Page 1

ASTRO

CDM-700 Series

(Covers Domestic 115V & European 220V Models)

Conveyor Stacker

USER’S GUIDE/PARTS CATALOG

Page 2

This manual is intended solely for the use and information of Astro Machine Corp., its designated agents,

customers, and their employees. The information in this guide was obtained from several different

sources that are deemed reliable by all industry standards. To the best of our knowledge, that information

is accurate in all respects. However, neither Astro Machine Corp. nor any of its agents or employees shall

be responsible for any inaccuracies contained herein.

All rights reserved. No part of this book may be reproduced or transmitted in any form or by any means, electronic or mechanical, including

photocopying, recording, or any information storage and retrieval system, without permission in writing from the publisher.

Page 3

Power Requirements:

Optional Availability:

115 VAC, 60 Hz, 9.0 AMP

220 VAC, 50/60 Hz, 0.5 AMP

Motor Circuit Breaker:

Fuse:

1 AMP

0.5 AMP

Speed Of Tapes:

0" - 250 feet per minute (variable)

Dimensions:

Width: 15" (38.1 cm)

L

ength: 34.5" (87.6 cm)

Height:

Table Top

Weight: 33 lbs. (15 kg)

WARNING!

ONLY CONNECT CONVEYOR TO A PROPERLY GROUNDED OUTLET!

INTRODUCTION

The CDM-700 Conveyor transports media from the Printer and stacks it. As the first piece of

stock exits the Printer, the motor-driven Conveyor Tapes under the Stacker Wheels move it. The

next piece of stock exits the Printer, overlaps the preceding piece, and is moved along the

Conveyor. After clearing the Stacker Wheels, the stock can be unloaded by hand without having

to stop the Printer.

SPECIFICATIONS*

* MANUFACTURER RESERVES THE RIGHT TO CHANGE

SPECIFICATIONS WITHOUT WRITTEN NOTICE.

SAFETY PRECAUTIONS

THIS EQUIPMENT PRESENTS NO PROBLEM WHEN USED PROPERLY.

OBSERVE SAFETY MEASURES WHEN OPERATING THE CONVEYOR:

READ THIS MANUAL CAREFULLY AND FOLLOW RECOMMENDED PROCEDURES.

¾ KEEP HANDS, HAIR, AND CLOTHING CLEAR OF ROLLERS, TAPES, AND

OTHER MOVING PARTS.

¾ ALWAYS TURN CONVEYOR OFF BEFORE ADJUSTING OR CLEANING.

¾ DISCONNECT POWER CORD WHEN MAKING ANY ADJUSTMENTS OR

PERFORMING ANY MAINTENANCE NOT COVERED IN THIS MANUAL.

FAILURE TO DO SO CREATES RISK OF ELECTRICAL SHOCK!

Page 4

USER GUIDE

CAUTION

CONVEYOR IS DESIGNED TO BE PLUGGED

FOR YOUR SAFETY, DO NOT REMOVE

GROUND PIN FROM LINE CORD.

Assembling Conveyor

1. Unpack Conveyor. Do not discard carton until

Conveyor is assembled.

2. Attach Receiving Tray to Conveyor with two

screws provided.

Positioning Conveyor

1. Place Conveyor on the same sturdy table or

workbench next to the Printer as shown.

2. Center Conveyor relative to Printer’s exit.

Operating Conveyor

Plug Conveyor into a properly grounded wall outlet

using power cord supplied.

INTO A GROUNDED OUTLET.

-1-

Page 5

USER GUIDE

WARNING!

DISCONNECT POWER CORD WHEN CHECKING OR REPLACING FUSE!

FAILURE TO DO SO MAY DAMAGE ELECTRONIC CIRCUIT BOARD.

