AdvanTag 9180

Technical Manual

Rev. Bx1 Date: 11/04/2008

P/N: 2000-6631-05

Copyright © 2008 Asyst Technologies, Inc.,

All rights reserved.

AdvanTag 9180 Technical Manual

Page ii 2000-6631-05 Draft Rev. Bx1

Disclaimers

This manual may not be reproduced, either wholly or in part, for any reason whatsoever, without prior written permission

from Asyst Technologies, Inc. (“Asyst”). Material contained in this manual is provided for informational purposes and is

subject to change without notice.

If this manual is marked “Preliminary” or “Draft,” then Asyst has not yet released a final version of the manual and the

manual is likely to be incomplete and will be revised. Contact Asyst at the address below to obtain a final copy of the

manual.

Manual Information

ECN: unreleased

Part Number: 2000-6631-05

Date: 11/04/2008

Release: Rev. Bx1

Asyst Technologies, Inc.

46897 Bayside Parkway

Fremont, California 94538

Telephone: (510) 661-5000

FAX: (510) 661-5166

Technical Support: 1-800-342-SMIF

AdvanTag 9180 Technical Manual

Disclaimers

Trademarks

Asyst, the Asyst logo(s), FLUOROTRAC, KPOD, ADU and MANUFACTURING CONNECTIVITY are registered trademarks

® of Asyst Technologies, Inc.

VERSAPORT, PLUS, INX, ADVANTAG, LINK MANAGER, SMART-TAG, SMART-STATION, SMART-STORAGE,

SMART-TRAVELER, SMART-COMM, AXYS, FASTRACK, FASTMOVE, FASTLOAD, FASTORE are trademarks

Asyst Technologies, Inc.

All other product and company names mentioned herein may be trademarks and/or service marks of their respective

owners.

Equipment Modification

Any change, alteration, or modification to this equipment, as well as use of this equipment in a manner inconsistent with its

intended use will void this equipment’s warranty and may render this equipment unsafe for use or unfit for its intended

purposes.

Training and Languages

User training for equipment operation and maintenance is conducted in English. Translators are available on an as needed

basis. English versions of the manuals and other technical materials are provided and reviewed during the training. Please

contact the Asyst Training department or http://www.asyst.com for the training schedule and signup requirements.

Warranty

For warranty information, see Asyst’s Standard Terms and Conditions.

TM

of

Draft Rev. Bx1 2000-6631-05 Page iii

AdvanTag 9180 Technical Manual

Reader Comments

Reader Comments

We welcome your comments regarding this manual. Your comments and suggestions

help us to improve our publications.

Please send comments and suggestions to:

Asyst Technologies, Inc.

Technical Publications Manager

46897 Bayside Parkway

Fremont CA 94538

Or fax: Attention—Tech Pubs Manager at 1-510-661-5157

Or email: TechPubs@asyst.com

Include the following:

Name:

Company:

Contact Phone # (in case we have questions):

Email:

Document Information (Name of document, Part Number, Revision):

Location of comment (page number or other reference):

Comments: (The more specific the comments, the more useful they are to us.)

Thank you for helping to improve the manuals and to maintain accuracy.

Page iv 2000-6631-05 Draft Rev. Bx1

Acronym List

AMHS Automated Material Handling System

ASCII American Standard Coding for Information Interchange

ATR AdvanTag Reader

CIDRW Carrier IDentification Read Write

CIM Computer-Integrated Manufacturing

EMF Electromagnetic Field

EMI Electromagnetic Interference

EMO Emergency (Machine) Off

ESD Electrostatic Discharge

FOUP Front Opening Unified Pod

HSMS High Speed Messaging System

LSB Least Significant Bit

MIDS Material IDentification Station

MSB Most Significant Bit

OEM Original Equipment Manufacturer

PN or P/N Part Number

RFID Radio Frequency IDentification

SECS Semiconductor Equipment Communication Standard

SEMI Semiconductor Equipment and Materials International

SMIF Standard Mechanical Interface

Draft Rev. Bx1 2000-6631-05 Page v

AdvanTag 9180 Technical Manual

Page vi 2000-6631-05 Draft Rev. Bx1

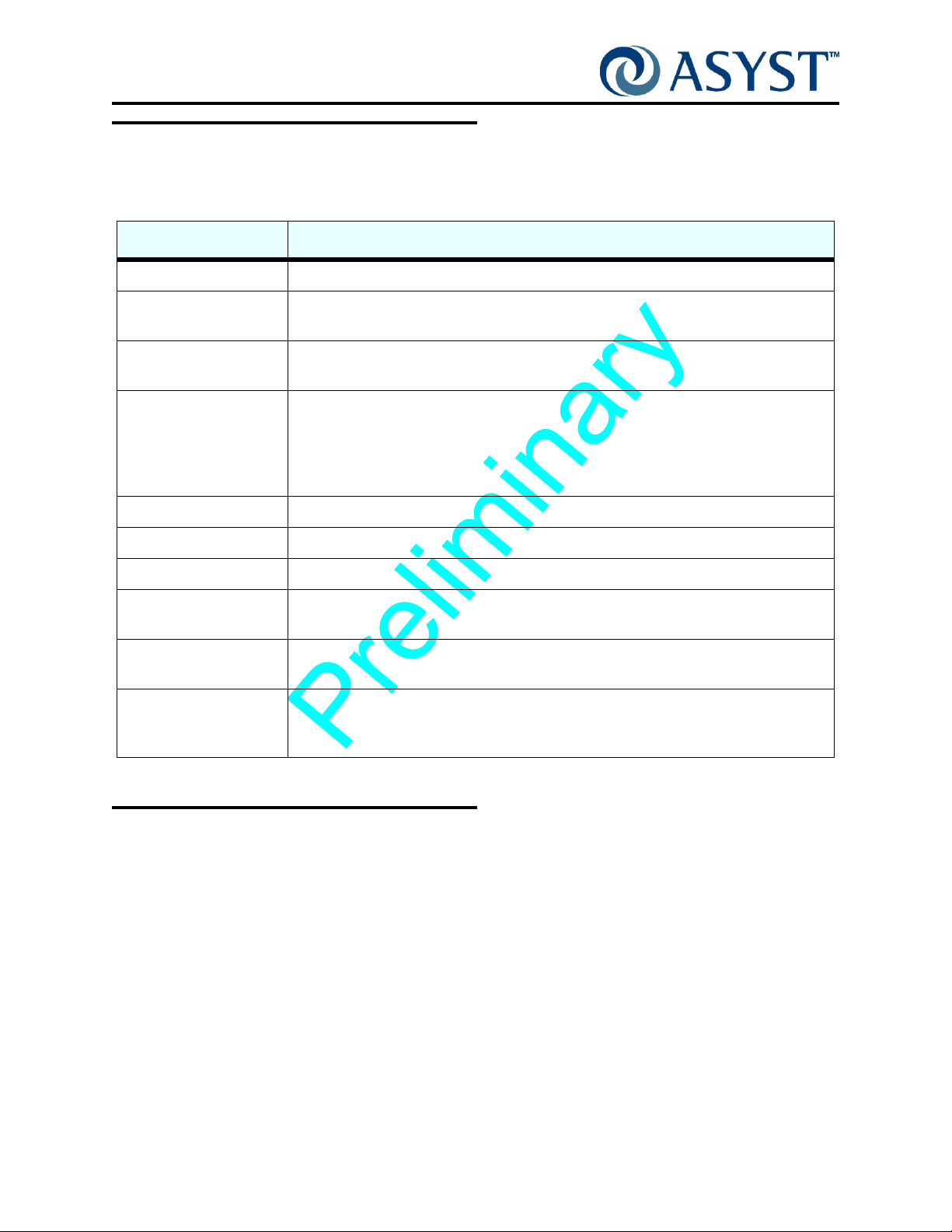

Revision History

Date Author Version Revision Information

6/3/2008 Catherine Day A Initial Release - ECN 09697

11/4/2008 Catherine Day Bx1 Made changes to Environmental, Antenna Requirements and

CE Mark Compliance in Chapter 1, per T. Vang. Clarified

Product Description in Chapter 2 per T. Vang.

Draft Rev. Bx1 2000-6631-05 Page vii

AdvanTag 9180 Technical Manual

Page viii 2000-6631-05 Draft Rev. Bx1

AdvanTag 9180 Technical Manual

Table of Contents

Disclaimers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Manual Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

Trademarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

Equipment Modification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Training and Languages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Reader Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iv

Acronym List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .v

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

List of Figures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

List of Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xv

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Purpose and Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Chapter 1: General Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Outline Drawing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

ESD / EMI Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Electrical Power/Input Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Warranty and Liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

FCC Compliance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

CE Mark Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Labeling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Location of Labels used on the AdvanTag . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Draft Rev. Bx1 2000-6631-05 Page ix

AdvanTag 9180 Technical Manual

Chapter 2: Theory of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Product Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

TargetID. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Using HSMS Protocol as Host . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Message Format and Translation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Messages Supported. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Integration of Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Data Storage—AdvanTag Reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

MicroTags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Default Values of R/W ATTRIBUTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Buttons/Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

To Host . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Read Range. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

SECS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Serial Communications Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Ethernet Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Web Configurator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

HSMS Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Read-Write Radio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Antenna Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Chapter 3: Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Troubleshooting Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Troubleshooting for RS232 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Troubleshooting for HSMS ATR9180 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Troubleshooting guide for the 9701-3651-01 ATR 9180 . . . . . . . . . . . . . . . . 43

For Additional Troubleshooting Assistance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Appendix A: Functional Test Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Page x 2000-6631-05 Draft Rev. Bx1

AdvanTag 9180 Technical Manual

Cycle Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Appendix B: HSMS Test Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Sample Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Draft Rev. Bx1 2000-6631-05 Page xi

AdvanTag 9180 Technical Manual

Page xii 2000-6631-05 Draft Rev. Bx1

AdvanTag 9180 Technical Manual

List of Figures

Figure 1 Outline Drawing, AdvanTag 9180 Reader . . . . . . . . . . . . . . . . . . . . . . . 6

