv

Acronym List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .v

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vii

Preface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Chapter 1: Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Chapter Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

General Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

General Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Electrical Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Responsibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safety Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Safety Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

ESD / EMI Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

EMO & Electrical Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Lockout/Tagout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Pinch Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

During Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Seismic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Ergonomic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Wafer Mapper Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

100-240VAC Option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

E84/PIO/ Interlock Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Draft Ax9 2000-6698-05 Page ix

Falcon Technical Manual

Tilt and Go Wheels Option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Agency Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

FCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

CE Mark. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Safety Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

DC Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

AC Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Pinch Hazard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Port Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

FOUP Advance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Moving and Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Labeling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Chapter 2: Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Product Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Major Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

FIMS Door. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Ball Joint with Clamping for Port Door Alignment. . . . . . . . . . . . . . . . . . . 30

Simplified Twist and Pull Latch Key Drive . . . . . . . . . . . . . . . . . . . . . . . . 30

Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Ground Path to FOUP Door. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Configurable Latch Key Over-Rotation. . . . . . . . . . . . . . . . . . . . . . . . . . . 31

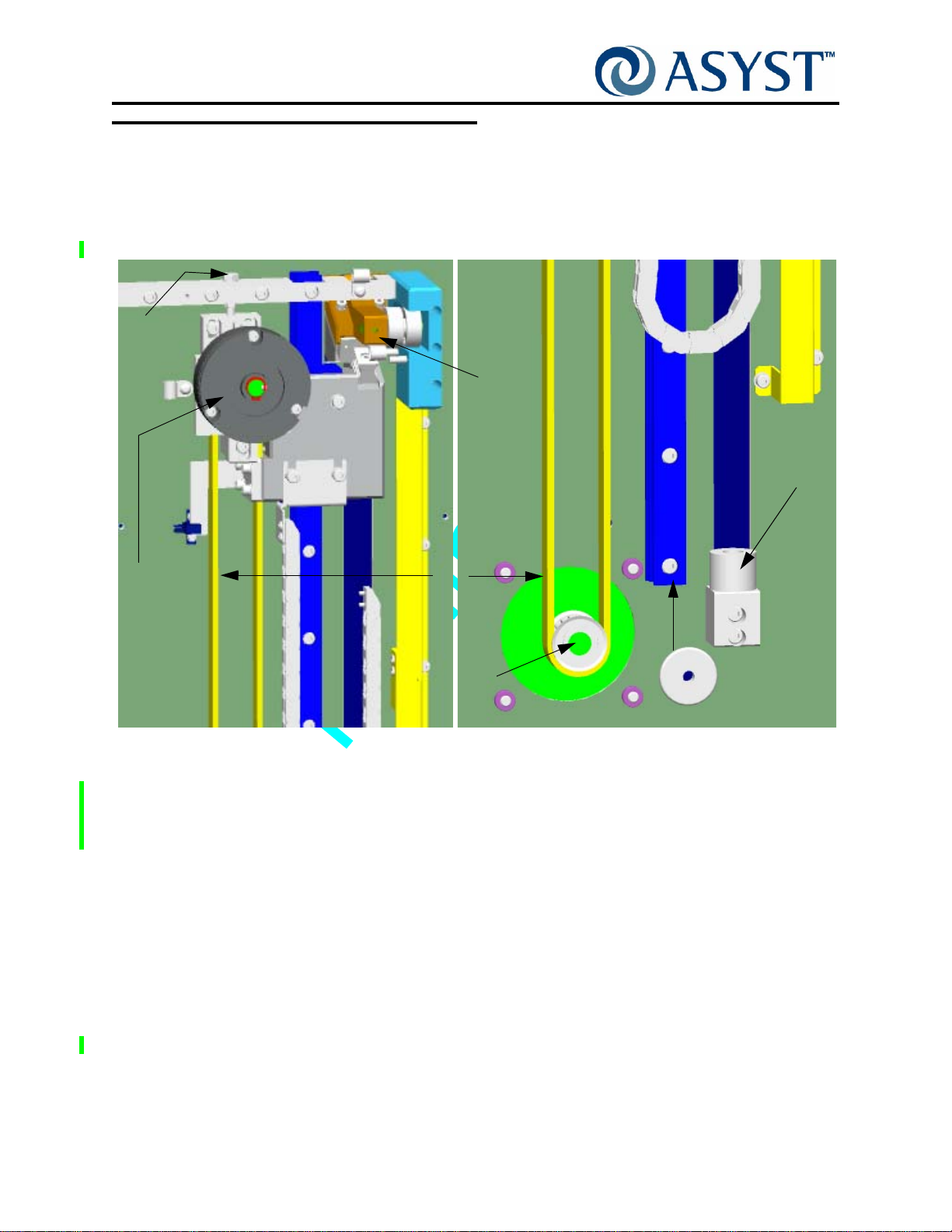

Vertical-Horizontal Door Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Single Motor for Two Axes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Upper Pulley/Brake/Encoder Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Fan Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

FOUP Advance Subassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Torque Tube with Cantilevered Supports. . . . . . . . . . . . . . . . . . . . . . . . . 35

Manual Load/Unload Push Button Switch . . . . . . . . . . . . . . . . . . . . . . . . 35

K-Plate Node PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Cam Activated Pod Hold Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Page x 2000-6698-05 Draft Ax9

Falcon Technical Manual

Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

BOLTS Frame. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Main Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Light Display Node PCB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Excessive Wafer Protrusion Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Static Entry Node PCB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Wafer Mapper Assembly Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

100-240VAC Power Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

E84/PIO/Interlock Option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Tilt & Go Wheels Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Operation Sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Chapter 3: Interfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Chapter Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Communication Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Status Indicator Lights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Command for LED Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Falcon Application Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Using the Falcon GUI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Accessing the GUI. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Navigating Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

System Icon Details. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Wafer Status Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Service Mode Commands Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Motor Control Commands Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

E84 Status Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

LED Controls Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

System Info Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Setup Icon Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Host Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Users and Passwords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Axes Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

E84 Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Wafer Mapper Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

DSP Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

LED Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Draft Ax9 2000-6698-05 Page xi

Falcon Technical Manual

System Log Icon. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Alarms Icon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Diagnostics Icon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Chapter 4: Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Safety Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

General Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Electrical Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Mechanical Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

ESD Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Tool and Fixture Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Remove and Replace Falcon 74

Corrective Service Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

CSP1: Replace Falcon K-Plate Node PCB . . . . . . . . . . . . . . . . . . . . . . . . . . 82

CSP2: Replace Falcon Door Node . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

CSP3: Replace Vertical/Horizontal Drive Motor . . . . . . . . . . . . . . . . . . . . . . 95

CSP4: Replace Pod Hold Down Motor Assembly . . . . . . . . . . . . . . . . . . . 106

CSP5: Replace Wafer Mapper Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . 112

CSP6: Replace Display Node PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

CSP7: Replace Static Entry Node . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

CSP8: Replace Link Manager/CPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

CSP9: Replace Latch Key Motor Assembly . . . . . . . . . . . . . . . . . . . . . . . . 131

CSP10: Replace V/H Drive Upper Pulley Assembly . . . . . . . . . . . . . . . . . . 137

CSP11: Replace Vertical Drive Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

CSP12: Upgrade Falcon Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

CSP13: Vertical Drive Belt Tensioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

CSP14: Remove and Replace E84 Board . . . . . . . . . . . . . . . . . . . . . . . . . 168

CSP15: Replace AC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Chapter 5: Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Collecting Falcon Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Emergency Removal of Pod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Remove Host Tool’s End-Effector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Removal Using Falcon Application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Error Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Page xii 2000-6698-05 Draft Ax9

Falcon Technical Manual

Falcon Alarm Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Auto Recovery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

About Alarm Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Recovery Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

About Alarm 1 “Position following error”. . . . . . . . . . . . . . . . . . . . . . . . . 190

About Alarm 2 “Vertical drive is not home”. . . . . . . . . . . . . . . . . . . . . . . 190

About Alarm 3 “Motion requested while already busy”. . . . . . . . . . . . . . 191

About Alarm 4 & 30 “Pod is missing” . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

About Alarm 5 “Aborted by user” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

About alarm 14, 24, 82, 83, 84, 86 & 87. . . . . . . . . . . . . . . . . . . . . . . . . 192

Abort/Failed Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Error Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Factory Default Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Appendix A: Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . 199

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Installing Falcon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Handling Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Operating Caution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Installation Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Verify Asyst Supplied Materials. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Verify the OEM Supplied Materials. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

