Asycube

User guide

Document

Asyril_ASYCUBE_User_Guide_EN

000.101.029

Version

C

Date

23.07.2019

Asycube

User Guide

© Copyright Asyril S.A.

000.101.029

Version: C

2/46

Table of Contents

1. INTRODUCTION .................................................................................................................................. 4

1.1. GENERAL INFORMATION ....................................................................................................................... 4

2. USER GUIDE INTRODUCTION ........................................................................................................ 5

2.1. GENERAL OPERATION .......................................................................................................................... 5

2.2. GENERAL PROCEDURE OVERVIEW ....................................................................................................... 7

2.3. DEFINITIONS ......................................................................................................................................... 8

3. ASYRIL HMI INSTALLATION ......................................................................................................... 11

3.1. PREREQUISITE ................................................................................................................................... 11

3.2. INSTALLING THE HMI SOFTWARE ON A SPECIFIC COMPUTER ........................................................... 11

3.2.1. Pre-installation ............................................................................................................................... 11

3.2.2. Installation ...................................................................................................................................... 11

3.2.3. Starting the HMI ............................................................................................................................ 11

3.2.4. Configuring the HMI ...................................................................................................................... 12

3.2.5. Troubleshooting ............................................................................................................................ 12

4. HOPPER VIBRATION/OUTPUT ACTIVATION ............................................................................ 13

4.1. ASYCUBES 50 AND 80 ........................................................................................................................ 13

4.2. ASYCUBES 240, 380 AND 530 ........................................................................................................... 14

5. PLATFORM VIBRATION.................................................................................................................. 16

5.1. ASYCUBES 50 AND 80 ........................................................................................................................ 17

5.2. ASYCUBES 240, 380 AND 530 ........................................................................................................... 20

5.3. ASYCUBE 240 & 380 & 530: SIMPLIFIED ADJUSTMENT METHOD "EASY-TUNING" .......................... 21

6. SEQUENCE ........................................................................................................................................ 24

6.1. ACTIONS ............................................................................................................................................. 25

6.1.1. Hopper/output ................................................................................................................................ 25

6.1.2. Platform .......................................................................................................................................... 25

6.1.3. Wait ................................................................................................................................................. 25

6.1.4. None ............................................................................................................................................... 25

6.2. DURATION MODES .............................................................................................................................. 26

6.2.1. ‘Fixed’ ............................................................................................................................................. 26

6.2.2. ‘Quantity adjusted’ ........................................................................................................................ 26

6.2.3. ‘Vibration ratio’ ............................................................................................................................... 27

6.3. SMART VIBRATIONS ............................................................................................................................ 27

6.3.1. ‘Centring’ ........................................................................................................................................ 27

6.3.2. ‘Quantity adjusted’ ........................................................................................................................ 28

6.4. HMI SIMULATION: TEST SEQUENCE ................................................................................................... 29

Asycube

User Guide

© Copyright Asyril S.A.

000.101.029

Version: C

3/46

6.4.1. Case 1: No smart vibration .......................................................................................................... 29

6.4.2. Case 2: ‘Quantity adjusted’ ......................................................................................................... 30

6.4.3. Case 3: ‘Centring’ ......................................................................................................................... 30

6.4.4. Case 4: Mixed smart vibrations .................................................................................................. 31

7. SAVING ............................................................................................................................................... 32

8. BACKLIGHT ....................................................................................................................................... 34

8.1. ACTIVATION ........................................................................................................................................ 34

8.2. INTENSITY ........................................................................................................................................... 35

9. EXAMPLE ........................................................................................................................................... 36

9.1. INSTALL AND CONFIGURE THE ASYRIL HMI ....................................................................................... 36

9.2. ADJUST PLATFORM AND HOPPER VIBRATIONS ................................................................................... 36

9.2.1. Platform vibration .......................................................................................................................... 36

9.2.2. Hopper vibration/output activation .............................................................................................. 38

9.3. ADJUSTING SEQUENCES .................................................................................................................... 39

9.3.1. Flat platform: Feed and distribute parts ..................................................................................... 39

9.3.2. Structured platform: Feed and pre-orient parts ........................................................................ 40

9.3.3. Flat platform: Distribute parts (Asycube 240, 380 and 530) ................................................... 40

9.4. SAVE ALL THE PARAMETERS IN THE ASYCUBE .................................................................................. 41

9.5. CONFIGURE THE BACKLIGHT .............................................................................................................. 41

9.6. EXECUTE COMMANDS FROM PLC ...................................................................................................... 41

9.7. CONTROL THE ASYCUBE FROM YOUR PLC THROUGH MODBUS TCP .............................................. 42

10. TECHNICAL SUPPORT ................................................................................................................... 44

10.1. FOR BETTER SERVICE … ................................................................................................................... 44

10.2. CONTACT ............................................................................................................................................ 44

Asycube

User Guide

© Copyright Asyril S.A.

000.101.029

Version: C

4/46

1. Introduction

1.1. General information

The following document is the property of Asyril S.A. and may not be copied or circulated

without permission. The information contained in this document is subject to change without

notice for the purpose of product improvement. Please read this document carefully before

operating your product, to ensure it is used correctly. Nevertheless, should you encounter

difficulties during operation or maintenance, please contact Asyril customer service.

In this manual, the safety precautions contained in this manual are placed in three categories:

“Danger”, “Warning” and “Note”; the following symbols are used:

DANGER!

Failure to observe this instruction may result in death or serious injury.

DANGER!

Failure to observe this instruction may result in electrocution or serious injury due to

electric shock

IMPORTANT!

Failure to observe this instruction may result in serious injury or damage to property.

NOTE:

The reader's attention is drawn to this point in order to ensure that the product is used

correctly. However, failure to respect this instruction does not pose a danger.

Refer to …

For more information on a specific subject, the reader is invited to refer to another manual or

another paragraph.

IMPORTANT!

Asyril shall not be liable whatsoever for any loss or damage arising from failure to observe

the instructions specified in “Safety Precautions” of the USER GUIDE. The customer is

solely responsible for ensuring the necessary instructions are passed on to all persons

concerned.

NOTE:

All dimensions in this document are expressed in millimetres

Asycube

User Guide

© Copyright Asyril S.A.

000.101.029

Version: C

5/46

2. User guide introduction

This chapter presents a brief introduction on the general operation of the Asycube and an

overview of the procedure for setting up the Asycube for your application, followed by a

definition of the expressions used throughout this and other Asyril documentation. The

following chapters detail how to use the Asycube and at the end, to conclude this document,

a step-by-step example is given.

The Asycube is a flexible feeder system, which spreads the parts on the picking surface

using smart vibrations. Displacements in all directions as well as more advanced trajectories

are the result of the sum of the excitations of the different actuators. The role of the Asycube

is to:

• Distribute and flip the components over the picking surface

• Manage the feeding from the hopper in order to have enough components on the

picking surface

2.1. General operation

The table below shows the general procedure for using the Asycube with interaction of a

vision system and a robot, starting from an initial empty platform.

#AllParts = number of parts detected on the picking surface

Threshold = upper limit of parts on the platform for feeding vibration

GoodParts = parts well oriented and ready to be picked by a robot

Initial state

#AllParts < Threshold

Feeding

The Asycube feeds the

platform from the hopper

#AllParts < Threshold

Feeding + spreading

The Asycube spreads

components with smart

vibration

Asycube

User Guide

© Copyright Asyril S.A.

000.101.029

Version: C

6/46

A vision system detects

which parts are ready to

be taken

Get the lists of AllParts &

GoodParts positions

A robot picks up the

good parts

The Asycube spreads

components with smart

vibration

#AllParts > Threshold

Spreading

A vision system detects

which parts are ready to

be taken

Get the lists of AllParts &

GoodParts positions

A robot picks up the

good parts

The Asycube feeds the

platform from the hopper

#AllParts < Threshold

Feeding + spreading

The Asycube spreads

components with smart

vibration

A vision system detects

which parts are ready to

be taken and a robot

picks up the good parts

…

Table 2-1: Sequence of use of a flexible feeder system

Asycube

User Guide

© Copyright Asyril S.A.

