Page 1

SYSTEMCIRCUIT

DIAGRAMS

2005MY Manual Coupe 13-7-05

ASTON MARTIN

Page 2

‘‘HHooww ttoo rreeaadd tthhee cciirrccuuiittss’’

Below is a simple guide to what some of the symbols mean on the circuit diagrams. For some

of the symbols there are descriptions as to how they function. This is not a comprehensive

guide by all means but just refers to the most common symbols.

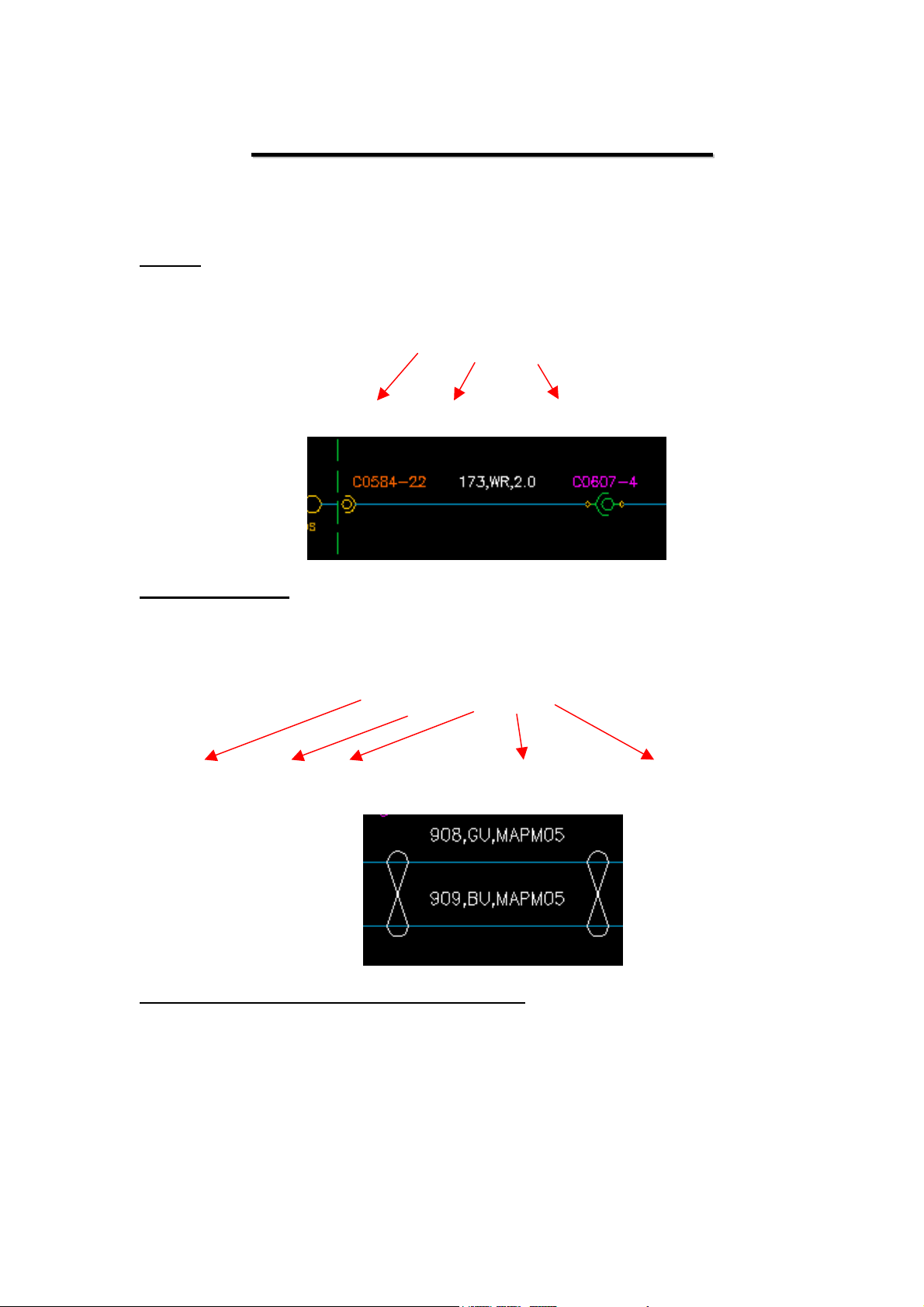

WIRES

The wires vary in size to allow different current to be carried. For example a wire with a

diameter of 0.50mm (This is the diameter of all the copper strands together) will carry 11

amps whilst a wire with a diameter of 2.00mm will carry 25 amps.

Wire no. in harness,Colour,Size (Dia of copper strands)

173,WR,2.0

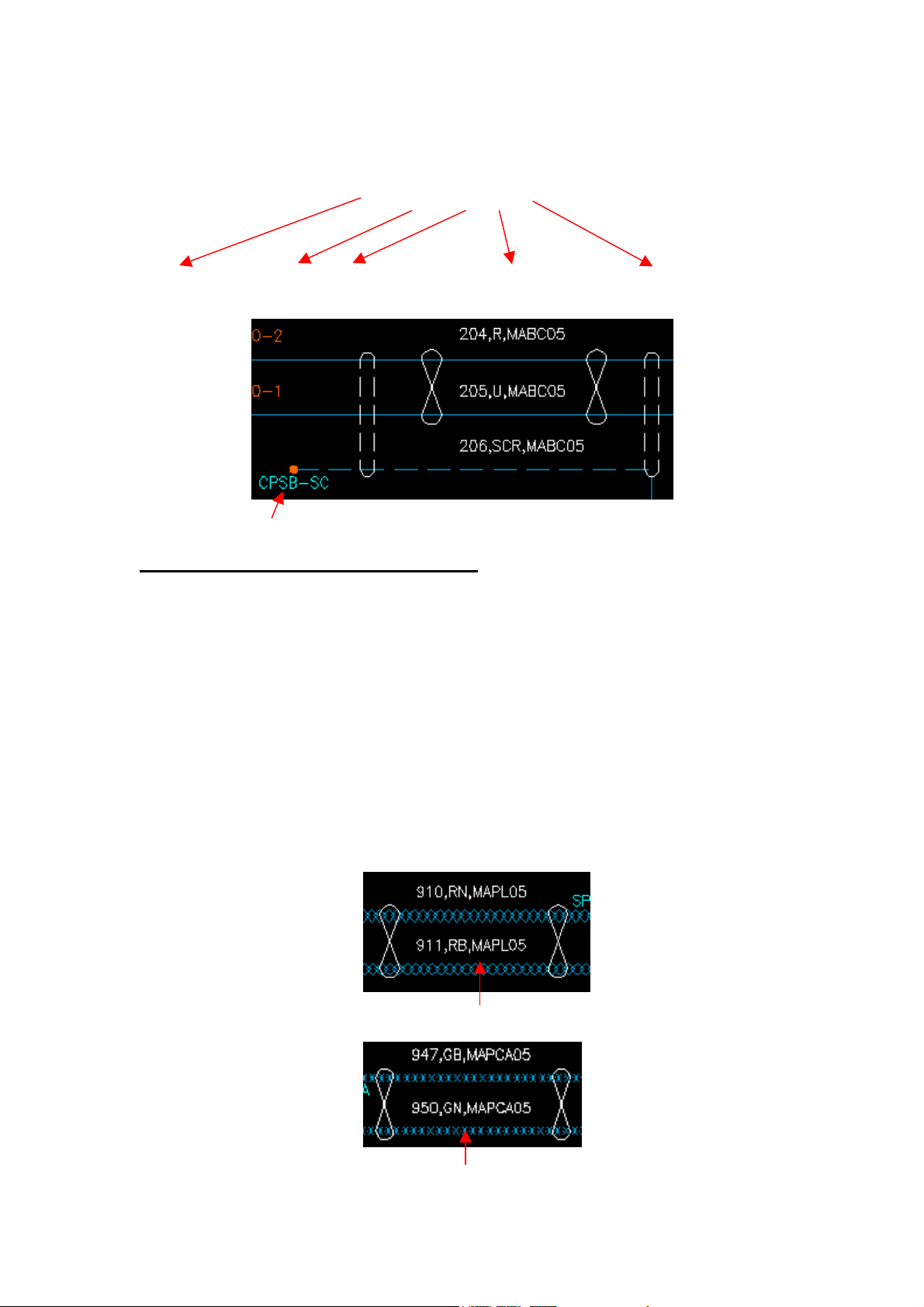

TWISTED WIRES

The ‘Figure of 8’ shown on circuits as below denotes this and shows the wires that are twisted

together. A wire generates a certain amount of ‘electrical noise’ when a current is passed

through it. By twisting the 2 wires together the ‘electrical noise’ is cancelled out on each wire

by the opposing wire. This is used more on sensors and audio speakers.

Wire no. in harness,Colour,MAP (Defines twisted),What wires are in the pair, Size (Dia of

copper strands)

908,GU,MAPM05

SCREENED & TWISTED SCREENED WIRES

The ‘Figure of 8’ shown on the circuits as below denotes this and shows the wires that are

twisted together. A wire generates a certain amount of ‘electrical noise’ when a current is

passed through it. By twisting the 2 wires together the ‘electrical noise’ is cancelled out on

each wire by the opposing wire. The twisting removes internal generated noise.

The signals through a wire can be affected by externally generated electrical noise. To reduce

the interference the wires are placed inside a conductive sleeve. One end of the conductive

sleeve is always open whilst the other end can be terminated to a ground, to a component, or

left open.

Page 3

The symbol for the screen is an oval with the wires that are to be screened inside it. The

letters ‘SCR’ define the screen.

908,U,MABC05

Wire no. in harness, Colour, MAB (Defines Screened),What wires are in screen, Size (Dia of

copper strands)

This defines the open end of screen.

CAN – HIGH SPEED AND LOW SPEED

‘CAN’ stands for Controller Area Network and is the intelligent wiring of the vehicle. This

wiring carries the electronic data around the vehicle allowing the various modules and

components to interrogate the network and remove their specific data signals.

There are 2 different speeds of network. A low speed that transmits at 125,000 bits per

second and a high speed that transmits at 500,000 bits per second. An analogue phone

modem is approximately 56,000 bits per second so it gives an idea of transmission speed.

The low speed network is mainly for body controller systems such as seats and doors whilst

the high-speed network is for engine management and powertrain associated systems such

as ABS.

All wiring in the CAN is twisted so the above naming convention applies. The twisted wires

always consist of one wire with a black trace in it for the negative side and one with a brown

trace in it for the positive.

High Speed CAN wire

Low Speed CAN wire

Page 4

The symbol below shows a module or component connector with the pin numbers that have

CAN wires coming from them.

Where ‘CAN LS-‘ refers to a Low Speed CAN Negative Side, this naming applies to the

positive side and to the High Speed CAN.

To aid identification of the different speed CAN’s in the car different colours of wire have been

used, for example the Low Speed Volcano is GB twisted with GN, the High Speed Volcano is

RB twisted with RN.

There is attached on a separate page a list for wire colour abbreviations and what colour they

refer to.

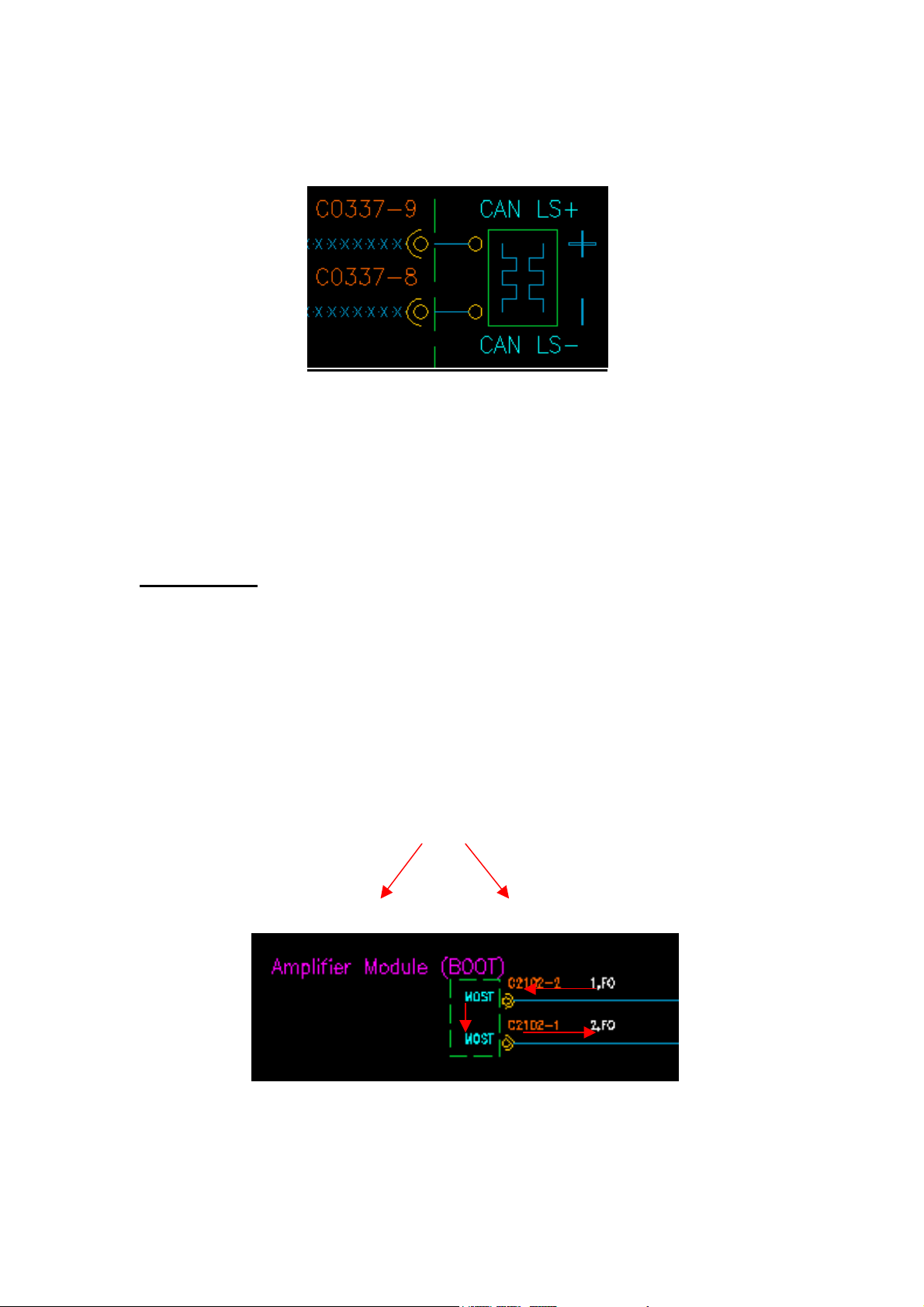

FIBRE OPTIC

A fibre optic carries out a similar function to that of a wire in that it transmits data signals. The

differences being that where a wire is made up of copper strands in an insulated sleeve a

fibre optic is a plastic tube with a highly polished reflective inside surface.

The fibre optic carries the data in the form of a pulse of light, which is sent via an infrared

transmitter and picked up at the next component in the loop via an infrared receiver. The light

pulse is then converted to an electrical signal that is used by that module or component.

The CAN sends signals around the vehicle where the modules or components remove their

specific signals. The fibre optic is in a loop with the module components in that loop, one fibre

goes in and one fibre goes out. This is shown below with the arrows.