BOLTS Interface Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Power Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Grounding Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Requirement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Communications Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Prepare for Mounting Falcon. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Mount Falcon to the Host Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

Verify Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Adjust and Level Falcon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

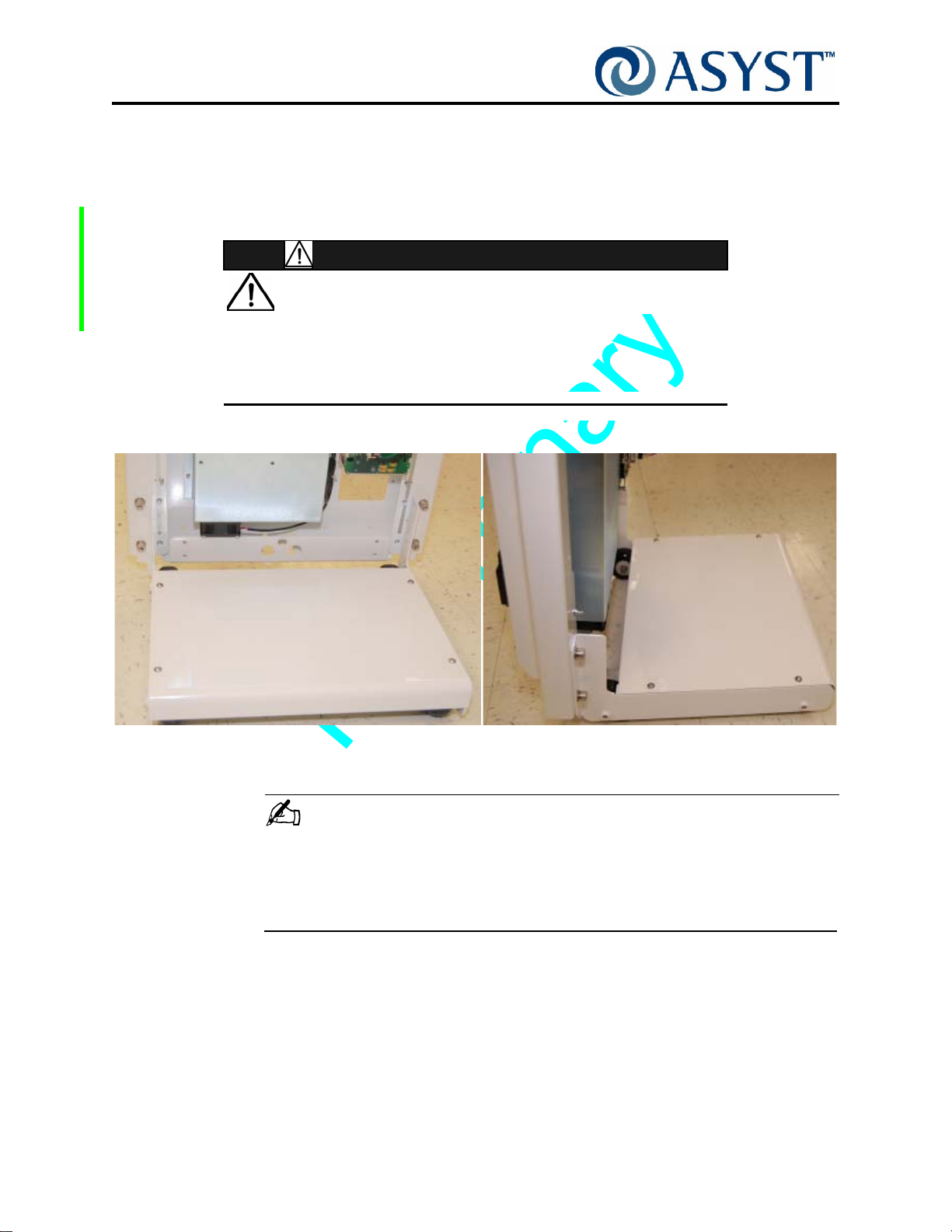

Open Falcon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Initial Height Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Perform Final Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Falcon Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

Display Light Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

Draft Ax9 2000-6698-05 Page xiii

Falcon Technical Manual

Appendix B: Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Compact Flash Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

Communication with VxWorks Operating System. . . . . . . . . . . . . . . . . . . . . . . 223

Communication with Falcon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Ethernet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Serial Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Description of Falcon.ini . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Communication Protocol Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Without Wafer Arm Assembled: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

With Wafer Arm Assembled: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Not Using 5mm Protrusion Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Use 5mm Protrusion Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Set-up Hyperterminal for Ethernet Communication . . . . . . . . . . . . . . . . . . . . . 230

Set-up Hyperterminal for Serial Communication. . . . . . . . . . . . . . . . . . . . . . . . 233

Appendix C: Material Safety Data Sheet Information . . . . . . . . . . . . 237

Appendix D: Wiring Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

3400-6653-01 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Appendix E: PCB Assemblies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

3200-4269-01 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

3200-4270-01 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

3200-4346-03 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

3200-4347-03 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

3200-4348-03 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

3200-4349-02 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

3200-4350-01 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

Appendix F: Bills of Material and Assembly Drawings . . . . . . . . . . . 261

Falcon Final Assembly, 9701-3995-01 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

BOM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

9701-3995-01 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

Falcon Sub-Systems Assembly, 9701-4033-01 . . . . . . . . . . . . . . . . . . . . . . . . 268

