Page 1

(800-401-1441

LS10 and LS20 Series

Hot Melt Units

Manual Number: 19600-121

Revision: E

(800-401-1441

Page 2

(800-401-1441

Page 3

LS10 and LS20 Series

Hot Melt Units

Manual Number: 19600-121

Revision: D

Date: 02/17/10

Copyright 2010 Astro Packaging

(800-401-1441

Page 4

(800-401-1441

Copyright 2010 Astro Packaging

Page 5

Table of Contents

1 Safety Precautions for Hot Melt Applicator Equipment ....................................................................... 1

1.1 Intended Use.................................................................................................................................... 1

1.2 Personal Safety................................................................................................................................ 1

1.3 Electrical Safety .............................................................................................................................. 2

1.4 Emergency Power Disconnect........................................................................................................ 2

1.5 Follow Directions ............................................................................................................................ 2

1.6 Safety Symbols and Signal Words................................................................................................. 2

2 Introduction............................................................................................................................................. 4

2.1 Description....................................................................................................................................... 4

2.2 Features............................................................................................................................................ 5

3 Specifications .......................................................................................................................................... 6

3.1 Electrical .......................................................................................................................................... 6

3.2 Physical ............................................................................................................................................ 6

3.3 Operating......................................................................................................................................... 6

3.4 Environmental................................................................................................................................. 6

3.5 Motor Speed, Adhesive Pressure, and Flow Rate ........................................................................ 7

3.6 Dimensions....................................................................................................................................... 7

4 Installation .............................................................................................................................................. 8

4.1 Setup................................................................................................................................................. 8

4.2 Component Installation.................................................................................................................. 9

4.2.1 Manual (Handgun) Systems....................................................................................................... 9

4.2.2 Automatic Systems .................................................................................................................... 9

4.3 Electrical Circuits and Wiring..................................................................................................... 10

4.3.1 Electrical Schematic................................................................................................................. 10

4.3.2 Power Requirements ................................................................................................................ 10

4.3.3 Electrical Connections ............................................................................................................. 10

4.3.4 Power-in Wiring....................................................................................................................... 11

4.3.5 Valve Group Control Circuits for Automatic Systems ............................................................ 11

4.3.6 VAC Valve Firing Voltage ...................................................................................................... 12

4.3.7 VDC Valve Firing Voltage ...................................................................................................... 12

4.3.8 Foot Switch Trigger for Semi-automatic Systems................................................................... 12

4.3.9 External Control of Pump Motor for Automatic Systems ....................................................... 13

5 Operation............................................................................................................................................... 14

5.1 Controls and Indicators................................................................................................................ 14

[1] System Power Switch/Circuit-Breaker and Indicator Light........................................................ 14

[2] Overtemperature Indicator Light................................................................................................. 14

[3] Tank Thermometer...................................................................................................................... 14

© Copyright 2010 Astro Packaging LS10 and LS20 19600-121 i

Page 6

[4] Tank Heating Indicator Light...................................................................................................... 14

[5] Pump Motor ON/OFF Breaker Switch........................................................................................ 14

[6] Pump Warm-Up Thermostat (Not Shown) ................................................................................. 14

5.2 Start-up .......................................................................................................................................... 16

5.3 Adjustments................................................................................................................................... 17

5.3.1 Temperature Adjustments........................................................................................................ 17

5.3.2 Flow Adjustments .................................................................................................................... 18

6 Maintenance.......................................................................................................................................... 19

6.1 Preventive Maintenance ............................................................................................................... 20

7 Troubleshooting .................................................................................................................................... 21

8 Repair and Replacement....................................................................................................................... 23

8.1 Hose Replacement......................................................................................................................... 23

8.2 Hose Controller Replacement...................................................................................................... 25

8.3 Tank Heater Replacement ........................................................................................................... 26

8.4 Tank Controller Replacement ..................................................................................................... 27

8.5 Hose Manifold Filter Block Replacement or Cleaning.............................................................. 28

8.6 Pump Filter Installation, Servicing, and Replacement.............................................................. 29

8.7 Pump Motor and Pump Shaft Assembly Replacement ............................................................. 30

9 Parts List................................................................................................................................................ 32

9.1 Control Panel - Front View.......................................................................................................... 32

9.2 Electrical Enclosure and Chassis Base........................................................................................ 33

9.3 Motor Group and Pump Shaft Assembly ................................................................................... 34

9.4 Pump Warm-up and Tank Overtemperature Thermostats ..................................................... 35

9.5 V1 Pump, Flow Control Valve, and Hose Manifold Filter........................................................ 36

9.6 Accessories ..................................................................................................................................... 38

Appendix A: Component Resistance Tables ........................................................................................... 39

Table 1. Tank Heater Resistance....................................................................................................... 39

Table 2. Motor Resistance.................................................................................................................. 39

Table 3. RTD Sensor Resistance........................................................................................................ 40

Table 4. Potentiometer/Variable Resistor......................................................................................... 40

Table 5. Valve Coil Resistance........................................................................................................... 40

Table 6. Heater Resistance for Common Applicators ..................................................................... 41

Table 7. Heater Resistance for Common Hoses (in Ohms)............................................................. 42

ii LS10 and LS20 19600-121 Copyright 2010 Astro Packaging

Page 7

1 Safety Precautions for Hot Melt Applicator Equipment

This manual contains important safety information and

instructions. Failure to comply with these instructions can result in

death, injury or permanent damage to this equipment and will void

the warranty.

1.1 Intended Use

This equipment is designed for use with standard adhesive and

sealant materials with flash points above 232 °C (450 °F). Use of

flammable material or material not compatible with the

specifications of this equipment can cause injury to operator and

damage to equipment.

The manufacturer has designed this equipment for safe operation.

Specified models are in compliance with EN 60204-1:1997.

However, heated thermoplastics and other hot melt materials are

dangerous and care must be exercised to ensure operational safety.

Handling must be in accordance with hot melt manufacturer

specifications. Never exceed the maximum application temperature

recommended by the adhesive manufacturer.

Dispose of hot melt properly. Refer to the Materials Safety Data

Sheet (MSDS) of the hot melt for recommended disposal methods.

1.2 Personal Safety

Wear Safety Goggles

Wear Heat-Resistant

Safety Gloves

Wear Protective Clothing

Wear the following protection when working on or around this

equipment:

Always wear heat resistant gloves rated to 205 °C (400 °F) and

allow all system temperatures to stabilize below 193 °C (380 °F)

before servicing. Properly ventilate equipment according to MSDS

of equipment.

Trained operators and service technicians should be aware of

exposed surfaces of the unit that cannot be practically safeguarded.

These exposed surfaces may be hot and take time to cool after the

unit has been operating.

Keep parts of the body away from rotating parts. Do not wear

loose articles of clothing when operating or servicing units with

rotating parts. Remove wristwatches, rings, necklaces, or other

jewelry and cover or pin up long hair before performing any work

on or with the unit.

Trained operators may perform only external equipment

adjustments. Trained service technicians must perform internal

adjustments and service.

© Copyright 2010 Astro Packaging LS10 and LS20 19600-121 1

Page 8

1.3 Electrical Safety

Determine voltage of this equipment before installation and

confirm compatibility with available power. Equipment must be

connected to a properly grounded circuit and installed in

accordance with all applicable electrical codes. Ground fault

protection must be provided in supply circuitry at site installation.

Models designed to EN60204-1: 1997 require power cords be

approved to a harmonized (HAR) standard and rated for 70 °C

(158 °F). A HAR approved Type B plug and strain relief for power

cord is required to meet standard IEC 309. Power conducting wires

must be nominal 5.3 mm2 (10 AWG) maximum and nominal

2.1 mm2 (14 AWG) minimum.

1.4 Emergency Power Disconnect

In the event of a malfunction, turn off power to the equipment at

the power off switch and remove source power to the system at the

nearest main disconnect.

1.5 Follow Directions

Read the product manual thoroughly before installation, operation

or maintenance. Failure to do so can result in a serious accident or

equipment malfunction. The manufacturer will not be held

liable for injuries or damage caused by misuse of this

equipment.

1.6 Safety Symbols and Signal Words

The following safety symbols and signal words are used

throughout the manual and on the product to alert the reader and

operator to personal safety hazards or to identify conditions that

may result in equipment or property damage.

!

!

!

DANGER: Indicates a hazard, which, if not

avoided, will result in serious injury, including

death, or equipment and property damage.

WARNING: Indicates a hazard, which, if not

avoided, can result in serious injury, or equipment

and property damage.

CAUTION: Indicates a hazard, which, if not

avoided, can result in minor injury, or equipment

and property damage.

