Aston Martin V8 Vantage Workshop Manual

Workshop Manual

Issue 1

Aston Martin Lagonda Limited

Banbury Road, Gaydon, WARWICK, Warwickshire,

England, CV35 0DB

Telephone: (01926) 644700 Fax: (01926) 644733

Aston Martin are constantly seeking to improve the specification, design and production of their vehicles and alterations

take place accordingly. While every effort has been made to ensure the accuracy of this Manual, it should not be regarded

as an infallible guide to current specifications of any particular vehicle.

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or transmitted, in any form,

electronic, mechanical, photocopying, recording or other means without prior written permission from Aston Martin

Lagonda Limited.

The manufacturer reserves the right to vary specifications without notice in accordance with its policy of continual product

improvement.

Produced by the Technical Publications Department

Aston Martin Lagonda Limited

Issue 1 - October 2005 DVD Part No. 6G43-43-10055

Contents

October 2005 Workshop Manual 0-0-3

V8 Vantage Workshop Manual

Contents

Introduction

Welcome..............................................................0-0-6

Safety Precautions.................................................0-0-7

Lifting and Jacking.................................................0-0-9

Vehicle Recovery ................................................0-0-10

Vehicle Identification Number ............................0-0-11

Body System (01.00)

Body Structure (01.01)..........................................1-1-3

Front End System (01.02) ......................................1-2-1

Body Closures (01.03)...........................................1-3-1

Interior Trim (01.05) .............................................1-4-1

Exterior Trim (01.08)............................................. 1-5-1

Mirrors (01.09)......................................................1-6-1

Seating (01.10)......................................................1-7-1

Glass, Frame and Mechanism (01.11)....................1-8-1

Instrument Panel (IP) (01.12).................................1-9-1

Handles and Lock Mechanisms (01.14) ...............1-10-1

Wipers and Washer System (01.16).....................1-11-1

Bumpers (01.19) .................................................1-12-1

Restraining Devices (01.20).................................1-13-1

Frame and Mounting (02.00)

Subframes (02.03).................................................2-1-2

Engine Assembly (03.00) .......................................4-3-1

Engine System (03.00)

Engine Structure (03.01)........................................3-1-1

Lubrication System (03.02)....................................3-2-1

Cooling System (03.03) .........................................3-3-1

Fuel Charging System (03.04)................................3-4-1

Accessory Drive System (03.05).............................3-5-1

Engine Cranking System (03.06) ............................3-6-1

Ignition System (03.07) .........................................3-7-1

Emission Control (03.08) .......................................3-8-1

Valve Train (03.09) ...............................................3-9-1

Engine Sealing (03.10).........................................3-10-1

Power Conversion (03.11)...................................3-11-1

Air Charging (03.12)............................................3-12-1

Evaporative Emissions (03.13) .............................3-13-1

Engine Management System (03.14)....................3-14-1

Throttle Control (03.16) ......................................3-15-1

Suspension (04.00)

Road Wheel Alignment (04.00) .............................4-1-2

Front Suspension (04.01).......................................4-2-1

Rear Suspension (04.02)........................................4-3-1

Road Wheels and Tyres (04.04) ............................4-4-1

Driveline (05.00)

Driveshaft (05.01) .................................................5-1-2

Rear Drive System (05.02).....................................5-2-1

Halfshafts (05.05)..................................................5-3-1

Brake System (06.00)

Description........................................................... 6-1-2

Front Disc Brake (06.03) ....................................... 6-2-1

Rear Disc Brakes (06.04)....................................... 6-3-1

Hand Brake (06.05) .............................................. 6-4-1

Brake Actuation System (06.06) ............................6-5-1

Power Brake System (06.09) .................................6-6-1

Transmission (07.00)

Automatic Transmission (07.01) ............................7-1-2

Transmission Cooling (07.02) ................................ 7-2-1

Manual Transmission (07.03) ................................7-3-1

Automatic Control System (07.05).........................7-4-1

Clutch (08.00)

Clutch Controls (08.02).........................................8-2-1

Exhaust (09.00)

Exhaust Overview .................................................9-1-2

Silencer Assembly (09.01) ..................................... 9-1-3

Pipes and Supports (09.03) ...................................9-2-1

Fuel (10.00)

Fuel Tank and Lines (10.01)................................10-1-2

Steering (11.00)

Steering Gear (11.01)..........................................11-1-2

Power Steering (11.02)........................................ 11-2-1

Steering Column (11.04) .....................................11-3-1

Steering Column Switches (11.05).......................11-4-1

Steering Wheel (11.06) ....................................... 11-5-1

Climate Control (12.00)

Body Ventilation system (12.01)..........................12-1-3

Heater System (12.02) ........................................12-2-1

Air Conditioning (A/C) System (12.03).................12-3-1

A/C Control System (12.04).................................12-4-1

Information, Gauge and Warning (13.00)

Instrument Cluster (13.01) .................................. 13-1-2

Power Supply (14.00)

Battery System (14.01) ........................................14-1-2

Alternator and Regulator System (14.02) .............14-2-1

Vehicle Entertainment (15.00)

Audio System......................................................15-1-1

Vacuum Distribution (16.00)

Body Vacuum System (16.01) ............................. 16-1-1

Lighting (17.00)

Front Lights (17.01)............................................. 17-1-2

Interior Lighting (17.02) ......................................17-2-1

Rear Lights (17.03).............................................. 17-3-1

Lighting Mechanisms (17.04)...............................17-4-1

Contents

0-0-4 Workshop Manual October 2005

Electric Distribution/Electronic Control (18.00)

Wiring and Circuit Protection (18.01) ................. 18-1-2

Vehicle Control System (18.08) .......................... 18-2-1

Electronic Features (19.00)

Active Anti-Theft System (19.01)......................... 19-1-2

Appendix & Glossary

Fluids/Capacities................................................. 20-1-2

Abbreviations ..................................................... 20-1-3

Terms................................................................. 20-1-3

Special Tools - Pictorial Index............................. 20-1-4

Specialist Tool Operation ................................... 20-1-6

Maintenance Schedules...................................... 20-1-7

Torque Table...................................................... 20-1-9

Torque Conversion Tables................................ 20-1-10

Contents

October 2005 Workshop Manual 0-0-5

Introduction

Contents .................................................................0-3

Welcome................................................................0-0-6

Chapters .................................................................0-6

Chapter Navigation................................................0-6

Page Numbering..................................................... 0-6

Systems Classification Coding................................ 0-6

Special Tools..........................................................0-0-6

Location References................................................ 0-6

Warnings, Cautions and Notes..............................0-0-6

Repairs and Replacements ..................................... 0-6

Safety Precautions .................................................0-0-7

Battery Disconnection ............................................ 0-7

Air Conditioning (A/C) System................................0-7

Chemical Handling and Storage.............................0-7

Electrical Equipment..............................................0-0-7

Exhaust Fumes........................................................ 0-7

Fire Precautions...................................................... 0-7

Tools and Equipment.............................................0-0-8

Used Engine Oil...................................................... 0-8

Health protection precautions................................ 0-8

Environmental Protection.......................................0-8

Lifting and Jacking .................................................0-0-9

Safety ......................................................................0-9

Jacking Points ........................................................0-0-9

Lifting.....................................................................0-0-9

Workshop Hoist.....................................................0-9

Workshop Jack....................................................... 0-9

Stands.................................................................... 0-9

Vehicle Recovery..................................................0-0-10

General................................................................. 0-10

Transporting .........................................................0-10

Suspended Towing............................................... 0-10

Adhere to Towing Regulations..............................0-10

Towing by Another Vehicle..................................0-10

Vehicle Identification Number ............................0-0-11

VIN Number Location..........................................0-11

Welcome

0-0-6 Workshop Manual October 2005

Welcome

This Workshop Manual is part of a suite of technical manuals

provided for V8 Vantage. Other technical manuals include:

• Parts manual

• OBDII Diagnostic manual

• Man hour schedules

Chapters

Each chapter in this workshop manual is associated with a 4

digit number, i.e. Transmission (07.00). Each chapter is then

further broken into sections, i.e. Automatic Transmission

(07.01).

Chapter Navigation

Example 1:

Older workshop manuals would have Steering and

Suspension together in one chapter. The structure now used

places Steering and Suspension into their own chapters.

When required references are made out to other chapters.

Page Numbering

The page numbering system used within this workshop

manual is as follows:

Systems Classification Coding

Alongside the ‘System’ and ‘Subsystem’ section titles appear

codes. For example Exhaust ‘09.00’ or Power Steering

‘11.02’. These codes relate to a Corporate Product Systems

Classification (CPSC) and are designed to segregate the parts

for engineering release and organise a variety of engineering

data.

Special Tools

Where special service tools are required to perform an

operation, the tool number is recorded at the point of use

within the procedure. Where the operation of a special

service tool is complicated or not obvious, refer to Appendix

and Glossary for detailed operation procedures. A pictorial

list of special service tools available for this vehicle can also

be found in Appendix and Glossary.

Location References

References to left, right, front or rear of the vehicle or of a

component are referenced from sitting in the drivers seat

facing forward. Any such references to assemblies removed

from the vehicle are to the normal orientation of the

assembly when installed in the vehicle.

The following Warnings, Cautions and Notes are used within

this Owner’s Guide to call your attention to specific types of

information.

Warnings, Cautions and Notes

Warnings

Cautions

Notes

Repairs and Replacements

Where replacement parts are required, it is essential that

only genuine Aston Martin parts are used. Your attention is

drawn to the following points concerning repairs and the

fitting of genuine Aston Martin parts and accessories:

• Safety features embodied in the vehicle may be impaired

if other than genuine Aston Martin parts are installed. In

certain territories, legislation prohibits the fitting of parts

which are not produced to the manufacturers

specification

• Adhere to torque wrench settings given in this manual

• Locking devices, where specified, must be installed. If the

efficiency of a locking device is impaired during removal,

it must be renewed

• The vehicle warranty may be invalidated by the

installation of other than genuine Aston Martin parts

3- 2- 5

System, i.e. Engine system

Subsystem, i.e. Engine lubrication system

Page Number, i.e. Number within subsystem

Warning

Identifies procedures which must be followed precisely

to help avoid the risk of personal injury.