BOM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

Page xiv 2000-6698-05 Draft Ax9

Falcon Technical Manual

9701-4033-01 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

FOUP Advance, 9701-3834-02. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

BOM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

9701-3834-02 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

FIMS Door, 9701-3909-01 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

BOM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

9701-3909-01 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

2000-6803-01 Falcon Outline Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

Draft Ax9 2000-6698-05 Page xv

Falcon Technical Manual

Page xvi 200 0-6698-05 Draft Ax9

Falcon Technical Manual

List of Figures

List of Figures

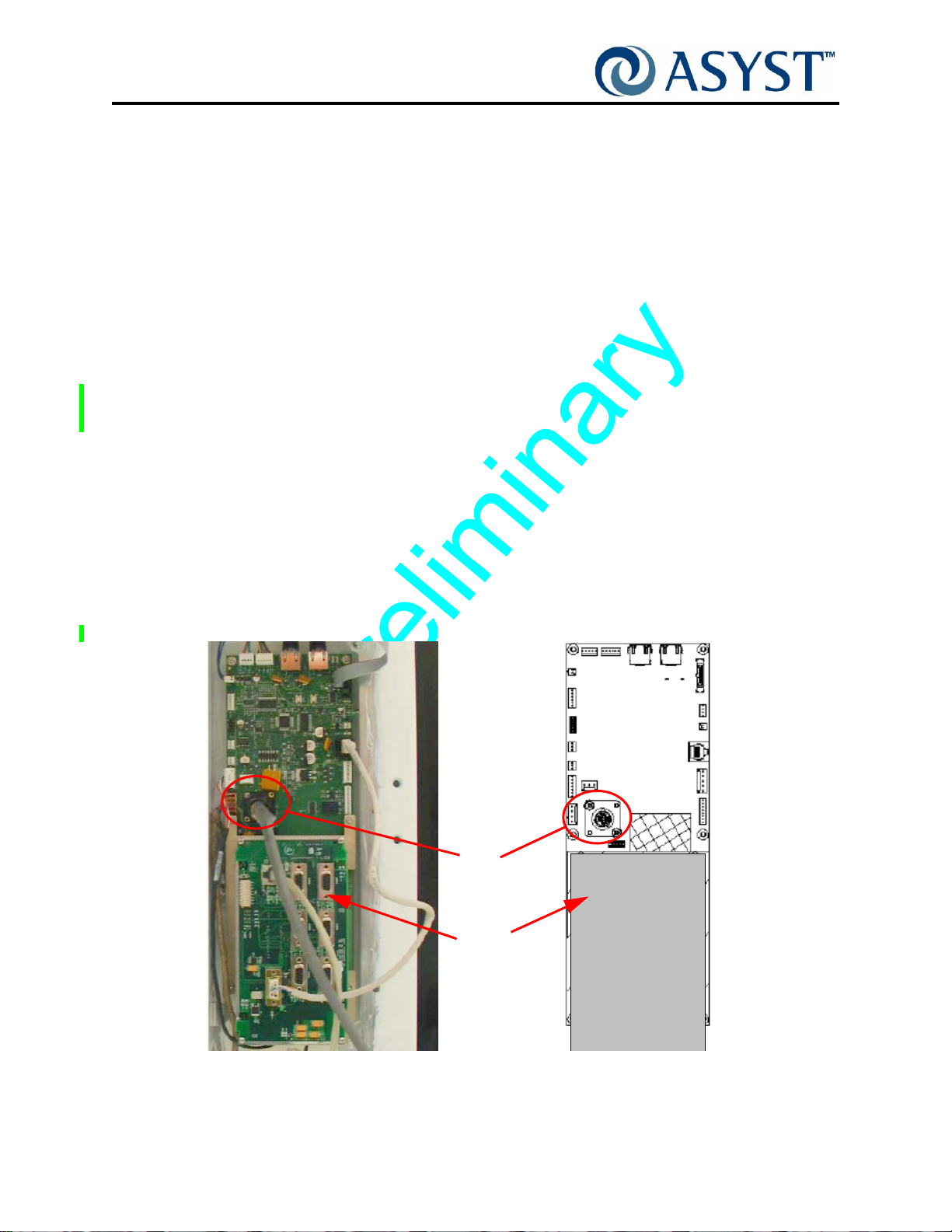

Figure 1 Falcon Ground Point. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 2 Pinch Hazards During Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 3 Shipping Bracket Securing FIMS Door. . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 4 Areas of Pinch/Crush Hazard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Figure 5 Seismic Attachment Points. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 6 Tool Side Corners. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 7 Falcon Label Placement (Operator Side). . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 8 Falcon Label Placement (Host Tool Side) . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 9 Falcon with AC Option Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 10 Falcon Loadport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 11 Falcon Loadport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 12 Static Entry Node PCB Assembly with Link Manager/CPU . . . . . . . . . . 26

Figure 13 Falcon Basic Outline. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 14 FIMS Door, Front View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 15 FIMS Door, Rear View (without Cover) . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 16 Ball Joint Design. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 17 Simplified Twist and Pull Latch Key Drive . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 18 Vertical/Horizontal Door Drive Components. . . . . . . . . . . . . . . . . . . . . . 32

Figure 19 FOUP Advance Plate without Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 20 FOUP Advance Load/ Unload Push Button Switch . . . . . . . . . . . . . . . . 35

Figure 21 Light Display Node PCB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 22 Static Entry Node PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 23 Wafer Mapper Uninstalled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 24 Components of the 100-240VAC Option . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 25 Tool Side View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

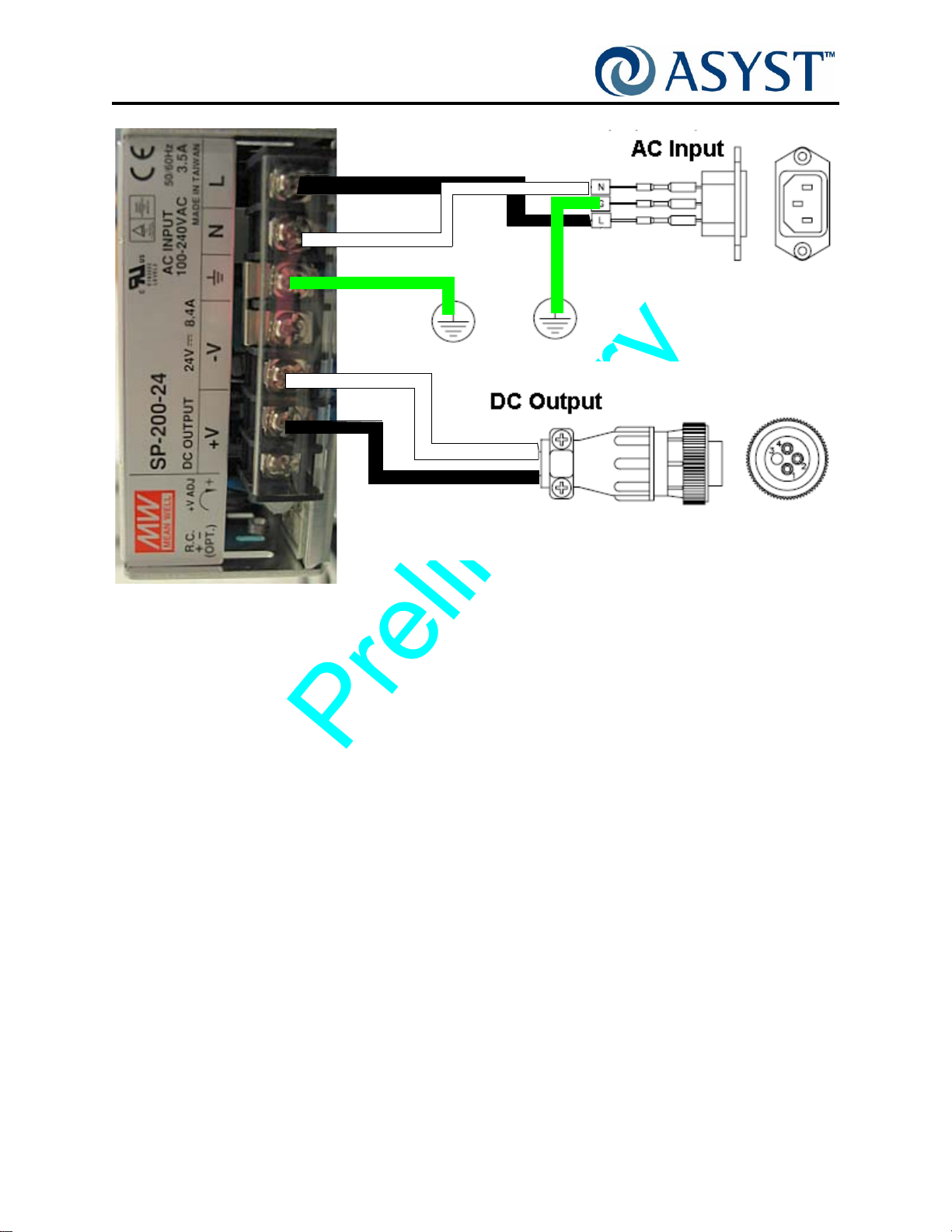

Figure 26 Wiring for the AC Option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 27 E84 Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 28 Falcon Tilt & Go Wheels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 29 Diagram of Falcon Communication Paths . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 30 LED-IDs, Indicator Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Figure 31 Falcon System Logon Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Figure 32 System Overview Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Figure 33 Wafer Status Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Figure 34 Service Mode Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Figure 35 Motor Drop-Down Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Figure 36 Servo Control Drop-Down Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Figure 37 Calibration Axes Drop-Down Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Figure 38 Wafer Mapper Arm Drop-Down Menu . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Figure 39 Laser Drop-Down Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Figure 40 FOUP Advance Drop-Down Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Figure 41 Vertical Door Drop-Down Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Figure 42 Latch Keys Drop-Down Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Figure 43 Miscellaneous Drop-Down Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Figure 44 Button Report Drop-Down Menu (Not Active) . . . . . . . . . . . . . . . . . . . . 59

Figure 45 Motor Control Commands Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Figure 46 E84 Status Page (Currently Inactive) . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Draft Ax9 2000-6698-05 Page xvii

Falcon Technical Manual

List of Figures

Figure 47 LED Controls Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Figure 48 System Info Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Figure 49 Host Communications Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Figure 50 Users and Passwords Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Figure 51 Axes Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Figure 52 E84 Configuration Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Figure 53 Wafer Mapper Parameters Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Figure 54 DSP Firmware Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Figure 55 LED Setup Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Figure 56 Falcon System Log Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Figure 57 Falcon Alarms Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Figure 58 Falcon Front Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Figure 59 Power and Communication Connections . . . . . . . . . . . . . . . . . . . . . . . . 75

Figure 60 AC Power Input (on Falcons with AC Option Only) . . . . . . . . . . . . . . . . 75

Figure 61 Shipping Bracket Securing FIMS Door. . . . . . . . . . . . . . . . . . . . . . . . . . 76

Figure 62 Falcon Tilt and Go Wheels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Figure 63 Falcon Mounting - Lower Pivot Mounting. . . . . . . . . . . . . . . . . . . . . . . . 78