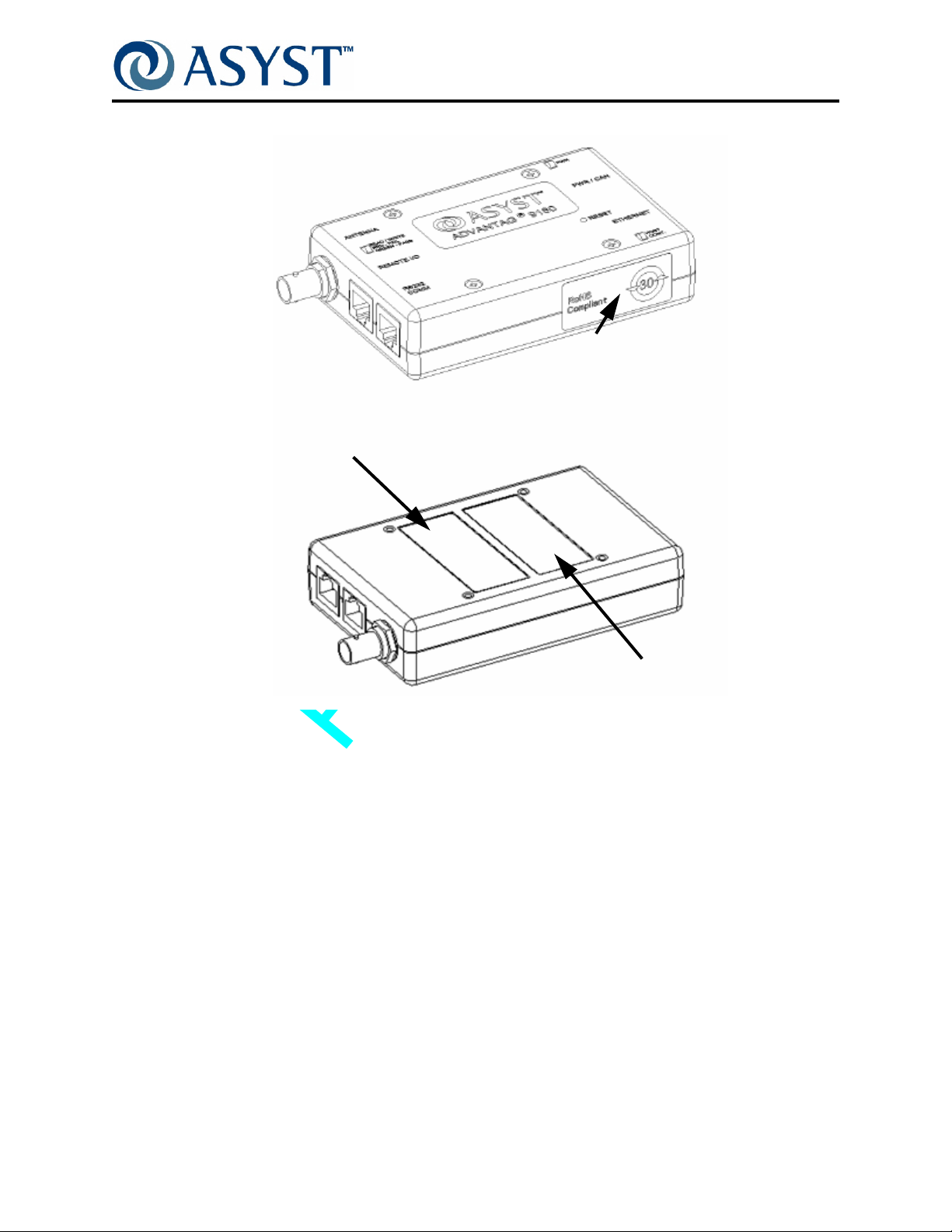

Figure 2 Label Locations, AdvanTag 9180 Reader . . . . . . . . . . . . . . . . . . . . . . 10

Figure 3 AdvanTag 9180 Top Views. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Figure 4 AdvanTag 9180 Reader LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 5 Locating the Reset Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 6 ATR 9180 Web Interface - Home Page . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 7 Web Interface - Configuration Page. . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 8 Web Interface - Read Write Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 9 Read MID Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 10 Read Data Response. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 11 Write MID Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 12 Write Data Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 13 Vertical Read Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 14 Horizontal Read Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Draft Rev. Bx1 2000-6631-05 Page xiii

AdvanTag 9180 Technical Manual

Page xiv 2000-6631-05 Draft Rev. Bx1

AdvanTag 9180 Technical Manual

List of Tables

Table 1 AdvanTag 9180 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Table 2 Labels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table 3 ATR9180 Configuration for Dual-Sensor Operation. . . . . . . . . . . . . . . 19

Table 4 ATR9180 Configuration for Event-Change operation. . . . . . . . . . . . . . 20

Table 5 Attribute Values (ECID and SVID) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 6 Power Cable Pin Outs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 7 Serial Port Pin Usage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Table 8 ATR 9180 Common Errors and Solutions . . . . . . . . . . . . . . . . . . . . . . 41

Draft Rev. Bx1 2000-6631-05 Page xv

AdvanTag 9180 Technical Manual

Page xvi 2000-6631-05 Draft Rev. Bx1

Purpose and Audience

This manual describes the Asyst AdvanTag 9180 Reader, also referred to as the ATR

9180, which is part of Asyst’s radio-frequency auto ID system, AdvanTag. The AdvanTag

Reader is an Asyst OEM, SEMI-standard device that reads and writes to tags embedded

in wafer cassettes, pods, FOUPs, reticle boxes, and other assets.

This document is intended for user of the AdvanTag system and the ATR 9180. Service is

not applicable to the ATR 9180; see “Servicing” on page 7.

About this Manual

The AdvanTag 9180 Reader Manual is organized as follows:

Chapter 1, “General Information” on page 5, provides specifications and describes safety

considerations and labeling for the AdvanTag 9180 Reader.

Preface

Chapter 2, “Theory of Operation” on page 11, provides an operational overview of the

AdvanTag 9180 Reader.

Chapter 3, “Troubleshooting” on page 41, provides troubleshooting information for

common problems when using the AdvanTag 9180 Reader.

An Index is also provided in the back of the manual.

References

This manual uses information from several sources, including application notes and other

internal documentation.

Draft Rev. Bx1 2000-6631-05 Page 1

AdvanTag 9180 Technical Manual

Conventions

Conventions

The following keyboard conventions and terminology are used.

Example Meaning

Bold User action on keyboard keys or other objects are bold.

Choose The word choose is used for menu choices. Submenus are separated by a >.

For example: Choose File > Import > File...

Click Refers to mouse actions.

For example: Click the hand icon.

Courier New Font Text displayed on the screen uses Courier New.

DOS and windows path names are displayed in Courier New.

For example: Use the C:\Folder\SubFolder\SubFolder2 to access this file.

Source code or DOS commands use courier new.

Hexidecimal streams and examples.

Double quotes Used when discussing or describing an action, functional word, or definition.

Folder Used instead of Directory, unless discussing DOS movement commands.

Italic Italics are used to show computer entry from the users keyboard or Teach Pendant.

Press Shows action by a user on a key or physical button.

For example: Press PF1, then type the file name.

Select Used if the user is to pick from several choices.

For example: Select the lot number from the list supplies.

Type Shows entry.

For example: Type the Product Name and Model Number at the top of the page. Press

Enter.

Safety Tags

Special tags are used in this document to alert technicians to personal and equipment

safety hazards.

Before using this document, personnel should have a thorough understanding of

AdvanTag safety issues detailed in the AdvanTag Reader ATR 9180 Manual.

The following types of safety tags appear in this document. Note that the following are

only examples; they do not indicate a specific hazard associated with the AdvanTag.

Page 2 2000-6631-05 Draft Rev. Bx1

AdvanTag 9180 Technical Manual

DANGER

CORROSION HAZARD

DANGERS ALERT PERSONNEL TO POTENTIALLY HAZARDOUS

SITUATIONS WHICH, IF NOT AVOIDED, WILL RESULT IN

SERIOUS INJURY OR DEATH.

WARNING

CORROSION HAZARD

WARNINGS ALERT PERSONNEL TO POTENTIALLY HAZARDOUS

SITUATIONS WHICH, IF NOT AVOIDED, MAY RESULT IN SERIOUS

INJURY OR DEATH.

CAUTION

GENERAL HAZARD

STANDARD CAUTIONS—AS OPPOSED TO EQUIPMENT-DAMAGE

CAUTIONS SHOWN BELOW—ALERT PERSONNEL TO

POTENTIALLY HAZARDOUS SITUATIONS WHICH, IF NOT

AVOIDED, MAY RESULT IN INJURY.

Safety Tags

HESE CAUTIONS ALERT PERSONNEL TO SITUATIONS THAT

T

MAY LEAD TO EQUIPMENT DAMAGE. FAILURE TO FOLLOW

DIRECTIONS WILL RESULT IN DAMAGE TO THE EQUIPMENT

AND/OR DAMAGE TO RELATED PRODUCTS (E.G., WAFERS)

AND VOIDING OF WARRANTY.

NOTE . . .

NOTES EMPHASIZE, OR EXPAND UPON, THE PRESENTED INFORMATION.