000.101.029

Version: C

7/46

2.2. General procedure overview

The table below presents the general procedure to set up your Asycube for your specific

application. The next chapters of this document follow the order of the general procedure and

at the end of this document, a step-by-step example summarises the different aspects

approached.

Steps

1. Install and configure the Asyril HMI

3. Asyril HMI installation

page 11

2. Adjust platform and hopper vibrations/output

activations

a. for part family 1 (vibration set 1)

b. for part family 2 (vibration set 2)

c. for part family 3 (vibration set 3)

d. etc.

4. Hopper

vibration/output

activation

5. Platform vibration

9. Example

page 13

page 16

page 36

3. Adjusting sequences

a. for scenario 1, smooth platform, (Sequence 1)

b. for scenario 2, structured platform, (Sequence 2)

c. for scenario 3, smooth platform, (Sequence 3)

d. etc.

6. Sequence

9. Example

page 24

page 36

4. Save all the parameters in the Asycube

7. Saving

page 32

5. Configure the backlight

8. Backlight

page 34

6. Control the Asycube from a PLC

(Programmable Logic Controller)

a. Select a vibration set

b. Execute a sequence

c. Activate the backlight

d. etc.

9. Example

page 36

Table 2-2: General procedure overview

Asycube

User Guide

© Copyright Asyril S.A.

000.101.029

Version: C

8/46

2.3. Definitions

Platform vibration:

A platform vibration is defined as the combination of the excitation of each actuator in order to

obtain the desired trajectory of parts on the platform. 26 platform vibrations (A – Z) are available.

Each of them is composed of several parameters for each actuator (e.g. amplitude, frequency,

etc.) as well as the vibration duration.

Please refer to chapter 5 on page 16 of this document for more information on platform

vibrations.

Hopper vibration/output activation:

Depending on the Asycube, a hopper is either integrated (Asycube 50 and 80) or not (Asycube

240, 380 and 530). The expression hopper vibration is used in the case of an integrated hopper

and the expression output activation is used for the Asycube 240, 380 and 530.

• Asycube 50/80 (integrated hopper): a hopper vibration corresponds to the excitation of

the actuator in order to obtain the desired trajectory of parts on the hopper. 26 hopper

vibrations (A – Z) are available. Each of them is composed of several parameters (e.g.

amplitude, frequency, vibration duration, etc.).

• Asycube 240/380/530: The Asycube 240/380/530 is equipped with two outputs, which

can be used to drive one or two hoppers or whatever is connected to these outputs. The

Asycube 240/380/530 contains 26 output activations (A – Z). Each of them can be

configured in order to activate or not an output, to select an analogue output value, to set

the duration of the signal etc.

Please refer to chapter 4 on page 13 of this document for more information on hopper

vibrations/output activations.

Standard vibration:

To simplify the configuration of parameters, some platform vibrations and hopper

vibrations/output activations are pre-defined vibrations called standard vibration. In the case of

Asycubes 50 and 80, there are nine standard platform vibrations (A – I) such as for example

‘Forward’, ‘Forward left’, ‘Right’, ‘Backward’ etc. In the case of Asycubes 240, 380 and 530, there

are two additional standard platform vibrations (J and K), which correspond to short and long axis

centring vibrations. Hopper vibrations / output activations present a similar structure.

Custom vibration:

Asycube

User Guide

© Copyright Asyril S.A.

000.101.029

Version: C

9/46

The non-standard vibrations are called custom vibrations and can be used for further

customisation.

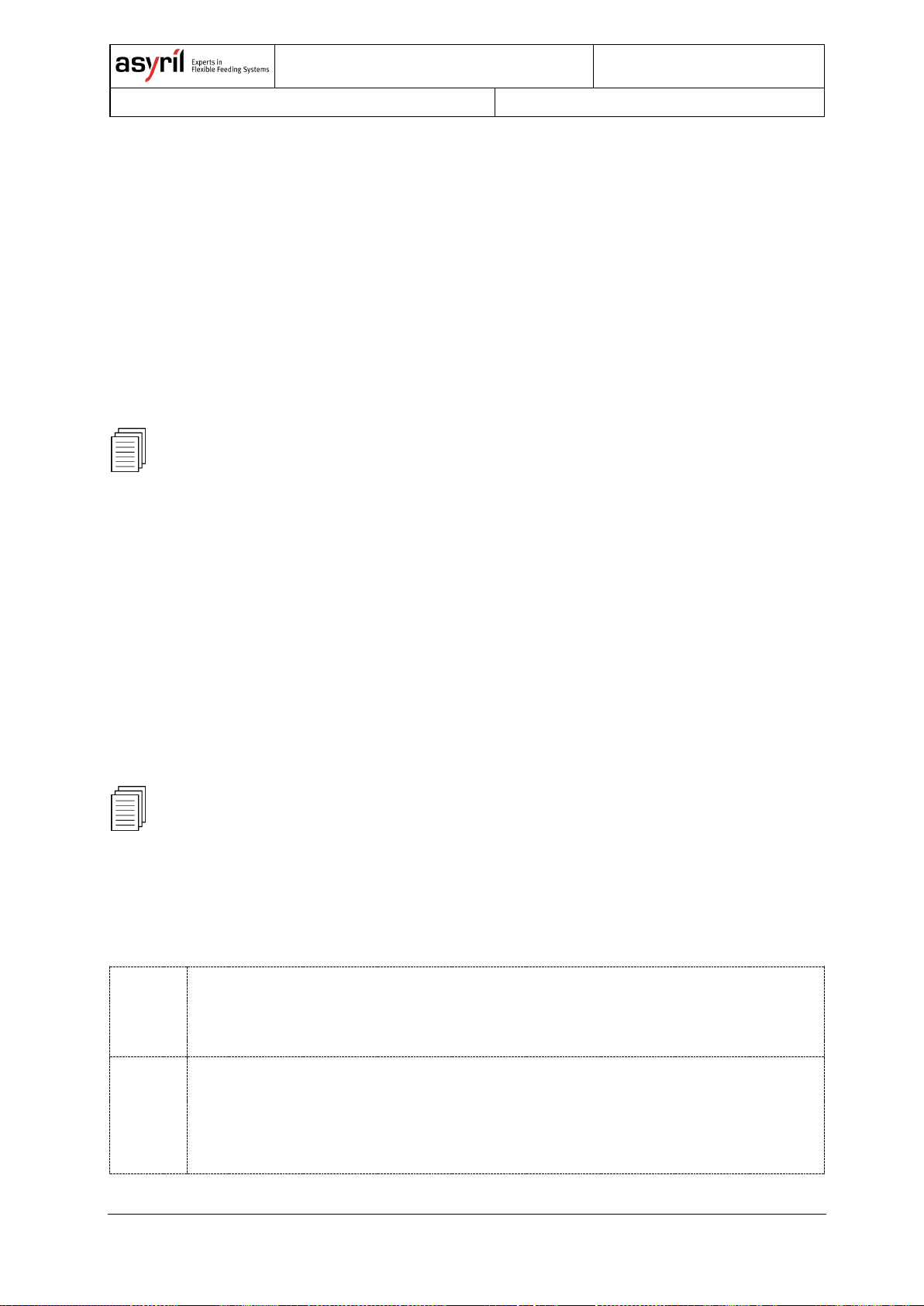

Vibration set:

26 vibration sets are contained in the Asycube and are identified by means of its ID. One vibration

set contains 26 platform vibrations and 26 hopper vibrations/output activations (See Figure 2-1).

Note that the vibration set 26 is not modifiable by the user as it corresponds to default parameters

already adjusted in order to obtain good behaviour of a standard part on your Asycube.

Smart vibration:

A smart vibration is based on the data of a vision system in order for the Asycube to adapt to the

current situation. In addition to data from a vision system, the system uses the parameters

configured in the vibration set. Thus, its effectiveness depends strongly on well-adjusted

vibrations. There are two types of smart vibrations:

• ‘Centring' vibration type: This vibration type is used to centre parts on the platform. The

direction and duration of the vibration is calculated based on the position of the parts

(centre of mass).

