Page 1

1500CYS

1-1/2 TON CAPACITY TRUCK

TRANSMISSION JACK

Product Information

• Designed for removal and installation of heavy-duty truck

transmissions or differentials

• Safety overload system prevents jack from

being used beyond its rated capacity

• Flash chrome ram prevents rust from entering the hydraulic system

• Fully adjustable universal saddle with adjustable corner brackets

and safety chain

• Pump handle rotates 360° for all position operation

• Safety by-pass system prevents damage to cylinder

• Four full-swivel ball bearing caster wheels for easy positioning

• Low frame easily clears undercarriage obstacles

• 4-way swivel

• MEETS ANSI STANDARD FOR PERFORMANCE AND SAFETY

1 YEAR LIMITED WARRANTY

• Astro Pneumatic Tool Co. warrants our products to the original user against

defective material or workmanship for a period of 1 year from the date of 1st use.

Astro reserves the right to determine whether the product failed because of

defective material, workmanship or other causes and to charge back for missing

parts. Astro Pneumatic Tool Co., at its discretion, will repair products covered

under this warranty free of charge. The original user is to return the product (with

the exceptions listed below) with the distributor’s name, address, adequate proof of

date of purchase or a copy of warranty card, and a short note explaining the

problem. Failures caused by accident, alteration, or misuse are not covered

by this warranty.

• Astro will replace free of charge defective power unit on select hydraulic

equipment during warranty period. After warranty period repair parts are

available, please call (800)221-9705 for specific information.

• Astro Pneumatic Tool Co. or its authorized service representatives must perform all

warranty repairs. Any repair to the product by unauthorized service representatives

voids this warranty. The rights under this warranty are limited to the original user

and may not be transferred to subsequent owners.

• This warranty is in lieu of all other warranties, expressed or implied, including

warranties of merchantability and fitness for a particular purpose. Some states do

not allow the exclusion of limitations of incidental or consequential damages so the

above limitations may not apply to you.

PLEASE DO NOT RETURN ANY PRODUCT WITHOUT CALLING

1-800-221- 9705 FOR INSTRUCTI ONS

Unpacking

When unpacking, check the parts diagram and part number listing

on pages 3 to 4 to make sure all parts are included. If any parts are

missing or damage, please call your distributor.

1-1/2 TON CAPACITY TRUCK TRANSMISSION JACK

SPECIFICATIONS:

Weight Capacity :

Min.Saddle Height :

Max.Saddle Height :

Hydraulic Lift :

Chassis Length :

Chassis Width :

Saddle Tilt Forward :

Saddle Tilt Backward :

Saddle Left & Right :

Net Weight :

3,000lbs. (1-1/2 Ton)

9" (225mm)

35-3/4" (905mm)

26-3/4" (690mm)

44-1/2" (1130mm)

25-1/2" (650mm)

30°

15°

12°

312lbs. (142kg)

MADE IN CHINA

Page 2

1500CYS

• Always read the manual and understand all operating and

safety instructions prior to operating and/or troubleshooting

this jack.

• Do not exceed the rated capacity of the jack. Operating at over

the rated capacity may cause serious injury and/or damage.

• Always place the jack on a solid, level surface while operating.

• Center the jack at a location under the vehicle recommended

by the manufacturer.

• Secure the vehicle from possible movement prior to lifting to

prevent serious injury and/or damage.

• The jack is a lifting device only. The load must be supported

with jack stands at locations under the vehicle recommended

by the manufacturer.

• When lowering the vehicle, turn the release valve slowly and

not more than two turns to prevent loss of load and cause

serious injury and/or damage.