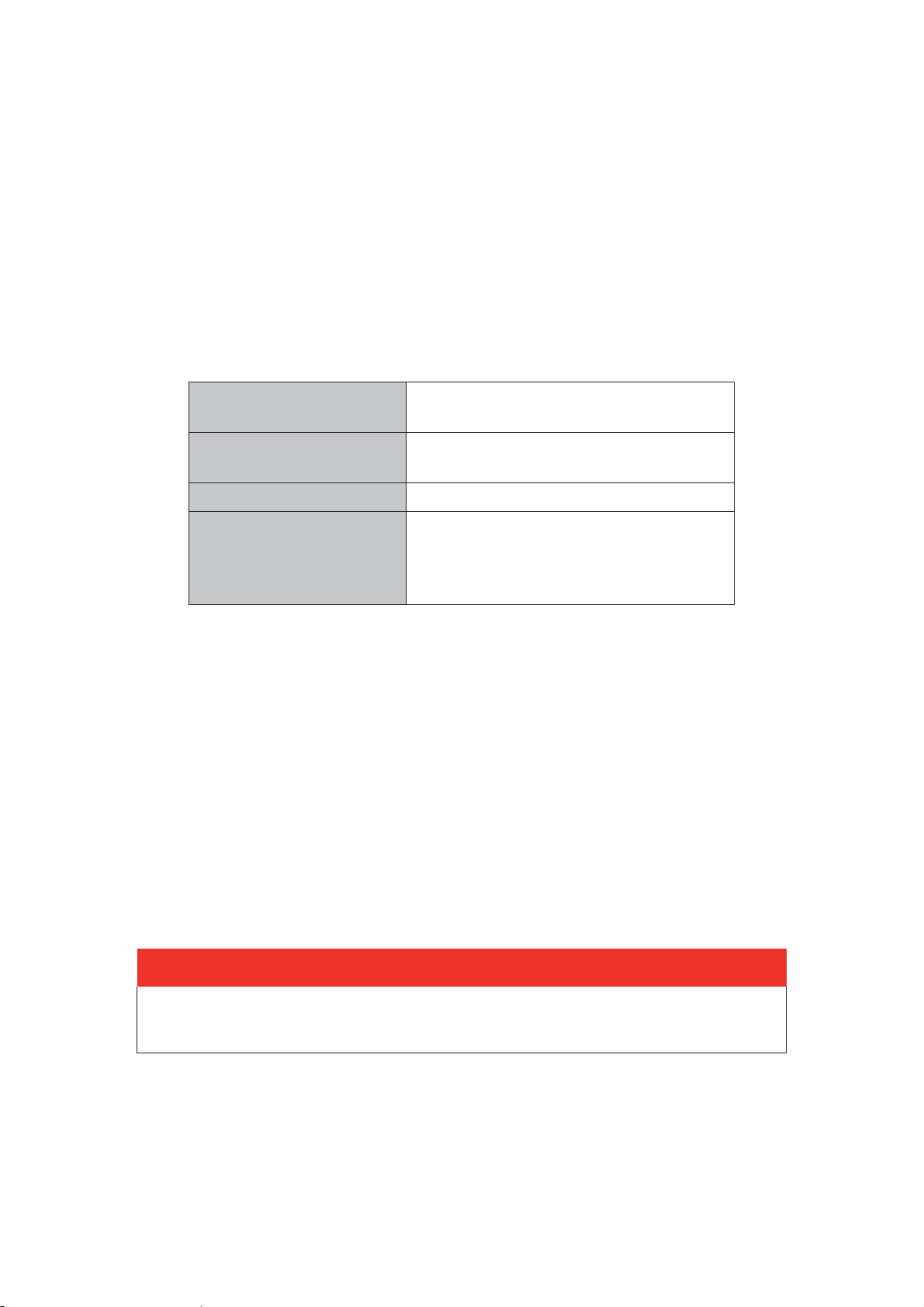

1. Turn Conveyor and Printer ON.

2. Feed stock through Printer and observe the way it is

received by the Conveyor.