• ‘Quantity adjusted’ duration mode: This mode is used to adapt the feeding duration of

new parts onto the picking surface based on the number of parts detected on the surface.

- The more parts detected on the surface, the less new parts are fed.

Please refer to section 6.3 on page 27 of this document for more information on smart

vibrations.

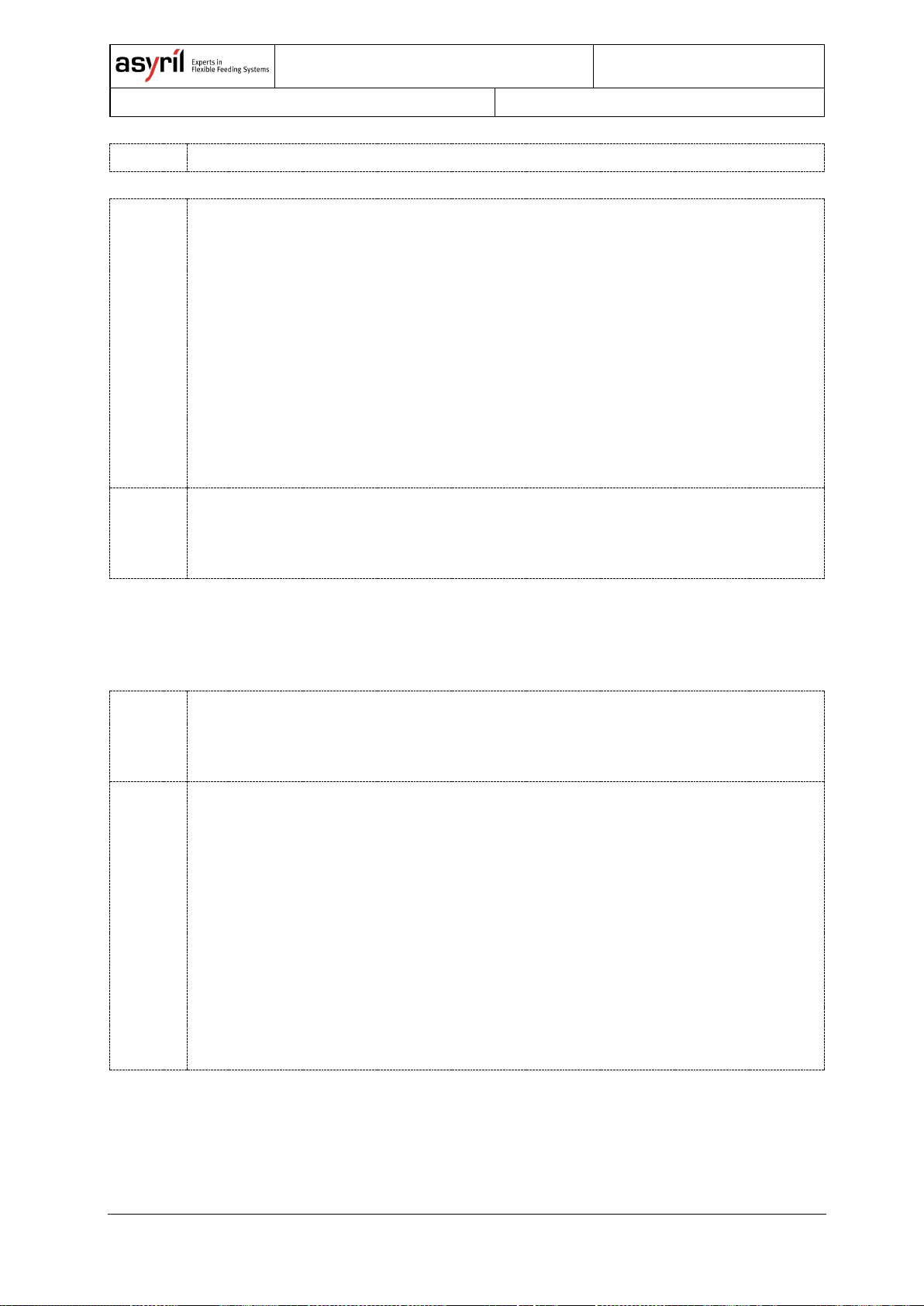

Sequence:

26 Sequences are available, each of them composed of seven actions. An action could be a

hopper or platform vibration, a certain waiting duration for part stabilisation, the 'centring' smart

vibration that adapts the direction and vibration duration depending on the part location etc.

Please refer to chapter 6 on page 24 of this document for more information on sequences.

Asycube

User Guide

© Copyright Asyril S.A.

000.101.029

Version: C

10/46

Vibration Sets

1 to 26

ID 26

Platform Vibration

Pag

e 1

B

C

D

E

F

Forward

Forward left

Forward right

Left

Right

Backward

A

G Backward left

H Backward right

I Flip

Pag

e 1

K

L

M

N

O

Custom

Custom

Custom

Custom

Custom

Custom

J

P Custom

Q Custom

R Custom

S

T

U

V

Custom

Custom

Custom

Custom

W Custom

X Custom

Y Custom

Z Custom

Custom

Hopper Vibration

Pag

e 1

B

C

D

E

F

Forward

Custom

Custom

Custom

Custom

Custom

A

G Custom

H Custom

I Custom

Pag

e 1

K

L

M

N

O

Custom

Custom

Custom

Custom

Custom

Custom

J

P Custom

Q Custom

R Custom

S

T

U

V

Custom

Custom

Custom

Custom

W Custom

X Custom

Y Custom

Z Custom

Custom

ID 1

Platform Vibration

Pag

e 1

B

C

D

E

F

Forward

Forward left

Forward right

Left

Right

Backward

A

G Backward left

H Backward right

I Flip

Pag

e 1

K

L

M

N

O

Custom

Custom

Custom

Custom

Custom

Custom

J

P Custom

Q Custom

R Custom

S

T

U

V

Custom

Custom

Custom

Custom

W Custom

X Custom

Y Custom

Z Custom

Custom

Hopper Vibration

Pag

e 1

B

C

D

E

F

Forward

Custom

Custom

Custom

Custom

Custom

A

G Custom

H Custom

I Custom

Pag

e 1

K

L

M

N

O

Custom

Custom

Custom

Custom

Custom

Custom

J

P Custom

Q Custom

R Custom

S

T

U

V

Custom

Custom

Custom

Custom

W Custom

X Custom

Y Custom

Z Custom

Custom

Standard

Vibrations

Standard

Vibration

Figure 2-1: Description of vibration sets for Asycube 50 & 80

Sequences

ID 1

Page 1

Action 2

Action 3

Action 4

Action 5

Action 6

Action 1

Action 7

ID 2

Page 1

Action 2

Action 3

Action 4

Action 5

Action 6

Action 1

Action 7

ID 26

Page 1

Action 2

Action 3

Action 4

Action 5

Action 6

Action 1

Action 7

1 to 26

Figure 2-2: Description of sequences

Asycube

User Guide

© Copyright Asyril S.A.

000.101.029

Version: C

11/46

3. Asyril HMI installation

NOTE:

If a computer is included in your product, the "HMI" software is already installed.

This chapter explains how to install the HMI on your own computer if needed.

3.1. Prerequisite

To install and execute the HMI, you need the following elements:

• Computer with Windows 7, 8 or 10 (64-bit)

• .Net 4.0 minimum installed.

• User access defined in order to be able to install and execute software.

NOTE:

Check that your version of the ".net framework" is up to date. You can download this version

from the Microsoft website: http://www.microsoft.com/download/

3.2. Installing the HMI software on a specific computer

3.2.1. Pre-installation

Step 1

Insert the USB key into the computer on which the HMI should be installed

Step 2

Double-click on the SurfaceToolkitRuntime.msi executable file to launch the installation

procedure

Step 3

Accept the licence agreement and follow the instructions provided by the wizard

Step 4

When installation is complete, click on "Finish" to close the wizard

3.2.2. Installation

Step 1

Insert the USB key into the computer on which the HMI should be installed

Step 2

Double-click on the setup.exe executable file to launch the installation procedure

Step 3

Follow the instructions provided by the wizard

Step 4

When installation is complete, click on "close" to close the wizard

3.2.3. Starting the HMI

Step 1

Click on the shortcut created on the desktop

Step 2

Configure the HMI (see next section)

Asycube

User Guide

© Copyright Asyril S.A.