1,FO

Fibre Optic number in harness, Abbreviation for Fibre Optic

Page 5

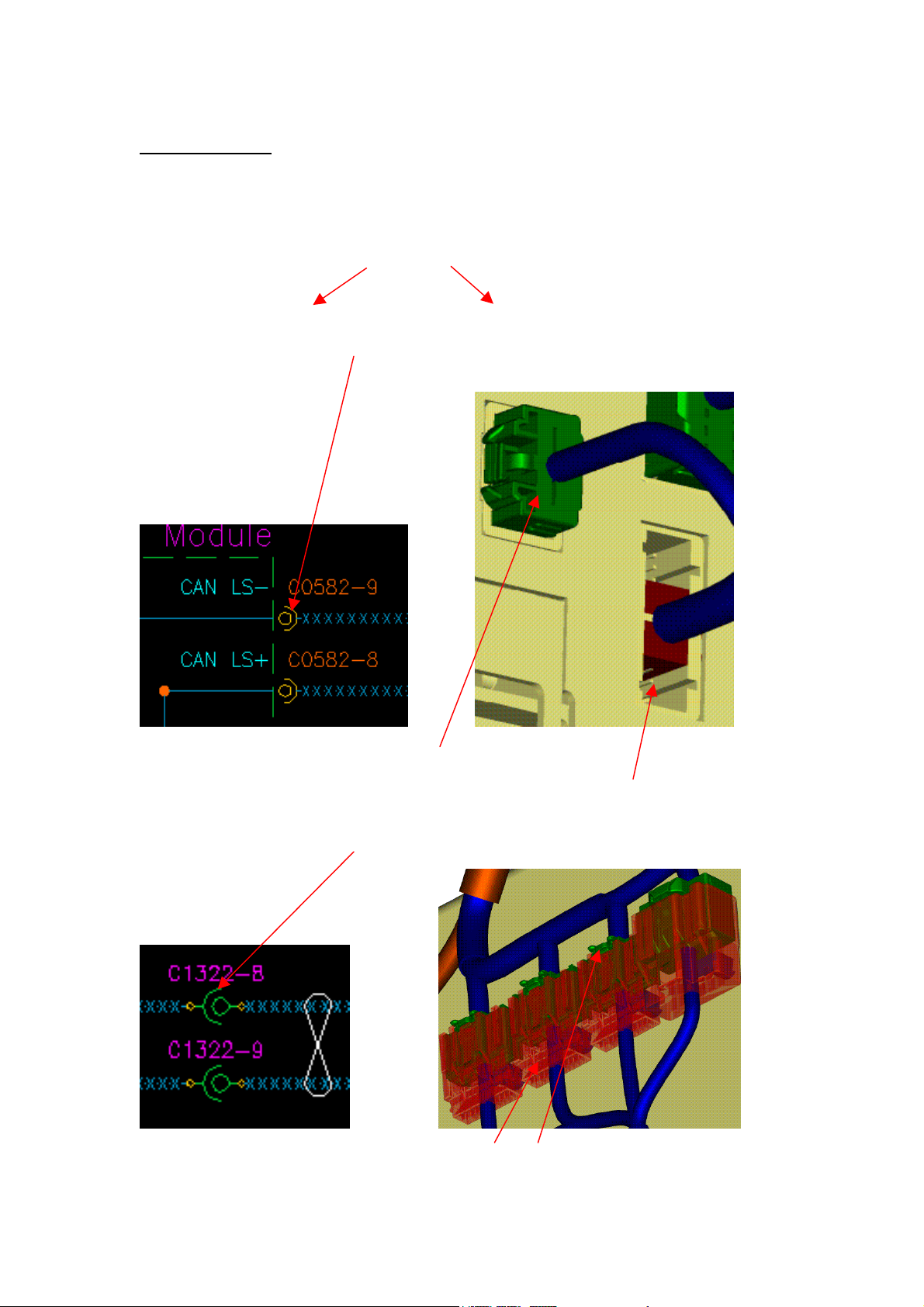

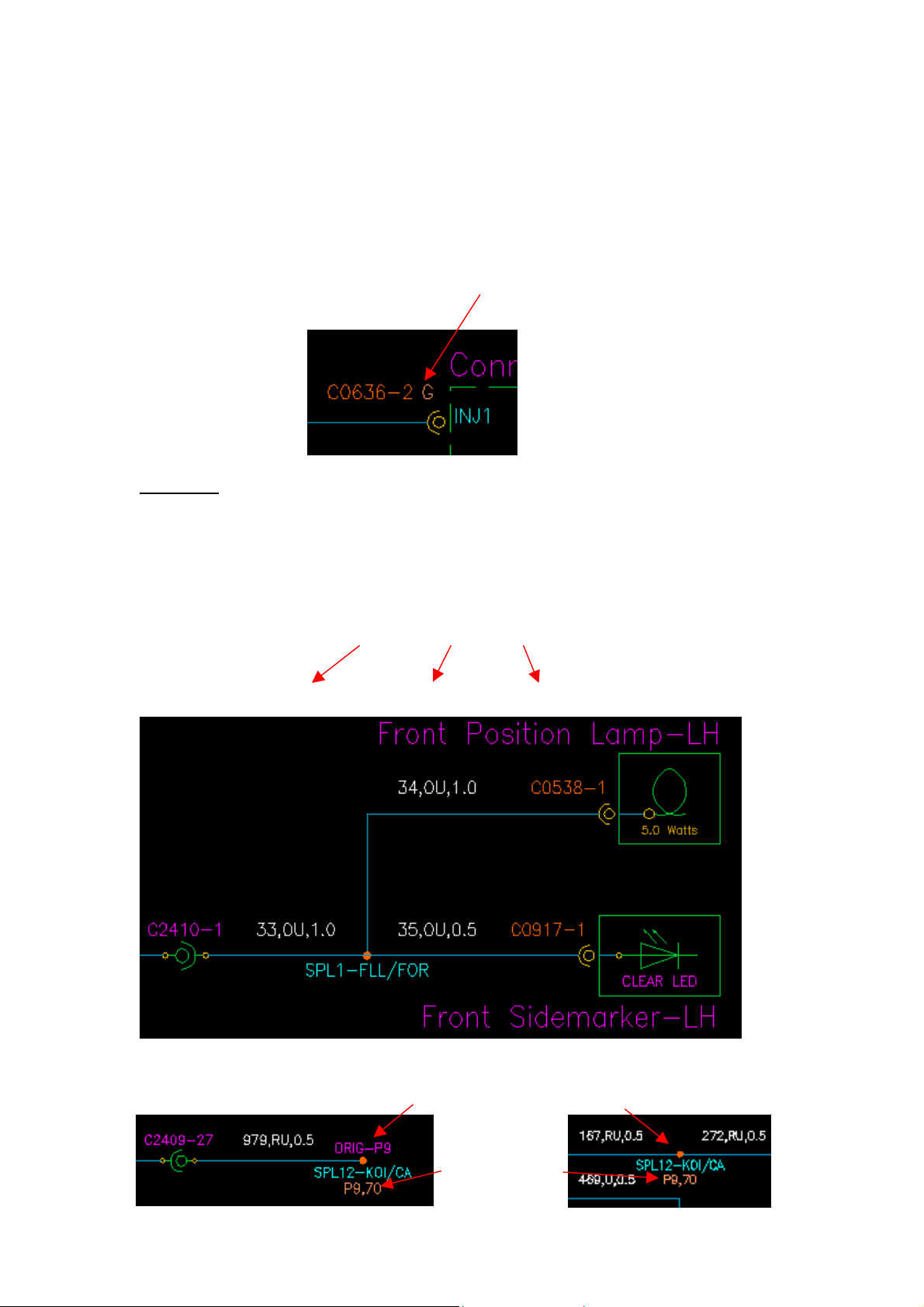

CONNECTORS

There are 2 types of interconnect shown on the circuits; these are shown below. Each

connector is given a dedicated C number. The number after the dash is the pin number, also

known as the cavity number. The example below is C0582 that when checked on the

attached list refers to the CEM CONNECTOR COCKPIT 2 (C3).

C0582-9

Connector C number, Connector pin / cavity number

st

The 1

type is shown for a connector that is on a module or component with a mating

harness connector attached to it.

The Module mating connector on the harness

The Module connector built into theunit

The 2nd type is shown for a connector on a harness with the mating connector on another

harness. This is known as an Inline. Again the above naming convention applies.

Cabin-Boot harness inline connectors

Page 6

The terminals that are in a connector housing can have a special coating on them. This

coating if required is selected using the following criteria.

• A specific coating requested by component / system owner.

Or

• The current passing through the terminal.

• The environment the connector is to be situated with respect to temperature.

• The open circuit voltage passing through the terminal at a given.

Depending on the above criteria the coating if required can either be gold, silver, phosphor

bronze. Generally tin is the common plating on the terminals but there are some that are gold.

These are identified in the circuits with the letter ‘G’ which stands for gold after the connector

number. An example of this is shown below.

SPLICES

A splice is used where more than 2 wire that have the same requirement i.e. they need the

same signal meet in the same harness. In the example below the Front Position Lamp-LH

and Front Sidemarker-LH require the same output signal from the Central Electronic Module.

Therefore the 2 wires for the lamps are spliced into the output wire from the Central Electronic

Module on the Forward Harness.

Splice Number, Associated Name, Harness that splice is on

SPL1-FLL/FOR

Some splices appear on pages as a wire that goes to one spot and seems to terminate in

space. An example of this is ahown below.

Page splice originates on Originating page

Pages splice is on

Page 7

There is attached on a separate page a list for splice abbreviations and what harness they

refer to.

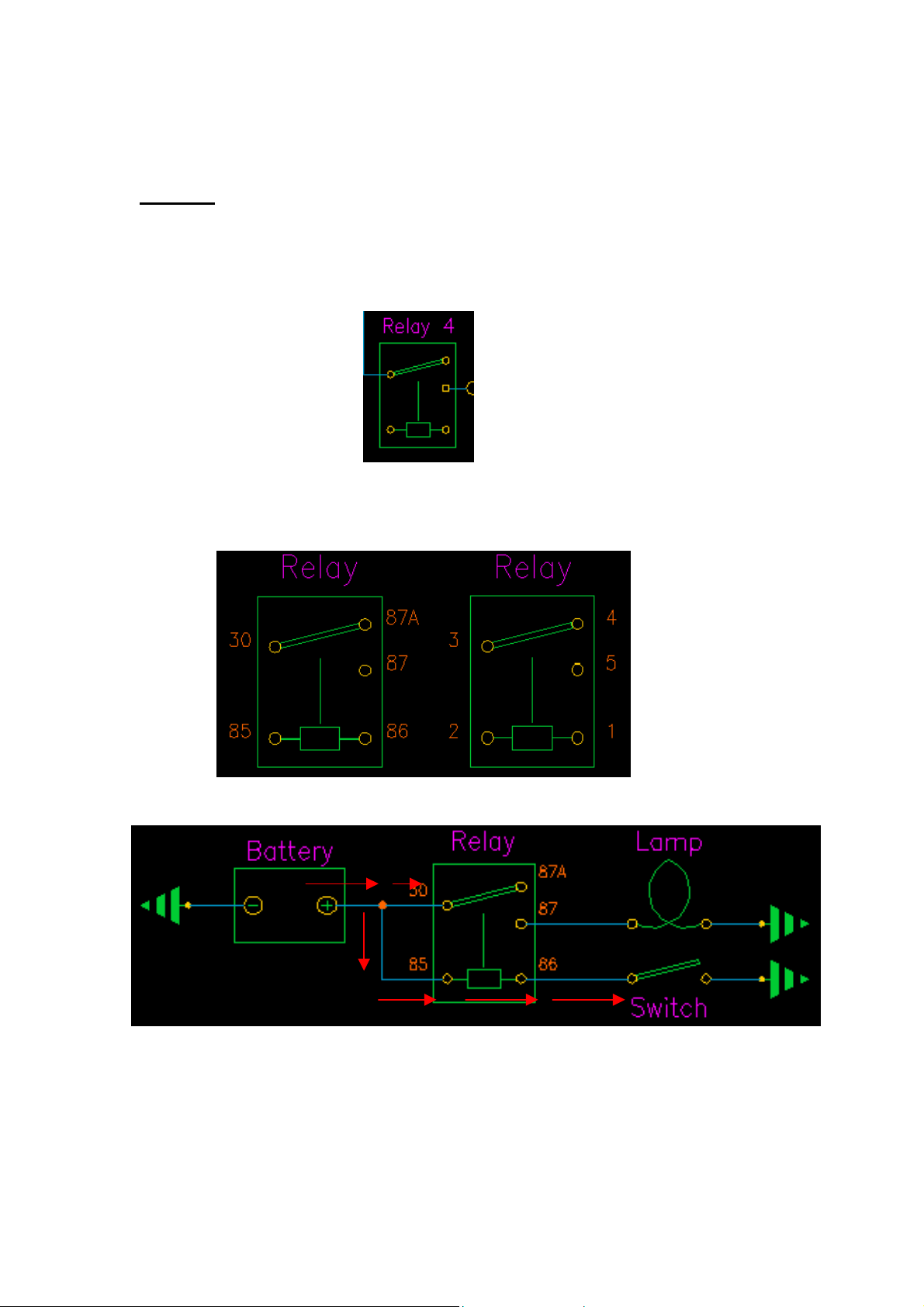

RELAYS

Another significant component in the circuits is a relay, this is in simple terms a switch that

operates on the principal of electromagnetism. Below is the circuit symbol for a typical relay.

The relay shown below is a normally open relay in its inoperative state i.e The arm is in the

open position.

Relays can have either 4 or 5 terminals on the there base with the circuit of the relay on the

base or the side of the housing. There are 2 types of numbering convention for the relay

terminals, both of which are shown below.

Below is a circuit diagram to show the function and operation of a relay in a simple circuit.

(The red arrows indicate the current flow)

The current from a battery for example flows through the wires to the high power normally

open switch (The arm between pins 30 & 87A) and the low power coil (The box between pins

85 & 86). As you can see in the example above the lamp is in not illuminated, this is due to

the switch being open.

Page 8

For the relay to operate there needs to be current flow through the low power coil i.e Current

in to the coil then through to an earth. How it works is that current passes through the relay

coil and creates a magnetic field, this magnetic field is strong enough to ‘grab’ the high power

normally open switch.

The magnetic field pulls the switch from it’s normally open contact to a normally closed

contact. The normally closed contact has a path to an earth, in this case it goes through a

lamp.

The high power current then flows through the high power normally open switch through the

lamp and then to an earth. This can be seen more clearly in the diagram below.

Lamp Illuminates

(The red arrows indicate the current flow)

(The yellow rings indicate the magnetic field generated)

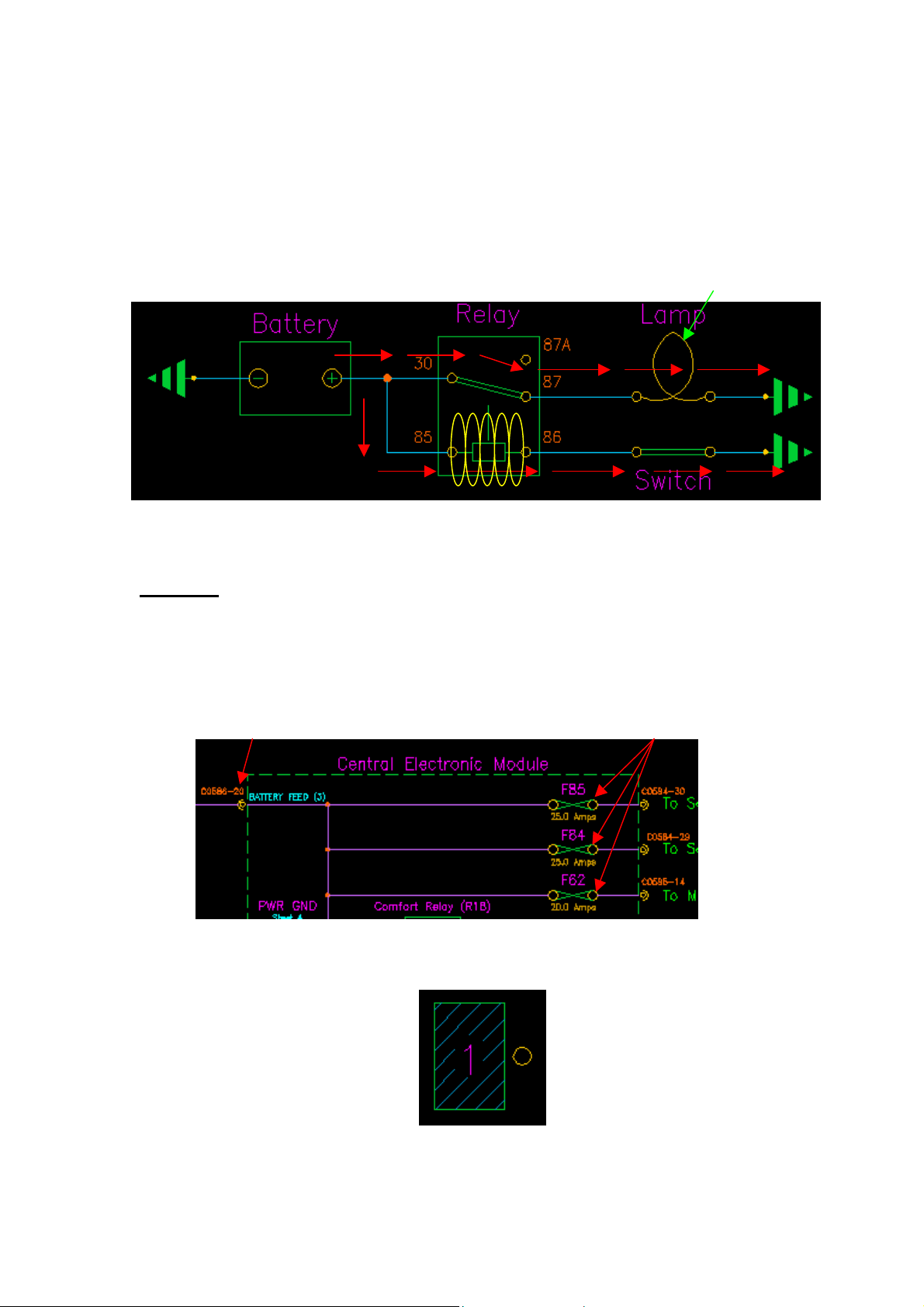

BUSBAR

A busbar is where a electrical supply is fed into a conductive bar, wire, pcb track or whatever

it is and various modules or components ‘tap’ into this busbar to draw there required power.

The Central Electronic Module has 4 of these busbars internally, each of which is supplied

from an external power supply, that supply can be a battery feed, ignition feed or a switched

supply.

One of the 4 inputs to a busbar Some outputs that tap into Busbar 3

The symbol shown below is the symbol used on the circuits for a busbar, the number inside

the box refers to what busbar it is in the Central Electronic Module.

Page 9

FUSE

A fuse is a device used to protect a module or component from excessive electrical current

which can cause damage or destroy that module or component. In practice the fuse is placed

in between the power source and the module or component that is being protected.

The size or ‘Rating’ of the fuse in amps is calculated according to the power requirements of

the module or component it is protecting with other factors being taken into consideration. If

the rating has been calculated correctly then the fuse when excessive current passes through

it will ‘blow’ before any harm or permanent damage occurs on the module or component it is

protecting.

An example of this is shown on the next page.

Lamp has blown due to excessive current flow

(The red arrows indicate the current flow)

The diagram below has the fuse placed ‘Inline’ between the power source in this case the

battery and the lamp.

Fuse has blown due to excessive current flow but not the lamp

Below is the circuit that are shown on the attached circuit diagrams. The number above the

fuse symbol is the fuse number; allocated to this fuse in the Central Electronic Module is the

number 59. The number below the fuse symbol is the rating.

Page 10

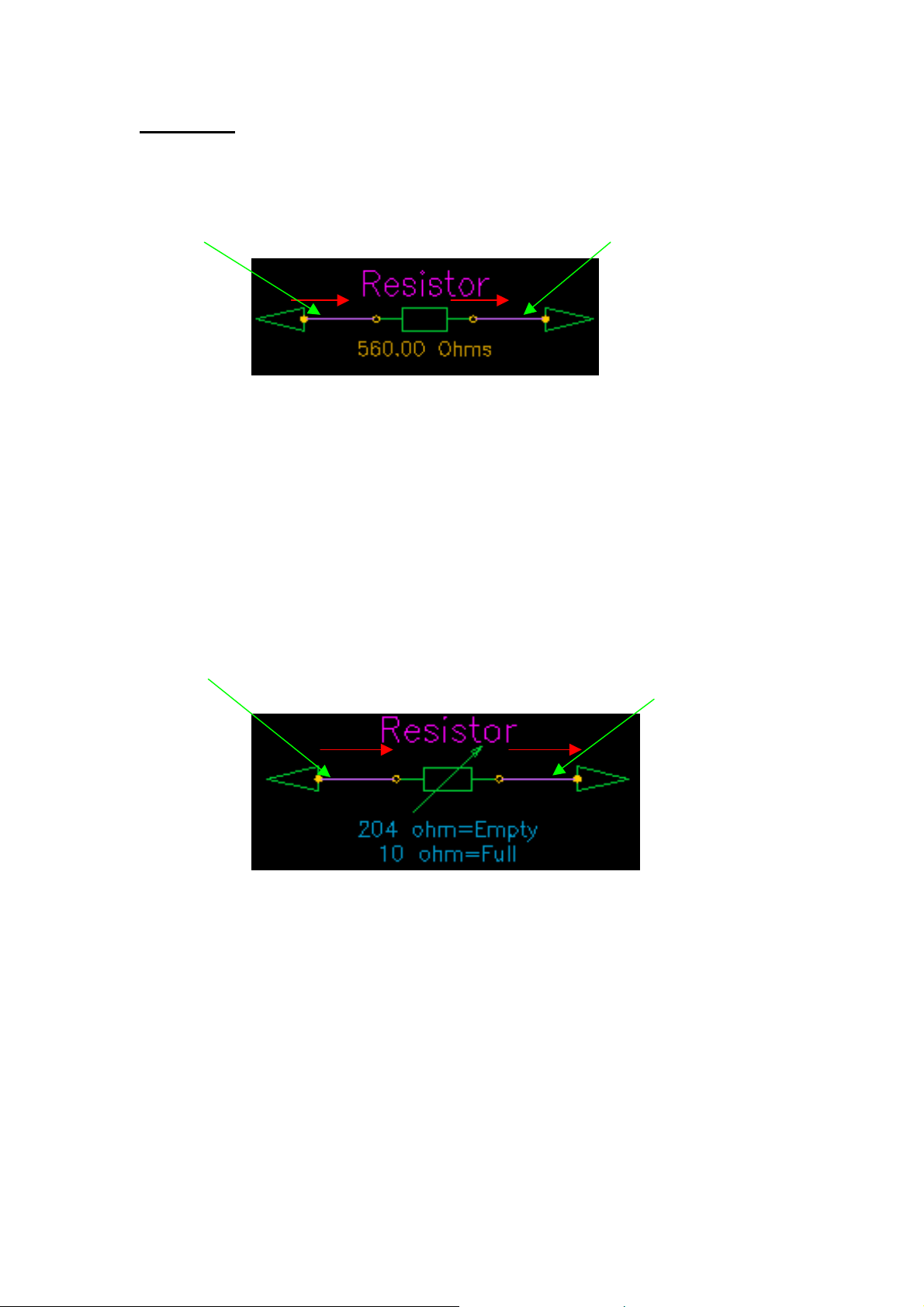

RESISTOR

A resistor is an electronic component that by way of its construction reduces the current

flowing through it. A resistors unit of measure is the Ohm; the symbol for this is ‘Ω’.