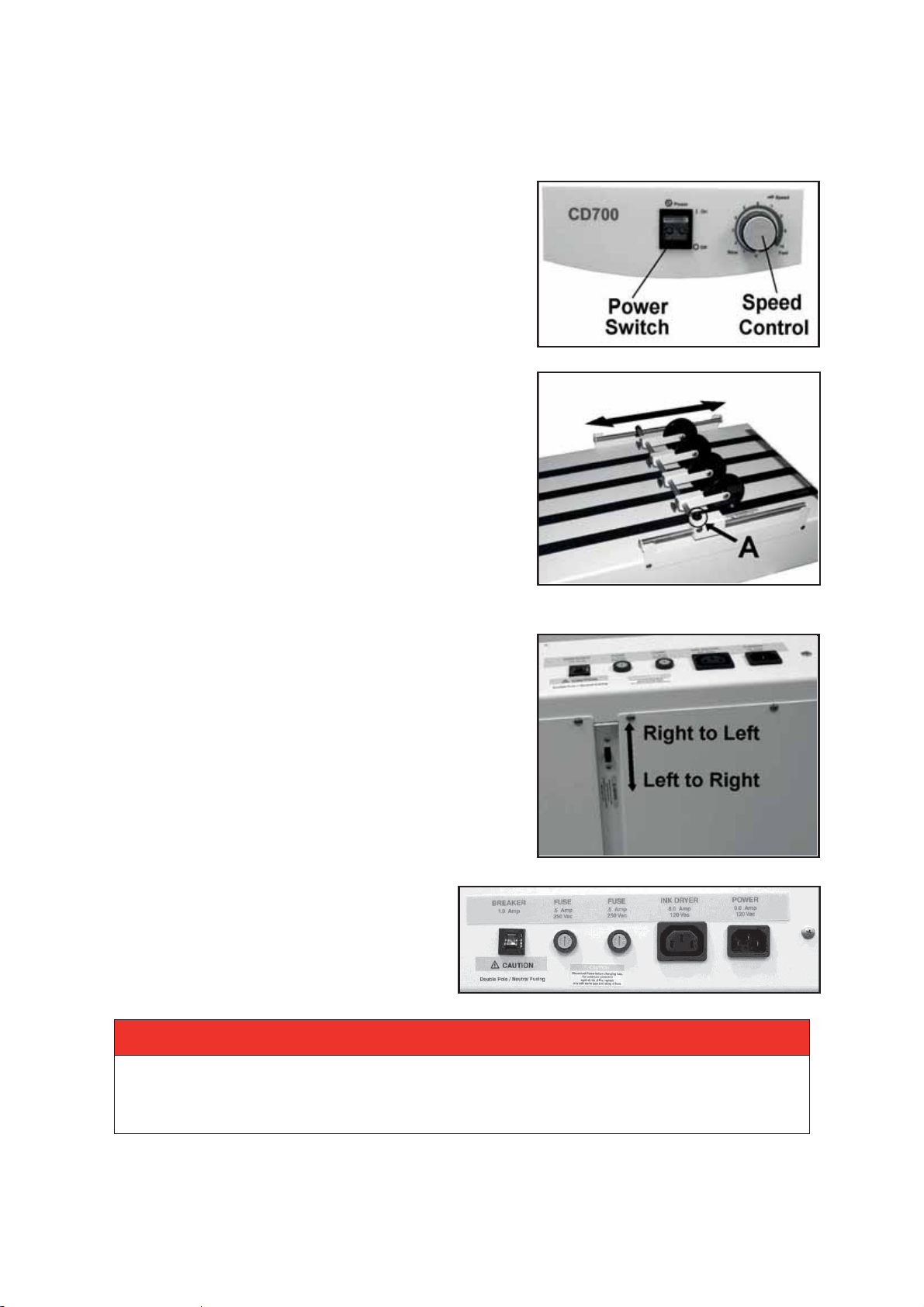

3. Loosen Locking Knob [A] and adjust Stacker

Wheels so lead edge of media just touches Stacking

Rollers as it exits the Printer.

4. Adjust Speed Control to set the amount of overlap

between the pieces. (For less overlap turn Speed

Control clockwise, for more overlap turn Speed

Control counterclockwise.)

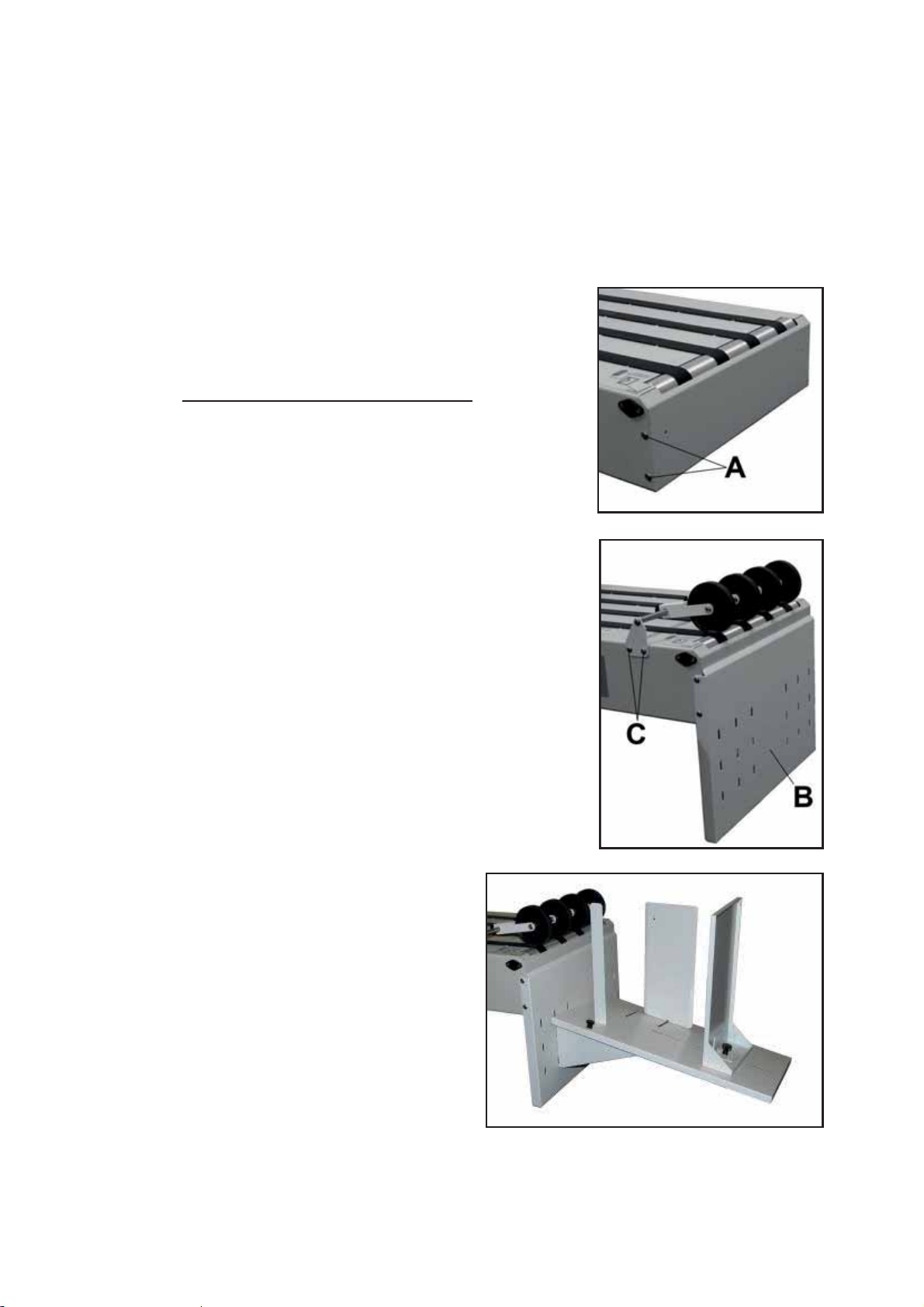

Reverse Operation

Conveyor is designed to run from right to left. It can also

operate from left to right. To switch operation direction,

first move Guide Roller Assembly and Stacking Tray to

opposite sides of the Conveyor. Then switch the

Reversing Switch (located under Conveyor) to the

reverse operating position.