Caution

Provided to indicate procedures which must be followed

precisely to reduce the possibility of damage to the

vehicle.

Provided to indicate procedures which will help to avoid

difficulties in the operation of the vehicle.

Safety Precautions

October 2005 Workshop Manual 0-0-7

Safety Precautions

All service workshops are a source of potential danger and

repair work should only be performed by technically trained

staff following procedures detailed in this manual. A safety

conscious approach to the performance of all service

procedures must be observed at all times. Statutory

requirements governing all aspects of health and safety at

work including directives for the proper use of materials and

equipment must be implemented.

The following contains a list of particular safety precautions

which should be observed; it is not intended to be

exhaustive.

Battery Disconnection

When a service manual procedure requires the vehicle

battery to be disconnected - always physically disconnect

the vehicle battery earth (Negative) lead.

Do not use the ‘Battery Disconnect Switch’.

After reconnecting the vehicle battery the following items

will have to be reset or re-learnt:

•Radio pre-sets

•Windows

• DTCs will be lost

Air Conditioning (A/C) System

Do not break into the A/C refrigeration system until the

refrigerant has been evacuated using the procedure detailed

in this manual. Do not disconnect any A/C refrigerant system

pipes unless trained and instructed to do so. The refrigerant

used can cause blindness if allowed to contact your eyes.

Chemical Handling and Storage

Chemicals used in the servicing of motor vehicles include

acids, adhesives, antifreeze, brake fluids, coolants, grease,

oil, paint, resin and solvents. Exposure to certain chemicals

through direct contact or inhalation can be fatal.

Potential hazards may also be present through the incorrect

use, storage and handling of chemicals causing a fire risk.

The following precautions should be observed.

• Strictly adhere to handling and safety information found

on containers and labels.

• Do not store chemicals in unlabelled or incorrectly

labelled containers.

• Containers used for storing chemicals should not be left

open; there is a risk of spilling, or evaporation of fumes

which may be inflammable or toxic.

• Do not mix chemicals unless instructed to do so following

manufacturers guidelines.

• Do not inhale chemical materials to determine identity,

they may be toxic.

• Do not use petrol, kerosene, diesel fuel, gas oil, thinners

or solvents for washing skin.

• Containers whose capacity is over 25 litres (5 gallons)

require a bund wall in order to contain spillages.

• Chemicals based on solvents such as paint should not be

sprayed in a confined space; work areas used for such

operations should be well ventilated and fume extraction

equipment should be utilised.

• Ensure that adequate ventilation is provided when volatile

de-greasing agents are being used.

• Avoid splashing the skin, eyes and clothing.

• Clean chemicals from the skin and clothing as soon as

possible after soiling.

• Wear protective clothing such as goggles, non porous

gloves and apron when handling battery acid and other

corrosive and toxic substances.

Electrical Equipment

• Ensure that electrical equipment is in safe working order

before use.

• Inspect power leads of all mains electrical equipment for

damage and security, and check that it is properly

earthed.

• Ensure that electrical equipment is protected by a fuse of

the correct current rating.

• Disconnect the battery before commencing repair

operations to the electrical system, fuel system and engine

or when working beneath the vehicle.

Exhaust Fumes

Engines should not be run in confined spaces, exhaust fumes

contain harmful and toxic substances including carbon

monoxide which can prove fatal if inhaled. Engines must

only be run where there is fume extraction equipment in

operation or where there is adequate ventilation.

Fire Precautions

• Ensure that a suitable form of fire extinguisher is

conveniently located near the work area.

• Keep oils, solvents and combustible materials away from

naked flames and other sources of ignition.

• Ensure that NO SMOKING signs are posted around areas

where combustible materials and vapour may be present

and ensure that the warnings are strictly observed.

• Ensure that dry sand is available to soak up any spillage of

fuel or other flammable solutions.

• Fume extraction equipment must be available and in full

working order to remove combustible and toxic vapours.

• All personnel should be aware of the fire drill procedures

and precautions.

Warning

Do not smoke in the vicinity of volatile de-greasing

agents.

Warning

Fume extraction equipment must be in operation when

solvents are used e.g. trichloroethane, white spirit,

SBP3, methylene chloride, perchlorethylene.

Safety Precautions

0-0-8 Workshop Manual October 2005

Tools and Equipment

• Do not leave tools, equipment, spilt oil, etc. around or on

the work area.

• Ensure that tools and equipment used are in good

condition; do not use damaged or defective tools or

equipment.

• Do not apply heat in an attempt to free stiff nuts or fittings;

as well as causing damage to protective coatings, the stray

heat may damage electronic equipment, harnesses and

brake lines.

• Use the recommended service tool where instructed to do

so.

Used Engine Oil

Prolonged and repeated contact with mineral oil will result

in the removal of natural fats from the skin, leading to

dryness, irritation and dermatitis. In addition, used engine

oil contains potentially harmful contaminants which may

cause skin cancer. Adequate means of skin protection and

washing facilities should be provided.

Health protection precautions

• Avoid prolonged and repeated contact with oils,

particularly used engine oil.

• Wear protective clothing, including impervious gloves

where practicable.

• Do not put oily rags in pockets.

• Avoid contaminating clothes with oil.

• Overalls must be cleaned regularly. Discard un-washable

clothes and oil impregnated footwear.

• First aid treatment should be obtained immediately for

open cuts or wounds.

• Use barrier creams, apply before each work period to help

the removal of oil from the skin.

• Wash with soap and water to ensure all oil is removed.

Preparations containing lanolin replace the natural skin

oils which have been removed.

• Do not use petrol, kerosene, diesel fuel, gas oil, thinners

or solvents for washing skin.

• If skin disorders develop, obtain medical advice.

• Where practicable, degrease components prior to

handling.

• Where there is a risk of eye contact, eye protection should

be worn. In addition, an eye wash facility should be

provided.

Environmental Protection

It is illegal to pour used oil on the ground, down sewers or

drains, or into water courses. The burning of used engine oil

in small space heaters or boilers is not recommended unless

emission control equipment is installed; in case of doubt,

contact the Local Authority for advice on disposal facilities.

Lifting and Jacking

October 2005 Workshop Manual 0-0-9

Lifting and Jacking

Safety

• Recommended procedures for lifting, jacking and

towing must be strictly observed to ensure personal

safety.

• Always use a vehicle hoist, ramp or pit for working

beneath the vehicle in preference to jacking.

• Never rely on a jack to support a car independently, use

axle stands or blocks carefully placed at jacking points

to provide rigid support.

• When working beneath a vehicle, chock wheels as well

as applying handbrake.

• Ensure vehicle is standing on firm, level ground before

jacking or lifting.

• Check lifting equipment has adequate capacity for load

being lifted and is in full working order.

Jacking Points

This vehicle jacking points are at positions shown.

May also be jacked on the front subframe front crossmember

Always use a jack with a rubber contact pad. Avoid use of

jacks with sharp contact pads which would damage floor

pan Always chock the opposite road wheels as well as

applying the handbrake when using a hydraulic jack.

To prevent body distortion, avoid single point or one side

jacking with the tunnel shear panel removed.

Lifting

Workshop Hoist

Use of a workshop hoist is recommended for all operations

where vehicles must be raised. Follow manufacturers

instructions. If using an adjustable arm type, ensure lifting

pads are correctly positioned at the four jacking points

before lifting.

Workshop Jack

To avoid any danger of bodywork damage when using a

hydraulic jack, the vehicle must only be lifted at the jacking

points.

Stands

When carrying out work (other than a wheel change) which

requires a wheel to be raised, a stand must be used, located

at the jacking point, to provide a secure support for the

vehicle.

Vehicle Recovery

0-0-10 Workshop Manual October 2005

Vehicle Recovery

General

Preferred method of vehicle recovery is by flat bed

transporter.

The towing eye is primarily for emergency use when towing

for short distances, e.g. removing vehicle if it is causing an

obstruction or winching vehicle onto a flatbed transporter.

If moving this vehicle in such a situation, install the towing

eye to the bracket in the lower grille aperture.

Transporting

If vehicle is to be transported on a trailer or flat bed

transporter the handbrake must be applied and the road

wheels must be chocked.

Suspended Towing

Take care when using 'spectacle frame' type towing

equipment that the towing device is well clear of front or

rear apron. Body damage may occur if vehicle passes over

uneven road surfaces.

Rear Suspended Tow

1. Set the steering in the ‘straight ahead’ position.

Remove the ignition key from the ignition. Ensure the

steering is locked in the straight ahead position.

2. Raise the vehicle using a 'spectacle frame' style lifting

device where a cradle is positioned under each rear

wheel as indicated below.

Adhere to Towing Regulations

In certain countries the registration number of towing

vehicle and an ‘ON TOW’ sign or warning triangle must be

displayed in a prominent position at the rear of vehicle being

towed.

Towi ng b y An o the r Ve h icl e

This vehicle may be towed short distances by another

vehicle provided that a speed of 48 km/h (30 mph) is not

exceeded. Ensure the towed vehicle gear selection is in

‘Neutral’ (manual) or position ‘N’ (automatic) with ignition

key turned to position ‘II’ to release steering lock and to

render horn, indicators and brake lights operational.

Caution

Take care to protect the paint work when installing the

towing eye. Ensure the towing eye is tight.

Caution

Do not tow with ‘sling’ type equipment as this

could result in damage to the bodywork.

Warning

When the engine is not running, the steering will no

longer be power-assisted and the brake booster will

become ineffective after a few applications of the

brakes. Be prepared for relatively heavy steering and

the need for greatly increased brake pedal pressure.