2 LS10 and LS20 19600-121 Copyright 2010 Astro Packaging

Page 9

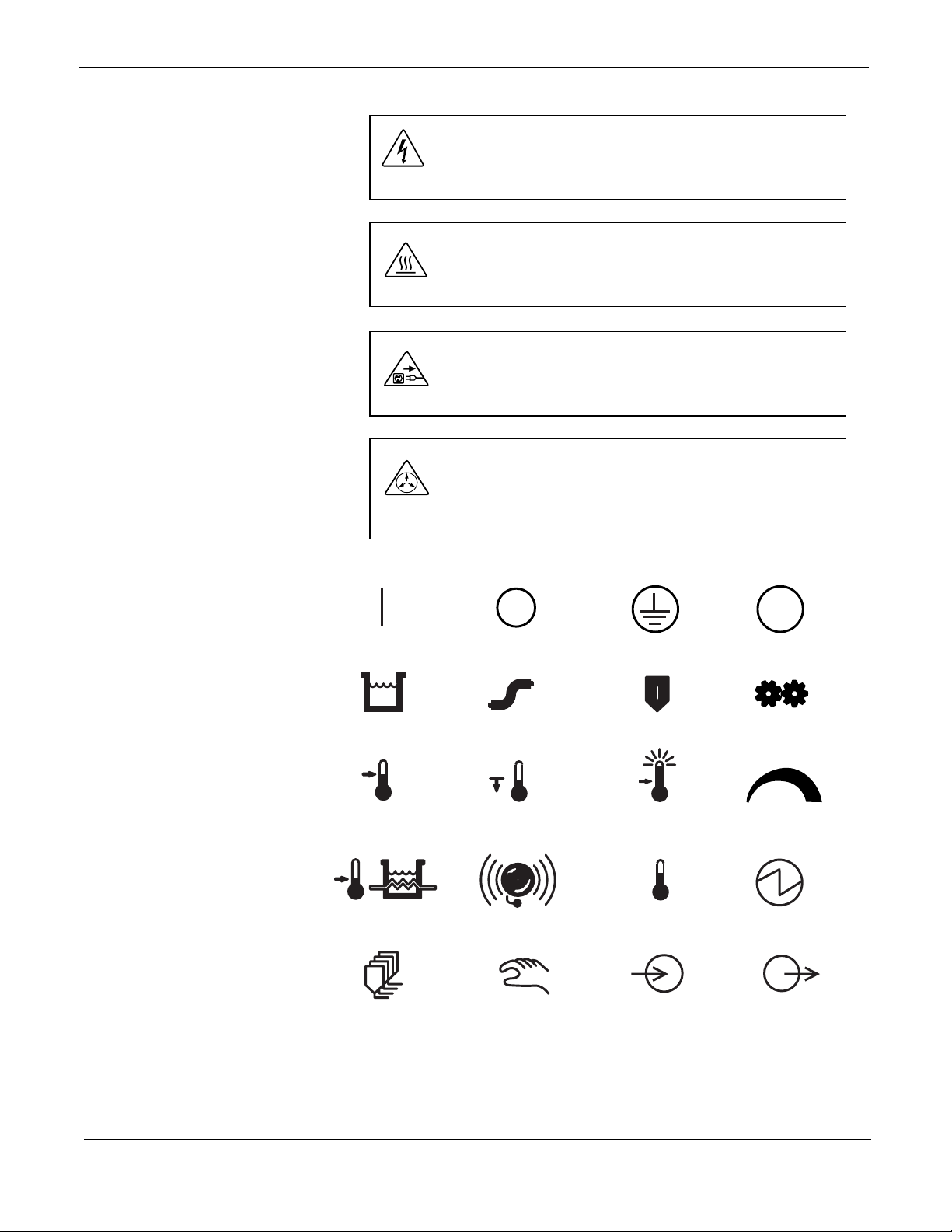

Specific Symbols and Signal Words

DANGER: High Voltage. Can cause serious

injury, including death. Disconnect electrical

power at external source before servicing

WARNING: Hot Surface. Can cause serious

injury and burns. Wear heat resistant clothing,

gloves and safety goggles.

WARNING: Disconnect electrical power at

external source. Failure to do so can cause

electrical shock.

WARNING: High Pressure. System contents

under pressure. Can cause serious injury and burns

or equipment and property damage. Relieve

pressure before servicing.

Other Product Symbols

On

Tank

Set Temp

Tank Heater

Valve Group

Heated Hose

Standby Temp

Off

Alarm

Manual Task

Ground

Applicator

Overtemp

Actual Temp

Input

PE

Protective Earth

Pump Motor

-

Adhesive Flow

Source Power

Output

+

The manufacturer reserves the right to make design changes for

product improvement. This manual may not reflect all details of

these improvements.

© Copyright 2010 Astro Packaging LS10 and LS20 19600-121 3

Page 10

2 Introduction

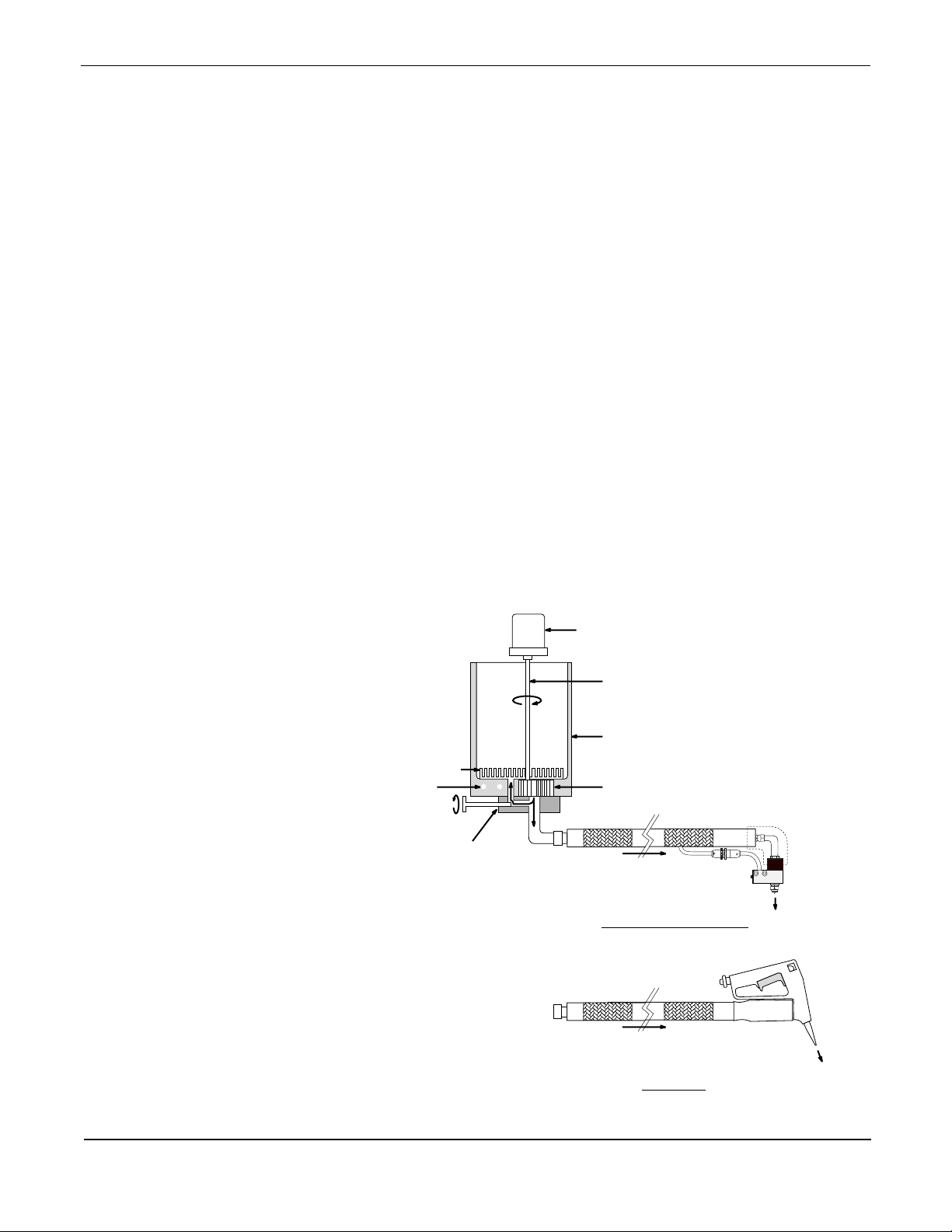

2.1 Description

The Astro Packaging LS Series Hot Melt Unit is a light to medium

duty machine used for melting and pumping a variety of hot melt

materials. The melt unit consists of a heated melt tank and a motordriven, positive displacement gear pump.

This all-electric melt unit accepts granular, pillow, pellet or block

forms of adhesive. The LS Melt Unit is equipped with a flow

control valve for fluid pressure and flow regulation. The melt unit

is available in 10 and 20 lb tank capacities and supports 1 or 2

automatic or manual applicators and hoses.