Draft Rev. Bx1 2000-6631-05 Page 3

AdvanTag 9180 Technical Manual

Safety Tags

Page 4 2000-6631-05 Draft Rev. Bx1

Specifications

TABLE 1 AdvanTag 9180 Specifications

Width 116.5 mm (4.60 inches)

Depth 75.0 mm (3.0 inches)

Height 27.9 mm (1.1 inches)

Weight 163.3g (0.36 pounds)

Communications Serial RS-232, Ethernet

Power Reader: 24 VDC (± 10%);

Environmental Operating Temperature 0°to 30° C (non-condensing)

Mounting Four M3 threaded inserts

Chapter 1: General Information

• Host Protocols supported: ASCII, CIDRW SECS, HSMS

70mA (current draw in normal condition—no read or write)

350mA maximum (long range, write mode), 250mA maximum (long

range, read mode)

Operating Humidity 30%- 95% (non-condensing)

Storage Temperature 0° to +55° C

Storage Humidity 5%- 90%

Draft Rev. Bx1 2000-6631-05 Page 5

AdvanTag 9180 Technical Manual

Chapter 1: General Information

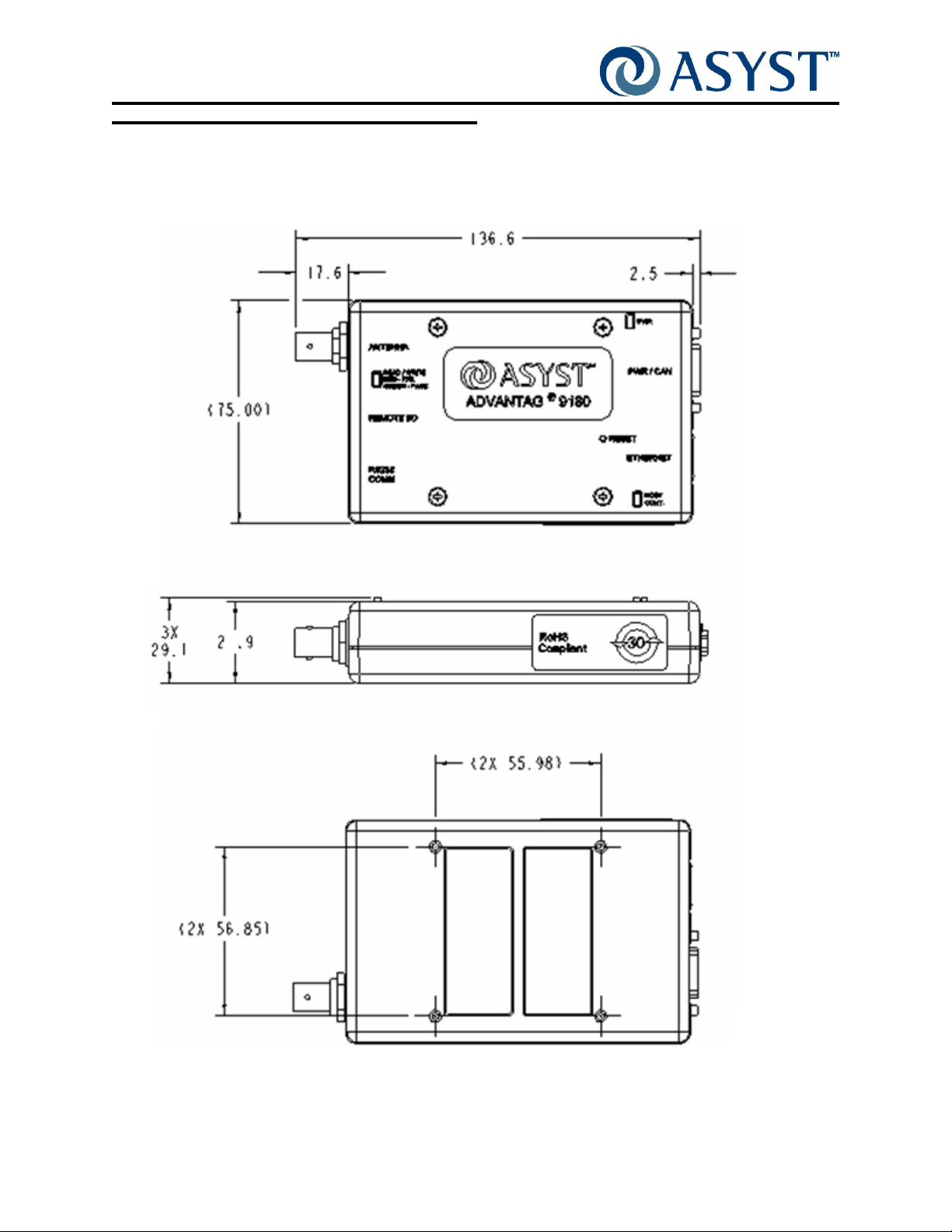

Outline Drawing

Outline Drawing

All measurements are in mm.

7

FIGURE 1 Outline Drawing, AdvanTag 9180 Reader

Page 6 2000-6631-05 Draft Rev. Bx1

Safety

Before attempting any operation or service, it is essential that the information presented

in this section be read and thoroughly understood. Important information is provided

regarding safety hazards that may be encountered while working with these systems.

General Requirements

Warnings and cautions are used throughout this manual to identify potential hazards to

personnel and equipment, respectively.

All warnings and cautions immediately precede the step or operation in which the

hazardous condition may be encountered. All personnel operating or performing service

on Asyst equipment must fully understand warnings, cautions, and all general safety

regulations associated with electromechanical equipment.

Personnel should become thoroughly familiar with all aspects of safety for individuals and

equipment prior to operating or performing service on this equipment.

Servicing

AdvanTag 9180 Technical Manual

Chapter 1: General Information

Safety

Refer all service to qualified personnel. There are no user-serviceable parts located

inside the chassis. Return defective units to Asyst Technologies.

ESD / EMI Precautions

The AdvanTag is a certified Radiated EMI Class A product.

CAUTION

GENERAL HAZARD

FOR ESD AND EMI CONSIDERATIONS AND POWER SUPPLY

PROTECTION, THE GROUND CABLE MUST BE PROPERLY

INSTALLED.

Electrical Power/Input Power Requirements

Electrical power for the AdvanTag is supplied by the host tool. Electrical power required

for the AdvanTag is 24V DC (±10%). In the event of an emergency, all power can be

removed from the AdvanTag by turning off the power to the Host equipment chassis if the

AdvanTag is connected to the EMO of the Host equipment.

Environmental

The AdvanTag uses no chemicals or combustibles, and creates no hazardous waste.

The AdvanTag is compliant to 2002/95/EC RoHS Directive.

Draft Rev. Bx1 2000-6631-05 Page 7

AdvanTag 9180 Technical Manual

Chapter 1: General Information

FCC Compliance

Warranty and Liability

See “Warranty” on page iii.

NOTE . . .

CHANGES OR MODIFICATIONS TO THE ADVANTAG 9180 NOT EXPRESSLY

APPROVED BY ASYST COULD VOID THE USER'S AUTHORITY TO OPERATE THE

EQUIPMENT.

FCC Compliance

Definition

Class A digital device. A digital device that is marketed for use in a commercial,

industrial or business environment, exclusive of a device which is marketed for use by the

general public or is intended to be used in the home.

Compliance

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction manual,

may cause harmful interference to radio communications. Operation of this equipment in

a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his/her own expense.

Antenna Requirements

The AdvanTag 9180 antenna is removable and does not employ a unique connector;

however, the ATR-9180 is professionally installed and maintained by Asyst trained

engineers and technicians. Therefore, the AdvanTag 9180 complies with FCC 15.203. In

addition, the antenna is design by Asyst Technologies, Inc specifically for the AdvanTag

9180 and substituting a different antenna will cause the AdvanTag 9180 to not function

and will violate FCC rules.

CAUTION

GENERAL HAZARD

ANY CHANGES OR MODIFICATIONS TO THE ATR-9180,

WITHOUT SPECIFIC WRITTEN APPROVAL FROM ASYST

TECHNOLOGIES, WILL VOID FCC COMPLIANCE.

Page 8 2000-6631-05 Draft Rev. Bx1

CE Mark Compliance

The AdvanTag 9180 complies with the following directives:

• 2006/95/EC Low Voltage Directive

• 2004/108/EC EMC Directive

• 99/5/EC Radio & Telecommunication Terminal Equipment

AdvanTag 9180 Technical Manual

Chapter 1: General Information

CE Mark Compliance

Draft Rev. Bx1 2000-6631-05 Page 9

AdvanTag 9180 Technical Manual

Chapter 1: General Information

Labeling

Labeling

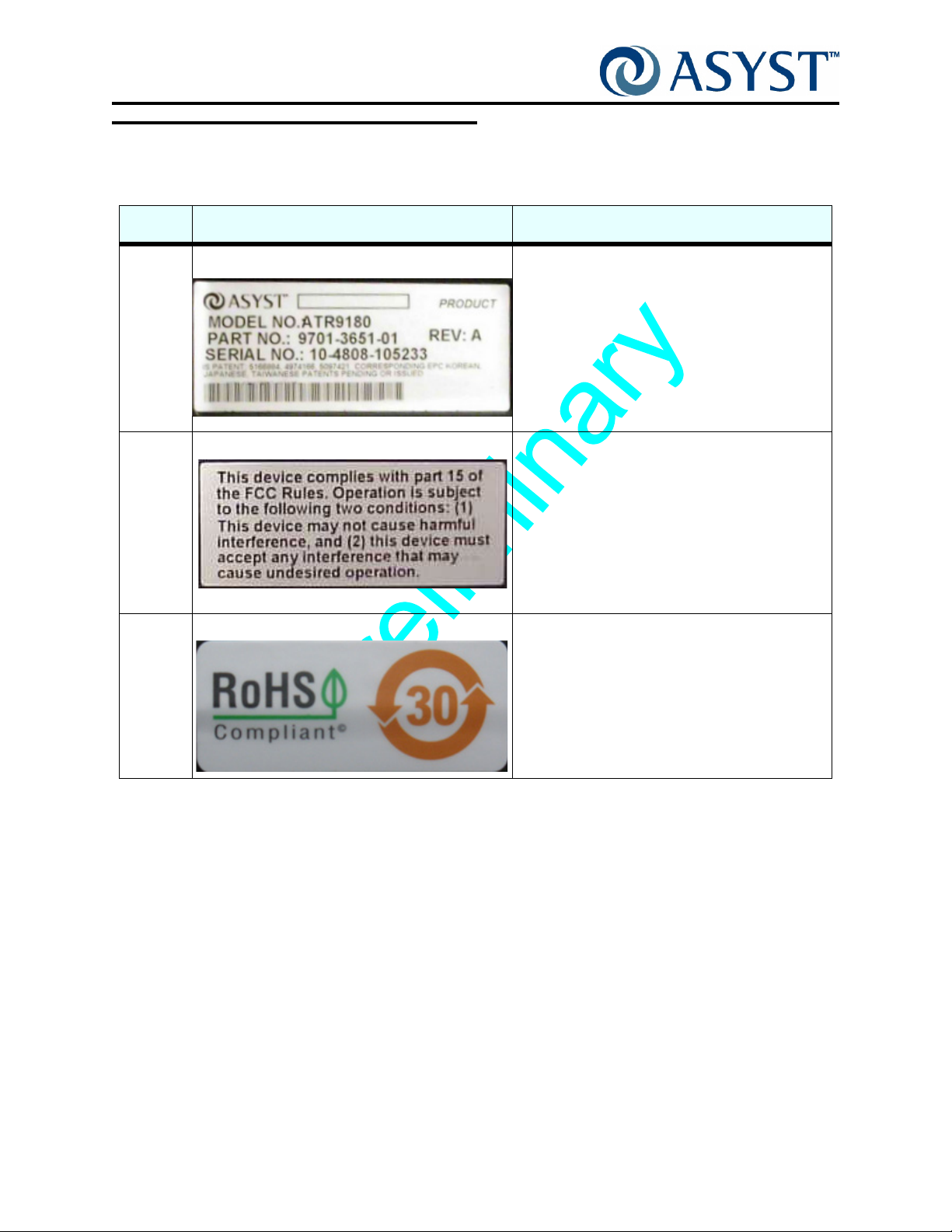

TABLE 2 Labels

No. Label Description/Location

1

2

3

Serial Number Label (9180 Reader) The model and serial number label for the

AdvanTag 9180 Reader is located on the bottom

of the unit. See Figure 2 on page 11.

