Page 1

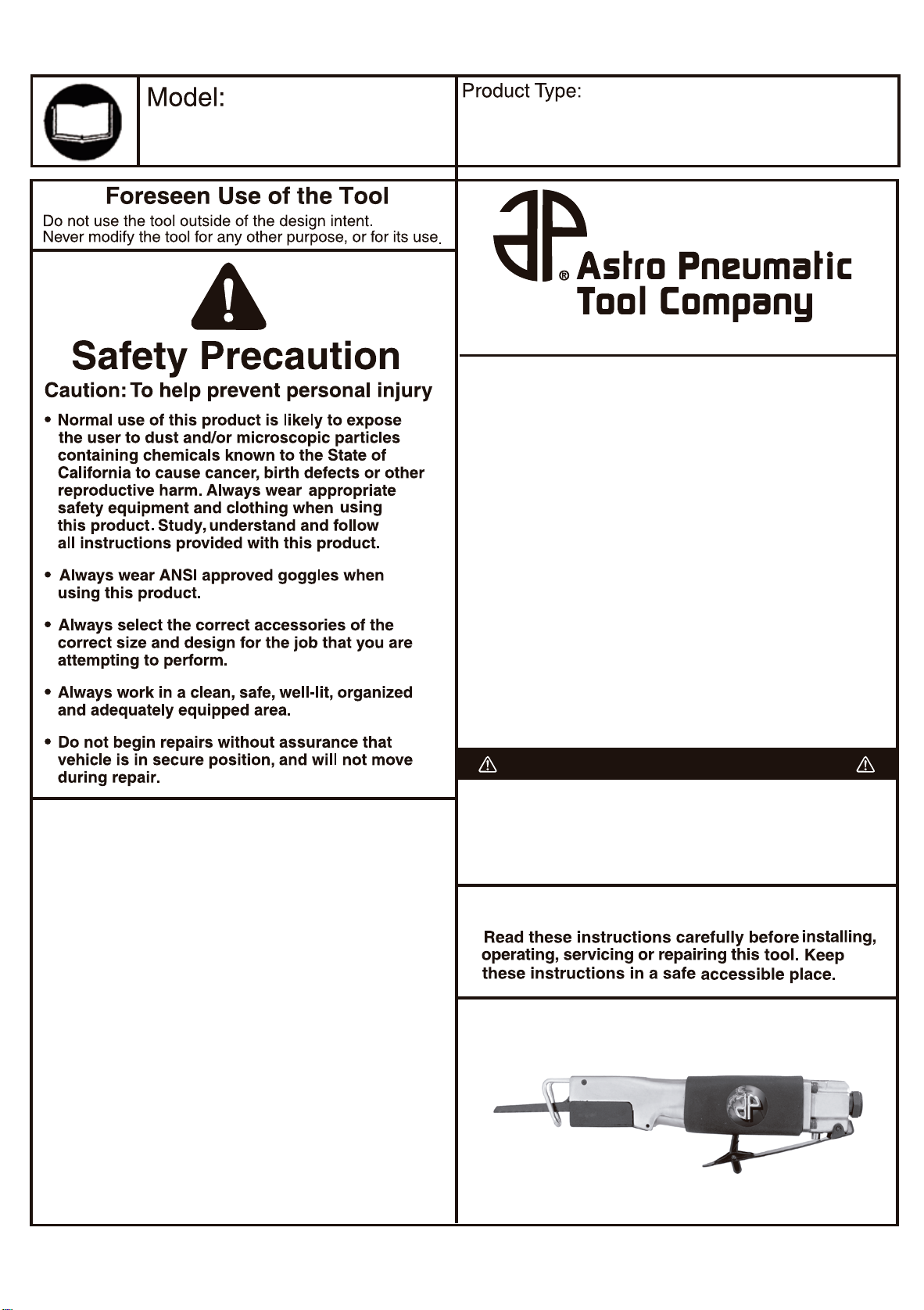

HEAVY DUTY AIR SABRE SAW

129TW

- 10,000 STROKES PER MINUTE

www.astrotools.com

1 YEAR LIMITED WARRANTY

• Astro Pneumatic Tool Co. warrants our products to the original user against defective

material or workmanship for a period of 1 year (except where noted on our price

schedule) from the date of 1st use. Astro reserves the right to determine whether the

product failed because of defective material, workmanship or other causes and to charge

back for missing parts. Astro Pneumatic Tool Co., at its discretion, will repair products

covered under this warranty free of charge. The distributor should direct the original user

to return the product (with the exceptions listed below) with the distributor’s name,

address, adequate proof of date of purchase or a copy of warranty card, and a short note

explaining the problem. Failures caused by accident, alteration, or misuse are not

covered by this warranty.