000.101.029

Version: C

12/46

3.2.4. Configuring the HMI

On the first start, the HMI contains no product. You have to add your product in the

configuration page to be able to work with it.

The following explanation shows you how:

Figure 3-1: HMI configuration page

Ref.

Designation

Description

(A)

Configuration"

button

Press this button to display the configuration screen.

(B)

"New product"

list

Select the product in this list that you wish to add (an Asycube in

this example).

(C)

“Asycube

parameters”

window

Fill in all the parameters for the chosen product.

(D)

"Save" button

Use this button to save the configuration changes. Then you

need to restart the HMI to apply your modifications.

Table 3-1: HMI configuration page description

For more detailed explanations, see HMI documentation.

3.2.5. Troubleshooting

Ref.

Problem

Solution

1

HMI crashes on starting

Try to start the HMI with administrator access (right-

click on shortcut, Properties/Compatibility, select “Run

this program as an administrator”).

2

The HMI starts but no buttons

are displayed

The SurfaceToolKit is missing or improperly installed.

Table 3-2: Troubleshooting list

(A)

(C)

(B)

(D)

Asycube

User Guide

© Copyright Asyril S.A.

000.101.029

Version: C

13/46

4. Hopper vibration/output activation

Depending on the Asycube, a hopper is either integrated (Asycube 50 and 80) or not

(Asycube 240, 380 and 530). Therefore, there are some little differences but the general

structure is similar. The following sections describe the organisation of the parameters as well

as the optimal configuration for standard hopper vibrations/output activations.

4.1. Asycubes 50 and 80

The Asycubes 50 and 80 have an integrated hopper to feed the necessary number of parts

onto the platform in order to obtain at each cycle an acceptable number of parts available for

picking by a robot. Table 4-1 below lists the parameters that are used to adjust the behaviour

of the hopper.

Parameter

name

Explanation

Effect

Unit

Range

Amplitude

Amplitude of the signal sent

to the actuator and defined

as the percentage of the

maximum amplitude

Increasing the amplitude

makes the parts jump more.

[%]

0 to 100%

Frequency

The frequency of the signal

sent to the actuator

Parts react more at a certain

frequency depending on

different factors

(mass/geometry/rigidity).

[Hz]

Typically 60-80

Hz

Waveform

Is defined as the shape of

the signal

A sinus waveform form

corresponds to smoother

part movement, whereas

with a ramp form the parts

move more hectically.

[-]

0=no signal

1=sinus

2=ramp up

3= ramp down

Duration

Amount of time the signal

(i.e. the vibration) lasts

Increasing the duration

makes the part travel a

longer distance on the

hopper (i.e. feeding more

parts). Choosing a value of

0 ms corresponds to

continuous vibration (until

the stop button is pushed).

[ms]

0 ms

1 to 30,000 ms

Table 4-1: Asycube 50 & 80 - Hopper parameters

For more information on the different commands, please refer to the programming guide for

your Asycube.

Asycube

User Guide

© Copyright Asyril S.A.

000.101.029

Version: C

14/46

4.2. Asycubes 240, 380 and 530

The Asycubes 240, 380 and 530 are equipped with two outputs, generally used to control

one or two hoppers to feed the necessary number of parts onto the platform in order to obtain

at each cycle an acceptable number of parts available for picking by a robot.

The configuration of the outputs obviously depends on what is actually connected to the

outputs. However, to simplify the feeding operation, 26 output activations are available in

order to customise the behaviour of a hopper or whatever is connected to the outputs. These

26 output activations (A – Z) are contained in one vibration set.

For more information on the electrical interface and connector reference, please refer to the

operating manual.

Each of the output activations contains five adjustable parameters listed in Table 4-2. These

parameters are used to choose which outputs are activated, to select the specific voltage of

each output as well as the duration of the execution of an output activation. Note that when

executing an output activation, the two outputs may be active and have a different output

value, but their duration is identical.

Parameter name

Effect

Unit

Range

Toggle output 1

Defines if the output 1 is active (1) or inactive (0)

during the execution of an output activation.

[ - ]

0 or 1

Analogue output 1

value

Gives the target value of analogue output 1 applied

during the execution of an output activation: 100%

corresponds to 10 V output.

[%]

0 to 100%

Toggle output 2

Defines if the output 2 is active (1) or inactive (0)

during the execution of an output activation.

[ - ]

0 or 1

Analogue output 2

value

Gives the target value of analogue output 2 applied

during the execution of an output activation: 100%

corresponds to 10 V output.

[%]

0 to 100%

Duration

Duration of the output activation. The two outputs may

be active and have a different output value, but the

activation duration is identical. If the value chosen is 0

ms, outputs will continue to be active until the stop

button is pressed.

[ms]

0 ms

1 to 30,000 ms

Table 4-2: Asycube 240 & 380 & 530 - Output activation parameters

NOTE:

The system has two standard vibrations: The first, ‘Output 1’ (A) activates by default the

output 1. The second, ‘Output 2’ (B) activates output 2.

Asycube

User Guide

© Copyright Asyril S.A.

000.101.029

Version: C

15/46

For more information on the different commands, please refer to the programming guide for

your Asycube.

Asycube

User Guide

© Copyright Asyril S.A.

000.101.029

Version: C

16/46

5. Platform vibration

Vibration behaviour is correct when:

• The parts slide on the surface and are able to cross the platform in all directions

• The parts jump only when the ‘Flip’ vibration type is activated

The movement of the parts on the platform depends on the combination of the different

actuator excitations of the Asycube. Each actuator can be adjusted individually using the four

parameters: Amplitude, frequency, phase and waveform (signal) in order to obtain the

desired part movement. In addition, it is necessary to set the vibration duration; This setting

applies to all the actuators. The result of these settings is called a platform vibration. See

Table 5-1 for the detailed explanation of parameters.

IMPORTANT NOTE:

It is IMPORTANT to set the vibration duration as the time the parts need to completely

cross the platform in a given direction. The effectiveness of the ‘Centring' smart vibration

and ‘Vibration ratio’ duration mode depends on well-adjusted parameters.

Parameter

Explanation

Effect

Unit

Range

Amplitude

Amplitude of the signal

sent to each actuator

and defined as the

percentage of the

maximum amplitude

Increasing the amplitude makes

the parts jump more.

[%]

0 to 100%

Frequency

The frequency of the

signal sent to the

actuators

Parts react more at a certain

frequency depending on different

factors (mass/geometry/rigidity).

Use the same frequency for all

actuators when tuning a platform

vibration.

[Hz]

Note: The

frequency range

depends on the

Asycube model

and the

configuration

(frame height,

etc.).

Phase

Phase shift with the

first actuator signal

(which corresponds to

the reference signal)

Actuator excitations combined

differently. Using a phase shift of

180° normally inverts the

movement of parts on the

platform.

[°]

0 to 359°

Waveform

Is defined as the

shape of the signal

A sinus waveform form

corresponds to smoother part

movement, whereas with a ramp

form the parts move more

[-]

0=no signal

1=sinus

2=ramp up

3=ramp down

Asycube

User Guide

© Copyright Asyril S.A.

000.101.029

Version: C

17/46

hectically (typically for the hopper)

Duration

Amount of time the

signal (i.e. the

vibration) lasts

Increasing the duration makes the

parts travel a longer distance on

the platform. Set the duration so

that the parts completely cross

the platform. Choosing a value of

0 ms corresponds to continuous

vibration (until the stop button is

pushed).

[ms]

0 ms

1 to 30,000 ms

Table 5-1: Platform vibration parameters

Asycubes 50 and 80 work with three actuators in contrast to Asycubes 240, 380 and 530

which have four. This causes slight differences in behaviour. The following sections present

more in detail the behaviour of your Asycube and give some general advice on how to tune

the parameters.

NOTE:

The vibration set 26 is defined as being the default vibration set (not modifiable by the user):

The parameters are pre-adjusted so that the standard parts of your Asycube work correctly.

