Page 1

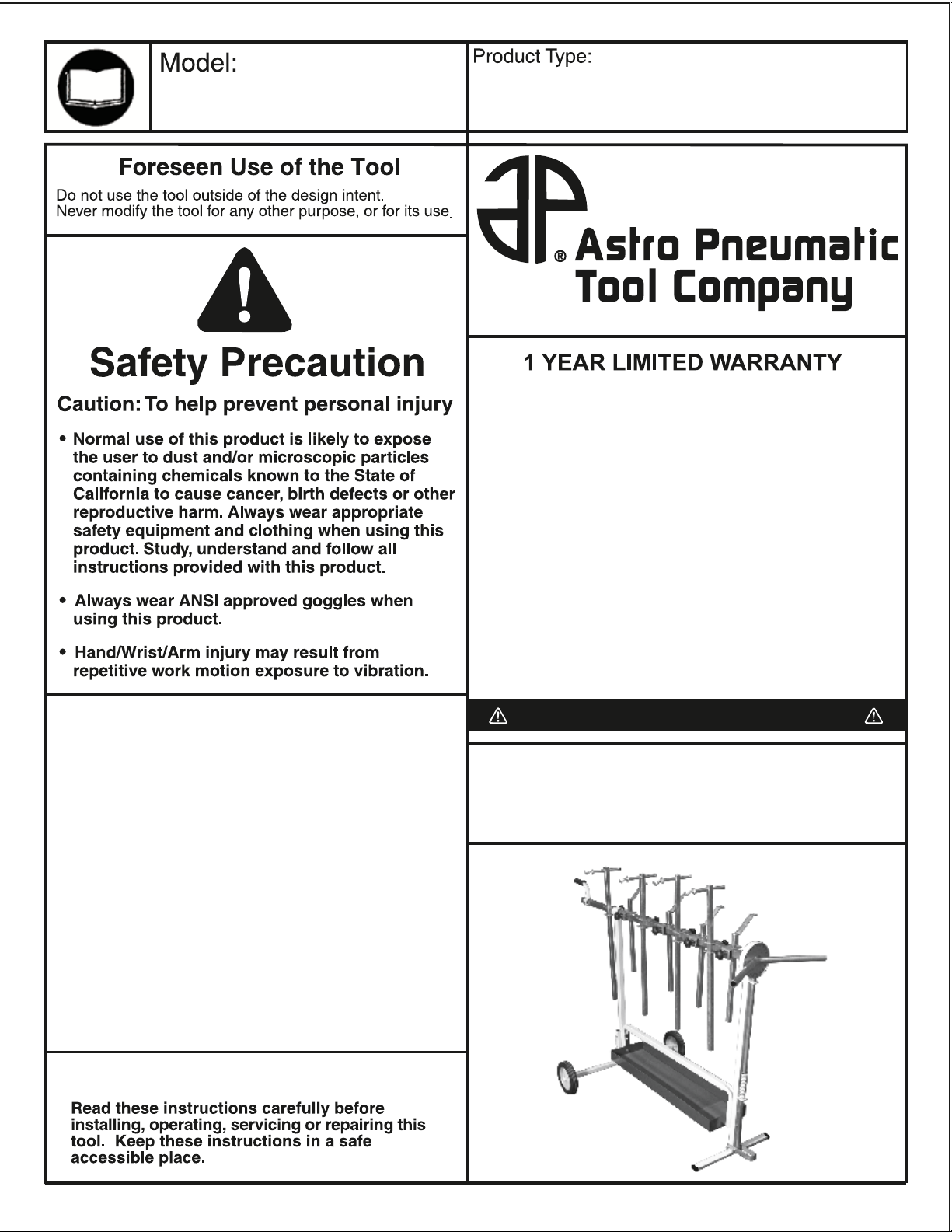

Super Stand

page 1

7300

- Universal Rotating Parts Work Stand

www.astrotools.com

Astro Pneumatic Tool Co. warrants our products to the original user against defective

material or workmanship for a period of 1 year from the date of 1st use. Astro

reserves the right to determine whether the product failed because of defective

material, workmanship or other causes and to charge back for missing parts. Astro

Pneumatic Tool Co., at its discretion, will repair products covered under this warranty

free of charge. The original user is to return the product (with the exceptions listed

below) with the distributor’s name, address, adequate proof of date of purchase or a

copy of warranty card, and a short note explaining the problem. Failures caused by

accident, alteration, or misuse are not covered by this warranty.

Astro Pneumatic Tool Co. or its authorized service representatives must per form all

warrant y repairs. Any repair to the product by unauthorized service representatives

voids this warranty. The rights under this warranty are limited to the original user and

may not be transferred to subsequent owners.

This warranty is in lieu of all other warranties, expressed or implied, including

warranties of merchantability and fitness for a particular purpose. Some states do not

allow the exclusion of limitations of incidental or consequential damages so the above

limitations may not apply to you. All claims must be sent to:

Astro Pneumatic Tool Company

P.O. Box 251935

Los Angeles, CA 90025

Product Information

The Universal Astro Super Stand can

•

handle any panel, fender, door, hood, or

bumper to make repairs and refinishing easy

The Astro Super Stand comes with 8

•

adjustable bars to fit almost any panel

securely

The Astro Super Stands portability allows

•

for fast and easy moving of the part from the

prep. station to the spray booth

The Astro Super Stand's unique design

•

allows for single handed rotation of panels

350 degrees in 16 degree increments

Weight capacity: 200lbs

•

Important

PLEASE DO NOT RETURN ANY PRODUCT TO THE P.O. BOX.

