CMA MACCHINE PER CAFFÈ S.R.L.

Via Condotti Bardini, 1 - 31058 SUSEGANA (TV) - ITALY - Tel. +39.0438.6615 - Fax +39.0438.60657 - www.astoria.com - info@astoria.com

2006/42/CE Machinery Directive

SAEP

ORIGINAL INSTRUCTIONS

ESPRESSO COFFEE MACHINE

Use and maintenance manual. Instructions for the user.

IMPORTANT: Read carefully before use - Store for future reference

Content rights The partial reproduction and dissemination of the contents in this document without the prior written consent

of the Manufacturer is forbidden. The Company logo is owned by the Manufacturer of the Machine.

Responsibility We are constantly striving to improve the accuracy of the information published in each Manual, but there may be

some inaccuracies. We assume no responsibility for any errors or omissions, or for damages resulting from the use of this document.

ESPRESSO COFFEE MACHINE

Use and maintenance manual. Instructions for the user.

1. SAFETY PRECAUTIONS

1.1 LEVEL OF TRAINING AND KNOWLEDGE REQUIRED OF THE USER

All users must be properly trained and knowledgeable about how the machine works and any residual risks present during its operation.

Users must be able to apply all the good practices in compliance with food

hygiene principles.

1.2 OPERATION

Even though the machine is provided with all the safety devices required to

eliminate possible risks for the User, there are still certain residual risks.

Such risks are related to machine parts that may pose a risk to users, if operated

improperly, assessed or deactivated incorrectly, or because the prescriptions

contained in this Manual were circumvented.

The machine is also equipped with appropriate warnings placed on residual

risk areas, which must be scrupulously observed.

The following residual risks present when the machine is in operation and being

used, must be observed as they cannot be eliminated:

WARNING FOR U.S.A:

Consuming beverages that have been prepared in this espresso machine will

expose you to lead, a chemical known to the State of California to cause birth

defects or other reproductive harm.

USER Manual

3 of 44

ELECTRICAL HAZARD

When using the electrical appliance, several safety standards must be observed:

• Do not touch the appliance with wet or damp hands or feet;

• Do not use the appliance barefooted;

• Do not use extension cords in rooms where there are showers or baths;

• Do not pull the power cord to disconnect the appliance;

• The appliance’s power cord must not be replaced by users. If the cord is dam-

aged, turn the appliance o and contact a Qualied Technician.

• Do not leave the appliance exposed to atmospheric agents (rain, sun, etc.);

• Do not access the inside of the machine;

• Do not spill liquids on the machine;

• Do not allow the appliance to be used by children or incompetent people.

HIGH TEMPERATURE HAZARD

Some parts of the machine can reach high temperatures:

• Avoid contact with the dispensing group, water spouts and steam nozzles;

• Do not place your hands or other body parts near the steam, hot water or

milk dispensing nozzle tips.

4 of 44

USER Manual

The appliance can only be used by people (including children under the

age of 8) with reduced physical, sensory or mental abilities, or lack of

experience or the necessary knowledge, if they are being supervised,

or have received instructions regarding using the appliance safely

and understanding the dangers inherent to it.

Children must be supervised to ensure that they do not play with the

appliance.

Users must promptly inform the Manufacturer if they notice any

machine or accident prevention system defects and/or malfunctions,

as well as any dangerous situations of which they become aware.

It is strictly forbidden to make changes of any kind or extent to the

machine and its functions, as well as to this document.

Make sure that a Qualied Technician periodically carries out routine

maintenance and inspects all safety devices.

Any unauthorised tampering with any parts of the machine renders

any guarantee null and void.

USER Manual

5 of 44

1.3 MAINTENANCE AND CLEANING

The following residual risks are present when maintaining and cleaning the

machine and cannot be eliminated:

ELECTRICAL HAZARD

The maintenance and cleaning operations must comply with the safety regulations:

• Do not carry out maintenance with the machine in operation;

• Do not immerse the machine in water;

• Do not spill liquids on the machine or use water jets when cleaning;

• Do not allow maintenance and cleaning operations to be carried out by chil-

dren or incompetent people;

• Do not remove the guards and/or parts of the body;

• Do not access the inside of the machine;

• Do not perform maintenance and cleaning operations other than those de-

scribed in this manual.

HIGH TEMPERATURE HAZARD

When cleaning, pay attention to the parts of the machine that can become

hot:

• Avoid contact with the dispensing group, water spouts and steam nozzles;

• Do not place your hands or other body parts near the steam, hot water or

milk dispensing nozzle tips.

6 of 44

USER Manual

1.4 PPE FEATURES

When maintaining and cleaning the machine, the following PPE is required:

Gloves

To protect all machine parts that come in contact with food (lter

holders, lters, etc.).

Only perform the maintenance and cleaning operations indicated in

this manual.

Any maintenance and cleaning operations not expressly discussed

in this document must only be performed by the Manufacturer's

Qualied Technicians.

All maintenance operations must be carried out when the power

supply has been turned o, the water mains has been closed o, and

the machine has completely cooled down.

If a malfunction cannot be resolved, turn the machine o and call

out one of the Manufacturer's Qualied Technicians. Do not attempt

any repairs.

The appliance must be descaled by one of the Manufacturer's Qualied

Technicians in order to ensure that its operation does not lead to the

release of materials which are hazardous for food use.

Any unauthorised tampering with any parts of the machine renders

any guarantee null and void.

USER Manual

7 of 44

Table of contents

ESPRESSO COFFEE MACHINE

Use and maintenance manual. Instructions for the user.

English

1. SAFETY PRECAUTIONS ............................................................ 3

1.1

LEVEL OF TRAINING AND KNOWLEDGE REQUIRED OF THE USER ..

1.2 OPERATION ............................................................................3

1.3 MAINTENANCE AND CLEANING .............................................. 6

1.4 PPE FEATURES ....................................................................... 7

2. INTRODUCTION .......................................................................9

2.1 Guidelines for reading the Manual ........................................ 9

2.2 Storing the Manual ............................................................... 9

2.3 Method for updating the Instruction Manual ...................... 10

2.4 Recipients ........................................................................... 10

2.5 Glossary and Pictograms ..................................................... 10

2.6 Guarantee ........................................................................... 10

3. MACHINE IDENTIFICATION .................................................... 11

3.1 Make and model designation .............................................. 11

3.2 General description ............................................................. 11

3.3 Customer service ................................................................. 11

3.4 Intended use ....................................................................... 11

3.5 Machine diagram ................................................................ 13

3.6 Control panel ....................................................................... 14

3.7 Data and marking ............................................................... 15

3.8 Energy Saving System ......................................................... 16

4. STORAGE ..............................................................................16

5. INSTALLATION ...................................................................... 16

6. COMMISSIONING .................................................................. 16

7. OPERATION ...........................................................................16

7.1 Safety precautions .............................................................. 16

7.2 Emissions ............................................................................ 16

7.3 Turning the machine on and o .......................................... 16

7.4 Water renewal ..................................................................... 17

7.5 Preparing the machine ........................................................ 18

7.6 Automatic coee dispensing function ................................. 18

7.7 Manual coee dispensing function (F.R.C. version) ............. 19

7.8 Dispensing steam ................................................................ 19

7.9 Dispensing with Autosteamer ............................................. 20

7.10 Dispensing hot water .......................................................... 20

7.11 Lighting .............................................................................. 21

7.12 Cup warmer ........................................................................ 21

7.13 Energy Saving Management ............................................... 22

8. PROGRAMMING ...................................................................23

8.1 COFFEE DOSE programming ................................................ 23

8.2 Print last dispensed beverage graph ................................... 26

8.3 SERVICE PARAMETER conguration ..................................... 27

3

8.4 DATE and TIME conguration............................................... 28

8.5 COFFEE RECIPE selection ...................................................... 29

8.6 SCREENSAVER conguration ................................................ 30

8.7 BEVERAGE COUNTER list ...................................................... 31

8.8 Viewing the WATER LITRE COUNTER .................................... 32

8.9 Tips for a good cup of coee ................................................ 32

9. MAINTENANCE AND CLEANING ............................................. 33

9.1 Safety precautions .............................................................. 33

9.2 Periodic maintenance .......................................................... 33

9.3 Scheduled maintenance ...................................................... 34

9.4 Grinder wear automatic check ............................................. 34

9.5 Water softener regeneration ............................................... 34

9.6 Malfunctions and solutions ................................................. 35

9.7 Cleaning operations ............................................................ 36

10. SPARE PARTS ........................................................................38

11. DECOMMISSIONING .............................................................. 38

11.1 Short period of machine inactivity ...................................... 38

11.2 Long period of machine inactivity ....................................... 38

12. DISASSEMBLY ....................................................................... 38

13. DISPOSAL ............................................................................. 39

13.1 Disposal information ........................................................... 39

13.2 Environmental information ................................................. 39

14. GLOSSARY ............................................................................ 39

15. ALPHABETICAL INDEX OF TOPICS ..........................................40

8 of 44

USER Manual

2. INTRODUCTION

Please read this Manual in its entirety before using

the appliance, in order to optimise machine performance

and operate it safely.

The espresso coee machine you have purchased

has been designed and manufactured with innovative

methods and technologies which ensure long lasting

quality and reliability.

This Manual is the guide that will enable you to learn

about the benets of choosing our brand. You will nd

information on how to get the best out of your appliance,

how to keep it running eciently and what you should

do if problems occur.

Keep this Manual in a safe place. If you lose it, you can

request another copy from the Manufacturer.

UNITS OF MEASUREMENT

The units of measurement are those provided by the In-

ternational System (SI).

PICTOGRAMS

Descriptions preceded by these symbols contain very

important information/requirements, particularly in regards

to safety. Failure to comply with these may result in:

• Danger to the operator's safety;

• Injury, including serious injury, to users (in some cases,

even death);

• Loss of the guarantee;

• The Manufacturer waiving liability.

DANGER symbol used when there is a risk of permanent serious

injury that would require hospitalisation, or in extreme cases,

even cause death.

Before using the machine, carefully read and follow the

instructions contained in this publication. Keep this manual

and all attached publications in an accessible and secure place.

This document assumes that the machine is installed in a location

where the current work safety and hygiene standards are observed.

The instructions, drawings and documentation contained in this Manual are technical and condential. They

are the sole property of the Manufacturer, and may not

be fully or partially reproduced in any way.

The Manufacturer reserves the right to make any

improvements and/or modications to the product. We

guarantee that this Manual reects the technical state of

the appliance at the time it was released to the market.

We take this opportunity to invite customers to make

any proposals to improve the product or its Manual.

2.1 Guidelines for reading the Manual

This Manual is divided into separate chapters. The chapter

order is linked to the temporal logic of the life of the machine.

Terms, abbreviations and pictograms are used to facilitate

the immediate understanding of the text.

This Manual consists of cover, index and a series of chapters.

Each chapter is sequentially numbered. The page number is

shown in the footer.

The rst page displays the machine identication data and

the last page displays the date and revision of the Instruction

Manual.

CAUTION symbol used when there is a risk of minor injury that

could require medical attention.

WARNING symbol used when there is a risk of minor injury that

could be treated with rst-aid or similar measures.

NOTE symbol used to provide important information about the

topic.

2.2 Storing the Manual

The Instruction Manual must be stored in a safe place and

accompany the machine in all ownership transfers.

The manual should be stored, handled with care with clean

hands and not placed on dirty surfaces. Do not remove, tear

or arbitrarily modify any of its parts.

