Astralux 9300A, 9300A2 Repair Manual

REPAIR MANUAL

REPAIR MANUAL

MODEL 9300A 9300A2

CONTENTS

1. Products specification

2. Out look

3. Names of principal parts

4. Names of electronic parts

5. Removing methods of external parts

5.1 Face plate..........................................................................................................6

5.2 Arm top cover ....................................................................................................6

5.3 Sewing table complete ......................................................................................6

5.4 Cord reel cover ..................................................................................................6

5.5 Belt cover...........................................................................................................7

5.6 Free arm cover ..................................................................................................7

5.7 Free arm foot bush ............................................................................................7

5.8 Front cover .....................................................................................................7-8

5.9 Back cover.........................................................................................................9

6. Adjusting methods of each part

.1 Symbol instructions .........................................................................................10

6

.2 Play of arm shaft..............................................................................................11

6

6.3 Drop middle point of needle.............................................................................11

6.4 Height of presser foot ......................................................................................12

6.5 Needle flow at maximum zigzag width ............................................................13

6.6 Drop middle point of needle.............................................................................14

6.7 Needle position of zigzag ................................................................................15

6.8 Automatic needle threader adjustment............................................................16

6.9 Adjustment of feed rock shaft and feed lifting rock cam ..................................17

6.10 Height of needle bar ........................................................................................18

6.11 Timing of needle and hook ..............................................................................19

6.12 Distance-needle-hook......................................................................................20

6.13 Play between shuttle driver shaft gear and lower shaft gear...........................21

6.14 Play of shuttle driver shaft ...............................................................................22

6.15 Feed-dog height ..............................................................................................23

6.16 Position of feed-dog in relation to the needle plate (left to right) .....................24

6.17 Upper thread tension adjustment ....................................................................25

6.18 Shuttle hook tension adjustment .....................................................................26

6.19 Motor belt tension ............................................................................................27

6.20 Drop point of needle ........................................................................................28

6.21 Adjustment of BH.............................................................................................29

6.22 Bobbin winding problem ..................................................................................30

6.23 Replace the fuse..............................................................................................31

7. Trouble shooting of electrical parts

8. Circuit diagram

.....................................................................................................................3

..................................................................................................36-41

.............................................................................................2

..........................................................................................4

........................................................................................5

.................................................................32-35

ATTENTION

Be sure to observe the following, as they may well become causes for fire,

electric-shock, injuries, and damage to parts.

- Be sure to unplug power source before engaged in disassembly, installation,

adjustment.

- In case of installing please pay special care to clamp electrical cords, etc., scars

to sheath, mis-circuit, etc.

- Be sure to use regular standard part in replacing.

1

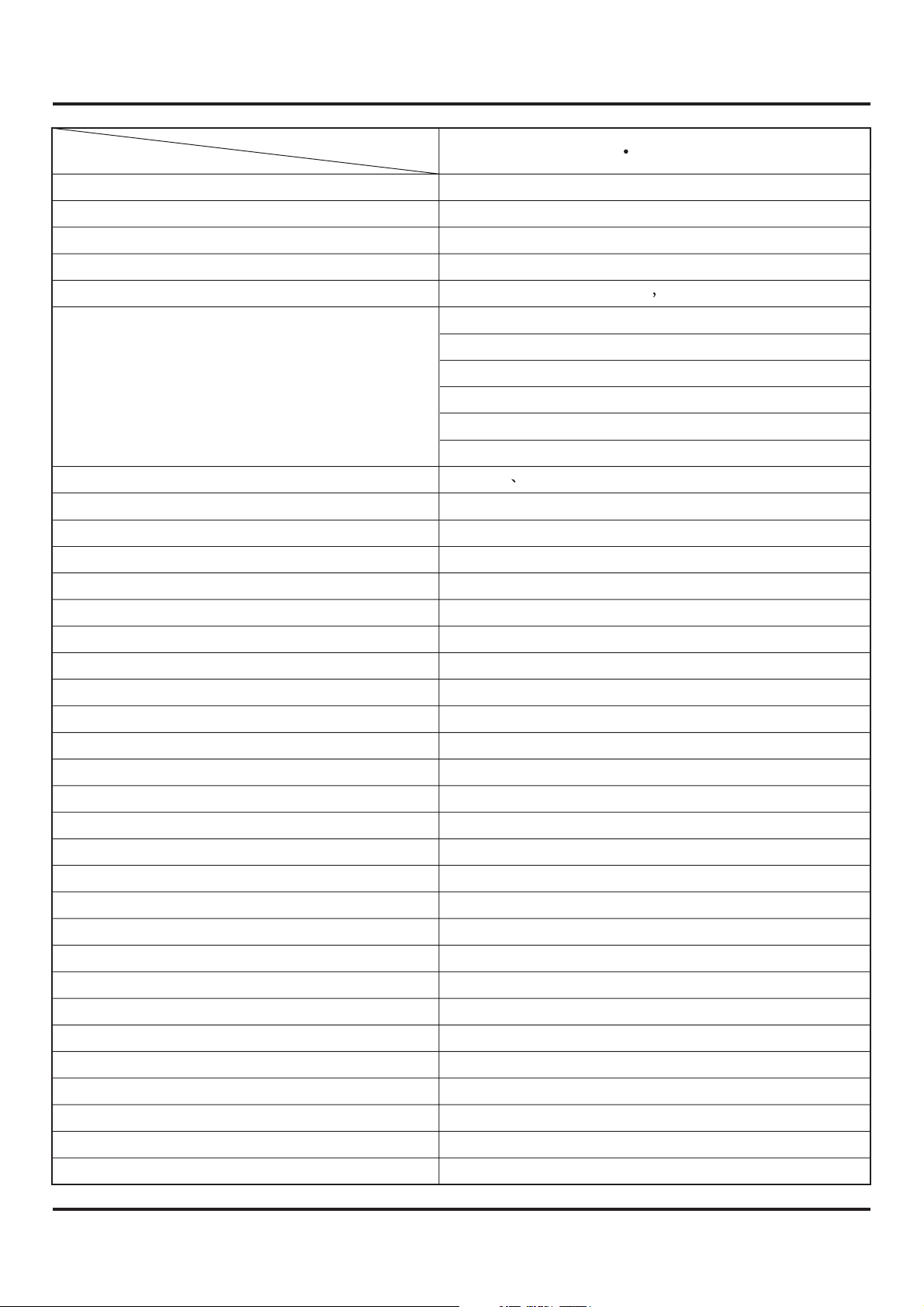

1. Products specification

ITEM

Machine style

Hook system

Size of machine (mm)LxWxH

Weight (kg)

Power

Revolution per minute (R.P.M)

Needle

Max. forward feeding

Max. reverse feeding

Max stitch width

Electricity consuming

TYPE

9300A 9300A2

Free arm

Drop-in Bobbin

407 x 175 x 290

8.5 (only machine)

AC 120V/60Hz (U.S.A) 230V/50Hz (Eur.)

