Page 1

3025

• Normal use of this product is likely to expose

the user to dust and/or microscopic particles

containing chemicals known to the State of

California to cause cancer, birth defects or other

reproductive harm. Always wear appropriate

safety equipment and clothing when using this

product. Study, understand and follow all

instructions provided with this product.

6“ Finishing Palm Sander

2

• Always wear ANSI approved goggles when

using this product.

• Hand/Wrist/Arm injury may result from

repetitive work motion exposure to vibration.

Cautions for Use

1.) This tool is intended for polishing and sanding with all types

of movement e.g. rotary, orbital and reciprocating,

using coated abrasive product and bonnets of

various soft materials and endless belts.

Any other use is forbidden.

2.)

Only use the polishing and sanding pads as recommended

by the pad manufacturer.

3.) It is forbidden to use the grinding wheels and

cut-off wheels on this tool.

4.)

Ensure the max. operating speed of the pad is higher

than the rated speed of the poser tool.

5.)

Centrally adhere sanding disc to support pad.

6.)

Always wear ANSI approved ear protection and

safety glasses when using this tool. Gloves and protective

clothing are recommended.

7.) Personal protection and dust collection devices shall

be chosen according to the material being worked upon.

Please consult provider of such devices.

8.) Release the start and stop device in case of failure

of energy supply.

