Astria Polaris36ZEN, Polaris42ZEN, Polaris36ZEP, Polaris42ZEP Installation Instructions Manual

Page 1

OUTDOOR DECORATIVE GAS FIREPLACE

DANGER

DANGER

CU

P/N 506023-33 REV. A 05/2014

INSTALLATION INSTRUCTIONS

OUTDOOR DECORATIVE GAS FIREPLACE

This appliance is only for use with the type of gas

indicated on the rating plate. This appliance is

not convertible for use with other gases, unless a

certified kit is used.

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

INSTALLATEUR: Laissez cette notice avec l'appareil.

CONSOMMATEUR: Conservez cette notice pour consulation ultérieure.

WARNING: DO NOT store or use gasoline or other

flammable vapors or liquids in the vacinity of this or

any other appliance.

CARBON

MONOXIDE

HAZARD

• This appliance can produce carbon monoxide

which has no odor.

P506023-33

MODELS

Polaris36ZEN Polaris42ZEN

Polaris36ZEP Polaris42ZEP

A French manual is available upon request. Order Form Number

506023-34.

Ce manuel d’installation est disponible en francais, simplement en

faire la demande. Numéro de la pièce 506023-34.

WARNING: Improper installation, adjustment, alteration, service

or maintenance can cause injury or property damage. Read the installation, operating and maintenance instructions thoroughly before

installing or servicing this equipment.

MONOXYDE

DE CARBONE

• Cet appareil peut

produire du monoxyde

de carbone, un gaz

inodore.

WARNING: For

Outdoor Use Only.

DANGER

IF YOU SMELL GAS:

1. Shut off gas to appliance.

2. Extinguish any open flame.

3. If odor continues, keep away from the appliance and immediately call your gas supplier

or your fire department.

• Using it in an enclosed

space can kill you.

• Never use this appliance in an enclosed

space such as a camper, tent, car or home.

PFS Report No. 14-020

S

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

• Son utilisation dans un

espace clos peut vous

tuer.

Avertissement:

Pour utilisation à

l'exérieur seulement.

• Ne jamais utiliser cet

appareil dans un espace clos, tel qu'une

caravane, tente, voiture

ou à la maison.

DANGER

SI VOUS UNE ODEUR DE GAZ:

1. Coupez l'admission de gaz de l'appariel.

2. Éteindre toute flamme nue.

3. Si l'odeur persiste, éloignez-vous de

l'appareil et appelez immédiatement votre

fournisseur de gaz ou le service d'incendie.

1

Page 2

Accessories

Wall Switch

Fireplace

Weatherproof

Enclosure

Optional Drain Pan

TABLE OF CONTENTS

Packaging .........................................page 2

Introduction ......................................page 2

Massachusetts Requirements ...........page 3

General Information ..........................page 3

Location ............................................page 4

Pre-Installation Notes .......................page 4

Assembly Steps ................................page 4

Waterproofing The Fireplace ............page 4

Appliance Clearances ........................page 5

Clearance Specifications ...................page 6

Fireplace Installation .........................page 7

Routing Gas Line ..............................page 7

Fireplace Specifications .....................page 8

Framing Specifications ......................page 9

Field Wiring .......................................page 10

Connecting Gas Line ........................page 11

Installing The Logs ............................page 12

Checking Appliance Operation ..........page 13

Firebox Finishes ................................page 13

Accessories And Components ..........page 14

Gas Conversion Kits .................. page 15

This installation manual will help you obtain a

safe, efficient, dependable installation for your

appliance.

This manual is part of a set of two supporting

this product. Refer to manual 506025-25 for

Care And Operations.

Please read and understand these

instructions before beginning your

installation.

3 - three (3) bags of volcanic stone, envelope

is located in the firebox area.

4 - Electrical kit containing the wall switch

components, battery holder, box and cover

(see Field Wiring Page 10).

INTRODUCTION

These outdoor gas fireplaces are designed for

exterior applications. These appliances must

be installed outdoors.

The Polaris™ Series Outdoor Gas Fireplace

is designed for outdoor use. It may also be

installed in screened porches and lanais that

meet these minimum requirements:

Minimum porch area - 96 square feet

Minimum ceiling height - 7 feet 8 inches

A minimum of two (2) walls can be screened

but must be open to outside ventilation.

Minimum screen area - 64 square feet

Minimum screen top height - 6 feet 8 inches

Refer to Outdoor Space definition below and

Clearance Specifications on Page 6.

AN OUTDOOR SPACE IS DEFINED AS FOLLOWS PER ANSI Z21.97-2012:

Outdoor spaces - An appliance is considered

to be outdoors if installed with shelter no more

inclusive than:

(a) With walls on all sides, but with no over-

head cover;

(b) Within a partial enclosure which includes an

overhead cover and no more than two side

walls. These side walls may be parallel, as in a

breezeway, or at right angles to each other; or

(c) Within a partial enclosure which includes an

overhead cover and three sidewalls, as long

as 30% or more of the horizontal periphery

of the enclosure is permanently open.