Straight Stitch 70-800RPM

Button Hole 70-600RPM

Normal Stitch 70-700RPM

Bobbin Winder 70-800RPM

Reverse Stitch 70-800RPM

Lowest Speed 70RPM

HAX1 #9-#16

4.5mm

3.5mm

7mm

Lamp 12V 5W

Thread take up lever

Exchange presser foot

Presser foot tension adjustment settlement

Needle plate

Handle

Spool rod

Thread cutting settlement

Needle settlement

Bobbin Winder

Upper thread threader

Sewing table

Patterns

Button hole system

Dial tension settlement

Presser foot lift settlement

Feed dog up-down change

Feed dog

Slit type

Touch controlling

Fixed type

Transparent window

Handle type

Horizontal style

Inclusive within face plate

Single direction availability

Self releasing with automatic stop

Automatic upper thread threader

Accessory placement

Practical usage 40 kinds

One step button hole lever

Standard settlement

2 steps

Yes, lever controlling in the base

6 gears

Slowest speed

Slide volume

Auto stop

Motor

Accessory placement

Yes. (Both forward and backward)

Feedback function

Self stopping while bobbin windering

Motor overload settlement

Inside of sewing table

2

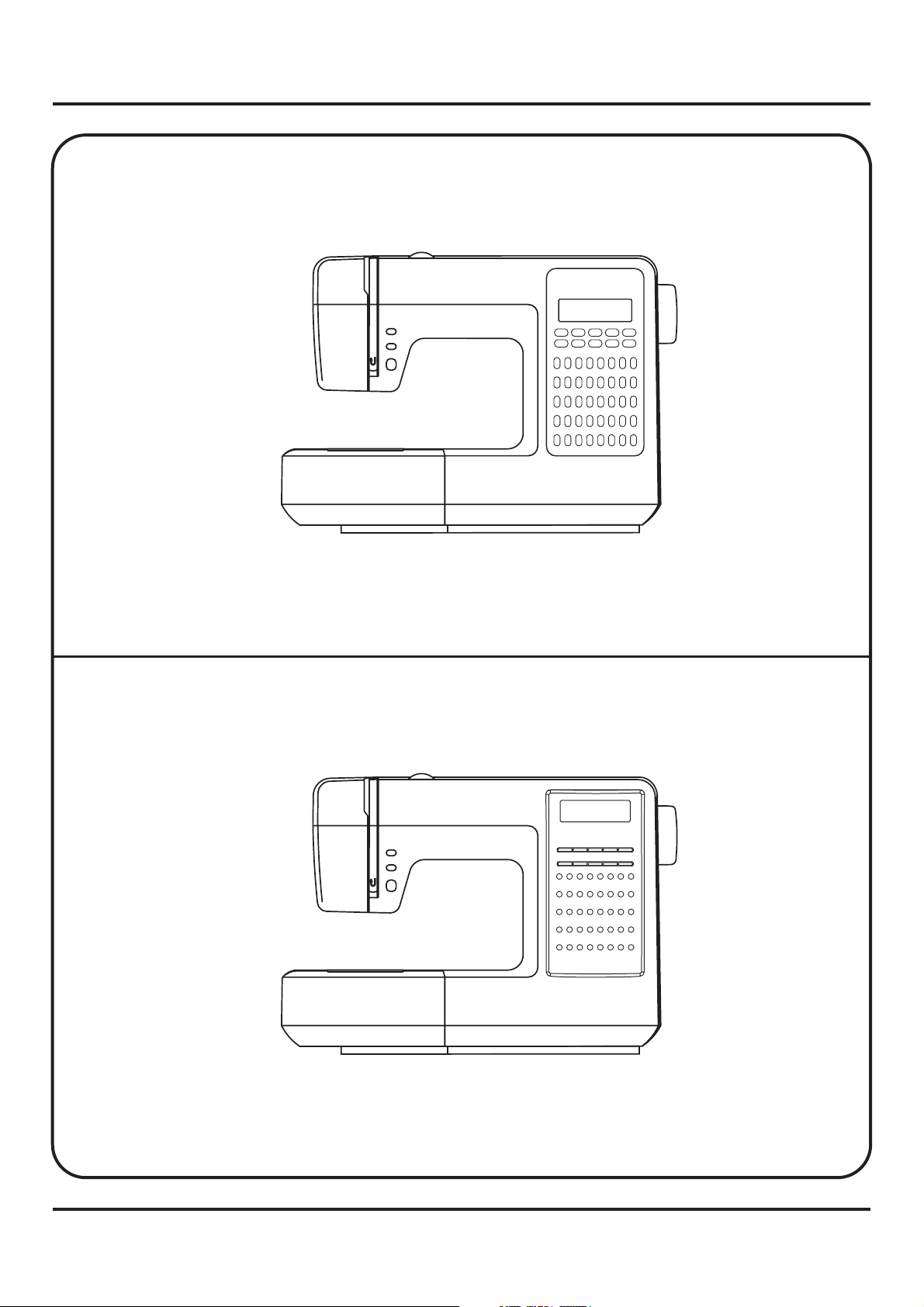

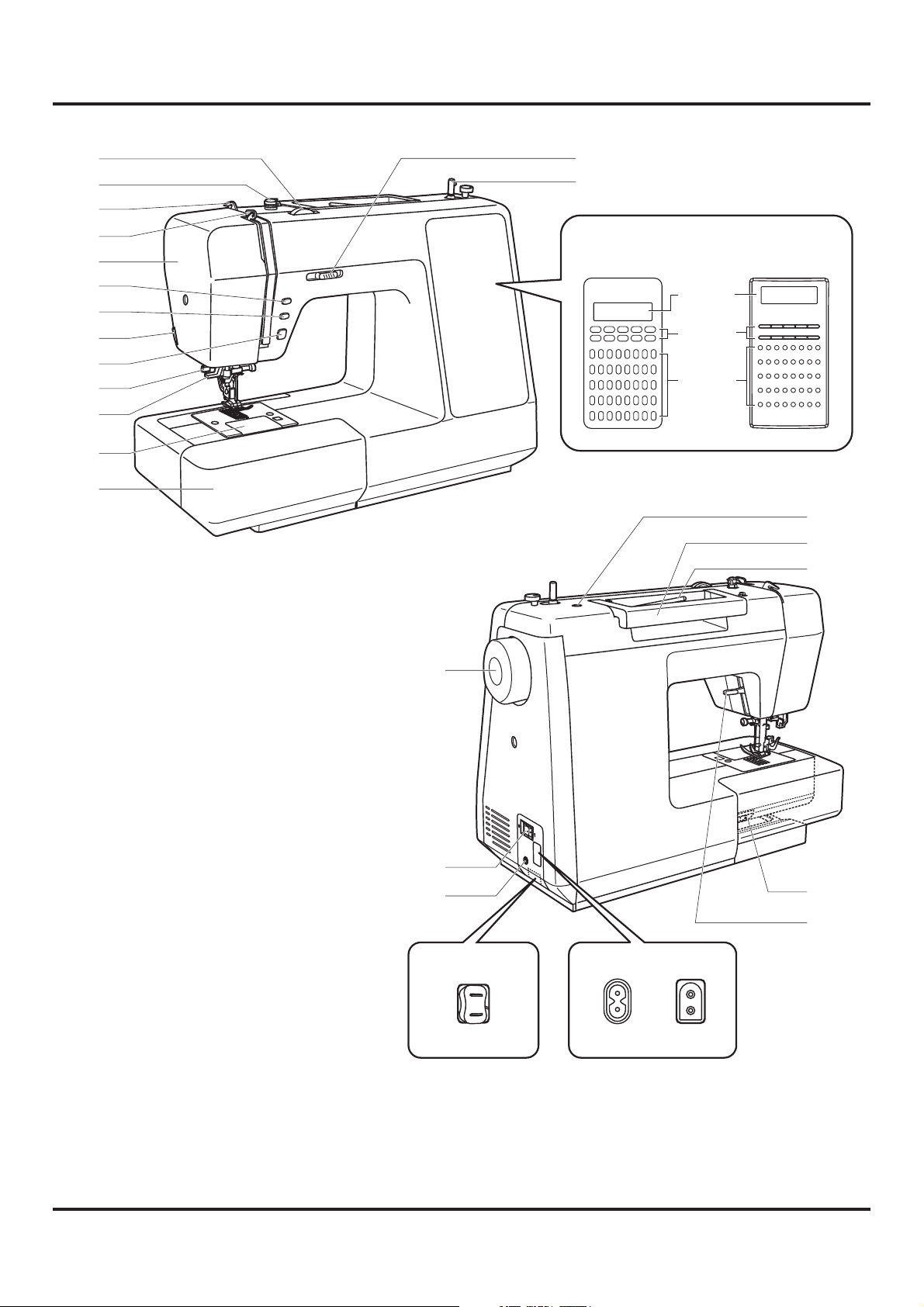

2. Out look

Model 9300A

5

1234

11

9

10

12 13 14 15 16

17

18 19 20 21 22 23 24

28 29

25 26

27

36 37

33 34

35

7

6

30 31 32

38 39 40

8

Model 9300A2

3

3. Names of principal parts

1

2

3

4

5

6

7

8

9

10

11

12

13

1. Tension dial

14

15

Model

9300A

1234

9

10

17

18 19 20 21 22 23 24

25 26

33 34

11

12 13 14 15 16

28 29

27

36 37

35

Model

9300A2

16 (A)

6

30 31 32

38 39 40

7

8

17 (B)

18 (C)

5

23

24

25

2. Bobbin thread guide

3. Upper thread guide

4. Thread take-up lever

5. Face plate

6. Needle up/down position button

7. Auto-lock button

8. Thread cutter

9. Reverse button

10.Buttonhole lever

11. Auto needle threader

12.Needle plate

13.Sewing table and accessory box

14.Speed limiting adjustment lever

15.Bobbin winder

16.LCD (Liquid crystal display)

17.Function of buttons

18. Stitch selection buttons

19

20

21

22-A 22-B

Eur.

26

27

U.S.A

19. Handwheel

20.Main power switch

21. Foot controller connector

22-A.

Japanese version (automatic

rewinding)

22-B.