The manual must be stored away from moisture and heat,

and in close proximity to the machine it refers to.

On the user's request, the Manufacturer can provide additional copies of the Instruction Manual.

ABBREVIATIONS

Sec. = Section

Chap. = Chapter

Para. = Paragraph

P. = Page

Fig. = Figure

Tab. = Table

USER Manual

9 of 44

2.3 Method for updating the Instruction

Manual

The Manufacturer reserves the right to modify and make

improvements to the machine without providing notice or updating the Manual that has already been received by the user.

Moreover, when substantial changes made to the machine

require the modication of one or more chapters of the Instruction Manual, the Manufacturer will send users the chapters

aected by the changes or a revision of the entire Manual.

It is the users' responsibility to replace the old document

with the new revision.

The Manufacturer is responsible for the Italian content.

Translations cannot be fully veried; therefore, in the event

of inconsistency, users can refer to the Italian version or if

necessary, contact the Manufacturer who will make the appropriate changes.

Should the Manual become illegible or otherwise hard to read,

the user must request a new copy from the Manufacturer before

carrying out any work on the machine.

IT is absolutely forbidden to remove or rewrite parts of the

Manual.

The instructions, drawings and documentation contained

in this manual are condential and the sole property of the

Manufacturer. They may not be reproduced in any way, either

in full, or in part without prior authorisation.

Users are responsible for complying with the instructions

contained in this Manual.

Should any incident occur as a result of incorrect use of these

recommendations, the Manufacturer declines any liability.

This manual is also available on the manufacturer’s website.

2.5 Glossary and Pictograms

This paragraph lists uncommon terms or terms whose

meanings are dierent from those most commonly used.

Abbreviations are explained below, as well as the

meaning of pictograms describing the operator's qualication and the machine status; they are used to quickly

and uniquely provide the information needed to correctly and safely use the machine.

2.5.1 GLOSSARY

User

The person or persons in charge of operating, maintaining and cleaning the machine described in this

manual.

Manufacturer's Qualied Technician

A person specially trained and qualied to connect,

install and assemble the machine; use special equipment

(hoists, forklifts, etc.); perform routine or unscheduled

maintenance that may be particularly complex or potentially dangerous if performed by the user; and, pay

special attention to safety and hygiene issues.

All other glossary entries are listed in Chap."14. GLOSSARY" on

page 39.

2.5.2 PICTOGRAMS

PICTOGRAM DESCRIPTION

2.4 Recipients

This Manual is addressed to the machine’s User,

namely, the person in charge of operating, maintaining

and cleaning the machine described in this document.

MACHINE RECIPIENT QUALIFICATIONS

The machine is intended for a professional nongeneralised use, so it is to be used by trained people,

and particularly those who:

• Are aged 18 and over;

• Are physically and mentally capable of using the

machine;

• Are able to understand and interpret the Instruction

Manual and safety requirements;

• Know the safety procedures and how they are imple-

mented;

• Are able to use the machine;

• Have understood the procedures of use as dened

by the machine's Manufacturer.

Electrical hazard

High temperature hazard

The use of protective gloves is mandatory

It is mandatory to read the documentation

2.6 Guarantee

All of the machine's components are covered by a

12-month guarantee, except for electrical and electronic

components and parts prone to wear and tear.

10 of 44

USER Manual

3. MACHINE IDENTIFICATION

3.1 Make and model designation

The machine and model ID information

is found on the unit's NAMEPLATE and in

the provided EC DECLARATION OF CONFORMITY.

3.4 Intended use

The espresso coee machine has been

designed to professionally prepare hot

drinks such as tea, cappuccinos and weak,

strong and espresso coee, etc.

The appliance is not intended for domestic use, it is intended for professional

purposes only.

3.2 General description

The machine described in this Manual

consists of mechanical, electrical, and

electronic components which, when used

together, produce milk, coee and waterbased beverages.

This product is manufactured in compliance with the EU Directives, Regulations and Standards indicated in the EC

DECLARATION OF CONFORMITY provided

with the machine.

This machine is designed and constructed to operate only after being

properly connected to a hydraulic and

electrical network and placed so as to be

sheltered from atmospheric agents.

The machine can be used under all the

conditions set forth, contained or described in this document; any other conditions must be considered dangerous.

The machine must be installed in a place

where its access is restricted to qualied

personnel only who have received suitable

training (coee shops, restaurants, etc.).

3.3 Customer service

CMA MACCHINE PER CAFFÈ S.R.L.

Via Condotti Bardini, 1 - 31058 SUSEGANA (TV) - ITALY

Tel. +39 0438 6615 - Fax +39 0438 60657

E-mail: service@astoria.com - Web-site: www.astoria.com

C.M.A. FRANCE

67 rue Marcel Dassault - 93140 BONDY - FRANCE

Tel. +33 1 48547208 - Fax +33 1 48546578

E-mail: bondy@astoria.fr - Web-site: www.astoria.com

G.E.E.C.

7912 Industrial Village Road - GREENSBORO NC 27409 - USA

Tel. 336 393 0224 - Fax 336 393 0295

E-mail: info@geec.com - Web-site: www.usa.astoria.com

USER Manual

SC MACCHINE PER CAFFE' ESPRESSO MCE SRL

Calea Sagului, DN 59, KM 8+300 - 300516 TIMISOARA - ROMANIA

Tel. +40 256 306 492/4 - Fax +40 256 306 496

E-mail: mce@mcesa.com - Web-site: www.mcesa.com

RCW RUS LLC

Business Center PORTPLAZA

Proektiruemy proezd 4062, 6/16 - 115432 MOSCOW - RUSSIA

Tel. +7(495) 925 75 56 - E-mail: info@rcwrussia.ru

11 of 44

PERMITTED USES

with the Manufacturer. Only operations

All uses compatible with the technical features, operations and applications

described in this document which do

not endanger the safety of users or cause

damage to the machine or its surrounding environment.

All uses not specically mentioned in this Manual

are prohibited and must be expressly authorised

by the Manufacturer.

INTENDED USES

The machine has been designed exclusively for professional use.

The use of products/materials other

than those specied by the Manufacturer,

which can cause damage to the machine

and be dangerous for the operator and/or

those in close proximity to the Machine,

is considered incorrect or improper.

CONTRAINDICATIONS OF USE

The machine must not be used:

• For uses other than those listed in para.

3.4, or for uses that dier from or are not

mentioned in this Manual;

• With materials other than those listed

in this Manual;

discussed in this document are allowed;

any operation not listed and described

herein is to be considered improper and,

therefore, hazardous.

IMPROPER USE

The only permitted uses are described

in the Manual; any other use is considered

improper and, therefore, hazardous.

GENERAL SAFETY FEATURES

The user must be aware of accident

risks, safety devices and the general safety

rules set forth in EU directives and by the

legislation of the country where the line

is installed.

The user must know how all the machine's devices work.

They must also have fully read this

Manual.

Maintenance work must be performed

by qualied technicians after the machine

has been properly assembled.

The tampering or unauthorised replacement of one or more machine components, the use of accessories which

modify its use and the use of materials

other than those recommended in this

Manual, can cause accidents.

• With safety devices that have been

disabled or are not working.