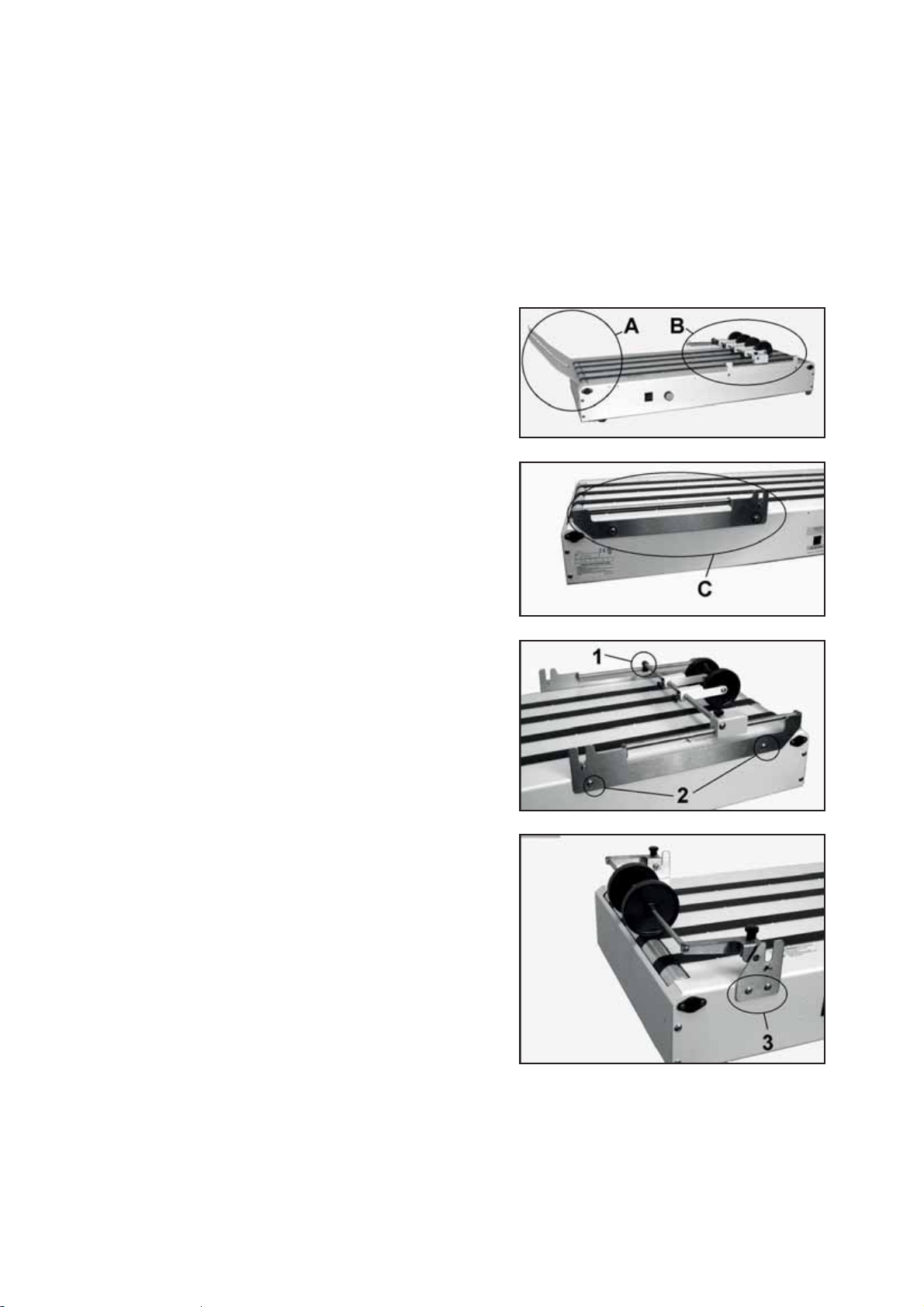

Troubleshooting

If Conveyor fails to run, check for jammed

paper between Tapes and Roller. Also, check

Fuse and Motor Circuit Breaker and replace

or reset if necessary. Fuse Holders and Circuit

Breaker located on rear of Conveyor.

ALWAYS REPLACE FUSE WITH THE SAME TYPE.

-2-

Page 6

USER GUIDE

Optional DTM-255/DTM-250 Conveyor Drop Tray Installation

DTM-255 Drop Tray is for Left-to-Right Operation. DTM-250 Drop Tray is for Right-toLeft Operation. Assemble and install Conveyor Drop Tray on exit end of Conveyor:

1. Remove two screws attaching Stacking Tray to

Conveyor and remove Tray.

2. Remove four screws [A] that mount Front Cover

Plate to Conveyor.

DO NOT remove Front Cover Plate.

3. While holding Front Cover Plate in place, install

Drop Tray Support Bracket [B] using four screws

removed in Step 2.

4. Install Media Guide Roller Assembly using four

screws supplied [C]. Mount Media Guide Roller

Assembly as shown with Rollers resting on Exit

Roller of Conveyor.