Vehicle Identification Number

October 2005 Workshop Manual 0-0-11

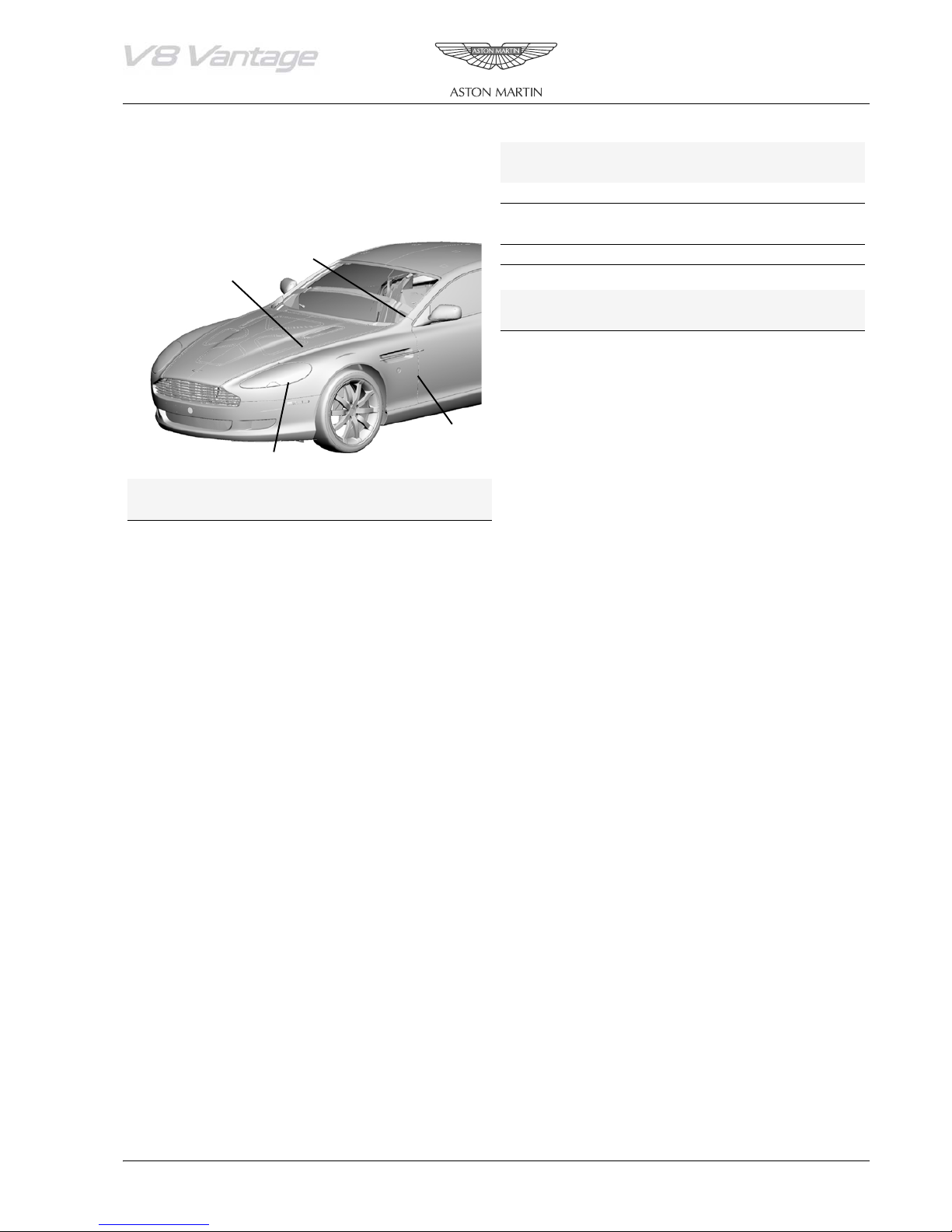

Vehicle Identification Number

The Vehicle Identification Number (VIN) is a 17 character number which uniquely identifies the vehicle and gives

fundamental data on the build site, date and initial configuration of the vehicle.