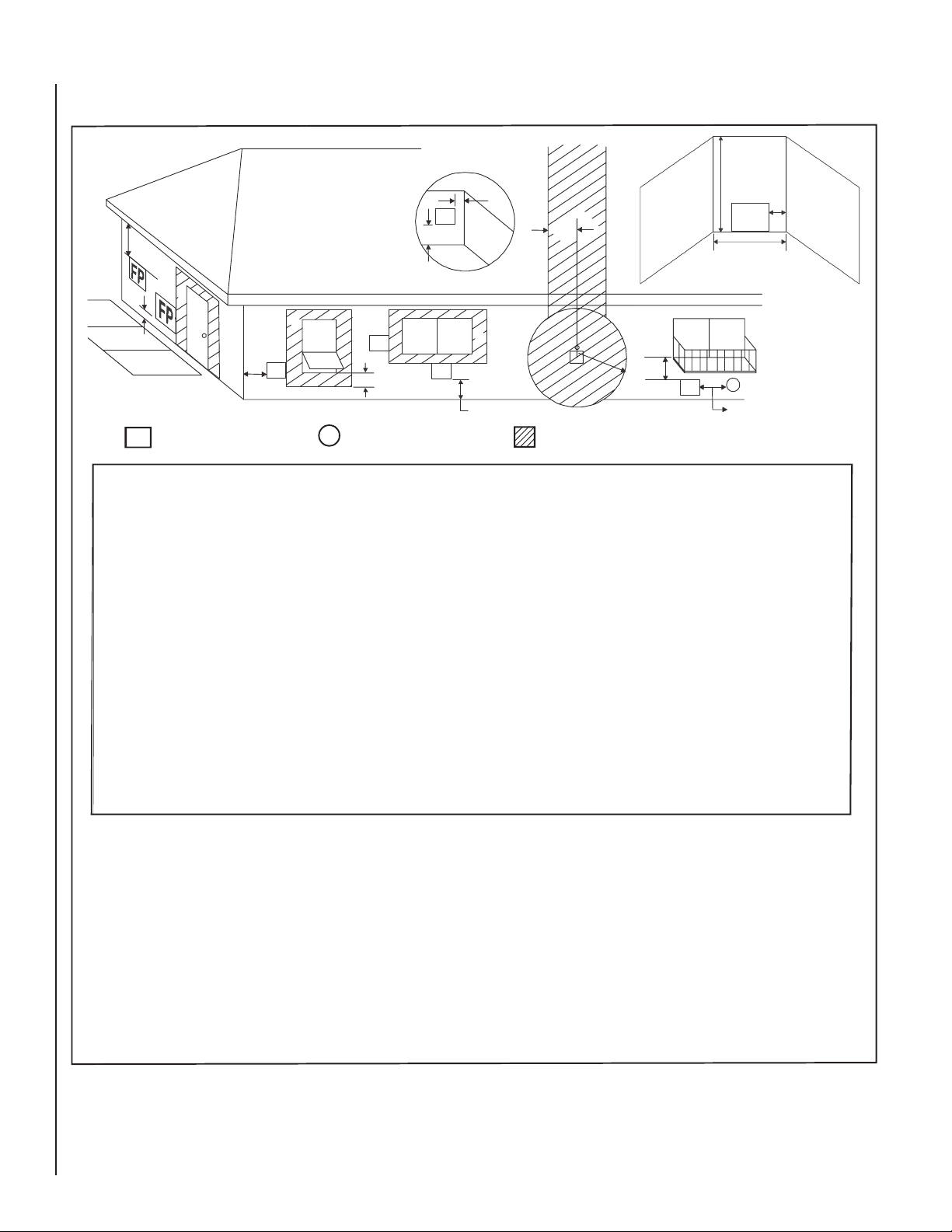

TYPICAL INSTALLATION

These appliances are designed to operate on

natural gas or propane. An electronic intermittent pilot ignition system provides safe,

efficient operation. A battery pack is required

to operate these units (2 "D" batteries).

These appliances comply with National Safety

Standards and are tested by PFS Corporation

(Report No. 14-020) and listed by ANSI Z21.97

(2012) in USA and to CSA 2.41 (2012) in

Canada, as outdoor gas fireplaces.

The Installation must conform to local codes or,

in the absence of local codes, with the National

Fuel Gas Code, ANSI Z223.1/NFPA 54, or the

Natural Gas and Propane Installation Code, CAN/

CGA B149.1; or Propane Storage and Handling

Code, B149.2, as applicable.

The appliance, when installed, must be electrically grounded in accordance with local codes or,

in the absence of local codes, with the National

Electrical Code, ANSI/NFPA 70, or the Canadian

Electrical Code, CSA C22.1.

DO NOT ATTEMPT TO ALTER OR MODIFY

THE CONSTRUCTION OF THE APPLIANCE OR

ITS COMPONENTS. ANY MODIFICATION OR

ALTERATION MAY VOID THE WARRANTY,

CERTIFICATION AND LISTINGS OF THIS UNIT.

Solid fuels shall not be burned in this appliance.

WARNING

An LP-cylinder not connected for

use shall not be stored in the vicinity of this or any other appliance.

2

PACKAGING

The assembled outdoor gas fireplace is packaged with the following:

1 - the logs are packaged in a carton located

within the firebox.

2 - one envelope containing the literature pack-

age which consists of the Care and Operation

manual and Installation Instructions.

Figure 1

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Page 3

MASSACHUSETTS REQUIREMENTS

These appliances may be installed in the

following USA locations with the following

requirements:

Installation of these appliances are approved

for installation in the US state of Massachusetts if the following additional requirements

are met -

• Installation and repair must be done by a

plumber or gas fitter licensed in the Commonwealth of Massachusetts.

• The exible gas line connectors shall not

exceed 36 inches (92 centimeters) in length.

• The individual manual shut-off must be a

t-handle type valve.

GENERAL INFORMATION

NOTE: Installation and repair should be per-

formed by a qualied service person. The appliance should be inspected annually by a qualied

professional service technician. More frequent

inspections and cleanings may be required due

to yard care, insects, etc. It is imperative that

the control compartment and burners of the

appliance be kept clean.