INCORRECT USE OF THE MACHINE

The type of application and per-

formance that this machine has been

designed for, requires a number of operations and procedures that cannot

be changed, unless previously agreed

12 of 44

USER Manual

3.5 Machine diagram

7. ON switch

8. Steam lever

9. Steam nozzle anti scalding

10. Hot water spout

11. Back light logo

12. Adjustable foot

13. Filter holders

14. Dispensing compartment

LED light

15. Display touchscreen

16. Cup holder grille

17. Cup warmer shelf

18. Machine on indicator light

19. Manual coee button

20. Manual coee lever

2

11

5

9

3

13

7

6

10

8

12

4

Standard version

14

11

5

7

6

10

2

9

3

13

1

USER Manual

12

8

4

F.R.C. version

13 of 44

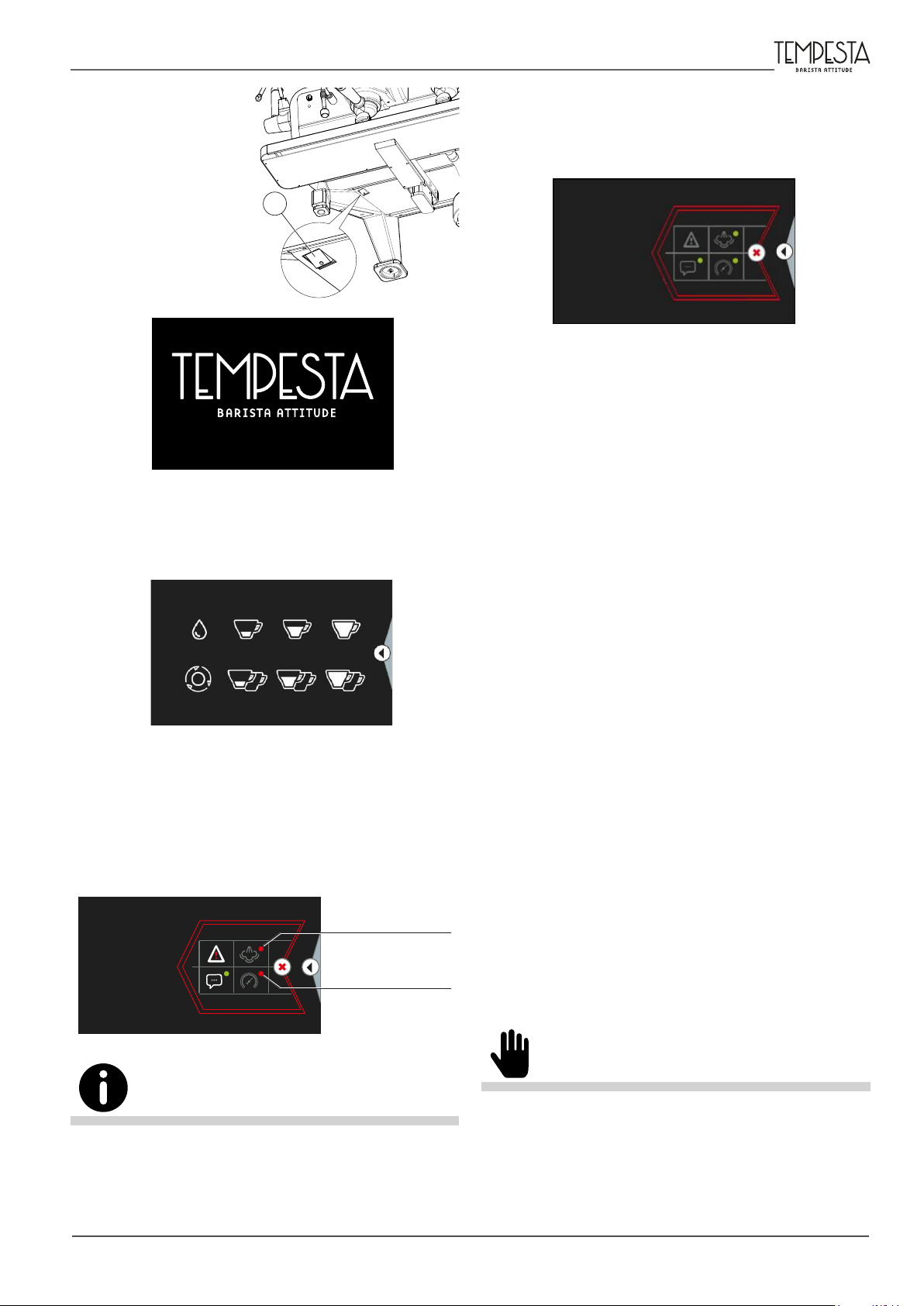

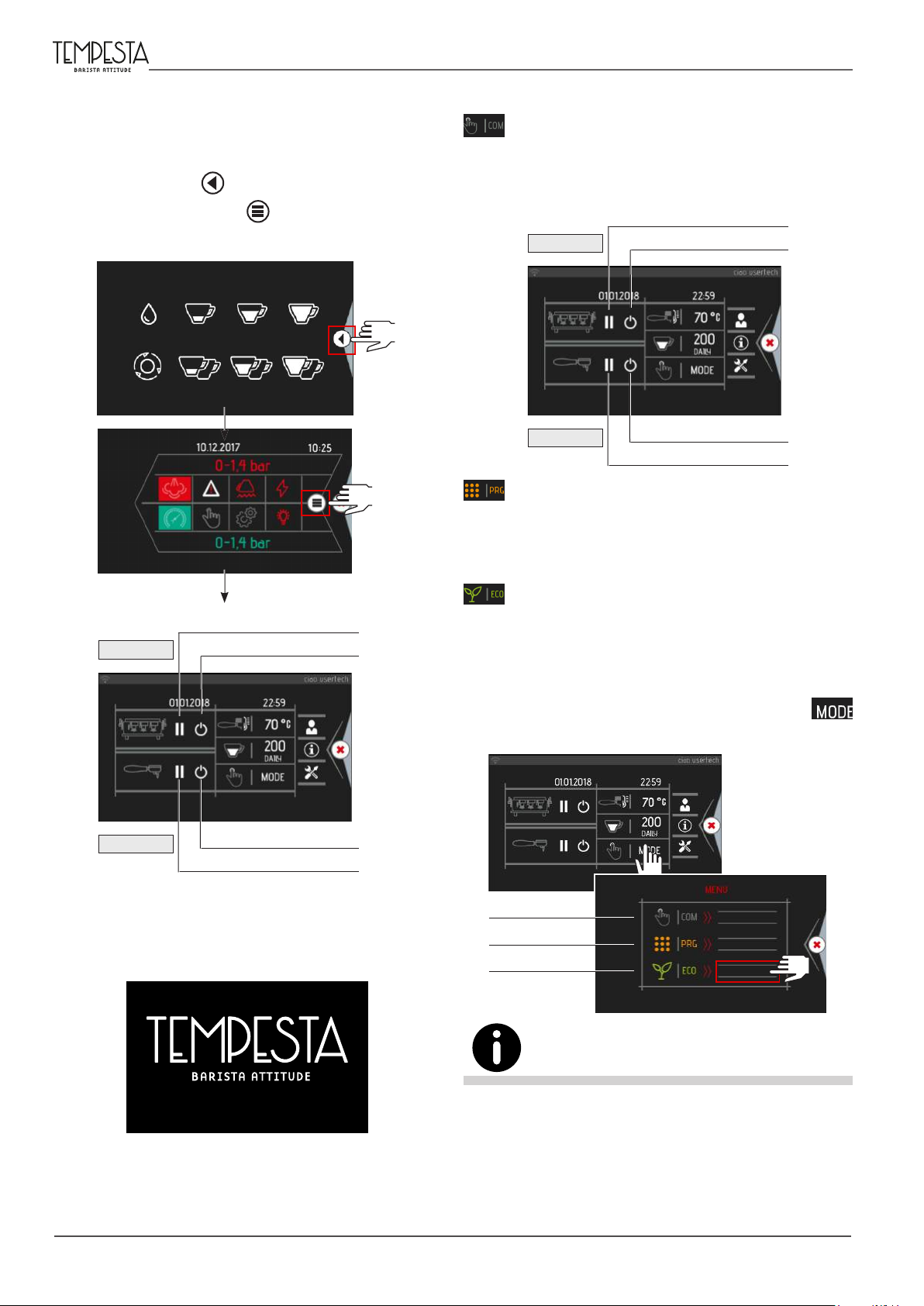

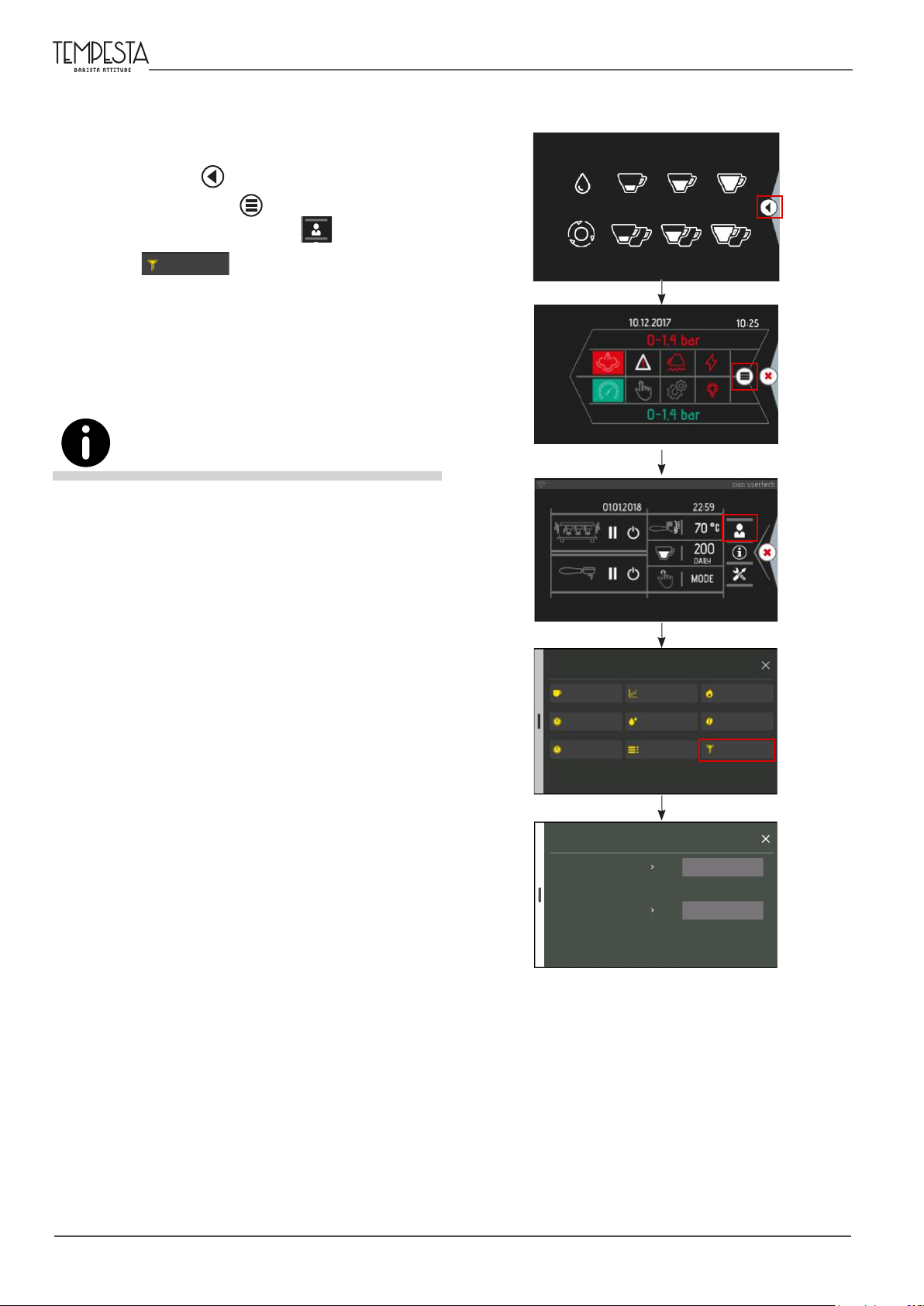

3.6 Control panel

The machine is completely controlled through the touch screen display located on the front. The display will also

show machine malfunctions, if any:

START/STOP button

Warning indication

Operating mode set up

Beverage selection button

Control access

Beverage selection buttons

The main machine parameters are accessible through the key :

MONDAY

steam pressure

value

Machine warnings

EXIT button

Cup warmer

Back light logo

EXIT button

water pressure

value

Parameter menu

Work surface light

The machine menu can be accessed through the key :

MACHINE

Manual shutdown Dispensing group temperature

Manual standby

MONDAY

GROUP

Manual standby

Beverages served over

the course of the day

User conguration

Machine informations

Technical conguration

Manual shutdown

14 of 44

Operating mode set up

CONF / PROG / ECO

USER Manual

3.7 Data and marking

The machine’s technical data is shown in the

following table:

TECHNICAL DATA

TABLE

Voltage (V)

Max. power (W)

Frequency (Hz)

Capacity coee

boiler

Capacity operation pressure

(l)

2GR

(STANDARD / FRC)

2GR

(FRC)

3GR

(STANDARD / FRC)

3GR

(FRC)

220/380 240/415 200 220/380 240/415 200

4.000 5.000 3.500 6.000 7.000 5.000

50-60

1,2 l x 2 1,2 l x 3

8,5

Width (mm) 1035 1175

Depth (mm) 618

Height (mm) 500

Net weight (kg) 97 117

Safety valve

calibration

0,19 MPa (1,9 bar)

Steam heating

unit opera-

0,08 - 0,14 MPa (0,8 - 1,4 bar)

tion pressure

Supply water

pressure

0,15 - 0,6 MPa MAX (1,5 - 6 bar MAX)

Recommended

coee delivery

0,8 - 0,9 MPa (8 - 9 bar)

pressure

Temperature

work envi-

5 - 35°C 95° U.R.MAX

ronment

Sound pressure

level

< 70 dB

According to Directive 2006/42/EC, the machine bears

a CE marking, meaning that the Manufacturer declares,

under his own responsibility, that the unit is safe for

people and property.

The CE label which provides the identication data

is axed under the drain tray. Below is an example of a

nameplate:

MARCHIO COMMERCIALE

CMA MACCHINE PER CAFFÈ S.r.l.

Via C. Bardini,1 SUSEGANA (TV) - ITALY

Tel. +39.0438.6615 Fax +39.0438.60657

S/N:

V

Mod.

W

Y

Hz

MADE IN ITALY

The CE label is axed

under the drain tray

MONDAY

INFO

Keypad software version

Ver. 338 Rev. 013.13

01/04/2016

Basic software version

Ver. 396 Rev. 013.14

18/03/2016

Serial number NNNNNN

WI-FI

Enter the "Menu” section (see the instructions in the

following chapters) and select the

button to view

the machine's serial number.

When contacting the Manufacturer, always provide

the following information:

• S/N - machine serial number;

• Mod. - machine model

• Y - year of manufacture;

The appliance data can also be found on the label

located on the machine's packaging.

It is forbidden to remove or damage the nameplate. If this occurs,

replace it as a matter of urgency, dealing exclusively through the

Manufacturer.

USER Manual

15 of 44

3.8 Energy Saving System

The machine is equipped with software that manages the automatic standby system during breaks, the

night energy-saving feature and the smart temperature

adjustment.

This allows a considerable amount of energy to be

saved during night breaks, whilst maintaining the machine in a condition that can quickly return to operating

mode.