These numbers are required when contacting

Asyst Technologies for any matter concerning

the equipment.

FCC Label The FCC label for the AdvanTag 9180 Reader is

located on the bottom of the unit. See Figure 2

on page 11.

RoHS The presence of this label indicates compliance

with regulations regarding Restriction of

Hazardous Substances (RoHS). The label is

located on the bottom of the unit. See Figure 2

on page 11.

Page 10 2000-6631-05 Draft Rev. Bx1

Location of Labels used on the AdvanTag

p

o

T

Serial Number Label

AdvanTag 9180 Technical Manual

Chapter 1: General Information

Labeling

RoHS Label

m

o

t

t

o

B

FCC Label

FIGURE 2 Label Locations, AdvanTag 9180 Reader

Draft Rev. Bx1 2000-6631-05 Page 11

AdvanTag 9180 Technical Manual

Chapter 1: General Information

Labeling

Page 12 2000-6631-05 Draft Rev. Bx1

Chapter 2: Theory of Operation

Product Description

The AdvanTag 9180 is a single Antenna Reader that reads and writes to the MicroTag

embedded in wafer cassettes, pods, FOUPs, reticle boxes, probe cards, photoresist

bottles, etc. The AdvanTag 9180 automatically communicates detailed lot information to a

process tool and fab CIM system when the lot arrives at a load port or during transport in

the AMHS.

LEDs

Antenna

Remote

I/O Port

E-Net

RS232 COMM

Power/CAN

F

IGURE 3 AdvanTag 9180 Top Views

Draft Rev. Bx1 2000-6631-05 Page 11

AdvanTag 9180 Technical Manual

Chapter 2: Theory of Operation

Product Description

The main component of this unit is a transmitter that generates radio waves through an

antenna. This TIRIS1 compatible, low-frequency (134.2 kHz), low-power RF energy is

used to read from or write to a transponder near the antenna. The 134.2 kHz carrier from

the RFID-ASIC is amplified to the proper levels to drive the dual MOSFET power

amplifier. This provides a 12V p-p low impedance drive to the antenna circuit. The

antenna is a series resonant LC circuit resonated at 134.2 kHz to achieve maximum

voltage on the antenna. The RFID Reader/Writer provides serial communication with a

host through an RS-232 port, using SECS protocol. It also supports HSMS protocol on its

LAN Port. Power is supplied by an external source. The Operating program is field

upgradeable using PICkit 2.

The AdvanTag 9180 is designed for versatile installation in many different situations. It

can be installed within OEM tools, within load ports, inside stockers, on WIP racks, in

storage cabinets, etc. Once a power source, an external antenna, and a communication

cable have been connected and the reader's address (TargetID and DeviceID as

described in “ Communications” on page 31) has been set, it is possible to communicate

using Stream 18 SECS messages or ASCII messages (depending on the host protocol

being used).

The software and hardware provide integrated self-test and diagnostics. A watchdog

timer and non-volatile memory provide power-failure recovery.

The AdvanTag 9180 operates on 24V DC (±10%) supplied by an external power source.

Communication is through a RS232 port, CAN Bus port (only for communicating with an

AdvanTag Gateway), or the Ethernet port.

TargetID

TargetID of the ATR9180 is configurable through the S18F3 command; default value = 1,

range = 1–99. The Remote I/O and the Antenna have the same ID.

Page 12 2000-6631-05 Draft Rev. Bx1

Using HSMS Protocol as Host

The HSMS supported by the ATR 9180 is derived from the SEMI E 37.1-96 single session

HSMS Standard.

The HSMS protocol can only be used in PASSIVE mode. The ATR 9180 would be used

as a PASSIVE device. In this mode of operation, the ATR 9180 opens up a socket that

listens for an incoming connection request from an ACTIVE HSMS host. After the initial

handshake, a connection between the Host and the ATR 9180 is established. Once a

connection had been established, the host and ATR 9180 can exchange messages

between each other.

To establish a connection with an ATR 9180, the following specific information must be

present with the host:

• ATR 9180 IP Address: The IP address of the ATR 9180 must be known to the host

so that a connection request could be made on that address. Please note that

HSMS is an IP address associated protocol thus for HSMS communication IP

address of the Passive entity must be known to the Active entity.

AdvanTag 9180 Technical Manual

Chapter 2: Theory of Operation

Using HSMS Protocol as Host

• ATR 9180 Port Number: The ATR 9180 opens a listening socket as mentioned

earlier but the connection is opened on an ETHERNET PORT. This number also

must be used by the Active entity (the host) to establish a connection.

NOTE . . .

IT MIGHT BE NOTED THAT THE IP ADDRESS ASSIGNED TO THE ATR 9180

WOULD BE A STATIC IP ADDRESS AND NOT ONE OBTAINED VIA DHCP SERVER.

THE REASON FOR THIS IS THAT HSMS IS AN IP ADDRESS BASED PROTOCOL.

Message Format and Translation

The messages as described in Section 1.1 have to be of the CIDRW SECS and ASCII

standard. The host could communicate with the ATR 9180 on either the RS-232 port or

the ethernet port. On the RS-232 port, the host could communicate over SECS or ASCII

version. When the host communicates over the ethernet, the communication would

happen over the HSMS protocol.

Each CIDRW SECS message (either on the SECS or HSMS port) would have a target ID

in its message body as an item. For example, the command Read MID (S18F9) has the

format

S18F9: 'S18F9' W

<A '##'>. * Target ID.

The item ## represents the Target ID of the node which the host wants to access.

Assuming the host needs to read the MID from node '01', following is the sequence of

operations that would take place:

Draft Rev. Bx1 2000-6631-05 Page 13

AdvanTag 9180 Technical Manual

Chapter 2: Theory of Operation

Using HSMS Protocol as Host

1. Host sends S18F9 command to the ATR 9180.

2. ATR 9180 parses the message for validity of data and format, extracts the Target ID

out of the data stream and then routes it to the correct antenna port.

S18F10

<L[4]

<A '01'> *Target ID

<A 'NO'> *SSACK

<A 'ABCDE'> *MID (Assuming ABCDE was the MID in MicroTag)

<L[4]

< A 'NE' >

< A 'O' >

< A 'IDLE' >

< A 'IDLE' >

>

>.

Messages Supported

The ATR 9180 supports only CIDRW ASCII and CIDRW SECS messages as described in

the message set documents P/N 2000-1455-01 and 2000-1442-01.

For any other message, the ATR sends back an error message saying that the command

is not supported.

Only one message at a time can be sent to the antennas. The host has to receive the

reply of a previous message before sending another message to the same node.

Specifications

• Firmware of the ATR9180 can be upgraded using PICkit 2.

• Can connect to a host on serial port at baud rates of 9600 and 19200.

• Supports a 10 Base-T ethernet connection for HSMS communication.

Page 14 2000-6631-05 Draft Rev. Bx1

Integration of Parts

Mounting

CAUTION

GENERAL HAZARD

ALL MOUNTING OPERATIONS SHOULD BE PERFORMED WITH

THE POWER CORD TO THE ADVANTAG DISCONNECTED. ALSO,

BE SURE THE 24 VDC POWER CONNECTOR IS

DISCONNECTED. FAILURE TO DISCONNECT BOTH COULD

RESULT IN DAMAGE TO THE ADVANTAG AND PERSONAL

INJURY FROM MECHANICAL AND/OR ELECTRICAL HAZARDS

WITHIN THE FRONT-LOAD ENCLOSURE.

I

F REMOVAL OF THE LOAD PORT FROM THE HOST TOOL IS

REQUIRED, ENSURE THAT THE POWER TO THE HOST TOOL IS

REMOVED AND THE POWER DISCONNECT DEVICE IS LOCKED

OUT IN THE OFF POSITION.

AdvanTag 9180 Technical Manual

Chapter 2: Theory of Operation

Integration of Parts

On the back of the AdvanTag reader, there are four M3 X .5 inserts that can be used for

mounting.

Other details:

• Install the AdvanTag reader in a dry and clean environment.

• The AdvanTag reader should be mounted to a grounded panel.

• The AdvanTag reader should be located as close as possible to the physical center of the devices that will be connected to it (the maximum recommended serial

cable length is 10 meters).

For more details, consult instructions for the appropriate installation kit.

Ports

For details on the AdvanTag reader’s ports, see “ Connectors” on page 27.

Draft Rev. Bx1 2000-6631-05 Page 15

AdvanTag 9180 Technical Manual

Chapter 2: Theory of Operation

Data Storage—AdvanTag Reader

Data Storage—AdvanTag Reader

Memory

The 9180 can read/write up to 136 bytes of data from/to the transponder (MicroTag). This

memory is divided into two sections. The first is for Material Identification (MID), which is

configurable using the attribute set and can be up to 136 bytes long (range: 8-136,

standard: 16). The second (Notepad) is for the balance of the memory. The amount of

available MID and Notepad memory is dependent upon the MicroTag used. Two types of

MicroTags are available, single page and seventeen page versions. Each page contains

64 bits, resulting in eight bytes of memory per page. MicroTags are available as read/write

or read only.

MicroTags

The AdvanTag reader can interact with MicroTags with regard to the following information:

SECS communication:

• Are You There - This message is used to perform the heartbeat between the host

and the connected device.

• Read Attribute Request - This message requests the current values of ECID or

SVID of the subsystem component indicated in TargetID.