It is strongly recommended to use the default vibration set as a starting point for setting your

parameters.

5.1. Asycubes 50 and 80

The Asycube 50 and 80 work with three actuators: Two in-plane actuators (Figure 5-1: Act.1

and Act.2) and a vertical one (Act.3). Below are some hints that are useful to adjust the

vibrations:

• Use a small vertical vibration (non-zero amplitude for Act.3) for smooth displacement

of parts on the platform. Use a stronger vertical vibration (larger amplitude for Act.3)

for the ‘Flip’ vibration.

• With the exception of the 'Flip' vibration, the frequency of all platform vibrations is

usually identical, meaning that once a suitable frequency is found for the displacement

of the parts on the platform, the same frequency can be used for other types of

displacement.

• The direction of the movement of the parts on the platform is a result of the

combination of the two in-plane actuator vibrations (Act. 1 and Act.2). Switching the

Asycube

User Guide

© Copyright Asyril S.A.

000.101.029

Version: C

18/46

phase from 0° to 180° inverts the direction of displacement (Figure 5-1). The

amplitude of the Act. 3. may be different from one direction of movement to the other.

Act. 1

Act. 3

Act. 2

Act. 2

Act. 1

Act. 3

Figure 5-1: Asycube 50 and 80 – Actuator disposition and example

(green arrow) (solid line: 0° phase, dashed line: 180° phase)

• If the parts do not move exactly towards the desired target, one can adjust the

amplitude of the two in-plane actuators (Act.1 and Act.2) in order to correct the

displacement direction of the parts.

NOTE:

The hints provided are general and may not be perfectly suited to your Asycube. We

recommend the use of vibration set 26 as a starting point, as it is configured and tested on

your product using a standard part.

Table 5-2 below illustrates the directions of standard platform vibrations.

Direction

Vibration

Forward

(A)

Forward left

(B)

Forward right

(C)

Left (D)

Right

(E)

Backward

(F)

Backward left

(G)

Backward right

(H)

A

…

H

Asycube

User Guide

© Copyright Asyril S.A.

000.101.029

Version: C

19/46

Flip

(I)

I

Table 5-2: Asycube 50 & 80 – Standard platform vibrations

Asycube

User Guide

© Copyright Asyril S.A.

000.101.029

Version: C

20/46

5.2. Asycubes 240, 380 and 530

The Asycubes 240, 380 and 530 are equipped with four actuators, one in each corner of the

platform. Below are some hints that are useful to adjust the vibrations:

• The direction of the movement of the parts on the platform is the result of the

combination of the excitation of actuators on the opposite side of the target end

position of parts.

Figure 5-2 : Activating both actuators Act.3 and Act.4 makes the parts move away

from them, resulting in this case in a forward vibration. When choosing an amplitude

that is larger for actuator Act.1 than for the two neighbouring actuators Act.2 and

Act.3, we obtain a diagonal movement of parts (backward left vibration).

• For all the platform vibrations except the ‘Flip’, ‘Short’- and ‘Long axis centring' the

frequency is usually the same. Once a suitable frequency is found for the

displacement of the parts on the platform, it generally suits the other displacements

too.

• If the parts do not move exactly towards the desired target, it is possible to adjust the

amplitude of neighbouring actuators in order to correct the displacement direction of

the parts.

Act. 1Act. 3

Act. 2

Act. 4

Act. 1Act. 3

Act. 2

Act. 4

Figure 5-2: Asycube 240, 380 and 530 – Actuator disposition and example

(green: Activated, grey: Deactivated)

NOTE:

The hints provided are general and may not be perfectly suited to your Asycube. We

recommend the use of vibration set 26 as a starting point, as it is configured and tested on

your product using a standard part.

Asycube

User Guide

© Copyright Asyril S.A.

000.101.029

Version: C

21/46

A simplified “Easy-Tuning” method is available through the Asyril HMI and is presented in

section 5.3 on page 21 of this document.

Table 5-3 below illustrates the directions of standard platform vibrations.

Direction

Vibration

Forward

(A)

Forward left

(B)

Forward right

(C)

Left (D)

Right

(E)

Backward

(F)

Backward left

(G)

Backward right

(H)

A

…

H

Flip

(I)

I

Centring on

the short axis

(J)

Centring on

the long axis

K

J

K

Table 5-3: Asycube 240 & 380 & 530 – standard platform vibrations

5.3. Asycube 240 & 380 & 530: Simplified adjustment method

"Easy-Tuning"

The system has a simplified adjustment method called “Easy-Tuning” applicable to all

parameters of Asycubes 240, 380 and 530. It is detailed in this section. This method involves

only the 11 standard vibrations (A – K).

Asycube

User Guide

© Copyright Asyril S.A.

000.101.029

Version: C

22/46

For each vibration, the number of adjustable parameters is reduced to the following five

parameters:

• 1 main amplitude (corresponds to the actuator(s) opposed to the target direction)

• 1 unique frequency (same for all actuators)

• 1 duration

• 2 balances to adjust the direction of displacement (fine adjustment of amplitude of all

actuators)

Figure 5-3: Asycube 240, 380 and 530 Easy-Tuning HMI

Balance “long side”

Balance “short side”

Main amplitude

Unique frequency

Duration

Theoretical movement

Programmed movement

Asycube

User Guide

© Copyright Asyril S.A.

000.101.029

Version: C

23/46

Figure 5-4: Example – Adjusting balance to correct a trajectory

NOTE:

Adjusting parameters in the Easy-Tune mode modifies the parameters in the ‘Platform’ and

‘Outputs’ tab. In certain cases, when the parameters are adjusted in the two latter tabs that

do not conform to the Easy-Tune mode (e.g. different frequencies for actuators), a warning

appears.

Asycube

User Guide

© Copyright Asyril S.A.

000.101.029

Version: C

24/46

6. Sequence

A sequence contains the different types of vibrations in order to feed, distribute, flip and orient

the components optimally on the picking surface. The sequence may vary depending on the

number of parts and their location on the platform in order to obtain optimal behaviour of

parts. This is the reason why the system may need data from the vision system such as the

number of parts on the platform (for feeding new parts onto the platform), their location (for

centring) and well-adjusted parameters of the vibration sets.

There are 26 sequences available and each of them is composed of up to seven actions. The

26 vibration sets are composed of the combination of the 26 platform vibrations and the 26

hopper vibrations/output activations. Any of the 26 sequences can be executed in

combination with any of the 26 vibration sets. This is useful in the case of different types of

parts (i.e. vibration sets) combined with various scenarios (i.e. sequences).

Please refer to the programming guide for more information on how to execute a sequence

using a certain vibration set.

Table 6-1 below gives the configuration options available to adjust a sequence. These

options are described in detail in the next section.

Action type

Vibration

Duration mode

Value

unit

Hopper/output

Hopper vibration/output

activation

(A – Z)

Fixed

Quantity adjusted

Vibration ratio

[ms]

[ms]

[%]

Platform

Platform vibration

(A – Z)

Fixed

Quantity adjusted

Vibration ratio

[ms]

[ms]

[%]

Smart vibration Centring

Maximum limit

[ms]

Wait

-

Fixed

[ms]

None

-

-

-

Table 6-1: Sequence options

Asycube

User Guide

© Copyright Asyril S.A.

000.101.029

Version: C

25/46

6.1. Actions

Four types of actions exist. The actions either concern the hopper/outputs, the platform or

none of the latter.

6.1.1. Hopper/output

Any of the 26 hopper vibrations/output activations (A – Z) of a vibration set can be selected in

order to feed parts onto the platform. By choosing between the three duration modes ‘Fixed’,

‘Quantity adjusted’ and ‘Vibration ratio’, the user can adjust the vibration duration of the

hopper in order to obtain different types of behaviour (see 6.2 Duration modes on page 26).

6.1.2. Platform

Any of the 26 platform vibrations (A – Z) of a vibration set can be selected in order to obtain

the desired part movement on the platform. By choosing between the three duration modes

‘Fixed’, ‘Quantity adjusted’ and ‘Vibration ratio’, the user can adjust the vibration duration of

the platform in order to obtain different types of behaviour (see 6.2 Duration modes on page

26).