The diagrams below show a resistor and a variable resistor.

12 Volts, 10 Amps in 12 Volts, 0.021 Amps out

(The red arrows indicate the current flow)

A variable resistor works in the same manner as a normal resistor but the resistance values

can fluctuate. The construction of a variable resistor depends upon its use and environment.

One example is for the fuel tank level sensor. The sensor sits in the fuel tank and the

resistance in the sensor varies according on the amount of fuel in the tank. This is all down to

the reaction between the liquid and the materials in the sensor.

The variable resistor can work using light, temperature, pressure to name but a few to change

the resistance. It is all down again to construction and environment. On the next page is an

example of a variable resisitor in a fuel tank level sensor. The tank full level is 10 ohms and

the tank empty level is 204 ohms, the resistance will vary between 10 and 204 ohms

depending on how fuel is in the tank.

12 Volts, 10 Amps in 12 Volts, Tank Full = 1.2 Amps out

12 Volts, Tank Empty = 0.058 Amps out

(The red arrows indicate the current flow)

Page 11

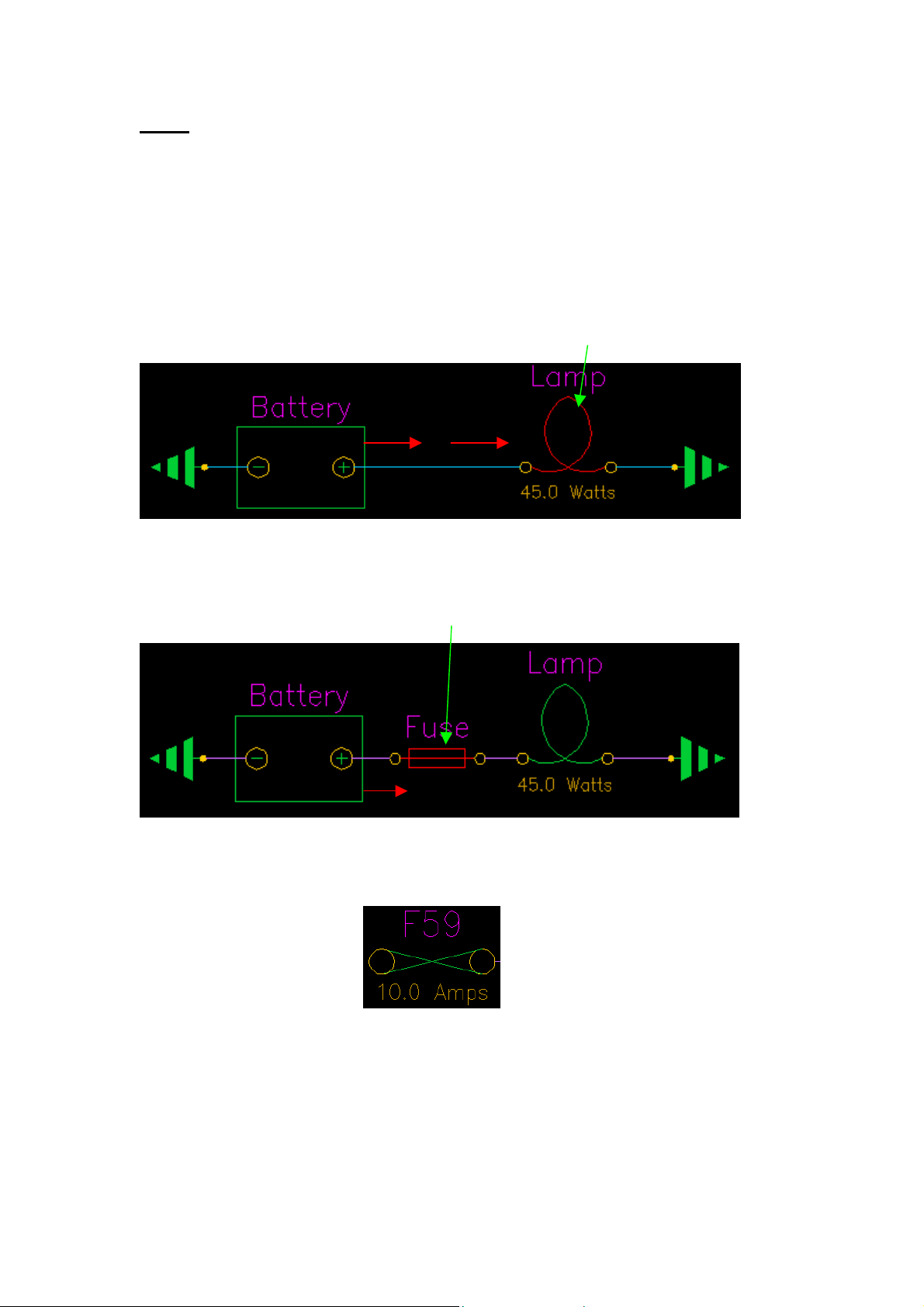

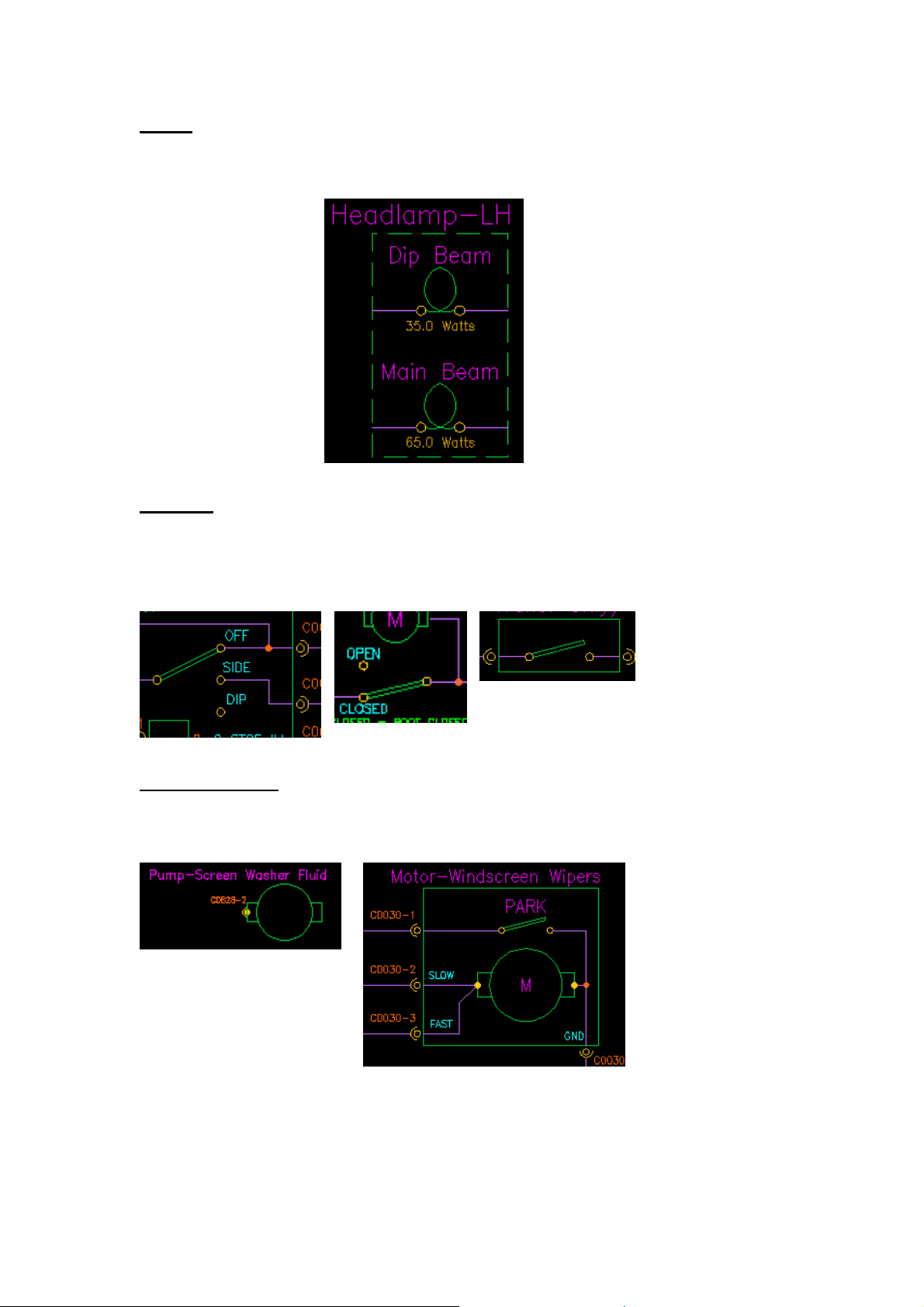

LAMP

This is self-explanatory as it refers to a light bulb. Below is the symbol for a light bulb, shown

below the symbol is the power of the light bulb in watts.

SWITCH

This is self-explanatory. There are numerous of types of switch, a couple of examples are

shown below as a rough guide.

3 Position Switch 2 Position Switch Normally Open Switch

MOTOR / PUMP

This is self-explanatory. It is the same symbol for a pump or a motor it’s just the description

differentiates them.

Page 12

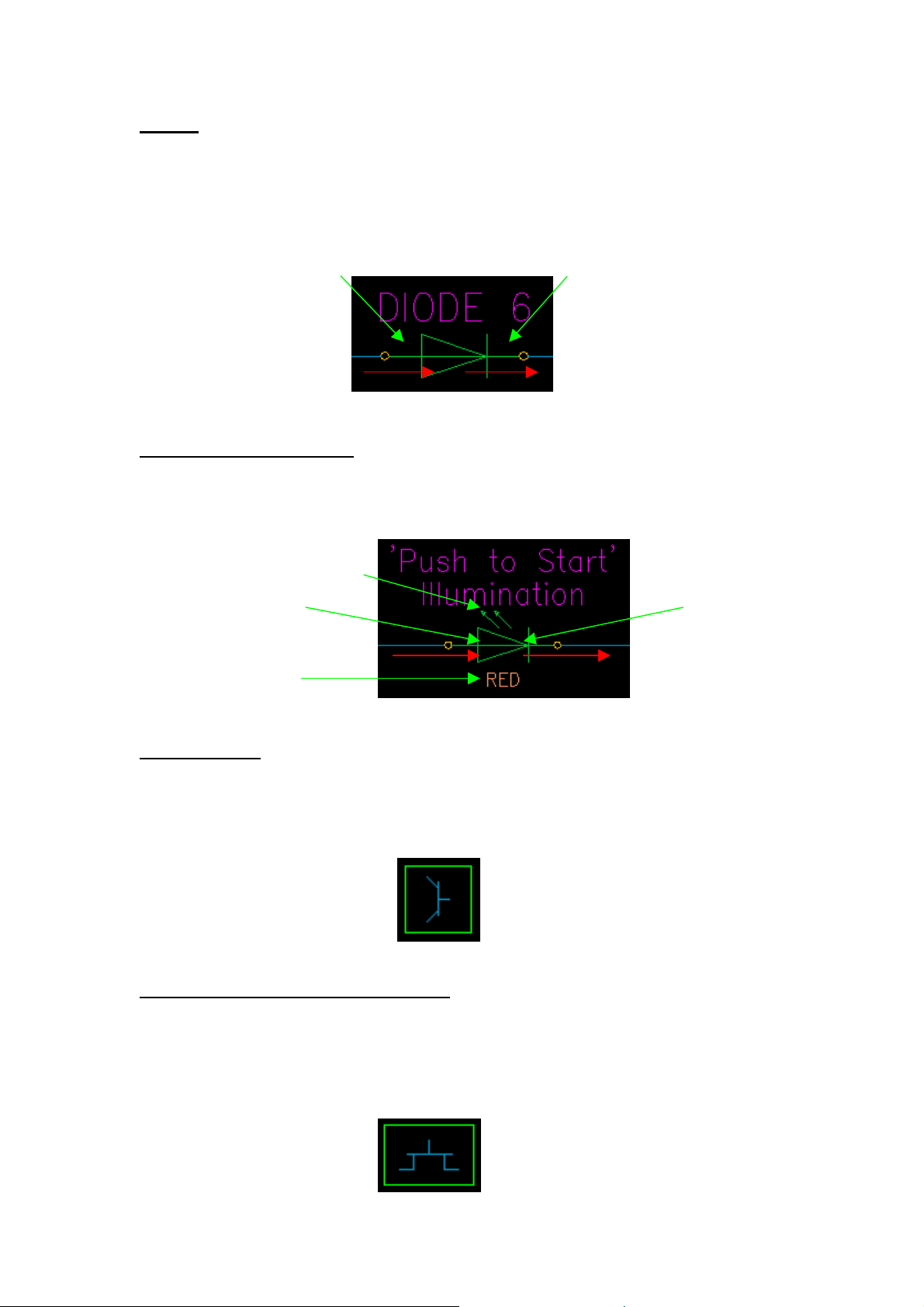

DIODE

The simplest way of describing a diode is ‘a non return valve’. The current will flow through

the diode from the anode to the cathode, due to the construction of it though current cannot

come back. Diodes are used to reduce the possibilities of ‘back feed’. This is where current

comes through the circuit the wrong way for one reason or another. Below is the circuit

symbol for a diode.

Anode Cathode

(The red arrows indicate the current flow)

LIGHT EMITTING DIODE

The light emitting diode works on the same principal as the diode. The main difference is that

in the manufacturing process one of the materials is replaced by another. This replacement

material has certain properties that when a certain voltage passes through glow.

Arrows that show it’s an LED

Anode Cathode

Colour

(The red arrows indicate the current flow)

TRANSISTOR

A transistor in simplistic terms is a switch with no moving parts. The ‘switching’ is controlled

by electronics and currents etc rather than a physical switch being operated.

Here is the circuit symbol for it. The example shown below is one of the most common basic

type used called a ‘Bipolar’.

FET (FIELD EFFECT TRANSISTOR)

A field effect transistor is again in simplistic terms a switch with no moving parts. The

‘switching’ is controlled by electronics and currents etc rather than a physical switch being

operated. The main difference between this and the type of transistor shown above is this one

operates using a magnetic field.

Here is the circuit symbol for it.