Figure 64 Guide Posts for Falcon Front Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Figure 65 Falcon K-Plate Node PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Figure 66 FOUP Advance Underside Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Figure 67 K-Plate Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Figure 68 The Underside of the FOUP Advance . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Figure 69 Screw Securing the K-Plate Node Board . . . . . . . . . . . . . . . . . . . . . . . . 86

Figure 70 Falcon Door Node . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Figure 71 Falcon Door Cover and Cable Grommet . . . . . . . . . . . . . . . . . . . . . . . . 90

Figure 72 Falcon Door Node PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Figure 73 Cable Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Figure 74 Attachment Screws - Falcon Door Node . . . . . . . . . . . . . . . . . . . . . . . . 92

Figure 75 Vertical/Horizontal Drive Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Figure 76 Shipping Bracket Securing FIMS Door. . . . . . . . . . . . . . . . . . . . . . . . . . 96

Figure 77 AC Option Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Figure 78 E84 Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Figure 79 Vertical Belt Cover/Fan Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Figure 80 Drive Belt Tension Adjust and Drive Motor Axle. . . . . . . . . . . . . . . . . . . 99

Figure 81 Jam Nut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Figure 82 Belt Tension Adjust. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Figure 83 Motor Cable Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Figure 84 Vertical Drive Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Figure 85 Drive Belt Teeth Engaged with the Gear Teeth. . . . . . . . . . . . . . . . . . . 103

Figure 86 Active FOUP Hold Down Motor Assembly . . . . . . . . . . . . . . . . . . . . . . 106

Figure 87 APHD Motor - Viewed from Underside of FOUP Advance. . . . . . . . . . 107

Figure 88 Access Holes for Motor Assembly Screws. . . . . . . . . . . . . . . . . . . . . . 108

Figure 89 Locator Guide Pins. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Figure 90 Motor Assembly Gear Wheel Engaged with Gear Rack. . . . . . . . . . . . 109

Figure 91 Wafer Mapper Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

Figure 92 Wafer Mapper and Screw Location . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

Figure 93 Wafer Mapper Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

Figure 94 Wafer Mapping Assembly Approaching Guide Pins. . . . . . . . . . . . . . . .114

Figure 95 Display Node PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

Figure 96 Bezel Over the Panel Display Board . . . . . . . . . . . . . . . . . . . . . . . . . . .118

Page xviii 2000-6698-05 Draft Ax9

Falcon Technical Manual

List of Figures

Figure 97 Panel Display PCB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .118

Figure 98 Hardware Stack for Securing Hardware. . . . . . . . . . . . . . . . . . . . . . . . .119

Figure 99 Static Entry Node . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Figure 100Belt Cover/Fan Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Figure 101Cable Connections and Link Manager/CPU Screws . . . . . . . . . . . . . . 123

Figure 102Screws and Standoff Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Figure 103Connections to Static Entry Node Board . . . . . . . . . . . . . . . . . . . . . . . 125

Figure 104Link Manager/CPU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Figure 105Belt Cover/Fan Assembly and Link Manager/CPU Location . . . . . . . . 128

Figure 106Compact Flash Socket on the Link Manager/CPU. . . . . . . . . . . . . . . . 129

Figure 107Latch Key Motor Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Figure 108Latch Key Motor and Latch Key Drive Plate Assemblies . . . . . . . . . . . 132

Figure 109Cable Clamp and Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . 133

Figure 110Placement of the Latch Key Motor Assembly. . . . . . . . . . . . . . . . . . . . 134

Figure 111 Motor Encoder Cable Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Figure 112Engaging the Lead Nut with the Lead Nut Retainer Pins. . . . . . . . . . . 135

Figure 113V/H Drive Upper Pulley/Brake/Encoder Assembly . . . . . . . . . . . . . . . . 137

Figure 114AC Option Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Figure 115E84 Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Figure 116Vertical Belt Cover/Fan Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Figure 117Encoder Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Figure 118Upper Pulley Cable Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Figure 119Encoder Cable Ground Wire on Upper Pulley Assembly . . . . . . . . . . . 142

Figure 120Drive Belt Tension Adjust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Figure 121Jam Nut on Drive Belt Tension Adjust . . . . . . . . . . . . . . . . . . . . . . . . . 143

Figure 122Belt Tension Adjust. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Figure 123V/H Drive Upper Pulley Assembly Screws. . . . . . . . . . . . . . . . . . . . . . 144

Figure 124Vertical Drive Belt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Figure 125Vertical Belt Cover/Fan Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Figure 126Vertical/Horizontal Drive Upper Pulley Assembly Screws . . . . . . . . . . 150

Figure 127Drive Belt Tension Adjust Bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Figure 128Jam Nut on Drive Belt Tension Adjust . . . . . . . . . . . . . . . . . . . . . . . . . 151

Figure 129Vertical/Horizontal Drive Motor Axle. . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Figure 130Lock Plate Securing the Drive Belt. . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Figure 131Copy Zip File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Figure 132Paste Zip File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Figure 133Extract Zip Contents to Compact Flash . . . . . . . . . . . . . . . . . . . . . . . . 156

Figure 134The Ensurehomesteps Value Below [VerticalDoor_1] . . . . . . . . . . . . . 158

Figure 135Compact Flash on the Link Manager/CPU. . . . . . . . . . . . . . . . . . . . . . 159

Figure 136Belt Tension Meter - Power Button. . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Figure 137Meter Screen Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Figure 138Buttons on Meter Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Figure 139Sensor Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Figure 140Vertical Drive Upper Pulley/Brake/Encoder Assembly Screws. . . . . . . 165

Figure 141Jam Nut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Figure 142Belt Tension Adjust Nut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Figure 143E84 PCB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Figure 144Belt Cover/Fan Assembly with E84 Board and AC Option. . . . . . . . . . 169

Figure 145Cable Connections and Screws. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Figure 146AC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Draft Ax9 2000-6698-05 Page xix

Falcon Technical Manual

List of Figures

Figure 147Cable Wiring Going to the AC Option Power Supply . . . . . . . . . . . . . . 174

Figure 148AC Option Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Figure 149Power Supply Mounting Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Figure 150AC Power Supply Mounting Hardware. . . . . . . . . . . . . . . . . . . . . . . . . 175

Figure 151AC Power Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Figure 152Run Pop-up Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Figure 153Command Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Figure 154Logged On to Falcon FTP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Figure 155Falcon.ini Opened in a Notepad Window. . . . . . . . . . . . . . . . . . . . . . . 181

Figure 156Factory Default Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Figure 157Falcon Handling Points. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Figure 158Falcon Ground Point. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Figure 159Interface Mounting Kit Components. . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Figure 160BOLTS Interface Kit Components Mounted on Host Tool. . . . . . . . . . . 206

Figure 161Alignment Plates. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Figure 162FIMS Door Shipping Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Figure 163Foam for Securing Wafer Mapper Arms. . . . . . . . . . . . . . . . . . . . . . . . 208

Figure 164Ground Connection and Cable Pass-Thru. . . . . . . . . . . . . . . . . . . . . . 209

Figure 165Static Entry Node Connector Panel (selected connectors shown). . . . 210

Figure 166AC Power Input (on Falcons with AC Option Only) . . . . . . . . . . . . . . . .211

Figure 167Falcon Mounting - Alignment Ball and Cam Adjustments . . . . . . . . . . 212

Figure 168Hyperterminal with Connection Description . . . . . . . . . . . . . . . . . . . . . 230

Figure 169Hyperterminal with Connect To. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

Figure 170ASCII Setup Pop-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Figure 171Hyperterminal Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Figure 172Hyperterminal with Connection Description . . . . . . . . . . . . . . . . . . . . . 233

Figure 173Connect To Pop-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Figure 174Com1 Properties Pop-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Figure 175ASCII Setup Pop-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Page xx 2000-6698-05 Draft Ax9

Falcon Technical Manual

List of Tables

List of Tables

Table 1 List of Falcon Labels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 2 Falcon Product Specifications*. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 3 Static Entry Node Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 4 Vertical Door Taught Positions (mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Table 5 Recommended Velocity and Acceleration Parameters for the Vertical

Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Table 6 FOUP Positions (mm). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Table 7 Latch Key Positions (mm). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Table 8 Special Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Table 9 Corrective Service Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Table 10 Falcon Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Table 11 Alarm Codes with Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Table 12 Alarm Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Table 13 Abort/Failed Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Table 14 General Problem Resolutions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Table 15 Wafer Mapping Problem Resolution. . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Table 16 Falcon Wiring Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Table 17 Falcon PCB Assembly Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Table 18 Assembly Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

Draft Ax9 2000-6698-05 Page xxi

Falcon Technical Manual

List of Tables

Page xxii 2000-6698-05 Draft Ax9

About this Manual

The Falcon Technical Manual is organized as follows:

Chapter 1, Safety Information, describes safety hazards related to operating and

maintaining Falcon, as well as safety interlocks and. labeling.