Other than the platform vibrations, the user may select the smart vibration ‘Centring' which

centres parts no matter where they are located.

For a complete explanation of smart vibration ‘Centring' please refer to section 6.3.1 on page

27 of this document.

6.1.3. Wait

This action corresponds to a fixed waiting time given in ms. It is principally used between the

end of a vibration and before image acquisition in order to wait for the parts to stabilise on the

platform (i.e. to stop rolling/moving).

6.1.4. None

‘None’ corresponds to an empty action (non-programmed). This option is used for sequences

that do not require all of the seven available actions.

Asycube

User Guide

© Copyright Asyril S.A.

000.101.029

Version: C

26/46

6.2. Duration modes

When using an action related to a hopper vibration/output activation or a platform vibration,

the user may choose between three duration modes: 'Fixed', 'Quantity adjusted' or 'Vibration

ratio'. It can therefore adapt the behaviour of the system to the application.

6.2.1. ‘Fixed’

The duration mode ‘Fixed’ corresponds to the simplest configuration. The duration of the

vibration will always take the same amount of time, namely the value entered in the dialogue

box (in ms).

Figure 6-1: Duration mode ‘Fixed’ [ms]

6.2.2. ‘Quantity adjusted’

The duration mode ‘Quantity adjusted’ is mainly used to fulfil the function on feeding new

parts on the picking zone. In addition, it is considered a smart vibration, since its behaviour

adapts to the situation and hence depends on the data of a vision system.

Figure 6-2: ‘Quantity adjusted’ duration mode [ms]

For the additional explanation on the smart vibration ‘Quantity adjusted’, please refer to

section 6.3.1 on page 28 of this document.

Asycube

User Guide

© Copyright Asyril S.A.

000.101.029

Version: C

27/46

6.2.3. ‘Vibration ratio’

The ‘Vibration ratio’ duration mode links the vibration duration to use in the sequence with the

duration programmed in the vibration set. Entering the value 100% corresponds to the

vibration duration entered in the vibration set and therefore, if correctly adjusted, to the time

needed for the parts to fully cross the platform. Choosing 50% represents a partdisplacement of half the platform length. This considerably simplifies calculations for the user.

The other advantage is that when the user changes a vibration set, there is no need to

readjust the vibration durations in the sequence.

Figure 6-3: Duration mode ‘Vibration ratio’ [%]

IMPORTANT NOTE:

It is IMPORTANT to set the vibration duration as the time the parts need to completely

cross the platform in a given direction. The effectiveness of the ‘Centring' smart vibration

and ‘Vibration ratio’ duration mode depend on well-adjusted parameters.

6.3. Smart vibrations

A smart vibration adapts the vibration parameters depending on the situation. To do so it

needs the data from a vision system. The following sections provide a detailed explanation of

the two smart vibrations available: ‘Centring and ‘Quantity adjusted’.

6.3.1. ‘Centring’

In a sequence, the user may choose the action type on the platform in combination with a

Platform vibration (A – Z) or with the 'Centring' smart vibration. The latter determines the

optimal vibration direction and computes the vibration duration based on the data from a

vision system. The location of parts on the platform (centre of mass) is used to define the

direction and the distance to the centre. Once these two characteristics are determined, the

‘Centring’ vibration chooses:

• The adapted standard platform vibration

• The adapted vibration duration based on the given durations indicated in the vibration

set (i.e. the duration adjusted such that parts cross the entire platform)

Asycube

User Guide

© Copyright Asyril S.A.

000.101.029

Version: C

28/46

The duration mode of ‘Centring’ is called ‘Maximum limit’ and corresponds to the upper limit

of the vibration duration in this mode. Hence, the user limits the computed vibration duration

by entering a value in ms in the box. This is useful if your application engages a time

constraint that must be respected. If there is no special constraint, keep the default value of

10 seconds.

IMPORTANT NOTE:

It is IMPORTANT to set the vibration duration as the time the parts need to completely

cross the platform in a given direction. The effectiveness of the ‘Centring' smart vibration

and ‘Vibration ratio’ duration mode depends on well-adjusted parameters.

6.3.2. ‘Quantity adjusted’

The ‘quantity adjusted’ duration mode can be combined with hopper vibrations/output

activations or platform vibrations. This mode is mainly used for feeding new parts on the

picking zone. As is the case for the other smart vibration, the ‘quantity adjusted’ duration

mode is based on the data from a vision system (number of parts detected on the picking

zone).

The value entered in the dialogue box (in ms) corresponds to the vibration duration when

there are no parts on the platform. The more parts are detected, the less time the vibration

takes and when the upper limit of parts on the platform is reached, the vibration duration

decreases to zero. In between, the vibration duration is linearly interpolated. Note that the

user has to indicate the upper limit of parts in the dialogue box that appears when using

‘quantity adjusted’. This dialogue box is located after the seventh action.

Example:

Let's suppose that the upper limit of parts on the platform for the vibration is defined at 40

and the vibration duration entered in the box is 1000 ms. In the first case, no part is present

on the platform, the effective vibration duration is 1000 ms. In a second case where 20 parts

are detected on the platform, the effective vibration duration will be 500 ms. In the case

where 30 parts are detected on the platform, the effective vibration duration will be 250 ms.

When 40 or more parts are detected, there will be no further vibration.

Asycube

User Guide

© Copyright Asyril S.A.

000.101.029

Version: C

29/46

Figure 6-4: ‘Quantity adjusted’ duration mode [ms]

6.4. HMI simulation: Test sequence

In the Asyril HMI, it is possible to test a sequence, even without vision system data (number

of parts on the platform and their location). The three general situations are presented in this

section, the fourth is a mix between the first three.

6.4.1. Case 1: No smart vibration

No action of the sequence uses a smart vibration (i.e. no vision system). To execute the

simulation, simply press the large button representing the vibrating platform. Note that the

currently active vibration set is indicated in the upper left corner of the display. To select the

desired vibration set, simply change its ID in the ‘Platform’ or ‘Hopper’/‘Outputs’ tab.

Figure 6-5: HMI simulation case 1 – No smart vibration

Asycube

User Guide

© Copyright Asyril S.A.

000.101.029

Version: C

30/46

6.4.2. Case 2: ‘Quantity adjusted’

The duration mode ‘quantity adjusted’ adapts the vibration duration depending on the number

of parts detected on the picking zone. Besides indicating the vibration duration when no parts

are detected as well as the upper limit of parts when no new parts are to be fed, the user also

has to simulate a vision system by manually entering the number of parts located in the

picking zone in the simulation panel. Pushing the large button representing the platform

executes the test sequence.

Figure 6-6: HMI simulation case 2 – ‘Quantity adjusted’

6.4.3. Case 3: ‘Centring’

The ‘Centring' smart vibration needs the data from a vision system to centre the parts on the

platform. For the simulation, the user indicates the approximate location of the parts using

one of the nine buttons each representing a zone on the platform. Pushing one of the nine

buttons starts the test sequence.

Asycube

User Guide

© Copyright Asyril S.A.

000.101.029

Version: C

31/46

Figure 6-7: HMI simulation case 3 – ‘Centring'

6.4.4. Case 4: Mixed smart vibrations

Most situations require the combination of both smart vibrations: a feeding vibration

(hopper vibration/output activation) in ‘Quantity adjusted’ duration mode combined

with ‘Centring'. In this mixed case, the simulation interface is the combination of the

ones presented previously (Figure 6-6 and Figure 6-7).

Asycube

User Guide

© Copyright Asyril S.A.

000.101.029

Version: C

32/46

7. Saving

Only one of the 26 vibration sets can be active at a time. Before switching the vibration set ID

in the ‘Platform’ tab or the ‘Hopper’/‘Outputs’ tab, the user has to save the modifications

made in the “flash memory”, i.e. in the Asycube memory, or discard them (see Figure 7-1).

Also, note that flashing the parameters from the ‘Platform’ tab automatically flashes all the

parameters of the selected vibration set (i.e. including the parameters in the

‘Hopper’/‘Outputs’ tab) and likewise when flashing from the ‘Hopper’/‘Outputs’ tab.

