Page 1

5820

ENGINE TRANSVERSE BAR

WITH SUPPORT ARM

www.astrotools.com

• Makes removal of transaxle easy by supporting

engine of front wheel drive vehicles

• Support Arm provides three point support

for off-center loads

• Includes 1/8" braided steel cables and

14" adjustable hooks

• Capacity: 700lbs.

• Weight: 21 lbs.

•Astro Pneumatic Tool Co. warrants our products to the original user against

defective material or workmanship for a period of 1 year (except where noted on our

price schedule) from the date of 1st use. Astro reserves the right to determine

whether the product failed because of defective material, workmanship or other

causes and to charge back for missing parts. Astro Pneumatic Tool Co., at its

discretion, will repair products covered under this warranty free of charge. The

distributor should direct the original user to return the product (with the exceptions

listed below) with the distributor’s name, address, adequate proof of date of

purchase or a copy of warranty card, and a short note explaining the problem.

Failures caused by accident, alteration, or misuse are not covered by this

warranty.

•Astro Pneumatic Tool Co. or its authorized service representatives must perform all

warranty repairs. Any repair to the product by unauthorized service representatives

voids this warranty. The rights under this warranty are limited to the original user and

may not be transferred to subsequent owners.

•This warranty is in lieu of all other warranties, expressed or implied, including

warranties of merchantability and fitness for a particular purpose. Some states do

not allow the exclusion of limitations of incidental or consequential damages so the

above limitations may not apply to you. All claims must be sent to:

Astro Pneumatic Tool Company

372 Old US Highway 52 South

Mt. Airy, NC 27030

1 YEAR LIMITED WARRANTY

PLEASE DO NOT RETURN ANY PRODUCT WITHOUT CALLING

1-800-221- 9705 FOR INSTRUCTIONS

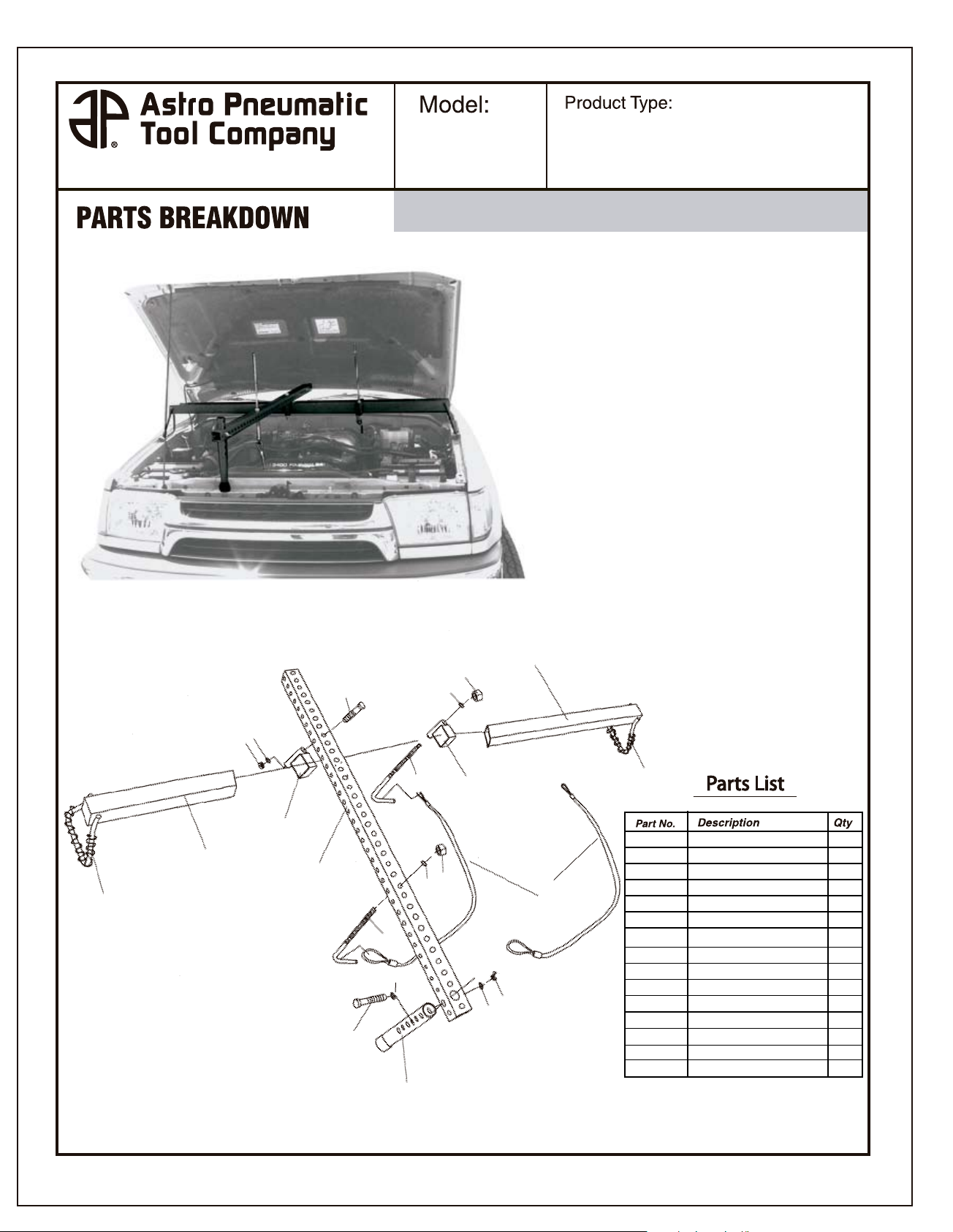

Unpacking

When unpacking, check the parts diagram and part number listing

on page 2 to make sure all parts are included. If any parts are

missing or damage, please call your distributor.

WARNING

For Your Safety & To Prevent Injury

1. ALWAYS read, understand and follow all safety warnings and instructions

included with this unit to avoid property damage and/or injury to self and others.

2. ALWAYS use Third Arm Support when using this unit.

3. ALWAYS test lip structure strength to assure adequate support prior to using this

unit. The lip structure surface must be flat in order to prevent slippage of this unit.

4. ALWAYS eliminate sagging of engine/transaxle by tightening nut on top of “J” hook

after positioning cables/or “J” hook.

5. NEVER overload. Maximum rated capacity is 700lbs. Overloading can cause

property damage and/or personal injury.

6. NEVER use this unit for purposes other than its intended design. This unit

designed to be used as engine support bar when a transverse axle or transmission

is being worked on or removed.

7. NEVER permit any body part to be under a load suspended by lifting or support

device. Accidental slippage of a lifting or support device can result in property

damage and/or personal injury.

ENGINE TRANSVERSE BAR WITH SUPPORT ARM

Page 2

372 Old US Highway 52 South

Mount Airy, NC 27030

(2)

(2)

(1)

(3)

(5)

(4)

5820-A09*

(5)

ENGINE TRANSVERSE BAR

5820

Call 1.800.221.9705 for questions concerning performance of the product

or other inquiries.

(3)

(1)

5820-A12*

5820-A13*

5820-A02

WITH SUPPORT ARM

OPERATING INSTRUCTIONS

1. Test lip structure (Fig. 1) strength to assure

adequate support prior to using this unit.

The lip structure surface must be flat in

order to prevent slippage of this unit. Mount

the Transverse Support Bar with Support Arm

on the area of the lip structure that is strongest.

2. Loosen the cap screw (Fig. 2) on the slide

for adjustment.

3. To line up “J” hook (Fig. 3) with the engine bracket

slide and/or pivot the arm into position.

4. The leg (Fig. 4) of the Third Arm Support must be

on a solid surface at the front of the vehicle. Wing

nut and cap screw can be removed to adjust the

height of the leg into a leveled position.

5. Attach the engine to the Engine Transverse

Bar. Hook the “J” hooks through the

engine bracket. When no lifting eye

is available, place the 1/8" braided

steel cable (Fig. 5) around the

engine and attach to the “J” hook.

If the engine sags once attached

to the Engine Transverse Bar,

adjust the “J” hooks.

5820-A14

5820-A12*

5820-A13*

5820-A01

5820-A06

5820-A03

5820-A10*

5820-A08

5820-A13*

5820-A04

5820-A08

5820-A12*

5820-A13*

5820-A07

5820-A11*

5820-A13*

5820-A14

5820-A01

5820-A02

5820-A05

* Please note that Part numbers with an asterisk

5820-A09*, 5820-A10*, 5820-A11*, 5820-A12*, 5820-A13*

are only available in the Hardware Kit 5820-AHK

and Not sold separately.

5820-A03

5820-A04

5820-A05

5820-A06

5820-A07

5820-A08

5820-A09*

5820-A10*

5820-A11*

5820-A12*

5820-A13*

5820-A14

5820-AHK

Support Arm (Left)

Support Arm (Right)

Support Arm (Middle)

Leg

Sling

Big Slider

Small Slider

“J” Hook

Cap Screw(M10x110mm)

Cap Screw(M10x50mm)

Wing Nut(M10)

Hex Nut(M10)

Washer(For M10 Bolt)

Protection Plastic Bar

Hardware Kit (A09-A13)

1

1

1

1

2

1

1

2

1

1

1

3

5

2

1

Page 2

Loading...

Loading...