The tank temperature ranges from ambient temperature to 205 °C

(400 °F), adjustable by a bimetallic tank temperature controller. An

internal melt grid transfers heat efficiently from the tank heaters to

the hot melt material. The melt grid is standard on the 20 lb melt

unit and an optional feature on the 10 lb tank.

Electrical power to the melt unit is controlled by a circuit breaker

located on the front panel. The electrical panel contains a terminal

block to make connections to the power-in supply circuit. See

Section 4.3: Electrical Circuits and Wiring.

Melt Grid

(Option on 10 lb)

Tank Heaters

Flow Control &

Hose Manifold Block

Drive Motor

Melt Unit

Drive Shaft

Heated Tank Reservoir

(Teflon Coated)

Positive Displacement

Gear Pump

Heated Delivery Hose

AUTOMATIC APPLICATOR

0970000

Heated Delivery Hose

HANDGUN

4 LS10 and LS20 19600-121 Copyright 2010 Astro Packaging

Page 11

2.2 Features

• System power circuit breaker protects the entire system from

overload.

• A tank-mounted overtemperature thermostat turns the tank

heaters off in the event of a tank controller failure.

• A circuit breaker protects the pump motor by turning the motor

off should a stall or overload condition occur.

• A pump warmup thermostat protects the pump-drive

mechanism by preventing motor/pump operation below 121 °C

(250 °F).

• Head firing with LS automatic melt units can be from direct

signal input or any AC or DC model of ET Series Pattern

Controllers.

• An optional filter block is available for applications requiring

adhesive filtering.

• AC power cords are supplied with 100 VAC and 115 VAC

units only.

• A “Little Squirt” is a 10-pound one or two hose manual

handgun configuration of the LS Series.

© Copyright 2010 Astro Packaging LS10 and LS20 19600-121 5

Page 12

3 Specifications

3.1 Electrical

3.2 Physical

Voltage ------------------------------ 100, 115, 200 or 230 VAC (±10%)

single phase

Power Requirements -------------- LS10: 900 W (melt unit only: hoses/

---------------------------------------- LS20: 1400 W applicators not included)

Frequency--------------------------- 50/60 Hz

Main Circuit Breaker Rating----- All VAC: 15 A

Pump Motor Circuit -------------- 200/230 VAC: 0.5 A

Breaker Rating --------------------- 100/115 VAC: 1 A

Tank Overtemperature Thermostat

---------------------------------------- 205 °C (400 °F) (standard, other ratings

available)

Pump Warmup Thermostat------- 121 °C (250 °F) (standard, other ratings

---------------------------------------- available)

Tank Capacity---------------------- LS10: 4.5 kg (10 lb)

---------------------------------------- LS20: 9.1 kg (20 lb)

Hose Capacity---------------------- 2 manual hoses or 2 automatic hoses

Shipping Weight ------------------- LS10: 29.1 kg (64 lb)

---------------------------------------- LS20: 35.4 kg (78 lb)

Storage Temperature -------------- 0–60 °C (32–140 °F)

Pump Size -------------------------- V1-450: 7.4 CCD (0.450 CID)

---------------------------------------- V1-675: 11.1 CCD (0.675 CID)

Melt Grid --------------------------- LS10: optional

---------------------------------------- LS20: standard

3.3 Operating

Warmup Time---------------------- 30–45 minutes

Viscosity ---------------------------- Maximum 25,000 centipoise (cps)

Melt Rate --------------------------- LS10: 3.6 kg/hr (8 lb/hr) - without melt

grid

---------------------------------------- LS20: 9.1 kg/hr (20 lb/hr) - with melt

grid

Temperature Range---------------- 38 °C – 232 °C (100 °F – 450 °F)

3.4 Environmental

Ambient Air Temperature -------- 5–40 °C (41–104 °F)

Altitude------------------------------ Sea level up to 2 km (1.24 miles)

Humidity ---------------------------- 30–95 R.H. (%)

6 LS10 and LS20 19600-121 Copyright 2010 Astro Packaging

Page 13

3.5 Motor Speed, Adhesive Pressure, and Flow Rate

Frequency 50-60 Hz

Motor Speed 44/min (rpm)

Recommended Adhesive

Pressure Range*

V4-675 Pump 6.89–20.68 bar

689.48–2,068.43 kPa

100–300 psi

Maximum Flow Rate*

V1-675 Pump 25 kg/hr 21 kg/hr

55 lb/hr 45 lb/hr

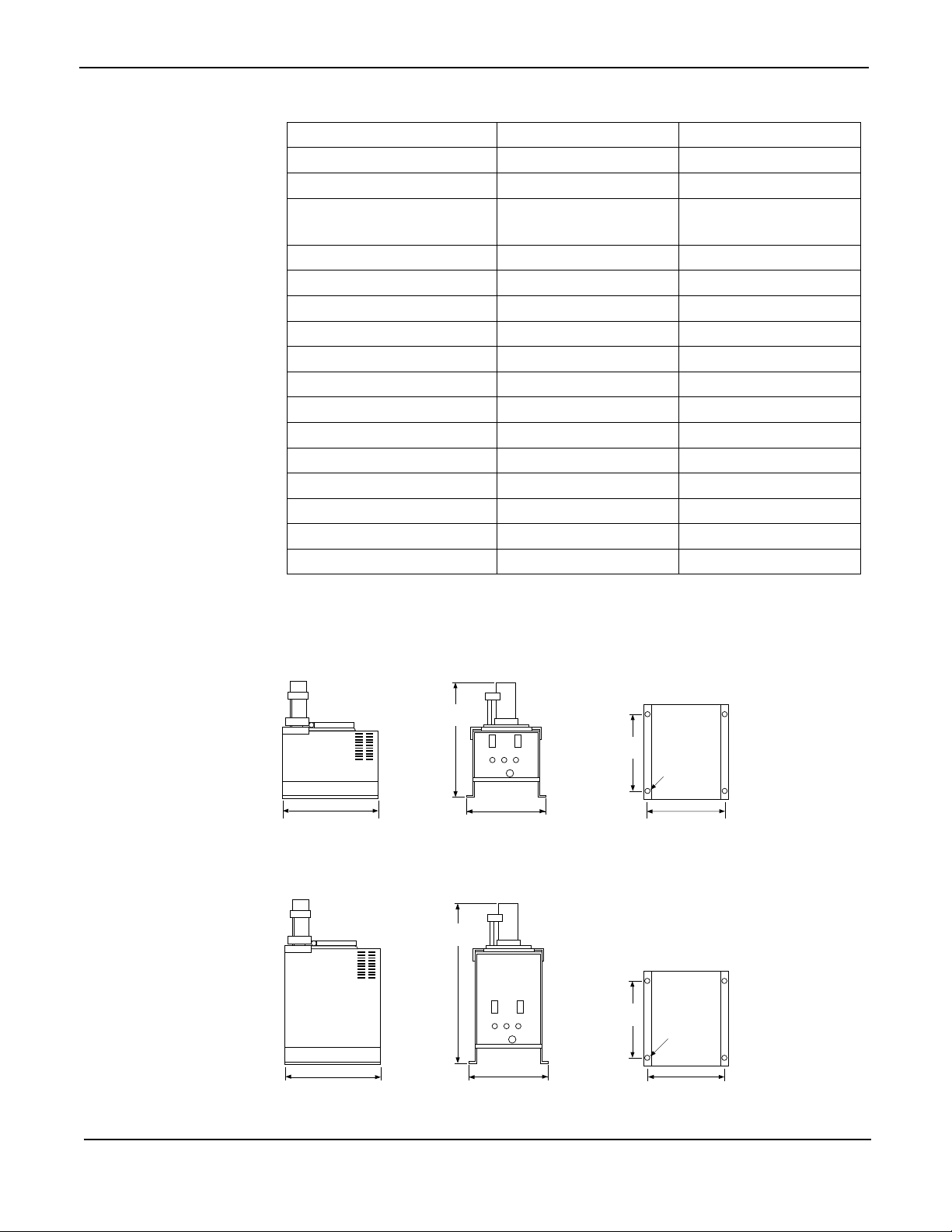

3.6 Dimensions

*Based on standard, packaging grade hot melts at 1000 cps. Varies with

adhesive and tank temperature. Consult factory representative for nonstandard requirements.

508 mm

(20 in.)

269.7 mm

355.6 mm (14 in.)

LS10 Hot Melt Unit

698.5 mm

(27.5 in.)

342.9 mm (13.5 in.)

(10.62 in.)

269.7 mm

(10.62 in.)

6.3 mm

(0.25 in.) dia.

317.5 mm (12.5 in.)

6.3 mm

(0.25 in.) dia.

0960149a

0970014

355.6 mm 14 in.)

342.9 mm 13.5 in.)

317.5 mm (12.5 in.)

LS20 Hot Melt Unit

© Copyright 2010 Astro Packaging LS10 and LS20 19600-121 7

Page 14

4 Installation

4.1 Setup

1. Remove all packaging material around melt unit.

2. Carefully lift melt unit out of box.

3. Unpack the binder containing product manuals, electrical

schematic, warranty information and flow control valve hex

wrench. Retain binder for future reference.