European version

USA version

23.Hole for second spool pin

24. Handle

4

25.Horizontal spool

pin

26. Drop feed lever

27.Presser foot lifter

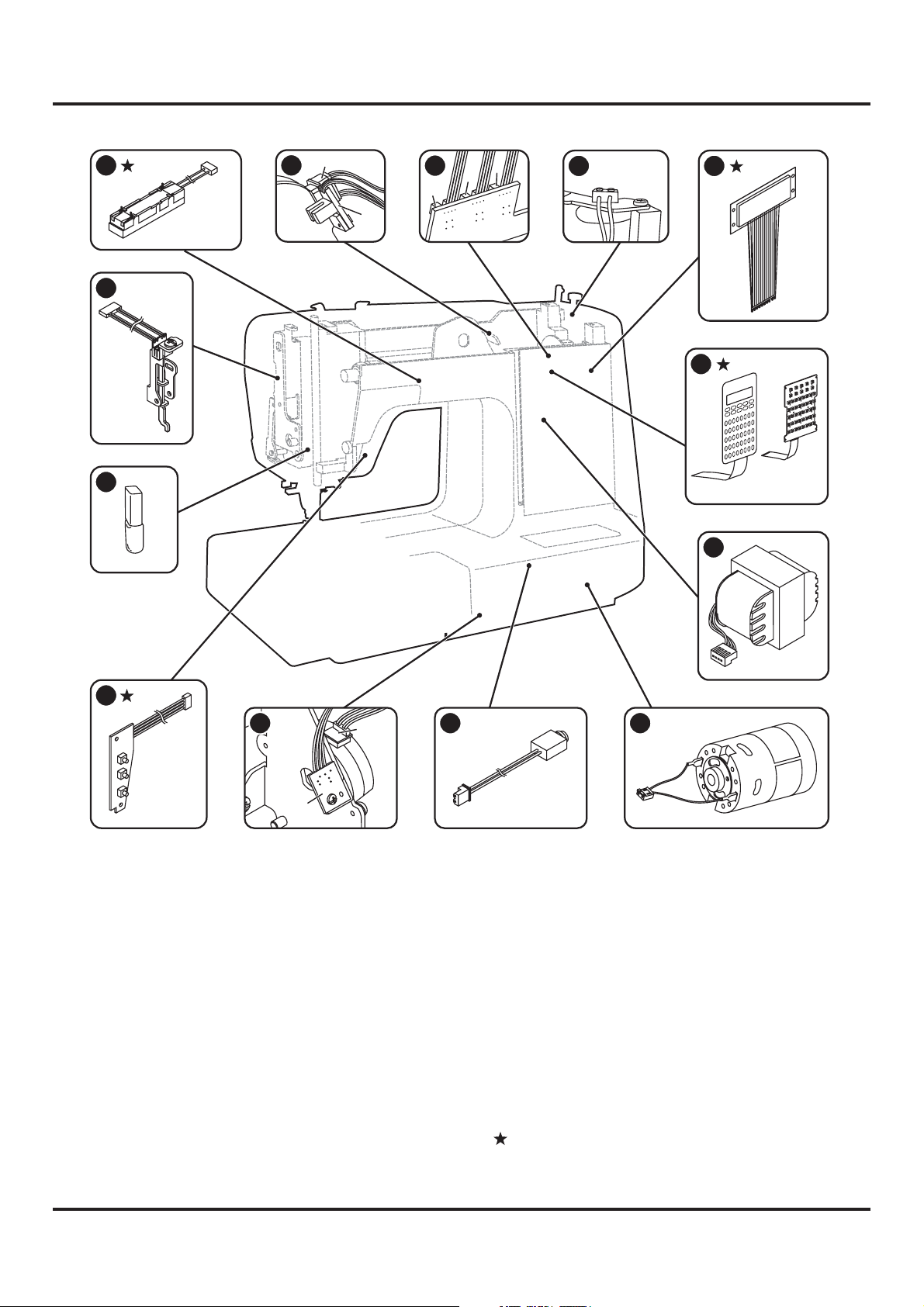

4. lectronic partsNames of e

1

13

12

A

2

3

C

B

4

5

A

B

6

8

7

6

5

4

3

2

6

1

1

5

1

4

1

13

12

11

10

24

9

23

22

1

2

20

9

1

18

32

17

31

30

9

2

28

27

26

0

4

25

39

8

3

7

3

36

35

34

33

9300A2

9300A

7

11

10

B

1.

Slide volume

2-A.

Pulse motor (zigzag)

2-B.

Photo sensor complete (zigzag)

3-A.

Photo sensor complete

(needle position)

3-B.

Photo sensor complete (needle flow)

3-C.

Photo sensor complete (speed)

4.

Bobbin winder micro switch

5. LCD panel

6. Keyboard

7. Transformer

A

9

8

8. DC motor

9. Foot controller connector

10-A.

Pulse motor (stitch length)

10-B.

Photo sensor complete

(stitch length)

11.

Up & down fixed position switch

12. Lamp

13.

Photo sensor complete (B/H)