Moreover, the software only distributes the power

where and when needed, thus allowing energy to also

be saved during normal operation.

When programmed, the system automatically puts

one or more groups into standby mode when the workload decreases and prepares them for full capacity when

needed.

Three choices are provided:

•

•

•

: Stand by manual activation

: programmed operation

: self-learning management.

7. OPERATION

7.1 Safety precautions

Carefully read the instructions provided in chapter "1. SAFETY

PRECAUTIONS" on page 3 .

7.2 Emissions

VIBRATIONS

Under conditions of use that meet the indications of

correct use provided in this manual, any detected vibrations do not give rise to dangerous situations.

SOUND EMISSIONS

The noise level emitted by the machine is on average

lower than 70 dB; therefore, there is no obligation to use

personal protective equipment for the auditory system.

Notify the Manufacturer if the machine emits unusual

noises.

To activate the Energy Saving mode, see para. 7.13 on page 22.

4. STORAGE

The machine is stored by the Manufacturer or the

Distributor.

5. INSTALLATION

The machine must only be installed by one of the

Manufacturer's Qualied Technicians.

The machine's support base must be perfectly level and have no

irregularities.

ELECTROMAGNETIC ENVIRONMENT

The machine is designed to work properly in any

industrial electromagnetic environment, falling within

the Emission and Immunity limits provided by current

standards.

7.3 Turning the machine on and o

After the hydraulic and electrical mains have been

connected by a Qualied Technician, make sure that the

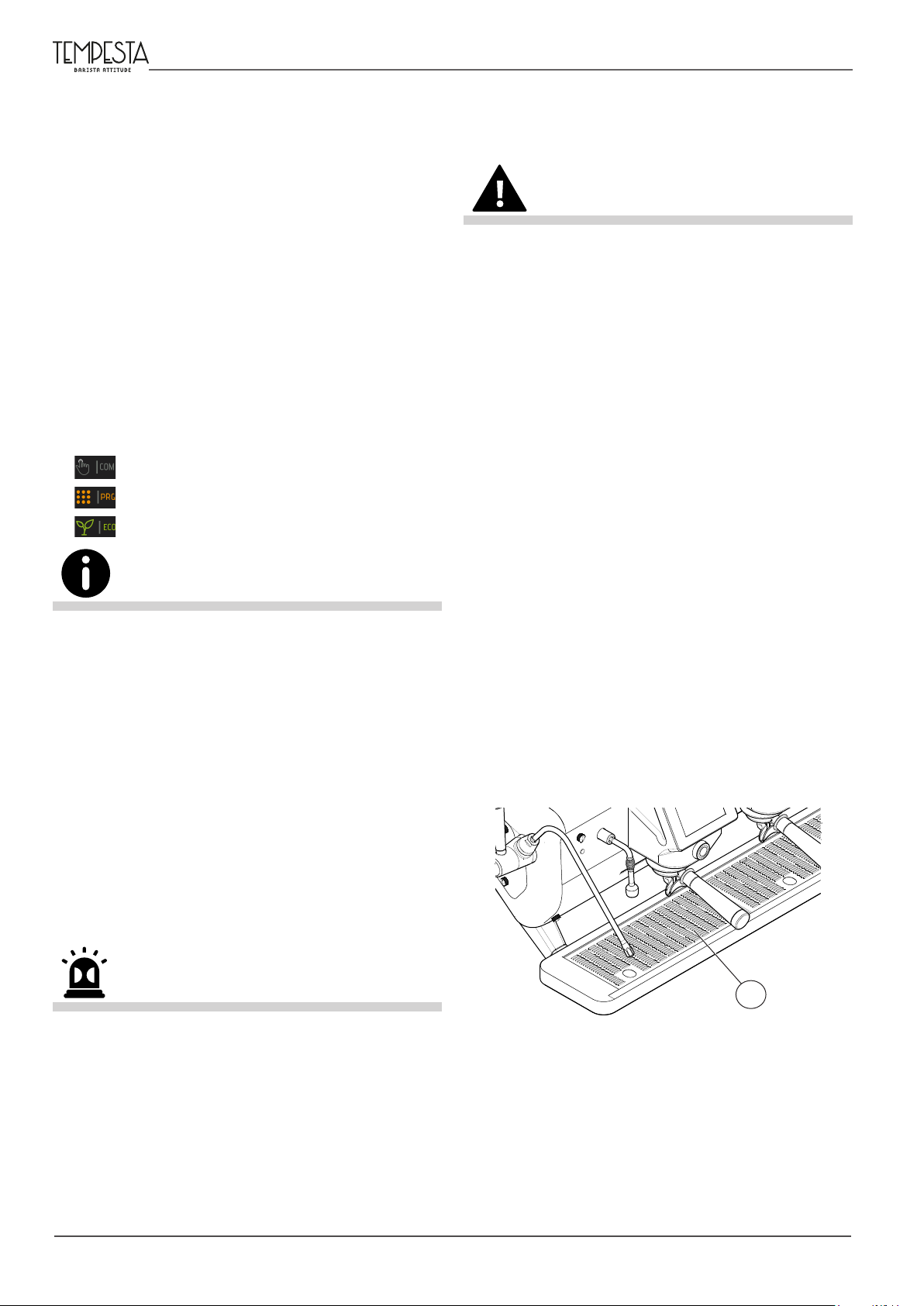

drain tray under the cup holder grille (10) is correctly

connected to the drain.

10

6. COMMISSIONING

The machine must only be commissioned by one of

the Manufacturer's Qualied Technicians.

16 of 44

USER Manual

Check that all the

steam valves are closed.

Turn the machine on

using the main switch (1)

and follow the instructions provided on the

display, as described below.

When the machine has started up, the warm-up phase

begins. When the warm-up phase has been completed,

the machine will be ready to dispense coee and the

screen shown below will appear on the display.

1

In some cases, such as, for example, after the groups

have been washed, all the selections may be inactive for

a short time, the display may have reduced brightness

and some messages may appear on the right bar.

Simply wait a few seconds until the temperature has

been fully regulated: the display will return to its normal

brightness and all the selections will once again be active.

7.3.1 Turning the machine o

Turn o the machine via the main switch (1).

7.4 Water renewal

When the machine is being installed, the Qualied

Technician must replace the water inside the hydraulic

circuits by following these steps:

It may sometimes take longer for the steam to be

ready for dispensing than the coee. If this occurs, wait

a few minutes until the green steam icon appears on

the display.

The green icon indicates that the machine is at the

programmed pressure and steam is ready to be dispensed.

Steam

not available

Coee supply

not available

• When the installation is complete, the appliance must

be started, brought to nominal working condition and

left in the “ready-to-operate” status for 30 minutes;

• Next, the appliance has to be turned o and fully

emptied of the rst water introduced into the entire

hydraulic circuit, in order to eliminate any initial

impurities;

• Then, the appliance must be lled with water and

brought to the nominal working conditions;

• Turn the machine o again and empty all the water

in the hydraulic circuit;

• Turn the machine back on, then ll it and bring it to

the nominal working conditions;

• When the "ready to operate" status is reached, continuously dispense from each coee group, in order

to empty the coee circuit of at least 0.5 litres.

• Continuously release steam for at least 1 minute from

each steam dispensing point.

Before using the machine, carry out some empty dispensing cycles

with the lter holders attached for several seconds. This procedure

releases any air inside the hydraulic circuit and in turn, allows the

dispensing groups to fully heat up.

USER Manual

If the machine remains idle for longer than a week, a Qualied

Technician must renew 100% of the water inside the hydraulic

circuits, as indicated above.

17 of 44

7.5 Preparing the machine

7.5.1 Grinding and dosing coee

It is important to have a grinder-dispenser next to the

machine so that the coee can be ground on a daily basis.

The coee must be ground and dispensed according to instructions provided by the manufacturer of the

grinder-dispenser. The following points should also be

kept in mind:

• To make a good espresso, we recommend that you

do not store large amounts of coee beans. Comply

with the expiry date indicated by the producer;

• Never grind large volumes of coee, it is advisable to

prepare the amount that can be held in the dosing

device and if possible, use it by the end of the day;

• Do not buy pre-ground coee, as it perishes quickly.

If necessary, buy coee

in small vacuum-sealed

packs.

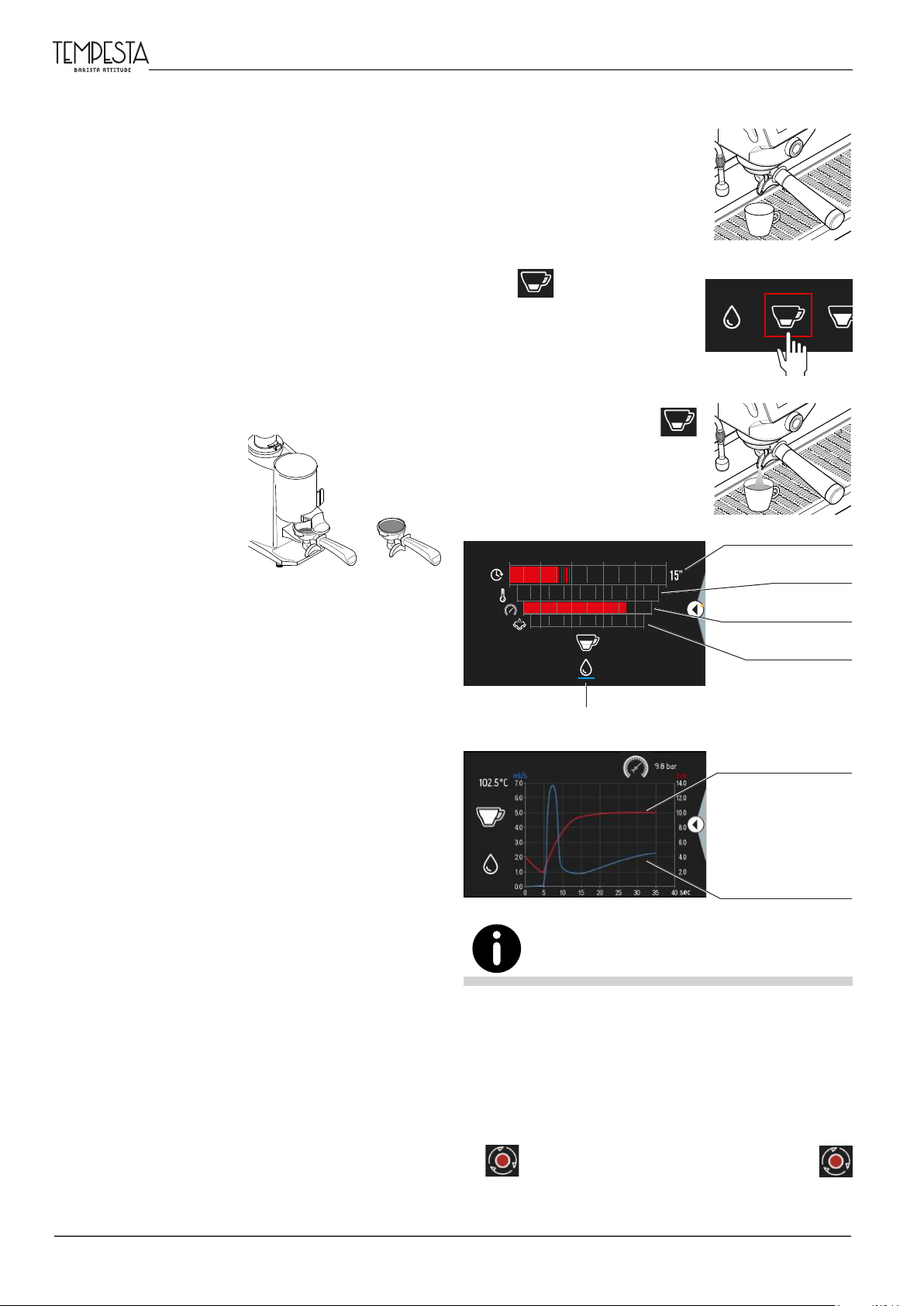

7.6 Automatic coee dispensing function

• Place the cup under the dispensing spout;

• press the desired dose button,

e.g.

coee is dispensed (LED will

switch on);

• To stop coffee dispensing

ahead of time, press the

button again;

and wait until the

Dispensing time

7.5.2 Preparing the lter holder

• Fill the lter with a dose of ground coee (approx. 6-7

g) and compress it with the press;

• Hook the lter holder to the group without closing it

too tightly in order to prevent the gasket from wearing quickly;

• For the same reason we recommend that the edge of

the lter is cleaned before attaching the lter holder

to the dispensing group;

• Follow the procedures specied by the manufacturer

of the grinder-dispenser.