Chapter 2, Product Overview , describes the major subassemblies and components of the

Falcon, and includes technical data, specifications and typical operation sequence.

Chapter 3, Interfaces, includes a description of Falcon’s indicator lights, FOUP Advance

Activator Button, and Falcon Application Software.

Chapter 4, Service, provides detailed procedures to perform Preventive Maintenance,

corrective service and software upgrade on the Falcon.

Chapter 5, Troubleshooting, pro vides an emergency pod removal procedure, a procedure

for data collection, lists of error and alarm codes and messages as well as error modes

and recommended corrective actions. An illustration showing factory default settings is

provided for reference.

Preface

Appendix A, Installation Instructions, gives information related to installing Falcon to a

Host Tool and initial set-up.

Appendix B, Communications Software, provides detailed information on ASCII

communication.

Appendix C, Material Safety Data Sheet Information.

Appendix D, Wiring Diagrams.

Appendix E, PCB Drawings

Appendix F, Assembly Drawings. For Final Assembly and major subassemblies, such as

the FIMS Door Drive and the FOUP Advance (Kinematic) Plate.

An Index is also provided in the back of the manual.

Draft Ax9 2000-6698-05 Page 1

Falcon Technical Manual

Conventions

Conventions

The following keyboard conventions and terminology are used.

Example Meaning

Bold User action on keyboard keys or other objects are bold.

Choose The word choose is used for menu choices. Submenus are separated by a

>.

For example: Choose File > Import > File...

Click Refers to mouse actions.

For example: Click the hand icon.

Courier New Font Text displayed on the screen uses Courier New.

DOS and windows path names are displayed in Courier New.

For example: Use the C:\Folder\SubFolder\SubFolder2 to access

this file.

Source code or DOS commands use courier new.

Hexidecimal streams and examples.

Double quotes Used when discussing or describing an action, functional word, or definition.

Folder Used instead of Directory, unless discussing DOS movement commands.

Italic Italics are used to show computer entry from the users keyboard or Teach

Pendant.

Press Shows action by a user on a key or physical button.

For example: Press PF1, then type the file name.

Select Used if the user is to pick from several choices.

For example: Select the lot number from the list supplies.

Type Shows entry.

For example: Type the Product Name and Model Number at the top of the

page. Press Enter.

Page 2 2000-6698-05 Draf t Ax9

Introduction

Before attempting any operation or service on the Falcon, it is essential that the

information presented in this chapter be read and thoroughly understood. Important

information is provided regarding safety hazards that may be encountered while working

with these Loadports.

Chapter Summary

This chapter addresses the following:

“ Safety Tags” on page 6— provides examples, with definitions, of warning labels used in

this manual.

“ Safety Requirements” on page 7— includes ESD/EMI precautions, lockout/tagout

procedure, seismic data, and description of hazards.

“ Options” on page 13 — includes

“ Agency Compliance” on page 14 — includes information on FCC and CE Mark

Compliance.

Chapter 1: Safety Information

“ Safety Features” on page 15 — includes information on the Safety Features of the

Falcon Loadport

“ Moving and Handling” on page 16— includes cautions on moving and handling the

Falcon.

“ Labeling” on page 18— description of labels, and their locations on the Falcon.

Draft Ax9 2000-6698-05 Page 3

Falcon Technical Manual

Chapter 1: Safety Information

General Requirements

General Requirements

Warnings and cautions are used throughout this manual to identify potential hazards to

personnel.

All warnings and cautions immediately precede the step or operation in which the

hazardous condition may be encountered. All personnel operating or performing service

on Asyst equipment must fully understand warnings, cautions, and all general safety

regulations associated with electromechanical equipment.

Personnel should become thoroughly familiar with all aspects of safety for individuals and

equipment prior to operating or performing service on this equipment.

General Safety

• Do not allow unauthorized or inexperienced personnel to operate the Falcon.

• Service personnel should follow standard cleanroom protocols.

• Ensure that another person in the area is aware that work is in progress on the

tool, and can provide assistance in the event of injury.

• The Host Tool manufacturer’s lockout/tagout procedures must be followed during

installation or when service is performed on the Falcon to prevent injury or equipment damage.

• Refer to the appropriate Material Safety Data Sheets; contact information for

obtaining MSDSs is located in this manual.

• Remove spilled materials immediately to prevent accidents.

Electrical Safety

• Do not bypass electrical interlocks or safety devices unless specifically required to

within a procedure.

• Remove power from Falcon prior to performing any service procedure, unless otherwise specified.

• Remove power from Falcon prior to removing or inserting electrical connectors.

• Remove metal jewelry such as rings, chains, and watches.

• Stand on dry insulating mats when working with energized electrical equipment.

• Ensure that all test equipment and accessory electrical units are grounded to facility ground.

Page 4 2000-6698-05 Draf t Ax9

Responsibility

It is the responsibility of the Customer to comply with all local, state, and federal

ordinances, regulations, and laws applicable to the installation and operation of this

equipment.

Asyst Technologies, Inc. assumes no liability, whatsoever, for any personal injuries or

damages resulting from the operation or service of this equipment in any manner

inconsistent or contrary to the methods supplied in Asyst Technologies, Inc. literature

including, but not limited to, manuals, instructions, bulletins, communications, and

recommendations.

For emergencies and for product safety related matters, contact:

Falcon Technical Manual

Chapter 1: Safety Information

Responsibility

Asyst Technologies, Inc.

46897 Bayside Parkway

Fremont, California, 94538

(510) 661-5000

Draft Ax9 2000-6698-05 Page 5

Falcon Technical Manual

Chapter 1: Safety Information

Safety Tags

Safety Tags

The manual includes the following alert categories. Note that the following are only

examples; they do not indicate a specific hazard associated with the Falcon.

EXPLOSION HAZARD

DANGERS ALERT PERSONNEL TO POTENTIALLY HAZARDOUS

SITUATIONS WHICH, IF NOT AVOIDED, WILL RESULT IN

SERIOUS INJURY OR DEATH.

MECHANICAL HAZARD

WARNINGS ALERT PERSONNEL TO POTENTIALLY HAZARDOUS

SITUATIONS WHICH, IF NOT AVOIDED, MAY RESULT IN SERIOUS

INJURY OR DEATH.

DANGER

WARNING

CAUTION

LIFT HAZARD

STANDARD CAUTIONS—AS OPPOSED TO EQUIPMENT-DAMAGE

CAUTIONS SHOWN BELOW—ALERT PERSONNEL TO

POTENTIALLY HAZARDOUS SITUATIONS WHICH, IF NOT

AVOIDED, MAY RESULT IN INJURY.

CAUTION

THESE CAUTIONS ALERT PERSONNEL TO SITUATIONS THAT

MAY LEAD TO EQUIPMENT DAMAGE. FAILURE TO FOLLOW

DIRECTIONS WILL RESULT IN DAMAGE TO THE EQUIPMENT

AND/OR DAMAGE TO RELATED PRODUCTS (E.G., WAFERS)

AND VOIDING OF WARRANTY.

Page 6 2000-6698-05 Draf t Ax9

Safety Requirements

ESD / EMI Precautions

The Falcon with its integrated AdvanTag is a certified Radiated EMI Class A product.

CAUTION

GENERAL HAZARD

FOR ESD AND EMI CONSIDERATIONS AND POWER SUPPLY

PROTECTION, THE GROUND CABLE MUST BE PROPERLY

INSTALLED.

The following instructions must be followed to provide ESD protection and reduced EMI

emissions:

• A braided copper ground wire (minimum 12 gauge) with ring-lug connectors (sized

for M5 screw) MUST be connected between the Falcon ground connection and

the Host Tool power supply earth ground point.

Falcon Technical Manual

Chapter 1: Safety Information

Safety Requirements

NOTE . . .

CHANGES OR MODIFICATIONS TO THE FALCON, NOT EXPRESSLY APPROVED BY

ASYST, COULD VOID THE USER'S WARRANTY.