Provide adequate clearances around air openings and adequate accessibility clearance for

service and proper operation. Never obstruct

the front openings of the appliance.

These appliances are designed to operate on

natural or propane gas only.

All Models -

All models have a manually modulated gas valve.

Input is shown in Table 1:

Gas Pressure - All Models

Tables 2 and 3 show the appliances' inlet and

manifold gas pressure.

Inlet Gas Supply Pressure

(all models)

Fuel # Minimum Maximum

Natural Gas

Propane

5.0" WC

(1.24 kPa)

11.0" WC

(2.74 kPa)

10.5" WC

(2.61 kPa)

13.0" WC

(3.23 kPa)

Table 2

Manifold Gas Supply Pressure

(all models)

Fuel # Low High

Natural

Gas

Propane

2.2" WC

(0.55 kPa)

6.3" WC

(1.57 kPa)

3.5" WC

(0.87 kPa)

10.0" WC

(2.49 kPa)

Table 3

Test gauge connections are provided on the front

of the gas control valve identified IN for the inlet

and OUT for the manifold side. A 1/8" NPT Test

gauge connection is provided at the inlet and

outlet side of the electronic gas control valve.

The appliance and its appliance main gas

valve must be disconnected from the gas

supply piping system during any pressure

testing of that system at test pressures in

excess of 1/2 psi (3.5 kPa).

The appliance must be isolated from the gas

supply piping system by closing its equipment

shutoff valve during any pressure testing of

the gas supply piping system at test pressures equal to or less than 1/2 psi (3.5 kPa).

Orifice Sizes - Sea Level To High Altitude

(All Models)

These appliances are tested and approved

for installation at elevations of 0-4500 feet

(0-1372 meters) above sea level, using the

standard burner orifice (See Table 4). For

elevations above 4500 feet, contact your gas

supplier or qualified service technician. Install

the appliance according to the regulations of

the local authorities having jurisdiction and, in

the USA, the National Fuel Gas Code NFPA 54 /

ANSI Z223.1 - latest edition or , in Canada, the

CAN/CSA-B149.1 and .2 codes - latest edition.

Burner Orifice Sizes

Elevation 0-4500 feet ( 0-1372 meters)

Model Nat.Gas

Polaris36

Polaris42

drill size (inches)

#28 (.1405") #47 (.0785")

#28 (.1405") #47 (.0785")

Propane

drill size (inches)

Table 4

WARNING

PROPANE TANKS ARE AT PRESSURES

THAT WILL CAUSE DAMAGE TO VALVE

COMPONENTS. VERIFY THAT THE

TANKS HAVE STEP DOWN REGULATORS TO REDUCE THE PRESSURE TO

SAFE LEVELS.

BTU Input (BTU/Hr)

Model No. Input Rate (BTU/Hr)

Natural Gas

Polaris36ZEN 50,000 to 39,500

Polaris42ZEN 50,000 to 39,500

Propane Gas (LP)

Polaris36ZEP 46,000 to 37,000

Polaris42ZEP 46,000 to 37,000

Table 1

3

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Page 4

ASSEMBLY OUTLINE

Before You Start

Check your inventory list to be sure you have

all the necessary parts supplied in good usable

condition. Check also for any concealed damage.

LOCATION OF FIREPLACE

Carefully select the proper location for any

obstructions, clearance to side wall(s), air

availability, location and aesthetics. With proper

pre-planning, a slight adjustment of a few inches

can save considerable time and expense later

during construction and assembly. See Figure

2 for some examples.

LIVING SPACE

Optional

Hearth

Extension

Figure 2

When choosing a location, care must be taken

to avoid places where ooding or running water

may be a problem.

Identify the desired location for the battery

pack/ON/OFF switch junction box location. This

should be easily accessible and convenient for

use and high enough on the wall to be protected

from water and drifted snow.

Do not use this appliance if any part has been

under water. Immediately call a qualified service technician to inspect the appliance and to

replace any part of the control system and any

gas control that has been under water.

Ne pas se servir de cet appareil s'il a été plongé

dans l'eau, complètement ou en partie. Appeler

un technicien qualifié pour inspecter l'appareil et

remplacer toute partie du système de contrôle et

toute commande qui ont été plongés dans l'leau.

If it is evident that the burner is damaged, the

burner must be replaced with one specified by

the manufacturer before the appliance is put

into operation.

PATIO

Carefully consider the position of the fireplace

opening with respect to the location of adjacent

or nearby stairwells, doors, windows, walkways

and over hanging trees, patios and wires.

When locating the fireplace, consideration must

be given to combustibles and final finishing.

See Figure 18 and confine the final location of

combustible finish materials to the "Safe Zone".

Also refer to Clearance Specifications on Page 6.

Consider the effects of heat when locating any

object in front of or near the fireplace opening.

PRE-INSTALLATION NOTES

The fireplace may be installed directly on a

combustible oor or raised on a platform of an

appropriate height. Do not place the fireplace

on vinyl or other soft oor coverings. It may,

however, be placed on at wood, plywood,

particle board or other hard surfaces.

Position the electrical junction box as detailed

in LOCATION OF FIREPLACE. (The umbilical

cord is 9 feet long).

Be sure the fireplace rests on a solid continu-

ous oor or platform with appropriate framing

for support.

The fireplace may be positioned and then the

framing built around it, or the framing may be

constructed and the fireplace positioned into

the opening.