5. Install Tray Base on Drop Tray

Support Bracket.

Tray adjusts up and down to allow

stacking more or less media.

6. Remove knobs from Guides.

Assemble Guides to Tray Base as

shown. Largest Guide is the Rear Stop

Guide. Second largest Guide is

installed on non-operator's side of

Conveyor and smallest Guide is

installed on operator's side as shown.

-3-

Page 7

USER GUIDE

Optional 57E-600-10 Conveyor Leg Kit Installation

(for Use with M-Series Printers)

Install Conveyor Legs on the Conveyor to allow proper alignment with M-Series Printers.

CONTENTS OF KIT:

1. Conveyor Legs (2)

2. Screws (4)

INSTALL CONVEYOR LEGS:

1. Remove (4) Rubber Feet from bottom of Conveyor.

2. Attach Conveyor Legs across the bottom front and

rear of Conveyor using Rubber Foot holes [A] and

four screws included with Kit.

3. Reattach Rubber Feet to Conveyor Legs using

predrilled holes [B] provided.

-4-

Page 8

USER GUIDE

Optional DK-700 Dryer Kit

Dryer Kit Includes: Front Exit Roller Assembly, Guide Roller Support, Front Roller

Support, Rear Roller Support, 2 Dryer Support Shafts, 8 mounting screws

1. Before installing DK-700 Dryer Kit, remove

these parts from the CDM-700 Conveyor.

A. Stacking Tray [A] (2 screws).

B. Guide Assembly [B] (4 screws).

Remove Operator’s Side Bracket first,

then the Rear Support Bracket.

2. Install new Rear Roller Support [C] using

two screws (as shown).

3. Hook Guide Roller Support over the shaft on

Rear Roller Support [1]. Install Front Roller

Support using two screws [2] (as shown).

4. Install Front Exit Roller Assembly by

attaching mounting brackets to Conveyor

Frame (as shown) using two screws on

each side [3].

-5-

Page 9

USER GUIDE

CAUTION

DO NOT OPERATE DRYER IF BELTS ON CONVEYOR ARE NOT TURNING.

DO NOT BLOCK CONVEYOR EXIT WHEN USING DRYER.

5. Remove two Levers [4] and Bearing Washers

[5] from two Dryer Support Shafts [6]. Install

two Shaft Assemblies into holes provided in

Dryer (as shown). Reinstall Levers [4] and

Bearing Washers [5] on Shafts.

NOTE: When installing the two Levers [4],

make sure the cams on the opposite end of the

shaft are in the same position as the cams on

the Levers.

6. Dryer Assembly can now be placed in Support Brackets.

Make sure Bearing Washers are between the Support

Brackets and the cams (as shown).

NOTE: Bearing Washers should go between Support

Brackets and cams.

7. Plug cord supplied with Dryer into Dryer

receptacle, then into receptacle labeled "Dryer"

on the Conveyor. Then plug the Conveyor into

the wall outlet.

8. To operate the Dryer, set the two Levers so

media can pass under the Dryer without

interference. Then turn Dryer power switch ON.

Turn Conveyor ON.

Dryer and Guide Rollers can be adjusted from

side to side (by sliding them on Shaft

Assemblies) to accommodate varying media

sizes and print positioning.

NOTE: Dryer will not operate if Conveyor is not

turned ON.

-6-

Page 10

USER GUIDE

-7-

Page 11

PARTS CATALOG

GROUP 1 – Mechanical

9

GROUP 2 – Electrical

11

GROUP 2A – Motor Drive

13

GROUP 3 – Labels

14

GROUP 4 – Wheel Guide and Bracket Assembly

15

GROUP 5 – DT-255 Drop Tray (R-L) (Optional)

16

GROUP 5A – Rear Wheel Guide & Bracket Assembly

17

GROUP 6 – DK-700 Dryer Kit Parts (Optional)

18

PARTS INDEX

20

Parts Table of Contents

NOTE: When you see a Key number repeated in a listing,

check the voltage of your particular model:

x Voltage: 115V or 220V

-8-

Page 12

PARTS CATALOG

GROUP 1

MECHANICAL

-9-

Page 13

PARTS CATALOG

KEY

PART NO.

DESCRIPTION

QTY.

1.

57-150-08

END CAP, BODY CLOSURE

2

2.

57-100-15

DRIVE ROLLER ASSEMBLY

1

3.

123-0309

BELT, CONVEYOR DELIVERY

4

4.

123-0771

BELT, 120XL037 NEOPRENE CLASS

1

5.

123-1136

SCREW, 8-32 x 1/4 PH TRUSS HD

22

6.

57P-600-02

CONVEYOR BODY WELDMENT (115V)

1

6.

57P-610-02

CONVEYOR BODY WELDMENT (220V)

1

7.

123-0620

FOOT, #7OASHORA

4

8.

57-100-84

MOTOR ASSEMBLY

1

9.

57-150-42

MOTOR BASE

1

10.

123-0100

WASHER, 1/2 x 0.218 x 0.048 THK

4

11.

123-0237

STAR-WASHER, #10 EXTERNAL

4

12.

123-0024

SCREW, 10-32 x 3/8 PH TRUSS HD. MS ZINC

4

13.

123-1135

SCREW, 6-32 x 1/4 PH TRUSS HD.