Ground Point

IGURE 1 Falcon Ground Point

F

Draft Ax9 2000-6698-05 Page 7

Falcon Technical Manual

Chapter 1: Safety Information

Safety Requirements

EMO & Electrical Power

Electrical power for the Falcon is supplied by the Host Tool. The main electronics are

enclosed in the main electronic area, located inside the front cover of the Falcon. Power

to the Falcon should be connected through the Host Tool EMO circuitry, and in the event

of an emergency all power can be removed from the Falcon by depressing the red

mushroom shaped EMO switch mounted on the Host Tool.

Lockout/Tagout

As determined by the Host tool owner, Lockout/tagout may be required on the Host tool

when service is performed on the Falcon or when the Falcon is removed /replaced to

prevent injury or equipment damage.

NOTE . . .

LOCKOUT/TAGOUT OF THE HOST TOOL MUST BE PERFORMED BY THE HOST

OOL OWNER. ASYST SERVICE PERSONNEL ARE NOT PERMITTED TO PERFORM

T

LOCKOUT/TAGOUT OF THE HOST TOOL.

Where no company procedures exist, follow the guidelines below:

_____1. Notify all affected employees and users that service is to be performed and that

the Host tool needs to be shut down and locked out.

_____2. The circuit that provides power to the Host tool must be switched off. (This may

require the Host Tool to be powered down.)

Requirements for circuit breaker provided by the customer: The

overcurrent device and disconnect device provided for the Falcon should be

rated for at least 10,000 RMS symmetrical amperes interrupting capacity.

_____3. Lock out the circuit with an assigned lock.

_____4. Test to make sure the Host tool cannot be turned on accidentally.

_____5. Tag the locked circuit with a statement indicating:

_____• Unauthorized operation of the equipment or removal of tag is prohibited

_____• Date of service performed

_____• Name(s) and contact information of the person(s) performing the service

Page 8 2000-6698-05 Draf t Ax9

Pinch Hazards

Normal Operation

There are no pinch hazards during Normal Operation of the Falcon.

During Service

WARNING

MECHANICAL HAZARD

MAINTENANCE PERSONNEL MUST KEEP HANDS AND FINGERS

AWAY FROM ALL MOVING PARTS DURING MOTION OF THE

FOUP A

COMPLY MAY RESULT IN INJURY.

A pinch hazard exists during the opening/closing of the Port Door.

DVANCE PLATE OR THE PORT DOOR. FAILURE TO

Pinch Hazard

During Door

Open/Close

Falcon Technical Manual

Chapter 1: Safety Information

Safety Requirements

F

IGURE 2 Pinch Hazards During Service

See “ Safety Features” on page 15 for Safety Features designed to prevent Pinch

Hazards.

Draft Ax9 2000-6698-05 Page 9

Falcon Technical Manual

Chapter 1: Safety Information

Safety Requirements

MECHANICAL HAZARD

FIMS DOOR MUST BE SECURED WITH THE SHIPPING BRACKET

EVERY TIME A COMPONENT OF THE VERTICAL/HORIZONTAL

D

SERIOUS INJURY.

WARNING

RIVE IS SERVICED. FAILURE TO DO SO MAY RESULT IN

Install shipping bracket (Asyst P/N 4003-0842-01)

to the FIMS Loadport Door and secure

with 8 screws to both the FIMS door and the BOLTS Frame. See Figure 3.

Screws

Screws

F

IGURE 3 Shipping Bracket Securing FIMS Door

Screws

If Vertical Drive Belt is disengaged or broken the Vertical Drive may free fall creating

pinch/crush hazards. All service procedures affecting the belt must use the FIMS door

shipping bracket (Asyst P/N 4003-0842-01) to assure the Vertical Drive is immobilized.

See Figure 4 on page 11 for affected areas.

Page 10 2000-6698-05 Draft Ax9

Falcon Technical Manual

Chapter 1: Safety Information

Safety Requirements

Operator Side

Host Tool Side

FIGURE 4 Areas of Pinch/Crush Hazard

During Installation

During installation, power to the Falcon must be off and the Host Tool in Lockout/Tagout

so there are no electrical (current) or mechanical hazards.

Draft Ax9 2000-6698-05 Page 11

Falcon Technical Manual

Chapter 1: Safety Information

Safety Requirements

Seismic

The position of the center of gravity (CG) will be shown in the forthcoming Outline

Drawing. Figure 5 shows seismic attachment points for the Falcon. Follow all installation

procedures to ensure compliance with SEMI S2: Safety Guidelines For Semiconductor

Manufacturing Equipment, Seismic Requirements.

Seismic

Attachment

Points

(top mount)

M8 Screw

Seismic

Attachment

Points

(regular)

M8 Screw

F

IGURE 5 Seismic Attachment Points

Ergonomic

A fully loaded FOUP exceeds recommended limits for handling by one operator. To

conform with SEMI S8, use of AGV, MGV, or OHS is recommended.

Page 12 2000-6698-05 Draft Ax9

Options

Wafer Mapper Option

See “ Wafer Mapper Assembly Option” on page 40 for details.

100-240VAC Option

See “ 100-240VAC Power Option” on page 41 for details

E84/PIO/ Interlock Option

See “ E84/PIO/Interlock Option” on page 43 for details.

Tilt and Go Wheels Option

See “ Tilt & Go Wheels Option” on page 44 for details.

Falcon Technical Manual

Chapter 1: Safety Information

Options

Draft Ax9 2000-6698-05 Page 13

Falcon Technical Manual

Chapter 1: Safety Information

Agency Compliance

Agency Compliance

FCC

Definition

Class A digital device

A digital device that is marketed for use in a commercial, industrial or business

environment, exclusive of a device which is marketed for use by the general public or is

intended to be used in the home.

Compliance

The Falcon with its integrated AdvanTag has been tested and found to comply with the

limits for a Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses,

and can radiate radio frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in

which case the user will be required to correct the interference at his/her own expense.

CAUTION

ANY CHANGES OR MODIFICATIONS TO THE FALCON

INTEGRATED RFID WITHOUT SPECIFIC WRITTEN APPROVAL

FROM ASYST TECHNOLOGIES WILL VOID FCC COMPLIANCE.

CE Mark

The Falcon with its integrated AdvanTag complies with the following directives:

• 2006/95/EC Low Voltage Directive

• 2004/108/EC EMC Directive

• 99/5/EC Radio & Telecommunication Terminal Equipment

• 98/37/EC Machinery Directive

Page 14 2000-6698-05 Draft Ax9

Safety Features

DC Voltage

The Falcon operating voltage is +24 VDC. This voltage is considered non-hazardous and

requires no mechanical power interlocks.

AC Option

If equipped with the 100-240VAC Option, the front cover has an electrical warning label

which alerts the user to an electrical hazard located behind the Front Cover. Shutdown

and lockout/tagout must be performed before opening the Front Cover. Also the front

cover is secured with a screw.

Pinch Hazard

During normal operation there is no pinch hazard.

During Service, a number of design points ensure that Service personnel in manual mode

are not exposed to hazards as described below:

Falcon Technical Manual

Chapter 1: Safety Information

Safety Features

Port Door

• Pinch hazards due to opening and closing of the Port Door.

The combination of the FOUP placement detection, and the FOUP-at-Port switch

provide an interlock to prevent a Port Door pinch hazard.

The FOUP must be in place on the FOUP advance and then must fully advance to

the port, sealing the port opening, before the Port Door will open during normal

operation in Auto Mode.

During Home Calibration, the Port Door , can move without a FOUP, but the motion

speed is slow and easily avoidable.

FOUP Advance

• Although there is no pinch hazard due to FOUP Advance motion, the following

safety feature is present:

Current Limiting Circuit limits the amount of force that can be exerted by the

FOUP Advance motion to a safe level. When FOUP comes in contact with an

object the FOUP Advance motion will stop.

Draft Ax9 2000-6698-05 Page 15

Falcon Technical Manual

Chapter 1: Safety Information

Moving and Handling

Moving and Handling

WARNING

TIP-OVER HAZARD

MOVING THE FALCON WITH A FOUP MOUNTED MAY CAUSE

THE FALCON TO TIP AND FALL OR OTHERWISE BECOME

UNSTABLE. INJURY AND/OR TOOL DAMAGE WILL OCCUR IF

FALCON FALLS.