CALL 1-800-221-9705 FOR INSTRUCTIONS.

Unpacking

When unpacking, check the parts diagram and part number

listing on page 3 to make sure all parts are included. If any

parts are missing or damaged, please call your distributor.

Page 2

Super Stand

page 2

7300

- Universal Rotating Parts Work Stand

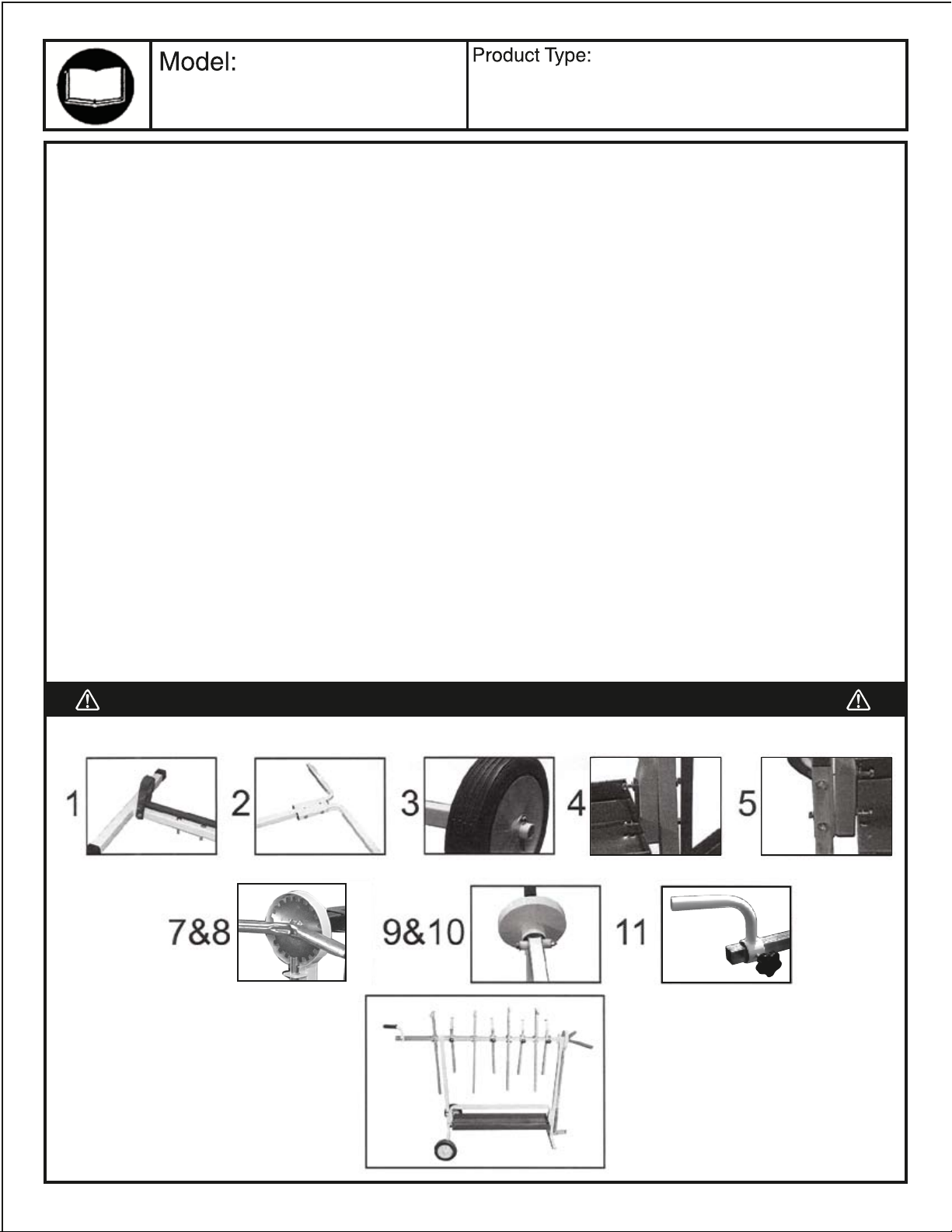

7300 Assembly Instructions

PRIOR TO BEGINNING ASSEMBLY COMPARE PARTS TO PARTS LIST TO ASSURE THAT ALL PARTS ARE INCLUDED.

1) Attach pedal on front brace (#9) with nut (#9E) & bolt (#9D) to the bottom of the front brace.

Completely secure nuts & bolts. Remove temporary bolt at top of front brace and discard.

2) Align the holes on the wheel poles (#12) to the holes of the rear brace (#11). Attach the wheel poles to rear brace

with bolts (#11A), washers (#9C) and nuts (#9B). Completely secure nuts & bolts.

