Page 1

ASTON MARTIN

A PRODUCT OVERVIEW

Part lV

Baby Astons

to

Casino Royale

Page 2

2

Bibliography

With thanks to

Aston Martin V8 Michael Bowler Cadogan Publishing

Aston Martin & Lagonda David G Styles The Crowwood Press

Aston Martin Buyers Guide Paul R Woudenberg Motorbooks International

Aston Martin V8s F Wilson McComb Osprey Auto History

Aston Martin Gold Portfolio R M Clarke Brooklands Books

Aston Martin Road Tests Adrian Feather The Scolar Press

Aston Martin Dudley Coram Motor Racing Publications

AMOC Registers AMOC

The Most Famous Car David Worrall Solo Publishing

in the World

Aston Journal of the Aston Aston Martin Heritage

Martin Heritage Trust Trust

Power, Beauty and Soul David Dowsey Peleus Press

www.astonmartin.com

Page 3

3

I have been working in the world of Aston Martin for the past 25 years. I came upon

the marque in my general course of business in the motor trade and have become as

enthusiastic as my customers about Aston Martin and their products.

My son Matthew and I with my first Aston Martin

There is an aura about Aston Martin, a heritage far beyond simple statistics. Winning

at Le Mans, victory in the World Sportscar Championship, the Zagatos and Royal

patronage would be enough for any car manufacturer. Aston Martin goes beyond that

– every car has its character and every owner, real pride in his or her car.

Any market place has pitfalls for the unwary and opportunities for the unscrupulous.

What I have tried to produce is an overview of Aston Martin cars that can act as an

introduction to the marque. It is my view, coloured by my experiences and the use of

my library of Aston Martin books as a reference. Most of the Aston Martin photos

are from my own archive and I have been fortunate enough to enjoy handling each of

these glorious cars.

This may represent your first foray into the world of Aston Martin; it may supplement

your own knowledge. Whatever your point of reference, I hope this overview adds

to your enjoyment.

Philip Jones

Byron International

Page 4

4

ASTON MARTIN DB7

Production dates: October 1994 – April 1999

Top Speed: 157 mph

Acceleration: 0 – 60 mph 5.8 secs 0 – 100 mph 14.4 secs

Chassis numbers: SCFAA111VK 100001 - 102703

Length 182.3 inches (4631mm)

Width 71.6 inches (1820 mm)

Height 50 inches (1268 mm)

Ground clearance

Track Front 60 inches (1524 mm)

Rear 60.2 inches (1530 mm)

Wheelbase 102 inches (2591 mm)

Turning circle

Dry weight 3,797 pounds (1,725 Kg)

Engine 3.2 straight six supercharged

Capacity 3228 cc

Cylinder bore 91mm (stroke 83 mm)

Compression ratio 8.3:1

Power output 335 bhp @ 5,600 rpm

Fuel Injection: Zytec electronic multi-point sequential

Chassis All steel semi-monocoque with steel panels

Composite bonnet, front wings, sill and boot lid

Transmission Getrag 5 speed gearbox

4 speed GM Automatic option

Clutch Hydraulically operated

Front suspension Independent, unequal length wishbones with anti dive geometry

Coils springs over telescopic dampers, anti roll bar

Rear suspension Independent wishbone with drive shaft as upper link

Longitudinal control arms, coil springs over telescopic dampers

Steering Power assisted rack and pinion

Brakes Teves anti lock control

Front 11.2” discs (285mm)

Back 11.6” discs (295mm)