15

14.

123-0425

NUT, HEX 4-40

2

15.

123-1105

SWITCH, S SERIES SLIDE

1

16.

123-1023

SCREW, 4-40 x 5/16 RH PH

2

17.

57-100-50

BRACKET, TRANSFORMER

1

18.

57-150-43

COVER

1

19.

123-1103

SWITCH

1

20.

57-100-17

IDLER ROLLER

3

KEY

PART NO.

DESCRIPTION

QTY.

21.

123-1104

CIRCUIT BREAKER

1

22.

123-0355

FUSE HOLDER

2

23.

57-500-01

AC OUTLET ASSEMBLY

1

24.

57-500-03

AC INLET ASSEMBLY (115V)

1

24.

57-500-21

FILTER, POWER ENTRY MODULE (220V)

1

25.

57-500-02

TRANSFORMER (115V, 60Hz)

1

25.

57-500-16

TRANSFORMER (220V, 50/60Hz)

1

26.

57-500-13

SPEED CONTROL

1

27.

123-0191

WASHER, PLAIN #6

1

28.

123-1106

RELAY

1

29.

123-1101

KNOB, PURE TOUCH

1

30.

90-103-52

BALL BEARING HOUSING ASSEMBLY

8

31.

123-0275

SCREW, 6-32 x 1/4 OVAL PH. HD.

16

32.

57-601-03

WHEEL BRACKET ASSY. (SEE GROUP 4)

1

33.

01

WHEEL GUIDE & BRACKET ASSEMBLY

(SEE GROUP 4)

1

34.

57P-601-16

RECEIVING TRAY

1

35.

123-0635*

POWER CORD (115V)

1

35.

123-0735*

POWER CORD (220V)

1

36.

57-550-25*

DECAL, POWER ENTRY 115V

1

36.

57-550-30*

DECAL, POWER ENTRY 220V

1

*

DROP TRAY KIT, RIGHT-TO-LEFT

(SEE PAGE 3) (SEE GROUP 6)

1

*

DROP TRAY KIT, LEFT-TO-RIGHT

(SEE PAGE 3) (SEE GROUP 6A)

1

*

57E

-10

CONVEYOR LEG KIT FOR USE WITH M-SERIES

PRINTERS

(SEE PAGE 4)

1

*NOT SHOWN

GROUP 1 – MECHANICAL

57-601-

DT-255

DT-250

-600

-10-

Page 14

PARTS CATALOG

GROUP 2 – ELECTRICAL

-11-

Page 15

PARTS CATALOG

KEY

PART NO.

DESCRIPTION

QTY.

1.

57-500-02

TRANSFORMER (115V, 60Hz)

1

1.

57-500-16

TRANSFORMER (220V, 50-60Hz)

1

2.

57-500-03

AC/INLET ASSEMBLY (115V)

1

2.

57-500-21

FILTER, POWER ENTRY MODULE (220V)

1

3.

57-500-01

AC/OUTLET ASSEMBLY

1

4.

123-0680

FUSE, .5A 250V (3AG) #313.500 (115V)

2

4.

123-1179

FUSE, .3A SLOW BLOW, #313.300 (220V)

2

5.

123-0355

FUSE HOLDER

2

6.

123-1104

CIRCUIT BREAKER

1

7.

57-500-04

SWITCH ASSEMBLY

1

8.

57-500-13

SPEED CONTROL ASSEMBLY

1

9.

57-550-20

INDICATOR PLATE

1

10.

123-1101

KNOB, PURE TOUCH

1

11.

123-1103

SWITCH

1

12.

123-1106

RELAY

1

13.

57-100-84

MOTOR ASSEMBLY, 24 V DC

1

14.

57-500-15

WIRE HARNESS, AC/OUTLET

1

15.

57-500-11

WIRE HARNESS, AC/OUTLET

1

16.

57-500-07

WIRE HARNESS, AC/INTLET

1

17.

57-500-10

WIRE HARNESS, FUSE

1

18.

57-500-08

WIRE HARNESS, FUSE

1

19.

57-500-05

WIRE HARNESS, FUSE

1

20.

57-500-17

WIRE HARNESS, TRANSFORMER-SPEED CONTROL

1

21.

57-500-12

WIRE HARNESS, A/C OUTLET

1

22.

57-500-06

WIRE HARNESS, A/C OUTLET

1

23.

57-500-14

WIRE HARNESS, FUSE

1

24.

57-500-09

WIRE HARNESS ASSEMBLY, MOTOR

1

GROUP 2 – ELECTRICAL

-12-

Page 16

PARTS CATALOG

KEY

PART NO.

DESCRIPTION

QTY.

1.

57-100-16

DRIVE ROLLER

1

2.

123-0036

ROLL PIN

1

3.

57-100-80

PULLEY, 12XLO

1

4.

123-0771

BELT, 120XLO31

1

5.

123-0322

SET SCREW, 8-32 x 1/4

1

6.

57-100-78

MOTOR PULLEY, 28 TEETH

1

7.

123-0017

SCREW, 10-32 x 1/4 PH TRUSS HD.

2

8.

CD-301-06

MOTOR BRACKET

1

9.

57-100-85

MOTOR

1

GROUP 2A – MOTOR DRIVE

-13-

Page 17

PARTS CATALOG

KEY

PART NO.