: Set on the front cover

5

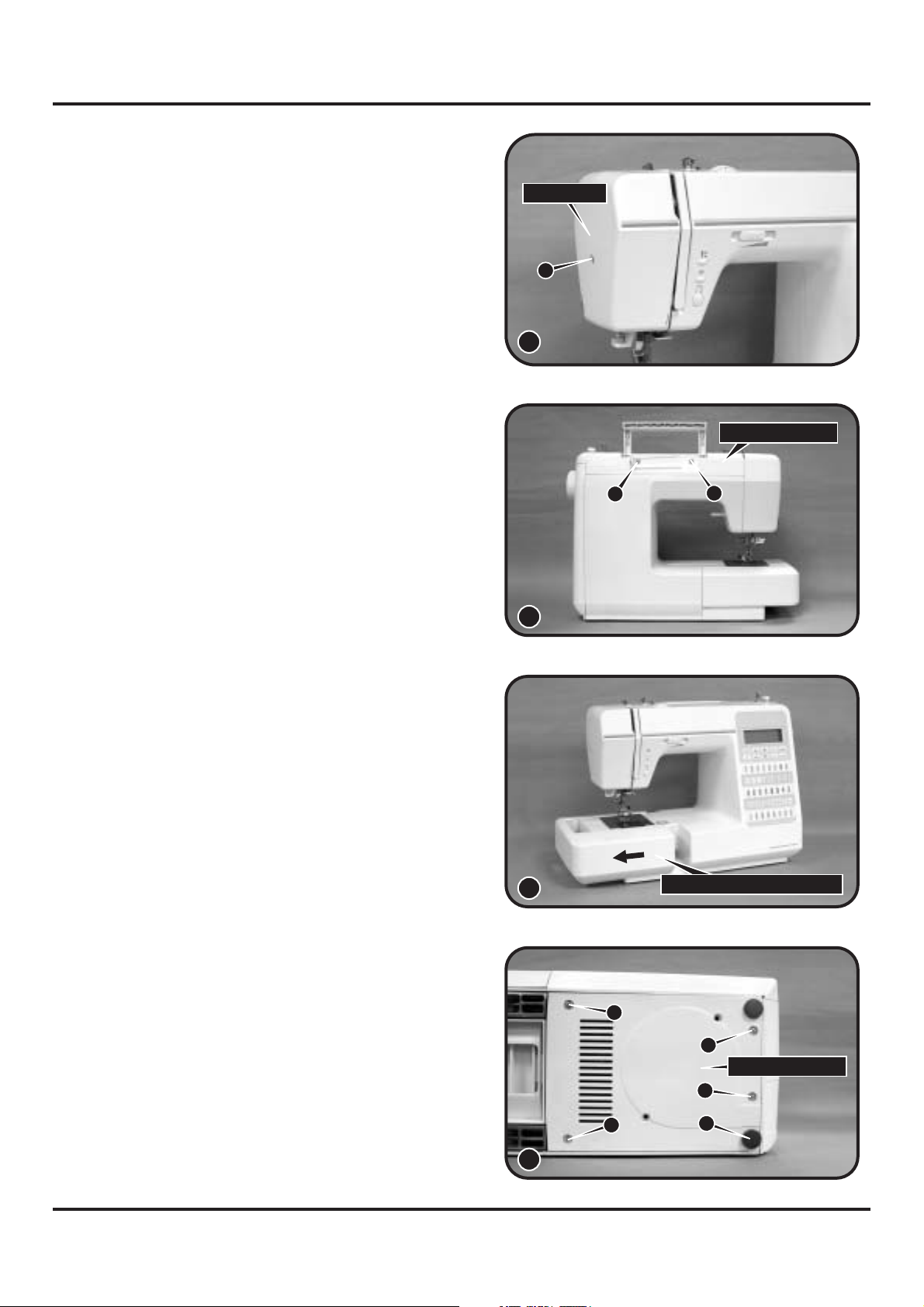

5. Removing methods of external parts

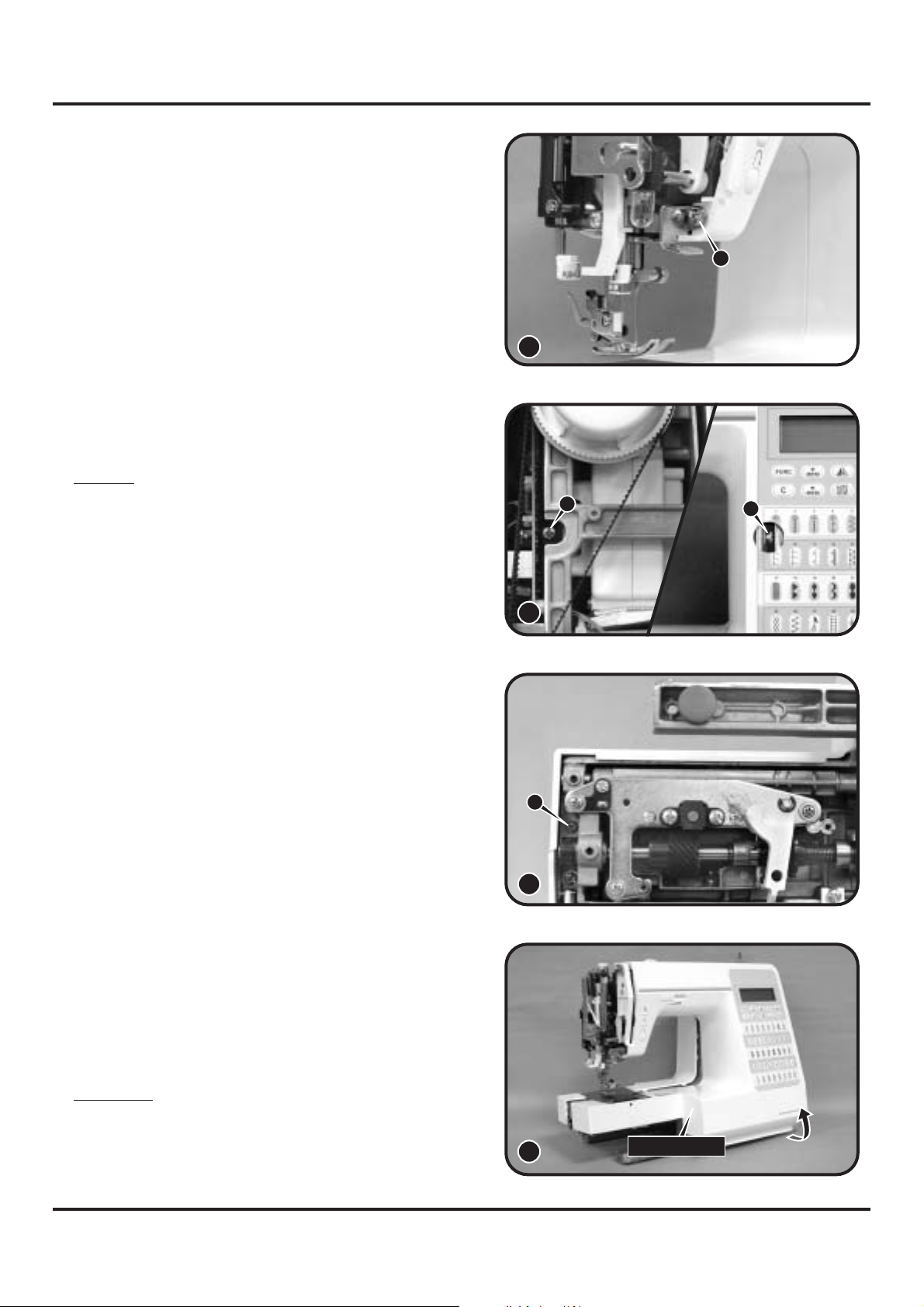

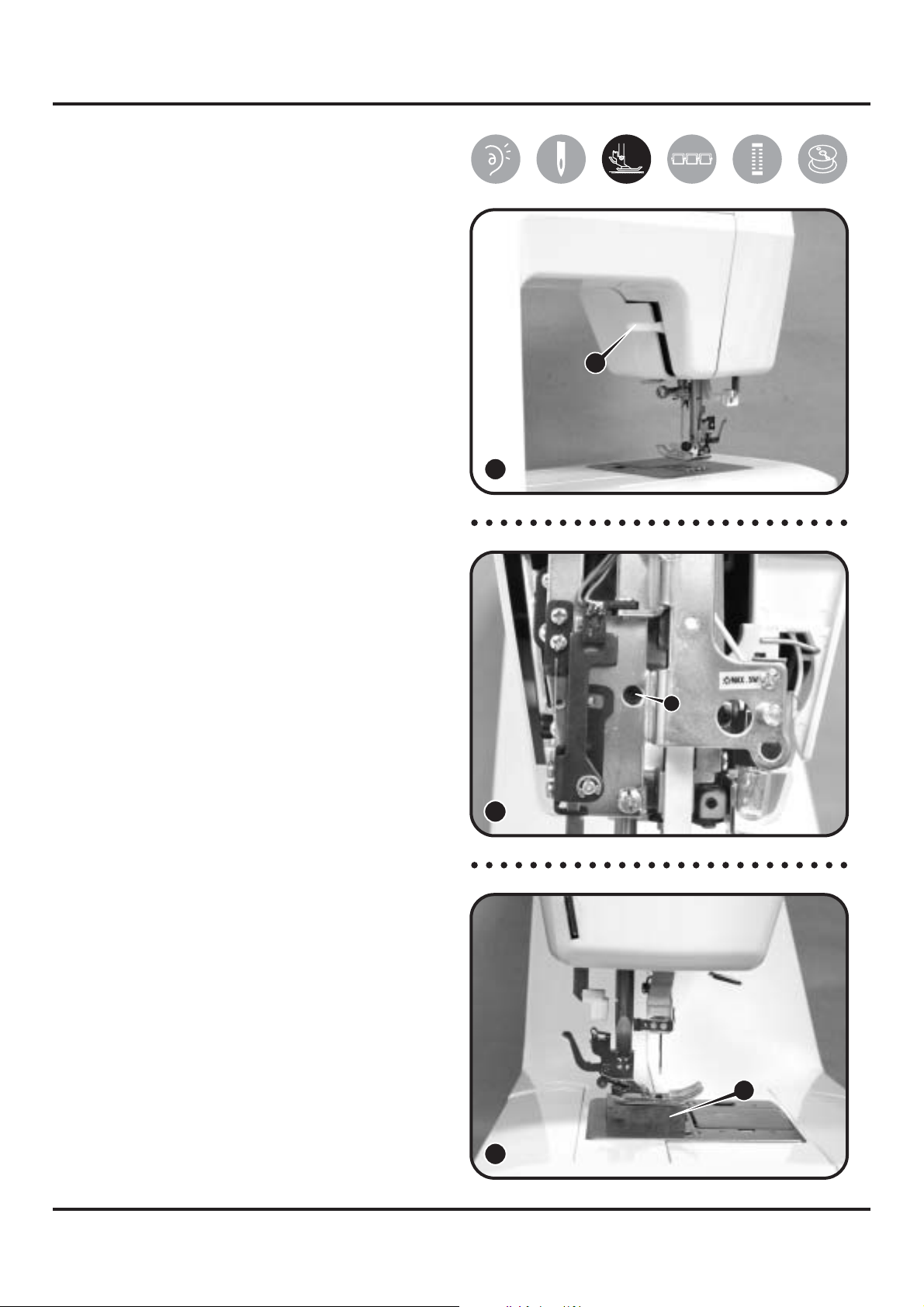

5-1 Face plate

Remove screw (a) and remove the face plate.

(1)

5-2 Arm top cover

Remove 2 screws (b, c) and remove the arm

top cover. (2)

Face plate

a

1

2

Arm top cover

b

c

5-3 Sewing table complete

Keep the snap-in sewing table horizontal, and

pull it in the direction of the arrow. (3)

5-4 Cord reel cover

- Lay down machine. Remove 1 cushion

rubbers (d).

- Remove 4 screws (e, f, g, h). (4)

- Remove cord reel cover.