Usually, no special oor support is needed for

the fireplace, however, to be certain:

1. Estimate the total weight of the fireplace system including surround materials such as brick,

stone, etc., to be installed. Shipping weights for

the fireplace may be found on Page 8.

2. Measure the square footage of the oor space

to be occupied by the system, surrounds and

hearth extensions.

3. Note the decking construction, i.e. 2 x 6’s,

2 x 8’s or 2 x 10’s, single or double joists, type

and thickness of oor boards.

4. Use this information and consult your local

building code to determine if you need additional support.

If you plan to raise the fireplace and hearth

extension, build the platform assembly then

position fireplace and hearth extension on

top. Secure the platform to the oor to prevent

possible shifting.

ASSEMBLY STEPS

NOTE: The following steps represent the normal

sequence of installation. Each installation is

unique, however, and might require a different

sequence.

1. Position firebox prior to framing or into

prepared framing (non-combustible framing

is recommended).

2. Position the electrical junction box as detailed

in LOCATION OF FIREPLACE.

(The umbilical cord is 9 feet long).

3. Waterproof the fireplace or install the optional

drip pan (see Waterproong The Fireplace and

Figure 3 on Page 5).

4. Plumb gas line. (Gas connections should

only be performed by an experienced, licensed/

certified tradesman.)

5. Complete the installation, finish wall material, surround and hearth extension to your

individual taste.

6. Assemble and attach optional accessories.

Study the three dimensional illustration (Fig-

ure 1) to get a general idea of each element

of your fireplace system.

WATERPROOFING THE FIREPLACE

Although the fireplace is designed to operate

safely outdoors, rain may enter the hearth area,

condensation and can cause water to collect

inside the fireplace bottom.

To prevent water collection, the builder must

provide a means to drain water from under

the fireplace by building or installing a water

collector of the builders choice, before positioning the fireplace in its location.

Special care must be taken when the fireplace is

installed against an exterior wall. The enclosure

surrounding the fireplace on the sides and back

must be treated as an exterior wall.

Innovative Hearth Products (IHP) provides an

optional drain pan to assist weatherproofing

the fireplace.

H4651 DPSS36 Drain Pan for Polaris36, H4652

DPSS42 Drain Pan for Polaris42.

4

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Page 5

When Planning for the installation of the fire-

47 1/4

Drain Connector Detail

Threaded

Reducer

3/4 x 1/2

(PVC)

Threaded

Elbow 3/4

@ 90

º

(PVC)

1/2” Airspace Clearance

To Sides And Back

No Material Within

The Face Opening

Noncombustables

May Overlap The Face

Combustable Materials

Allowed Flush With

The Face Front

No Combustables

Below The Top Spacers

Noncombustable

Material Only

Only

Noncombustable

Material May

Overlap The

T

op Face

Do NOT Overlap

Material Within

The Face Opening

1/2”

Airspace

Clearance

To Back

TOP VIEW

SIDE VIEW

5”

Combustible Material

May Overlap The

Face Bottom Up To 2”

Below The Face Opening

No Material

Allowed in

This Area

1/2” Clearance

1/2” Airspace Clearance

To Sides And Back

Nailing Flange May

Make Direct Contact

With Combustible

Framing

place, the framing height must be increased

from 46-1/2" to 47-1/4", when installing the

drain pan. An additional space below the

fireplace will also be required to plumb a

drain line.

Step 1. Seal all joints, gaps and corners around

the bottom of the drain pan before positioning

the fireplace on its location (Figure 3).

Step 2. On the exposed drain hole, install a PVC

threaded coupling reducer, 3/4" x 1/2" going

from the top of the pan down through the hole.

Apply a silicone-based sealant around the base

and threads before installation.

Step 3. Holding the reducer coupling with a

wrench, thread a 3/4", 90 degree, PVC elbow to

the reducer until it is tight to the metal.

Step 4. Add additional piping to route the drain

to an appropriate location.

NOTE: To assure proper drainage, the replace

must be installed on a leveled surface.

CLEARANCES

Minimum clearance to combustibles for the

fireplace is as follows; sides and back – 1/2"

(13mm), combustible oor – 0" (0mm), adjacent wall 6" (152mm), ceiling – 50" (1270mm).

Refer to Figure 4 on this page and Figure 18

on Page 13 for more detail.

NOTE: Clearance behind the nailing ange for

both replace models is 1/2" (13mm).

NOTE: Adjacent wall considerations are for an

adjacent wall to only a single side. Walls should

not be placed at the minimum distance on both

sides of the replace. Allow at least 4 feet on

one side of the replace.

Figure 3

Figure 4

5

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Page 6

CLEARANCE SPECIFICATIONS

FP

= FIREPLACE OPENING

X

= AIR SUPPLY INLET

= AREA WHERE FIREPLACE IS NOT PERMITTED

FP

(See Note 2)

D

L

A

H

M

X

J or K

I

G

F

FP

FP

FP

FP

FP

B

B

B

A = 2 in. . . . . . . . . . clearances above grade,

veranda, porch, deck or

balcony.

B = 12 in. . . . . . . . . . clearances to window or door

that may be opened, or to

permanently closed window.

36 in. . . . . . . . . . vinyl windows or siding.

D = 47 in. . . . . . . . . . vertical clearance to unventi-

lated soffit or to ventilated soffit

located above the fireplace.

60 in. . . . . . . . . . vinyl clad soffits.

F = 9 in. . . . . . . . . . clearance to outside corner.

G = 6 in. . . . . . . . . . clearance to inside corner.

48 in. . . . . . . . . . vinyl windows or siding.