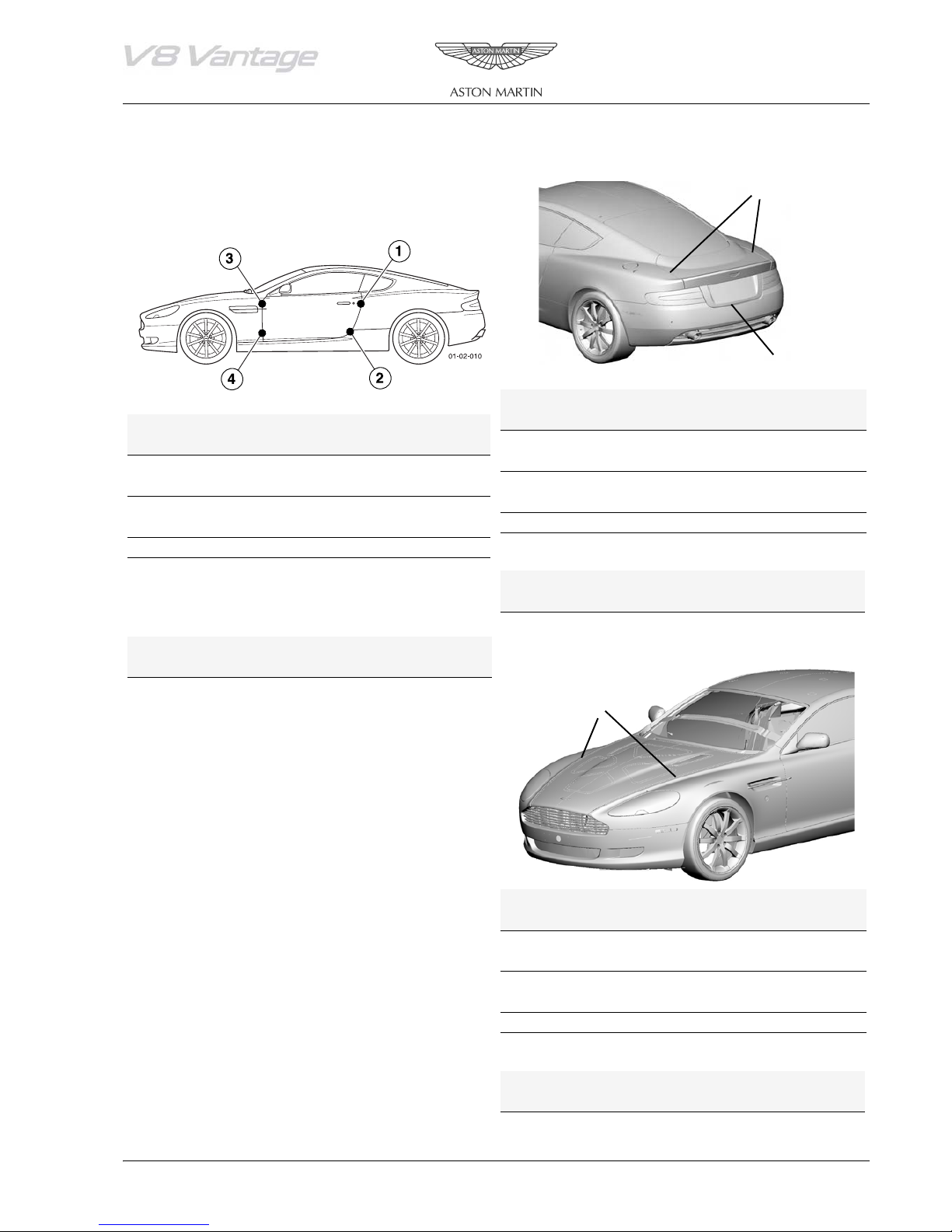

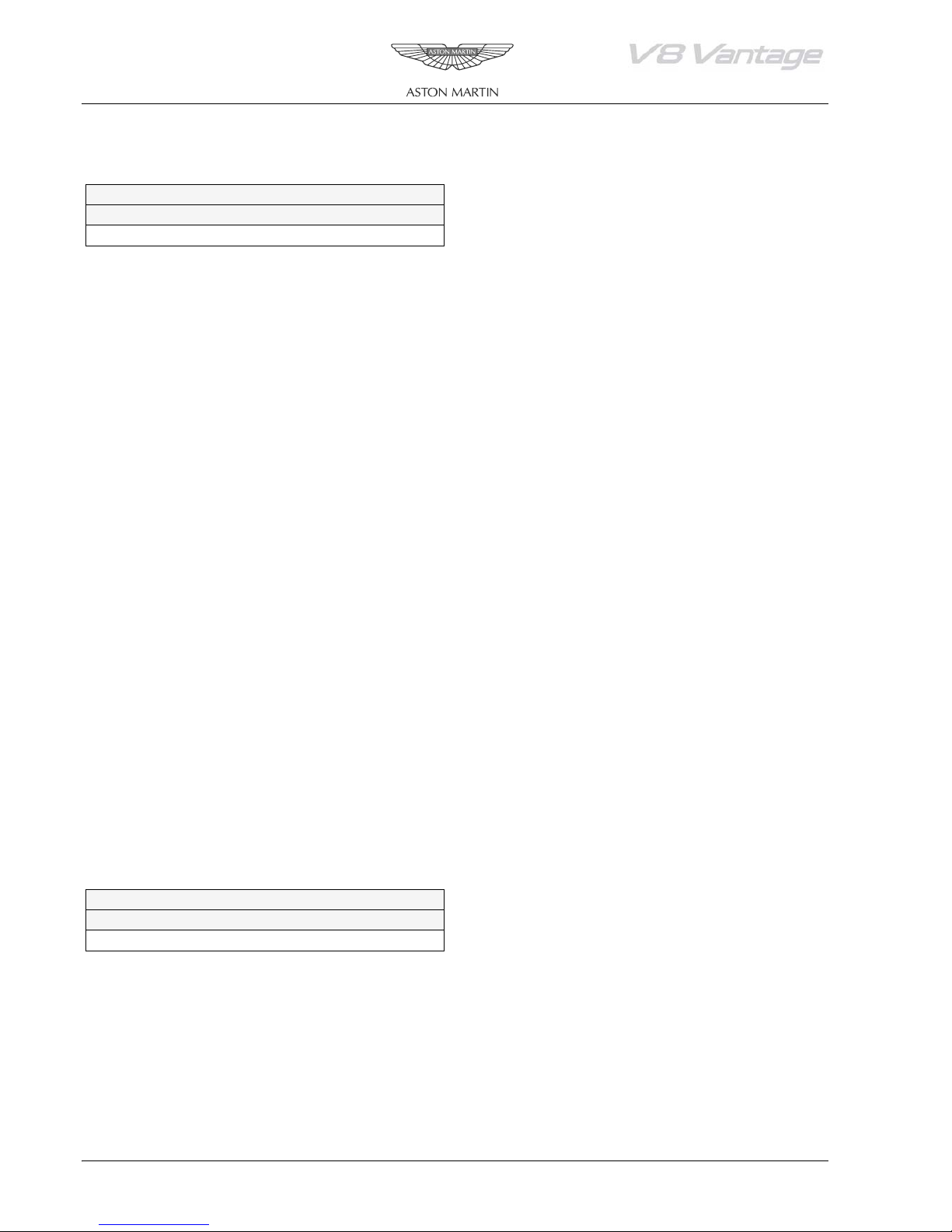

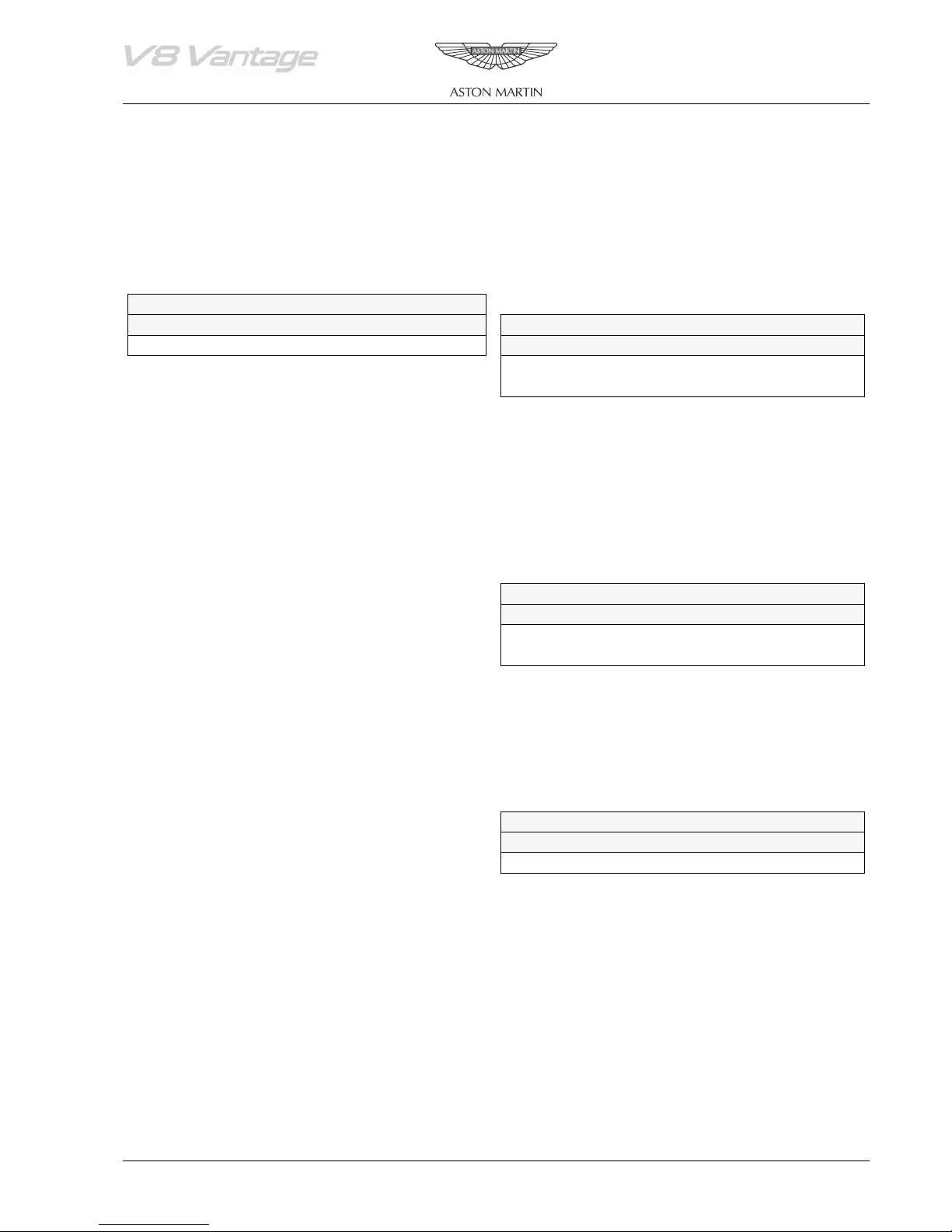

VIN Number Location

The VIN number is shown on two labels in the vehicle:

1 Under the lower edge of the windscreen.

2 Front of the engine bay.

• The VIN number is also engraved on the floorpan in the

right front footwell.

SCFBC3A45GC00001

Code for AML

Restraint System

Transmission and Steering

Body Type

Engine Type

Calculated Check Digit

Model Year

Manufacturing Plant

Series Identifier

Sequential Chassis Number

Body System (01.00)

Contents

Body Structure (01.01)...........................................1-1-3

Undertray Vehicle Set-Renew ................................ 5-2

5-2

Overview ................................................................1-3

RH/LH Front Wheel Arch Liner-Renew ..................

Front End (01.02)...................................................1-2-1

RH/LH Rear Wheel Arch Liner-Renew ................... 5-2

Front Wings ............................................................2-1

Specifications.........................................................2-1

Specifications ......................................................... 6-1

Body Closures (01.03) ...........................................1-3-1

Maintenance........................................................... 6-1

6-1

6-1

Tailgate.................................................................. 3-1

7-1

7-1

7-1

7-1

Specifications.......................................................... 3-1

RH/LH Door Mirror Assembly-Renew ....................

Doors ....................................................................3-1

Door Mirror Glass and Pad Assembly-Renew .........

Bonnet................................................................... 3-1

Description.............................................................

Maintenance........................................................... 3-2

Heated Seats .........................................................

Tailgate Assembly-Renew....................................... 3-2

Specifications ........................................................

Hood Assembly-Renew.......................................... 3-2

Maintenance...........................................................

Interior Trim (01.05)..............................................1-4-1

Maintenance........................................................... 4-1

Rear Centre Console-Renew

8-1

8-1

8-1

8-1

8-1

8-1

8-1

8-2

8-2

Door Trimboard Assembly-Remove for Access/Refit4-3

9-1

9-1

........................................ 9-1

9-6

9-6

9-6

.......................... 9-6

new ....................................................................... 4-5

9-7

9-7

9-8

.................................... 9-8

9-8

......................................... 9-9

..................................4-1

Description.............................................................

RH/LH Front Sill Plate-Renew ................................ 4-1

Frameless doors .....................................................

RH/LH Front Sill Name Plate-Renew ...................... 4-1

Specifications.........................................................

Header Panel Assembly-Renew..............................4-1

Maintenance...........................................................

RH/LH Upper Rear Pillar Panel Assembly-Renew ...4-2

Glass Regulator ......................................................

RH Sun Visor-Renew ............................................. 4-2

RH/LH Door Glass-Renew .....................................

LH Sun Visor-Renew.............................................. 4-2

Door Glass-Adjust/Reset.........................................

Rear Header Panel Assembly-Renew...................... 4-3

Front Windshield-Renew .......................................

Door Trimboard Assembly-Renew..........................4-3

Rear Windshield-Renew ........................................

RH/LH Door Trim Upper Veneer Panel-Renew ...... 4-4

Specifications .........................................................

LH Door Trim Upper Panel-Renew........................4-4

Maintenance...........................................................

RH/LH Interior Door Assembly Handle and Armrest-Re-

Instrument Panel-Renew

new ....................................................................... 4-4

Driver Upper Inner Panel Assembly-Renew............

RH/LH Door Pocket Assembly-Renew.................... 4-4

Driver Outer Upper Panel Assembly-Renew ..........

Lower Panel Assembly Quarter Trim-Renew ..........4-4

Passenger Upper Panel Assembly-Renew ...............

RH/LH Middle Section Quarter Trim Panel Assembly-Re-

Passenger Panel Assembly-Renew

RH/LH Upper Quarter Moulding Trim-Renew........4-5

Driver Lower Panel Assembly-Renew.....................

RH/LH Rear Heel Board Assembly-Renew..............4-5

Airbag Panel and Door Assembly-Renew ...............

Tailgate Lid Trim Assembly-Renew......................... 4-5

Instrument Cluster Hood Assembly-Renew.............

RH/LH Side Luggage Compartment Carpet Assembly-Re-

Glovebox Assembly-Renew

new ....................................................................... 4-5

Knee Protector-Renew...........................................

Luggage Compartment Front Carpet Assembly-Renew4-6

Glovebox Shield-Renew

Mirrors (01.09) ......................................................1-6-1

Seating (01.10).......................................................1-7-1

RH/LH Front Seat-Renew....................................... 7-1

Glass, Frame and Mechanism (01.11)................... 1-8-1

Instrument Panel (IP) (01.12)................................1-9-1

............... Passenger Lower Panel Assembly-Renew9-7

Luggage Compartment Floor Rear Carpet Assembly-Renew

Glove Compartment Damper Spring-Renew .......... 9-9

4-6

Cluster Bezel Panel-Renew .................................... 9-9

9-10

9-10

9-10

Tailgate Scuff Plate-Renew ..................................... 4-6

Driver Panel Assembly-Renew .............................