NEVER move the Falcon with a FOUP mounted. Always remove the FOUP before

removing the Falcon from the Host tool, moving or installing the unit.

WARNING

TIP-OVER HAZARD

MOVING THE FALCON ON UNEVEN OR NON-LEVEL SURFACES

MAY CAUSE THE FALCON TO TIP AND FALL OR OTHERWISE

BECOME UNSTABLE. INJURY AND/OR TOOL DAMAGE WILL

OCCUR IF FALCON FALLS.

The Falcon may have wheels; therefore, once it is removed from the shipping container it

should be placed on a level surface. The extended portion of the shipping container base

enables the Falcon to be removed from the shipping container in its vertical position.

Store and Move the Falcon only in Vertical Position

Page 16 2000-6698-05 Draft Ax9

Falcon Technical Manual

Chapter 1: Safety Information

Moving and Handling

CAUTION

HANDLING OR BUMPING CERTAIN AREAS OF THE FALCON MAY

RESULT IN DAMAGE TO THE FOUP ADVANCE, DOOR DRIVE,

AND PORT DOOR ASSEMBLIES, AS WELL AS THE FRONT

COVER.

When moving the Falcon D

o NOT place hands on the top section of the FOUP advance

assembly, the door drive assembly, or by the wafer mapper assembly.

When moving the Falcon, PUSH from the Tool Side ONLY, placing hands on the corners

on the Tool SIde of the Falcon. See Figure 6.

Corners

F

IGURE 6 Tool Side Corners

The Falcon is designed to be pushed from the Tool Side only. Do not pull from the

Operator Side; do not push from the Operator Side except when mounting.

When moving the Falcon, use both hands to push at all times and push evenly. Keep all

four wheels on the ground at ALL times. Do not tilt or rock the Falcon while moving and

turning. Doing so may cause the Falcon to tip and fall.

Draft Ax9 2000-6698-05 Page 17

Falcon Technical Manual

Chapter 1: Safety Information

Labeling

Labeling

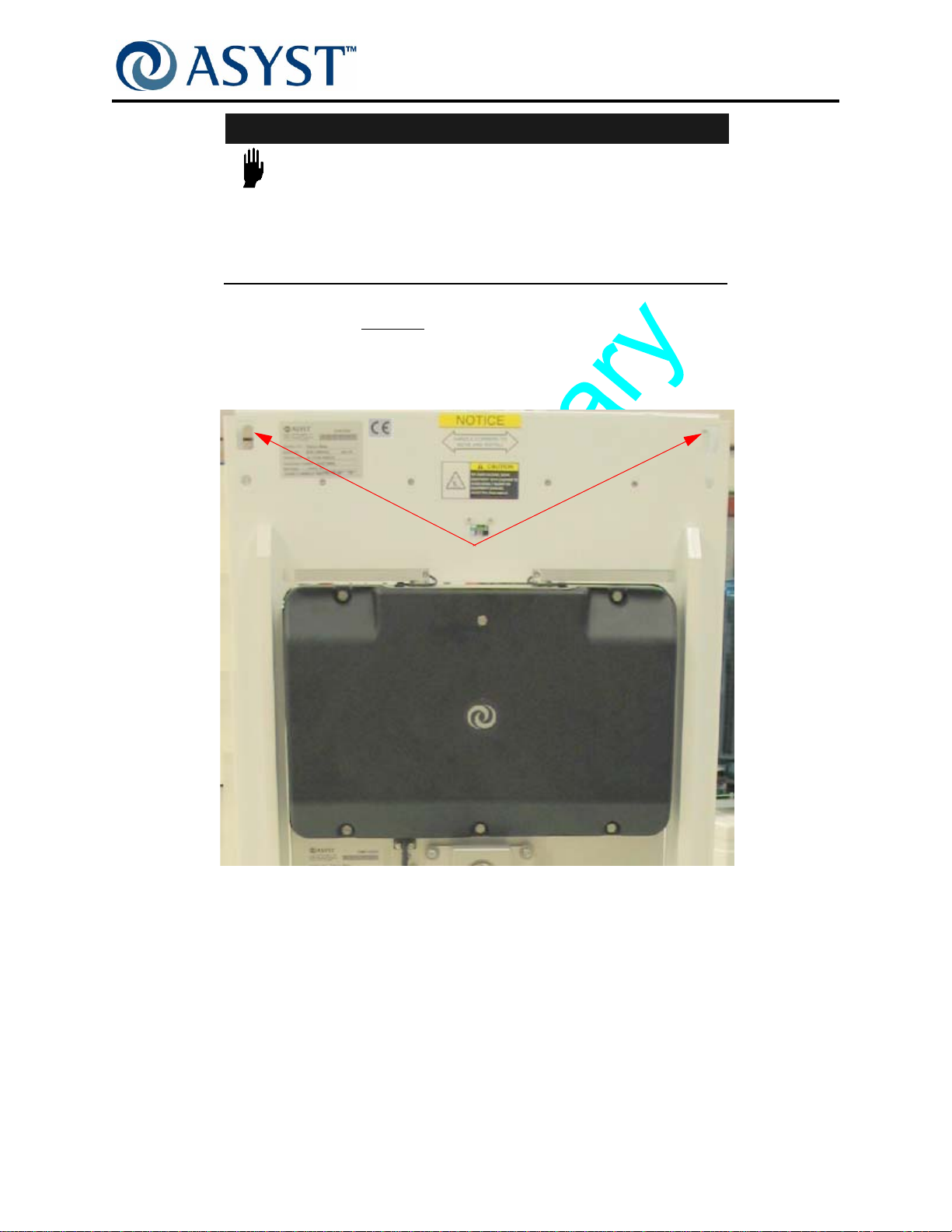

See Table 1 for a description of labels used on the Falcon. See Figure 7 on page 20,

Figure 8 on page 21 and Figure 9 on page 22 for typical label locations.