• Write Attribute Request - This message requests the subsystem to set the value

of ECID of the component specified in TargetID to configure desired behavior.

Only applicable write-able attributes (like ECID) may be used in this message.

• Read Data Request - This message reads the “NOTEPAD” (Linear Memory) section of the subsystem component indicated in TargetID.

• Write Data Request - This message writes data to the NOTEPAD section of the

subsystem component indicted in TargetID.

• Read Material ID Request - This message is used to request the subsystem indicated by TargetID to read an MID.

• Write Material ID Request - This message is used to request the subsystem indicated by TargetID to write a Material identifier.

• Subsystem Command Request - This message is used to request the subsystem

indicated in TargetID to perform a specific action. Included in this set are the following commands: SSCMD 04 - LED BLINK/ON/OFF on Node Device; SSCMD

07 - Perform Diagnostics; SSCMD 13 - Reset; SSCMD 15 - Change State;

SSCMD GetStatus.

• Event Report Send - This message is used to send events to the host. Included in

this set are the following commands: CEID 01 - Material (Pod/Cassette) Arrival

Event; CEID 02 Material (pod/Cassette) Removal Event; CEID 08 - AdvanTag/LinkManager Power up.

• Read STATE Request - This message will query the CIDRW state of the transition

model.

Page 16 2000-6631-05 Draft Rev. Bx1

AdvanTag 9180 Technical Manual

Chapter 2: Theory of Operation

Data Storage—AdvanTag Reader

Retry Count Feature

The attribute RETRY_DIAGNOSTICS is a feature new to the AdvanTag family of readers.

This read-only attribute supports a diagnostic capability which allows the reader to

provide the number of retries performed in the last radio read/write command. Please

note that the information returned is the count for the previous read only.

Dual-Sensor Functionality

Dual-Sensor Host communicates with ATR9180 over serial port on SECS protocol.

New attributes added:

1. HOST_CONT_PORT1_LED (Value = ON/OFF)

Default value OFF. Set above attribute to ON using S18F3 commands Dual-Sensor

Functionality, HOST can control LED through S18F13 commands.

2. DUAL_SENSOR (Value = ON/OFF)

Default value OFF. Set above attribute to ON using S18F3 commands Dual-Sensor

Functionality.

Button 1 will produce Arrival Event (S18F71) with MID of the PILL. LED 1 stays ON during

read.

Button 2 will produce Removal Event (S18F75) with MID of the PILL. LED 2 stays ON

during read.

3. During Radio Operation on the Antenna port both LEDs on the port turn ON.

4. LED 1 corresponds to Button 1 and LED 2 corresponds to Button 2.

Led 1 and 2 can be addressable using Sub system command (S18F13) and can be

turned ON, OFF or BLINK.

Case 1. Button 1 press produces POD Arrival Event with S18F71 Message. LED 1 turns

ON till ATR reads the TAG and then turns OFF. LED ON Time should not be less than 1

Sec.

Case 2. Button 1 release doesn’t produce any event.

Case 3. Button 2 press produces POD Removal Event with S18F75 Message. LED 2

turns ON till ATR reads the TAG and then turns OFF. LED ON Time should not be less

than 1 Sec.

Case 4. Button 2 release doesn’t produce any event.

Case 5. LEDs are ON due to previous command (S18F13) and Radio is not busy in

Read/Write operation.

New command from the Host is executed right away.

Draft Rev. Bx1 2000-6631-05 Page 17

AdvanTag 9180 Technical Manual

Chapter 2: Theory of Operation

Data Storage—AdvanTag Reader

Case 6. LEDs are ON and Radio is BUSY in Read/Write operation.

New command from the Host is queued.

Case 7. LEDs are ON and Radio is busy in Read/Write operation button press should be

ignored.

Case 8. While Host is accessing the TAG LED 1,2 should turn ON and OFF once the

access is finished.

LED ON Time should not be less than 1 Sec.

Message Structure for S18F71 and S18F75 on Button Press is described below.

S18F71<L,4

<TargetID>

<SSACK> * SSACK STATUS -->NO/CE

<01> * CEID POD ARRIVAL Event

>

S18F75<L,4

<L,2

<”AUTOREADDATA”>

<MID>

>

<TargetID>

<SSACK> * SSACK STATUS -->NO/CE

<02> * CEID POD REMOVAL Event

<L,2

<”AUTOREADDATA”>

<MID>

>

>

Page 18 2000-6631-05 Draft Rev. Bx1

AdvanTag 9180 Technical Manual

Chapter 2: Theory of Operation

Data Storage—AdvanTag Reader

ABLE 3 ATR9180 Configuration for Dual-Sensor Operation

T

ATTRIBUTE VALUE

SECS_T1 5

SECS_T2 8

MANTWRITEONLY DI

CID_ERROR OFF

CID_PAD NUL

HOST_CONT_PORT1_LED ON

DUAL_SENSOR ON

HSMS Functionality

Single session HSMS protocol derived from the SEMI E37.1-96 standard over TCP/IP.

The unit only communicates over 10Mbps Ethernet speed. The HSMS support is based

on static IP address mechanism. The unit defaults to the following settings on HSMS.

LOCAL_IP_ADDRESS: 128.5.10.93

LOCAL_PORT: 5000

DEFAULT_GATEWAY: 0.0.0.0

SUBNET_MASK: 255.255.0.0

Only the settings shown above are required for establishing and maintaining the HSMS

connection on the ATR 9180.

The ATR 9180 support only the PASSIVE mode of HSMS communication. The host or the

remote entity should be always in the ACTIVE mode of HSMS in order to communicate

with the ATR 9180.

The HSMS functionality of the ATR 9180 is always enabled on the reader. The same unit

can work on HSMS without the need of downloading a different software.

NOTE . . .

THE ATR 9180 ALWAYS DEFAULTS TO THE SECS1 PROTOCOL OVER RS-232

WHEN SHIPPED FROM THE FACTORY.

Power Up Sequence of HSMS

When moving on to communicating over HSMS, the user needs to send the S18F3 (Write

Attribute Request) command on the RS-232 port over SECS1 protocol to set the LAN

settings to the required values and power cycle the unit.

The first time when the protocol is switched from SECS1 to HSMS, the power up event

S18F71 – CEID 8 will not be sent to the host. After this point, the software switches to the

Draft Rev. Bx1 2000-6631-05 Page 19

AdvanTag 9180 Technical Manual

Chapter 2: Theory of Operation

Data Storage—AdvanTag Reader

HSMS mode and every subsequent power cycle will result into a power up event sent to

the host after HSMS is connected.

To establish the connection, the host must send a Select.Req message to the ATR 9180

and in response to that, the ATR 9180 will send back a Select.Rsp message to declare

acceptance and HSMS CONNECTION establishment. Any of the CIDRW commands can

be sent after this stage.

HSMS Connection Management

Once the remote entity has dropped the connection, the ATR 9180 detects the break right

away to open up a new socket and get ready to accept a new connection from the remote

entity. The ATR 9180 generates its own Link Test request. It still replies back to the

LinkTest.Req message sent by the remote entity with a LinkTest.Rsp message. All the

CIDRW commands are supported as in the case of the RS-232 mode.

After being IDLE for LinkTest Frequency defined time the ATR 9180 sends a LinkTest.Req

message and starts a T6 timer to wait for LinkTest.Rsp from the remote entity. If the

response is not received during this timeout, the ATR9180 closes the previous socket and

opens a new one. The Host must reconnect on the same port.A similar socket disconnect

will take place when the LAN cable is removed from the ATR or the hub to which the ATR

is connected.

Event-Change Functionality

Event-Change Host communicates with ATR9180 over LAN port on HSMS protocol.

Event-Change functionality supports single sensor per port.

New attributes added:

1. HP_EVENT (Value = ON/OFF). Default value OFF. Set above attributes to ON using

S18F3 commands for HP functionality.

2. On Power up once HSMS is connected to the Host, all the Antenna ports are read and

respective MIDs are stored in the memory.

3. POD Arrival Event read respective Antenna port and MID read is stored in memory

and Event displays MID.

4. POD Removal Event returns MID read from last Arrival Event.

T

ABLE 4 ATR9180 Configuration for Event-Change operation

ATTRIBUTE VAL UE

HOST_CONT_PORT1_LED OFF

DUAL_SENSOR OFF

S18F71<L,4

<TargetID>

<SSACK> * SSACK STATUS -->NO/CE

Page 20 2000-6631-05 Draft Rev. Bx1

>

S18F71<L,4

AdvanTag 9180 Technical Manual

Chapter 2: Theory of Operation

Data Storage—AdvanTag Reader

<01> * CEID POD ARRIVAL Event

<L,2

<”AUTOREADDATA”>

<MID>

>

<TargetID>

<SSACK> * SSACK STATUS -->NO/CE

<02> * CEID POD REMOVAL Event

<L,2

<”AUTOREADDATA”>

<MID>

>

>

Default Values of R/W ATTRIBUTES

TABLE 5 Attribute Values (ECID and SVID)

Attribute Typ e Description and Limits or Values

AlarmStatus RO The Alarm Status

Value = 0 or 1

ASCII_T1 (ASCII only) RW Inter-byte timeout

Default = 100

BAUDRATE RW SECS and ASCII Baud rate 9600, 19200,

28800, and 57600 Default = 9600

CarrierIDOffset RW 0 to CID_MAX_LENGTH-1

CarrierIDOffset + CarrierIDLength <=

CID_MAX_LENGTH

Default = 0

CarrierIDLength RW 1 to CID_MAX_LENGTH

CarrierIDOffset + CarrierIDLength <=

CID_MAX_LENGTH

CID_MAX_LENGTH RW (8*N) N = Page1 to 17 Default = 16

CID_DISPLAY RW ON = Enable

OFF= Disable

Draft Rev. Bx1 2000-6631-05 Page 21

Default = ON

Default = 16

AdvanTag 9180 Technical Manual

Chapter 2: Theory of Operation

Data Storage—AdvanTag Reader

TABLE 5 Attribute Values (ECID and SVID)

Attribute Typ e Description and Limits or Values

CID_NP_ASCII RW ON = Enable

CID_ERROR RW ON = Enable

CID_JUSTIFY RW R = Right

CID_PAD RW NUL = 0x00

CID_E99_PAD RW ON = Enable

CHECKSUM (ASCII only) RW Checksum enabled or disabled.