Temperature

Pump pressure

Steam pressure

Hot water dispensing

enabled

Red chart:

delivery pressure

Blue chart:

supply quantity

The graph represents the exact performance of the pressure in the

pre infusion only if only one dispensing is in eect.

In case of two or more concomitant deliveries, the graph on the

other displays will not indicate the actual pressure value of the

pre infusion, but that of the instantaneous pressure because the

pump is already in operation.

18 of 44

• In order to continuously dispense coee, select the

button and stop it by pressing the same

button again.

USER Manual

Continuous

dispensing

7.8 Dispensing steam

• Immerse the steam nozzle into

the liquid to be heated;

COFFEE can be dispensed via

the button under the individual

displays (13).

When the button is pressed, the

machine will dispense the type of

coee pre-set by the manufacturer.

Press the same button again to

stop dispensing.

13

7.7 Manual coee dispensing function

(F.R.C. version)

• Place the cup under the dis-

pensing spout;

• Lower the lever located next

to the group (14). The amount

of coffee dispensed will be

proportional to the downward

position of the lever;

• To stop dispensing, push the

lever back up again.

14

• lower the tap lever;

• to end the delivery, bring the

lever upwards.

Avoid contact with the steam nozzles, do not place your hands or

other body parts near the steam nozzle tips.

To optimally froth the milk, follow these simple rules:

For a better coee, leave the lter to infuse for a few seconds

using the lever.

Do not remove the lter holder from the dispensing group when

coee is being dispensed.

The machine is programmed by default. If you would like to modify

the coee doses, proceed as indicated in para. 8.1 on page 23.

Provided that a group rinse operation has been scheduled, it

is possible to carry it out by pressing the START/STOP button

(continuous supply) or the manual button prior to inserting the

lter holder.

In this case, the 2 buttons must NOT be used to supply coee, as

the quantity of water produced is not sucient.

• Only heat the amount of milk that you intend to use;

once heated, it will have to be completely poured out

of the jug and cannot be reheated;

• Froth the milk which should be at a temperature of

around 4°C.

To keep the steam nozzle tips in perfect working order, it is

advisable to carry out a brief dry dispensing run after each use.

Keep the tips clean at all times using a cloth dampened in

lukewarm water.

The condensation draining operation must be carried out for

at least 2 seconds before using the steam

nozzle.

Only leave the steam wand immersed in the

milk for the time needed to heat it.

Do not open the steam valve with the steam

wand immersed in milk while the machine

is switched o.

MILK

USER Manual

19 of 44

7.9 Dispensing with Autosteamer

• Immerge the tips of the Autosteamer into the milk;

• sur l'écran, sélectionner la touche désirée, par exemple

et patienter jusqu'à ce que la

vapeur s'échappe;;

• wait until the delivery is nished;

Before using the milk frother, press one of the autosteamer

selection buttons to let out some short spurts of air, until all the

condensation water has been released. To stop dispensing, press

the same button again.

• To stop dispensing ahead of

time, press the same key

again.

Medium

autosteamer

dose

Short autoste-

amer dose

• Only heat the amount of milk that you intend to use;

once heated, the milk will have to be completely

poured out of the jug and cannot be reheated;

Long autoste-

amer dose

Continuous

frothing

Keep the tips clean at all times using a cloth dampened in

lukewarm water. The milk can be kept in the refrigerator for a

maximum of 3-4 days.

Leave the steam nozzle immerged in the milk only for the heating

time required.

To change the autosteamer's temperature or to adjust the milk

foaming, require the intervention of a Qualied Technician.

7.10 Dispensing hot water

• Place the pot under the hot

water spout;

• Select the

display and wait for the hot

water to be dispensed;

• To stop the hot water dispensing ahead of time, press the

button again.

button on the

• The steam wand guarantees a correspondence of

± 3°C between the set temperature and the real

temperature of the milk, only if the starting milk

temperature is 4°C;

• Since the steam stops dispensing when the set milk

temperature is reached, in order to prevent the milk

froth from spilling out, do not ll the jug more than

half way with liquid;

• Use a suitably-sized container for the amount of milk

that requires frothing (recommended 200 ml approx.),

and cylindrical shape, not conical (see gure).

20 of 44

Avoid contact with the hot water nozzle,

do not place your hands or other body

parts near the hot water nozzle tips.

The machine is programmed by default. If you would like to modify

the doses, proceed as indicated in para. 8.1 on page 23.

USER Manual

7.11 Lighting

To turn the work surface light on and o, press the

button.

Work surface

light

To turn the side panel lighting on and o, press the

button.

Back light

logo

7.12 Cup warmer

Place the cups to be heated on the specic shelf (11).

11

To activate the cup warmer, press the button.

When the button turns red, the cup warmer is on.

The light intensity calibration (on the work surface or on the sides)

is activated by keeping buttons pressed.

Light intesity

bar

Cup warmer

To change the temperature of the cup warmer, see para. "8.3

SERVICE PARAMETER conguration" on page 27.

USER Manual

21 of 44

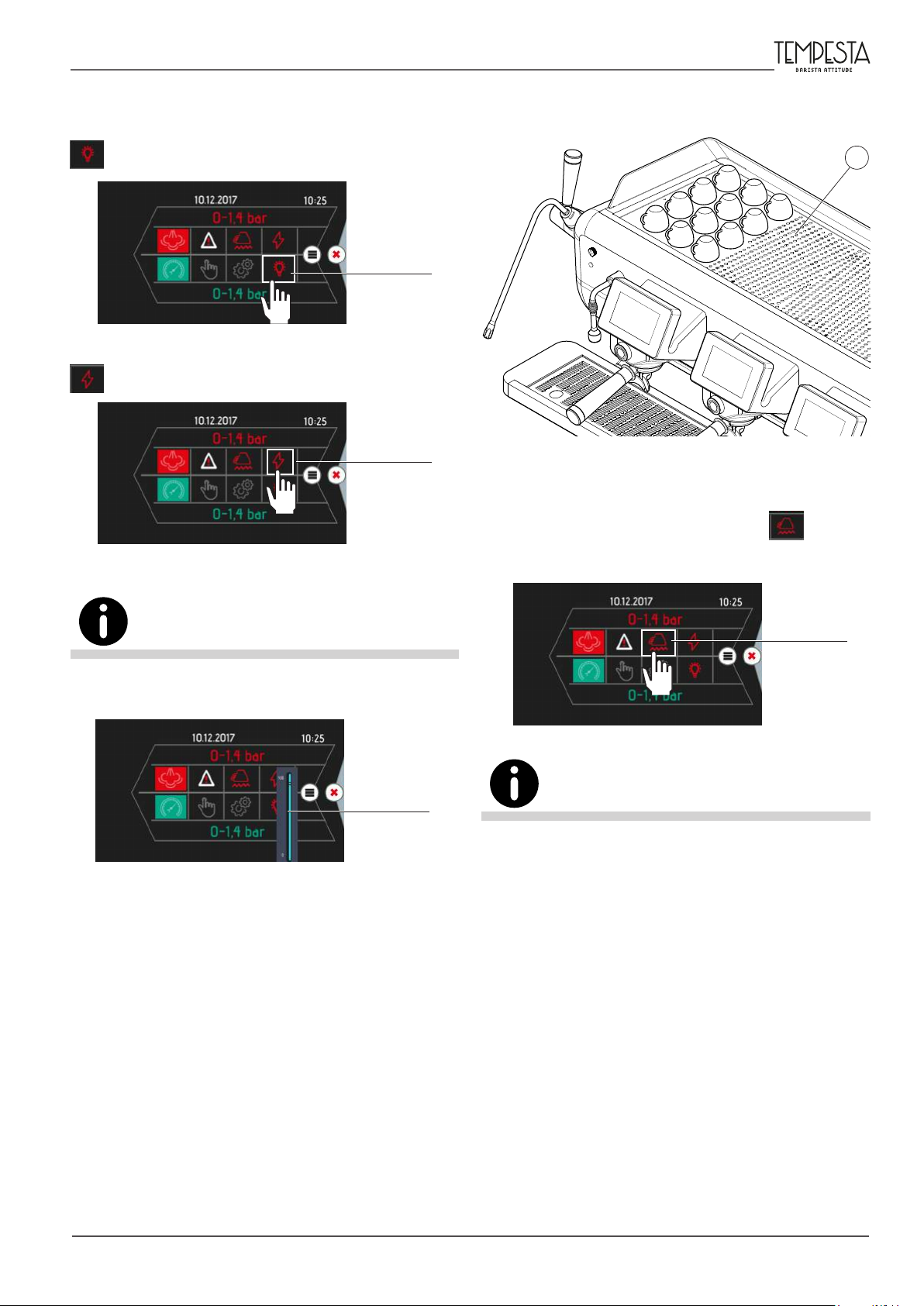

7.13 Energy Saving Management

To turn o the machine or activate the Energy Saving

mode, proceed as follows:

• Select the button

• Select the menu button

• Select the desired function.

;

;

Three "Energy Saving" systems are available:

MANUAL

The Energy Saving features can only be enabled manually by selecting the machine or group icon, as shown

in the gure.

Manual standby

MACHINE

Manual shutdown

MACHINE

GROUP

Manual standby

Manual shutdown

Manual shutdown

Manual standby

GROUP

Manual shutdown

Manual standby

PROGRAMMED

The Energy Saving functions are enabled according to

the programming. Contact a Qualied Technician to

modify the programming.

SELF-LEARNING

The Energy Saving functions are enabled and in selflearning mode. The system automatically manages the

energy saving by lowering the temperature based on the

cycles performed in previous days and weeks.

To enable the "Energy Saving" system, press the

button and select the desired mode:

If the machine is o or in "Energy saving" mode, sim-

ply tap the display to resume operation. The machine

will return to full operation in approximately 1 minute.

In any case, the system will continue to follow the

congured energy-saving settings.

22 of 44

Manual

Scheduled

Self-learning

Mode set

Select

Select

Call out a Qualied Technician to programme the Energy Saving

system.