9.) Only use the lubricant recommended by the manufacturer

6“ Finishing Palm Sander

Page 1

Page 2

3025

6“ Finishing Palm Sander

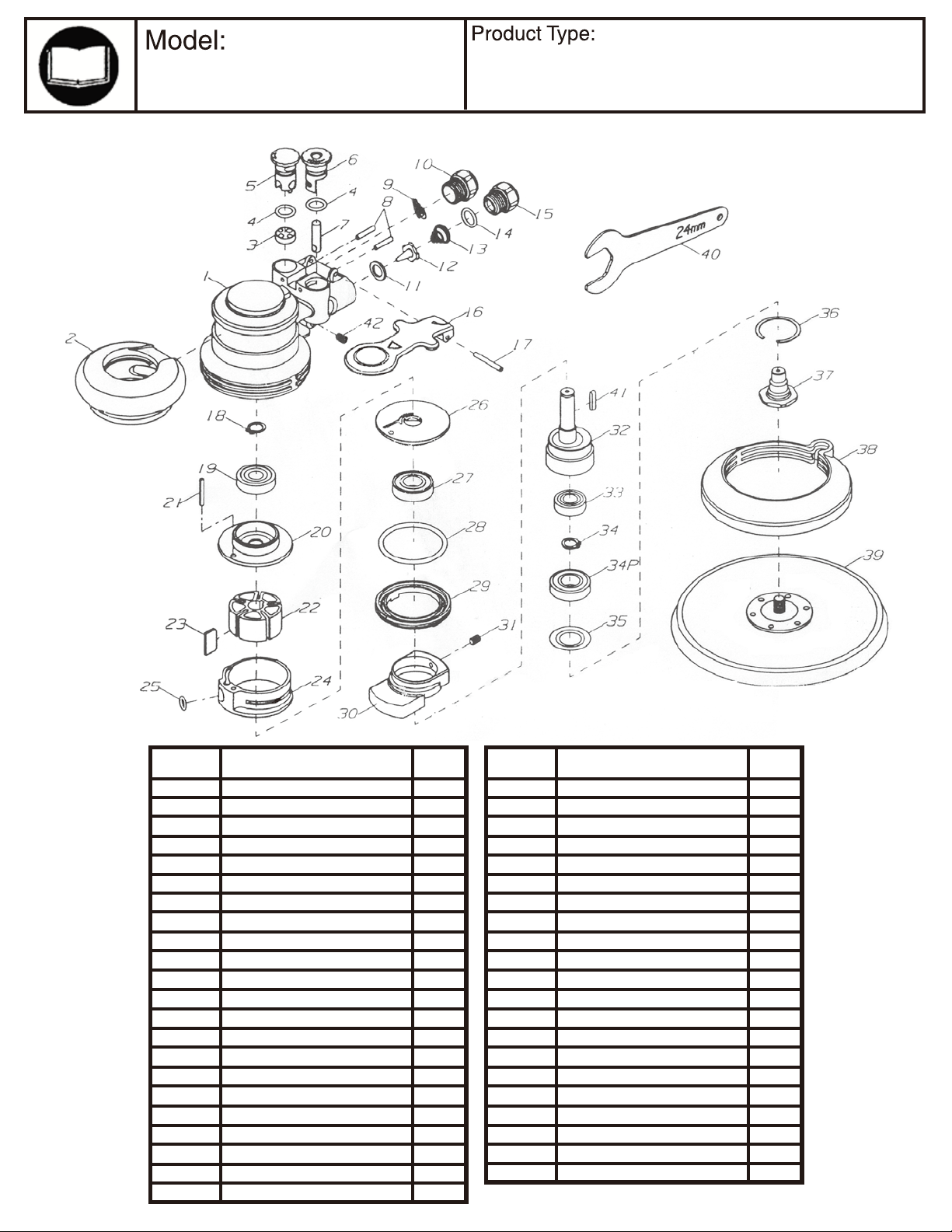

PART

NO.

3025-01

3025-02

3025-03

3025-04

3025-05

3025-06

3025-07

3025-08

3025-09

3025-10

3025-11

3025-12

3025-13

3025-14

3025-15

3025-16

3025-17

3025-18

3025-19

3025-20

3025-21

3025-22

DESCRIPTION

Housing

Housing Cover

Washer

O-Ring

Regulator

Regulator

Valve Stem

Pin

Muffler

Exhaust Deflector

Spacer

Controller

Spring

O-Ring

Air Inlet

Lever

Pin

Retaining Ring

Ball Bearing

Rear Plate

Pin

Rotor

QTY.

1

1

1

2

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Page 2

PART

NO.

3025-23

3025-24

3025-25

3025-26

3025-27

3025-28

3025-29

3025-30

3025-31

3025-32

3025-33

3025-34

3025-34P

3025-35

3025-36

3025-37

3025-38

3025-39

3025-40

3025-41

3025-42

DESCRIPTION

Rotor Blade

Cylinder

O-Ring

Front Plate

Ball Bearing

O-Ring

Motor Cover

Balance

Set Screw

Rotor Shaft

Ball Bearing

Retaining Ring

Ball Bearing

Washer

Retaining Ring

Drive Spindle

Pad Cover

6” Pad

Wrench

Key

Set Screw

QTY.

5

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Page 3

3025

Maintenance instruction:

1)Lubrication:

Before connecting the hose, apply 4 to 5 drops of

#60 spindle oil at the air inlet. After 3 to 4 hours

of operation, oiling may be necessary again.

2)Tightness of parts:

Regularly check whether all connecting parts are

fastened securely. Follow this procedure daily

before beginning work.

3)Cleanness:

Dust may accumulate around spindle inside

shield. It is recommended to remove

the dust on daily basis.

4)Storage:

Avoid storing the tool in a location subject to high

humidity. If the tool is left unused, the residual

moisture inside the tool can cause rust. Before

storing and after operation, oil the tool at the air

inlet with spindle oil and run it for a short period.

5)Disposal:

Follow national legislation of Waste disposal. Never

drop into fire.

6)Ordering service part:

For further operational and handling information or

for replacement of parts and components, contact the

sales agent from whereyou purchased the tool, or the

service division of our company.

In ordering parts and components, give each part

*

number, name and quantities.

6“ Finishing Palm Sander

8) Slip/Trip/Fall is a major reason of serious injury or death.

Beware of excess hose left on the walking or work surface.

9) Wearing eye/face protector could reduce the danger to

person from high speed splinters being emitted from the

tool or work surface.