LH Side front Carpet Assembly-Renew...................4-6

Instrument Panel Bezel Assembly-Renew .............

Centre Stack Assembly-Remove for Access/Refit..... 4-6

Radio Speaker Grille Assembly-Renew .................

Exterior Trim (01.08) .............................................1-5-1

Maintenance

9-11

9-11

9-11

9-11

9-11

RH Wing Side Strake-Renew.................................. 5-1

10-1

10-1

10-1

........................................................... 5-1

Console Panel Assembly-Renew...........................

Radiator Grille-Renew............................................5-1

Master Lock Switch-Renew ..................................

RH/LH Hood Mesh Assembly-Renew..................... 5-1

IDV Control Switch-Renew ..................................

RH Side Strake Mesh-Renew..................................5-1

Heated Front Screen Switch-Renew.....................

LH Side Strake Mesh-Renew..................................5-1

PDC Off Switch-Renew .......................................

LH Wing Side Strake-Renew .................................. 5-1

Description...........................................................

Front Undertray-Renew .........................................5-2

Vehicle Key/Remote Transmitter ..........................

Rear Undertray-Renew .......................................... 5-2

Central Locking System........................................

Glovebox Open Switch-Renew............................ 9-11

Handles and Lock Mechanisms (01.14) .............. 1-10-1

October 2005 Workshop Manual 1-1-1

Remote Transmitter..............................................10-1

Fuel Filler Assembly..............................................10-1

Boot Emergency Release ......................................10-1

Specifications........................................................10-2

Maintenance .........................................................10-2

RH/LH Front Door Latch Assembly-Renew ...........10-2

0114BD|Latch Assembly - Hood - Renew............10-2

RH/LH External Front Door External-Renew .........10-2

Reduced Guard Switch-Renew.............................10-3

Passenger Airbag On/Off Switch-Renew ...............10-3

Tailgate Release Switch-Renew.............................10-3

Passenger Window Lift Switch-Renew ..................10-3

Driver Window Lift Switch-Renew........................10-3

Wipers and Washer System (01.16).................... 1-11-1

Headlamp Washing ..............................................11-1

Windscreen Reservoir and Motor Assembly-Renew11-3

Headlamp Wash Motor and Pump Assembly-Renew11-4

Specifications........................................................11-2

Maintenance .........................................................11-2

Windscreen Wiper Motor Assembly-Renew..........11-2

Wiper Linkage Assembly-Renew...........................11-2

Driver Wiper Arm Assembly-Renew .....................11-2

Passenger Wiper Arm Assembly-Renew................11-3

Windshield Wash Filler Neck-Renew....................11-3

Low Level Water Sensor-Renew ...........................11-3

Washer Fluid Reservoir-Renew.............................11-4

Bumpers (01.19) ................................................. 1-12-1

Front Bumper........................................................12-1

Rear Bumper.........................................................12-1

Specifications........................................................12-2

Maintenance .........................................................12-2

Front Bumper Cover-Renew.................................12-2

Rear Bumper Cover-Renew..................................12-2

RH/LH Rear Lower Bumper Mesh-Renew.............12-3

Rear Diffuser-Renew ............................................12-3

Rear Lower Assembly Centre Mesh-Renew...........12-3

Restraining Devices (01.20)................................ 1-13-1

Seat Belts...............................................................13-1

Emergency Locking Retractor (ELR).......................13-2

Airbag System .......................................................13-3

Maintenance .........................................................13-4

Driver’s Airbag Module-Renew.............................13-4

Passenger Airbag-Renew.......................................13-4

Side Impact Door ARS Sensor Assembly-Renew....13-5

1-1-2 Workshop Manual October 2005

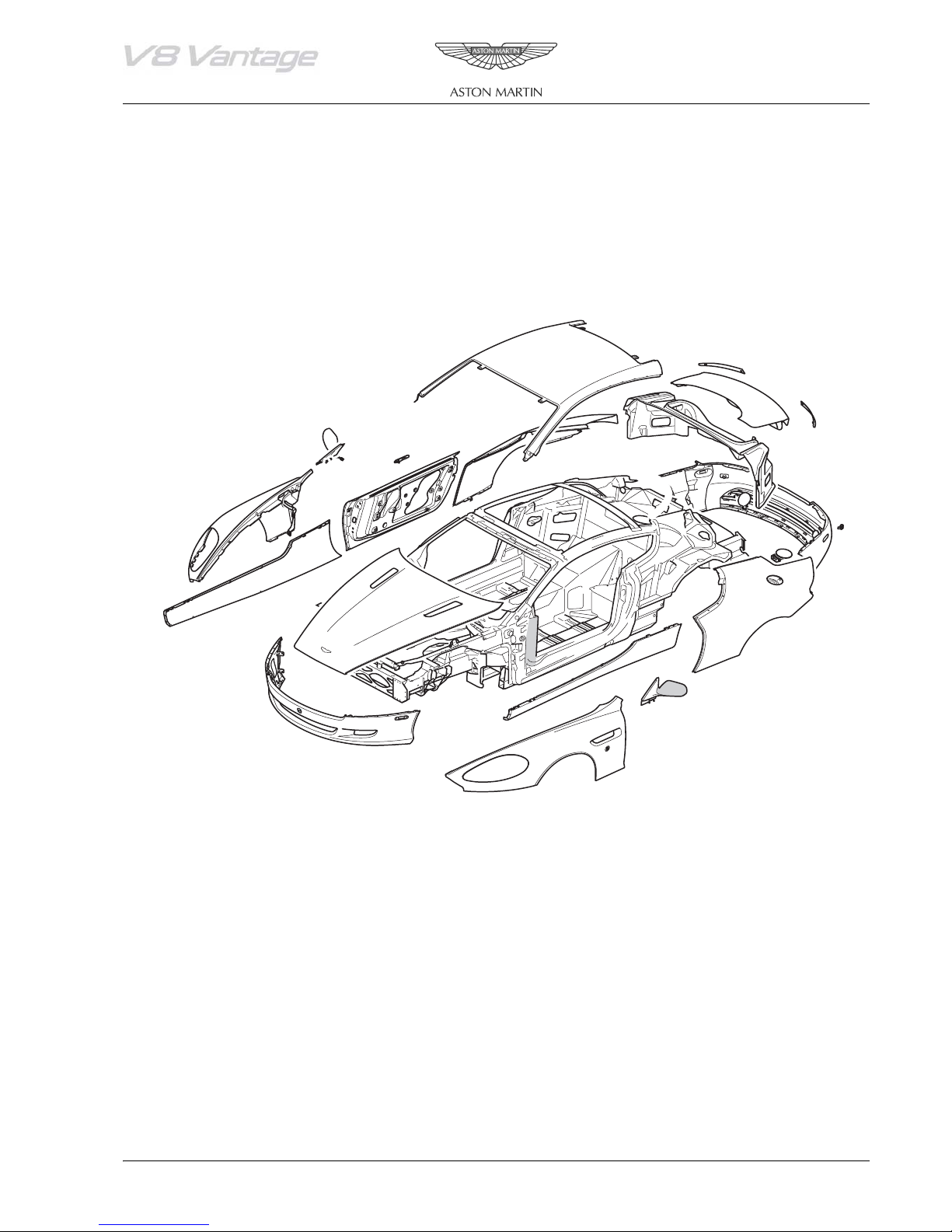

Body Structure (01.01)

Body System (01.00)

Body System (01.00)

Body Structure (01.01)

Overview

The all aluminium body underframe is bonded using an immensely strong hot-cured XD4600 red adhesive.

The rear quarter panels, roof and side mouldings are bonded to the structure using cold-cured 2810 MV adhesive. The

curing cycle is improved by using a hot air impingement system.

The composite front wings are bolted to the structure.

At no time should the body structure be subjected to temperatures in excess of 120°C (248°F).

01-01-020

October 2005 Workshop Manual 1-1-3

Body Structure (01.01)

Body System (01.00)

1-1-4 Workshop Manual October 2005

Front End (01.02)

Body System (01.00)

Body System (01.00)

Front End (01.02)

Wing Standard (mm)

Item 1 2 3 4

Front Wings

Tolerance ±0.75 +0.5 / -0.0 ± 0.75 ±0.5

Specifications

Flush -0.0 0.0 0.0 -0.5

Tolerance ±1.5 +0.0 / -0.5 ±1.5 ±0.5

Taper N/A

Symmetry N/A

Torque Figures

Description Nm

Wing Top 8

Wing Top Single nut Tight with

‘Threadlock’

Lower Rear 8

Slam panel 8

PCM Bracket 10

Bonnet Damper 25

Wing Standard (mm)

1

2

4

3

Item 1 2 3 4

Nominal gap 3.5 2.0 3.75 3.0

October 2005 Workshop Manual 1-2-1

Front End (01.02)

Body System (01.00)

1-2-2 Workshop Manual October 2005

Body Closures (01.03)

Body System (01.00)

Body System (01.00)

Body Closures (01.03)

Tail ga te

Specifications

Doors

2

1

Tailgate Standard (mm)

Door Standard (mm)

Item 1 2

Item 1 *2 3 4

Nominal gap 3.5 3.5

Nominal gap 3.5 3.00 3.00 3.75

Tolerance ±0.75 ±1.0

Tolerance ±0.75 ±1.0 ±1.0 ± 0.75

Flush -0.5 N/A

Flush 0.0 -1.0 -1.0 0.0

Tolerance +0.5 / -1.0 N/A

Tolerance ±1.5 / 0.0 +0.0 / -1.0 ±1.0 ±1.5

Taper 1 mm Max. across the length

Taper N/A

Symmetry 1 mm Max. difference LH to RH

Symmetry N/A

* Flushness blends to 0.0 at the rear quarter

Torque Figures

* Gap blends to 3.5 at rear quarter

Description Nm

Hinge to Body 25

Torque Figures

Bonnet

Description Nm.