Figure 7-1: Vibration set ID

Switching between sequences does not require flashing the parameters beforehand, you may

freely jump from a sequence to another and modify parameters. Also, note that a copy/paste

function is available not only to copy a whole sequence but also in the context of vibration

tuning.

Figure 7-2: Sequence ID and copy/paste function

Flashing the parameters, whether parameters of the vibration sets or the sequences, saves

them in the Asycube which means that they do not need loading from an external file.

Nevertheless, you can import/export .xml files via the HMI (see Table 7-1).

Figure 7-3: Import/export an .xml file

Asycube

User Guide

© Copyright Asyril S.A.

000.101.029

Version: C

33/46

Label

Content

Saving

.Fconf

Vibration set parameters such

as amplitude, frequency,

duration etc.

Only one vibration set can be saved in a .Fconf file at a

time.

.fseq

Sequence parameters such

as actions, vibrations,

duration values etc.

A sequence can either be saved individually, or all 26

sequences can be saved at once. Note that when

saving all the sequences, the sequence ID is saved.

Table 7-1: File formats

For more information on loading, saving and related commands please refer to the

programming guide for your Asycube.

Asycube

User Guide

© Copyright Asyril S.A.

000.101.029

Version: C

34/46

8. Backlight

The use of suitable lighting is an important factor for parts to be detected on the platform and

their orientation. All the Asycubes can be equipped with an integrated backlight. This chapter

summarises the different possibilities to activate the backlight as well as how to configure its

intensity.

8.1. Activation

There are two ways to activate the backlight illumination and to synchronise it with the image

acquisition (see Table 8-1).

Description

Method 1

Software commands:

a.) Command to switch ON and then command to

switch OFF

b.) Flashing-mode

Method 2

(recommended)

Hardware connection:

Using the backlight synchronisation input. The illumination time

corresponds to the impulse length.

Table 8-1: Backlight activation modes

When using both activation methods, the backlight will be ON if the command OR the signal

is activated.

Note that using a camera that is able to control the backlight of the Asycube (Method 2 –

Hardware connection) is more reliable in terms of timing than using software commands to

activate the Asycube backlight and then commands to a camera for image acquisition.

For more information on the commands related to the activation of the backlight, please refer

to the programming guide for your Asycube.

For more information on the electrical interface and connector reference of the backlight

synchronisation, please refer to the operating manual for your Asycube.

NOTE:

The backlight is optional and has to be ordered with your Asycube, as well as its colour.

Asycube

User Guide

© Copyright Asyril S.A.

000.101.029

Version: C

35/46

8.2. Intensity

The lighting intensity can be adjusted from a minimum given value to 100% using the slider in

the backlight tab of the HMI. The minimum intensity value can change from one Asycube

model to another. There is no need to flash this parameter manually as it is automatically

saved when modified. Also, note that this illumination level applies to both methods of

backlight activation described in Table 8-1.

Asycube

User Guide

© Copyright Asyril S.A.

000.101.029

Version: C

36/46

9. Example

This chapter presents a step-by-step example on how to work with the Asycube and

describes the concepts presented in the previous chapters. The order of the sections

respects the order of the general procedure presented in section 2.2 General procedure

overview on page 7 of this document.

9.1. Install and configure the Asyril HMI

Please refer to chapter 3 on page 11 of this document for the detailed and illustrated

procedure for installing the software.

9.2. Adjust platform and hopper vibrations

For each new part, follow the steps presented below. Note that usually, there is no need to

re-configure a completely new vibration set for each new part as it is possible to reuse

existing vibration sets. Therefore, a vibration set is usually connected to a family of parts

rather than a single version of a part. Also, vibration set 26 is a non-modifiable set of default

vibration parameters specifically set by Asyril for a standard part to work optimally on your

Asycube.

Please refer to chapter 4 on page 13 and chapter 5 on page 16 of this document for the

detailed explanation of the adjustable parameters and general adjustment advice.

9.2.1. Platform vibration

Step 1

Place a few parts on the Asycube platform, ideally the number of parts that seem to be

adequate (enough to be representative, not too many such as to minimise overlapping

parts).

Step 2

Test the behaviour of your parts on the Asycube either using vibration set number 26,

which contains the default parameters for a standard part (not modifiable by the user) or

by using one of your own parametrised vibration set.

If no adjusting is needed, you may skip steps 3 and 4.

Asycube

User Guide

© Copyright Asyril S.A.

000.101.029

Version: C

37/46

Step 3

There are different ways to start adjusting the parameters:

• Import an already configured vibration set (strongly encouraged)

Export a vibration set (for example vibration set 26) as an .Fconf file then import it

in the vibration set you assigned to your part type.

• Copy/paste a platform vibration

Method mainly used during the fine-tuning of the parameters of a vibration set.

Copy/paste option for one vibration at a time.

• Start tuning from zero (not recommended)

Some indications are given for the frequency range (references below).

Step 4

Adjust the parameters in order to obtain rapid and smooth part movement on the platform

and parts that jump only during the ‘Flip’ vibration. For coarse-tuning, you may take

advantage of continuous mode, which enables you to change parameters such as

frequency, amplitude etc. while the platform vibrates continuously. For fine-tuning, better

results are obtained when the vibration duration corresponds approximately to the real

situation.

• Part displacement vibrations (A – H):

Use the sinus signal.

1. Find an adequate frequency. Once the optimal frequency is found, you

may reuse the same frequency for adjusting the other platform vibrations.

2. Adjust the amplitude of the different actuators.

3. Adjust the vibration duration so that the parts completely cross the

platform in a given direction.

• ‘Flip’ vibration (I):

Use the sinus signal.

1. Find an adequate frequency.

(Asycube 50 & 80: See Table 5-2, Asycube 240, 380 and 530: See Table

5-3)

2. Adjust the amplitude.

3. Adjust the vibration duration; short, but enough time in order for the parts

to flip.

• Asycube 240, 380 and 530: ‘Long’- and ‘Short axis centring (J and K):

Use the sinus signal.

1. Find an adequate frequency.

(Asycube 240, 380 and 530: see Table 5-3)

2. Adjust the amplitude.

3. Adjust the duration.

Note that the procedure is identical when using the Easy-Tuning method, the adjusting

Asycube

User Guide

© Copyright Asyril S.A.

000.101.029

Version: C

38/46

interface is simplified as some parameters are regrouped.

Step 5

Troubleshooting:

• Trajectory deviation:

If parts do not move precisely enough towards the desired target, you may want to

correct the trajectory with help of the other actuators. (Asycube 50 & 80: See

section 5.1, Asycube 240, 380 and 530: See section 5.2 or use the balance slider

in the Easy-Tune mode).

• Invisible wall or obstacles:

For certain parameters, parts seem to encounter an invisible wall/obstacle or their

movement differs depending on their position on the platform. Test different

phases, this might help achieve a more steady movement.

Step 6

Make sure that the vibration duration for the standard platform vibrations corresponds to

the time the parts need to fully cross the platform. It is important to respect this; the

effectiveness of the Asycube depends on well-tuned parameters.

9.2.2. Hopper vibration/output activation

Step 1

Place parts in the hopper (homogeneous filling). When tuning parameters it is important

that the conditions are as close as possible to the production situation. Depending if your

parts are sticky or present the tendency to bundle, using a dam might be helpful.

Step 2

Perform the adjustments depending on your needs: You can either use a slower part

displacement in the hopper in order to obtain a better repeatability on the number of parts

fed (for the same vibration duration) or you can use a faster one, if you need a shorter

cycle.

• Asycube 50 & 80 (integrated hopper):

Adjust the frequency and amplitude.

• Asycube 240, 380 and 530:

Use the outputs to drive a hopper. You can select the output(s) that are active and

adjust signal amplitude from 0 to 100% (corresponding to 10 V) as well as the

duration of the signal. Please refer to the documentation for your specific hopper.

Asycube

User Guide

© Copyright Asyril S.A.

000.101.029

Version: C

39/46

9.3. Adjusting sequences

A sequence is used to combine different vibrations and usually corresponds to a scenario.