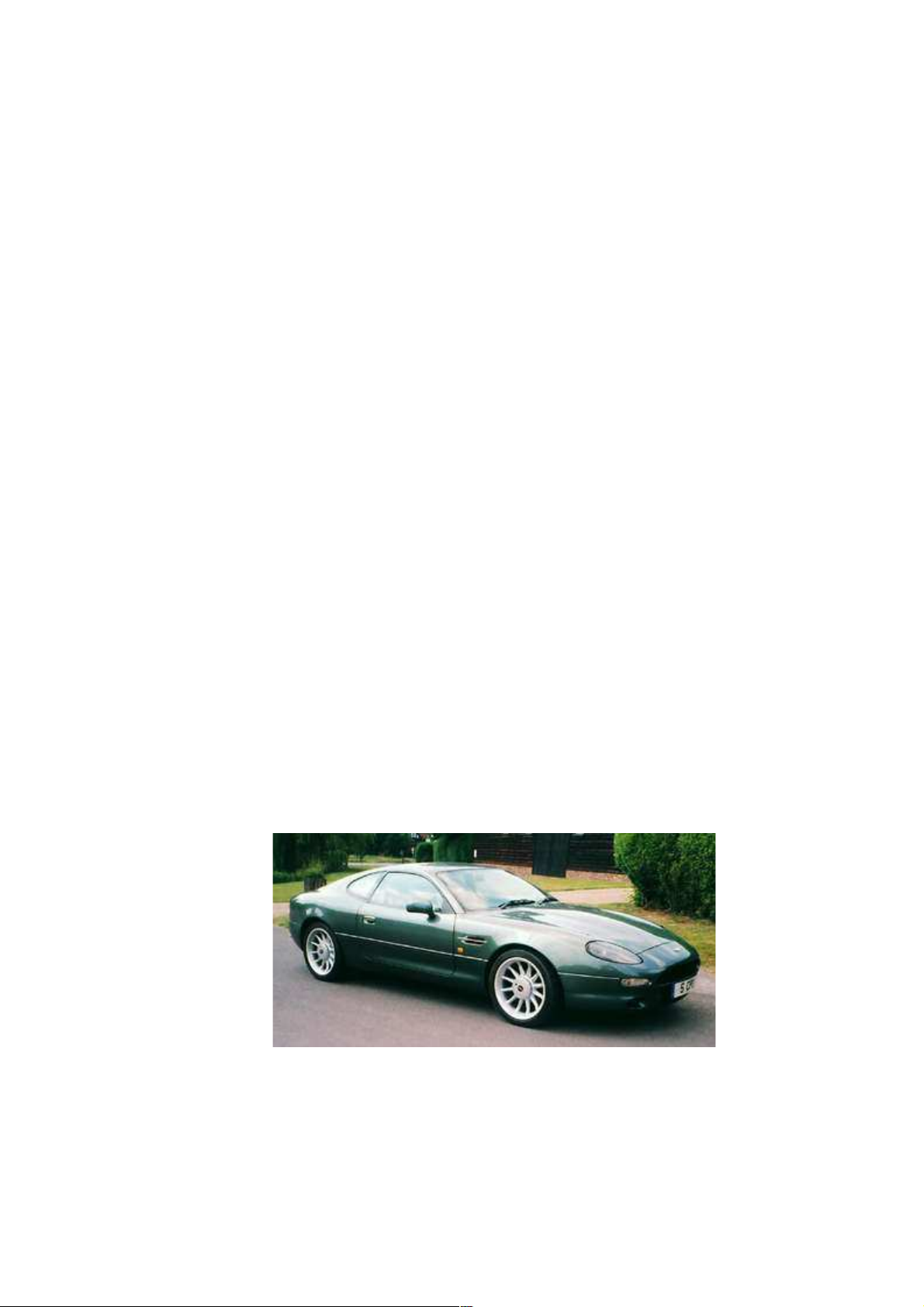

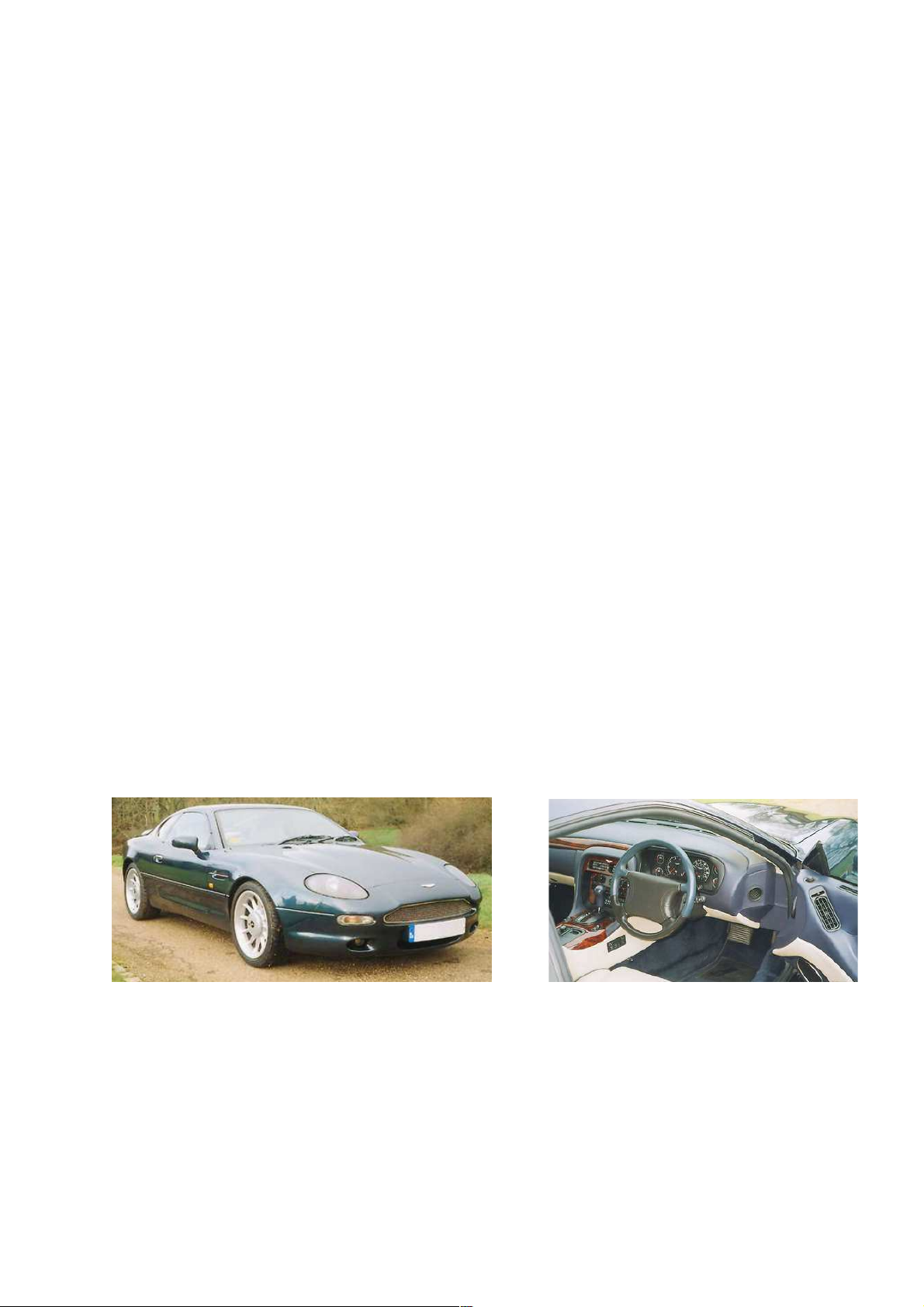

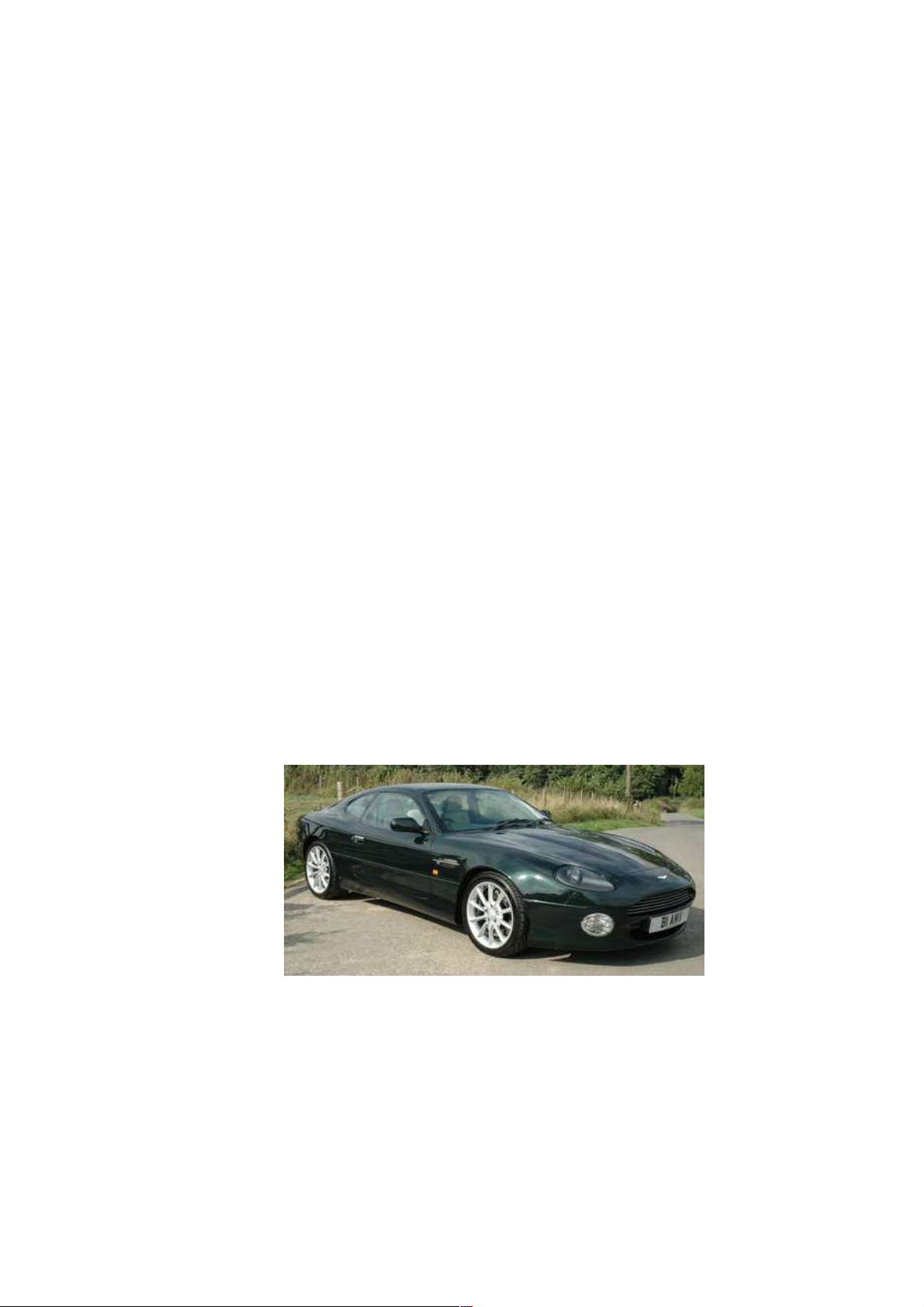

1995 Aston Martin DB7

Chassis No: SCFAA1115SK 100165

© BYRON INTERNATIONAL

Page 5

5

Aston Martin had always looked to the support of its shareholders but economic conditions of the

early 1980’s meant that for a change, Newport Pagnell was propping up its shareholders’ businesses.