Page 13

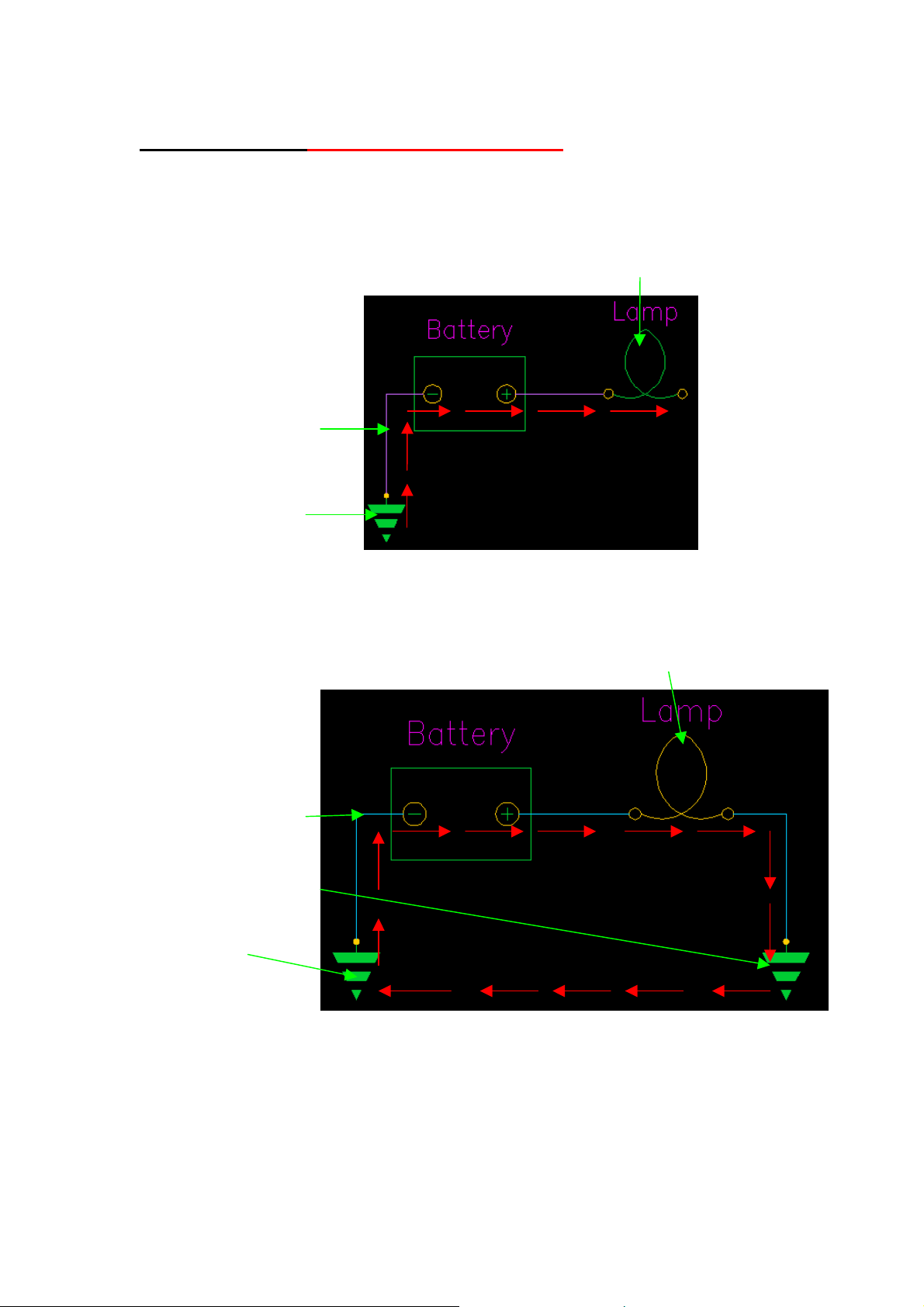

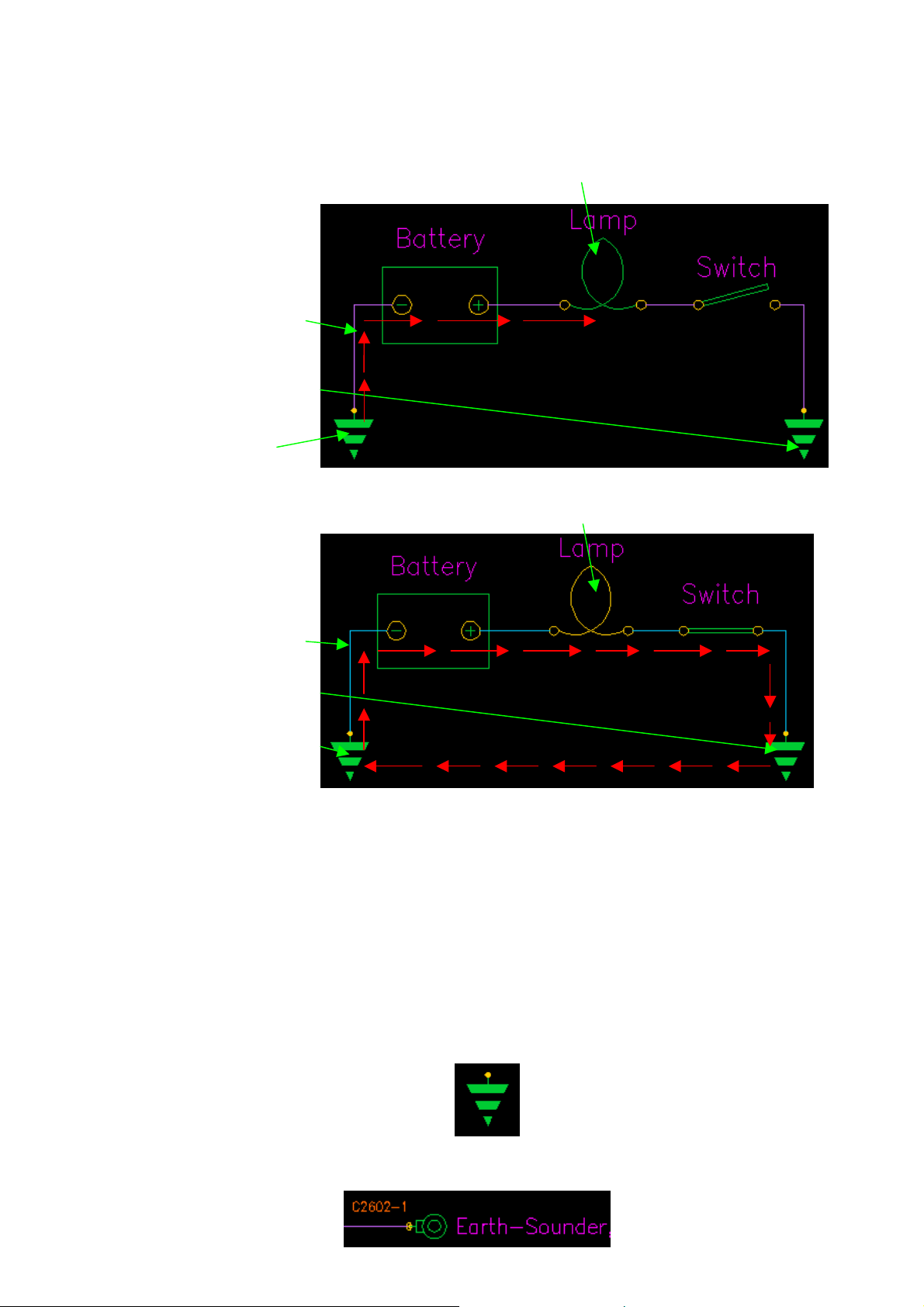

EARTH / GROUND (THE VERY IMPORTANT BIT)

For an electrical current to ‘flow’ around a circuit it has to start from a power source and go to

an earth / ground. If there are any breaks in this circuit then current will not flow, this is called

an ‘Open circuit’

The example below will demonstrate this.

The lamp does not illuminate as there is no earth / ground.

Earth Braid from Battery

Main Earth Point

(In this case the car body)

(The red arrows indicate the current flow)

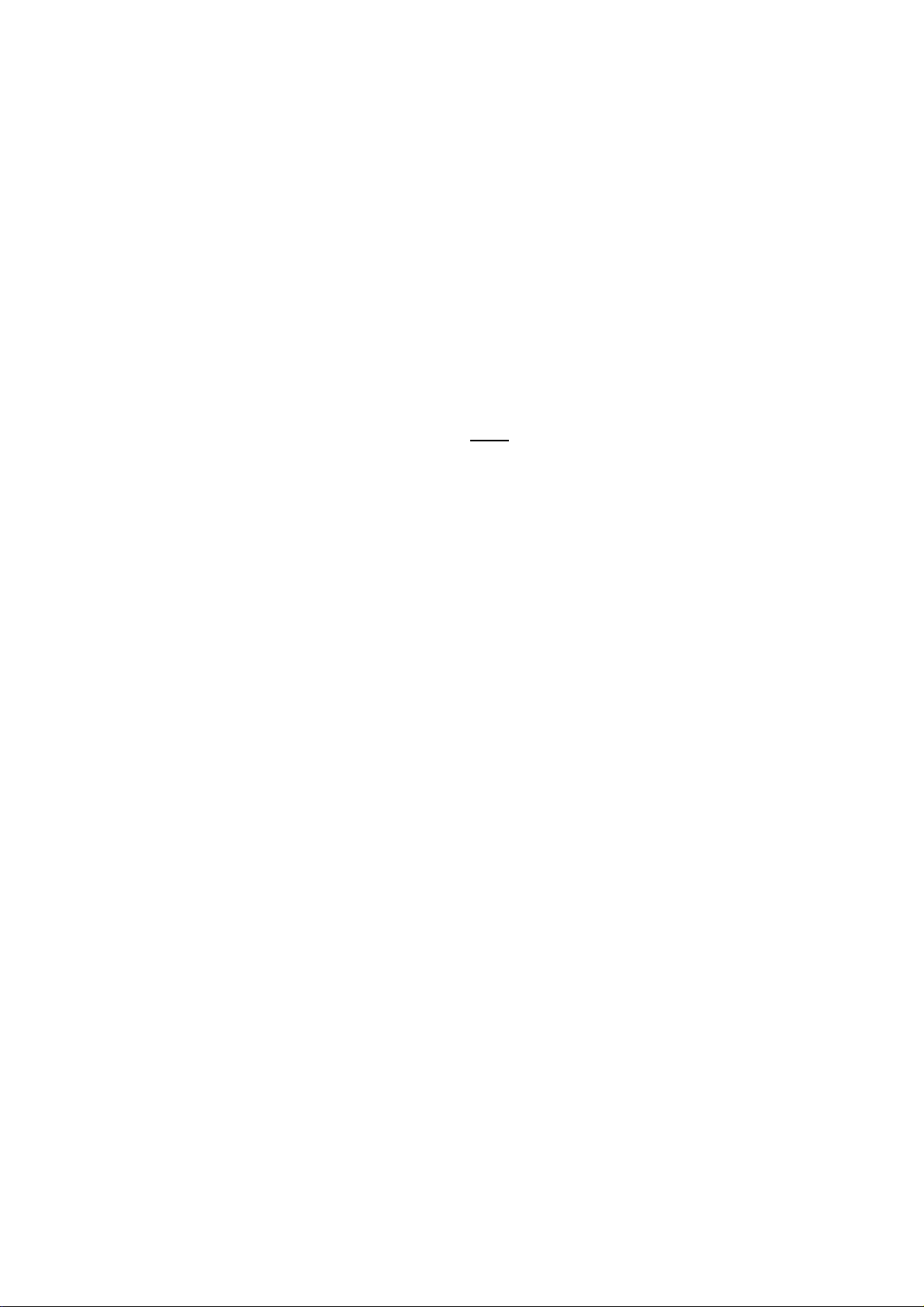

The example below shows what happens when you put the other side of the lamp to the earth

/ ground and complete the circuit. As you can see the lamp illuminates.

Earth Braid from Battery

Earth Point

(In this case the car body)

Main Earth Point

(In this case the car body)

(The red arrows indicate the current flow)

Page 14

The flow can be interrupted or controlled by various means such as switches, relays etc. A

switched sample is shown below. Lamp not illuminated as no ground path

as switch is open

Earth Braid from Battery

Earth Point

(In this case the car body)

Main Earth Point

(In this case the car body)

(The red arrows indicate the current flow)

Lamp illuminates to ground path now switch is closed

Earth Braid from Battery

Earth Point

(In this case the car body)

Main Earth Point

(In this case the car body)

(The red arrows indicate the current flow)

There are 2 types of earth, Signal Earth and Chassis Earth, these are referred to sometimes

as a Quiet Earth and Noisy Earth respectively.

Some sensors for example specify a Signal / Quiet Earth. While components such as pumps

and motors can have a Chassis / Noisy Earth. The reason behind this is that pumps, motors

and the like can generate ‘electrical noise’ by the way of there operation. Some of this

‘electrical noise can be transferred through wires, it is this ‘electrical noise’ can have an

adverse effect on sensor signals and affect the readings they back.

Keeping Signal / Quiet and Chassis / Noisy earths separate reduces the effect of ‘electrical

noise’ being transferred from component to component.

This symbol is a standard symbol for earths.

On the attached circuit diagrams earths are shown as eyelets with the description of Earth**** next to it, the earths also comply with the 4 digit C number. An example of this is shown.

Page 15

AAMMLL SSPPLLIICCEE DDEESSCCRRIIPPTTIIOONN CCHHAARRTT

VVAANNTTAAGGEE 22000055MMYY MMaannuuaall CCoouuppee 1133--0077--0055

Abbreviation Harness

TR Transmission

BMP Rear Bumper

CA Cabin

CENST Centre Stack

DRDR Drivers Door

EN Engine

FA Facia

FOR Forward

PADR Passenger Door

Page 16

AAMMLL WWIIRREE CCOOLLOOUURR && TTYYPPEE CCHHAARRTT

VVAANNTTAAGGEE 22000055MMYY MMaannuuaall CCoouuppee 1133--0077--0055

Abbreviation

B Black

G Green

K Pink

N Brown

O Orange

P Purple

R Red

S Slate (Grey)

U Blue

W White

Y Yellow

SCR Screen

FO Fibre Optic

MAP Twisted Wire

MAB Screened Wire

Colour

Page 17

AAMMLL CCIIRRCCUUIITT DDIIAAGGRRAAMM IINNDDEEXX

VVAANNTTAAGGEE 22000055MMYY MMaannuuaall CCoouuppee 1133--0077--0055

Page 1 Engine Controller

Page 2 Active Restraint System

Page 3 Low Speed & High Speed CAN

Page 4 IVD / DSC / ABS

Page 5 Air Conditioning

Page 6 Heated Manual Electric Seat

Page 7 Wash Wipe (Inc H.I.D only Headlamp Wash)

Page 8 Auxiliary Driver Operated Systems

Page 9 Security System (Inc RHD

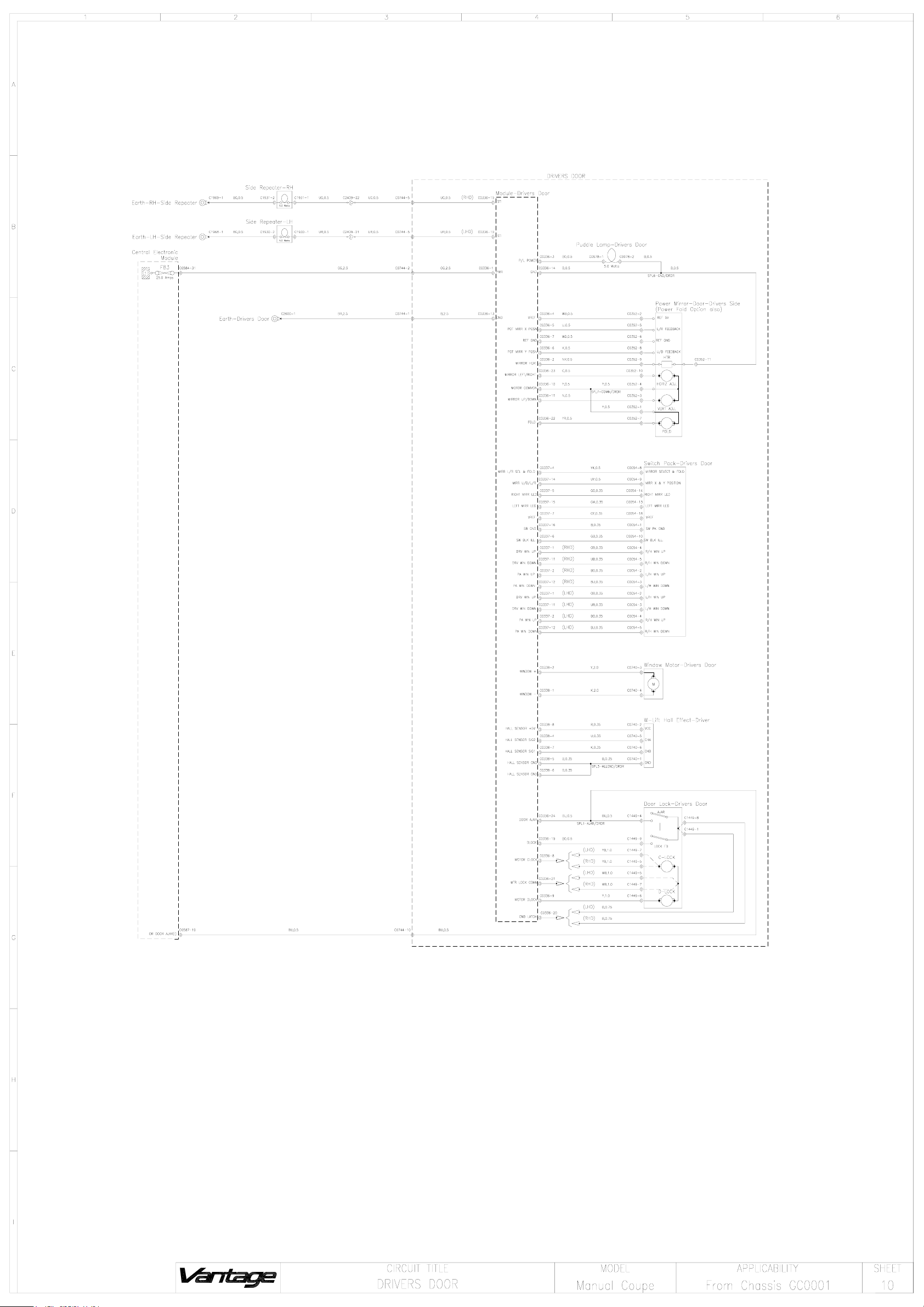

Page 10 Drivers Door

Page 11 Passenger Door

Page 12 Parking Aid (Rear Sensors only)

Page 13 Driver Information Module

Page 14 Interior Illumination (Excluding Puddle & Boot Lamps)

Page 15 Exterior Lighting (Including Boot Lamps)

Page 16 Exterior Lighting (H.I.D Lamps only)

Page 17 MOST

Page 18 Audio System - Alpine Amplifier (Lo-Line)

Page 19 Audio System - Alpine Amplifier (Hi-Line)