OFF= Disable

OFF= Disable

L= Left

Default = L

ZERO = 0x30

OFF= Disable

EN = Enabled

DI = Disabled

Default = OFF

Default = ON

Default = ZERO

Default = OFF

Configuration RO 01 through 31

DEFAULT_GATEWAY

(HSMS only)

DEVICEID

(SECS only)

RW Default Gateway address for ATR9180.

Default: 0.0.0.0

RW DeviceID of the Target, used in the SECS1

Header

DUAL_SENSOR RW Dual Sensor operation enable/disable

Default = OFF

ENABLE_TIMEOUTS

(ASCII only)

RW Enable Communication Timeouts

ON = Timeout events will be generated.

OFF = Timeout events will not be generated.

Default = ON

ENABLE_EVENTS RW Enable Events (Pod or Operator

arrival/removal, and powerup.

ON = Event will be generated.

OFF = Events will not be generated.

Default = ON

EXTENDEDSSACK RW Enables the extended error codes in SSACK.

The SEMI standard specifies only five codes

(NO, EE, CE, HE, and TE). When this option

is ON, up to 100 error codes might be

generated.

Please see SSACK for all error code.

ON = All error codes generated.

OFF= Only SEMI standard error codes

generated

HeadID RO Returns the HeadID or TargetID

Two digits

Page 22 2000-6631-05 Draft Rev. Bx1

AdvanTag 9180 Technical Manual

Chapter 2: Theory of Operation

Data Storage—AdvanTag Reader

TABLE 5 Attribute Values (ECID and SVID)

Attribute Typ e Description and Limits or Values

HeadStatus RO IDLE or MANT

HOST_CONT_PORT1_LED RW LED controlled by Host on Remote I/O Port 1

Default = OFF

HSMS_T5

(HSMS only)

HSMS_T6

(HSMS only)

HSMS_T7

(HSMS only)

HSMS_T8

(HSMS only)

LOCAL_IP_ADDRESS

(HSMS only)

LOCAL_PORT

(HSMS only)

LinkTestFrequency

(HSMS only)

RW T5 Timeout in HSMS

(1 - 240 sec.)

Default = 10

RW T6 Timeout in HSMS

(1 - 240 sec.)

Default = 10

RW T7 Timeout in HSMS

(1 - 240 sec.)

Default = 10

RW T8 Timeout in HSMS

(1-120 sec.)

Default = 10

RW Local IP Address.

Default: 128.5.10.93

RW Local port on which the ATR 9180 would

listen Default: 5000

RW This timer is used to send periodic link test

messages. If a response is not received the

connection is dropped.

Default: 20 seconds

Manufacturer

(Applicable only to version 21A

and later)

MANTWRITEONLY RW If this attribute is enabled, then MID (CID)

MDLN RO Asyst Model designation of Upstream

ModelNumber

(Applicable only to version 21A

and later)

OperationalStatus RW IDLE or MANT

Draft Rev. Bx1 2000-6631-05 Page 23

RO Returns “Asyst”

and Data is read and written according to the

E99 standard

EN = Enable

DI = Disable

Default = EN

Controller OR Head (as applicable)

Up to 6 bytes

RO Same as MDLN

Note: Set through only Subsystem commands

AdvanTag 9180 Technical Manual

Chapter 2: Theory of Operation

Data Storage—AdvanTag Reader

TABLE 5 Attribute Values (ECID and SVID)

Attribute Typ e Description and Limits or Values

PIP_AUTOREAD RW Auto read On or OFF

PIP_AUTOREAD_DATA RW The memory type to read upon Pod-In-Place

PIP_AUTOREAD_LENGTH RW Length of NOTEPAD data to read upon Pod

ON = On

OFF = Off

Default = ON

Event:

(Offset, or MID)

Note: Offset applies only to NOTEPAD.

Note: This attribute should be modified with

respect to PIP_AUTOREAD_LENGTH

Default = MID

arrival.

Note: Applicable only if data type is

NOTEPAD

Note: This attribute should be modified with

respect to PIP_AUTOREAD_DATA

Default = 16

PIP_SENSOR_POLARITY RW PIP Sensor Polarity.

HI = Active-High. When Sensor goes high,

Pod Arrival event is generated

LO = Active-Low. When Sensor goes low, Pod

Arrival event is generated

Default = LO

RETRY_DIAGNOSTICS R Returns number of retries that occurred during

last radio read/write operation.

RADIO_RETRY RW Retry Count for Radio operation in case of

failure

Default: 3

RDA RW AdvanTag returns either RD or RDA in

response to the ASCII RD command.

EN = Enabled, returns RDA

DI = Disabled, returns RD

Default = EN

SENSOR_TIMEOUT RW Value 1 - 20

Default 10

SCAN_ENABLE RW Value = ON/OFF

Default = OFF

SECS_T1 (SECS only) RW SECS T1 timeout

Default = 5

SECS_T2 (SECS only)

(Host port on LM)

Page 24 2000-6631-05 Draft Rev. Bx1

RW SECS T2 timeout

Default = 50

AdvanTag 9180 Technical Manual

Chapter 2: Theory of Operation

Data Storage—AdvanTag Reader

TABLE 5 Attribute Values (ECID and SVID)

Attribute Typ e Description and Limits or Values

SECS_T3 (SECS only)

(Host port on LM)

SECS_T4 (SECS only)

(Host port on LM)

SECS_RETRY (SECS only)

(Host port on LM)

SOFTREV RO Subsystem Software Rev. of Upstream

SoftwareRevisionLevel RO Same as SOFTREV

SELF_TEST_RESULT RO Last self test result

STATUS_ENABLE RW If set to Enable communicates Status

SUBNET_MASK (HSMS only) RW Default Subnet Mask for ATR 9180. Default:

TARGETID RW The TargetID of the device

RW SECS T3 timeout

Default = 45

RW SECS T4 timeout

Default = 45

RW SECS-1 Protocol Retry limit

Default = 3

Controller OR Head (as applicable)

6 bytes

P = Pass

F = Fail

information of the Head. Default “EN”.

255.255.0.0

Please refer to the Asyst CIDRW Messages SECS protocol manual (Asyst part number

2000-1442-01) and Asyst CIDRW Messages ASCII protocol manual (Asyst part number

2000-1455-01) for more detailed information on communication with the AdvanTag.

Draft Rev. Bx1 2000-6631-05 Page 25

AdvanTag 9180 Technical Manual

Chapter 2: Theory of Operation

Interfaces

Interfaces

There are three LEDs to signify activity, a RESET button, and a switch panel for

specifying the unit's address (TargetID). See below for more details.

LEDs

The LEDs located on the top of the reader (see Figure 4) indicate the operational status

of the AdvanTag.

Read/Write LED

Power LED

Host Controller LED

F

IGURE 4 AdvanTag 9180 Reader LEDs

Power Indicator LED

The POWER indicator, when lit, indicates that power is applied to the AdvanTag.

Light Status Power

Off No power

Green Power on

Host Controller LED

Green, controllable by host command (on/off/blinking).

Page 26 2000-6631-05 Draft Rev. Bx1

AdvanTag 9180 Technical Manual

Chapter 2: Theory of Operation

Read/Write LED

The Read/Write LED indicates communication status:

Light Communication Status

Off Radio off

Green Successful read/write

Red Read/Write failure (details below)

Read/Write failures occur as a result of one of the following:

• Attempted to read multiple pages of a single-page MicroTag

• Multiple MicroTags are in range

• No MicroTags are in range

• Attempted a write operation on a read-only MicroTag or a looked page

Interfaces

For read/write ranges, see “ Antenna Performance” on page 38.

Connectors

The AdvanTag reader features four external ports.

Power

The port labeled PWR is for a power supply of 24VDC. Asyst can supply a 120-220V

adapter (Asyst P/N 6200-6210-01) or the OEM can supply this power.

This is a DB9 male receptacle, 24 VDC (+/- 10%), 70mA typical, 350mA maximum. See

Table 1, “AdvanTag 9180 Specifications,” on page 5 for further details. The following table

shows the pin outs.

T

ABLE 6 Power Cable Pin Outs

Pin Signal

1Not Used

2 CAN Low

3 Signal Ground

4Not Used

5 Power Ground

6 Signal Ground

7 CAN High

8Not Used

9+24VDC

Draft Rev. Bx1 2000-6631-05 Page 27

AdvanTag 9180 Technical Manual

Chapter 2: Theory of Operation

Interfaces

Communication

The port labeled RS232 COMM is for RS232 communication.

This is a shielded RJ45 socket. A cable which connects the Reader to a PC is available

from Asyst.

ABLE 7 Serial Port Pin Usage

T

Pin

Number

1 (N/C) not used

2 (N/C) not used

3 (N/C) not used

4 Ground X

5 TX X

6 RX X

7 (N/C) not used

8 (N/C) not used

Name

Serial Comm

(SECS/ASCII) RJ45

CAUTION

ELECTRICAL HAZARD

DO NOT TOUCH THE INSIDE OF THE ANTENNA CONNECTOR.

FAILURE TO COMPLY MAY RESULT IN INJURY.

Antenna

CAUTION

ANTENNAS SHOULD ONLY BE INSTALLED BY QUALIFIED

PERSONNEL. FAILURE TO COMPLY MAY RESULT IN

MALFUNCTION OR DAMAGE TO THE UNIT AND/OR ANTENNA.

The port labeled REMOTE ANTENNA is for an external antenna. Contact Asyst for

available antennas.

This is a BNC socket; use with Asyst antennas is required.

Page 28 2000-6631-05 Draft Rev. Bx1

AdvanTag 9180 Technical Manual

Chapter 2: Theory of Operation

Interfaces

CAUTION

GENERAL HAZARD

NEVER USE A NON-ASYST ANTENNA WITH THE ADVANTAG

9180. F

CERTIFICATION.

AILURE TO COMPLY WILL VOID FCC AND CE

External Presence

The port labeled REMOTE I/O is for an external presence sensor that detects events

such as pod arrival and pod removal.

The REMOTE I/O port is a shielded RJ45 socket used for the external presence sensor.