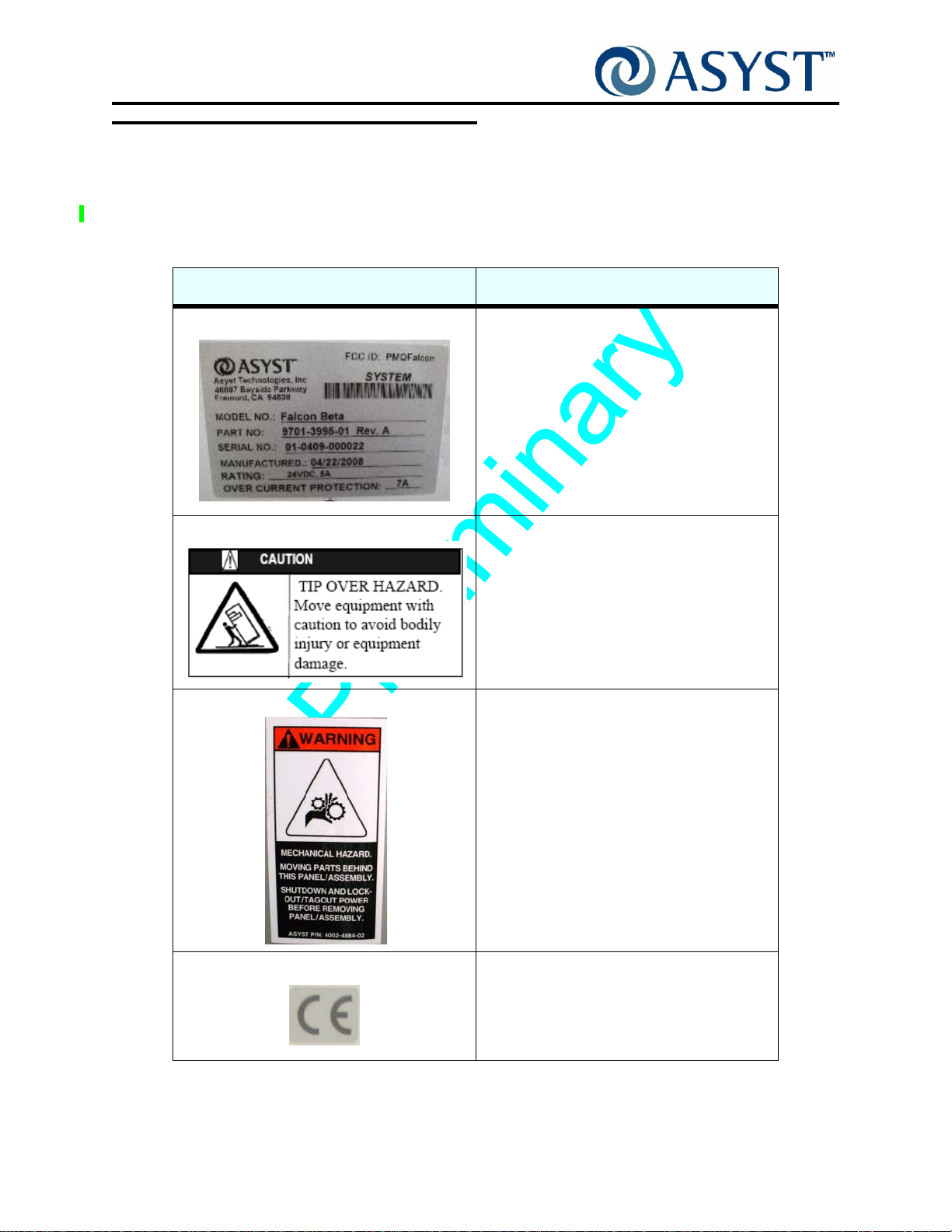

ABLE 1 List of Falcon Labels

T

Label Description/Location

Model/Serial Number Label The model and serial number label for the

Falcon provides FCC ID and unit specific

information required when contacting Asyst

Technologies for any matter concerning the

equipment.

Tip Over Hazard The Tip Over Hazard label is an alert to move

the Falcon with caution. It is located above

the port door on the Host Tool side.

Mechanical Hazard The Mechanical Hazard label is an alert to

moving parts located behind the Cover with

the label. Shutdown and lockout/tagout must

be performed before opening the Cover.

Both Vertical and Horizontal styles are used.

CE Label This label identifies equipment that conforms

to testing and certification requirements of

the European Community.

Page 18 2000-6698-05 Draft Ax9

Falcon Technical Manual

Chapter 1: Safety Information

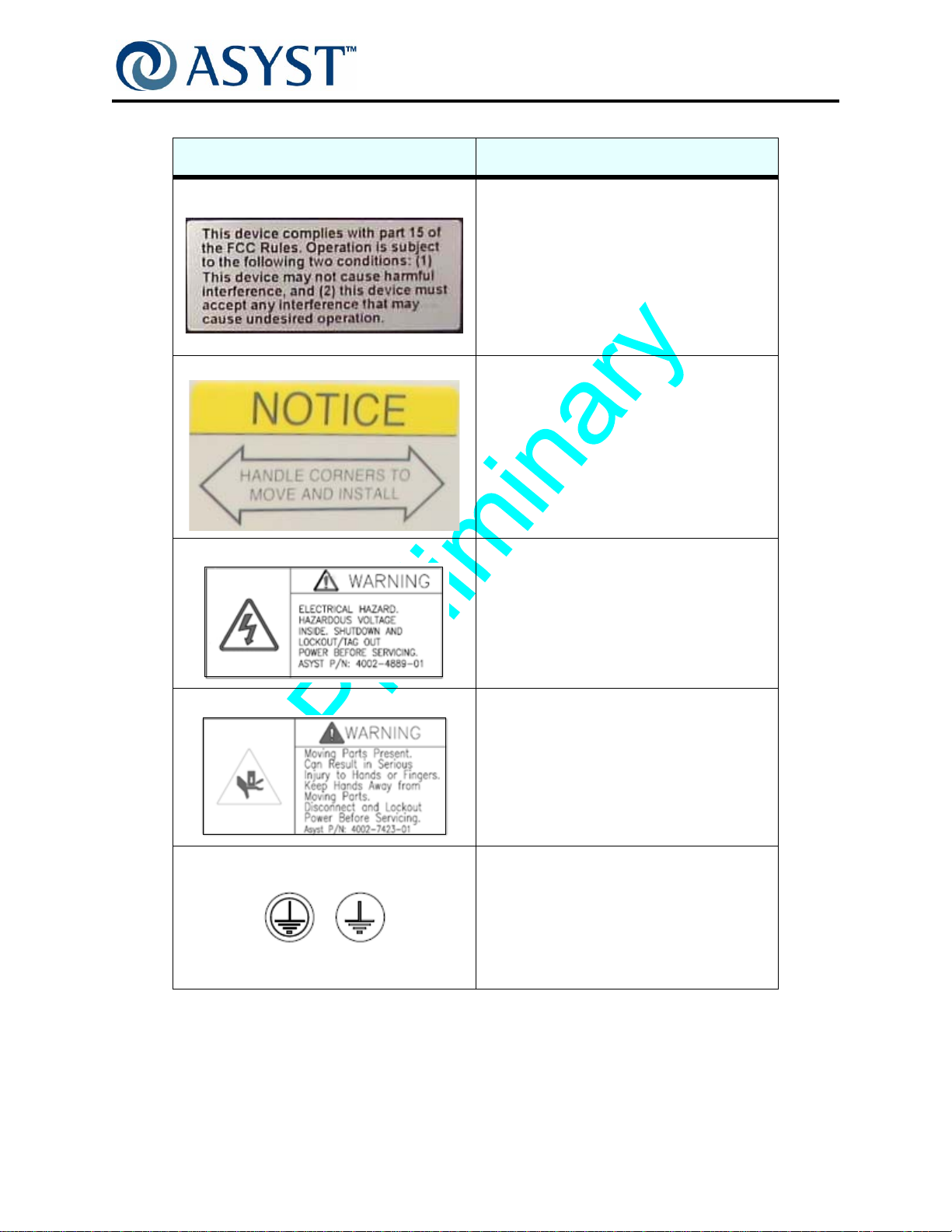

TABLE 1 List of Falcon Labels

Label Description/Location

FCC Label The presence of the FCC label indicates

compliance with FCC Rules and Regulations

as specified on the Label.

Handle Corners Label This label identifies where to handle

equipment.

Labeling

Electrical Hazard Label The Electrical Hazard label is an alert to

electrical hazard located behind the Front

Cover when the Falcon is configured with the

AC Power Option. Shutdown and

lockout/tagout must be performed before

opening the Front Cover.

FOR AC OPTION ONLY

Pinch Hazard Label The Pinch Hazard label is an alert to moving

parts located behind the Cover with the

label.Shutdown and lockout/tagout must be

performed before opening the Cover.

Ground Point Label The Ground Point Label indicates the Falcon

grounding point use to connect earth ground

wires from the Host tool.

AC

DC

Draft Ax9 2000-6698-05 Page 19

Falcon Technical Manual

Chapter 1: Safety Information

Labeling

Mechanical

Hazard

Label

Pinch

Hazard

Label

Belt

Cover

Ground

Label

FIGURE 7 Falcon Label Placement (Operator Side)

Page 20 2000-6698-05 Draft Ax9

Falcon Technical Manual

Chapter 1: Safety Information

Labeling

Name Plate

Label

FCC ID Label

FCC Label

CE Label

Handle

Corners

Label

Tip Over

Hazard

Label

Pinch

Hazard

Label

FIGURE 8 Falcon Label Placement (Host Tool Side)

Draft Ax9 2000-6698-05 Page 21

Falcon Technical Manual

Chapter 1: Safety Information

Labeling

Electrical

Hazard Label

FIGURE 9 Falcon with AC Option Only

Page 22 2000-6698-05 Draft Ax9

Chapter 2: Product Overview

This chapter describes the operation of Falcon and the interrelation of all of its

mechanical, electromechanical, and electronic subsystems.

The product overview is divided into the following sections:

“ Product Description” on page 24— an overall description of Falcon product.

“ Specifications” on page 27— Technical Data for Falcon.

Major Subassemblies with features, Options and Operational Descriptions:

• “ FIMS Door” on page 29

• “ Vertical-Horizontal Door Drive” on page 32

• “ FOUP Advance Subassembly” on page 34

• “ BOLTS Frame” on page 38

• “ Options” on page 40

• “ Operation Sequence”— describes Falcon’s typical operation sequence.

IGURE 10 Falcon Loadport

F

Draft Ax9 2000-6698-05 Page 23

Falcon Technical Manual

Chapter 2: Product Overview

Product Description

Product Description

The Falcon is an all-new loadport design based on Asyst’s many ye ars of experience with