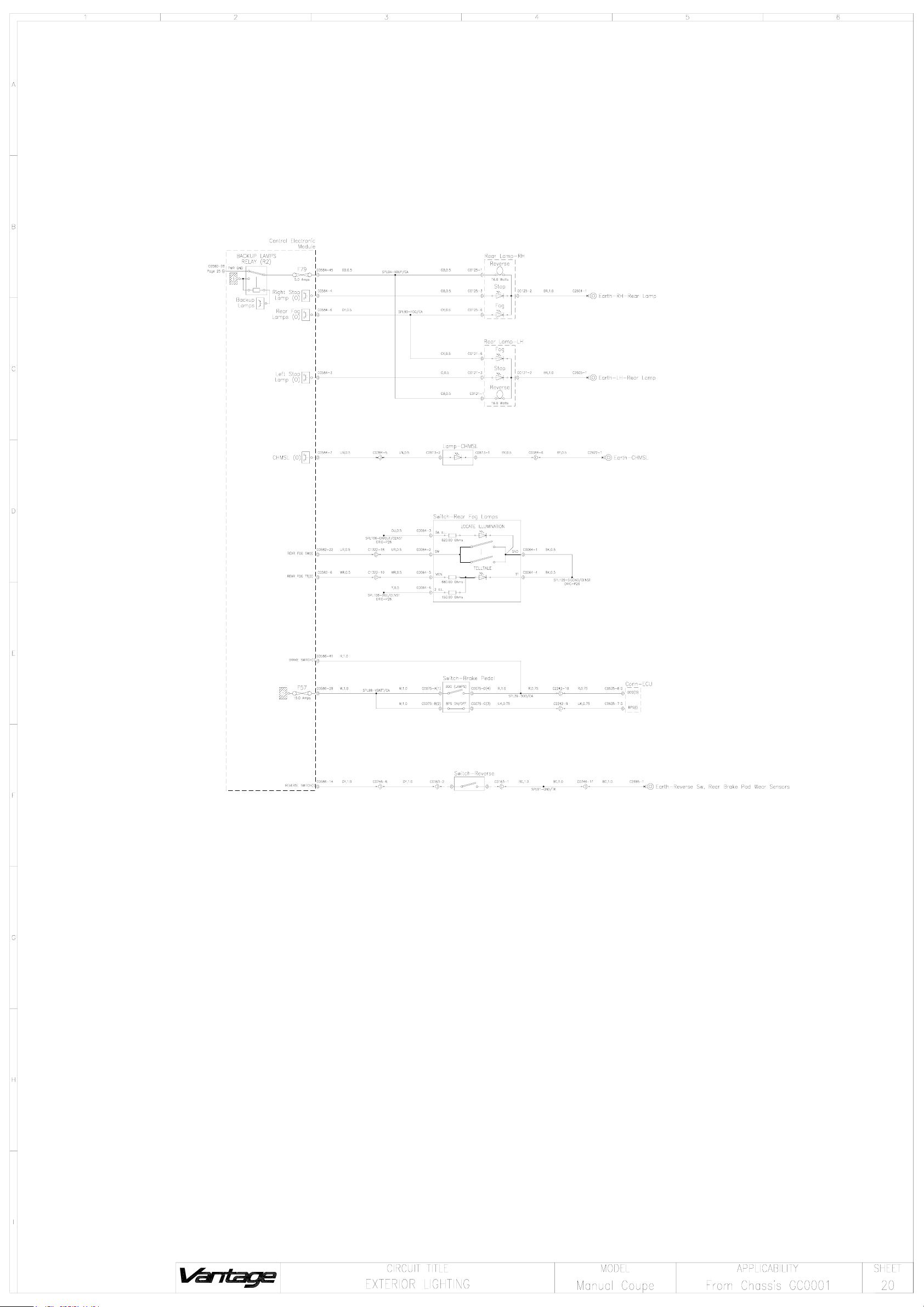

Page 20 Exterior Lighting

Page 21 Exterior Lighting

Page 22 Starting & Charging

Page 23 Auxiliary Engine Operated Systems

Page 24 Infotainment System

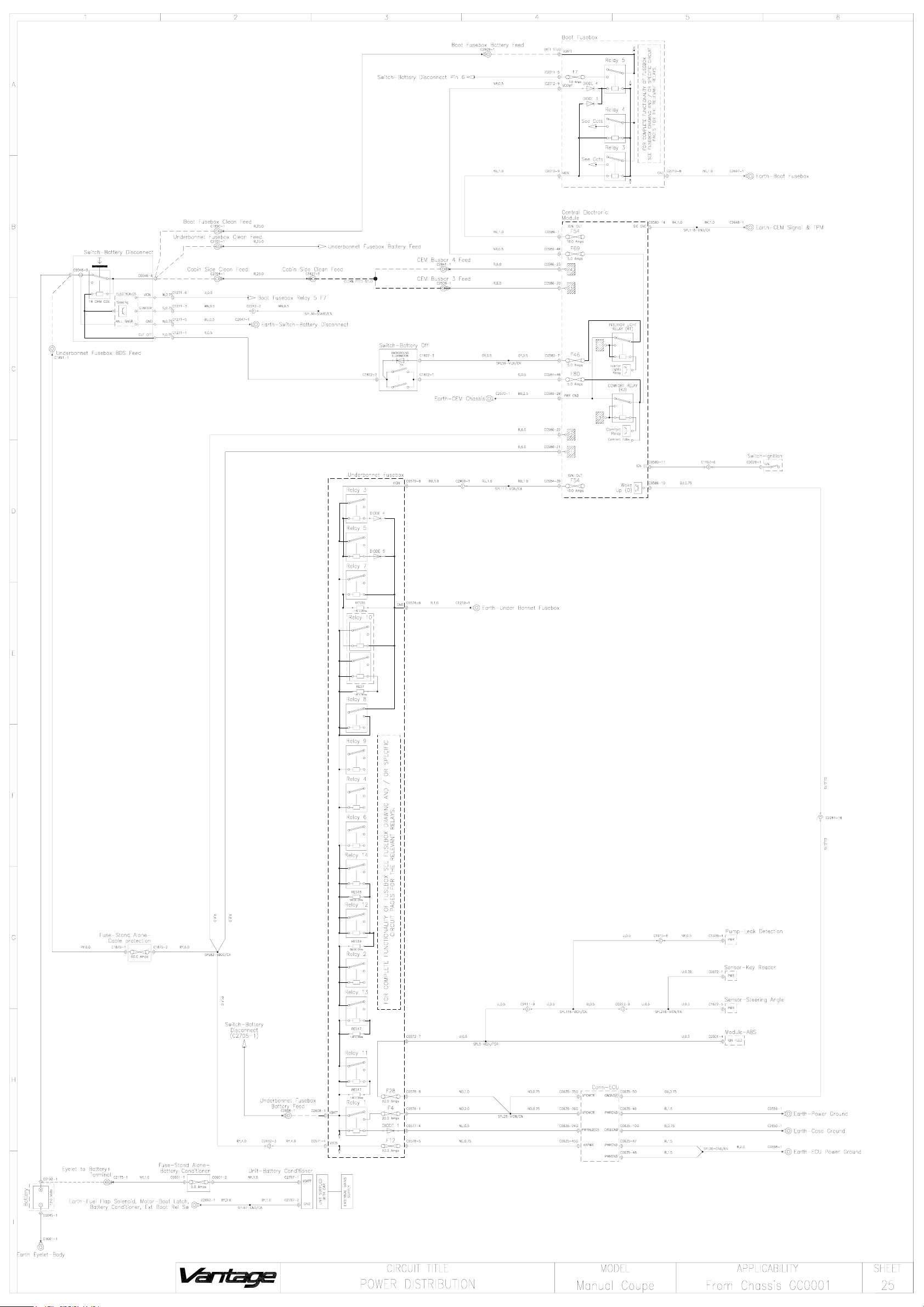

Page 25 Power Distribution

Page 26 Background Illumination

Page 27 Centre Console Module

Page 28 Earths

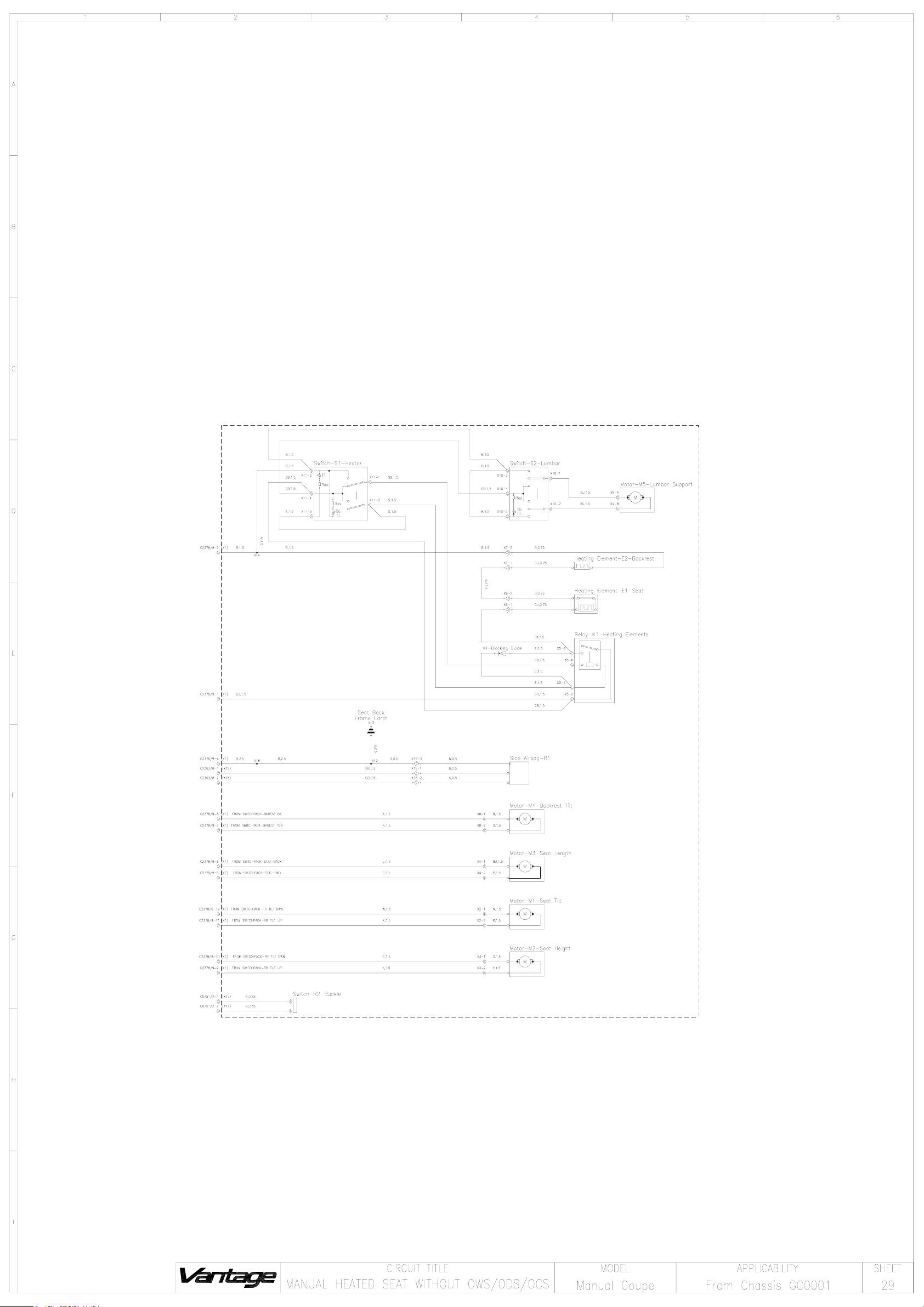

Page 29 Manual Heated Seat without OWS / ODS / OCS

Page 30 Engine Controller – Spanish Oak

Page 31 Rear Fusebox – 4G43-14A073-AF

Page 32 Underbonnet Fusebox – 4G43-14A173-AE

Page 33 Central Electronic Module

only Tracker

Page 18

AAMMLL CC NNUUMMBBEERR LLOOCCAATTIIOONN CCHHAARRTT

VVA

A

A

A

p

T

NNT

GGEE 22000055MMYYMMaannuuaallCCoou

pee1133--0077--0055

u

C0257 Airbag-Driver1

C0251 Airbag-Passenger1

C0261 Airbag-Passenger2

C0948 Airbag-Side-Left

C0949 Airbag-Side-Right

C0226 Alternator/Generator

C2538 AM/FM Receiver Module (Power)

C2219 AM/FM Receiver Module (Fakra)

C0102 AM/FM Receiver Module (MOST)

C2588 Amplifier (Aud Power)

C2511 Antenna Amplifer2 (AM/FM)

C1598 Antenna-GPS

C2233 Antenna-Phone

C2797 Battery Conditioner

C0800 Battery-Backup-Tracker

C1891 BDS Power Eyelet

C2013 BOOT FUSEBOX - CONN D

C1890 Boot Fusebox Battery Feed Eyelet

C0119 Boot Lamp1

C0120 Boot Lamp2

C0384 BOOT LID-LINK-CABIN

C0570 C1 ENGINE BAY FUSEBOX

C0579 C10 ENGINE BAY FUSEBOX

C0571 C2 ENGINE BAY FUSEBOX

C0572 C3 ENGINE BAY FUSEBOX

C0573 C4 ENGINE BAY FUSEBOX

C0574 C5 ENGINE BAY FUSEBOX

C0575 C6 ENGINE BAY FUSEBOX

C0576 C7 ENGINE BAY FUSEBOX

C0577 C8 ENGINE BAY FUSEBOX

C0578 C9 ENGINE BAY FUSEBOX

C2704 Cabin Battery Feed BDS Eyelet

C1627 Cabin Battery Feed Bulkhead Stud Eyelet

C2982 Cabin-Alpine Link (AUD)

C2983 Cabin-Alpine Link (Power)

C1898 CABIN-CENTRE STACK INLINE (MOST)

C0083 CABIN-CENTRE STACK INLINE 1

C1165 CABIN-CENTRE STACK INLINE 2

C1185 CABIN-CENTRE STACK INLINE 3

C0273 CABIN-DRIVER AIRBAG INLINE 1

C2242 CABIN-ENGINE INLINE 1

C2243 CABIN-ENGINE INLINE 2

C2244 CABIN-ENGINE INLINE 3

C0610 Cabin-GSM Phone Microphone Inline

C0333 Cabin-Microphone Link

C0421 Cabin-Microphone Link

C0305 CABIN-PASS AIRBAG INLINE

C0580 CEM CONNECTOR - COCKPIT 1

C0588 CEM CONNECTOR - FRONT END 2

C0585 CEM CONNECTOR - ROOF 1

C0589 CEM CONNECTOR - ROOF 2

C0582 CEM CONNECTOR COCKPIT 2

C0232 Clock

C0127 Clutch-Compressor-Air Conditioning (A/C)

C0997 Coil Suppressor1

C0037 D/I Resistor-LH

C0038 D/I Resistor-RH

C0877 Diagnostic Connector B - Body

C0413 Direction Mode Actuator

C2509 Distribution Point 3

C2841 Distribution Point 4

C1449 Door Lock-Drivers Door

C1451 Door Lock-Passenger Door

C2378 Driver Seat-Conn1-(Pwr & Gnd)

C0751 Driver Seat-Conn3-(ARS)

C0744 DRIVERS DOOR-CABIN INLINE

C3000 Earth Eyelet-Ignition Coils

C2647 Earth Eyelet-BDS Switch

C2999 Earth Eyelet-Bluetooth Receiver

C2719 Earth Eyelet-Body

C1972 Earth Eyelet-Bonnet Switch

C2697 Earth Eyelet-Boot Fusebox

Earth Eyelet-Boot Motor, Exterior Boot Rel Switch,

C2692

Fuel Flap Solenoid, Battery Conditioner

2

2

2

2

2

22

24

24

24

18,19

24

24

24

25

9

25

Various

25

15

15

8,15,20

Various

Various

Various

Various

Various

Various

Various

Various

Various

Various

25

25

18,19

18,19

17

Various

Various

Various

Various

Various

Various

Various

18,19

18,19

18,19

2

Various

Various

Various

Various

Various

13

1

1

21

21

3

5

25

25

10

11

6

2

Various

1

25

18,19

25

9

25

8,15,25 C1771 Ignition Coil 5 1

C2924 Earth Eyelet-Multi-Media Module

C2926 Earth Eyelet-Number Plate Lamps, Rear Sidemarkers

C2569 Earth Eyelet-Passenger Seat (Heater)

C2630 Earth Eyelet-PDC Module

C2998 Earth Eyelet-Phone

C0558 Earth Eyelet-Power Ground

C0559 Earth Eyelet-Power Ground

C2603 Earth Eyelet-Pump-Headlamp Wash

C2712 Earth Eyelet-Rear Door Ajar Signal

C2605 Earth Eyelet-Rear Lamp-LH

C2604 Earth Eyelet-Rear Lamp-RH

C2716 Earth Eyelet-Reduced Guard Switch, Glovebox Switch

C0564 Earth Eyelet-Regulator Blower Speed

C0707 Earth Eyelet-Remote Receiver

C2695 Earth Eyelet-Reverse Switch, Rear Brake Pad Wear Sensors

C1947 Earth Eyelet-RH Headlamp

C1969 Earth Eyelet-RH Side Repeater

C0836 Earth Eyelet-SAI Pump

C2567 Earth Eyelet-Seat-Driver

C0811 Earth Eyelet-Seat-Passenger

C0555 Earth Eyelet-Signals

C2599 Earth Eyelet-Socket Accessory/Cigar Lighter

C2602 Earth Eyelet-Sounder, Vac Pump, Rear Power Socket

C0017 Earth Eyelet-Steering Wheel Switches

C2562 Earth Eyelet-Switch-Brake Fluid Level

C3002 Earth Eyelet-Switcher-Front Speaker

C0553 Earth Eyelet-Tracker

C0018 Earth Eyelet-Twin Horns

C1210 Earth Eyelet-Underbonnet Fusebox

C1971 Earth Eyelet-Wash Fluid Level Sensor

C0554 Earth Eyelet-Wash Wipe Switch

C2652 Earth Eyelet-Washer Fluid Pump

C0809 Earth Eyelet-Windscreen Wiper Motor

C1679 Earth-Heated Rear Window Coupe

C0635 ECU A (C-COWL)

C0636 ECU A (E-ENGINE)

C0634 ECU A (T-TRANS)

C0901 Eyelet-Battery Feed Terminal UBFB

C2175 Eyelet-Battery Feed to Battery Conditioner

C0047 FACIA-CABIN INLINE 1

C0229 FACIA-CABIN INLINE 5

C0231 FACIA-CABIN INLINE 6

C2246 FACIA-CABIN INLINE HIROSE MMM

C1167 FACIA-CABIN INLINE 12

C1168 FACIA-CABIN INLINE 13

C1363 FACIA-CABIN INLINE 2

C0223 FACIA-CABIN INLINE 4

C0469 FACIA-CABIN INLINE 8

C0765 FACIA-CABIN INLINE 9

C0738 FACIA-CABIN PHONE ANTENNA INLINE

C2409 FORWARD-CABIN INLINE3

C2410 FORWARD-CABIN INLINE 1

C2411 FORWARD-CABIN INLINE 2

C2412 FORWARD-CABIN INLINE 4

C2275 FORWARD-ENGINE INLINE 1

C2276 FORWARD-ENGINE INLINE 2

C0419 Fresh/Recirc Actuator

C0355 Front Interior Lamp-LH

C0356 Front Interior Lamp-RH

C0917 Front Sidemarker-LH

C0916 Front Sidemarker-RH

C0601 Fuse-Stand Alone-Battery Conditioner

C1599 GPS Antenna Inline

C1608 GPS Tuner

C0009 Headlamp-LH

C0011 Headlamp-RH

C0246 Heated Front Screen

C0382 Heated Rear Window Gnd

C0381 Heated Rear Window Power

C0156 Ignition Coil 1

C0276 Ignition Coil 3

C1770 Ignition Coil 4

24

15

6

12

24

25

25

7

11

15,20,21

15,20,21

8,9,26

5

9

13,20

15,21

11

23

6

6

13,24,26

8

1,8,9

8,18,19

4

18,19

9

8

25

7

7

7

7

8

Various

Various

Various

25

25

Various

Various

Various

24

Various

Various

Various

Various

Various

Various

24

Various

Various

Various

Various

Various

Various

5

14,27

14,27

15

15

25

24

24

15,16,21

15,16,21

8

8

8

1

1

1

Page 19

C0563 Earth Eyelet-Cam / Crank Sensors Screen

C2650 Earth Eyelet-Case Ground

C1170 Earth Eyelet-CCM

C1169 Earth Eyelet-CCM Signal

C1355 Earth Eyelet-CCM Trip Switch

C2570 Earth Eyelet-CEM (Noisy)

C2648 Earth Eyelet-CEM (Quiet), TPM

C2922 Earth Eyelet-CHMSL

C0560 Earth Eyelet-Clutch-Compressor-Air Condition

C0562 Earth Eyelet-Cooling Fan Module

C0709 Earth Eyelet-Driver Information Module

C2568 Earth Eyelet-Drivers Seat (Heater)

C2727 Earth Eyelet-FPDM

C2564 Earth Eyelet-Front Brake Pad Wear Sensor

C2920 Earth Eyelet-Fuel Flap Release Switch

C2921 Earth Eyelet-Fuel Flap Release Tell Tale

C2718 Earth Eyelet-Fuel Tank

C2929 Earth Eyelet-Glovebox Release Solenoid

C2634 Earth Eyelet-GPS Tuner

C2597 Earth Eyelet-Heated Front Screen-LH

C2598 Earth Eyelet-Heated Front Screen-RH

C0821 Earth Eyelet-Indicator Stalk Trip Switch

Earth Eyelet-Key Reader, Indicator Switch,

C0706

Steering Angle Sensor

C1626 Earth Eyelet-LH Headlamp

C1968 Earth Eyelet-LH Side Repeater

C0551 Earth Eyelet-Mass Air Flow Sensor A R/H

C0552 Earth Eyelet-Mass Air Flow Sensor B L/H

Earth Eyelet-Master Locking Switch,

C2646

Interior Boot Release Switch

C1398 Earth Eyelet-Module Aircon

C0362 Earth Eyelet-Module-ABS

C0434 Earth Eyelet-Module-ABS

C0808 Earth Eyelet-Module-Amplifier

C2928 Earth Eyelet-Module-HID Lighting

C0556 Earth Eyelet-Multi-Media Display

C2155 Module-Amplifier-Subwoofer (MOST)

C0241 Module-Bluetooth Display

C2207 Module-Bluetooth Receiver

C0947 Module-Centre Console (Sim)

C2522 Module-Centre Console (Trip Switches)

C0428 Module-Centre Console-Conn1 (Key A)

C0429 Module-Centre Console-Conn2 (Midd)