Up to 1987 there had been a number of changes in stockholdings but it was in that year that, Victor

Gauntlett had realised that with ever more stringent legislation on automotive production, exhaust

emissions and type approval, Aston Martin needed a more stable financial platform and assistance in

research and development. Later that year, the announcement was made that Ford had acquired

75% of Aston Martin Lagonda with Gauntlett remaining as Chairman and retaining 12 ½ % equity

with the remaining 12 ½ % in the hands of Peter Livanos.

In 1990, Victor Gauntlett had instigated thoughts of a “small” Aston Martin but had departed for

pastures new before that idea came to fruition on the company’s stand at the 1993 Geneva Motor

Show under the direction of Ford’s Walter Hayes. In deference to the new Life President it was

named the DB7 and was a truly collaborative success.

Walter Hayes had persuaded a reluctant Ford board to invest in the project and he had been able to

call on Ford expertise and resource to bolster the Aston Martin engineers. Utilising the old Jaguar

XJ220 factory at Bloxham, Aston Martin Oxford Limited, a joint venture with Tom Walkinshaw,

became the home of the new car. Tom was also instrumental in the design of the car insofar as a

young Scottish designer had left Ford in 1990 and become General Manager and Chief Designer for

TWR’s design studios. That designer was Ian Callum and he was tasked to design the new small

Aston.

The designer claimed that the design processes leading up to the DB7 owed their generation to his

childhood when a family friend had a DB4. The brief was that the car had to be clearly a 1990’s car

whilst paying due homage to the DB heritage. Callum grew to understand that the old DB’s looked

the way they did because the cabin got narrower as it gets towards the tail. Combining these design

cues with a muscularity in the rear wings, shaping of the body corners and giving the car a long

raking backlight delivered a car that, whilst a little wider than the DB6, was virtually identical in

overall length.

Ian Callum described the old Aston Martin grille as having facial characteristics, “....a contented,

elegant, slightly arrogant smile that no other car could ever have. Its pure James Bond... It’s Sean

Connery, that car!” But Aston Martin heritage isn’t Bond, it’s racing – what was needed was a very

elegant, very simple design.