10) Wearing correct breathing protection will help avoid

inhaling dust or handling debris form work process that

can be harmful to your health.

12) High sound level can cause permanent hearing loss.

Use hearing protection while operating tool.

13) Due to the material being processed, there may be a

risk of explosion or fire. Be aware of work suface dangers

prior to begining work.

14) There is a risk of being cut due to high speed

rotation. Do not touch high speed rotating disc.

15) This power tool is not insulated. If contact is made with

an electric current injury may occur.

16) Dust created by sanding, sawing, grinding, drilling and

other related activities may expose the user to dust and/or

microscopic particles that may contain chemicals known to

the State of California to cause cancer, birth defects or

other reproductive harm.

Users of this tool should review the chemical composition

of the work surface and any products used in conjunction

with the operation of this tool for any such chemicals prior

to engaging in any activity that creates dust and/or

microscopic particles.

Users should obtain the Material Safety Data Sheets for all

identified chemicals, either from the manufacturer or their

employer, and proceed to study, understand, and follow all

instructions and warnings for exposure to such chemicals.

1) The tool shall not be used in potentially explosive

atmospheres.

2) Disconnect the air hose before changing or

adjusting any inserted tools.

3) Before using tool, please confirm all couplings

and plugs are fixed securely. Air hose that is under

pressure may lash out when disconnected

and could lead to serious injuries.

4) Prevent loose clothes, long hair or any other

personal accessories from coming close to moving

parts to reduce the risk of being caught, trapped

or drawn into the rotating spindle.

5) Excessive high air pressure, that exceeds the

maximum pressure, may cause injuries to user.

6) Exposure to strong vibration for extended time

may cause harm to operator.

7) Make sure of the rotation direction before starting

the tool to reduce hazardous situations due to

unexpected rotation direction.

Some examples of these chemicals are: lead from leadbased paints; crystalline silica from bricks, cement and

other masonry products; and arsenic and chromium from

chemically treated lumber. A listing of the chemicals can

be obtained from www.oehha.ca.gov under Proposition 65.

In order to reduce their exposure to such chemicals, users

should always:

work in well-ventilated areas.

*

wear appropriate safety equipment and clothing that are

*

specifically designed to filter out microscopic particles.

Cautions for Use

1) Always wear ear protection and safety glasses when using

this tool. Gloves and protective clothing are recommended.

2) Personal protection and dust collection devices shall be

chosen according to the material being worked upon. Please

consult provider of such devices.

3) Release the start and stop device incase of failure of energy

supply.

4) Never use hand sockets. Only use power drive sockets.

5) Basic safety instructions and warnings must always be

followed. in addition, safety instructions & warnings identified

in ANSI B186.1 Safety Code for Portable Air Tools must be

followed. For further ANSI information see www.ansi.org or

call (212) 642-4900

Page 3

Page 4

3025

6“ Finishing Palm Sander

6“ Finishing Palm Sander

3025 - 6“ Finishing Palm Sander

PRODUCT INFORMATION:

• High powered

• 3/32” Stroke Finish

• Super lightweight (1.62lbs./.74kg)

•

Compact for minimum operator fatigue

• Orbital action assures final swirl-free finish

• Built-in speed regulator

• Ergonomic design suits for long term

operation and greater comfort and control

• Compact and lightweight motor for long

term operation

• Composite lever housing and rotors

• Special design reduces sound level

• Also available replacement pad - Astro model # 4508

SPECIFICATIONS:

Pad Size: 6"

Free Speed: 10,000rpm

Overall Length: 7"(17.78cm)

Net Weight: 1.62lbs. (.74kg)

Spindle Thread Size: 5-16" - 24

Air Inlet Thread NPT: 1/4"

Air Hose I.D. Size: 3/8" (10mm)

Avg. Air Consumption.:13cfm

Air Pressure: 90psi

Page 4

Loading...

Loading...