C0430 Module-Centre Console-Conn3 (Key B)

C2471 Module-Cooling Fan Pack

C0230 Module-Driver Information

C0336 Module-Drivers Door-Conn1

C0337 Module-Drivers Door-Conn2

C0338 Module-Drivers Door-Conn3

C0032 Module-EGR

C1543 Module-HID Lighting

C2115 Module-Infotainment Control

C2105 Module-Infotainment Control (MOST)

C0957 Module-Parking Aid

C1457 Module-Parking Aid 3

C0322 Module-Passenger Door-Conn1

C0323 Module-Passenger Door-Conn2

C0324 Module-Passenger Door-Conn3

C2537 Module-Phone (Antenna)

C2118 Module-Phone (Main)

C1644 Module-Phone (SIM)

C0674 Module-Remote Receiver

C0520 Module-Sounder

C2838 Module-Tracker

C1537 Module-Tyre Pressure Monitor

C2052 Motor-Boot Latch

C2465 Motor-Electronic Throttle A

C0690 Motor-Fuel Flap Release

C0056 Motor-Heater Blower

C0030 Motor-Windscreen Wipers

C2516 Multi Media Display (Power)

C2515 Multi Media Display (Screen)

C2104 Multi Media Module (MOST)

C2113 Multi Media Module (Power)

C2114 Multi Media Module (Screen)

C0549 OBD2-Powertrain 'A'

C0733 PASSENGER DOOR-CABIN INLINE

C0752 Passenger Seat-Conn3 (ARS)

C1023 Phone Link Harness

C1645 PHONE LINK-CENTRE STACK

1

25

24,27

24,27

13

25

25,13

20

5

5

13

6

23

13

8,26

8,26

23

8

24

8

8

13

C1772 Ignition Coil 6

C0052 Ignition Coil 2

C0074 Illumination-Accessory/Cigar Lighter

C0351 Illumination-Rear Power Outlet

C2529 Indicator-Passenger Airbag Deactivation

C0522 Injector 1

C0523 Injector 2

C0524 Injector 3

C0525 Injector 4

C0526 Injector 5

C0527 Injector 6

C1875 'Keep Alive' Fuse

C0613 Lamp-CHMSL

C0077 Lamp-Footwell-LH

C0076 Lamp-Footwell-RH

C0138 Lamp-Number Plate

C0140 Lamp-Number Plate

C0192 Main Battery Feed Cable Battery Eyelet

C0045 Main Earth Cable Battery Eyelet

C1661 Main Earth Cable Body Eyelet

C2111 Media Player

C2107 Media Player (MOST)

1

1

8

8

2

1

1

1

1

1

1

25

20

14

14

15

15

25

25

25

24

17

4,9,15,21 C1303 Microphone 18,19

15,21

11,10

1

1

C0352 Mirror-Door-Driver side

C0353 Mirror-Door-Passenger side

C0501 Module-ABS

C1649 Module-Airbag

10

11

4

2

11 C0791 Module-Aircon-Conn A 5,27

5

4

4

18,19

16

24

17

18,19

18,19

24

13

3,5,8,14,24,27

7,15

4,5,8,15,18,19,21,27

23

3,12,13,16

10

3,10

10

1

16

24

17

12

12

11

3,11

11

24

24

24

9

9

9

13

15

1

8

5

7,27

24

24

17

24

24

3

2,3,11,18,19

2

24

24

C0792 Module-Aircon-Conn B

C2589 Module-Amplifier (AUD2)

C2102 Module-Amplifier Inline (MOST)

C2154 Module-Amplifier (MOST)

C2702 Module-Amplifier-Subwoofer

C1621 Module-Amplifier-Subwoofer (Aud Power)

C2346 Sensor-Side Impact-Right

C1672 Sensor-Steering Angle

C0881 Sensor-Sun

C2405 Sensor-Switch Buckle-Driver

C1656 Sensor-Yawrate Acceleration

C1930 Side Repeater-LH

C1931 Side Repeater-RH

C0089 Socket-Accessory/Cigar Lighter

C1632 Socket-Rear Power Outlet

C1417 Solenoid-Eair Vacuum

C2833 Solenoid-Glovebox Release

C0405 Sounder-PDC (Rear)

C0340 Speaker-Dual-Front Left

C0339 Speaker-Dual-Front Right

C0310 Speaker-Dual-Rear Left

C0308 Speaker-Dual-Rear Right

C0369 Speaker-Front Centre

C1876A Stand Alone Fuse Holder-SAI

C1876B Stand Alone Fuse Holder-SAI

C1886 Stand Alone Relay Holder-SAI

C0179 Starter-Motor

C0082 Stator-Steering Wheel

C0656 Subwoofer

C0054 Switch Pack-Drivers Door

C0087 Switch-Window-Passenger Door

C1494 Switch-Aircon Request

C1822 Switch-Battery Off

C1271 Switch-BDS

C0046 Switch-BDS Stud

C1393 Switch-Bluetooth

C0007 Switch-Bonnet

C0221 Switch-Boot Release (Exterior)

C1681 Switch-Boot Release (Interior)

C2448 Switch-Brake Boost

C0026 Switch-Brake Fluid Level

C0075 Switch-Brake Pedal

C0262 Switch-Buckle-Passenger

C0667 Switch-Clutch Bottom Of Travel

C1491 Switch-Clutch Top of Travel

C0749 Switch-Cruise Control

C0036 Switch-Direction Indicator

C1427 Switcher-Speaker-Front

C0748 Switch-Fuel Flap Release

C0238 Switch-Glovebox Release

5,27

18,19

17

17

18,19

18,19

2

3,4,25

5

2

4

11

11

8

8

23

8

12

18,19

18,19

18,19

18,19

18,19

23

23

23

22

2,8,18,19

18,19

10

11

5,26

25

22,25

25

18,19

9

15

15

4

4

4

2

22

22

8,18,19

13,15,21,27

18,19

8,26

8,26

Page 20

C2103 Phone Module (MOST)

C1497 Pretensioner-Driver

C0252 Pretensioner-Passenger

C0978 Puddle Lamp-Drivers Door

17

2

2

10

C0648 Switch-Handbrake

C0096 Switch-Hazard

C0131 Switch-Heated Front Screen

C1908 Switch-Horn (Steering Wheel)

C0979 Puddle Lamp-Passenger Door 11 C0028 Switch-Ignition

C1342 Pump-Headlamp Wash

C1339 Pump-Leak Detection

C0828 Pump-Screen Washer Fluid

C0879 Pump-Secondary Air Injection

C1914 REAR BUMPER-CABIN INLINE

C0121 Rear Lamp-LH

C0125 Rear Lamp-RH

C0919 Rear Sidemarker-LH

C0918 Rear Sidemarker-RH

C0068 Regulator-Blower Speed

C1948 Rotator-Steering Wheel

C2287 Rotator-Steering Wheel

C1254 Rotator-Steering Wheel

C0210 Rotor-Steering Wheel

C2363 Seat-Left-Conn2 (Airbag)

C2368 Seat-Right-Conn2 (Airbag)

C1465 Sensor-Aircon Pressure (MID)

C1257 Sensor-Aircon Presure (HI & LO)

C0884 Sensor-Ambient Temp

C0188 Sensor-Barometric Pressure

C0050 Sensor-Brake Pad Wear (F/L)

C0968 Sensor-Brake Pad Wear (F/R)

C2578 Sensor-Brake Pad Wear (R/L)

C2579 Sensor-Brake Pad Wear (R/R)

C2446 Sensor-Brake Pedal Travel

C2444 Sensor-Brake Pressure

C0643 Sensor-Catalyst Monitor-FRNT (1-4)

C0644 Sensor-Catalyst Monitor-REAR (5-8)

C0147 Sensor-Engine Coolant Level

C0169 Sensor-Engine Coolant Temp

C1549 Sensor-Engine Oil Temp

C0417 Sensor-Evap

C0516 Sensor-F/L/ABS

C0517 Sensor-F/R/ABS

C1652 Sensor-Front Impact-Left

C1653 Sensor-Front Impact-Right

C2467 Sensor-Fuel Rail Pressure/Temperature

C1574 Sensor-Headlamp Level-FR

C1575 Sensor-Headlamp Level-RR

C0370 Sensor-Heated Oxygen-FRNT (1-4)

C0642 Sensor-Heated Oxygen-REAR (5-8)

C0174 Sensor-IAT (Manifold Temp)

C0412 Sensor-In Car Temp

C0672 Sensor-Key Reader

C0149 Sensor-Mass Air Flow (R/H)

C0359 Sensor-Mass Movement

C0964 Sensor-PDC-RIL

C0965 Sensor-PDC-RIR

C0963 Sensor-PDC-ROL

C0966 Sensor-PDC-ROR

C1589 Sensor-Pedal Position A (Primary)

C0787 Sensor-Pedal Position B (Secondary)

C3150 Sensor-Pressure-Door-LH

C3149 Sensor-Pressure-Door-RH

C0502 Sensor-R/L/ABS

C0503 Sensor-R/R/ABS

C0620 Sensor-Screen Wash Fluid Level

C2345 Sensor-Side Impact-Left

7

1

7

23

1,9,12

15,20,21

15,20,21

15

15

5

2

2

18,19

8

2

2

1

1

5

1

13

13

13

13

4

4

1

1

1

1

1

1

4

4

2

2

1

16

16

1

1

1

5

9,25

1

9

12

12

12

12

1

1

2

2

4

4

7

2

C0984 Switch-IVD

C0041 Switch-Master Light

C1082 Switch-Master Light

C0328 Switch-Master Locking

C0187 Switch-Oil Pressure

C0773 Switchpack-Seat-Manual 1

C0776 Switchpack-Seat-Manual 1

C0774 Switchpack-Seat-Manual 2

C2800 Switchpack-Seat-Manual 2

C0775 Switchpack-Seat-Manual 3

C2801 Switchpack-Seat-Manual 3

C2992 Switch-Passenger Airbag Cut Off

C1541 Switch-PDC Disable

C0064 Switch-Rear Fog Lamps

C0750 Switch-Recirc

C2787 Switch-Reduced Guard

C0163 Switch-Reverse (Trans. Mounted)

C2453 Switch-Start Button

C0278 Switch-Steering Column-Wiper

C0491 TAILGATE-ANTENNA ASSY

C0385 TAILGATE-CABIN

C2130 Temp Actuator

C0897 TMC Module (Power)

C2220 TMC Module (Fakra)

C0899 TMC Module (MOST)

C2517 Tuner-GPS (MOST)

C0003 Twin Horns

C2705 Underbonnet Fusebox Battery Feed Eyelet

C2472 Valve-Electric Vapour Management

C1685 Valve-Exhaust Bypass

C0740 Window Motor-Drivers Door

C0741 Window Motor-Passenger Door

C1609 GPS Tuner Antenna

C2512 Antenna-AM/FM Rod-Power

C2600 Earth Eyelet-Drivers Door

C2483 Switcher-Speaker-Front-Blank

C2470 Module-Cooling Fan Pack

C2469 Transducer-Power Steering Pressure

C2379 Passenger Seat-Conn1 (Pwr & Gnd)

8,22

21,26

8,26

8,18,19

1,2,3,5,12,13,

16,22,23,25,26

4

15,26

26

11

1

6

6

6

6

6

6

2

12,26

20,26

5,26,27

9,26

20

22

27,7

24

8,24

5

24

24

24

24

8

25

1

1

10

11

24

24

10

18,19

23

1

6

Page 21

AAMMLL CC NNUUMMBBEERR LLOOCCAATTIIOONN CCHHAARRTT

VVA

A

A

A

p

C0003 Twin Horns 8 C0413 Direction Mode Actuator 5

C0007 Switch-Bonnet 9 C0417 Sensor-Evap 1

C0009 Headlamp-LH 15,16,21 C0419 Fresh/Recirc Actuator 5

C0011 Headlamp-RH 15,16,21 C0421 Cabin-Microphone Link 18,19

C0017 Earth Eyelet-Steering Wheel Switches 8,18,19 C0428 Module-Centre Console-Conn1 (Key A) 3,5,8,14,24,27

C0018 Earth Eyelet-Twin Horns 8 C0429 Module-Centre Console-Conn2 (Midd) 7,15

C0026 Switch-Brake Fluid Level 4 C0430 Module-Centre Console-Conn3 (Key B) 4,5,8,15,18,19,21,27

C0028 Switch-Ignition

C0030 Motor-Windscreen Wipers 7,27 C0469 FACIA-CABIN INLINE 8 Various

C0032 Module-EGR 1 C0491 TAILGATE-ANTENNA ASSY 24

C0036 Switch-Direction Indicator 13,15,21,27 C0501 Module-ABS 4

C0037 D/I Resistor-LH 21 C0502 Sensor-R/L/ABS 4

C0038 D/I Resistor-RH 21 C0503 Sensor-R/R/ABS 4

C0041 Switch-Master Light 15,26 C0516 Sensor-F/L/ABS 4

C0045 Main Earth Cable Battery Eyelet 25 C0517 Sensor-F/R/ABS 4

C0046 Switch-BDS Stud 25 C0520 Module-Sounder 9

C0047 FACIA-CABIN INLINE 1 Various C0522 Injector 1 1

C0050 Sensor-Brake Pad Wear (F/L) 13 C0523 Injector 2 1

C0052 Ignition Coil 2 1 C0524 Injector 3 1

C0054 Switch Pack-Drivers Door 10 C0525 Injector 4 1

C0056 Motor-Heater Blower 5 C0526 Injector 5 1

C0064 Switch-Rear Fog Lamps 20,26 C0527 Injector 6 1

C0068 Regulator-Blower Speed 5 C0549 OBD2-Powertrain 'A' 3

C0074 Illumination-Accessory/Cigar Lighter 8 C0551 Earth Eyelet-Mass Air Flow Sensor A R/H 1

C0075 Switch-Brake Pedal 4 C0552 Earth Eyelet-Mass Air Flow Sensor B L/H 1

C0076 Lamp-Footwell-RH 14 C0553 Earth Eyelet-Tracker 9

C0077 Lamp-Footwell-LH 14 C0554 Earth Eyelet-Wash Wipe Switch 7

C0082 Stator-Steering Wheel 2,8,18,19 C0555 Earth Eyelet-Signals 13,24,26

C0083 CABIN-CENTRE STACK INLINE 1 Various C0556 Earth Eyelet-Multi-Media Display 24

C0087 Switch-Window-Passenger Door 11 C0558 Earth Eyelet-Power Ground 25

C0089 Socket-Accessory/Cigar Lighter 8 C0559 Earth Eyelet-Power Ground 25

C0096 Switch-Hazard 21,26 C0560 Earth Eyelet-Clutch-Compressor-Air Condition 5

C0102 AM/FM Receiver Module (MOST) 24 C0562 Earth Eyelet-Cooling Fan Module 5

C0119 Boot Lamp1 15 C0563 Earth Eyelet-Cam / Crank Sensors Screen 1

C0120 Boot Lamp2 15 C0564 Earth Eyelet-Regulator Blower Speed 5

C0121 Rear Lamp-LH 15,20,21 C0570 C1 ENGINE BAY FUSEBOX Various

C0125 Rear Lamp-RH 15,20,21 C0571 C2 ENGINE BAY FUSEBOX Various

C0127 Clutch-Compressor-Air Conditioning (A/C) 1 C0572 C3 ENGINE BAY FUSEBOX Various

C0131 Switch-Heated Front Screen 8,26 C0573 C4 ENGINE BAY FUSEBOX Various

C0138 Lamp-Number Plate 15 C0574 C5 ENGINE BAY FUSEBOX Various

C0140 Lamp-Number Plate 15 C0575 C6 ENGINE BAY FUSEBOX Various

C0147 Sensor-Engine Coolant Level 1 C0576 C7 ENGINE BAY FUSEBOX Various

C0149 Sensor-Mass Air Flow (R/H) 1 C0577 C8 ENGINE BAY FUSEBOX Various

C0156 Ignition Coil 1 1 C0578 C9 ENGINE BAY FUSEBOX Various

C0163 Switch-Reverse (Trans. Mounted) 20 C0579 C10 ENGINE BAY FUSEBOX Various

C0169 Sensor-Engine Coolant Temp 1 C0580 CEM CONNECTOR - COCKPIT 1 Various

C0174 Sensor-IAT (Manifold Temp) 1 C0582 CEM CONNECTOR COCKPIT 2 Various

C0179 Starter-Motor 22 C0585 CEM CONNECTOR - ROOF 1 Various

C0187 Switch-Oil Pressure 1 C0588 CEM CONNECTOR - FRONT END 2 Various

C0188 Sensor-Barometric Pressure 1 C0589 CEM CONNECTOR - ROOF 2 Various

C0192 Main Battery Feed Cable Battery Eyelet 25 C0601 Fuse-Stand Alone-Battery Conditioner 25

C0210 Rotor-Steering Wheel 8 C0610 Cabin-GSM Phone Microphone Inline 18,19

C0221 Switch-Boot Release (Exterior) 15 C0613 Lamp-CHMSL 20

C0223 FACIA-CABIN INLINE 4 Various C0620 Sensor-Screen Wash Fluid Level 7

C0226 Alternator/Generator 22 C0634 ECU A (T-TRANS) Various

C0229 FACIA-CABIN INLINE 5 Various C0635 ECU A (C-COWL) Various

C0230 Module-Driver Information 3,12,13,16 C0636 ECU A (E-ENGINE) Various

C0231 FACIA-CABIN INLINE 6 Various C0642 Sensor-Heated Oxygen-REAR (5-8) 1

C0232 Clock 13 C0643 Sensor-Catalyst Monitor-FRNT (1-4) 1

C0238 Switch-Glovebox Release 8,26 C0644 Sensor-Catalyst Monitor-REAR (5-8) 1

C0241 Module-Bluetooth Display 18,19 C0648 Switch-Handbrake 8,22

C0246 Heated Front Screen 8 C0656 Subwoofer 18,19

C0251 Airbag-Passenger1 2 C0667 Switch-Clutch Bottom Of Travel 22

C0252 Pretensioner-Passenger 2 C0672 Sensor-Key Reader 9,25

C0257 Airbag-Driver1 2 C0674 Module-Remote Receiver 9

C0261 Airbag-Passenger2 2 C0690 Motor-Fuel Flap Release 8

C0262 Switch-Buckle-Passenger 2 C0706

C0273 CABIN-DRIVER AIRBAG INLINE 1 Various C0707 Earth Eyelet-Remote Receiver 9

C0276 Ignition Coil 3 1 C0709 Earth Eyelet-Driver Information Module 13

C0278 Switch-Steering Column-Wiper 27,7 C0733 PASSENGER DOOR-CABIN INLINE 2,3,11,18,19

