Page 1

4550

AIR OPERATED PAINT SHAKER

www.astrotools.com

Astro Pneumatic Tool Co. warrants our products to the original user against defective

material or workmanship for a period of 1 year from the date of 1st use. Astro

reserves the right to determine whether the product failed because of defective

material, workmanship or other causes and to charge back for missing parts. Astro

Pneumatic Tool Co., at its discretion, will repair products covered under this warrant y

free of charge. The original user is to return the product (with the exceptions listed

below) with the distributor’s name, address, adequate proof of date of purchase or a

copy of warranty card, and a short note explaining the problem. Failures caused by

accident, alteration, or misuse are not covered by this warranty.

Astro Pneumatic Tool Co. or its authorized service representatives must per form all

warrant y repairs. Any repair to the product by unauthorized service representatives

voids this warranty. The rights under this warranty are limited to the original user and

may not be transferred to subsequent owners.

This warranty is in lieu of all other warranties, expressed or implied, including

warranties of merchantability and fitness for a particular purpose. Some states do not

allow the exclusion of limitations of incidental or consequential damages so the above

limitations may not apply to you. All claims must be sent to:

Astro Pneumatic Tool Company

P.O. Box 251935

Los Angeles, CA 90025

Product Information

• Heavy duty construction

• Compact design

• Rubber coated clamps will accommodate

Pints Quarts and Gallons

• Quieter and faster operation

• Includes oiler

SPECIFICATIONS:

• Capacity:

• Air Consumption:

• Air Inlet:

• Speed:

• Operating Pressure Ranges:

• Shaking Time:

• Shaking Distance:

Important

8.45Pint (1.06 Gallon)

1.35 CFM

1/4" NPT

1400 Cycles/Min.

90 to 120 PSI at Inlet

1.5 Min.

85~90mm

PLEASE DO NOT RETURN ANY PRODUCT TO THE P.O. BOX.

CALL 1-800-221-9705 FOR INSTRUCTIONS.

Unpacking

When unpacking, check the parts diagram and part number

listing on page 3 to make sure all parts are included. If any

parts are missing or damaged, please call your distributor.

AIR OPERATED PAINT SHAKER

Also Available:

#4551Paint Shaker Stand

Page 2

4550

MAINTENANCE INSTRUCTION:

1.) LUBRICATION:

Oil paint shaker with 2 - 3 drops of air tool oil once every 3 weeks if there

is no moisture in air line or air supply. If moisture in air line or air

supply exists, use 2 - 3 drops or air tool oil, daily. DO NOT OVER OIL.

2.) TIGHTNESS OF PARTS:

Regularly check whether all connection parts are fastened securely.

Follow this procedure daily before beginning work.

3.) STORAGE:

Avoid storing the tool in a location subject to high humidity. If the tool is

left unused, the residual moisture inside the tool can cause rust. Before

storing and after operation, oil the tool at the air inlet with spindle oil and

run it for a short period.

4.) DISPOSAL:

Follow national legislation of waste disposal. Never drop into fire.

5.) ORDERING SERVICE PART:

For further operational and handling information or for replacement of

parts and components, contact the sales agent from where you purchased

the tool, or the service division of our company. *When ordering parts and

components, give each part number, name and quantities.

OPERATION INSTRUCTION:

1.) Before operating

use caution not to crush can.

2.) To start shaker: Open On/Off control valve.

3.) IMPORTANT: NOT FOR USE WITH AEROSOL CANS

4.) Recommended air pressure 90 to 120 psi at inlet

shaker, clamp can securely and

AIR OPERATED PAINT SHAKER

1) The tool shall not be used in potentially explosive atmospheres.

2) Disconnect the air hose before changing or adjusting any inserted tools.

3) Before using tool, please confirm all couplings and plugs are

fixed securely. Air hose that is under pressure may lash out when

disconnected and could lead to serious injuries.

4) Prevent loose clothes, long hair or any other personal accessories from

coming close to moving parts to reduce the risk of being injured.

5) Excessive high air pressure, that exceeds the maximum pressure,

may cause injuries to user.

6) Exposure to strong vibration for extended time may cause harm to operator.