• If one part of this product fails, please do not return the entire product. Astro will

replace free of charge component parts of this product that fail within 1 year of first

use by the original user. Items included in this category include but are not limited

to kits, hand tool kits and any other product where there are multiple items or

components that make up the unit. Please contact the phone number below in

order to obtain the replacement components covered under warranty.

• Astro Pneumatic Tool Co. or its authorized service representatives must perform all

warranty repairs. Any repair to the product by unauthorized service representatives

voids this warranty. The rights under this warranty are limited to the original user and may

not be transferred to subsequent owners.

• This warranty is in lieu of all other warranties, expressed or implied, including warranties

of merchantability and fitness for a particular purpose. Some states do not allow the

exclusion of limitations of incidental or consequential damages so the

above limitations may not apply to you.

PLEASE DO NOT RETURN ANY PRODUCT WITHOUT CALLING

1-800-221-9705 FOR INSTRUCTIONS

PRODUCT INFORMATION:

• Ideal for body shop repair, muffler and exhaust work

• Adjustable blade guide increases blade life

• Cuts all types of aluminum, plastic,

fiberglass and sheet metal

• Cuts intricate shapes and tight radius curves

on flat and curved surfaces

• Conforms to CE standards

SPECIFICATIONS:

Cutting Capacity:

Stroke Length:

Strokes Per Minute:

Overall Length:

Net Weight:

Piston Stroke:

Air Inlet Thread NPT:

Air Hose I.D. Size:

Avg. Air Consumption:

Air Pressure:

3/32" (2mm) - Steel,1/8" (3mm) - Aluminum

3/8" (9.5mm)

10,000Bpm

9-1/4" (235mm)

1.54lbs. (0.7kgs)

1/4"

1/4"

3/8" (10mm)

6cfm (170L/Min)

90psi

Unpacking

When unpacking, check the parts diagram and part number

listing on page 4 to make sure all parts are included. If any

parts are missing or damaged, please call your distributor.

IMPORTANT

HEAVY DUTY AIR SABRE SAW - 10,000 STROKES PER MINUTE

MADE IN TAIWAN

Page 1

Page 2

129TW

1.) LUBRICATION:

Before connection of the hose, apply 4 to 5 drops of a good

quality air tool oil at the air inlet. After 3 to 4 hours of

operation, oiling may be necessary again.

2.) TIGHTNESS OF PARTS:

Regularly check whether all connection parts are

fastened securely. Follow this procedure daily

before beginning work.

3.) STORAGE:

Avoid storing the tool in a location subject to high humidity. If

the tool is left unused, the residual moisture inside the tool

can cause rust. Before storing and after operation, oil the tool

at the air inlet with a good quality air tool oil and run it for a

short period.

4.) DISPOSAL:

Follow national legislation of waste disposal.

HEAVY DUTY AIR SABRE SAW

- 10,000 STROKES PER MINUTE

5.) ORDERING SERVICE PART

For further operational and handling information or for

replacement of parts and components, contact the sales

agent from where you purchased the tool, or the service

division of our company, phone number 800-221-9705.

*When ordering parts and components, give each part

number, name, and quantities.

WARNING

a) This tool contains sharp cutting blades and must be

handled with extreme care.

b) Always disconnect the air supply from the tool prior

to removing or installing blades.

c) Keep hands and body away from the blade at all times.

d) Failure to read and follow these warnings may result

in serious injury.

Always wear ANSI approved safety goggles when using this

product. Normal use of this product is likely to expose the user

to dust and/or microscopic particles containing chemicals

known to the State of California to cause cancer, birth defects or

other reproductive harm. Always wear approved safety equipment and clothing when using this product. Study, understand,

and follow all instructions provided with this product.

Page 2 Page 3

Page 3

129TW

HEAVY DUTY AIR SABRE SAW

- 10,000 STROKES PER MINUTE

PRODUCT INFORMATION:

• Ideal for body shop repair, muffler and exhaust work

• Adjustable blade guide increases blade life

• Cuts all types of aluminum, plastic,

fiberglass and sheet metal

• Cuts intricate shapes and tight radius curves

on flat and curved surfaces

• Conforms to CE standards

SPECIFICATIONS:

Cutting Capacity:

Stroke Length:

Strokes Per Minute:

Overall Length:

Net Weight:

Piston Stroke:

Air Inlet Thread NPT:

Air Hose I.D. Size:

Avg. Air Consumption:

Air Pressure:

3/32" (2mm) - Steel,1/8" (3mm) - Aluminum

3/8" (9.5mm)

10,000Bpm

9-1/4" (235mm)

1.54lbs. (0.7kgs)

1/4"

1/4"

3/8" (10mm)

6cfm (170L/Min)

90psi

The oil and water extractor should not be mounted on or near the air

compressor.