C0305 CABIN-PASS AIRBAG INLINE 2 C0738 FACIA-CABIN PHONE ANTENNA INLINE 24

C0308 Speaker-Dual-Rear Right 18,19 C0740 Window Motor-Drivers Door 10

C0310 Speaker-Dual-Rear Left 18,19 C0741 Window Motor-Passenger Door 11

C0322 Module-Passenger Door-Conn1 11 C0744 DRIVERS DOOR-CABIN INLINE Various

C0323 Module-Passenger Door-Conn2 3,11 C0748 Switch-Fuel Flap Release 8,26

C0324 Module-Passenger Door-Conn3 11 C0749 Switch-Cruise Control 8,18,19

C0328 Switch-Master Locking 11 C0750 Switch-Recirc 5,26,27

C0333 Cabin-Microphone Link 18,19 C0751 Driver Seat-Conn3-(ARS) 2

C0336 Module-Drivers Door-Conn1 10 C0752 Passenger Seat-Conn3 (ARS) 2

C0337 Module-Drivers Door-Conn2 3,10 C0765 FACIA-CABIN INLINE 9 Various

T

NNT

GGEE 22000055MMYYMMaannuuaallCCoou

1,2,3,5,12,13,

16,22,23,25,26

C0434 Earth Eyelet-Module-ABS 4

pee1133--0077--0055

u

Earth Eyelet-Key Reader, Indicator Switch,

Steering Angle Sensor

4,9,15,21

Page 22

C0338 Module-Drivers Door-Conn3 10 C0773 Switchpack-Seat-Manual 1 6

C0339 Speaker-Dual-Front Right 18,19 C0774 Switchpack-Seat-Manual 2 6

C0340 Speaker-Dual-Front Left 18,19 C0775 Switchpack-Seat-Manual 3 6

C0351 Illumination-Rear Power Outlet 8 C0776 Switchpack-Seat-Manual 1 6

C0352 Mirror-Door-Driver side 10 C0787 Sensor-Pedal Position B (Secondary) 1

C0353 Mirror-Door-Passenger side 11 C0791 Module-Aircon-Conn A 5,27

C0355 Front Interior Lamp-LH 14,27 C0792 Module-Aircon-Conn B 5,27

C0356 Front Interior Lamp-RH 14,27 C0800 Battery-Backup-Tracker 9

C0359 Sensor-Mass Movement 9 C0808 Earth Eyelet-Module-Amplifier 18,19

C0362 Earth Eyelet-Module-ABS 4 C0809 Earth Eyelet-Windscreen Wiper Motor 7

C0369 Speaker-Front Centre 18,19 C0811 Earth Eyelet-Seat-Passenger 6

C0370 Sensor-Heated Oxygen-FRNT (1-4) 1 C0821 Earth Eyelet-Indicator Stalk Trip Switch 13

C0381 Heated Rear Window Power 8 C0828 Pump-Screen Washer Fluid 7

C0382 Heated Rear Window Gnd 8 C0836 Earth Eyelet-SAI Pump 23

C0384 BOOT LID-LINK-CABIN 8,15,20 C0877 Diagnostic Connector B - Body 3

C0385 TAILGATE-CABIN 8,24 C0879 Pump-Secondary Air Injection 23

C0405 Sounder-PDC (Rear) 12 C0881 Sensor-Sun 5

C0412 Sensor-In Car Temp 5 C0884 Sensor-Ambient Temp 5

C0897 TMC Module (Power) 24 C2052 Motor-Boot Latch 15

C0899 TMC Module (MOST) 24 C2102 Module-Amplifier Inline (MOST) 17

C0901 Eyelet-Battery Feed Terminal UBFB 25 C2103 Phone Module (MOST) 17

C0916 Front Sidemarker-RH 15 C2104 Multi Media Module (MOST) 17

C0917 Front Sidemarker-LH 15 C2105 Module-Infotainment Control (MOST) 17

C0918 Rear Sidemarker-RH 15 C2107 Media Player (MOST) 17

C0919 Rear Sidemarker-LH 15 C2111 Media Player 24

C0947 Module-Centre Console (Sim) 24 C2113 Multi Media Module (Power) 24

C0948 Airbag-Side-Left 2 C2114 Multi Media Module (Screen) 24

C0949 Airbag-Side-Right 2 C2115 Module-Infotainment Control 24

C0957 Module-Parking Aid 12 C2118 Module-Phone (Main) 24

C0963 Sensor-PDC-ROL 12 C2130 Temp Actuator 5

C0964 Sensor-PDC-RIL 12 C2154 Module-Amplifier (MOST) 17

C0965 Sensor-PDC-RIR 12 C2155 Module-Amplifier-Subwoofer (MOST) 17

C0966 Sensor-PDC-ROR 12 C2175 Eyelet-Battery Feed to Battery Conditioner 25

C0968 Sensor-Brake Pad Wear (F/R) 13 C2207 Module-Bluetooth Receiver 18,19

C0978 Puddle Lamp-Drivers Door 10 C2219 AM/FM Receiver Module (Fakra) 24

C0979 Puddle Lamp-Passenger Door 11 C2220 TMC Module (Fakra) 24

C0984 Switch-IVD 4 C2233 Antenna-Phone 24

C0997 Coil Suppressor1 1 C2242 CABIN-ENGINE INLINE 1 Various

C1023 Phone Link Harness 24 C2243 CABIN-ENGINE INLINE 2 Various

C1082 Switch-Master Light 26 C2244 CABIN-ENGINE INLINE 3 Various

C1165 CABIN-CENTRE STACK INLINE 2 Various C2246 FACIA-CABIN INLINE HIROSE MMM 24

C1167 FACIA-CABIN INLINE 12 Various C2275 FORWARD-ENGINE INLINE 1 Various

C1168 FACIA-CABIN INLINE 13 Various C2276 FORWARD-ENGINE INLINE 2 Various

C1169 Earth Eyelet-CCM Signal 24,27 C2287 Rotator-Steering Wheel 2

C1170 Earth Eyelet-CCM 24,27 C2345 Sensor-Side Impact-Left 2

C1185 CABIN-CENTRE STACK INLINE 3 Various C2346 Sensor-Side Impact-Right 2

C1210 Earth Eyelet-Underbonnet Fusebox 25 C2363 Seat-Left-Conn2 (Airbag) 2

C1254 Rotator-Steering Wheel 18,19 C2368 Seat-Right-Conn2 (Airbag) 2

C1257 Sensor-Aircon Presure (HI & LO) 1 C2378 Driver Seat-Conn1-(Pwr & Gnd) 6

C1271 Switch-BDS 22,25 C2379 Passenger Seat-Conn1 (Pwr & Gnd) 6

C1303 Microphone 18,19 C2405 Sensor-Switch Buckle-Driver 2

C1339 Pump-Leak Detection 1 C2409 FORWARD-CABIN INLINE3 Various

C1342 Pump-Headlamp Wash 7 C2410 FORWARD-CABIN INLINE 1 Various

C1355 Earth Eyelet-CCM Trip Switch 13 C2411 FORWARD-CABIN INLINE 2 Various

C1363 FACIA-CABIN INLINE 2 Various C2412 FORWARD-CABIN INLINE 4 Various

C1393 Switch-Bluetooth 18,19 C2444 Sensor-Brake Pressure 4

C1398 Earth Eyelet-Module Aircon 5 C2446 Sensor-Brake Pedal Travel 4

C1417 Solenoid-Eair Vacuum 23 C2448 Switch-Brake Boost 4

C1427 Switcher-Speaker-Front 18,19 C2453 Switch-Start Button 22

C1449 Door Lock-Drivers Door 10 C2465 Motor-Electronic Throttle A 1

C1451 Door Lock-Passenger Door 11 C2467 Sensor-Fuel Rail Pressure/Temperature 1

C1457 Module-Parking Aid 3 12 C2469 Transducer-Power Steering Pressure 1

C1465 Sensor-Aircon Pressure (MID) 1 C2470 Module-Cooling Fan Pack 23

C1491 Switch-Clutch Top of Travel 22 C2471 Module-Cooling Fan Pack 23

C1494 Switch-Aircon Request 5,26 C2472 Valve-Electric Vapour Management 1

C1497 Pretensioner-Driver 2 C2483 Switcher-Speaker-Front-Blank 18,19

C1537 Module-Tyre Pressure Monitor 13 C2509 Distribution Point 3 25

C1541 Switch-PDC Disable 12,26 C2511 Antenna Amplifer2 (AM/FM) 24

C1543 Module-HID Lighting 16 C2512 Antenna-AM/FM Rod-Power 24

C1549 Sensor-Engine Oil Temp 1 C2515 Multi Media Display (Screen) 24

C1574 Sensor-Headlamp Level-FR 16 C2516 Multi Media Display (Power) 24

C1575 Sensor-Headlamp Level-RR 16 C2517 Tuner-GPS (MOST) 24

C1589 Sensor-Pedal Position A (Primary) 1 C2522 Module-Centre Console (Trip Switches) 13

C1598 Antenna-GPS 24 C2529 Indicator-Passenger Airbag Deactivation 2

C1599 GPS Antenna Inline 24 C2537 Module-Phone (Antenna) 24

C1608 GPS Tuner 24 C2538 AM/FM Receiver Module (Power) 24

C1609 GPS Tuner Antenna 24 C2562 Earth Eyelet-Switch-Brake Fluid Level 4

C1621 Module-Amplifier-Subwoofer (Aud Power) 18,19 C2564 Earth Eyelet-Front Brake Pad Wear Sensor 13

C1626 Earth Eyelet-LH Headlamp 15,21 C2567 Earth Eyelet-Seat-Driver 6

C1627 Cabin Battery Feed Bulkhead Stud Eyelet 25 C2568 Earth Eyelet-Drivers Seat (Heater) 6

C1632 Socket-Rear Power Outlet 8 C2569 Earth Eyelet-Passenger Seat (Heater) 6

C1644 Module-Phone (SIM) 24 C2570 Earth Eyelet-CEM (Noisy) 25

C1645 PHONE LINK-CENTRE STACK 24 C2578 Sensor-Brake Pad Wear (R/L) 13

C1649 Module-Airbag 2 C2579 Sensor-Brake Pad Wear (R/R) 13

C1652 Sensor-Front Impact-Left 2 C2588 Amplifier (Aud Power) 18,19

C1653 Sensor-Front Impact-Right 2 C2589 Module-Amplifier (AUD2) 18,19

C1656 Sensor-Yawrate Acceleration 4 C2597 Earth Eyelet-Heated Front Screen-LH 8

Page 23

C1661 Main Earth Cable Body Eyelet 25 C2598 Earth Eyelet-Heated Front Screen-RH 8

C1672 Sensor-Steering Angle 3,4,25 C2599 Earth Eyelet-Socket Accessory/Cigar Lighter 8

C1679 Earth-Heated Rear Window Coupe 8 C2600 Earth Eyelet-Drivers Door 10

C1681 Switch-Boot Release (Interior) 15 C2602 Earth Eyelet-Sounder, Vac Pump, Rear Power Socket 1,8,9

C1685 Valve-Exhaust Bypass 1 C2603 Earth Eyelet-Pump-Headlamp Wash 7

C1770 Ignition Coil 4 1 C2604 Earth Eyelet-Rear Lamp-RH 15,20,21

C1771 Ignition Coil 5 1 C2605 Earth Eyelet-Rear Lamp-LH 15,20,21

C1772 Ignition Coil 6 1 C2630 Earth Eyelet-PDC Module 12

C1822 Switch-Battery Off 25 C2634 Earth Eyelet-GPS Tuner 24

C1875 'Keep Alive' Fuse 25 C2646

Earth Eyelet-Master Locking Switch,

Interior Boot Release Switch

11

C1876A Stand Alone Fuse Holder-SAI 23 C2647 Earth Eyelet-BDS Switch 25

C1876B Stand Alone Fuse Holder-SAI 23 C2648 Earth Eyelet-CEM (Quiet), TPM 25,13

C1886 Stand Alone Relay Holder-SAI 23 C2650 Earth Eyelet-Case Ground 25

C1890 Boot Fusebox Battery Feed Eyelet 25 C2652 Earth Eyelet-Washer Fluid Pump 7

C1891 BDS Power Eyelet 25 C2692

Earth Eyelet-Boot Motor, Exterior Boot Rel Switch,

Fuel Flap Solenoid, Battery Conditioner

8,15,25

C1898 CABIN-CENTRE STACK INLINE (MOST) 17 C2695 Earth Eyelet-Reverse Switch, Rear Brake Pad Wear Sensors 13,20

C1908 Switch-Horn (Steering Wheel) 8,18,19 C2697 Earth Eyelet-Boot Fusebox 25

C1914 REAR BUMPER-CABIN INLINE 1,9,12 C2702 Module-Amplifier-Subwoofer 18,19

C1930 Side Repeater-LH 11 C2704 Cabin Battery Feed BDS Eyelet 25

C1931 Side Repeater-RH 11 C2705 Underbonnet Fusebox Battery Feed Eyelet 25

C1947 Earth Eyelet-RH Headlamp 15,21 C2712 Earth Eyelet-Rear Door Ajar Signal 11

C1948 Rotator-Steering Wheel 2 C2716 Earth Eyelet-Reduced Guard Switch, Glovebox Switch 8,9,26

C1968 Earth Eyelet-LH Side Repeater 11,10 C2718 Earth Eyelet-Fuel Tank 23

C1969 Earth Eyelet-RH Side Repeater 11 C2719 Earth Eyelet-Body 25

C1971 Earth Eyelet-Wash Fluid Level Sensor 7 C2727 Earth Eyelet-FPDM 23

C1972 Earth Eyelet-Bonnet Switch 9 C2787 Switch-Reduced Guard 9,26

C2013 BOOT FUSEBOX - CONN D Various C2797 Battery Conditioner 25

C2800 Switchpack-Seat-Manual 2 6

C2801 Switchpack-Seat-Manual 3 6

C2833 Solenoid-Glovebox Release 8

C2838 Module-Tracker 9

C2841 Distribution Point 4 25

C2920 Earth Eyelet-Fuel Flap Release Switch 8,26

C2921 Earth Eyelet-Fuel Flap Release Tell Tale 8,26

C2922 Earth Eyelet-CHMSL 20

C2924 Earth Eyelet-Multi-Media Module 24

C2926 Earth Eyelet-Number Plate Lamps, Rear Sidemarkers 15

C2928 Earth Eyelet-Module-HID Lighting 16

C2929 Earth Eyelet-Glovebox Release Solenoid 8

C2982 Cabin-Alpine Link (AUD) 18,19

C2983 Cabin-Alpine Link (Power) 18,19

C2992 Switch-Passenger Airbag Cut Off 2

C2998 Earth Eyelet-Phone 24

C2999 Earth Eyelet-Bluetooth Receiver 18,19

C3000 Earth Eyelet-Ignition Coils 1

C3002 Earth Eyelet-Switcher-Front Speaker 18,19

C3149 Sensor-Pressure-Door-RH 2

C3150 Sensor-Pressure-Door-LH 2

Page 24

Page 25

Page 26

Page 27

Page 28

Page 29

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

Page 36

Page 37

Page 38

Page 39

Page 40

Page 41

Page 42

Page 43

Page 44

Page 45

Page 46

Page 47

Page 48

Page 49

Page 50

Page 51

Page 52

Page 53

Page 54

Page 55

Page 56

Page 57

AAMMLL EEAARRTTHH SSTTUUDD LLOOCCAATTIIOONN

VVAANNTTAAGGEE 22000055MMYY MMaannuuaall CCoouuppee 0011--0088--0055

To be used in conjunction with harness earth pages

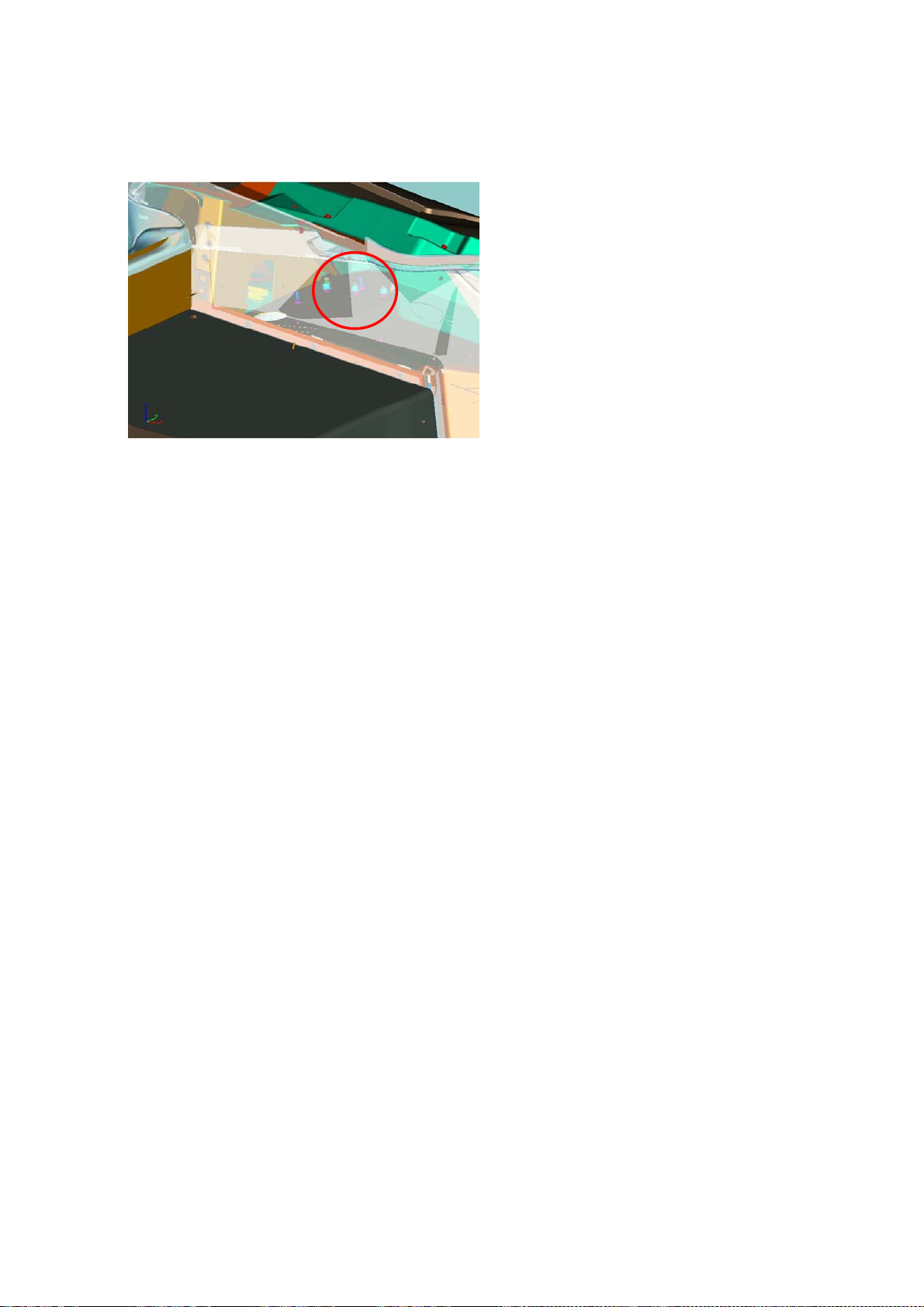

Location numbers shown refer to the image number on the harness earth pages. The views below are to be

used as an initial indicator for the approximate location of the earth point. Below cover a LHD & RHD

manual coupe.