DESCRIPTION

QTY.

1.

57-550-25

DECAL, POWER ENTRY (115V)

1

1.

57-550-30

DECAL, POWER ENTRY (220V)

1

2.

123-1033

LABEL, CAUTION DISCONNECT POWER

1

3.

123-1115

LABEL, CAUTION/ DOUBLE POLE

1

4.

123-1962

DECAL, DATA PLATE GENERIC

1

5.

123-1121

LABEL, CAUTION REVERSE SWITCH

1

6.

123-2597

LABEL, CAUTION EXPOSED ROLLER

2

GROUP 3 – LABELS

-14-

Page 18

PARTS CATALOG

KEY

PART NO.

DESCRIPTION

QTY.

KEY

PART NO.

DESCRIPTION

QTY.

1.

57P-601-11

WHEEL BRACKET

2 9.

95-105-19

MEDIA GUIDE KNOB ASSEMBLY

4

2.

123-0017

SCREW, 10-32 x 1/4 PH TRUSS HD.

3 10.

57-601-13

FORK

4

3.

57-601-10

ROD

2 11

57P-601-05

WHEEL ASSEMBLY

4

4.

57-150-27

BRACKET

1 11.1

57-150-37

WHEEL ARM WELDMENT

4

5.

57-100-19

THUMBSCREW

1

11.2

57-100-30

WHEEL SHAFT

4

6.

57-601-06

WHEEL GUIDE SHAFT

1

11.3

CD-300-21

STACKER WHEEL

4

7.

57-100-28

SHAFT BRACKET

1

11.4

123-0017

SCREW, 10-32 x 1/4 PH TRUSS HD.

8

8.

123-0695

SPRING PIN, 3/32 x 1/2

1

GROUP 4 – WHEEL GUIDE AND BRACKET ASSEMBLY

-15-

Page 19

PARTS CATALOG

KEY

PART NO.

DESCRIPTION

QTY.

1.

123-0068

WASHER, #10 PLAIN, SS 18-8

3

2.

57P-602-04

DROP TRAY BASE

1

3.

57P-602-01

WHEEL GUIDE AND BRACKET ASSEMBLY (SEE GROUP 6B)

1

4.

29-400-16

NUT

2

5.

29-400-28

KNOB ASSEMBLY, 10-32 x 1/2

2

6.

25P-252-09

DROP TRAY PLATFORM

1

7.

25P-252-17

MEDIA GUIDE

1

8.

25P-252-20

SIDE GUIDE ASSEMBLY

1

9.

25P-252-22

STOPPER ASSEMBLY

1

10.

94-104-06

KNOB, METERING BRACKET

1

GROUP 5 – DT-255 LEFT-TO-RIGHT DROP TRAY (OPTIONAL)

-16-

Page 20

PARTS CATALOG

KEY

PART NO.

DESCRIPTION

QTY.

57P-602-01

WHEEL GUIDE AND BRACKET ASSEMBLY

1

1.

123-0017

SCREW, 10-32 x 1/4 PH TRUSS HD.

2

2.

57-602-10

WHEEL ROD

1

3.

57P-602-11

BRACKET

2

4.

57-601-13

FORK

4

5.

95-105-19

MEDIA GUIDE KNOB ASSEMBLY

4

6.

57P-601-05

WHEEL ASSEMBLY

4

6.1

123-0017

SCREW, 10-32 x 1/4 PH TRUSS HD.

8

6.2

57-100-30

WHEEL SHAFT

4

6.3

57-150-37

WHEEL ARM WELDMENT

4

6.4

CD-300-21

STACKER WHEEL

4

GROUP 5A – DT-255 REAR WHEEL GUIDE AND BRACKET

-17-

Page 21

PARTS CATALOG

GROUP 6 – DK-700 DRYER KIT PARTS (OPTIONAL)

-18-

Page 22

PARTS CATALOG

KEY

PART NO.

DESCRIPTION

QTY.

1.

123-0002

SCREW, 10-32 x 3/8 PH UNDERCUT SS

2

2.

123-0017

SCREW, 10-32 x 1/4 PH TRUSS HD.

10

3.

123-1135

SCREW, 6-32 x 1/4 PH TRUSS HD.

2

4.

123-1136

SCREW, 8-32 x 1/4 PH TRUSS HD.

8

5.

123-1986

BEARING CLIP

4

6.

123-1987

O-RING

4

7.

123-2067

SCREW, 6-32 x 5/16 SOC. HD. CAP

2

8.

123-2078

SCREW, 6-32 SOC. HD.

2

9.

20-100-38

SPACER

4

10.

24-101-11

THUMBSCREW, 10-32

2

11.

32-110-48

SPACER

6

12.

57-100-19

THUMBSCREW

1

13.

57-100-25

WHEEL GUIDE SHAFT

1

14.

57-150-27

BRACKET

1

15.

57P-601-05

WHEEL ASSEMBLY

2

15.1

123-0017

SCREW, 10-32 x 1/4 PH TRUSS HD.

4

15.2

57-100-30

WHEEL SHAFT

2

15.3

57-150-37

WHEEL ARM WELDMENT

2

15.4

CD-300-21

STACKER WHEEL

2

KEY

PART NO.

DESCRIPTION

QTY.

16.

57-601-10

WHEEL ROD

2

17.