USER Manual

8. PROGRAMMING

8.1 COFFEE DOSE programming

To programme coee doses, proceed as follows:

• Select the button

;

8.1.1 Programming standard model

• Press the

• To conrm and stop the dose, press the

• Repeat this operation for the other dose buttons;

• To check the dose, press the “Test the dose” button

Start

• To delete the dose settings, press the

Start

button to start dispensing;

button;

Stop

.

button;

• Press the menu

button

;

• Select the conguration button

;

• The dose can be manually adjusted via the

and

buttons.

• you can also change the coee pre-infusion time

by pressing the icon

PREINFUSION

TIME

: Acting with the

and keys (or with the numeric keypad

) modify the selected parameter and conrm with

the ok key.

Do not remove the lter holder from the dispensing group when

coee is being dispensed.

Each dose must be programmed with ground coee and not with

previously-used coee grounds.

Programmable

pre-infusion time

Start/End dispensing

dose simulated

programming

programmed dose

Check the

• Press the dose

MENU UTENTE

programme

button

Programme doses

;

• Select the desired dose

button (e.g.

programme doses

date and time

screensaver

Select the dose to be programmed

Ultima erogazione

washes

counter

PROGRAMME DOSES

recipe selection

“1 espresso”

);

Depending on the machine model, proceed as fol-

lows.

parameter

water lters

Pre-infusion

time

Single group

preinfusion

time 1

PROGRAMME DOSES

PRE-INFUSION

TIME

0.0"

DETAILED

ADJUSTMENT

Manual dose

adjustment (ml)

SINGLE EXTRACTION CURVE

5 20 s0

PROGRAMME

DOSE

TEST THE DOSE

COPY TO ALL

GROUPS

DOSE RESET

0 10 60

Start

Stop

Start

Stop

Delete dose

conguration

USER Manual

23 of 44

8.1.2 Programming FRC model

select the desired programming mode: STANDARD or

WITH LEVER.

Standard doses programming

• press the "STANDARD DOSES

PROGRAMMING", button,

the screen will

appear with the

programming

graph and its

parameters:

• Pre-infusion

time (tenths of

a second)

• Pre-infusion

type

• Phase delivery

level 1

• Start phase 2

erogazione (milliliters)

• Phase delivery

level 2

• Total dose (milliliters)

• Press the key for

the data to be

modified and

change the selected parameter to the desired value, in

order to adjust

the delivery.

• When Setup is

complete, you

can press the

"check dose"

button. Press

the (

) key

to terminate it

in advance.

• Save or cancel

the extraction

curve obtained,

and then switch

to the next dose

schedule.

Selected

dose

pre-infusion

modify

PROGRAM DOSES

PROGRAMMING

STANDARD DOSES

SAVE

DELIVERY CONFIGURATION

DELIVERY CONFIGURATION

1

PRE-INFUSION: 10 ml

PROGRAM DOSES

PROGRAMMING

STANDARD DOSES

SAVE

DOSE PROGRAMING

Which setting do you want to use for

subsequent payments?

parameters

PROGRAMMING

WITH LEVER

CANCEL

15s

8

TOTAL DOSE: 37ml

PROGRAMMING

WITH LEVER

CANCEL

lever

check

dose

Programming with lever

• Press the button "PROGRAMMING WITH LEVER ", the

screen will appear with the programming graph;

• Lower the lever, to start the dispensing, then once the

desired dose

has been obtai-

PROGRAM DOSES

ned, return the

lever to the resting position.

The graph and

PROGRAMMING

STANDARD DOSES

SAVE

PROGRAMMING

WITH LEVER

CANCEL

the length of

the dose will be

updated in real

time according

to the position

of the lever during the dispensing.

• Change the parameter of the

total dose duration (milliliters)

by pressing but-

DELIVERY CONFIGURATION

ton (A).

• When Setup is

complete, you

can press the

selected

dose

"check dose"

button. Press

the (

to terminate it

in advance.

• Save or cancel

the extraction

curve obtained,

) key

selected

dose

PRE-INFUSION: 10 ml

TOTAL DOSE

: 37ml

check

dose

and then switch

to the next dose

schedule.

PROGRAM DOSES

PROGRAMMING

STANDARD DOSES

SAVE

DOSE PROGRAMING

Which setting do you want to use for

subsequent payments?

parameters

PROGRAMMING

WITH LEVER

CANCEL

lever

24 of 44

USER Manual

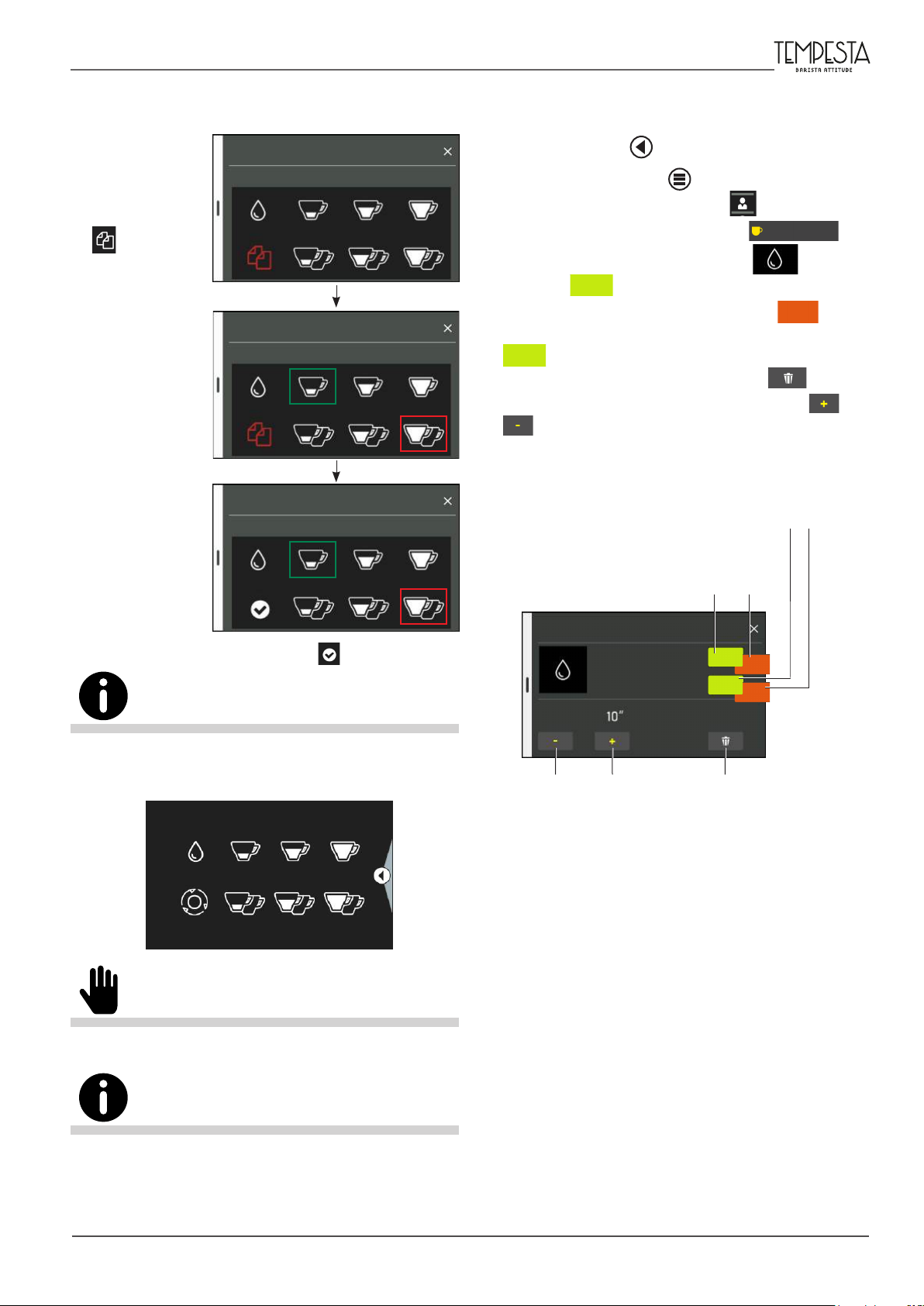

Copy One Dose To Another

To copy a programmed dose to another, proceed as

follows:

• From the dose

selection scre-

Select the dose to be copied

PROGRAM DOSES

en, press the

Copy button

;

• Select the

source dose,

Select the target dose

PROGRAM DOSES

which will be

highlighted in

green;

8.1.3 Water programming

To programme hot water dose, proceed as follows:

• Select the button

• Press the menu button

• Select the conguration button

• Press the dose programme button

• Select the "Hot water" dose button

• Press the

Start

• To conrm and stop the dose, press the

• To check the dose, press the “Test the dose” button

Start

.";

• To delete the dose settings, press the

• The dose can be manually adjusted via the

buttons.

;

;

;

Programme doses

button to start dispensing;

Stop

;

);

button

button;

and

• Select the

target dose,

Copy dose: Conrm your choice

PROGRAM DOSES

which will be

highlighted in

red;

• Conrm by pressing the button

.

The programmed doses refer to the currently selected recipe. The

recipe you are using is displayed on the coee doses selection page.

If no prescription is displayed, the standard recipe will be modied.

"Ricetta in uso"

PROGRAMME DOSES

PRE-INFUSION

TIME

DETAILED

ADJUSTMENT

Manual dose

adjustment (secs)

Check the pro-

grammed dose

Start/End dispensing

dose simulated pro-

gramming

PROGRAMME

DOSES

TEST THE DOSE

DOSE RESET

avvia

avvia

stop

stop

Delete dose

conguration

Do not remove the lter holder from the dispensing group when

coee is being dispensed.

Each dose must be programmed with ground coee and not with

previously-used coee grounds.

USER Manual

25 of 44

8.2 Print last dispensed beverage graph

To view the data of the last dispensed beverage in a

graph, proceed as follows:

• Select the button ;

• Press the menu button

• Select the user conguration button

• Press the

last dispensed

beverage graph

To view the graph of the last delivery it is necessary that this

function has been programmed by the Qualied Technician.

;

button.

;

programme doses

date and time

screensaver

LAST DISPENSED BEVERAGE

USER MENU

last dispensed

beverage graph

Washes

counter

parameters

recipe selection

water lters

26 of 44

USER Manual

8.3 SERVICE PARAMETER conguration

To adjust the parameters of some of the machine’s

services, proceed as follows:

• Select the button ;

• Press the menu button

• Select the conguration button

• Press the

parameters

• Select the button of the parameter to be modied;

;

button;

;

• Press the

and

buttons to change the desired

value.

The adjustable parameters are:

- The dispensing group temperature

- The heating unit temperature

- The cup warmer temperature

- pressure of the boiler services

- percentage water mixing

Quick access

programme doses

date and time

screensaver

MENU UTENTE

last dispensed

beverage

washes

counter

parameters

recipe selection

water lters

USER Manual

Gruop temperature

Coee heating unit

temperature

Cup warmer temperature

boiler services pressure

percentage water mixing

CUP WARMER TEMPERATURE

27 of 44

8.4 DATE and TIME conguration

To set the date and time on the machine, proceed

as follows:

• Select the button ;

• Press the menu button

• Select the conguration button

• Press the

date and time

• Select the button of the information you would like

to modify;

;

button;

;

• Press the

and

lected parameter and conrm via the

buttons to modify the se-

button.

OK

The adjustable parameters are:

- The date

- The time

- The time zone

- Automatic Daylight Saving Time.