11, 13

6

15

7, 16 13

9, 10 12

Plan view is for approximate horizontal position.

Location Numbers 1 – 4 - Forward Harness LHD & RHD.

Location Number 5 - Engine Harness.

Location Number 6 - Fuel Tank / Engine braid earth.

Location Numbers 7 – 8 - Cabin Coupe Harness LHD.

Location Numbers 9 – 15 - Cabin Coupe Harness LHD & RHD.

Location Numbers 16 & 17 - Cabin Coupe Harness RHD.

Correct as of 01-08-05. Subject to change.

Sideways view is for approximate vertical position.

3

7, 8, 16, 17

1, 2, 5 15

9, 10 12 14

3, 4

14

1, 5

8, 17 11

6

2

4

6

Page 58

AAMMLL EEAARRTTHH SSTTUUDD LLOOCCAATTIIOONN

VVAANNTTAAGGEE 22000055MMYY MMaannuuaall CCoouuppee 2255--0077--0055

Fuel Tank / Engine Braid Earths

Location number 6 - View looking into transmission tunnel from rear of car

Left hand side of the transmission tunnel.

Pair - C2719 Earth – Fuel Tank - B, 2.0 - Eyelet

Right hand side of the transmission tunnel.

Single - Engine Earth - Braid - Eyelet

Correct as of 01-08-05. Subject to change.

Page 59

AAMMLL EEAARRTTHH SSTTUUDD LLOOCCAATTIIOONN

VVAANNTTAAGGEE 22000055MMYY MMaannuuaall CCoouuppee 1133--0077--0055

Forward Harness RHD Earths

Location number 1 - LHS of bulkhead looking into car. Location number 2 - RHS of bulkhead looking into car.

RHS of bulkhead looking into car.

Pair - C1968 Earth – Side Repeater L/H - BG, 0.5 - RH Eyelet

- C0552 Earth – Sensor-MAF L/H - BG, 0.5 - LH Eyelet

Single - C1626 Earth – Headlamp L/H - BG, 4.0 - Eyelet

LHS of bulkhead looking into car.

Pair - C1969 Earth – Side Repeater R/H - BG, 0.5 - RH Eyelet

- C0551 Earth – Sensor-MAF R/H - BG, 0.5 - LH Eyelet

Single - C1947 Earth – Headlamp R/H - BG, 4.0 - Eyelet

Location number 3 - Front right wing looking from front. Location number 4 - Front left wing looking from front.

Page 60

Front right wing looking from front.

Pair - C0434 Earth – Module-ABS - BK, 1.0 - LH Eyelet

- C0362 Earth – Module-ABS - BK, 1.0 - RH Eyelet

Pair - C2564 Earth – Front Brake Pad Wear - B, 0.5 - LH Eyelet

- C1210 Earth – Underbonnet Fusebox - B, 1.0 - RH Eyelet

Single - C0018 Earth – Horns - B, 1.0 - Eyelet

Single - C0562 Earth – Cooling Fan Pack - B, 6.0 - Eyelet

Front left wing looking from front.

Single - C2603 Earth – Headlamp Wash Pump - B, 1.5 - Eyelet

Single - C2652 Earth – Washer Fluid Pump - B, 1.0 - Eyelet

Pair - C1971 Earth – Wash Fluid Level Sensor - B, 0.5 - LH Eyelet0

- C1972 Earth – Bonnet Switch - B, 0.5 - RH Eyelet

Pair - C2597 Earth – Heated Front Screen-L/H - B, 4.0 - LH Eyelet

- C2598 Earth – Heated Front Screen-R/H - B, 4.0 - RH Eyelet

Single - C2562 Earth – Switch-Brake Fluid Level - BK, 0.5 - Eyelet

Single - C0809 Earth – Windscreen Wiper Motor - B, 2.0 - Eyelet

Correct as of 26-07-05. Subject to change.

Page 61

AAMMLL EEAARRTTHH SSTTUUDD LLOOCCAATTIIOONN

VVAANNTTAAGGEE 22000055MMYY MMaannuuaall CCoouuppee 1133--0077--0055

Location Number 1 - LHS of Bulkhead looking into car. Location number 2 - RHS of Bulkhead looking into car.

RHS of Bulkhead looking into engine bay.

Pair - C1968 Earth – Side Repeater L/H - BG, 0.5 - RH Eyelet

- C0552 Earth – Sensor-MAF L/H - BG, 0.5 - LH Eyelet

Single - C1626 Earth – Headlamp L/H - BG, 4.0 - Eyelet

LHS of Bulkhead looking into engine bay.

Pair - C1969 Earth – Side Repeater R/H - BG, 0.5 - RH Eyelet

- C0551 Earth – Sensor-MAF R/H - BG, 0.5 - LH Eyelet

Single - C1947 Earth – Headlamp R/H - BG, 4.0 - Eyelet

Location number 3 - Front right wing looking from front. Location number 4 - Front left wing looking from front.

Forward Harness LHD Earths

Page 62

Front right wing looking from front.

Pair - C0434 Earth – Module-ABS - BK, 1.0 - LH Eyelet

- C0362 Earth – Module-ABS - BK, 1.0 - RH Eyelet

Pair - C2564 Earth – Front Brake Pad Wear - B, 0.5 - LH Eyelet

- C1210 Earth – Underbonnet Fusebox - B, 1.0 - RH Eyelet

Single - C0018 Earth – Horns - B, 1.0 - Eyelet

Single - C0562 Earth – Cooling Fan Pack - B, 6.0 - Eyelet

Front left wing looking from front.

Single - C2603 Earth – Headlamp Wash Pump - B, 1.5 - Eyelet

Single - C2652 Earth – Washer Fluid Pump - B, 1.0 - Eyelet

Pair - C1971 Earth – Wash Fluid Level Sensor - B, 0.5 - LH Eyelet

- C1972 Earth – Bonnet Switch - B, 0.5 - RH Eyelet

Pair - C2597 Earth – Heated Front Screen-L/H - B, 4.0 - LH Eyelet

- C2598 Earth – Heated Front Screen-R/H - B, 4.0 - RH Eyelet

Single - C2562 Earth – Switch-Brake Fluid Level - BK, 0.5 - Eyelet

Single - C0809 Earth – Windscreen Wiper Motor - B, 2.0 - Eyelet

Correct as of 26-07-05. Subject to change.

Page 63

AAMMLL EEAARRTTHH SSTTUUDD LLOOCCAATTIIOONN

VVAANNTTAAGGEE 22000055MMYY MMaannuuaall CCoouuppee 1133--0077--0055

Pair - C0560 Earth – Air conditioning Clutch Compressor - B, 2.0 - RH Eyelet

- C0836 Earth – Secondary Air Injection Pump - B, 4.0 - LH Eyelet

Pair - C0561 Earth – Knock Sensors Screen - B, 1.0 - RH Eyelet

- C0559 Earth – Power Ground - B, 1.5 - LH Eyelet

Pair - C2650 Earth – Case Ground - B, 0.75 - RH Eyelet

- C0558 Earth – Power Ground - B, 2.0 - LH Eyelet

Single - C0563 Earth – Cam / Crank Sensors Screen - B, 0.5 - Eyelet

Correct as of 26-07-05. Subject to change.

Engine Harness Earths

Location number 5 - LHS of Bulkhead looking into engine bay.

Page 64

AAMMLL EEAARRTTHH SSTTUUDD LLOOCCAATTIIOONN

VVAANNTTAAGGEE 22000055MMYY MMaannuuaall CCoouuppee 2255--0077--0055

Cabin Coupe Harness RHD Earths

Location number 16 - RHS of Bulkhead from RH seat. Location number 17 - LHS of Bulkhead from RH seat.

RHS of Bulkhead from RH seat.

Pair - C2716 Earth – Glovebox Sw, Red Grd Sw - BU, 0.5 - LH Eyelet

- C1398 Earth – Module-Aircon - BU, 0.5 - RH Eyelet

Pair - C2567 Earth – Seat-Driver - BU, 2.5 - LH Eyelet

- C2629 Earth – OBD2 - B, 0.5 - RH Eyelet

Pair - C2920 Earth – Fuel Flap Rel Sw - BK, 0.5 - RH Eyelet

- C2628 Earth – OBD2 - BK, 0.5 - LH Eyelet

Pair - C2999 Earth – Bluetooth Receiver - BK, 0.5 - LH Eyelet

- C2928 Earth – Module-HID Lighting - BK, 0.5 - RH Eyelet

Pair - C0564 Earth – Regulator-Blower Speed - BR, 3.0 - LH Eyelet

- C2921 Earth – Fuel Flap Rel Sw TT - BR, 0.5 - RH Eyelet

Pair - C2600 Earth – Drivers Door - BR, 2.5 - RH Eyelet

- C0556 Earth – Multi Media Display - BR, 0.5 - LH Eyelet

LHS of Bulkhead from RH seat.

Single - C2570 Earth – CEM Noisy - BU, 2.5 - Eyelet

Pair - C2648 Earth – CEM Quiet, TPM - BK, 1.0 - RH Eyelet

C0709 Earth – DIM - BK, 0.5 - LH Eyelet

Pair - C0017 Earth – Rotary Coupler - BR, 0.5 - LH Eyelet

C2601 Earth – Passenger Door - BR, 2.5 - RH Eyelet

Single - C2998 Earth – Phone - BR, 0.5 - Eyelet

Pair - C2929 Earth – Glovebox Release Sol - BG, 0.5 - RH Eyelet

C3002 Earth – Switcher-Speaker-Front - B, 1.0 - LH Eyelet

Page 65

Location number 9 - Front of top panel under facia from Location number 10 - Rear of top panel under facia from

RH seat. RH seat.

Front of top panel under facia from RH seat.

Pair - C2646 Earth – Mstr Lock Sw, Boot Rel Sw - BG, 0.5 - RH Eyelet

- C1355 Earth – CCM Trip Switch - BG, 0.5 - LH Eyelet

Single - C0553 Earth – Tracker - BG, 0.5 - Eyelet

Rear of top panel under facia from RH seat.

Pair - C1169 Earth – CCM Signal - BK, 1.5 - LH Eyelet

- C2712 Earth – Rear Door Ajar - BK, 0.5 - RH Eyelet

Single - C1170 Earth – CCM - BG, 1.5 - Eyelet

Single - C0555 Earth – Signals - BK, 2.5 - Eyelet

Correct as of 21-07-05. Subject to change.

Location number 11 - Behind LHS seat in rear quarter. Location number 12 - Between seats under rear trim.

Behind LHS seat in rear quarter.

Pair - C0811 Earth – Seat-Passenger - BU, 2.5 - RH Eyelet

C2727 Earth – FPDM - BU, 2.0 - LH Eyelet

Page 66

Pair - C2569 Earth – Seat-Passenger-Heater - BU, 1.5 - LH Eyelet

C2630 Earth – Module-PDC - BU, 0.5 - RH Eyelet

Between seats under rear trim.

Pair - C2922 Earth – CHMSL - BY, 0.5 - RH Eyelet

- C2692 Earth – Bt Mtr, Fuel Flap Sol - BY, 2.0 - LH Eyelet

Single - C2599 Earth – Socket Access / Lighter - BU, 2.0 - Eyelet

Location number 13 - Behind RHS seat in rear quarter. Location number 14 - Inside RH rear wheel arch liner.

Behind RHS seat in rear quarter.

Pair - C0706 Earth – Ind Sw, SAS, Key Reader - BR, 1.0 - LH Eyelet

- C0707 Earth – Remote Receiver - BR, 0.5 - RH Eyelet

Pair - C0821 Earth – Ind Stalk Trip Switch - BR, 0.5 - LH Eyelet

- C0554 Earth – Wash Wipe Switch - BR, 1.5 - RH Eyelet

Pair - C2647 Earth – BDS Switch - BU, 0.5 - LH Eyelet

- C2568 Earth – Seat-Driver-Heater - BU, 1.5 - RH Eyelet

Inside RH rear wheel arch liner.

Pair - C0808 Earth – Amplifier - BG, 4.0 - RH Eyelet

C2634 Earth – GPS Tuner - BG, 0.5 - LH Eyelet

Pair - C2697 Earth – Boot Fusebox - BG, 1.0 - RH Eyelet

C2695 Earth – Rev Sw, Rr Brake Pad Wr - BG, 1.0 - LH Eyelet

Page 67

Location number 15 - In RHS boot compartment.

In RHS boot compartment.

Pair - C1679 Earth – Heated Rear Window - BR, 2.5 - RH Eyelet

- C2605 Earth – Rear Lamp-LH - BR, 1.0 - LH Eyelet

Pair - C2604 Earth – Rear Lamp-RH - BR, 1.0 - RH Eyelet

- C2602 Earth –Sounder, Vacuum Pump - BR, 2.0 - RH Eyelet

Pair - C2924 Earth – Multi-Media Module - BR, 0.5 - RH Eyelet

- C2926 Earth – Number Plate Lamps - BR, 0.5 - LH Eyelet

Correct as of 26-07-05. Subject to change.

Page 68

AAMMLL EEAARRTTHH SSTTUUDD LLOOCCAATTIIOONN

VVAANNTTAAGGEE 22000055MMYY MMaannuuaall CCoouuppee 2255--0077--0055

Cabin Coupe Harness LHD Earths

Location number 7 - RHS of Bulkhead from RH seat.

LHS of Bulkhead from RH seat.

Pair - C2929 Earth – Glovebox Release Sol - BG, 0.5 - RH Eyelet

C0811 Earth – Seat-Passenger - BU, 2.5 - LH Eyelet

Pair - C2920 Earth – Fuel Flap Rel Sw - BK, 0.5 - RH Eyelet

C0709 Earth – DIM - BK, 0.5 - LH Eyelet

Pair - C2998 Earth – Phone - BR, 0.5 - LH Eyelet

- C2921 Earth – Fuel Flap Rel Sw TT - BR, 0.5 - RH Eyelet

Pair - C2600 Earth – Drivers Door - BR, 2.5 - RH Eyelet

C0017 Earth – Rotary Coupler - BR, 0.5 - LH Eyelet

RHS of Bulkhead from RH seat.

Pair - C2570 Earth – CEM Noisy - BU, 2.5 - RH Eyelet

- C3002 Earth – Switcher-Speaker-Front - B, 1.0 - LH Eyelet

Pair - C0556 Earth – Multi Media Display - BR, 0.5 - RH Eyelet

- C0554 Earth – Wash Wipe Switch - BR, 1.5 - LH Eyelet

Pair - C2716 Earth – Glovebox Sw, Red Grd Sw - BU, 0.5 - RH Eyelet

- C1398 Earth – Module-Aircon - BU, 0.5 - LH Eyelet

Pair - C0706 Earth – Ind Sw, SAS, Key Reader - BR, 1.0 - RH Eyelet

- C0564 Earth – Regulator-Blower Speed - BR, 3.0 - LH Eyelet

Pair - C2629 Earth – OBD2 - B, 0.5 - LH Eyelet

C2601 Earth – Passenger Door - BR, 2.5 - RH Eyelet

Pair - C0821 Earth – Ind Stalk Trip Switch - BR, 0.5 - LH Eyelet

- C0707 Earth – Remote Receiver - BR, 0.5 - RH Eyelet

Location number 8 - LHS of Bulkhead from RH seat.

Page 69

Pair - C2628 Earth – OBD2 - BK, 0.5 - RH Eyelet

C2648 Earth – CEM Quiet, TPM - BK, 1.0 - LH Eyelet

Pair - C2999 Earth – Bluetooth Receiver - BK, 0.5 - RH Eyelet

- C2928 Earth – Module-HID Lighting - BK, 0.5 - LH Eyelet

Location number 9 - Front of top panel under facia from Location number 10 - Rear of top panel under facia from

RH seat. RH seat

Front of top panel under facia from RH seat.

Pair - C2646 Earth – Mstr Lock Sw, Boot Rel Sw - BG, 0.5 - RH Eyelet

- C1355 Earth – CCM Trip Switch - BG, 0.5 - LH Eyelet

Single - C1169 Earth – CCM Signal - BK, 1.5 - Eyelet

Rear of top panel under facia from RH seat.

Single - C1170 Earth – CCM - BG, 1.5 - Eyelet

Single - C0555 Earth – Signals - BK, 2.5 - Eyelet

Location number 11 - Behind LHS seat in rear quarter.

Location number 12 - Between seats under rear trim.

Page 70

Behind LHS seat in rear quarter.

Pair - C2630 Earth – Module-PDC - BU, 0.5 - RH Eyelet

C2727 Earth – FPDM - BU, 2.0 - LH Eyelet

Pair - C2568 Earth – Seat-Driver-Heater - BU, 1.5 - RH Eyelet

- C2567 Earth – Seat-Driver - BU, 2.5 - LH Eyelet

Between seats under rear trim.

Pair - C2922 Earth – CHMSL - BY, 0.5 - RH Eyelet

- C2692 Earth – Bt Mtr, Fuel Flap Sol - BY, 2.0 - LH Eyelet

Single - C2599 Earth – Socket Access / Lighter - BU, 2.0 - Eyelet

Location number 13 - Behind RHS seat in rear quarter. Location number 14 - Inside RH rear wheel arch liner.

Behind RHS seat in rear quarter.

Pair - C2647 Earth – BDS Switch - BU, 0.5 - RH Eyelet

C2569 Earth – Seat-Passenger-Heater - BU, 1.5 - LH Eyelet

Single - C2712 Earth – Rear Door Ajar - BK, 0.5 - Eyelet

Inside RH rear wheel arch liner.

Pair - C0808 Earth – Amplifier - BG, 4.0 - RH Eyelet

C2634 Earth – GPS Tuner - BG, 0.5 - LH Eyelet

Pair - C2697 Earth – Boot Fusebox - BG, 1.0 - RH Eyelet

C2695 Earth – Rev Sw, Rr Brake Pad Wr - BG, 1.0 - LH Eyelet

Page 71

Location number 15 - In RHS boot compartment.

In RHS boot compartment.

Pair - C1679 Earth – Heated Rear Window - BR, 2.5 - RH Eyelet

- C2605 Earth – Rear Lamp-LH - BR, 1.0 - LH Eyelet

Pair - C2604 Earth – Rear Lamp-RH - BR, 1.0 - RH Eyelet

- C2602 Earth –Sounder, Vacuum Pump - BR, 2.0 - LH Eyelet

Pair - C2924 Earth – Multi-Media Module - BR, 0.5 - RH Eyelet

- C2926 Earth – Number Plate Lamps - BR, 0.5 - LH Eyelet

Correct as of 26-07-05. Subject to change.

Page 72

AAMMLL CCiirrccuuiitt AAmmmmeennddmmeennttss

VVAANNTTAAGGEE 22000055MMYY MMaannuuaall CCoouuppee

This lists the pages that have been modified / added / deleted since the initial release on 15

Amendment page added to circuits. - 2

Pages for earth stud location added. - 2

Rear Door Ajar Earths added. - Page 28 - 8

Spanish Oak location detail modified. - Page 30 - 8

C Number list – numeric order added. - 10

th

July 05.

nd

August 05

nd

August 05

th

August 05

th

August 05

th

August 05

Loading...

Loading...