H = 3 ft. (Canada). not to be installed above a gas

meter/regulator assembly within

3 ft (914 mm) horizontally from

the center line of the regulator.

I = 3 ft. (USA)

6 ft. (Canada)

clearance to service regulator

vent outlet and electric service.

J = 9 in. (USA)

12 in. (Canada)

clearance to non-mechanical air

supply inlet to building or the

combustion air inlet to any other

appliance.

K = 3 ft. (USA)

6 ft. (Canada)

clearance to a mechanical air

supply inlet.

L* = 54 in. . . . . . . . . . clearance above paved sidewalk

(See note 1) or a paved driveway located on

public property.

M** = 47 in. . . . . . . . . . clearance under veranda, porch,

deck, balcony or overhang.

Not allowed: . . . . . . vinyl.

P = 92 in.

* A fireplace shall not open directly above a sidewalk or paved

driveway which is located between two single family dwellings

and services both dwellings.

* * Only permitted if veranda, porch, deck or balcony is fully open

on a minimum of 2 sides beneath the floor, or if the screened

porch guidelines are followed.

Note 1: Local codes or regulations may require different clearances.

Note 2: Fireplaces

in an alcove space (spaces open only on one

side and with an overhang) are permitted with the dimensions

specified for vinyl or non-vinyl siding and soffits. 1) There must

be a 3 ft minimum between terminations or between the

fireplace and termination. 2) All mechanical air intakes within

10 ft of the top of the fireplace opening must be a minimum of

3 ft below the top of the fireplace opening.

3)

All gravity air intakes within 3 ft of the fireplace must

be a minimum of 1 ft below the face top opening.

This fireplace is approved for installation in screened porches with the

following guidelines:

Minimum porch area - 96 sq ft

Minimum ceiling height - 92 in.

Minimum of two walls must be screened or open

Minimum top of screen height, side walls - 6 ft 8 in.

Minimum screen area - 64 sq ft

Note: There may be some odor and small amounts of soot associated

with burning the fireplace in a screened porch. Ensuring good cross

draft ventilation and routine maintenance of the fireplace will maximize

comfort and cleanliness.

. . . .

. . . .

Q = 72

in.

C = 72 in. . . . . . . . . . clearance below an

opperable window.

.

. . . .

C

P

G

Q

A

6

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Page 7

Right Side

Front Corner

Of Fireplace

Framing

3-3/4"

(95 mm)

1-3/4"

(44 mm)

FIREPLACE INSTALLATION

Step 1. Frame these appliances as illustrated in

Figures 7 through 9. All framing details must

allow for a minimum clearance to combustible

framing members, as shown in Figure 4 on

Page 5. Also refer to Fireplace Specifications

on Page 8. Headers may be in direct contact

with the appliance top spacers but must not be

supported by them or notched to fit around them.

All construction above the appliance must be

self supporting. DO NOT USE THE APPLIANCE

FOR STRUCTURAL SUPPORT.

NOTE: The framed depth from a framed wall,

must always be measured from a nished

surface. If a wall covering such as durrock is

to be attached to the rear wall, then the depth

must be measured from the wall surface. It is

important that this dimension be exact.

NOTE: Non-combustible framing members are

not required, but are recommended.

Step 2. Level the firebox by checking the top

edge of the firebox. Shim if necessary.

Step 3. The fireplace should be secured to the

side framing members, using the full length

nailing ange located on both sides of the

fireplace. Use 8d nails, or screws.

IMPORTANT: UNDER NO CIRCUMSTANCES

SHALL THE FIREBOX TOP SPACERS BE REMOVED OR MODIFIED. THE HEADER MAY BE

IN DIRECT CONTACT WITH THE TOP SPACERS

BUT MUST NOT BE SUPPORTED BY THEM OR

NOTCHED TO FIT AROUND THEM.

Step 4. Identify the desired location for the

battery pack/ON/OFF switch junction box. This

should be easily accessible and connivent

for use. Avoid installing where the opening

could be blocked by snow, bushes, etc. Also,

considerations need to be made to avoid water

infiltration. The electrical junction box must be

positioned within range of the electrical umbilical cord (9 feet). Route the umbilical cord to

the box to ensure proper length. Secure the

umbilical cord per appropriate local and national

electrical codes.

ROUTING GAS LINE

Route a 1/2" (13 mm) gas line along the inside

of the right side framing as shown in Figure

5. Gas lines must be routed, constructed and

made of materials that are in strict accordance

with local codes and regulations.

All appliances are factory-equipped with a

exible gas line connector and 1/2" shutoff

valve. (See Figure 12 on Page 11).

Figure 5

NOTE: An addiional inlet has been provided on

the left side (see Figure 6).

7

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Page 8

FIREPLACE SPECIFICATIONS

BC

C

Top View

1 (25)

7-1/16

(179)

20

(508)

Top Stand-Off

Spacers (4

places)

To p of Firebox

Opening

Dimensions - Inches (millimeters)

Dimensions - Inches (millimeters)

Model A B C

Model No.A

37

(940)

43

230 lbs

41-3/4

41-3/4

(1061)

(1061)

47-3/4

47-3/4

(1213)

(1213)

Polaris36

Polaris36

Polaris42

Polaris42

Model Ship. Wt. Shipping Volume

Model

Polaris36

Polaris36

Polaris42

Polaris42

37

(940)

43

(1092)

(1092)

Weight And Volume

Ship. Weight (lbs)

200 lbs

200 lbs

230 lbs

23-1/2

23-1/2

(597)

(597)

29-1/2

29-1/2

(749)

(749)