3) Attach wheels (#13) to wheel pole (#12). Position the wheels and large washer (#15) onto the

wheel pole (#12) and secure into place by inserting cotter pin (#14) into predrilled holes in the wheel pole.

Slightly spread ends of cotter pins to assure wheels will not fall off wheel pole.

4) Align the holes on the fixed pole, the holes on the brackets of the tray and the holes on the front brace (#9).

Attach with bolts (#9A), washers (#9C) and nuts (#9B). Do not completely secure.

5) Attach the rear brace (#11) to the fixed pole (#10) and tray (#16) by repeating procedure in step 4.

6) Completely secure nuts & bolts used in steps 4 and 5.

7) Press down pedal and insert the adjustable gear wheel (#5) into the hole at the top of the front brace

(#9) assuring that the predrilled hole on the adjustable gear wheel is facing up.

8) Insert stand pole (#6) onto the adjustable gear wheel (#5).

9) Insert stand pole (#6) through hole of rear brace (#11) and onto stand extension pole (#7).

Secure stand extension pole to stand pole by tightening screw (#7A) on extension.

10) Align the holes of the adjustable gear wheel (#5), stand pole (#6), plastic bushing (#6C), and washer

(#6B) and completely secure with nut (#6D) & bolt (#6A).

11) Handle (#8) to be used for moving stand for storage only.

Do not use to move stand while parts are mounted on stand.

NOTE: When mounting parts onto "Super Stand" select the appropriate suspend arm (#1) or prop arm (#2) for the job.

Do not begin work until you have checked and assured that parts are securely mounted onto "Super Stand"

ALWAYS WEAR ANSI APPROVED SAFETY GLASSES AND CLOTHING WHEN USING THIS UNIT.

Page 3

7300

page 3

Super Stand

- Universal Rotating Parts Work Stand

6B

6D

6C

6A

9B

9C

11A

9C

7A

9C

9C

9C

9B

9A

4

9A, 9B, 9C

9D, 9E

9G

9H

9F

7300-01

7300-02

7300-03

7300-04

7300-05

7300-06

7300-6A

7300-6B

7300-6C

7300-6D

7300-07

Suspend Arm

Prop Arm

Buckle

Knob

Adjustable Gear Wheel

Stand Pole

Stand Bolt

Stand Washer

Plastic Bushing

Stand Nut

Stand Extension Pole

4

4

8

9

1

1

1

2

1

1

1

7300-7A

7300-08

7300-09

7300-9A

7300-9B

7300-9C

7300-9D

7300-9E

7300-9F

7300-9G

7300-9H

Bolt

Handle

Front Brace

3” Bolt

Nut

Washer

Pedal Bolt

Pedal Nut

Pedal

Front Bar

Front Spring

12

1

1

1

4

6

2

2

1

1

1

7300-10

7300-11

7300-11A

7300-12

7300-13

7300-14

7300-15

7300-16

Fixed Pole

Rear Brace

3 1/2” Rear Brace Bolt

Wheel Pole

Wheel

Cotter Pin

Large Washer

Tray

1

1

2

2

2

2

2

1

Page 4

Super Stand

page 4

7300

PART MOUNTING

INSTRUCTIONS FOR

MODEL 7300

Due to the universal nature of this unit and its

capabilities to mount many types of

automobile parts, mounting instructions must

be given in a general manner. When

mounting any part you must first determine

what would be the safest way to secure the

automobile part to the Part Stand.

1)

Begin by examining the specific part that

is being mounted and look for holes on the

partthat will allow the Suspend Arm (part

#1) or Prop Arm (part #2) to be inserted

into.

Hints:

•

Select holes that are as close to the size of

the hook/straight mount for best support.

•

Select holes at the furthest point on the part

being mounted for better support.

•

Suspend Arm and/or Prop Arm can be set

at an angled position for wider range and

support.

•

Suspend Arms and Prop Arms can be used

separately or in conjunction.

•

Suspend Arms have hook on one side and

straight mount on opposite side. Depending

on size of hole selected to mount part,

select which will secure part best.

•

Prop Arms have holes at the end which can

be used to secure part being mounted. If

part being mounted has a lip/tab with hole,

align the hole on the Prop Arm with the hole

on the lip/tab and secure by using a nut &

bolt (not included).

- Universal Rotating Parts Work Stand

MOUNTING SOLUTIONS

BUMPER

DOOR

HOOD

Begin mounting process by deciding length

2)

necessary for Suspend Arm/Prop Arm.

Secure Suspend Arm/Prop Arm into place

by tightening knobs.

Mount part onto Suspend Arm/Prop Arm.

3)

Before proceeding to next step, assure that

part is secure and weight is well distributed

and will not cause stand to tip over.

Next, mount bottom of part to Suspend

4)

Arm/Prop Arm. Follow instructions in step 1.

Assure that part is mounted securely. Test

5)

by slowly rotating part.

FURTHER ASSISTANCE PLEASE

CONTACT YOUR NEAREST DISTRIBUTOR, OR

ASTRO PNEUMATIC TOOL COMPANY AT

IF YOU NEED

(800)221-9705.

CHROME

Loading...

Loading...