Select the

button to enable the keypad where you

can directly enter the desired value. Press the button

to conrm the value.

Programme doses

date and time

screensaver

USER MENU

last dispensed

beverage

washes

counter

SET DATE AND TIME

parameters

recipe selection

water lters

28 of 44

Date

Time

Time zone

Automatic Daylight Saving Time

Date

2020/12/12

Time

Time zone < GMT+1 Central Europe>

Automatic Daylight

Saving Time

22:59

no < YES > yes

06/11/2021

16:54

GMT+1

Central Europe

YES

X X X

USER Manual

8.5 COFFEE RECIPE selection

To set the machine according to the type of coee

recipe used, proceed as follows:

• Select the bar on the right-hand side of the display;

• Select the button

• Select the conguration button

• Press the

recipe selection

• Select the desired recipe button, e.g.

• Press

OK

to conrm the selection;

;

button;

;

Recipe 4

;

• Wait a few moments and then the machine will be

ready to brew the new recipe;

• The various dispensing groups can be programmed

for dierent recipes. In this case, the display will show

the recipe type.

The coee recipes can only be chosen if they have already been

set up in the machine’s system.

Contact the Technical Support if you would like to insert new

recipes.

The recipe extraction parameters have been programmed by the

installation technician.

programme doses

date and time

screensaver

USER MENU

last dispensed

beverage

washes

counter

parameters

recipe selection

water lters

Group 1 with

Recipe type 1

Recipe 1

Group 2 with

Recipe type 4

Recipe 4

Recipe number 01

Recipe number 02

Recipe number 03

Recipe number 04

Group setpoint

Grind neness

Recipe SELECTION

Recipe 1

Recipe 2

Recipe 3

Recipe 4

Recipe SELECTION

Recipe 4

RECIPE SELECTION

Please wait…

OK recipe selected

USER Manual

29 of 44

8.6 SCREENSAVER conguration

To set the display screensaver, proceed as follows:

• Select the button ;

• Press the menu button

• Select the conguration button

;

;

• Press the

Screensaver

button;

• To set how long after the machine’s last operation to

activate the screensaver, select the

• Press the

and

buttons to change the screen-

saver activation time and conrm via the

3 | Set time

button;

OK

button.

The value can be entered directly by selecting the

button and using the keypad;

• To set the screensaver's brightness, select the

4 | Brightness

• Use the

brightness and conrm via the

button;

and

buttons to adjust the display

OK

button.

Contact a Qualied Technician to insert new screensavers.

programme doses

date and time

screensaver

USER MENU

last dispensed

beverage

washes

counter

parameters

recipe selection

water lter

1 | Start slideshow

4 | Brightness

SET TIME 10 60 mins0

BRIGHTNESS 10 101

SCREENSAVER

2 | Upload slides

5 | Delete slideshow

SCREENSAVER

SCREENSAVER

3 | Set time

0 10 60

30 of 44

USER Manual

8.7 BEVERAGE COUNTER list

To view the beverages dispensed by the machine,

proceed as follows:

• Select the button ;

• Press the menu button

• Select the conguration button

;

;

• Press the

• Use the

Counter

2/14

button;

buttons to scroll through the various

pages and view the counts.

To reset the counter list, contact a Qualied Technician.

programme doses

date and time

USER MENU

last dispensed

beverage

washes

parameters

recipe selection

Part. No. of single short coees

Group 1

Part. No. of single standard coees

Group 1

Part. No. of single long coees

Group 1

Part. No. of double short coees

Part. No. of single long coees

Group 1

Group 1

Part. No. of double standard coees

Group 1

Part. No. of double long coees

Group 1

Total partial coee group 2

Part. No. of double long coees

Group 1

Total partial coee group 2

Total partial coee group 2

Total coee group 2gruppo 1

screensaver

COUNTER LIST1/14

Total coee group 2

Total coee group 3

Total coee group 4

Total global coee supplied

counter

0

0

COUNTER LIST2/14

0

0

COUNTER LIST16/17

water lters

0

0

0

0

0

0

COUNTER LIST16/17

0

0

0

0

0

0

USER Manual

31 of 44

8.8 Viewing the WATER LITRE COUNTER

To view the machine’s water consumption and the wa-

ter softener regeneration threshold, proceed as follows:

• Select the button ;

• Press the menu button

• Select the conguration button

• Press the

Water lters

• When the water consumption exceeds the set value,

the system displays the automatic water softener

regeneration warning;

• If the threshold value is set to zero, the regeneration

warning is not displayed.

To reset the counter list, contact a Qualied Technician.

;

button;

;

8.9 Tips for a good cup of coee

Wash the lters and lter holders on a daily basis,

as indicated in para. 9.7.2 on page 36. The failure to

perform this cleaning operation will negatively aect the

quality of the dispensed coee.

To obtain high-quality coee, it is important that the

water hardness does not exceed 6-7°f (French degrees).

If the water hardness exceeds these values, it is advisable to use a water lter or softener. Avoid using a water

softener if the water hardness is less than 4°f.

If the taste of chlorine in the water is particularly

strong, install a special lter.

Do not to keep large amounts of coee beans on

hand. If you change the type of coee, it is advisable to

contact one of the Manufacturer's Qualied Technicians

to adjust the water temperature and coee grinder.

If the machine has not been used for a certain period

of time (2-3 hours), carry out a few dry runs. Make sure

that the machine is constantly cleaned and periodic

maintenance is carried out.

programme doses

date and time

screensaver

Regeneration threshold

Water consumption

MENU USER

last dispensed

beverage

washes

counter

WATER FILTERS

parameters

recipe selection

water lters

0 L

263 L

32 of 44

USER Manual

9. MAINTENANCE AND CLEANING

9.1 Safety precautions

Carefully read the instructions provided in chapter "1. SAFETY PRECAUTIONS" on page 3 .

9.2 Periodic maintenance

In addition to performing the following maintenance operations at the specied frequency, have a Qualied

Technician perform an overall inspection of the machine whenever prompted by the warning on the display, as

indicated in para. 9.3 on page 34.

Component Type of operation Weekly Monthly Quarterly

DISPLAY

DISPLAY

FILTERS AND FILTER

HOLDERS

GRINDER-DISPENSER

WATER FILTER

WATER SOFTENER

HEATING UNIT

Keep the heating unit pressure between 0.08 and 0.14 MPa (0.8 and 1.4

bar).

Check the water pressure when coee is being dispensed: check the pressure indicated on the gauge, which must be between 0.8 and 0.9 MPa (8

and 9 bar).

Check the condition of the lters. Check for any damage on the edge of

the lters and check whether any coee grounds settle in the coee cup,

and replace the lters and/or lter holders, as required.

Check the ground coee dose (between 6 and 7 grams per time) and

check the degree of grinding. Grinders must always have sharp cutting

edges. Too much powder in the grounds is an indication that the coee is

deteriorating. We recommend contacting a Qualied Technician to replace

the at burrs after every 400/500 kg of coee, or after every 800/900 kg

for conical burrs.

If the automatic grinder wear warning is enabled, follow the instructions

in para. 9.4 on page 34 .

Replace the water lter cartridge or regenerate the water softener at the

frequency indicated by the manufacturer or whenever the automatic

regeneration warning is displayed (see para. 9.5 on page 34).

We recommend that you call out the Technical Assistance at least once

every three months to replace the water in the heating unit.

X

X

X

X

X

X

Component problems highlighted in grey require the machine to be switched o and one of the Qualied Technicians to be called out.

USER Manual

33 of 44

9.3 Scheduled maintenance

If enabled, this function displays a message to alert

the user when it is necessary to perform scheduled

maintenance.

The rst request for assistance appears when the

number of coee, tea, heating unit lling cycles, or the

number of days elapsed since installation of the machine,

is close to the programmed threshold value.

After reaching the programmed threshold value, the

display shows a window with messages:

Press the icon to read the message:

9.4 Grinder wear automatic check

If enabled, this function displays a message to alert

the user that it is necessary to replace the grinderdispenser burrs.

WARNING: Burr wear and tear

The warning appears when the amount of coee used

(kg) reaches the programmed limit.

The message will remain on the display in the selection standby phase or the programming standby phase.

The warning for reached/exceeded thresholds does

not prevent the machine from functioning.

The count can be reset at any time (even before the

warning is triggered) and by a technician.

WARNING: Maintenance threshold A

This message continues to be displayed until main-

tenance is performed.

If enabled, the display may show various scheduled

maintenance thresholds.

The threshold reached/exceeded warnings do not

prevent the machine from operating.

The messages on the display can be reset at any

time (also before the warning is triggered) and can be

performed by the technician.

When the machine is in operation, the system increases both the cycle counter and time since installation

counter.

The system only operates if the machine is paired with a single

grinder. Contact a Qualied Technician to programme this function.

9.5 Water softener regeneration

The machine counts the amount of water that has

been used (see para. 8.8 on page 32) and if enabled,

indicates the need to regenerate the softener on the

display when the programmed amount is exceeded.

WARNING: Water softener regeneration

The warning for reached/exceeded thresholds does

not prevent the machine from functioning.

The count can be reset at any time (even before the

warning is triggered) by a technician.

Contact a Qualied Technician to programme this function.

34 of 44

Contact a Qualified Technician to programme this function.

To regenerate the water softener, follow the manufacturer’s

instructions.

USER Manual

9.6 Malfunctions and solutions

Problem Cause Action

NO MACHINE POWER The machine is switched o. Turn on the machine.

NO WATER IN THE HEATING UNIT The water mains tap is shut o. Open the water mains tap.

TOO MUCH WATER IN THE HEATING

UNIT

STEAM NOZZLES DO NOT RELEASE

STEAM

STEAM NOZZLES RELEASE WATER OR

STEAM MIXED WITH WATER

NO BEVERAGES ARE BEING

DISPENSED

WATER LEAKS FROM THE MACHINE

COFFEE IS TOO HOT OR TOO COLD Electrical system or hydraulic system fault.

COFFEE IS BEING DISPENSED TOO

QUICKLY

COFFEE IS BEING DISPENSED TOO

SLOWLY

COFFEE GROUNDS ARE WET

THE DISPLAY INDICATES NONCOMPLIANT PRESSURE

COFFEE GROUNDS FOUND IN CUPS

THE CUP IS DIRTY WITH COFFEE

SPLASHES

• THE COFFEE IS NOT BEING

DISPENSED CORRECTLY

• THE COFFEE DOSE IS NOT CORRECT

THE ELECTRONIC SYSTEM HAS

SHUTDOWN

WATER IS LEAKING FROM THE PUMP Pump fault.

THE MOTOR STOPS SUDDENLY OR THE

THERMAL PROTECTOR IS TRIGGERED

BY A POWER OVERLOAD

THE PUMP IS WORKING BELOW THE

NOMINAL FLOW RATE

THE PUMP IS NOISY Pump fault.

Electrical system or hydraulic system fault.

• The nozzle sprayer is clogged.

• The machine is switched o.

Electrical system or hydraulic system fault.

• The water mains tap is shut o.

• The coee has been ground too nely.

• The tray is not draining.

• The drain pipe is broken, has detached, or the water

ow is obstructed.

The coee has been ground too coarsely. Adjust the coee grind.

The coee has been ground too nely. Adjust the coee grind.

• The dispensing group is dirty.

• The dispensing group is too cold.

• The coee has been ground too nely.

• The coee is too old.

Hydraulic system fault.

• The lter holder is dirty.

• The lter holes are worn.