Pin Signal Input/Output

+5 or +12 VDC Output

1

Sensor 1 Input

2

3

4

5

6

7

8

NOTE . . .

POWER OUTPUT IS CONFIGURABLE AND SELECTED BY USE OF JUMPERS

APPLIED TO THE PRESENCE SENSOR. JUMPER PINS 1&2 FOR +12VDC AND

JUMPER PINS 2&3 FOR +5VDC.

LED 1 Output

Ground

LED 2 Output

NC

Sensor 2 Input

NC

Draft Rev. Bx1 2000-6631-05 Page 29

AdvanTag 9180 Technical Manual

Chapter 2: Theory of Operation

Interfaces

Ethernet

The Ethernet port is a shielded RJ45 socket used for communication to a host using

HSMS.

Use a standard CAT5 Ethernet straight cable when connecting the ATR9180 to a 10/100

Mbps hub or switch. A shielded ethernet cable is preferred.

NOTE . . .

FOR INFORMATION ON COMMUNICATION THROUGH ALL PORTS, PLEASE REFER

TO THE SOFTWARE MANUAL.

Buttons/Switches

Reset

Press this button (see Figure 5) to reset the unit. The default baud rate is 9600.

NOTE . . .

THE ATR9180 WILL TAKE 10 SECONDS TO BOOT UP AND RUN THE SOFTWARE.

IGURE 5 Locating the Reset Switch

F

Code Upgrade

Code Upgrade of the ATR9180 can be performed using PICkit 2. The Procedure can be

found in the ATR9180 Upgrade Procedure P/N 2000-6779-01.

Reset

Switch

Page 30 2000-6631-05 Draft Rev. Bx1

Communications

To Host

The AdvanTag reader communicates to the host via RS-232 or LAN ports.

NOTE . . .

THE ATR9180 REMEMBERS THE LAST PROTOCOL USED TO COMMUNICATE. THE

DEFAULT PROTOCOL IS SECS WITH 4 RETRIES.

Read Range

Typical read range of the AdvanTag reader is 10-12 cm. Read range is dependent on the

antenna design and the operational environment in which the antenna is installed. See “

Antenna Performance” on page 38 for further details.

AdvanTag 9180 Technical Manual

Chapter 2: Theory of Operation

Communications

SECS

Refer to the specific protocol documentation concerning Stream 18 SECS messages for

details. The basic functions available are to read and write attributes, read and write

material IDs (MIDs), read and write data, and various subsystem commands such as

turning an LED on or off. Note that the single-page transponders hold an 8 byte MID only

and the multi-page transponders hold a 16-byte MID and 120 bytes of data.

The TargetID (as described in the SEMI E99 and E5 standards) can be set with the

S18F3 command; default value is 1. The SECS I DeviceID can be set through an

attribute. The baud rate can also be set through an attribute setting. Byte format is 8 data

bits, 1 stop bit and no parity. The SECS I timeouts and retries can be set through attribute

settings; defaults are T1 = 0.5 secs, T2 = 10 secs, T3 = 45 secs, T4 = 45 secs, Retries =

3.

Serial Communications Interface

The AdvanTag has one port for serial-computer-communications interface (Asyst P/N

9701-2914-XX). It is an RJ45 RS232 interface. It has a transmit (TX) and a receive (RX)

line and ground. See Table 7 on page 28.

Ethernet Communications

The ATR 9180 has an Ethernet port, which is an RJ45 socket. Communication protocol is

single session HSMS.

Draft Rev. Bx1 2000-6631-05 Page 31

AdvanTag 9180 Technical Manual

Chapter 2: Theory of Operation

Software

Software

For more software information, please refer to the Asyst CIDRW Messages SECS

protocol Manual (Asyst part number 2000-1442-01) and the Asyst CIDRW Messages

ASCII protocol Manual (Asyst part number 2000-1455-01).

Page 32 2000-6631-05 Draft Rev. Bx1

Web Configurator

The ATR 9180 supports a web configurator on ethernet using HTTP Protocol. See Figure

6 for Web Interface Home Page.

AdvanTag 9180 Technical Manual

Chapter 2: Theory of Operation

Web Configurator

F

IGURE 6 ATR 9180 Web Interface - Home Page

HSMS Configuration

Upon clicking HSMS Configuration link on the main page, the configuration page is

displayed. The configuration page takes a few seconds to load as it reads all the

necessary configuration attributes from the flash and displays the values against the

name in a tabular format as shown in Figure 7 on page 34.

Draft Rev. Bx1 2000-6631-05 Page 33

AdvanTag 9180 Technical Manual

Chapter 2: Theory of Operation

Web Configurator

WARNING:

FIGURE 7 Web Interface - Configuration Page

NOTE . . .

THE VALUES IN TEXT BOXES ARE THE DEFAULT VALUES FOR THE ATTRIBUTE.

T

HE ACTUAL (CURRENT) VALUE OF THE SAME ATTRIBUTE IS DISPLAYED IN THE

BRACKET NEXT TO THE TEXT BOX. EXAMPLE: IN FIG THE ATTRIBUTE

ARRIERIDOFFSET HAS THE CURRENT VALUE AS 0 AND THE DEFAULT VALUE IS

C

ALSO 0.

To change the value of any of the attributes, the new value must be entered in the text

box (which always shows the default value). Once the new value has been entered, click

on the Write ___ Attributes button to write the attributes to the flash memory.

Page 34 2000-6631-05 Draft Rev. Bx1

AdvanTag 9180 Technical Manual

Chapter 2: Theory of Operation

Web Configurator

Read-Write Radio

Upon clicking Read-Write Radio link on the main page, the Read Write page is displayed.

See Figure 8. The Read Write page is divided in two parts Read and Write. The read

commands are Read MID and Read Data. The write commands are Write MID and Write

Data

F

IGURE 8 Web Interface - Read Write Page

Read

Read MID is a simple HTML link which executes a ReadMID command on the reader and

returns the ID on the web page along with the Error/Success code. The Read MID

command would be executed by clicking the Read MID button on the read/write page.

See Figure 9 for sample response.

IGURE 9 Read MID Response

F

Draft Rev. Bx1 2000-6631-05 Page 35

AdvanTag 9180 Technical Manual

Chapter 2: Theory of Operation

Web Configurator

A Read Data command would be executed by entering Offset and Data length in the

fields provided and clicking the Read Data button on the read/write page. See Figure 10

for sample response.

NOTE . . .

OFFSET AND DATA LENGTH MUST BE ENTERED IN ORDER TO READ THE

NOTEPAD DATA FROM THE TAG.

The maximum data that could be read through the web read data interface is 45 bytes.

IGURE 10 Read Data Response

F

Write

The Write MID button writes the MID entered in the text box in front of the Write MID

button to the MID area of the tag. Enter the MID to be written in the text box in front of the

Write MID button then click on the Write MID button. Figure 11 displays a sample

response.

F

IGURE 11 Write MID Response

Page 36 2000-6631-05 Draft Rev. Bx1

The Write Data button writes the data entered in the data field of the page to the Notepad

area of the tag.Enter the Data to be written in the text box in front of the Write Data button

then click on the Write Data button. Figure 12 displays a sample response.

NOTE . . .

OFFSET AND DATA LENGTH MUST BE ENTERED IN ORDER TO WRITE THE

NOTEPAD DATA TO THE TAG.

AdvanTag 9180 Technical Manual

Chapter 2: Theory of Operation

Web Configurator

F

IGURE 12 Write Data Response

Draft Rev. Bx1 2000-6631-05 Page 37

AdvanTag 9180 Technical Manual

Chapter 2: Theory of Operation

Antenna Performance

Antenna Performance

The AdvanTag antennas work in conjunction with the AdvanTag Reader ATR9180 to read

and write the MicroTag. Communications occur between the antenna and the MicroTag

using very low radio frequency (134.2khz). Performance of these antennas (read and

write distance as well as speed) is affected by the presence of metal and RF generators,

such as color monitors in the antenna communication field.

Read/Write Performance Factors

Factors that influence tag read and write performance:

• Proximity of the tag and antenna

• Length of cable between the AdvanTag Reader and the antenna (including exten-

sion cables)

• Orientation of the tag to the antenna

• Amount of metal adjacent to either the tag or the antenna

• Amount of background EMF in the environment

NOTE . . .

IF AN ANTENNA IS POSITIONED AGAINST A MICROTAG, THE ANTENNA WILL NOT

READ IN MOST CASES. ALL OF THE RESULTS LISTED WERE TESTED IN AN OFFICE

ENVIRONMENT.

RF Field Diagrams

The diagrams accompanying the types of antenna for reference only. Note the following

conditions for each diagram:

• The coil of micro-tag must be completely contained in write area.

• The shaded area in center is a non-write area (null).

• Write ranges are approximately 50% of read ranges.

• The read and write distances cited are for reference only. Ranges are dependent

upon actual installed environment.

• It may not be possible to replicate the same results outside of lab environments

due to a variety of environmental conditions.

Page 38 2000-6631-05 Draft Rev. Bx1

AdvanTag 9180 Technical Manual

Chapter 2: Theory of Operation

Antenna Performance

Stick Antennas

The stick antenna 9701-2879-03 is designed to be attached to the external antenna

connector of the ATR 9180 and optimized for use in a variety of applications. The average

read range is 10-12 cm. This stick antenna diagram refers to a stick antenna as being flat

on the YZ axis, centered at 0,0,0.

Read Pattern using 9701-2879-03 antenna in air

Transponder in vertical position relative to antenna

(distance units in mm)

0º

10º

20º

30º

40º

50º

60º

70º

290º

300º

310º

320º

330º

340º

350º

140

120

100

80

60

40

280º

270º

260º

250º

240º

230º

20

0

220º

210º

200º

190º

F

IGURE 13 Vertical Read Range

180º

170º

80º

90º

100º

110º

120º

130º

140º

150º

160º

Draft Rev. Bx1 2000-6631-05 Page 39

AdvanTag 9180 Technical Manual

Chapter 2: Theory of Operation

Antenna Performance

Read Pattern using 9701-2879-03 antenna in air

Transponder in horizontal position relative to antenna

330º

320º

310º

(distance units in mm)

0º

340º

350º

160

140

120

100

10º

20º

30º

40º

50º

290º

280º

270º

260º

250º

300º

240º

230º

220º

210º

200º

190º

80

60

40

20

0

180º

170º

60º

70º

80º

90º

100º

110º

120º

130º

140º

150º

160º

FIGURE 14 Horizontal Read Range

Page 40 2000-6631-05 Draft Rev. Bx1

Chapter 3: Troubleshooting

This chapter identifies common problems that may occur when using the AdvanTag 9180

unit and provides a step-by-step process to identify the root cause for reader

failure/malfunction and common solutions.