You can use different vibrations sets (i.e. types of parts) in combination with one or more

sequences. Three scenarios are discussed in this section:

1. Scenario - Flat platform: Feed and distribute parts

2. Scenario - Structured platform: Feed and pre-orient parts

3. Scenario - Flat platform: Distribute parts (Asycube 240, 380 and 530)

These scenarios are examples, you may be confronted with other scenarios and other

parameters may work better for your specific application. The goal here is to give you a

general idea on what you can do with sequences.

Please refer to chapter 6 for the explanation on sequences and more specifically the test

procedure for a sequence in section 6.4 page 29 of this document.

9.3.1. Flat platform: Feed and distribute parts

In the case of a flat platform, usually the ‘Centring' smart vibration followed by a ‘Flip’ is used

in order to distribute parts evenly on the platform.

Type

Vibration

duration mode

value

unit

1

Hopper/outp

ut

Forward

‘Quantity adjusted’

500

[ms]

2

Platform

Centring

Maximum limit

10,000

[ms]

3

Platform

Flip

Fixed

200

[ms]

4

Wait

-

Fixed

300

[ms]

Table 9-1: Example of scenario 1

Asycube

User Guide

© Copyright Asyril S.A.

000.101.029

Version: C

40/46

9.3.2. Structured platform: Feed and pre-orient parts

In the case of a structured platform, the goal is to sufficiently pre-orientate parts in grooves,

holes etc. such that the desired cycle time is obtained. In this case, the ‘Flip’ vibration is used

before smoother platform vibrations such as ‘Forward’ that enables the parts to be swept over

the structured platform. These sweeping vibrations may be very short or not even necessary

in some cases.

Type

Vibration

Duration mode

value

unit

1

Hopper/outp

ut

Forward

‘Quantity adjusted’

500

[ms]

2

Platform

Flip

Fixed

200

[ms]

3

Platform

Forward

Vibration ratio

100

[%]

4

Platform

Backward

Vibration ratio

50

[%]

5

Wait

-

Fixed

300

[ms]

Table 9-2: Example of scenario 2

Please refer to the operating manual for more information on structured platforms.

9.3.3. Flat platform: Distribute parts (Asycube 240, 380 and 530)

This example shows how to use a very simple sequence to centre the parts and distribute

them across the platform, available for Asycubes 240, 380 and 530 due to their two additional

standard platform vibrations: ‘Short axis centring' (J) and ‘Long axis centring' (K), which

enable the parts to be centred on the platform regardless of their position.

Type

Vibration

duration mode

value

unit

1

Platform

Long axis centring

Vibration ratio

100

[%]

2

Platform

Short axis centring

Vibration ratio

100

[%]

3

Platform

Flip

Fixed

3000

[ms]

4

Wait

-

Fixed

300

[ms]

Table 9-33: Example of scenario 3

Asycube

User Guide

© Copyright Asyril S.A.

000.101.029

Version: C

41/46

9.4. Save all the parameters in the Asycube

If not already done, save the parameters in the flash memory in the Asycube. If needed, it is

possible to export a vibration set or sequences as .xml files.

Please refer to chapter 7 on page 32 of this document for a detailed explanation on saving

procedures.

9.5. Configure the backlight

Please refer to chapter 8 on page 34 of this document for details on how to activate the

backlight and how to adjust its intensity.

NOTE:

For preliminary tests, it is sufficient to use the backlight activation button in the home tab of

the HMI or software commands (see next section).

9.6. Execute commands from PLC

A console mode is available in the Asyril HMI in order to test the communication with the

Asycube as well as the execution of commands as if they were sent from the client’s PLC

(Programmable Logic Controller).

NOTE:

The console mode can only be accessed with Integrator level access rights. Please refer to

the HMI user guide for more information on access rights.

Please refer to the programming guide for your Asycube for the full list of commands as well

as their detailed explanation.

Step 1

Use a vibration set

Command {UV1} Response {UV1}

Select vibration set 1.

Asycube

User Guide

© Copyright Asyril S.A.

000.101.029

Version: C

42/46

Step 2

Execute a sequence

Command {ES:(23;40;-1;1;5)} Response {ES:(23;40;-1;1;5; 1560)}

23 parts were detected on the picking zone, at 40 parts there is no feeding of new parts.

The location of the centre of mass of parts is located in the back left corner (x = -1, y = 1,

see Figure 9-1). The sequence to use is sequence 5. As a response, the system returns

the exact duration of the sequence (here 1560 ms).

Step 3

Backlight

Command {K1} Response {K1}

{K0} {K0}

Switching backlight ON (first command), then OFF.

The positions on the platform are normalised and defined as shown in Figure 9-1 below.

-1 / 1

1 / -1

-1 / -1

Plateforme

Trémie

Y

Figure 9-1: Normalized coordinate system on a platform

9.7. Control the Asycube from your PLC through Modbus

TCP

As an alternative to sending commands through TCP/IP, your PLC can control the Asycube

through Modbus TCP.

Asycube

User Guide

© Copyright Asyril S.A.

000.101.029

Version: C

43/46

NOTE:

The Modbus TCP communication interface is only available for Asycubes with a firmware

version greater than or equal to V4.0.0.

Please, refer to the programming guide for your Asycube for more information on Modbus

TCP and for the list of all Holding Registers in the Asycube register table.

Step 1

Use a vibration set

Change the value of the Holding Register HR_SELECT_VIBRATION_SET

Select vibration set 1: Set the value at 1.

Check which is the current vibration set

Read the value of the Holding Register HR_VIBRATION_SET_SELECTED

Step 2

Execute a sequence

1. Prepare the vibration parameters in HR_SEQUENCE_EXECUTION_NBPARTS,

HR_SEQUENCE_EXECUTION_NBMAX, HR_SEQUENCE_EXECUTION_X,

HR_SEQUENCE_EXECUTION_Y and

HR_SEQUENCE_EXECUTION_SEQUENCEID.

Example: 23, 40, -100, 100, 5.

2. Start the sequence by changing the value of the trigger

HR_SEQUENCE_EXECUTION_TRIG from 0 to 1.

23 parts were detected on the picking zone, at 40 parts there is no feeding of new parts.

The location of the centre of mass of parts is located in the back left corner (x = -1, y = 1,

see Figure 9-1). The sequence to use is sequence 5.

Monitor the execution sequence

Read the value of HR_MODBUS_SEQUENCE_STATUS and

HR_SEQUENCE_REMAINING_TIME.

Example: The HR_SEQUENCE_REMAINING_TIME register’s value will decrease from

the total duration (here 1560 ms) to 0. The HR_MODBUS_SEQUENCE_STATUS value

will change from 1 (BUSY) to 0 (DONE) as soon as the sequence is complete.

Step 3

Backlight

Switch ON: Change the value of HR_BACKLIGHT_STATE_CONTROL from 0 to 1

Switch OFF: Change the value of HR_BACKLIGHT_STATE_CONTROL from 1 to 0

Asycube

User Guide

© Copyright Asyril S.A.

000.101.029

Version: C

44/46

10. Technical support

10.1. For better service …

Have you read the relevant manuals and not found the answers to your questions? Before

calling the support service, note the following information for your system:

• Serial number and product key for your equipment

• Software version

• Alarm or error message displayed on the screen

10.2. Contact

A wealth of information is available on our website: www.asyril.com

You can also contact us by mail or call our support service:

support@asyril.com

+41 26 653 71 90

Asycube

User Guide

© Copyright Asyril S.A.

000.101.029

Version: C

45/46

Review history

Rev.

Date

Author

Comments

A

27.10.2016

PeA

Original version

A1

14.12.2016

HsJ

Modify figures and images for translation

B

17.08.2017

PeD

Addition of Asycube 530 and references to Modbus TCP

C

23.07.2019

PeD

Addition of Asycube 380 and various improvements

The following document is the property of Asyril S.A. and may not be copied or circulated

without permission. The information contained in this document is subject to change without

notice for the purpose of product improvement.

Asyril SA

Z.I. du Vivier 22

1690 Villaz-St-Pierre

Switzerland

Tel. +41 26 653 71 90

Fax +41 26 653 71 91

info@asyril.com

www.asyril.com

Loading...

Loading...