OPERATING INSTRUCTIONS

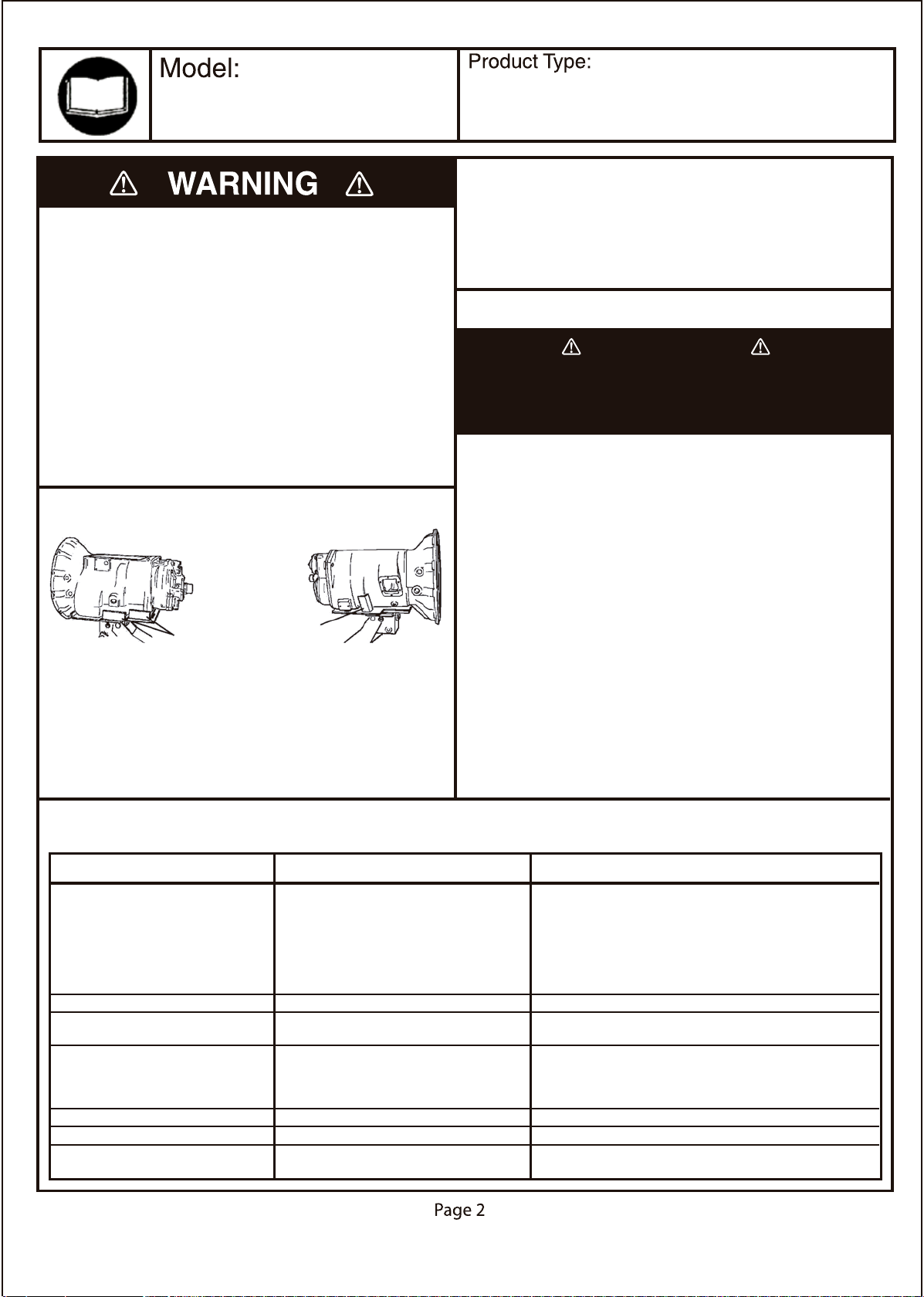

Figure 1

The transmission

must rest against

the angle plates

as shown.

Angle Plates

1. Position the jack under the transmission.

2. Close the control valve. Operate the pump handle to raise

the boom and align the mounting plate with the transmission.

See Figure 1.

3. Remove the transmission according to the instructions

in the vehicle service manual.

4. Position the transmission on the mounting plate, resting

against the angle plates as shown in Figure 1.

Angle Plates

1-1/2 TON CAPACITY TRUCK

TRANSMISSION JACK

5. Secure the transmission to the mounting plate.

• The mounting plate may be tilted forward

and backward by turning the tilt knob.

• The mounting plate may be tilted side-to-side by

adjusting the two vertical hex hd. cap screws.

6. Lower the load by slowly opening the control valve. The

control valve regulates how fast the boom is lowered.

MAINTENANCE

IMPORTANT

Dirt is the greatest single cause of failure in hydraulic units. Keep the jack

clean and well lubricated to prevent foreign matter from entering the system.