4. Unscrew 4 screws from plywood board base; remove and

discard plywood.

5. Carefully uncoil hoses from around melt unit and remove

protective wrap from applicators. Inspect all packing material

for separately wrapped items.

6. Position melt unit for easy access to control panel and

convenient servicing.

7. Level mounting surface to prevent warping of melt unit and to

avoid misalignment of the pump and motor shaft.

8. Using the base mounting holes, bolt melt unit down to a

durable mounting surface in accordance with dimensions in

illustrations in Section 3.6 to prevent accidental upset and

possible injury.

9. Tighten all screws before startup and after melt unit

experiences excessive vibration.

8 LS10 and LS20 19600-121 Copyright 2010 Astro Packaging

Page 15

4.2 Component Installation

4.2.1 Manual (Handgun) Systems

All standard components are normally installed on the melt unit at

the factory with no user installation required. If not installed, refer

to Hose Replacement. Refer to handgun product manual for

complete information on installation and service of the

handgun/hose assembly.

4.2.2 Automatic Systems

Hoses

Hoses are normally installed on an automatic melt unit at the

factory with no user installation required. If not installed, refer to

Hose Replacement. Refer to heated supply hoses product manual

for complete installation and service information.

Automatic Applicators (Heads)

Automatic applicators may be attached to hoses or packaged

separately. If not installed, proceed as follows:

1. With system power off, attach hose output electrical connector

to applicator. Heat fluid fittings on applicator and output end

of hose by attaching the electrical connector and applying

power for 3–5 minutes or until hose fitting will rotate.

2. Connect output end of the hose to adhesive input fitting on the

applicator.

3. When system reaches operating temperature, retighten all

adhesive connections. Check for leaks.

Refer to applicator product manual for installation and service

information.

Pattern Controllers, Head Drivers and Optional External

Components

Pattern controllers, head drivers and other external components

normally need to be connected to melt unit during installation.

Refer to electrical schematic, located in manual binder or back of

melt unit, for appropriate wire connections to the melt unit. Refer

to individual component product manual for complete installation

and service information.

© Copyright 2010 Astro Packaging LS10 and LS20 19600-121 9

Page 16

4.3 Electrical Circuits and Wiring

4.3.1 Electrical Schematic

Consult the electrical schematic provided with the melt unit for all

wire connections and component interconnections. Schematics are

shipped with each system and are found in the binder with the

product manuals. A copy of the schematic should remain with the

melt unit at all times.

4.3.2 Power Requirements

!

The LS Melt Unit uses single phase 100,115, 200, or 230 VAC

power sources, each with earth ground for safety. Refer to

illustration below for terminal block configuration. The standard

230 VAC melt units are wired for 2-wire single phase power. An

identification plate is attached to each melt unit on the outside rear

door of the tank housing. This plate specifies the exact voltage of

the melt unit and frequency of the pump motor. Pump motor

voltage, frequency and current are specified on the motor data

plate located on the motor. For safe and proper installation, refer to

the identification plate before applying electrical power to the melt

unit.

CAUTION: Power conducting wires must be rated

for intended current and 75 °C (167 °F).

4.3.3 Electrical Connections

Standard 230 VAC Single Phase, 2 Wire

L1

115

115 VAC Single Phase

L1

115

100 VAC Single Phase

L1

100

200 VAC Single Phase, 2 Wire

L1

100

L2 Ground

230

115

Neutral Ground

115

Neutral Ground

100

L2 Ground

200

100

0960358a

10 LS10 and LS20 19600-121 Copyright 2010 Astro Packaging

Page 17

4.3.4 Power-in Wiring

100–115 VAC

The melt unit comes equipped with an 2.44 m (8 ft) power cord,

unless it is a conduit model.

200–230 VAC

1. Inspect melt unit identification plate and inside electrical panel

to verify actual capacity and type of 230 VAC power plug

required for the system (2- or 3-wire).

2. Open front control panel.

3. Install appropriate power-in 16 AWG wires in the terminal

blocks provided. For automatic systems only, also configure

and install applicator program wires and jumpers. Refer to

Terminal Block Configuration diagram. Liquidtight conduit

and fittings are recommended when routing wires to electrical

terminal blocks. Holes in the chassis are provided for these

installations.

4. Close the front control panel after electrical hookup.

4.3.5 Valve Group Control Circuits for Automatic

Systems

An automatic applicator, or valve, contains one or more adhesive

valves which are activated by a solenoid. A valve group is a

number of valves powered by the same source which activate at

the same time. There are several options to activate electric valves

and valve groups:

Two Types of Valves and Firing Circuits

Automatic applicators are specified by solenoid voltage and valve

type. Valves must match the VAC or VDC firing voltage. Multiple

valve applicators may have more than one firing circuit within a

single applicator.

© Copyright 2010 Astro Packaging LS10 and LS20 19600-121 11

Page 18

4.3.6 VAC Valve Firing Voltage

Firing Voltage

Source

Melt unit any VAC

External customer

External customer

External customer

* Timer adaptor relay isolates melt unit power from an external

power source

Trigger Signal

Source

trigger

VAC trigger

VAC trigger

VDC trigger

Optional Timer

Adaptor Relay *

no relay present

no relay not present

AC relay present

DC relay present

Pattern Control

Jumpers

4.3.7 VDC Valve Firing Voltage

Firing Voltage

Source

DC Head

Driver

Trigger Signal

Source

any 3–32

VDC trigger

Head Driver

Required

DC Head Driver not present

Pattern Control

Jumpers

4.3.8 Foot Switch Trigger for Semi-automatic Systems

A manually operated foot switch allows operator to control

adhesive deposition through automatic applicators while keeping

hands free. The foot switch assembly may be factory installed or

added later. See Section 9.7: Accessories.

12 LS10 and LS20 19600-121 Copyright 2010 Astro Packaging

Page 19

4.3.9 External Control of Pump Motor for Automatic

Systems

The pump motor circuit may be connected to a parent machine or

other control device to enable the parent machine to control the hot

melt system pump. This extends pump life and provides added

safety when the melt unit is used in conjunction with other

machinery.

1. Using melt unit electrical schematic, locate parent machine

interface jumper.

2. Remove parent machine interface jumper.

3. Wire contacts from external device to the melt unit main

terminal block where the parent machine interface jumper was

located.

© Copyright 2010 Astro Packaging LS10 and LS20 19600-121 13

Page 20

5 Operation

5.1 Controls and Indicators

DANGER: Disconnect power before opening front

!

panel. Hazardous voltage can shock, burn, or cause

death.

Please read and see illustration opposite before operating melt unit.

[1] System Power Switch/Circuit-Breaker and Indicator Light

A magnetic type breaker opens the circuit when current exceeds 15

A. The system power switch illuminates white when in ON

position.

[2] Overtemperature Indicator Light

Illuminates red and ceases power to the tank heaters when melt

tank temperature exceeds thermostat rating. In the event of an

overtemperature condition, turn down tank temperature with

control or replace control if defective. See Section 7: Troubleshooting.

[3] Tank Thermometer

Indicates temperature of hot melt material in the melt tank. The

hose temperature adjustment, located behind front panel, indicates

the set temperature of the material in the hose.

[4] Tank Heating Indicator Light

Illuminates amber when tank heaters are powered and assists user

in making temperature adjustments to tank temperature controller.

[5] Pump Motor ON/OFF Breaker Switch

Turns off pump motor during system warmup or system

maintenance. A circuit breaker in the pump motor circuit protects

motor during a stall or overload condition.

[6] Pump Warm-Up Thermostat (Not Shown)

This close-on-rise thermostat prevents the motor from running

before system reaches operating temperature.

14 LS10 and LS20 19600-121 Copyright 2010 Astro Packaging

Page 21

APPLICATOR

POWER

1

5

2

0960130b

PUMP

ON

OFF

HEATING

TANK

OVERTEMP

TEMPERATURE

34

© Copyright 2010 Astro Packaging LS10 and LS20 19600-121 15

Page 22

5.2 Start-up

1. Become familiar with Section 5.1: Controls and Indicators.

2. Install melt unit as specified in Section 4.

3. Fill tank with hot melt material to 38 mm (1.5 in.) from top.

4. Turn unit on and allow 30 minutes warmup time.

5. Align the motor, if necessary. Motor alignment is necessary on

receipt of a new unit or after transportation; when replacing

the motor, pump-shaft, bearing block, or pump; or when the

motor is noisy.

a. Loosen the screws holding the motor.

b. Warm up melt unit and run the motor. This causes the

motor to center itself.

c. With motor running, tighten screws in a crisscross pattern.

6. Set hose and tank temperature to desired settings. Lower

settings will increase the material pot life.

7. Set the tank temperature as low as possible for each

application. Certain materials degrade over time due to

oxidation.