Hinge to Door 47.5

Hinge to Body 36

Door Striker plate

1

Bonnet Standard (mm)

Item 1

Nominal gap 3.5

Tolerance ±0.75

Flush -0.0

To le r an ce ± 1 .5

Taper N/A

Symmetry N/A

Torque Figures

Description Nm.

Hinge to Body 25

October 2005 Workshop Manual 1-3-1

Body Closures (01.03)

Body System (01.00)

Maintenance

Installation

Tailgate Assembly-Renew

1. Position hood to hinge and install bolts (x4).

2. Install hood ball studs.

Repair Operation Time (ROT)

Item Code

Tailgate Assembly-Renew 01.03.GG

3. Install Buffers to hood.

4. Install sound deadening.

5. Align hood to aperture.

Removal

6. Raise hood. Nip up one hinge bolt either side.

1. Remove RH quarter upper trim panel (see Workshop

7. Lower hood and check alignment.

Manual Procedure 01.05.CX Moulding Assembly -

8. Raise hood and tighten hinge bolts (x4) and tighten.

Quarter Trim Upper - RH - Renew).

9. Install gas struts.

2. Remove LH quarter upper trim panel.

10. Close bonnet to check engagement of latch assembly,

3. Remove rear header trim panel.

adjust if necessary.

4. Disconnect LH and RH tailgate harnesses in cabin

11. Close hood and check operation of hood release lever.

5. Remove LH and RH harness grommets from body shell

6. Remove tailgate trim panel (see Workshop Manual

Procedure 01.05.EF Trim - Tailgate Lid Assembly Renew).

7. Disconnect one multiplug and remove securing bolts

(x3) for GPS aerial and place to one side.

8. Disconnect multiplug and remove securing nuts (x2) for

central high stop lamp assembly, place to one side.

9. Disconnect multiplug and remove securing nuts (x2) for

tailgate release switch, place to one side.

10. Remove tailgate buffer stops and place to one side.

11. Provide collision protection between tailgate corners

and bodywork.

12. With assistance remove bolts (x4) from hinges and place

tailgate to one side.

Installation

1. With assistance align tailgate to hinges and install bolts

(x4), nip but do not tighten.

2. Adjust alignment of tailgate and tighten hinge bolts.

3. Install tailgate buffers and adjust height as necessary

4. Install tailgate release switch and secure with nuts (x2),

connect multiplug.

5. Install central high level stop lamp assembly, secure with

nuts (x2) and connect multiplug.

Hood Assembly-Renew

Repair Operation Time (ROT)

Item Code

Tailgate Assembly-Renew 01.03.AB

Removal

1. Open hood.

2. Disconnect windscreen wash pipe.

3. Remove ball studs from hood.

4. Remove buffers from hood.

5. Remove hood sound insulation.

6. Loosen hood hinge bolts (4).

7. Disconnect gas struts and remove hinge bolts.

8. Remove hood.

1-3-2 Workshop Manual October 2005

Interior Trim (01.05)

Body System (01.00)

Body System (01.00)

Interior Trim (01.05)

This section covers removal and installation of the interior moldings and trim panels. In many instances, one component

overlaps another component. If this condition is found, it will be necessary to loosen or remove the overlapping

component before removal, to prevent damage to either component.

Maintenance

Rear Centre Console-Renew

Repair Operation Time (ROT)

Item Code

Rear Centre Console-Renew 01.04.BB

Removal

1. Remove storage compartment door.

2. Remove bolt and screws (x5) from storage compartment

support rail.

3. Release and remove centre arm rest (see Fig. 1).

Fig. 1

4. Install storage compartment door.

RH/LH Front Sill Plate-Renew

Repair Operation Time (ROT)

Item Code

Front Sill Plate-Renew

Front Sill Plate-Renew

RH

LH

01.05.AJ

01.05.AK

Removal

1. Remove screws (x2) name plate to front plate.

2. Remove bolts (x6) front plate to sill.

3. Remove front plate

Installation

1. Position front plate and install bolts (x6).

2. Install front sill name plate.

RH/LH Front Sill Name Plate-Renew

Repair Operation Time (ROT)

Item Code

Front Sill Name Plate-Renew

Front Sill Name Plate-Renew

RH

LH

01.05.AL

01.05.AM

Removal

1. Remove screws (x2) name plate to front plate.

2. Remove name plate.

Installation

4. Remove nuts (x3), screws (x4) from panel assembly rear

1. Install name plate to front plate.

console (see Fig. 2).

Header Panel Assembly-Renew

Fig. 2

Repair Operation Time (ROT)

Item Code

Header Panel Assembly-Renew 01.05.BB

Removal

1. Remove grill from front header courtesy light console.

Installation

1. Install panel and tighten nuts (x3) and screws (x4).

2. Install centre arm rest.

3. Install support rail and tighten screws (x5) and bolt.

October 2005 Workshop Manual 1-4-1

Interior Trim (01.05)

Body System (01.00)

Fig. 1

3. Remove courtesy light console from header.

4. Remove sun visor Allen screws (x2 (see Fig. 2)).

2. Remove screw securing courtesy light console to header

Installation

(see Fig. 1).

1. Position sun visor and install screws (x2).

2. Install courtesy light console.

3. Install grille.

RH/LH Upper Rear Pillar Panel

Assembly-Renew

Repair Operation Time (ROT)

Item Code

Upper Rear Pillar Panel Assembly-

Renew

Upper Rear Pillar Panel Assembly-

Renew

RH

LH

01.05.BF

01.05.BG

Removal

1. Remove rear header.

2. Remove nut (x1) rear pillar panel assembly to body.

3. Release panel from fir tree clip (x1).

4. Disconnect multiplug (x1) light assembly and remove

panel.

Installation

1. Connect multiplug, position panel and secure with fir

tree clip.

2. Install nut (x1) panel to body.

3. Install rear header.

RH Sun Visor-Renew

Repair Operation Time (ROT)

Item Code

Sun Visor-Renew RH 01.05.BH

Fig. 2

5. Remove sunvisor (see Fig. 3).

Removal

1. Remove front header trim panel (see Workshop Manual

procedure 01.05.BB Panel Assembly - Header - Renew).

2. Remove rear header trim panel screws (x2) and fir trees

(x3).

3. Remove headliner rear retainers.

4. Remove headliner.

Installation

1. Position headliner and secure with rear retainers.

2. Install rear header trim panel.

3. Install front header trim panel (see Workshop Manual

procedure 01.05.BB Panel Assembly - Header - Renew).

LH Sun Visor-Renew

Removal

1. Remove grill from front header courtesy light console.

Fig. 3

Repair Operation Time (ROT)

Item Code

Sun Visor-Renew LH 01.05.BJ

1-4-2 Workshop Manual October 2005

Interior Trim (01.05)

Body System (01.00)

2. Remove screw securing courtesy light console to header

(see Fig. 1).

Fig. 1

3. Remove courtesy light console from header.

4. Remove sun visor allen screws (x2) (see Fig. 2).

Fig. 2

5. Remove sunvisor.

Installation

1. Position sun visor and install screws (x2).

2. Install courtesy light console.

3. Install grille.

Rear Header Panel Assembly-Renew

Repair Operation Time (ROT)

Item Code

Rear Header Panel Assembly-Renew 01.05.BK

Removal

1. Remove LH moulding assembly quarter trim upper (see

Workshop Manual procedure 01.05.CY Moulding

Assembly - Quarter Trim Upper - LH - Renew).

2. Remove RH moulding assembly quarter trim upper (see

Workshop Manual procedure 01.05.CX Moulding

Assembly - Quarter Trim Upper - RH - Renew).

3. Remove rear header panel assembly.

Installation

1. Install rear header panel assembly.

2. Install RH moulding assembly quarter trim upper (see

Workshop Manual procedure 01.05.CX Moulding

Assembly - Quarter Trim Upper - RH - Renew).

3. Install LH moulding assembly quarter trim upper (see

Workshop Manual procedure 01.05.CY Moulding

Assembly - Quarter Trim Upper - LH - Renew).

Door Trimboard Assembly-Renew

Repair Operation Time (ROT)

Item Code

Door Trimboard Assembly-Renew 01.05.CA

Removal

1. Lower door glass fully.

2. Disconnect vehicle battery.

3. Release door handle (bolts x2).

4. Remove door handle trim plate and disconnect door

catch inner release cable and remove bolts (x2) from

outer retaining plate.

5. Remove screw (x1) securing trim panel to top front of

door frame.

6. Remove door trim panel bolts (x5).

7. Lift trim out and up to release trim from door frame and

disconnect multiplugs (x2).

Installation

1. Position door trim panel and connect harness

multiplugs.

2. Place trim over top of retaining clips and pull out and

down to fit panel.

3. Install the door trim panel screws (x5).

4. Install screw (x1) trim panel to top front of door frame.

5. Connect release cable and position door handle trim

plate.

6. Install door handle (Bolts x2).

7. Connect vehicle battery.

Door Trimboard Assembly-Remove for

Access/Refit

Repair Operation Time (ROT)

Item Code

Door Trimboard Assembly-Remove/

Refit

01.05.CB

Removal

1. Lower door glass fully.

2. Disconnect vehicle battery.

3. Release door handle (bolts x2).

4. Remove door handle trim plate and disconnect door

catch inner release cable and remove bolts (x2) from

outer retaining plate.

5. Remove screw (x1) securing trim panel to top front of

door frame.

October 2005 Workshop Manual 1-4-3

Interior Trim (01.05)

Body System (01.00)

6. Remove door trim panel bolts (x5).

7. Lift trim out and up to release trim from door frame and

disconnect multiplugs (x2).

Installation

1. Position door trim panel and connect harness

multiplugs.