3

e

f

Sewing table complete

g

Cord reel cover

h

d

4

6

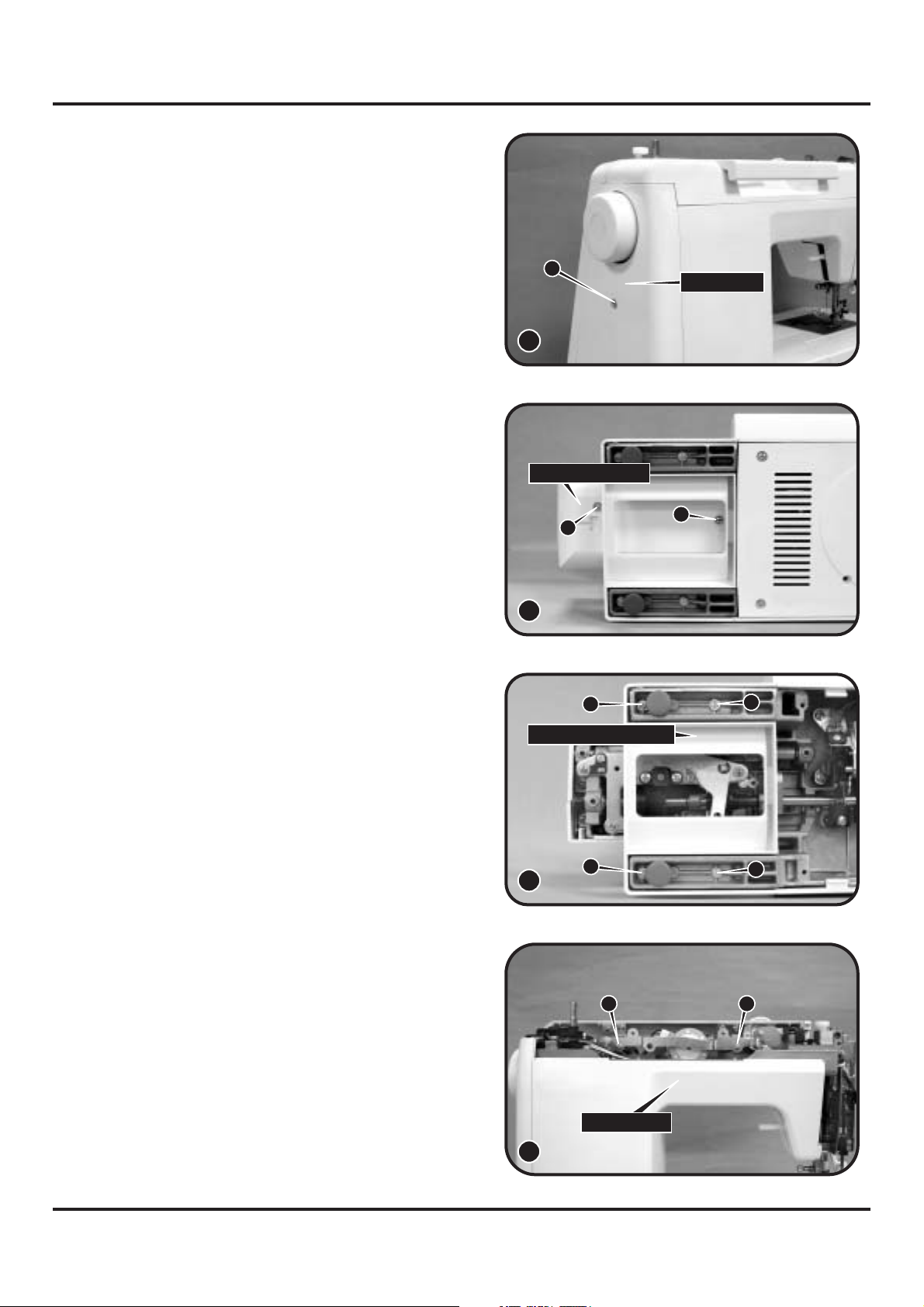

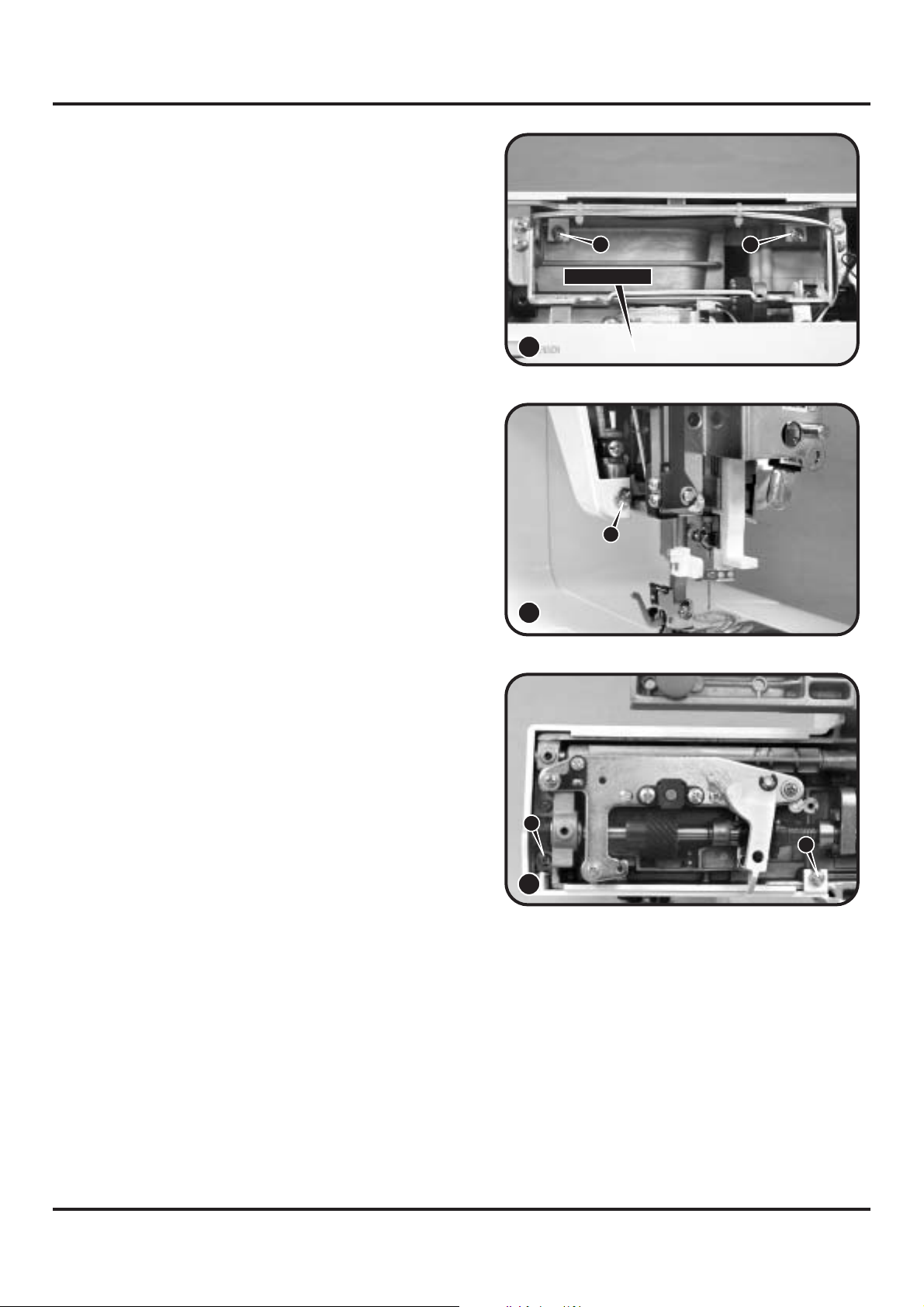

5-5 Belt cover

- Remove screw (i) and remove belt cover. (5)

5-6 Free arm cover

Remove 2 screws (j, k) and remove the free

arm cover. (6)

5-7 Free arm foot bush

Remove 4 screws (l, m, n, o) and remove the

free arm foot bush. (7)

i

5

Free arm cover

j

6

l

Free arm foot bush

Belt cover

k

m

5-8 Front cover

- Remove face plate, arm top cover, sewing

box complete, cord reel cover, belt cover, and

free arm cover and free arm foot bush first.

- Lift handle and remove 2 screws (p, q). (8)

n

o

7

p

Back cover

q

8

7

- Loosen screw (r) about 3mm. (9)

- Loosen screw (s) about 3mm. (10)

Note 1:

First using electric torch (flash light) etc to

locate screw (s) position which deeply inside

the machine.

r

9

s

s

- Remove screw (t). (11)

- Remove front cover following direction of

arrow. (12)

10

t

11

Attention:

Be sure to remove the front cover carefully,

because the leader wire and the body are

connected together.