8. To prevent stalling the motor, adjust flow control valve to

minimum flow requirement.

16 LS10 and LS20 19600-121 Copyright 2010 Astro Packaging

Page 23

5.3 Adjustments

5.3.1 Temperature Adjustments

Hose Temperature Controller

Temperature graduations on hose controllers reflect approximate

hose temperature.

1. For precise readings, measure inside hose temperature with a

pyrometer and bead probe. Hose temperature should be the

minimum temperature required for application to prevent

degradation of material in the hose and maximize hose life.

2. To raise hose temperature, turn knob [2] in illustration below

clockwise to desired temperature.

3. To lower hose temperature, turn knob [2] counterclockwise to

desired temperature.

4. Refer to Temperature Check in Maintenance section of the

Astro Packaging Heated Hose Manual.

Tank Temperature Controller

1. To prevent hot melt degradation, set melt tank temperature to

the minimum temperature specified by the hot melt

manufacturer.

2. To raise melt tank temperature, turn tank temperature

controller adjustment shaft [1] in illustration below clockwise

with screwdriver.

3. To lower melt tank temperature, turn adjustment shaft [1]

counter-clockwise with screwdriver. The melt tank

temperature controller ranges 260 °C (500 °F) in one 320°

rotation of the adjustment shaft.

4. Verify temperature on tank thermometer.

5. Allow melt tank temperature to stabilize 30 minutes before

adjusting further. See Section 3: Specifications for melt tank

temperature range.

2

1

© Copyright 2010 Astro Packaging LS10 and LS20 19600-121 17

Page 24

5.3.2 Flow Adjustments

WARNING: High Pressure. System contents under

pressure. Can cause serious injury and burns or

equipment and property damage. Relieve pressure

before servicing.

CAUTION: For maximum performance and motor

!

life, do not allow pump motor to stall. A prolonged

stall condition will cause motor to go into thermal

overload.

Flow Control Valve

An adjustable pressure regulating device is mounted on the pump

under the melt unit chassis. See illustration below.

1. Adjust flow control from the lower right side of melt unit

using the hex wrench supplied with unit.

2. To increase pressure, turn hex wrench clockwise.

3. To decrease pressure, turn hex wrench counterclockwise.

4. To achieve minimum pressure and lowest flow rate, turn hex

wrench fully counterclockwise.

5. Gradually turn hex wrench clockwise until desired pressure

and flow rate is reached.

Increase

Decrease

0960141a

Hex

wrench

18 LS10 and LS20 19600-121 Copyright 2010 Astro Packaging

Page 25

6 Maintenance

WARNING: Hot melt materials can cause severe burns

!

resulting in disfigurement or blindness. Take the

following precautions before beginning any

maintenance:

• Wear protective clothing, safety goggles, and safety

gloves.

• Turn pump motor switch off position. Depressurize

applicator(s) by triggering.

• Unless stated otherwise, always allow melt unit to

cool before beginning any maintenance.

• Disconnect hose electrical connector when hose

fittings are disconnected and power is off.

CAUTION: To prevent damage to components (hose

!

fittings, etc.), heat part(s) being serviced to

approximately 121 °C (250 °F) prior to dismantling,

assembling, or adjusting. Heat parts by applying power

to the unit using a hand held hot air gun or placing parts

on a hot plate. Failure to do this will result in stripped

threads and ruining both parts and tools.

CAUTION: To avoid arcing of electrical contacts and

!

possible failure of components, do not connect

electrical connectors when the hose power switch is on.

© Copyright 2010 Astro Packaging LS10 and LS20 19600-121 19

Page 26

6.1 Preventive Maintenance

Procedure Daily Monthly As

Required*

Check for foreign material in

tank.

Wipe off excess hot melt from

cover.

Check for leaks. X

Purge tank and hoses. X X

Inspect hoses. ** X

Check tank temperature. *** X

Clean applicator nozzles. X

* Extra maintenance required for continuous duty machines.

** Verify hose is properly supported so it is not stressed during

use. Minimum bend radius is 8 in. when hot.

Check temperatures.

Adjust temperature according to Hose Temperature Controller

section. On multi-hose systems, a temperature difference

between hoses is quickly noted by touching outer insulation of

each hose.

*** Verify system is not operating in overtemperature mode by

observing Overtemperature Indicator Light.

Determine tank temperature and adjust as explained in Tank

Temperature Controller section.

X

X

20 LS10 and LS20 19600-121 Copyright 2010 Astro Packaging

Page 27

7 Troubleshooting

Problem Solutions

Tank does not heat

Tank heats slowly

Tank overtemperature

Applicator and hose heat slowly

1. Turn on main power breaker switch. If switch light

fails to illuminate, replace switch.

2. Inspect power-in connections for proper fit.

3. Check for faulty wires.

4. Inspect power wires or power plug at main power

source.

5. Check supply voltage to melt unit with voltmeter.

The voltage of each component must equal the

supply voltage or system damage will occur.

6. Check incoming control voltage to terminal blocks.

7. Check tank controller for proper operation.

8. Check wire connections against electrical schematic

to ensure melt unit is properly wired.

9. If problem still exists, replace tank heaters as

specified under Tank Heater Replacement.

1. Check status of components with a voltmeter

(system powered) or ohmmeter (system unpowered,

wires disconnected).

2. Adjust tank temperature controller. Inadequate tank

heat can affect performance.

3. If problem still exists, replace tank heaters as

specified under Tank Heater Replacement.

1. Check tank temperature when overtemp indicator is

lit. If too high, turn tank controller counterclockwise

to reduce temperature. If light is on at acceptable or

low temperature, switch is faulty or rated at a low

temperature. Replace overtemperature switch.

1. Adjust hose and applicator temperature controllers.

Inadequate heat can affect performance.

2. Verify hose electrical connector is properly

connected.

3. Check supply voltage to hose controller with volt

meter.

4. If problem persists, refer to Hose Controller

Replacement.

© Copyright 2010 Astro Packaging LS10 and LS20 19600-121 21

Page 28

Problem Solutions

Applicator and hose fail to heat

Adhesive output too high

Adhesive output too low

1. Check incoming hose power connector to see if

properly installed. Connector wire pins may be

misaligned or loose.

2. If no change, disconnect incoming hose power

connector and check hose heater resistance with

ohmmeter. If hose heater fails, replace hose. See

Slautterback Heated Hose Manual.

3. Determine if applicator is heating by using a

pyrometer or temperature sensing device. Do not

touch applicator by hand to determine temperature.

Refer to the handgun manual.

1. Decrease system fluid pressure with flow control

valve. If no change, remove nozzle and replace with

a smaller orifice nozzle.

2. Decrease hose temperature by 4–10 °C (25–50 °F).

If no change, consult your hot melt material vendor

regarding application.

1. Increase system fluid pressure without stalling the

motor by adjusting flow control valve. If no change,

remove nozzle and replace with a larger orifice

nozzle

2. Clean applicator nozzle.

3. Purge system.

4. Increase hose temperature by 4–10 °C (25–50 °F). If

no change, consult your hot melt material vendor

regarding application.

5. Hot melt formulations tend to be a factor in

previously listed problems. Refer to Start-up for

cautions.

• If troubleshooting attempts fail, please contact your distributor.

22 LS10 and LS20 19600-121 Copyright 2010 Astro Packaging

Page 29

8 Repair and Replacement

See Parts List, in Section 9, for all replacement parts listed in this

section.

8.1 Hose Replacement

a. Removal

1. Switch system power off, and allow hot melt in tank to

2. Switch system on for 5 minutes to allow fittings to warm or

3. Switch system power off, and disconnect melt unit electrical

4. Per illustration below, disconnect hose electrical connector [2]

CAUTION: For safe and proper hose replacement,

!

verify that all material in melt tank has completely

solidified.

completely solidify.

heat fitting with a hand-held hot air gun.

power from external source.

by tilting melt unit back until underside is accessible. Support

the melt unit with block on back of housing so hot melt does

not spill. Do not turn melt unit upside down.

5. Remove screws from hose mounting block [1].

6. Loosen hose JIC fitting [5] and remove hose from the

fitting [4] on the flow control block [3].

5

4

3

1

2

© Copyright 2010 Astro Packaging LS10 and LS20 19600-121 23

Page 30

b. Replacement

1. Switch off system power and disconnect melt unit electrical

power from external source.

2. Never flex a hose when cold. Hoses have a minimum bend

radius of 20.32 cm (8 in.) when hot. Further flexing will cause

permanent damage.

3. Per illustration below, heat hose JIC fittings [5] before

adjusting or damage may result. New or clean hose fittings

may not require heating.

4. Install hoses on melt unit by tilting melt unit back until

underside is accessible. Support melt unit with block on back

of housing so hot melt does not spill. Do not turn melt unit

upside down.

5. Support hose to prevent excessive flexing. Do not support

hose in a way which may add to its thermal insulating

characteristics or overheating will result. Failure to properly

support the hose will result in premature failure.