Shipping Volume

35 Cu. Ft.

35 Cu. Ft.

38 Cu. Ft.

38 Cu. Ft.

5

(127)

28-1/2

(724)

5-3/4

(146)

Figure 6

A

B

Front View

Bottom of

Firebox

Opening

5-3/4

(146)

41-5/16

(1049)

34-1/4

(870)

1-3/4

11-15/16

(303)

Gas Line

Access (Both Sides)

4-3/8

(111)

Right Side View

Access Opening for

Umbilical Cord -

Right Side Only

2

(51)

8-1/4

(210)

Left Side Gas Inlet

8

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Page 9

FRAMING SPECIFICATIONS

Opening Polaris36 Polaris42

A

B

C

D

E

F

G

H

Table A - This Table Corresponds To Figures 7,8 and 9

42-3/4" (1086) 48-3/4" (1238)

46-1/2" (1181) 46-1/2" (1181)

23-9/16" (599) 29-9/16" (751)

11-1/4" (286) 14-1/4" (362)

63-1/2" (1613) 69-1/2" (1765)

31-3/4" (807) 34-3/4" (883)

20-1/2"( 521) 20-1/2"( 521)

44-3/16" (1122) 49-1/8" (1248)

Corner

Figure 8

Installation

H

Back Wall Of

Chase/Enclosure

Including Finishing

Materials If Any

D

F

G

C

A

E

Rough Framing Face

(Unfinished Shown)

B*

* Increase Framing Height By 3/4”

When Using Optional Drain Pan

Figure 7

Header

Parallel Installation

Back Wall Of

Chase/Enclosure

Including Finished

Rough Framing Face

Materials - If Any

(Unfinished Shown)

C

A

G

A

Figure 9

Figures 7, 8 and 9 Correspond To Table A.

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

9

Page 10

BROWN

BROWN

BLACK

WEATHER

SEAL

COVER

REMOTE

WALL

SWITCH

REMOTE WALL SWITCH

D-CELL BATTERIES

BATTERY

WALL SWITCH BOX

WALL SWITCH BOX

BLACK

BLACK

IGNITER MODULE - 3V

RED

PILOT

IN

OUT

VENT

LO

HI

TH

TP

TH

TP

IN

ORANGE

BLACK

GREEN

BLACK JUMPER

HIGH LIMIT

SWITCH

UMBILICAL CORD (9 Feet)

NOTES:

1. If any of the original wire as supplied must be replaced, use Type AWM 105°C - 18 gage wire ONLY.

2. Electrical Rating: 3V DC.

CAUTION: label all wires prior to disconnection when servicing controls. Wiring errors can cause

improper and dangerous operation. Verify proper operation after servicing.

Schematic Representation Only

ELECTRONIC GAS CONTROL VALVE - DEXEN

PILOT TUBE

(THTP)

(TP)

(TH)

PILOT BURNER

IGNITER-SENSOR

ASSEMBLY

PILOT SENSOR CABLE

SPARK WIRE CABLE

FLAME

SENSOR

IGNITER

ROD

FIELD WIRING

Switch

Cover

Weather Seal

Orient Batteries Vertically

To Fit Within Box

CAUTION: Label all wires prior to disconnection when servicing controls. Wiring errors

can cause improper and dangerous operation.

Verify proper operation after servicing.

Refer to Figure 10 for the wiring schematic

for these fireplaces.

This fireplace is completely wired internally.

On the right hand side of the fireplace, at the

rear, are four (4) wires required to connect the

Battery and switch for operation.

Two brown wires are for the connection of the

switch. These are labeled SW and SW. A black

and red pair are for connection to the battery

pack. These are labeled (+) and (–).

These wires are for low voltage current. An

electrical box has been provided to contain both

the switch and battery pack. Mount the box in

an appropriate location within the length of the

wiring provided. Feed all four wires through one

of the lower inlets to the box. Connect the switch

wires to the switch and the corresponding (+),

(–) to the battery holder.

ELECTRONIC IGNITION WIRING DIAGRAM

Figure 10

Install two D-cell batteries (not provided) and

test the switch before closing the switch box

(refer to Figure 11). The igniter should spark

to the pilot when the switch is on.

Figure 11

10

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Page 11

CONNECTING GAS LINE

Access

Cover

Control

Valve

Refractory

Cover

Gas Flex Line Connector

Gas

Stub

1/2" x 3/8" Flare

Shut-Off Valve

3/8" Flex Tubing

3/8" NPT x 3/8"

Flare Fitting

3/8" Nipple

3/8" Union

3/8" Close Nipple

3/8" Shut-Off Valve

1/2" x 3/8"

Reducer

Gas

Valve

Codes require a shut-off valve mounted in the

supply line. Figure 12 illustrates two methods

for connecting the gas supply. The ex-line

method is acceptable in the U.S., however,

Canadian requirements vary depending on

locality. Installation must be in compliance

with local codes.

These appliances are equipped with a gas ex

line for use (where permitted) in connecting the

unit to the gas line. A gas ex line is provided

to aid in attaching the direct vent appliance to

the gas supply. The gas ex line can only be

used where local codes permit. See Figure 12

for ex line description. The ex line is rated

for both natural and propane gas. A manual

shut off valve is also provided with the ex line.

The gas control valve is located under the

refractory cover in front of the burner.

To access the valve, lift out the center refractory

and remove the access cover (see Figure 13).

The control valves have a 3/8" (10 mm) NPT

thread inlet port.

Figure 12 - GAS CONNECTION

Secure all joints tightly using appropriate

tools and sealing compounds (ensure propane

resistant compounds are used in propane

applications).