2. Place trim over top of retaining clips and pull out and

down to fit panel.

3. Install the door trim panel screws (x5).

4. Install screw (x1) trim panel to top front of door frame.

5. Connect release cable and position door handle trim

plate.

6. Install door handle (Bolts x2).

7. Connect vehicle battery.

RH/LH Door Trim Upper Veneer PanelRenew

Repair Operation Time (ROT)

Item Code

Door Trim Upper Veneer Panel-Renew

Door Trim Upper Veneer Panel-Renew

RH

LH

01.05.CC

01.05.CD

Removal

1. Remove door trimboard assembly (see Workshop

Manual procedure 01.05.CB Trimboard Assembly Door - Remove for Access & Refit).

2. Remove screws (x9), release clip securing trim upper

veneer panel to trimboard, and remove trim panel.

Installation

1. Install trim upper veneer panel, install clip, install and

tighten screws (x9).

2. Install door trimboard assembly ((see Workshop Manual

procedure 01.05.CB Trimboard Assembly - Door Remove for Access & Refit).

LH Door Trim Upper Panel-Renew

Repair Operation Time (ROT)

Item Code

Door Trim Upper Panel-Renew

Door Trim Upper Panel-Renew

RH

LH

01.05.CE

01.05.CF

Removal

1. Remove door trimboard assembly (see Workshop

Manual procedure 01.05.CB Trimboard Assembly Door - Remove for Access & Refit

2. Remove upper veneer door trim panel securing screws

(x9) and clip (x1).

3. Remove speaker grille securing screws (x2) and unclip

(x3) from panel.

4. Remove upper door trim panel securing screw (x1) and

drill out 7 pop-rivets

Installation

1. Install upper door trim panel, securing screw (x1) and

pop-rivets (x7).

2. Install speaker grille, clips (x3) and screws (x2).

3. Install upper veneer door trim panel, screws (x9) and

clip (x1).

4. Install door trimboard assembly (see Workshop Manual

procedure 01.05.CB Trimboard Assembly - Door Remove for Access & Refit).

RH/LH Interior Door Assembly Handle

and Armrest-Renew

Repair Operation Time (ROT)

Item Code

Interior Door Handle and Armrest-

Renew

Interior Door Handle and Armrest-

Renew

RH

LH

01.05.CG

01.05.CH

Removal

1. Open door.

2. Remove bolts (x2) securing interior door handle and

armrest.

3. Disconnect latch inner and outer cable from handle,

remove handle/armrest assembly.

Installation

1. Connect latch inner and outer cable to handle

mechanism.

2. Install handle/armrest assembly to trimboard, install and

tighten bolts (x2).

RH/LH Door Pocket Assembly-Renew

Repair Operation Time (ROT)

Item Code

Door Pocket Assembly-Renew

Door Pocket Assembly-Renew

RH

LH

01.05.CJ

01.05.CK

Removal

1. Remove door trimboard assembly (see Workshop

Manual procedure 01.05.CB Trimboard Assembly Door - Remove for Access & Refit).

2. Remove door ajar puddle lamp.

3. Remove nuts (x10), securing door pocket to trimboard,

remove door pocket.

Installation

1. Install door pocket, install and tighten nuts (x10).

2. Install door ajar puddle lamp.

3. Install door trimboard assembly (see Workshop Manual

procedure 01.05.CB Trimboard Assembly - Door Remove for Access & Refit).

Lower Panel Assembly Quarter TrimRenew

Repair Operation Time (ROT)

Item Code

Lower Panel Assembly Quarter Trim-

Renew

RH 01.05.CR

1-4-4 Workshop Manual October 2005

Interior Trim (01.05)

Body System (01.00)

Repair Operation Time (ROT)

Item Code

Lower Panel Assembly Quarter Trim-

Renew

LH 01.05.CS

Removal

1. Remove RH quarter trim middle panel (see Workshop

Manual procedure 01.05.CT Panel Assembly - Quarter

Trim Middle Section - RH - Renew).

2. Remove nuts (x3) from lower to middle trim panel and

remove lower trim panel.

Installation

1. Install lower trim to middle trim panel and tighten nuts

(x3).

2. Install RH quarter trim middle panel (see Workshop

Manual procedure 01.05.CT Panel Assembly - Quarter

Trim Middle Section - RH - Renew).

RH/LH Middle Section Quarter Trim

Panel Assembly-Renew

Repair Operation Time (ROT)

Item Code

Middle Section Quarter Trim Panel

Assembly-Renew

Middle Section Quarter Trim Panel

Assembly-Renew

RH

LH

01.05.CT

01.05.CU

Removal

1. Remove screw securing RH/LH quarter trim middle

section to rear bulkhead cover.

2. Release and remove trim panel fir tree clips (x4).

3. Remove fir tree clips (x4) and spring clip from trim

panel.

Installation

1. Install fir tree clips (x4) and spring clip in trim panel.

2. Install trim panel, secure with clips and tighten screw.

RH/LH Upper Quarter Moulding TrimRenew

Repair Operation Time (ROT)

Item Code

Upper Quarter Moulding Trim-Renew

Upper Quarter Moulding Trim-Renew

RH

LH

01.05.CX

01.05.CY

Removal

1. Remove RH quarter trim middle panel (see Workshop

Manual procedure 01.05.CT/01.05.CU Panel Assembly

- Quarter Trim Middle Section - RH/LH - Renew).

2. Remove bolts (x2) and screw (x1) securing upper quarter

trim to body.

3. Feed seatbelt through trim panel aperture and remove

panel.

4. Disconnect speaker multiplug.

5. Remove nuts securing speaker to trim panel (x3).

Installation

1. Install speaker (nuts x3).

2. Connect speaker multiplug.

3. Feed seat belt harness through panel and secure panel

to body.

4. Install RH quarter trim middle panel (see Workshop

Manual procedure 01.05.CT/01.05.CU Panel Assembly

- Quarter Trim Middle Section - RH/LH - Renew).

RH/LH Rear Heel Board Assembly-Renew

Repair Operation Time (ROT)

Item Code

Rear Heel Board Assembly-Renew

Rear Heel Board Assembly-Renew

RH

LH

01.05.EC

01.05.ED

Removal

1. Power drivers seat fully forward.

2. Remove stowage compartment door.

3. Release rear carpet studs (x2), move carpet aside.

4. Remove screws (x2), RH rear heel board to support rail.

5. Remove nuts (x2), RH rear heel board to body, remove

heel board.

Installation

1. Install RH rear heel board, install and tighten nuts (x2)

and screws (x2).

2. Position rear carpet, secure with studs (x2).

3. Install stowage compartment door.

4. Reposition drivers seat.

Tailgate Lid Trim Assembly-Renew

Repair Operation Time (ROT)

Item Code

Tailgate Lid Trim Assembly-Renew 01.05.EF

Removal

1. Disconnect emergency release handle from cable.

2. Remove closing strap handle securing bolt.

3. Remove fir tree trim pins (x16).

4. Place panel to one side.

Installation

1. Install panel and fit fir tree trim pins (x16).

2. Install closing strap.

3. Connect emergency release cable.

RH/LH Side Luggage Compartment

Carpet Assembly-Renew

Repair Operation Time (ROT)

Item Code

Side Luggage Compartment Carpet

Assembly-Renew

Side Luggage Compartment Carpet

Assembly-Renew

RH

LH

01.05.FB

01.05.FC

Removal

October 2005 Workshop Manual 1-4-5

Interior Trim (01.05)

Body System (01.00)

1. Release and remove rear luggage compartment floor

carpet.

2. Remove front floor carpet retainers (x6).

3. Remove luggage compartment front floor carpet.

4. Remove tailgate scuff plate (see Workshop Manual

procedure 01.05.FL Plate - Tailgate Scuff - Renew).

5. Partially remove tailgate aperture seal.

6. Release and remove RH/LH side luggage compartment

carpet.

Installation

1. Install and secure RH/LH side luggage compartment

carpet.

2. Install aperture seal.

3. Install tailgate scuff plate (see Workshop Manual

procedure 01.05.FL Plate - Tailgate Scuff - Renew).

4. Install luggage compartment front floor carpet and

secure with carpet retainers.

5. Install luggage compartment rear floor carpet.

Luggage Compartment Front Carpet

Assembly-Renew

Repair Operation Time (ROT)

Item Code

Luggage Compartment Front Carpet

Assembly-Renew

01.05.FE

Removal

1. Release and remove luggage compartment rear floor

carpet.

2. Remove carpet retainers (x6).

3. Remove luggage compartment front floor carpet.

Installation

1. Install luggage compartment front floor carpet and

secure with carpet retainers.

2. Install luggage compartment rear floor carpet.

Luggage Compartment Floor Rear Carpet

Assembly-Renew

Repair Operation Time (ROT)

Item Code

Luggage Compartment Front Carpet

Assembly-Renew

01.05.FF

Removal

1. Release and remove rear luggage compartment floor

carpet.

Installation

1. Install rear luggage compartment floor carpet

Tail ga te S cuf f Pl at e -Re new

Removal

1. Remove screws (x2) securing tailgate striker and remove

striker.

2. Remove screws securing tailgate scuff plate.

Installation

1. Position tailgate scuff plate and install screws (x3)

2. Install tailgate striker.

3. Adjust striker as necessary.

LH Side front Carpet Assembly-Renew

Repair Operation Time (ROT)

Item Code

Side Front Carpet Assembly-Renew LH 01.05.FM

Removal

1. Remove LH side rear luggage compartment carpet (see

Workshop Manual procedure 01.05.FC Carpet

Assembly - Luggage Compartment - Side Rear - LH Renew).

2. Remove front floor carpet retainers and carpet.

3. Remove LH front luggage compartment carpet.

Installation

1. Install LH front luggage compartment carpet.

2. Install front floor carpet and secure with carpet retainers

(x6).