6. Install hose as follows:

a. Loosely connect the hose JIC swivel fitting [5] to

fitting [4] on the flow control block or hose manifold [3].

b. Fasten hose support block [1] to chassis.

c. Tighten JIC swivel fitting [5].

d. Attach hose electrical connector [2].

e. Tuck electrical connector under melt unit.

f. Position and support hose before using.

g. After heating, tighten JIC swivel fitting [5].

5

4

1

2

3

24 LS10 and LS20 19600-121 Copyright 2010 Astro Packaging

Page 31

8.2 Hose Controller Replacement

1. Turn off system power and allow hot melt in tank to

completely solidify.

2. Turn system power back on for five minutes to allow fittings to

warm up, or heat fittings with a hand-held hot air gun.

3. Turn off system power and disconnect melt unit electrical

power.

4. Tilt melt unit backward.

5. Loosen hose JIC fitting and remove hose from fitting on flow

control valve.

6. Remove thermostat bulb from hose end; take care not to kink

capillary tube.

7. Open front control panel.

8. Disconnect controller wires.

9. Remove screws fastening controller to electrical panel.

10. Install new controller.

a. Insert thermostat bulb into hose end.

b. Coil capillary tube so it hangs in a suitable position under

chassis.

11. Reconnect hose to JIC as specified in Section 4.2: Component

Installation.

12. Reconnect melt unit power, turn on power switch, and adjust

controller as specified in Section 5.3.1.

© Copyright 2010 Astro Packaging LS10 and LS20 19600-121 25

Page 32

8.3 Tank Heater Replacement

1. Before considering replacement, check each heater with amp

2. To measure heater resistance, switch off system power and

3. Per illustration below, open control panel and remove tank

4. Determine resistance of each individual heater [2]. Refer to

5. If heater requires replacement, disconnect wires of defective

6. Pull heater out of bore using pliers. If heater does not come

7. Apply a coating of heat release and transfer agent to new

probe (system power on) or ohmmeter (system power off,

wires disconnected). Refer to electrical schematic, located in

back of melt unit.

disconnect electrical power from external source.

access panel [1].

Appendix A for Component Resistance Tables.

heater.

out easily, drive out using a 6.35 mm (0.25 in.) diameter rod

inserted in knockout holes in back of tank base.

heater and slide it into tank heater bore from the front.

8. Route heater lead wires through electrical panel, and reconnect

heater wires in original locations. See electrical schematic

included with melt unit.

9. Replace tank access panel.

10. Close and fasten control panel.

1

2

26 LS10 and LS20 19600-121 Copyright 2010 Astro Packaging

Page 33

8.4 Tank Controller Replacement

1. Disconnect melt unit electrical power.

2. Open front control panel.

3. Remove tank access panel at bottom of electrical panel.

4. Remove wires connected to thermostat. Tank thermostat

controller is the elongated thermostat mounted horizontally on

the tank base plate.

5. Remove screws holding tank thermostat to tank.

6. Apply even coating of heat sink compound to base of the new

thermostat.

7. Attach replacement thermostat to the tank assembly using the

mounting clip and screws. Reconnect wires.

8. Replace tank access plate.

!

WARNING: Failure to replace the access plate will

result in an electrical hazard and possible heat damage

to electrical components.

9. Close front control panel.

(800-401-1441

© Copyright 2010 Astro Packaging LS10 and LS20 19600-121 27

Page 34

8.5 Hose Manifold Filter Block Replacement or Cleaning

The hose manifold filter block is an optional component that is

required when a pump filter is used.

1. If possible, pump out all adhesive in melt unit before

disconnecting power. If not possible, disconnect power and

allow hot melt in tank to solidify.

2. Switch on system power for 5 minutes to warm fittings.

3. Switch off system power and disconnect electrical power at

external source.

4. Disconnect hose electrical connector and tilt melt unit

backwards. Support the melt unit with block on back of

housing so hot melt does not spill. Do not turn melt unit

upside down.

5. Per illustration below, loosen JIC fittings [5] and remove

hose(s) from fitting(s) [6] on hose manifold [3].

6. Remove screws [4] from hose manifold filter block [3].

7. Ease hose manifold [3] from flow control block [1]. Two

screws remain (3 for reverse mounting) holding flow control

block [1] and pump to tank base plate.

8. Clean hose manifold [3] thoroughly, especially flow control

block mating surface, or replace with a spare hose manifold.

9. Refit hose manifold [3] with hardware. After lubricating with

a silicone-based grease such as DC 5, replace o-rings [2].

10. Switch on system power, and allow melt unit to reach

operating temperature.

11. Reconnect hose as specified in Hose Replacement.

1

2

3

6

5

4

0950175

28 LS10 and LS20 19600-121 Copyright 2010 Astro Packaging

Page 35

y

8.6 Pump Filter Installation, Servicing, and Replacement

A pump filter is an optional accessory for use when adhesive

filtering is desired. The pump filter is installed in the hose

manifold filter block. See illustration below for installation and

servicing the filter element.

WARNING: Contents at high temperature and

pressure. Remove pressure before opening filter or

drain valve to prevent accidental discharge of system

pressure. Do not touch hot surfaces. Failure to follow

these instructions ma

1. Bring melt unit to operating temperature.

2. Switch off pump motor.

3. Activate applicator several times to relieve all pressure in the

system.

4. Place a disposable container below filter access area to catch

all adhesive spillage or run off.

5. Slowly remove plug [1] with o-ring [2] to release any residual

pressure trapped in hose manifold filter block [6]. A 9/16 in.

hex wrench is required.

result in severe burns.

6. Remove spring [3], spring retainer [4], and filter [5]. Clean all

parts.

7. Carefully switch pump motor on for approximately 1 to 2

seconds causing a small amount of adhesive to flush the filter

chamber. Clean filter chamber of all foreign material. Repeat

if necessary.

8. Insert spring retainer [4] and spring [3] into clean filter [5].

Place clean filter assembly into manifold filter block [6].

9. Inspect o-ring [2], and replace if damaged.

10. Install plug [1] with o-ring [2] securely into hose manifold

filter block [6].

5

6

4

3

2

1

© Copyright 2010 Astro Packaging LS10 and LS20 19600-121 29

Page 36

8.7 Pump Motor and Pump Shaft Assembly Replacement

1. Disconnect electrical power and allow melt unit to cool to

121 °C (250 °F).

2. Per illustration below, open motor junction box cover [1],

disconnect wiring and liquidtite fitting [2].

3. Remove screws [4] holding motor mounting plate to melt unit.

4. Lift motor assembly off melt unit.

5. Inspect motor shaft coupler [3] for wear. Replace if necessary.

6. If not replacing shaft assembly, skip to Step 8. If replacing

pump shaft assembly or individual shaft assembly parts,

remove bronze spider [6], coupler and key [11 and 12],

washer [7], retaining ring [10], and shaft [8], and shaft

retainer [9].

7. Install new shaft assembly or individual components as

needed.

8. Remove screws [5] holding pump motor to motor mounting

plate [13].

9. Install new pump motor on motor mounting plate.

10. Check pump shaft alignment on pump in tank.

11. Align motor coupling [3] with pump shaft in tank and lower

onto shaft.

12. Align motor mounting plate to melt unit with mounting

screws [4].

13. Verify that pump shaft seats properly with pump, and verify

that coupler clearance [14] of 0.8 mm ±0.3 mm (0.030 in.

±0.010 in.) exists.

14. Replace liquidtite fitting and wires [2].

15. Reconnect wires according to electrical schematic, located in

back of melt unit. Refer to melt unit identification plate to

determine exact voltage.

16. Turn on melt unit and allow melt unit to heat to normal

operating temperature. Turn on pump motor.

17. Tighten screws [4] in a crisscross pattern while motor is

operating to align pump shaft.

18. If replacing complete motor group, also replace pump motor

switch on front panel and motor capacitor inside electrical

enclosure.