If the jack has been exposed to rain, snow, sand, or grit, it must be cleaned

before it is used.

1. Store the jack in a well-protected area where it will not be

exposed to corrosive vapors, abrasive dust, or any other

harmful elements.

2. Regularly lubricate the moving parts.

3. To check the oil level, place the jack on level ground and lower

the lift arm completely. Remove the filler plug. The oil level

should be within 3/8” of the filler plug hole. Do not overfill. If

necessary, add approved anti-wear hydraulic jack oil, and

install the filler plug again.

IMPORTANT: The use of alcohol, hydraulic brake fluid or

detergent motor oil could damage the seals

and result in jack failure.

4. Inspect the jack before each use. Take corrective action if

any of the following problems are found:

• Cracked or damaged housing

• Excessive wear, bending, or other damage

• Leaking hydraulic fluid

• Scored or damaged piston rod

• Malfunctioning swivel heads or adjusting screws

• Loose hardware

• Modified or altered equipment

TROUBLESHOOTING

Trouble Probable Cause Remedy

Jack does not lift

Jack lifts only partially

Jack advances slowly

Jack lifts load, but doesn’t hold

Jack leaks oil

Jack will not retract

Jack retracts slowly

1. Release valve is open.

2. Low/no oil in reservoir.

3. Air-locked system.

4. Load is above capacity of jack.

5. Delivery valve and/or bypass

valve not working correctly.

6. Packing worn out or defective

1. Too much or not enough oil

1. Pump not working correctly.

2. Leaking seals.

1. Cylinder packing is leaking.

2. Valve not working correctly (suction,

delivery, release, or bypass).

3. Air-locked system.

1. Worn or damaged seals

1. Release valve is closed.

1. Cylinder damages internally.

2. Link section is binding.

1. Close release valve.

2. Fill with oil and bleed system.

3. Bleed system.

4. Use correct equipment

5. Clean to remove dirt or foreign matter. Replace oil.

6. Replace power unit.

1. Check oil level.

1. Replace power unit.

2. Replace power unit.

1. Replace power unit.

2. Inspect valves. Clean and repair seat surfaces.

3. Bleed system.

1. Replace power unit.

1. Open or clean release valve.

1. Send jack to Astro authorized service center for repair.

2. Lubricate link section.

Page 3

1-1/2 TON CAPACITY TRUCK

1500CYS

Call 1.800.221.9705 for questions concerning performance of the product

or other inquiries.

TRANSMISSION JACK

3

Page 4

Index

1-1

1-4

1-6

1-9

1-10

1-11

1-15

1-16

1-17

1-18

1-19

1-20

1-21

1-24

1-25

1-26

1-27

1-28

1-29

1-30

1-31

1-32

1-33

1-34

1-35

1-39

1-40

1-42

1-44

1-45

1-46

2-1

2-3

2-4

2-5

2-6

2-7

2-8

2-9

3-1

3-2

3-3

3-5

3-6

3-7

3-8

3-9

3-10

3-11

4-0

4-1

4-2

4-3

4-4

1500CYS-1-1

1500CYS-1-4

1500CYS-1-6

1500CYS-1-9

1500CYS-1-10

1500CYS-1-11

1500CYS-1-15

1500CYS-1-16

1500CYS-1-17

1500CYS-1-18

1500CYS-1-19

1500CYS-1-20

1500CYS-1-21

1500CYS-1-24

1500CYS-1-25

1500CYS-1-26

1500CYS-1-27

1500CYS-1-28

1500CYS-1-29

1500CYS-1-30

1500CYS-1-31

1500CYS-1-32

1500CYS-1-33

1500CYS-1-34

1500CYS-1-35

1500CYS-1-39

1500CYS-1-40

1500CYS-1-42

1500CYS-1-44

1500CYS-1-45

1500CYS-1-46

1500CYS-2-1

1500CYS-2-3

1500CYS-2-4

1500CYS-2-5

1500CYS-2-6

1500CYS-2-7

1500CYS-2-8

1500CYS-2-9

1500CYS-3-1

1500CYS-3-2

1500CYS-3-3

1500CYS-3-5

1500CYS-3-6

1500CYS-3-7

1500CYS-3-8

1500CYS-3-9

1500CYS-3-10

1500CYS-3-11

1500CYS-4-0

1500CYS-4-1

1500CYS-4-2

1500CYS-4-3

1500CYS-4-4

Frame

Plate

Tilting Saddle

Screw

Pin with Female Screw

Pin

Grip

Spring Pin

Collar

Collar

Set Screw

Thrust Bearing

Snap Ring

Bracket (LH)