3. Install LH side rear luggage compartment carpet (see

Workshop Manual procedure 01.05.FC Carpet

Assembly - Luggage Compartment - Side Rear - LH Renew).

Centre Stack Assembly-Remove for

Access/Refit

Repair Operation Time (ROT)

Item Code

Centre Stack Assembly-Remove/Refit 15.01.CB

Removal

1. Remove panel assembly - console (see Workshop

Manual procedure 01.12.DB Panel Assembly Console Renew).

2. Remove bezel assembly instrument panel (see

Workshop Manual procedure 01.12.AV Bezel Assembly

- Instrument Panel - Renew).

Repair Operation Time (ROT)

Item Code

Tailgate Scuff Plate-Renew 01.05.FL

1-4-6 Workshop Manual October 2005

Interior Trim (01.05)

Body System (01.00)

3. Remove screws (x4) that secure centre stack assembly to

IP (see Fig. 1).

Fig. 1

4. Release centre stack assembly and disconnect

multiplugs (x12).

Installation

1. Position centre stack assembly and install multiplugs

(x12).

2. Install and torque tighten screws (x4).

3. Install bezel assembly instrument panel (see Workshop

Manual procedure 01.12.AV Bezel Assembly Instrument Panel - Renew).

4. Install panel assembly - console (see Workshop Manual

procedure 01.12.DB Panel Assembly Console - Renew).

October 2005 Workshop Manual 1-4-7

Interior Trim (01.05)

Body System (01.00)

1-4-8 Workshop Manual October 2005

Exterior Trim (01.08)

Body System (01.00)

Body System (01.00)

Exterior Trim (01.08)

Maintenance

Radiator Grille-Renew

Repair Operation Time (ROT)

Item Code

Radiator Grille-Renew 01.08.AA

Removal

1. Remove number plate plinth (see Workshop Manual

procedure 01.19.BD Licence Plate - Plinth Assembly Front - Renew).

2. Remove number plate plinth securing plate.

3. Remove radiator grill screws (x6) and nuts (x2).

4. Remove grill assembly.

Installation

1. Position radiator grill and install screws (x6) and nuts

(x2).

2. Install number plate plinth securing plate.

3. Install number plate plinth (see Workshop Manual

procedure 01.19.BD Licence Plate - Plinth Assembly Front - Renew).

RH/LH Hood Mesh Assembly-Renew

Repair Operation Time (ROT)

Item Code

Hood Mesh Assembly-Renew

Hood Mesh Assembly-Renew

RH

LH

01.08.BA

01.08.BB

Removal

1. Release 4 trim clips securing sound deadening around

mesh.

2. Remove nuts and washers (x6) mesh to hood.

3. Release and remove mesh.

Installation

1. Position mesh to hood and install nuts and washers.

2. Secure sound deadening around mesh.

RH Side Strake Mesh-Renew

Repair Operation Time (ROT)

Item Code

Side Strake Mesh-Renew RH 01.08.CE

Removal

1. Remove engine control module.

2. Remove nuts (x3) securing mesh to side strake.

3. Remove mesh.

Installation

1. Position mesh to side strake and install nuts (x3).

1. Install engine control module.

LH Side Strake Mesh-Renew

Repair Operation Time (ROT)

Item Code

Side Strake Mesh-Renew LH 01.08.CF

Removal

1. Remove nuts (x3) mesh to side strake.

2. Remove mesh.

Installation

1. Position mesh to side strake and install nuts (x3).

RH Wing Side Strake-Renew

Repair Operation Time (ROT)

Item Code

Wing Side Strake-Renew RH 01.08.CG

Removal

1. Remove engine control module (see Workshop Manual

procedure 03.14.BB Engine Control Module - RH

Renew).

2. Remove nuts (x3) mesh to side strake.

3. Remove mesh.

4. Remove screw inside 'A' post securing side strake to

body.

5. Remove nut side strake to wheel arch.

6. Remove side strake.

Installation

1. Install side strake, nut and screw.

2. Position mesh to side strake and install nuts (x3).

3. Install engine control module (see Workshop Manual

procedure 03.14.BB Engine Control Module - RH

Renew).

LH Wing Side Strake-Renew

Repair Operation Time (ROT)

Item Code

Wing Side Strake-Renew LH 01.08.CH

Removal

1. Remove LH front wheel arch liner (see Workshop

Manual procedure 01.02.FB Wheel Arch Liner - Front LH - Renew).

2. Remove nuts (x3) mesh to side strake.

3. Remove mesh.

4. Remove screw inside 'A' post side strake to body.

5. Remove nut side strake to wheel arch.

6. Remove side strake.

Installation

1. Install side strake, nut and screw.

2. Position mesh to side strake and install nuts (x3).

October 2005 Workshop Manual 1-5-1

Exterior Trim (01.08)

Body System (01.00)

3. Install LH front wheel arch liner (see Workshop Manual

RH/LH Front Wheel Arch Liner-Renew

procedure 01.02.FB Wheel Arch Liner - Front - LH Renew).

Front Undertray-Renew

Repair Operation Time (ROT)

Item Code

Wheel Arch Liner-Renew RH

Wheel Arch Liner-Renew LH

01.02.GB

01.02.FB

Repair Operation Time (ROT)

Item Code

Removal

Front Undertray-Renew 01.02.NB

Removal

1. Raise vehicle on ramp.

2. Remove screws (x2),Torx screws (x12), front undertray

to body.

3. With assistance, remove front undertray.

Installation

1. With assistance, install undertray, install and tighten

Torx screws (x12) to (19-26 Nm) and screws (x2) to (810 Nm)

2. Lower vehicle on ramp.

Rear Undertray-Renew

4. Raise vehicle on ramp.

5. Remove road wheel(s).

6. Remove screws (x23), wheel arch liner to body.

7. Release and remove wheel arch liner.

8. Remove inner pad from liner.

Installation

1. Install inner pad to wheel arch liner.

2. Install wheel arch liner, fit and tighten screws (x23).

3. Install road wheel(s).

4. Lower vehicle on ramp.

RH/LH Rear Wheel Arch Liner-Renew

Repair Operation Time (ROT)

Repair Operation Time (ROT)

Item Code

Item Code

Rear Undertray-Renew 01.02.PB

Rear Wheel Arch Liner-Renew RH 01.02.HB

Removal

Rear Wheel Arch Liner-Renew LH 01.02.JB

1. Raise vehicle on ramp.

2. Remove Torx screws (x10), rear undertray to subframe.

3. Remove rear undertray.

Installation

1. Install rear undertray, install and tighten Torx screws

(x10) to (8-10 Nm).

2. Lower vehicle on ramp.

Undertray Vehicle Set-Renew

Repair Operation Time (ROT)

Item Code

Undertray Vehicle Set-Renew 01.02.PD

Removal

1. Raise vehicle on ramp.

2. Remove Torx screws (x12), screws (x2), front undertray

to subframe.

3. With assistance, remove front undertray.

4. Remove Torx screws (x10), rear undertray to subframe.

5. Remove rear undertray.

Installation

1. With assistance, install front undertray, install and

tighten Torx screws (x12), screws (x2).

2. Install rear undertray, install and tighten Torx screws

(x10).

3. Lower vehicle on ramp

Removal

1. Raise vehicle on ramp.

2. Remove road wheel(s).

3. Release vent pipe clips (x2) - Right-hand side only.

4. Remove screws (11), wheel arch liner to body.

5. Release and remove wheel arch liner, remove inner pad

from liner.

Installation

1. Install inner pad to wheel arch liner.

2. Install wheel arch liner, fit and tighten screws (x11).

3. Install vent pipe to liner, clips (x2) - Right-hand side

only.

4. Install road wheel(s).

5. Lower vehicle on ramp.

1-5-2 Workshop Manual October 2005

Mirrors (01.09)

Body System (01.00)

Body System (01.00)

Mirrors (01.09)

3. Turn on ignition and drive mirror to maximum away

from door, turn off ignition and disconnect lucar

Specifications

connectors (x2).

Installation

Torque Figures

1. Connect lucar connectors to mirror glass (x2).

Description Nm

2. Align mirror glass inboard clip with pad and fit white

Mirror Mounting 20-25

tags into their appropriate channels.

Maintenance

3. Press outboard edge of mirror glass until it can be heard

to clip into place.

RH/LH Door Mirror Assembly-Renew

Repair Operation Time (ROT)

Item Code

Door Mirror Assembly-Renew

Door Mirror Assembly-Renew

RH

LH

01.08.GC

01.08.GD

Removal

1. Remove door trimboard (see Workshop Manual

procedure 01.05.CB Trimboard Assembly - Door Remove for Access & Refit).

2. Lift rear of fixed window, remove rubber surround at

top and pull out window.

3. Remove the door mirror rubber cheater panel.

4. Disconnect multiplug and release harness from fir tree

clips (x2) and self adhesive clip.

5. Remove Torx bolts (x3) and screw from glass channel,

remove mirror assembly.

Installation

1. Position mirror, install and torque tighten Torx bolts (x3)

and screw (glass channel).

2. Connect multiplug and secure harness fir tree clips (x2)

and self adhesive clip.

3. Install rubber mirror cheater panel and insert rubber

guttering.

4. Refit fixed window, ensure rubber surround is correctly

installed.

5. Install door trimboard (see Workshop Manual procedure

01.05.CB Trimboard Assembly - Door - Remove for

Access & Refit).

Door Mirror Glass and Pad AssemblyRenew

Repair Operation Time (ROT)

Item Code

Door Mirror Glass and Pad Assembly-

Renew

Door Mirror Glass and Pad Assembly-

Renew

RH

LH

01.08.GE

01.08.GF

Removal

1. Switch ignition on, motor mirror fully inwards, switch off

ignition.

2. Support outer edge of mirror glass, using a suitable flat

blade between inboard glass edge and casing, lever glass

outwards to release from outboard clip.

October 2005 Workshop Manual 1-6-1

Loading...

Loading...