57-601-13

FORK

4

18.

57-603-08

FRONT WHEEL BRACKET

1

19.

57-603-09

REAR WHEEL BRACKET

1

20.

57-603-12

HEIGHT ADJUSTMENT ARM

2

21.

57-603-13

HEIGHT ADJUSTMENT WHEEL

2

22.

57-603-15

WHEEL ROD

2

23.

57-603-16

STUD

2

24.

57-603-21

EXIT WHEEL ARM

1

25.

57-603-23

EXIT WHEEL BRACKET, L/H

1

26.

57-603-24

EXIT WHEEL BRACKET, R/H

1

27.

57-603-26

WHEEL ROD

1

28.

95-105-19

MEDIA GUIDE KNOB ASSEMBLY

2

29.

CD-300-21

STACKER WHEEL

2

GROUP 6 – DK-700 DRYER KIT PARTS (OPTIONAL)

-19-

Page 23

PARTS INDEX

PART NO.

GROUP

KEY

123-0002

6

1

123-0017

4

2

123-0017

2A

7

123-0017

5A

1

123-0017

5A

6.1

123-0017

6

2

123-0017

6

15.1

123-0024

1

12

123-0036

2A

2

123-0068

5

1

123-0100

1

10

123-0191

1

27

123-0237

1

11

123-0275

1

31

123-0309

1

3

123-0322

2A

5

123-0355

1

22

123-0355

2

5

123-0425

1

14

123-0620

1

7

123-0635

1

35

123-0680

2

4

123-0695

4

8

123-0735

1

35

123-0771

1

4

123-0771

2A

4

123-1023

1

16

123-1033

3

2

123-1081

1

26

123-1101

1

29

123-1101

2

10

123-1103

1

19

123-1103

2

11

123-1104

1

21

123-1104

2

6

123-1105

1

15

123-1106

1

28

123-1106

2

12

123-1115

3

3

123-1117

3

1

123-1121

3

5

123-1135

1

13

123-1135

6

3

123-1136

1

5

123-1136

6

4

123-1179

2

4

123-1962

3

4

123-1986

6

5

PART NO.

GROUP

KEY

123-1987

6

6

123-2067

6

7

123-2078

6

8

123-2597

3

6

20-100-38

6

9

24-101-11

6

10

25P-252-09

5

6

25P-252-17

5

7

25P-252-20

5

8

25P-252-22

5

9

32-110-48

6

11

29-400-16

5

4

29-400-28

5

5

57-100-15

1

2

57-100-16

2A

1

57-100-17

1

20

57-100-19

4

5

57-100-19

6

12

57-100-25

6

13

57-100-28

4

7

57-100-30

4

9.4

57-100-30

5A

6.2

57-100-30

6

15.2

57-100-50

1

17

57-100-78

2A

6

57-100-80

2A

3

57-100-84

1

8

57-100-84

2

13

57-100-85

2A

9

57-150-08

1

1

57-150-27

4

4

57-150-27

6

14

57-150-37

4

9.3

57-150-37

5A

6.3

57-150-37

6

15.3

57-150-42

1

9

57-150-43

1

18

57-500-01

1

23

57-500-01

2

3

57-500-02

1

25

57-500-02

2

1

57-500-03

1

24

57-500-03

2

2

57-500-04

2

7

57-500-05

2

19

57-500-06

2

22

57-500-07

2

16

57-500-08

2

18

PART NO.

GROUP

KEY

57-500-09

2

24

57-500-10

2

17

57-500-11

2

15

57-500-12

2

21

57-500-13

2

8

57-500-14

2

23

57-500-15

2

14

57-500-16

1

25

57-500-16

2

1

57-500-17

2

20

57-500-21

1

24

57-500-21

2

2

57-550-20

2

9

57-550-25

1

36

57-550-25

3

1

57-550-30

1

36

57-550-30

3

1

57-601-01

1

33

57-601-03

1

32

57-601-06

4

6

57-601-10

4

3

57-601-10

6

16

57-601-13

4

9.2

57-601-13

5A

4

57-601-13

6

17

57-602-10

5A

2

57-603-08

6

18

57-603-09

6

19

57-603-12

6

20

57-603-13

6

21

57-603-15

6

22

57-603-16

6

23

57-603-21

6

24

57-603-23

6

25

57-603-24

6

26

57-603-26

6

27

57E-600-10

1

--

57P-600-02

1

6

57P-601-05

4

11

57P-601-05

5A

6

57P-601-05

6

15

57P-601-11

4

1

57P-601-16

1

34

57P-602-01

5

3

57P-602-01

5A

--

57P-602-04

5

2

57P-602-04

5A

2

57P-610-02

1

6

-20-

Page 24

PARTS INDEX

90-103-52

1

30

94-104-06

5

10

95-105-19

4

9.1

95-105-19

5A

5

95-105-19

6

28

CD-300-21

4

9.5

CD-300-21

5A

6.4

CD-300-21

6

15.4

CD-300-21

6

29

CD-301-06

2A

8

DT-250

1

--

DT-255

1

--

DT-255

5

--

-21-

Page 25

Page 26

Copyright © 2017 Astro Machine Corporation

07

/2017

Part Number: 200-CD700 Rev F

Elk Grove Village, Illinois 600

01/16

Loading...

Loading...