12

Front cover

8

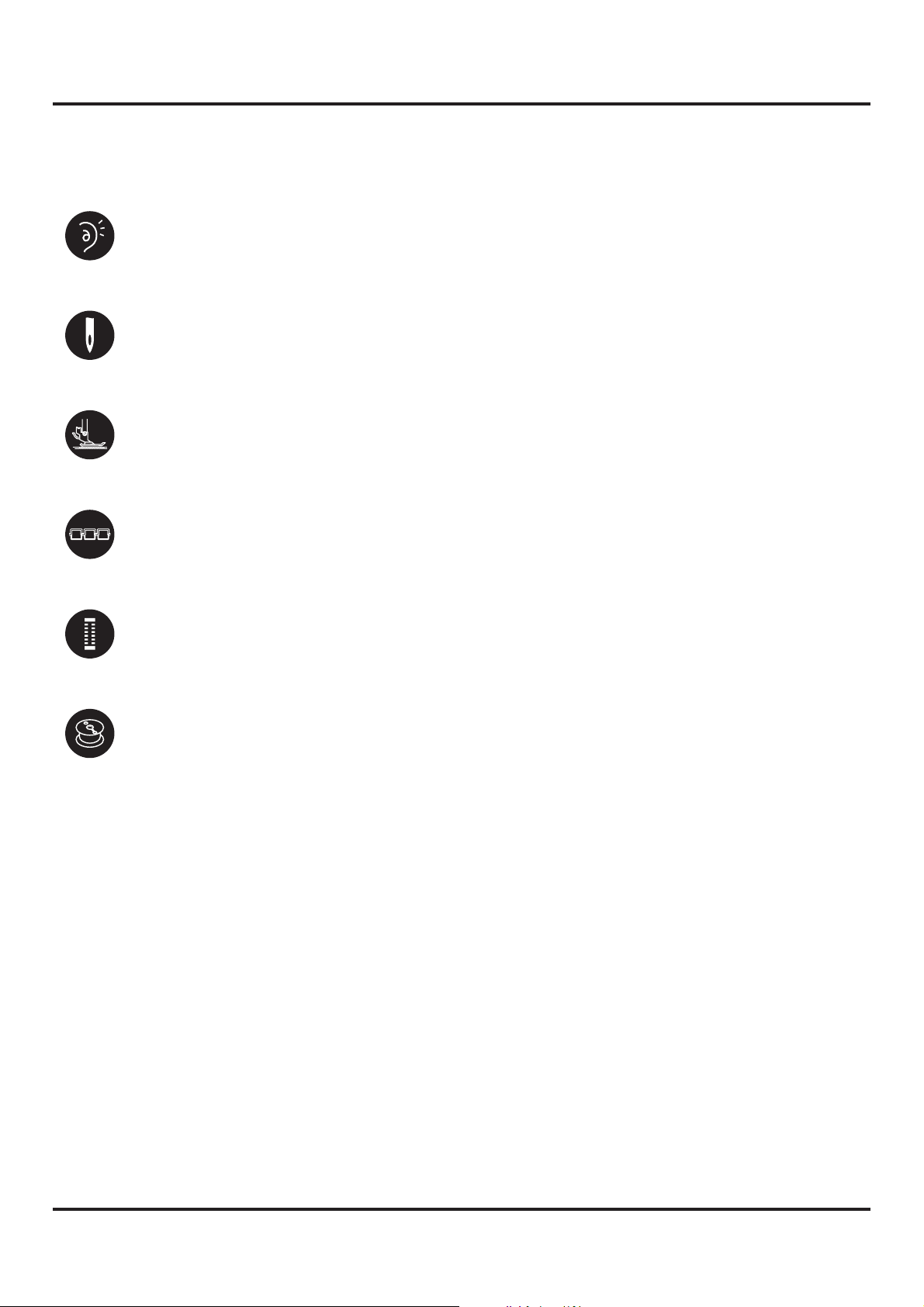

5-9 Back cover

- Remove front cover first.

- Remove 2 screws (u, v). (13)

- Loosen screw (w) about 3mm. (14)

- Remove screw (x).

13

14

u

Back cover

w

v

- Loosen screw (y) about 3mm.

- Remove the back cover. (15)

x

y

15

9

6. Adjusting methods of each part

6-1 Symbol instructions

Noise occur while the machine is running.

Skip-over stitching, needle breakage, and problems associated with needle.

Delivery of cloth to be in disorder and insufficient, problems associated with delivery

amount.

Stitch tightening problem.

BH right and left stitching is not even, incorrect length and problems associated with

buttonhole sewing.

Bobbin winding problem.

10

6-2 Play of arm shaft

1) Remove the face plate and arm top

cover.

2) Remove the 2 screws (a, b) of arm shaft

collar (A). (1)

3) Pull hand wheel backward.

4) Push arm shaft collar (A) to left tightly

against arm shaft bushing (B), and then

fasten and secure screws (a, b). (1)

B

b

a

A

5) Be sure proper distance between arm

shaft collar and arm shaft bushing. (2)

6) Be sure arm shaft operates smoothly

after adjustment.

7) Arm shaft collar and arm shaft bushing

being too tightly closed might cause

insufficient operation of arm shaft.

8) Follow step 1, 2, 3 in order to re-adjust.

6-3 Drop middle point of needle

1

2

- Choose patterns #1.

1) Remove face plate.

2) Loosen screw (a) of needle bar

supporter.

3) Turn needle bar supporter (A) forward /

backward to adjust needle.

Backward = to move needle forward

Forward = to move needle backward

4) Set needle position above center of

needle plate and fasten screw (a).

a

A

backward

forward

11

6-4 Height of presser foot

1) Remove face plate and lift up presser

bar lifter lever (A). (1)

2) Loosen screw (a) of presser bar bracket.

(2)

3) Place gauge (B) (6.0~6.2mm) on top of

needle plate. (3)

4) Pull down presser bar lifter lever so

bottom of presser foot and top surface

of gauge would meet.

A

5) Secure tightly screw (a).

6) The correct setting of gauge should be

6.0~6.2mm.

1

a

2

12

B

3

Loading...

Loading...