• The coee has not been ground evenly.

• The coee has been ground too coarsely.

• The lter's edge is damaged.

The coee has been ground too nely. Adjust the coee grind.

Electrical system or hydraulic system fault.

Pump fault.

Pump fault.

Turn o the machine and call out the Technical

Support.

• Clean the steam nozzle sprayer.

• Turn on the machine.

Turn o the machine and call out the Technical

Support.

• Open the water mains tap.

• Adjust the coee grind.

• Check the sewer drain.

• Check and restore the drain pipe connection to

the tray.

Turn o the machine and call out the Technical

Support.

• Wash the group with the blind lter.

• Wait for the group to fully heat up.

• Adjust the coee grind.

• Replace with fresh coee.

Turn o the machine and call out the Technical

Support.

• Clean the lter holder.

• Replace the lter.

• Adjust the grind as appropriate.

• Adjust the coee grind.

• Replace the lter.

Turn o the machine and call out the Technical

Support.

Turn o the machine and call out the Technical

Support.

Turn o the machine and call out the Technical

Support.

Turn o the machine and call out the Technical

Support.

Turn o the machine and call out the Technical

Support.

Problems highlighted in grey require the machine to be switched o and one of the Qualied Technicians to be called out.

USER Manual

35 of 44

9.7 Cleaning operations

9.7.1 General instructions

A few simple cleaning tasks are required to have a perfectly sanitised and ecient appliance. The instructions

provided here apply when the machine is being used

on a regular basis. If the machine is used consistently,

cleaning should be performed more frequently.

Do not use alkaline cleaners, solvents, alcohol or aggressive

substances. The products/cleaners used must be suitable for this

purpose and not corrode the water circuit elements.

Do not use abrasive cleaners which may scratch the bodywork’s

surface.

Always use clean and sanitised cloths when cleaning.

When washing the filters, filter holders and all machine

components, use Manufacturer-supplied cleaners or products

specic for cleaning professional coee machines.

9.7.2 Cleaning the lters and lter holders

Daily:

• Soak the lter and lter holder in hot water overnight

so that the fatty coee deposits can dissolve;

• Rinse everything in cold

water.

Weekly:

• Use a screwdriver to detach the lter from the

lter holder;

• Soak the lter and lter

holder in warm water with a suitable cleaner for 10

minutes;

• Rinse everything in cold water.

Caution: Only immerse the lter holder cup, avoid soaking the

handle in water.

The cleaner must be diluted in cold water in the doses indicated

on the package (see the manufacturer).

Cleaning

Body and Grilles:

Clean the panels of the body with a cloth dampened in

lukewarm water.

Remove the drip tray and cup holder grille and wash with

hot water.

Filters and Filter Holders:

Wash the lters and lter holders on a daily and weekly

basis, as indicated in para. 9.7.2 on page 36.

Perform cleaning operations daily as indicated in paragraph

9.7.6 on page 38.

Steam nozzle:

Keep the nozzle clean at all times using a cloth dampened

in lukewarm water.

Check and clean the nozzle tips, by clearing the steam

outlet holes with a small needle.

Wash these on a weekly basis, as indicated in para. 9.7.7

on page 38.

Dispensing group:

Wash the dispensing group as described in para. 9.7.3 on

page 36 and 9.7.4 on page 37 .

Perform cleaning operations daily as indicated in paragraph

9.7.6 on page 38.

Grinder-dispenser and Hopper:

Clean the hopper and the dispenser inside and out with a

cloth dampened with warm water.

When nished, dry all parts thoroughly.

Daily

X

X X

X X

X X

Weekly

9.7.3 Dispensing group scheduled wash

If provided, the machine automatically requests that

the dispensing groups be washed on a daily basis.

To begin the wash cycle, proceed as shown on the

display. However you can also cancel the wash prompt

and resume normal operation.

X

36 of 44

USER Manual

9.7.4 Arbitrary dispensing group wash

If desired, it is possible to wash the groups at any time,

proceeding as follows:

• Select the button

• Press the menu button

• Select the conguration button

• Press the

washes

;

;

;

button;

• The display will indicate the date of the last wash cycle

and the number of wash cycles;

• To start the wash, press the

Perform wash

button;

• Insert a suitable detergent in the blind lter holder,

secure it to the dispensing group and press the

Start

button;

• Wait for wash cycle to nish, then remove the lter

holder from the dispensing group and press the

Start

button;

• When the rinse cycle has nished, remove the lter

holder from the dispensing group and press the

End

button.

programme doses

date and time

screensaver

USER MENU

last dispensed

beverage

washes

counter

parameters

recipe selection

water lters

During the washing stage, all the coee selections of that group

are disabled.

Washes are interrupted if the machine is switched o; to resume

the washes automatically, turn the machine on again.

If it has been programmed, it is possible to perform a brief rinsing

of the group (about 3 seconds) by pressing the manual button or

the START/STOP button on the display.

If a certain number of cycles has been programmed and such

number is exceeded, the message “Perform group washing now?”

appears on the display. Proceed with washing following the

instructions on the display.

gruppi

date of last wash

number of wash cycles

Perform a wash

Wash in progress

Rinse in progress

WASHES

WASHES

WASHES

Insert the blind

lter with the

cleaner.

Start

End of wash.

Remove the blind

lter holder.

Start

End of wash

WASHES

WASHES

WASHES

USER Manual

End

37 of 44

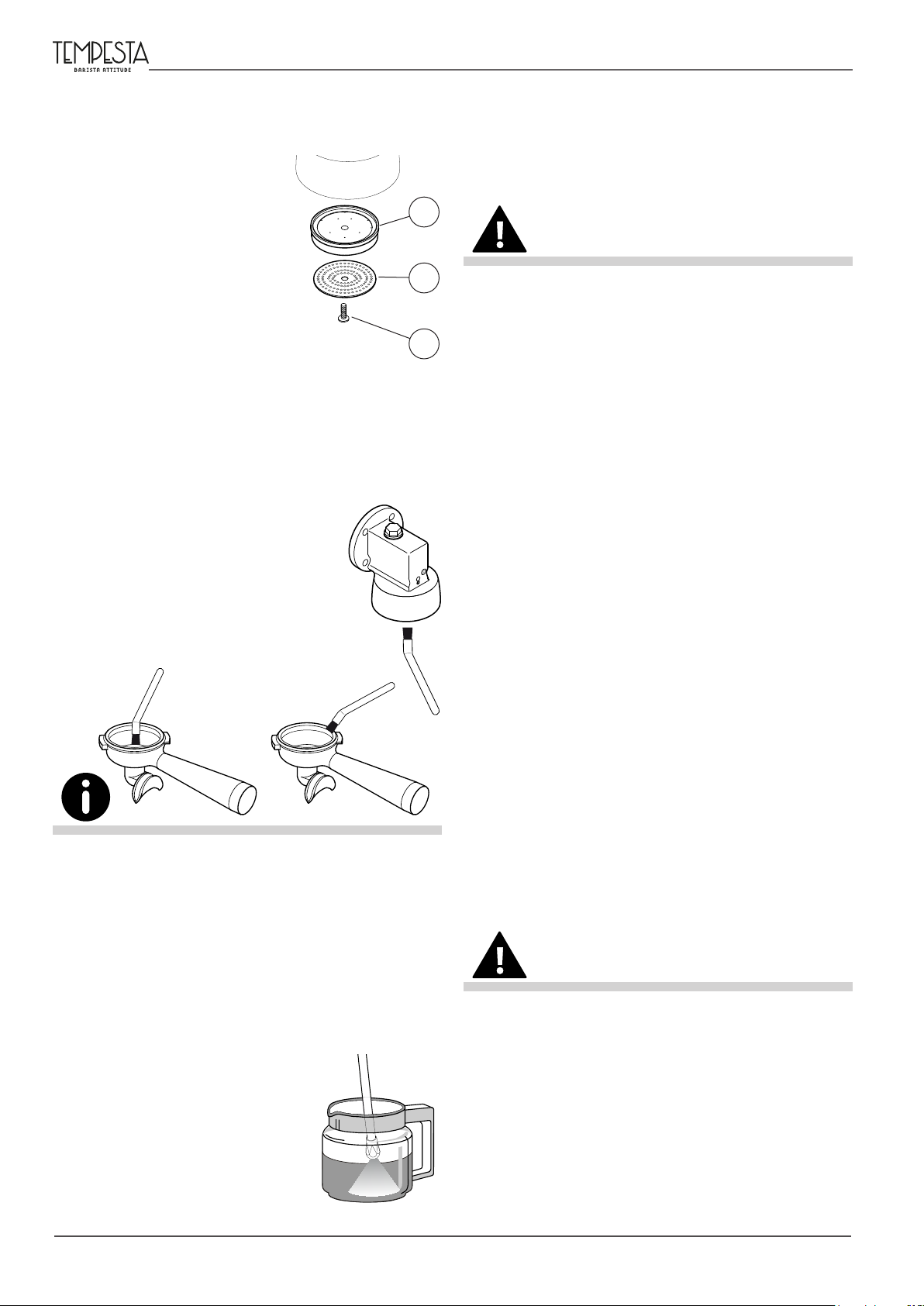

9.7.5 Cleaning the shower screen and shower screen

containment ring

Clean the shower screen and

shower screen containment

ring on a weekly basis, following the steps indicated below:

• Loosen the screw using a

screwdriver (1);

• Remove the shower screen

(2) and the shower screen

containment ring (3);

• Carefully wash the two com-

ponents with hot water;

• Reposition the shower screen and shower screen

containment ring in their original position and lock

everything in place with the screw.

3

2

1

9.7.6 Cleaning the shower screen group and lter holder

Clean daily the shower screen group

and of the lter holder with the brush

provided.

Thoroughly clean the inside of the

coupling ring and of the lter holder; as

well as the edge and the wings of the lter

holder, so as to eliminate any accumulated coee residues.

10. SPARE PARTS

Machine components and/or parts must only be

replaced by one of the Manufacturer's Qualied Technicians.

Under no circumstances are Users authorised to replace machine

components and/or parts.

11. DECOMMISSIONING

11.1 Short period of machine inactivity

“Short period of machine inactivity” refers to a period

of time exceeding one working week.

If the machine is switched back on after this period,

a Qualied Technician must replace all the water inside

the hydraulic circuits as indicated in para. "7.4 Water

renewal" on page 17.

Furthermore, all periodic maintenance operations

must be carried out, see para. "9.2 Periodic maintenance"

on page 33.

Use the special toothbrush supplied (see spare parts catalog).

9.7.7 Cleaning the steam nozzle

Clean the steam nozzle on a weekly basis as follows:

• Insert the steam wand into a jug with water and a

specic cleaner, in accordance with the manufacturer's instructions;

• Heat the solution with the steam nozzle;

• Let the nozzle cool down whilst

keeping it immersed in the solution for at least 5 minutes, so that

cleaner can rise inside the nozzle

due to the cooling eect;

• Repeat the operation 2 or 3 times

until no more milk residue is

dispensed.

11.2 Long period of machine inactivity

"Long period of machine inactivity" refers to a period

of time exceeding 30 working days.

THE machine must be decommissioned by one of

the Manufacturer's Qualied Technicians because the

equipment must be disconnected from the electricity

and water mains, and all the internal circuits must be

emptied of water.

After being decommissioned, the machine can only

be recommissioned by a Manufacturer Qualied Technician.

Under no circumstances are Users authorised to decommission