30 LS10 and LS20 19600-121 Copyright 2010 Astro Packaging

Page 37

1

2

14

3

4

13

4

5

6

7

0950178

11, 12

10

8

9

© Copyright 2010 Astro Packaging LS10 and LS20 19600-121 31

Page 38

9 Parts List

9.1 Control Panel - Front View

Item Description (Quantity) Part Number

1 Circuit breaker/switch, main 15 A 115 VAC 12015-1

1 Circuit breaker/switch, main 15 A 230 VAC 12015-3

2 Lamp, round red (overtemperature indicator) 12030-1

3 Thermometer 11029

4 Thermometer, spring 14488-1

5 Lamp, round amber (tank heating indicator) 12030-10

6 Circuit breaker/switch, pump motor, 1 A (100/115 VAC unit) 12055-1

6 Circuit breaker/switch, pump motor, 0.5 A (200/230 VAC unit) 12055-3

APPLICATOR

POWER

1

6

2

0960130c

PUMP

ON

OFF

HEATING

TANK

OVERTEMP

TEMPERATURE

3, 45

32 LS10 and LS20 19600-121 Copyright 2010 Astro Packaging

Page 39

9.2 Electrical Enclosure and Chassis Base

Item Description (Quantity) Part Number

1 Tank heater kit, 115 VAC, 400 W (2 heaters for 10 lb. unit) 79005

1 Tank heater kit, 230 VAC, 400 W (2 heaters for 10 lb. unit) 79005-1

1 Tank heater kit, 100 VAC, 400 W (2 heaters for 10 lb. unit) 79005-2

1 Tank heater kit, 200 VAC, 400 W (2 heaters for 10 lb. unit) 79005-3

1 Tank heater kit, 230 VAC, 600 W (2 heaters for 20 lb. unit) 79044

1 Tank heater kit, 115 VAC, 600 W (2 heaters for 20 lb. unit) 79044-1

1 Tank heater kit, 100 VAC, 600 W (2 heaters for 20 lb. unit) 79044-2

1 Tank heater kit, 200 VAC, 600 W (2 heaters for 20 lb. unit) 79044-3

2 Tank controller, kit 38–232 °C (100–450 °F) 79006

3 Panel, access 70350-1

4 Connector 9-pin, for solid capillary controlled melt units 12115-9

5 Flange, 9-pin connector, panel mount 12115-10

6 Female electrical pins 12116

7 Hose controller, kit 38–93 °C (100–200 °F) 79125-1

7 Hose controller, kit 93–149 °C (200–300 °F) 79125-2

7 Hose controller, kit 149–204 °C (300–400 °F) 79125-3

7 Hose controller, kit 177–232 °C (350–450 °F) 79125-4

7

1

1

6

2

3

4

5

© Copyright 2010 Astro Packaging LS10 and LS20 19600-121 33

Page 40

9.3 Motor Group and Pump Shaft Assembly

Item Description (Quantity) Part Number

2 Motor assembly, 44/36 rpm, 50/60 Hz, 100/115 VAC 73012-32

3 Capacitor, 3 µf, 370 VAC, flat pack 12045-3

4 Circuit breaker/switch, pump motor, 1 A (100/115 VAC unit) 12055-1

4 Circuit breaker/switch, pump motor, 0.5 A (200/230 VAC unit) 12055-3

5 Key, motor coupler to pump shaft 14475-18

6 Coupler, HF&FS, 1/2 in. w/ keyway 70460-2

7 Spacer, AL. 10 x .50 x 1.25 LG 14471-6

8 Washer, lock 14451-FA

9 Screw, socket head cap 10-32 x 1.75 LG 14431-FDO

10 Screw, set flat point, 1/4 - 28 x 3/16 14401-HDB

11 Pump shaft assembly, 10 lb. melt unit 73726-21

11 Pump shaft assembly, 20 lb. melt unit 73726-22

12 Washer, rat trap 14528-4

13 Retaining ring 14502-12

14 Shaft, pump with keyway, 10 lb. melt unit 70461-3

14 Shaft, pump with keyway, 20 lb. melt unit 70461-4

15 Retaining spring pump shaft 70028

Retainer seal for pump shaft 70028-1

Kit, gearbox repair, 44/36 rpm motor 79295-01

Wire nuts (medium low temperature) 12277-2

* Motor group includes Motor Assembly, Capacitor, Pump “ON/OFF” breaker, and hardware.

2

3

4

5

10

6

7

8

9

11

12

13

14

15

34 LS10 and LS20 19600-121 Copyright 2010 Astro Packaging

Page 41

9.4 Pump Warm-up and Tank Overtemperature Thermostats

Item Description (Quantity) Part Number

LS10, LS20 Pump Warm-up Thermostat Kit

1 37.78 °C (100 °F) 79068-100

1 93.33 °C (200 °F) 79068-200

1 107.22 °C (225 °F) 79068-225

1 129.44 °C (265 °F) 79068-265

1 148.89 °C (300 °F) 79068-300

1 176.67 °C (350 °F) 79068-350

LS10 Overtemperature Thermostat Kit

2 65.56 °C (150 °F) 79126-150

2 93.33 °C (200 °F) 79126-200

2 148.89 °C (300 °F) 79126-300

2 204.44 °C (400 °F) 79126-400

2 232.22 °C (450 °F) 79126-450

LS20 Overtemperature Thermostat Kit

2 65.56 °C (150 °F) 79127-150

2 93.33 °C (200 °F) 79127-200

2 148.89 °C (300 °F) 79127-300

2 204.44 °C (400 °F) 79127-400

2 232.22 °C (450 °F) 79127-450

0960370

2

1

1

2

© Copyright 2010 Astro Packaging LS10 and LS20 19600-121 35

Page 42

9.5 V4 Pump, Flow Control Valve, and Hose Manifold Filter

Item Description (Quantity) Part Number

1 Pump seal kit, all V4 pumps 79081

2 Pump Kit, V4-675, 0.675 CID flange thickness = 15.9 mm (0.625 in.) 79290-2

3 Washer, lock, 0.25 in. 14451-GA

4 Screw, socket head cap 1/4-20 x 2.5 in. (for V4-675) 14431-GDQ

5 Flow control valve replacement kit, 1 hose 79025-4

5 Flow control valve replacement kit, 2 hose 79082-4

5 Flow control valve replacement kit, for units with filter block 75011-010

6 Flow control valve repair kit, 2 hose 79082-2

7 Flow control valve replacement 79082-8

8 Spring, flow control valve 14489-10

9 Damper, flow control valve 70392-1

10 Plug, 1/4 NPTF, flush, steel 11603-4D

11 Hex wrench 1/4 in. 11050-1/4

12 Pump filter kit, 50 mesh 79064

13 Plug, socket head No. 12, with o-ring 10456, for filter chamber 11604-12

14 O-ring for 11604-12, viton, 0.116 in. W x 0.924 in. 10456

15 Filter block, kit, 1 hose (for rear entry only), optional 79133-01

15 Filter block, kit, 2 hose (for rear exit only), optional 79133-02

16 Plug, 3/8 NPTF, steel 11603-6A

17 Fitting, male, 1/4 in. NPT to No. 6 JIC, straight 11408-64A

18 Screw, socket head cap 1/4-20 x 2.50 in. (both pumps) 14431-GDR

19 Screw, socket head cap 1/4-20 x 3.75 in. (for V1-450) 14431-GDV

19 Screw, socket head cap 1/4-20 x 4.25 in. (for V1-675 14431-GDY

20 Hose manifold filter block 70122

21 O-ring, viton, 0.86 in. ID x 0.070 in. for hose manifold filter block 10420

36 LS10 and LS20 19600-121 Copyright 2010 Astro Packaging

Page 43

© Copyright 2010 Astro Packaging LS10 and LS20 19600-121 37

Page 44

9.6 Accessories

Item Description (Quantity) Part Number

Melt Grid, for LS10

(included as standard equipment on LS20)

79033-1

Kit, Gun Hanger 79023

Filter Block Assembly - 1 hose

Filter Block Assembly - 2 hoses

Kit, Pump Inlet Screen

Kit, Pump Filter

(use with pump Filter Block Assembly

(used with a melt grid)

Kit, Reverse 1 Hose Mounting

Kit, Reverse 2 Hose Mounting

(recommended for adhesive filtering)

(recommended for adhesive filtering)

) 79064

(Filter Block Assembly not included

(Filter Block Assembly not included

79133-01

79133-02

79282-01

) 79135-10

) 79135-11

Kit, Knob Assembly FCV, V1 Retrofit to existing units 79287-01

1 B

oom 99786-B

2 Base 99786-A

3

Hose Hammock

73464-9

4 Tension Balancer, Hose, 5 Lb RF-8

5 Hose Boom & Balancer Assembly 99786

Power Cord Assembly, 115 VAC 73712-12

Kit, Hose Mole (use for in place cleaning of hoses) 79281-01

Kit, Tank Thermometer 79014

1

4

3

2

5

38 LS10 and LS20 19600-121 Copyright 2010 Astro Packaging

Page 45

Appendix A: Component Resistance Tables

Minimum and maximum resistance (R) of common melt unit components, hoses, and applicators.

Unless otherwise specified, resistance values are measured at 20° + 5° C (68° + 10° F).

Table 1. Tank Heater Resistance

Spare Kit Voltage Heater Ohms*

79005 115 12532 32.4–37.8

79005-1 230 12538 136.8–158.4

79044 230 12546-1 91–106

79044-1 115 12456-2 23–26

79088-30 230 12600 55–63.3

79088-50 230 12600 55–63.3

79088-100 230 12610 91.5–100.5

*Resistance shown is for one heater only. Spare kit may include more than one heater.