Turn on gas supply and test for gas leaks, using a gas leak test solution (also referred to as

bubble leak solution). NOTE: Using a soapy

water solution (50% dish soap, 50% water)

is an effective leak test solution but it is not

recommended, because the soap residue that

is left on the pies/fittings can result in corrosion over time. Never use an open flame to

check for leaks.

A. Light the appliance (refer to the lighting

instructions label in the control compartment

or in the Care and Operation Instructions).

B. Brush all joints and connections with the gas

leak test solution to check for leaks. If bubbles

are formed, or gas odor is detected, turn the

gas control knob to the “OFF” position. Either

tighten or refasten the leaking connection and

retest as described above.

C. When the gas lines are tested and leak free,

be sure to rinse off the leak testing solution.

Figure 13 - VALVE ACCESS

11

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Page 12

WARNING

DO NOT OPERATE THE FIREPLACE

FOR ANY EXTENDED PERIOD OF TIME

WITHOUT THE VOLCANIC STONE IN

PLACE. THE PAN CAN OVER HEAT AND

MAY WARP AND THE FIREPLACE MAY

SHUT OFF AUTOMATICALLY.

INSTALLING THE LOGS

After verifying that the fireplace operates

properly, replace the cover and set the bottom

refractory components in place.

Use two (2) bags of volcanic stone to fill the

bottom of the burner tray to completely cover

the burner tube. Level the volcanic stone evenly.

Place the rear log approximately centered as

shown in Figure 14.

Rear Log

Figure 14

Place the base log approximately as shown in

Figure 15.

The remaining logs can be placed across the

rear and base log approximately as shown in

Figure 16. The exact position of these logs is

not critical. Due to the nature of an outdoor

environment, the ame will never be strictly

controlled. You may need to reposition the

logs to get the effect you find most desirable.

A more detailed description is provided in the

Care and Operation manual.

CAUTION: LOGS GET HOT WHILE THE FIREPLACE IS IN OPERATION. DO NOT ATTEMPT

TO ADJUST OR MOVE THE LOGS WHILE THE

FIREPLACE IS HOT.

Figure 15

Top Left Log

Base Log

Top Center Log

Top Right Log

12

Figure 16

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Page 13

CHECKING APPLIANCE OPERATION

6" Minimum

For Combustible

Materials

12" Max.

3-3/4" Max.

See Note

29" Min.

Wall

Switch

5"

Min.

Note: The Area Above The Face To The Top Of The Spacers

Must Be Non-Combustable Materials

ELECTRONIC

Pilot

Hood

Sensor

Igniter

With gas line installed run initial system checkout before installing any additional accessories. Follow the lighting instructions provided

in the Care and Operation Instructions.

NOTE: Lighting Instructions are also found on

the literature tag tied to the gas piping next

to the gas valve. To access the tag, open the

lower control compartment door (refer to

Figure 13 - Valve Access).

When first lighting the appliance, it will take

a few minutes for the line to purge itself of

air. Once purging is complete, the pilot and

burner will light and operate as indicated in

the instruction manual. Subsequent lighting

of the appliance will not require such purging.

Inspect the pilot ame (remove logs, if necessary, handling carefully).

After the logs have been placed and the fireplace

has been checked for proper ame presentation, use the remaining volcanic stone to fill in

voids and spaces. Remember, you may need

to access the high/low ame control beneath

the refractory cover.

Carbon Monoxide Poisoning: Early signs

of carbon monoxide poisoning are similar

to the flu with headaches, dizziness and/

or nausea. If you have these signs, obtain

fresh air immediately. Turn off the gas supply to the appliance and have it serviced by

a qualified professional, as it may not be

operating correctly.

FIREBOX FINISHES

There are a wide variety of "finished looks" for

your outdoor fireplace, from formal wall decor

with elaborate mantels to rustic wood paneling

or warm brick facings.

Only noncombustible materials like marble,

stone, tile, brick, etc. may overlap the top

and sides of the front facing. Seal all joints

between the black facing and wall surrounds

to prevent air intrusion. Use noncombustible

caulking materials only to seal the metal facing

to the surround material on the finished wall.

See Figure 18.

CAUTION: DO NOT BLOCK THE FACE OPENING ON THESE FIREBOXES. DOING SO MAY

CREATE A POTENTIAL FIRE HAZARD.

Electronic Appliance Checkout

To light the burner, turn ‘ON’ the remote wall

switch. The battery will energize a spark that

will light the pilot. The pilot ame will engulf

the sensor and open the main valve. Within

seconds the main burner will light. Ensure the

igniter lights the pilot. The pilot ame should

engulf the sensor as shown in Figure 17.

Figure 17

Figure 18 - Clearances To Combustibles

13

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Page 14

INSTALLATION ACCESSORIES

AND COMPONENTS

Drain Pan

The drain pan is used with the appliance.

Drain Pan

Cat. No. Model Description

H4651 DPSS36 Drain Pan (36)

H4652 DPSS42 Drain Pan (42)

14

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Page 15

GAS CONVERSION KITS

Remove Tube

Regulator

Orifice

Remove Clip

Shutter

Opening

WARNING

This conversion kit shall be installed by a qualified service agency in

accordance with the manufacturer’s instructions and all applicable codes

and requirements of the authority having jurisdiction. If the information in

these instruction is not followed exactly, a fire, explosion or production of

carbon monoxide may result causing property damage, personal injury

or loss of life. The qualified service agency is responsible for the proper

installation of this kit. The installation is not proper and complete until the

operation of the converted appliance is checked as specified in the manufacturer’s instructions supplied with the kit.The qualified service agency

performing this installation assumes responsibility for this conversion.