Hook with Thread

Pin for Hook

Nut

Spring Washer

Wing Nut

Bracket (RH)

Bolt

Wing Nut

Washer

Chain

Bolt

Screw

Shaft for Tilting

U Type Nut

Cover

Bolt

Spring Washer

Arm Connecting Joint

Link Rod Pin

Arm Pin

Link Rod

Link Rod Pin

Nut

Spring Washer

Snap Ring

Arm Pin

E-type Ring

Arm

Connecting Joint

Tension Rod

Tension Rod Pin

Grease Nipple

Snap Ring

Cotter Pin

Cotter Pin

Castor Assembly

Caster

Bolt

Nut

Spring Washer

1500CYS

Call 1.800.221.9705 for questions concerning performance of the product

or other inquiries.

Index

No.

5-1

1

1

1

1

1

1

2

2

2

2

7

4

4

2

2

2

2

2

2

2

4

4

4

2

2

1

1

2

1

2

2

2

1

1

2

2

2

2

4

1

1

1

1

2

2

1

2

1

2

4

4

16

16

16

5-2

5-3*

5-4

5-5

5-14

5-17

6-1

6-3

6-4

6-5*

6-6*

6-7*

6-8

6-9

6-10

7-2

7-3

7-4

8-1

8-2

8-3*

8-4*

8-5*

8-6

8-7

8-8

8-9*

8-10

8-11

8-12*

9-1

9-2

9-3

9-4

9-5

9-6

10-0

10-1

10-2

10-3

10-4

10-5*

10-6*

10-7*

10-8

1500CYS-5-1

1500CYS-5-2

1500CYS-5-3*

1500CYS-5-4

1500CYS-5-5

1500CYS-5-14

1500CYS-5-17

1500CYS-6-1

1500CYS-6-3

1500CYS-6-4

1500CYS-6-5*

1500CYS-6-6*

1500CYS-6-7*

1500CYS-6-8

1500CYS-6-9

1500CYS-6-10

1500CYS-7-2

1500CYS-7-3

1500CYS-7-4

1500CYS-8-1

1500CYS-8-2

1500CYS-8-3*

1500CYS-8-4*

1500CYS-8-5*

1500CYS-8-6

1500CYS-8-7

1500CYS-8-8

1500CYS-8-9*

1500CYS-8-10

1500CYS-8-11

1500CYS-8-12*

1500CYS-9-1

1500CYS-9-2

1500CYS-9-3

1500CYS-9-4

1500CYS-9-5

1500CYS-9-6

1500CYS-10-0

1500CYS-10-1

1500CYS-10-2

1500CYS-10-3

1500CYS-10-4

1500CYS-10-5*

1500CYS-10-6*

1500CYS-10-7*

1500CYS-10-8

TRANSMISSION JACK

Tank Nut

Packing Seat

UN seal ring

Washer

Snap Ring

Oil Seal

O-Ring

Cylinder Assembly

Cap Plug

Back-Up Ring

O-Ring

Steel Ball

Steei Ball

Bolt

Spring Washer

Spring

O-Ring

Cap

O-Ring

Pump Plunger

Plunger Guide

Back-Up Ring

O-Ring

Oil Seal

Lever Branket

Link

Pin

Snap Ring

Lever

Knob

Copper Packing

Cap Plug

O-Ring

Nut

Steel Ball

Spring

Spring Seat

Release Valve Assembly

Release Valve

Release Valve Guide

Release Valve Grip

Spring Pin

O-Ring

O-Ring

Packing

Repair Kit

1

1

1

1

1

1

1

1

1

1

1

1

1

2

2

1

1

1

1

1

1

1

1

1

1

2

3

6

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1/2 TON CAPACITY TELESCOPING

Items marked with an (*) are available in the Repair Kit

4

Loading...

Loading...