7) Slip/Trip/Fall is a major reason of serious injury or death.

Beware of excess hose left on the walking or work surface.

9) Wearing correct breathing protection will help avoid inhaling dust or

handling debris from work process that can be harmful to your health.

10) High sound level can cause permanent hearing loss.

Use hearing protection while operating tool.

11) Be aware of work surface dangers prior to beginning work.

It is recommended that shaker is installed a minimum of 2’-3’ from

other objects that could lead to damage or injury if shaker comes in contact.

12) This power tool is not insulated. If contact is made with an

electric current, injury may occur.

13) Dust created by sanding, sawing, grinding, drilling and other related activities

may expose the user to dust and/or microscopic particles that may contain

chemicals known to the State of California to cause cancer, birth defects or

other reproductive harm.

14) Not for use with aerosol cans.

Users of this tool should review the chemical composition of the work

surface and any products used in conjunction with the operation of this tool

for any such chemicals prior to engaging in any activity that creates dust

and/or microscopic particles.

Users should obtain the Material Safety Data Sheets for all identified

chemicals, either from the manufacturer or their employer, and proceed to

study, understand, and follow all instructions and warnings for exposure

to such chemicals.

Some examples of these chemical are: lead from lead based paints;

crystalline silica from bricks, cement and other masonry products;

and arsenic and chromium from chemically treated lumber.

A listing of the chemicals can be obtained at www.oehha.ca.gov

under Proposition 65.

In order to reduce their exposure to such chemicals users should always:

- work in well-ventilated areas .