It includes:

• “ Troubleshooting Chart” on page 41

• “ Troubleshooting for RS232” on page 42

• “ Troubleshooting for HSMS ATR9180” on page 43

• “ For Additional Troubleshooting Assistance” on page 45

Troubleshooting Chart

If there are any other problems, or if none of the corrective actions/solutions shown in this

chapter clears the problem, replace the AdvanTag 9180.

ABLE 8 ATR 9180 Common Errors and Solutions

T

Error or Symptom Likely Cause(s) Corrective Action

Unit not functioning

properly

During read and write

programs, the

READ/WRITE LED turns

red.

During read and write

programs, the

READ/WRITE LED turns

red instead of green.

During read and write

programs, the

READ/WRITE LED does

not blink.

No Power - LEDs on the

front of the unit are not

illuminated.

Communication cables loose

or disconnected.

MicroTag or antenna is not

installed correctly.

MicroTag is not present or

out of range.

The antenna cable is loose.

The antenna is bad.

The RS232 cable is loose.

The RS232 cable is bad.

The ATR is bad.

Host command is wrong.

Check connection for power cables. Make

sure the power is connected and then verify

the Power LED is lit.

Check the power supply being used. Swap

with another power supply to make sure that

the power supply is functioning properly.

Check serial cables for loose connector.

Check connector for bent pin(s).

Install MicroTag correctly. The

READ/WRITE LED should turn green only.

Refer to ATR magnetic field pattern diagram.

Install MicroTag or antenna properly. The

READ/WRITE LED should turn green.

Tighten the antenna cable.

Replace the antenna.

Adjust the location of the antenna.

Tighten the RS232 cable.

Replace the RS232 cable.

Replace the ATR.

Check Host command and target ID.

Draft Rev. Bx1 2000-6631-05 Page 41

AdvanTag 9180 Technical Manual

Chapter 3: Troubleshooting

Troubleshooting for RS232

Troubleshooting for RS232

Problem ATR9180 P/N 9701-3651-01 fails to follow normal power up sequence.

1. Turn the ATR9180 power on and observe the Host Controller LED.

It should turn ON for a second and then it should turn OFF. This verifies power-on

sequence and that the software is running.

If the ATR9180 does not follow this power on process then the unit may be defective

or the software is not functioning.

Solution

Upgrade the software using PICkit 2 (refer to upgrade procedure document, PN

2000-6779-01), restart the ATR9180, and observe the power-on sequence.

A successful power-on sequence at this time means that there was no software in the

unit. A failed power-on sequence at this time means that the hardware in the unit may

have been damaged.

• For further information, refer to the SW Release Notes (PN 2000-6719-01).

Problem No RS232 Communication

Solution

Check for loose connectors and cables.

Use only the cable recommended by Asyst Technologies, Inc. Asyst part number

9700-4859-XX (non-ROHS)/ 9701-2914-XX (RoHS).

NOTE . . .

THE ATR9180 MUST BE RESTARTED AFTER CHANGING TARGET ID USING A

WRITE ATTRIBUTE S18F3 COMMAND.

Page 42 2000-6631-05 Draft Rev. Bx1

Problem No Communications After a Hard Reset

Solution

A brand new ATR9180 on hard reset (see Asyst document 2000-1442-01 for details)

communicates power up event to the Host in SECS protocol. If the host is not present

ATR9180 will go in to retry mode and retry 3 more times before finally timing out. Timeout

is approximately 45 seconds. If you are using ASCII protocol, wait until SECS has

finished retrying. Then send the ASCII message.

NOTE . . .

THE ATR9180 REMEMBERS THE PREVIOUS SUCCESSFUL PROTOCOL IT

COMMUNICATED ON AND WILL CONTINUE TO COMMUNICATE WITH THAT

MESSAGE SET.

AdvanTag 9180 Technical Manual

Chapter 3: Troubleshooting

Troubleshooting for HSMS ATR9180

Troubleshooting for HSMS ATR9180

Troubleshooting guide for the 9701-3651-01 ATR 9180

NOTE . . .

THIS ATR WORKS AT ONLY 10 MBPS SPEED.

Problem ATR 9180 does not respond to ping command

Solution

1. Check the IP address, subnet mask and default gateway settings of the ATR. The IP

address must be unique for every ATR. The subnet mask of the PC and that of the

ATR should be same. The default gateway entry should also be the same.

2. To ensure that the proper software is installed, observe the ethernet LED on the LAN

connector.

3. Try changing the IP address to some other value. If an ATR is used with one address

and another one is connected after disconnecting the first from the network, the new

ATR will not be able to use the same IP address. In this case the new ATR must be

set to a new address.

4. Try clearing the arpcache from the PC.

Refer to the Software Release Notes (2000-6719-01) on how to configure the IP address.

Draft Rev. Bx1 2000-6631-05 Page 43

AdvanTag 9180 Technical Manual

Chapter 3: Troubleshooting

Troubleshooting for HSMS ATR9180

Problem The LED on the hub does not turn ON

Solution

1. Check the LAN cable used. When connected to a hub, a straight CAT 5 cable must be

used to connect the ATR 9180.

2. The port on which the ATR is connected is bad. Move the ATR cable to some other

port on the hub, and try again.

Problem No Communication with Tag

Solution

1. Make sure a TIRIS tag is present and positioned in the correct orientation and position

relative to the antenna. See the antenna read/write range graphs for details on the

correction locations.

2. Verify the Antenna is connected properly to ATR9180.

3. Check the orientation of the antenna.

4. Make sure there are no metallic objects within 30mm of the antenna or the TIRIS Tag.

5. Check to ensure that only one TIRIS tag is within the read range of the antenna.

Multiple tags in the read range of the antenna will prohibit reading of any tag.

Page 44 2000-6631-05 Draft Rev. Bx1

AdvanTag 9180 Technical Manual

Chapter 3: Troubleshooting

For Additional Troubleshooting Assistance

For Additional Troubleshooting Assistance

If you continue to have problems working with the ATR 9180, please collect the following

information and contact Asyst Technical Support at 1-800-342-SMIF (7643), enter 2 then

3 or e-mail techsupport@asyst.com for assistance.

1. Part Number and Serial Number of ATR9180

2. Part Number of RS232 cable connected

3. Part Number of the power supply

4. Part Number of the Antenna

5. Software Revision Level

6. Note the type of Presence Sensor connected, if any

7. List of responses to troubleshooting steps listed in this chapter

To Determine Software Revision

While Observing the power up event on the Host side, send a S1F1 SECS command with

AConfig and note the software revision in the return message from the ATR9180.

If there are any other problems, or if none of the above corrective actions clears the

problem, replace the AdvanTag. Other considerations to assure proper ATR functioning:

• The baud rate is to be the same between Host and ATR.

• The target ID is to be correct in the SECS message that gets sent to the ATR.

• The MicroTag is to be in the proper range and relative location to the antenna.

Draft Rev. Bx1 2000-6631-05 Page 45

AdvanTag 9180 Technical Manual

Chapter 3: Troubleshooting

For Additional Troubleshooting Assistance

Page 46 2000-6631-05 Draft Rev. Bx1

Appendix A: Functional Test Log

5/4/2007 10:58:20 AM - RECEIVED PRIMARY MESSAGE: S18F71

<L

<A 01>

<A NO>

<A 8> <== Power Up Event

<L

>

>.

10:58:20 AM - PRIMARY MESSAGE SENT:

S1F1

.

10:58:20 AM - RECEIVED SECONDARY REPLY: S1F2

<L

< A AT9180 >

< A R10B > <== R U There

>

READ MID CMD

10:58:36 AM - PRIMARY MESSAGE SENT:

S18F9

< A 1 > <== Read MID

10:58:37 AM - RECEIVED SECONDARY REPLY: S18F10

<L

<A 01>

<A NO>

<A Antenna Port --8>

<L <== Read MID Response

<A NE>

<A 0>

<A IDLE>

<A IDLE>

>

>.

WRITE 120 Bytes

11:00:11 AM - PRIMARY MESSAGE SENT:

S18F7

<L

<A 1>

<A 00>

<A 120> <== Write 120 bytes Data

<A

Draft Rev. Bx1 2000-6631-05 Page 47

AdvanTag 9180 Technical Manual

Appendix A: Functional Test Log

test 120 bytes write using ATR9180.test 120 bytes write using ATR9180.test 120 bytes

write using ATR9180.end of the data

>.

11:00:16 AM - RECEIVED SECONDARY REPLY: S18F8

<L

<A 01>

<A NO> <== Write Data Request Success

<L

<A NE>

<A 0>

<A IDLE>

<A IDLE>

>

>.

READ 120 bytes

11:00:28 AM - PRIMARY MESSAGE SENT:

S18F5

<L

<A 1>

<A 00>

<A 120> <== Read 120 Bytes Data

>.

11:00:30 AM - RECEIVED SECONDARY REPLY: S18F6

<L

<A 01>

<A NO> <== Read 120 Bytes Data Success

<A

test 120 bytes write using ATR9180.test 120 bytes write using ATR9180.test 120 bytes

write using ATR9180.end of the data

>.

11:02:03 AM - PRIMARY MESSAGE SENT:

S18F13

<L

<A 1>

<A 15>

<A M> <== MANT Mode ON

>.

11:02:03 AM - RECEIVED SECONDARY REPLY: S18F14

<L

<A 01>

<A NO>

<L

Page 48 2000-6631-05 Draft Rev. Bx1

<A NE>

<A 0>

<A MANT>

<A IDLE>

>

>.

WMID:

11:02:42 AM - PRIMARY MESSAGE SENT:

S18F11

<L

<A 1>

<A ATR9180--PORT001><== Write MID CMD

>.

11:02:43 AM - RECEIVED SECONDARY REPLY: S18F12

<L

<A 01>

<A NO> <== Write MID Success

<L

<A NE>

<A 0>

<A MANT>