AVERTISSEMENT

Cette trousse de conversion doit être installée par un technicien agréé,

selon les instructions du fabricant et selon toutes les exigences et tous les

codes pertinents de l’autorité compétente. Assurez-vous de bien suivre

les instructions dans cette notice pour réduire au minimum le risque

d’incendie, d’explosion ou la production de monoxyde de carbone pouvant

causer des dommages matériels, des blessures ou la mort. Le tecnicien

agréé est responsable de l’installation de cette trousse. L’installation n’est

pas adéquate ni complète tant que le bon fonctionnement de l’appareil

converti n’a pas été vérifié selon les instructions du fabricant fournies avec

la trousse. Le fournisseur de service qualifié ayant réalisé l'installation

assume les responsabilités liées à la conversion.

In Canada:

THE CONVERSION SHALL BE CARRIED OUT

IN ACCORDANCE WITH THE REQUIREMENTS

OF THE PROVINCIAL AUTHORITIES HAVING

JURISDICTION AND IN ACCORDANCE WITH

THE REQUIREMENTS OF THE CAN/CGA-B149.1

AND .2 INSTALLATION CODE.

LA CONVERSION DEVRA ÊTRE EFFECTUÉE

CONFORMÉMENT AUX RECOMMANDATIONS

DES AUTORITÉS PROVINCIALES AYANT

JURIDICTION ET CONFORMÉMENT AUX

EXIGENCES DU CODE D'INSTALLATION CAN/

CGA-B149.1 ET.2.

Gas conversion kits are available to adapt your

appliance from the use of one type of gas to

the use of another. These kits contain all the

necessary components needed to complete the

task including labeling that must be affixed to

ensure safe operation.

Step 1. Turn off the gas supply to the appliance.

Step 2. Carefully remove the logs. Exercise

care so as not to break the logs.

Step 3. Refer to Figure 19.

Remove the burner assembly with attached

venturi tube.

Natural to Propane Gas Conversion Kits

Model No. Unit Type Cat. No.

Polaris36 GCK-DB078P H4916

Polaris42 GCK-DB078P H4916

Propane to Natural Gas Conversion Kits

Model No. Unit Type Cat. No.

Polaris36 GCK-DB140N H4915

Polaris42 GCK-DB140N H4915

Figure 19

Electronic Appliances

Step 4. Dexen Electronic Valves - See Figure

20 and the instructions provided with the kit.

Remove and discard the two pressure regulator

mounting screws. Remove the pressure regulator and diaphragm. Discard all removed components. Ensure the rubber gasket installed on the

back of the replacement pressure regulator is

properly positioned. Install the new pressure

regulator using the new screws supplied with

the kit. Tighten screws to 25 In. lb. torque.

NOTE: Natural gas regulators are identied with

a blue dot. Propane regulators have a red dot.

Step 5. See Figure 21 and replace the pilot

orifice as follows: Remove pilot hood assembly

by grasping the hood and pulling the assembly

straight up. Under the hood is the pilot orifice.

With caution and using a magnetic screwdriver,

undo the pilot orifice and remove it from the

assembly. Carefully replace the orifice with the

one provided with the kit. Press the pilot hood

back over the assembly. The orientation should

be aligned as shown in Figure 21. Exercise

extreme care to prevent damage to or breakage of the igniter assembly.

NOTE: Propane pilot orices are identied with

a countersink in the head. Natural gas orices

do not have this countersink. See Figure 21.

Kit part numbers are listed here and the following steps detail the conversion procedure.

15

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Page 16

Step 6. (Refer to Figure 19 on Page 15)

ELECTRONIC PILOT

Pilot

Hood

Sensor

Igniter

PROPANE

NATURAL

P506023-33

A. Remove the orifice from the manifold with

a 1/2" deep throat socket. See the following

table for orifice sizes for natural and propane

models. Figure 22 illustrates the orifice. Use

pipe joint compound or Teon tape on all

pipe fittings before installing (ensure propane

resistant compounds are used in propane applications, do not use pipe joint compounds

on are ttings).

B. Retrieve the burner and slide the venturi tube

over the orifice. Secure the burner in place with

the clip shown in Figure 19.

Step 7. Reassemble the remaining components

by reversing the procedures outlined in the

preceding steps.

Ground

(TP)

Gas Outlet

To Burner

Figure 20

Pilot Stage

Terminal

TP

Burner Stage

Terminal

TH

TP

TH

Regulator

Mounting Screw

Pressure-Tap

(Inlet)

HI

LO

VENT

IN

OUT

Pressure-Tap

(Manifold)

Pilot Gas

Outlet

PILOT

IN

Supply

Gas

Inlet

Burner Orifice Sizes

Elevation 0-4500 feet ( 0-1372 meters)

Model Nat.Gas

drill size (inches)

Polaris36

Polaris42

#28 (.1405") #47 (.0785")

#28 (.1405") #47 (.0785")

Propane

drill size (inches)

IHP reserves the right to make changes at any time, without notice, in design, materials,

specifications, prices and also to discontinue colors, styles and products. Consult your local

distributor for fireplace code information.

Printed in U.S.A. © 2014 IHP LLC

16

P/N 506023-33 REV. A 05/2014

Figure 22

NOTE: If the igniter is damaged, a replacement kit is available, order Catalog

Number 87L54.

Figure 21

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

1508ElmHillPike,Suite108•Nashville,TN37210

Loading...

Loading...