- wear appropriate safety equipment and clothes that are specifically

designed to filter out microscopic particles

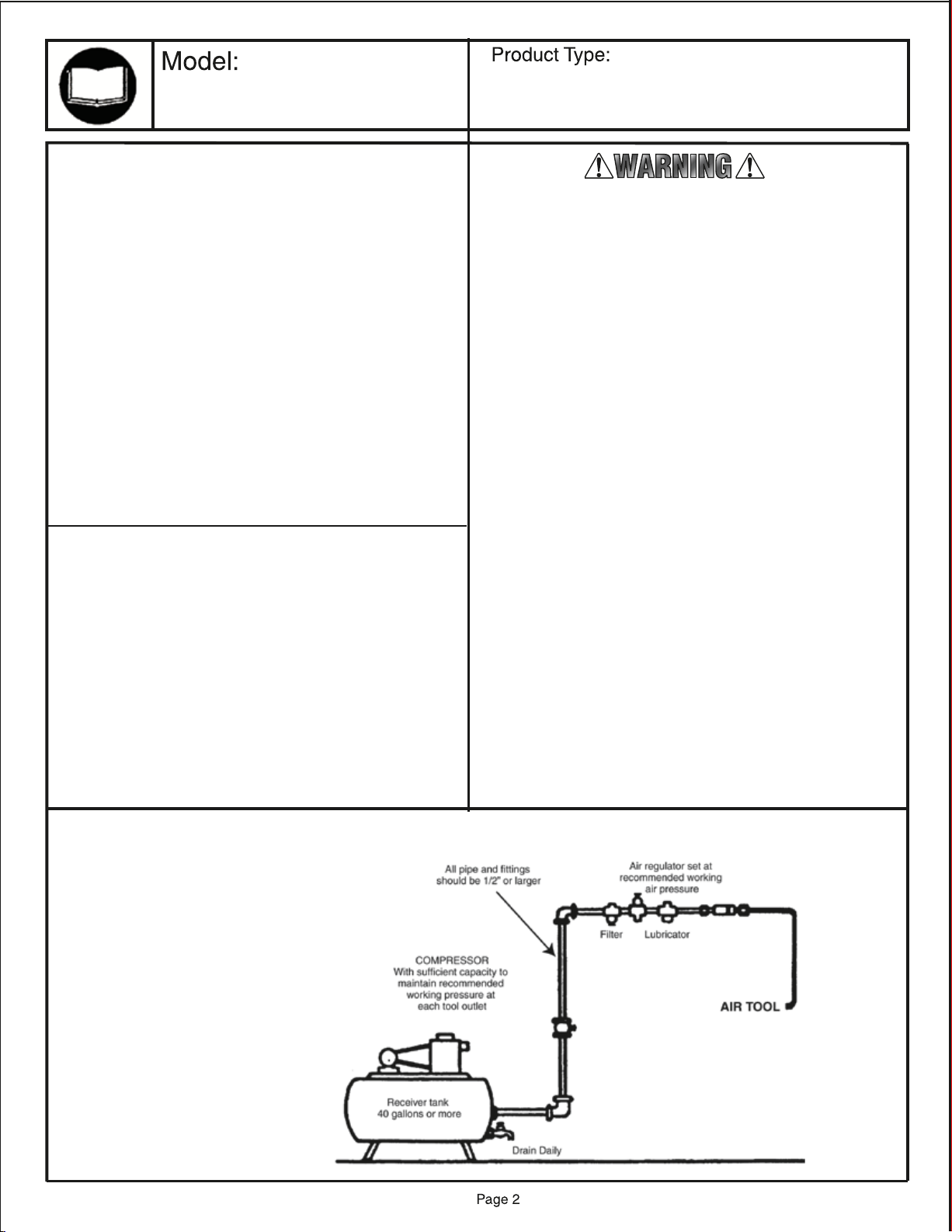

SUGGESTED AIR LINE CONNECTION

Page 3

372 Old US Highway 52 South

Mount A iry, NC 27030

50

44

52

48

45

47

57

46

4

58

AIR OPERATED PAINT SHAKER

4550

Call 1.800.221.9705 for questions concerning performance of the product

or other inquiries.

56

54

51

55

53

49

43

42

8

10

12

13

15

17

16

15

14

28

29

37

36

30

11

18

9

19

41

23

6

24

25

26

21

39

40

39

38

31

32

33

34

33

32

35

22

20

3

2

27

1

4550-A01

4550-A02

4550-A03

4550-A04

4550-A05

4550-A06

4550-A07

4550-A08

4550-A09

4550-A10

4550-A11

4550-A12

4550-A13

4550-A14

4550-A15

35

Safety Valve

Oil Gage

Pipe Joint

Safety Guard

Collar

Cap Nut

Plate

Oil Collar

Oil Collar

Screw Shaft

Driven Shaft

Spring Washer

Nut (1/2" - 12)

Oil Cup

Retaining Ring

7

4550-A16

1

4550-A17

1

1

4550-A18

4550-A19

1

4550-A20

3

4550-A21

1

4550-A22

1

4550-A23

1

4550-A24

1

4550-A25

1

4550-A26

1

4550-A27

1

4550-A28

1

4550-A29

1

4550-A30

2

5

Washer

Shaft

Bearing

Cylinder Drive Shaft

Cylinder

Oil Seal

Oil Collar

Piston

O-Ring (40.64 x 5.34)

Piston Washer

Screw Bolt

Cylinder Washer

Valve Casing

O-Ring (40.8 x 1.85)

Valve Seat

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

4550-A31

4550-A32

4550-A33

4550-A34

4550-A35

4550-A36

4550-A37

4550-A38

4550-A39

4550-A40

4550-A41

4550-A42

4550-A43

4550-A44

4550-A45

Screw Bolt

Washer

Vibration Washer

Screw Bolt

Nut (3/8" - 16)

Screw Bolt

Valve Washer

Pipe Joint (90 )

Pipe Clip

Pipe

Screw Bolt

Washer

U-Bolt

Nut (3/8" - 16)

Screw Base

4550-A46

3

4550-A47

2

4550-A48

2

4550-A49

1

4550-A50

5

4550-A51

1

4550-A52

1

4550-A53

1

4550-A54

2

4550-A55

1

4550-A56

1

4550-A57

1

1

4550-A58

Screw Base

Screw Bolt

Nut (M10)

Screw Hand

Screw Base

Washer

Support Base

Hand Wheel

Spring Pin

Spring Pin

Oil-Paint Base

Screw Bolt

Washer

1

4

4

1

1

1

1

1

1

1

2

3

6

2

1

3

Loading...

Loading...