The temperature of air is greatly increased during compression. As the air

cools down to room temperature, in the air line, on its way to the Air Power

Tool, the moisture contained in it condenses. Thus, for maximum

effectiveness, the oil and water extractor should be mounted at some point

SUGGESTED AIR LINE CONNECTION

Pitch pipe back toward air receiver

PIPE SIZE, I.D. (Inches)

Drain

Daily

Compressor unit

Air Flow

CFM

10

20

30

40

50

70

Oil and Water Extractor should be at least 25 ft. from the compressor. Further if possible.

Length of Pipe (feet)

50

1/2"

3/4"

3/4"

1"

1"

1"

in the air supply system where the temperature of the compressed air in the

line is likely to be lowest. Air lines must be properly drained daily. Each low

point in an air line acts as a water trap. Such points should be fitted with an

easily accessible drain. See diagram below. Pitch all air lines back towards

the compressor so that condensed moisture will flow back into the air

receiver where it can be drained off. Drain daily.

Install drain at

100

3/4"

3/4"

3/4"

1"

1"

1"

150

3/4"

3/4"

3/4"

1"

1"

1"

1-1/4"

1-1/4"

25 FEET OR MORE

200

1"

1"

1"

each low point

Drain

Daily

Oil and Water

Extractor

Drain

Daily

Page 4

372 Old US Highway 52 South

Mount Airy, NC 27030

34 B

AAA

AA

35 B

HEAVY DUTY AIR SABRE SAW

129TW

Call 1.800.221.9705 for questions concerning performance of the product

or other inquiries.

28 A

A

- 10,000 STROKES PER MINUTE

B

A

Index

No.

1

2

3

4

5

6

7A

7B

8

9

10

11

12

13

15

16

17

18

129TW-01

129TW-02

129TW-03

129TW-04

129TW-05

129TW-06

129TW-07A

129TW-07B

129TW-08

129TW-09

129TW-10

129TW-11

129TW-12

129TW-13

129TW-15

129TW-16

129TW-17

129TW-18

38 A

Valve Screw

O-Ring (P11)

O-Ring (P7)

Air Controller

Valve Spring

Valve Stem

P006 O-Ring (P006)

P007 O-Ring (P007)

Valve Bushing

Air Inlet Bushing

Cap Screw (M4 x 15)

Washer (M4)

Lever Pin (Ø3 x 23)

Throttle Lever

Valve Case

Bush (0806)

Cylinder

Valve Sleeve

Index

No.

1

1

1

1

1

1

1

1

1

1

4

4

1

1

1

1

1

1

19

20

21

22

23

24

25

26

27

28

28A

29

30

31

32

33

34A

129TW-19

129TW-20

129TW-21

129TW-22

129TW-23

129TW-24

129TW-25

129TW-26

129TW-27

129TW-28

129TW-28A

129TW-29

129TW-30

129TW-31

129TW-32

129TW-33

129TW-34A

Actuate valve

Washer (Ø3 x Ø8 x 0.8 t)

Cap Screw (M3 x 23)

Gasket

Valve Block

Screw (M4 x 6)

Bush (1010)

Chuck Cover

Screw (M5x10)

Housing

Housing Sleeve

Piston Assembly

Screw (5/16" x 5/16")

Service Wrench (2mm)

Guide Plate

Blade Chuck

Work Guide (Long)

Index

No.

1

1

3

1

1

2

2

1

2

1

1

1

2

1

1

1

1

34B

35A

35B

36

38

38A

39

40

41

42

43

44

45

46

47

48

49

129TW-34B

129TW-35A

129TW-35B

129TW-36

129TW-38

129TW-38A

129TW-39

129TW-40

129TW-41

129TW-42

129TW-43

129TW-44

129TW-45

129TW-46

129TW-47

129TW-48

129TW-49

Work Guide (short)

Blade (32T)

Blade (24T)

Service Wrench (4mm)

Screw (M4 x 10)

Retaining Ring E3

Upper Wear Shoe

Blade Guide

Bridge

Front Bumper

Rear Bumper

Spring Pin (Ø2.5 x 5)

Spring

Packing

Packing

Packing

Screw (M5 x 5)

1

1

1

1

1

1

1

2

1

1

1

2

1

1

1

1

1

Page 4

Loading...

Loading...