Table 2. Motor Resistance

Melt Unit Model Motor Label Spare Motor Group RPM Hz Voltage Ohms

SS10G, Mark II 73714-24 73714-24 38/31 50/60 100–115 6

SS10G, Mark II 73714-24 73714-24 38/31 50/60 200–230 16

LS/SQ10 & 20 73795-01 73714-20 44/36 50/60 100–115 25–28

LS/SQ10 & 20 73795-02 73714-21 44/36 50/60 200–230 102–105

KS10 & 20 73795-01 73714-25 44/36 50/60 100–115 25–28

KS10 & 20 73795-02 73714-26 44/36 50/60 200–230 102–105

KB/FS10 & 20 73794-01 73714-41/-43 86/72 50/60 100–115 6–9

73794-02 73714-42/-44 86/72 50/60 200–230 16–20

73794-06 73714-45/-46 72 50 200–230 16–20

KB/FS30–100 73794-02 73278-42 86/72 50/60 200–230 16–20

73794-06 73278-45/-46 72 50 200–230 16–20

73207-03 73278-98 170 60 200–230 8–10

73207-04 73278-97 140 50 200–230 19

73012-20 73278-70 340 60 200–230 8–10

73012-82 73278-71 280 50 200–230 16

LS/KS10e & 20e 73789-05 79301-01/-03 47 50 200–230 45–50

KB10e & 20e 73794-07 79301-02/-04 70 50 200–230 60–65

Model 115C 73789-05 79301-01/-03 47 50 200–230 45–50

© Copyright 2010 Astro Packaging LS10 and LS20 19600-121 39

Page 46

Table 3. RTD Sensor Resistance

Temperature Ohms

0 °C (32 °F) 100

38 °C (100 °F) 115

66 °C (150 °F) 126

93 °C (200 °F) 136

121°C (250 °F) 147

149 °C (300 °F) 158

177 °C (350 °F) 168

204 °C (400 °F) 178

Same RTD sensor is used in tank, hose and applicator.

Table 5. Valve Coil Resistance

E100XT Style Coil E900 Style Coil

Voltage Ohms Voltage Ohms

100 39–42 100 64–75

115 45–48 115 77–89

200 156–157 200 239–281

230 172–201 230 285–335

40 LS10 and LS20 19600-121 Copyright 2010 Astro Packaging

Page 47

Table 6. Heater Resistance for Common Applicators

Model Voltage Heater

Quantity

Automatic Applicators

E100XT 230 2 120 240 216–264

E100 230 1 150 150 369–399

E901 230 1 150 150 369–399

E902 230 2 150 300 182–211

E904 230 2 150 300 182–211

M101 230 2 150 300 182–211

M102 230 4 150 600 91–106

M104 230 4 150 600 91–106

Manual Applicators

L4/SW4 230 1 80 80 664–720

L1 115 1 50 50 247–314

L4/SW4 115 1 80 80 170–190

*For applicators with more than 1 heater, resistance shown is for heaters in parallel.

Heater

Wattage

Total

Wattage

Ohms*

© Copyright 2010 Astro Packaging LS10 and LS20 19600-121 41

Page 48

Table 7. Heater Resistance for Common Hoses (in Ohms)

HC Style Automatic Hoses

Part No. (VAC) 4 ft 6 ft 8 ft 10 ft 12 ft 14 ft 16 ft

Capillary Sensor

25132 (115 VAC) 153–159 105–109 80–83 65–67 54–56 47–49 41–43

26288 (230 VAC) 560–583 385–401 294–306 237–247 199–207 171–178 150–157

RTD Sensor

26701 (115 VAC) 127–140 86–96 66–72 53–58 44–49 39–41 33–37

26703 (230 VAC) 510–563 347–384 264–291 212–235 178–196 153–169 134–148

Handgun Hoses

Part No. (VAC) 8 ft 12 ft 16 ft

L1 Hose, Capillary Sensor

26257 (115 VAC) 80–83 54–56 41–42

26276 (230 VAC) 293–305 199–207 150–156

L1 Hose, RTD Sensor

26499 (115 VAC) 73–80 49–54 36–40

26500 (230 VAC) 298–306 199–204 149

L4 Hose, Capillary Sensor

21260 (115 VAC) 71–74 48–50 36–38

21262 (230 VAC) 283–294 192–200 145–152

L4 Hose, RTD Sensor

21285 (115VAC) 75–79 45–52 37–39

21287 (230VAC) 298–315 199–209 149–157

SW4 Hose, RTD Sensor

21261 (115 VAC) 75–79 49–52 37–39

21263 (230 VAC) 298–314 199–209 149–157

42 LS10 and LS20 19600-121 Copyright 2010 Astro Packaging

Page 49

(800-401-1441

A. Astro Packaging warrants its products, when operated and maintained in accordance with

Astro Packaging recommended procedures, are free of defects in material and workmanship during the periods

indicated below commencing with the date the product is placed in service.

Product Warranty Period

1. Tank heater (including entire tank when 5 years or 10,000 hours of use,

heater is cast into tank) whichever occurs first

2. Melt unit (unless specified below); pattern 1 years or 2,000 hours of use,

controller; head driver whichever occurs first

3. Stationary hose; automatic electric head; JR™ 1 year or 2,000 hours of use,

Series Hot Melt System or melt unit; standard pail whichever occurs first

unloader; standard accessory purchased with a system

4. Manual hose; handgun; Mini Squirt III; any butyl 6 months or 1,000 hours of use,

system; any PUR system (including hose, gun whichever occurs first

or head used with PUR); any spare or replacement

component; pneumatic head; industrial heated hose;

T100 Temperature Controller; nozzle; nozzle bar

5. Rebuilt equipment 90 days or 500 hours of use,

whichever occurs first

B. The sole liability of Astro Packaging and exclusive remedy extended to any Astro Packaging customer shall be limited

to replacing or repairing, at the option of Astro Packaging, any product returned under the terms of this warranty.

Labor and related expenses incurred to install replacement or repaired parts are not covered by this warranty.

C. Astro Packaging is not responsible for repair or replacement of any product that has been subject to abuse,

misuse, alteration, accident, or negligent use, nor for repairs made by an unauthorized person or with parts

other than those provided by Astro Packaging.

D. Astro Packaging assumes no responsibility for the performance of adhesives or other materials used with its

products.

E. The warranty for a product repaired or replaced under this warranty shall continue in effect for the remainder of

the original warranty period, or for ninety (90) days following the day of shipment by Astro Packaging of the

repaired or replaced product, whichever period is longer.

No warranty is made with respect to custom products or products developed, designed and manufactured to

F.

customer specifications, except as specifically stated in writing by Astro Packaging.

G. Astro Packaging is responsible only for payment of shipping charges for delivery of a repaired or replaced product,

via the least expensive means of transport, to customer or an authorized Sales and Service Center in the

Continental United States only. Payment for shipment to Astro Packaging or an authorized Sales and Service

Center for evaluation, repair or replacement is the responsibility of the customer.

H. For service under this warranty, contact the Factory Authorized Representative from which the product was

purchased.

THIS WARRANTY IS IN LIEU OF ANY OTHER WARRANTY EXPRESSED OR IMPLIED, INCLUDING THE

WARRANTY OF MERCHANTABILITY AND FITNESS FOR THE PARTICULAR PURPOSE.

Complete Reverse Side and Retain for Your Records

Astro Packaging 3845 E. Miraloma Ave, Suite A, Anaheim, CA 92806 1-800-642-7876 phone 714-572-1943 fax

1 of 2

Page 50

Equipment Record

Record the information below on all equipment received and retain for your records.

(

Systems, melt units, hoses, guns, heads, pattern controllers, drivers, etc)

Products were purchased from:___________________________________________

Astro Packaging

Product Model/Description__________________________ Serial No._____________

Product Part Number______________________________ Order No._____________

Date Received____________ Start-Up Date____________ Invoice No.____________

Product Model/Description__________________________ Serial No._____________

Product Part Number______________________________ Order No._____________

Date Received____________ Start-Up Date____________ Invoice No.____________

Product Model/Description__________________________ Serial No._____________

Product Part Number______________________________ Order No._____________

Date Received____________ Start-Up Date____________ Invoice No.____________

Product Model/Description__________________________ Serial No._____________

Product Part Number______________________________ Order No._____________

Date Received____________ Start-Up Date____________ Invoice No.____________

Product Model/Description__________________________ Serial No._____________

Product Part Number______________________________ Order No._____________

Date Received____________ Start-Up Date____________ Invoice No.____________

Product Model/Description__________________________ Serial No._____________

Product Part Number______________________________ Order No._____________

Date Received____________ Start-Up Date____________ Invoice No.____________

Product Model/Description__________________________ Serial No._____________

Product Part Number______________________________ Order No._____________

Date Received_____________ Start-Up Date___________ Invoice No.____________

Astro Packaging 3845 E. Miraloma Ave, Suite A, Anaheim, CA 92806 1-800-642-7876 phone 714-572-1943 fax

2 of 2

Loading...

Loading...