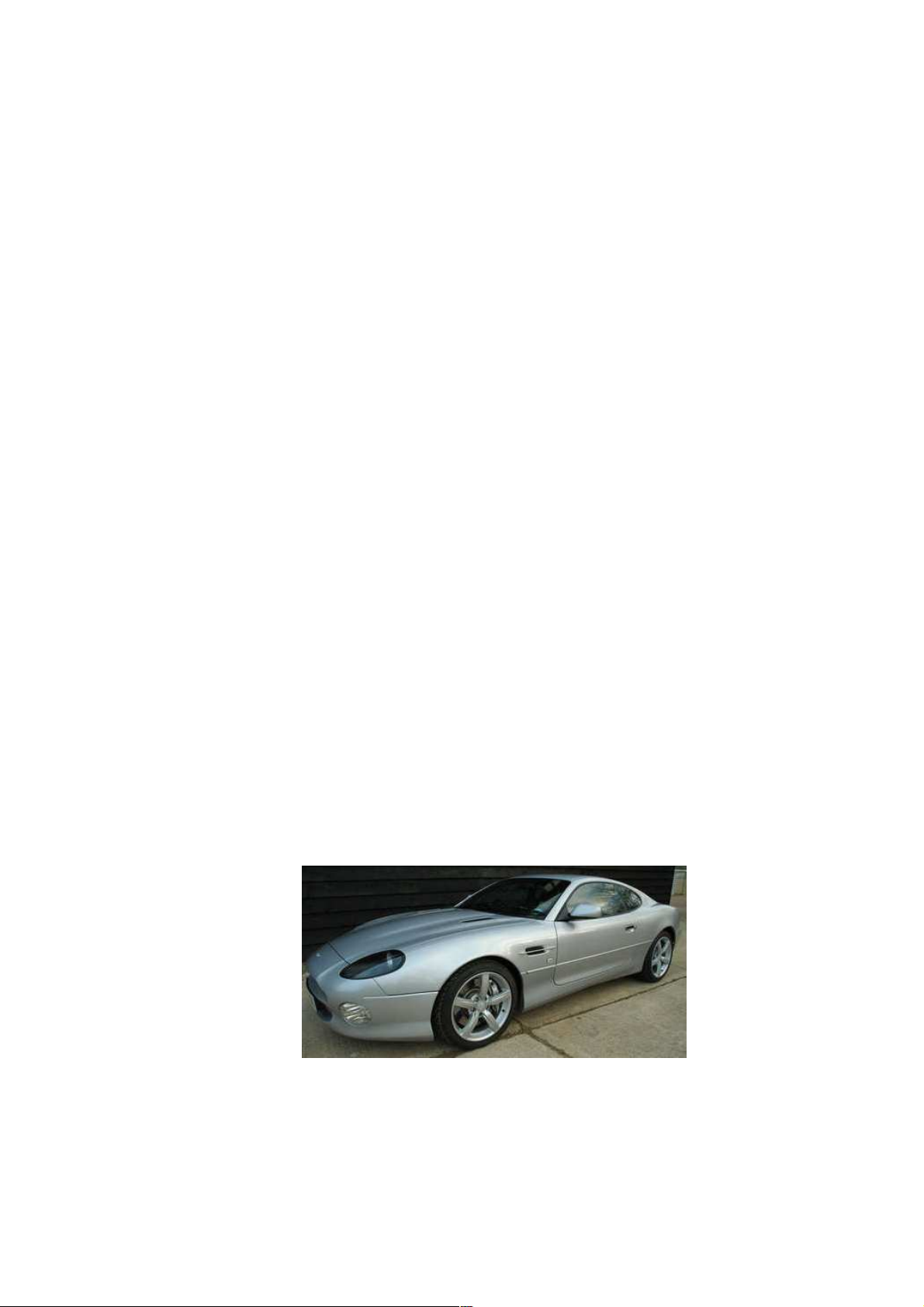

1996 Aston Martin DB7

Chassis No: SCFAA111XVK101218

© BYRON INTERNATIONAL

Callum knew there was no place for “hair shirt nostalgia” on the interior. However, Walter Hayes

rejected the first efforts as too stark and by blending a combination of traditional veneers and softer

colours, the final effect was traditional Aston Martin in the shell of a modern sports car. When you

sank into the hand sewn Connolly hide, you had to have an emotional vista – as Ian Callum

concluded, “..why should people on the outside have the best view of it.

Page 6

6

ASTON MARTIN DB7 VOLANTE

Production dates: October 1996 – 2003

Top Speed: 152 mph

Acceleration: 0 – 60 mph 6.5 secs 0 – 100 mph 17.6 secs

Chassis numbers: SCFAA311 – TK 201001

Length 184 inches (4646mm)

Width 72 inches (1830 mm)

Height 49 ½ inches (1260 mm)

Ground clearance

Track Front 60 inches (1524 mm)

Rear 60.2 inches (1530 mm)

Wheelbase 102 inches (2591 mm)

Turning circle

Dry weight 4,132 pounds (1,875 Kg)

Engine 3.2 straight six supercharged

Capacity 3228 cc

Cylinder bore 91mm (stroke 83 mm)

Compression ratio 8.3:1

Power output 335 bhp @ 5,600 rpm

Fuel Injection: Zytec electronic multi-point sequential

Chassis All steel semi-monocoque with steel panels

Composite bonnet, front wings, sill and boot lid

Transmission Getrag 5 speed gearbox

4 speed GM Automatic option

Clutch Hydraulically operated

Front suspension Independent, unequal length wishbones with anti dive geometry

Coils springs over telescopic dampers, anti roll bar

Rear suspension Independent wishbone with drive shaft as upper link

Longitudinal control arms, coil springs over telescopic dampers

Steering Power assisted rack and pinion

Brakes Teves anti lock control

Front 11.2” discs (285mm)

Back 11.6” discs (295mm)

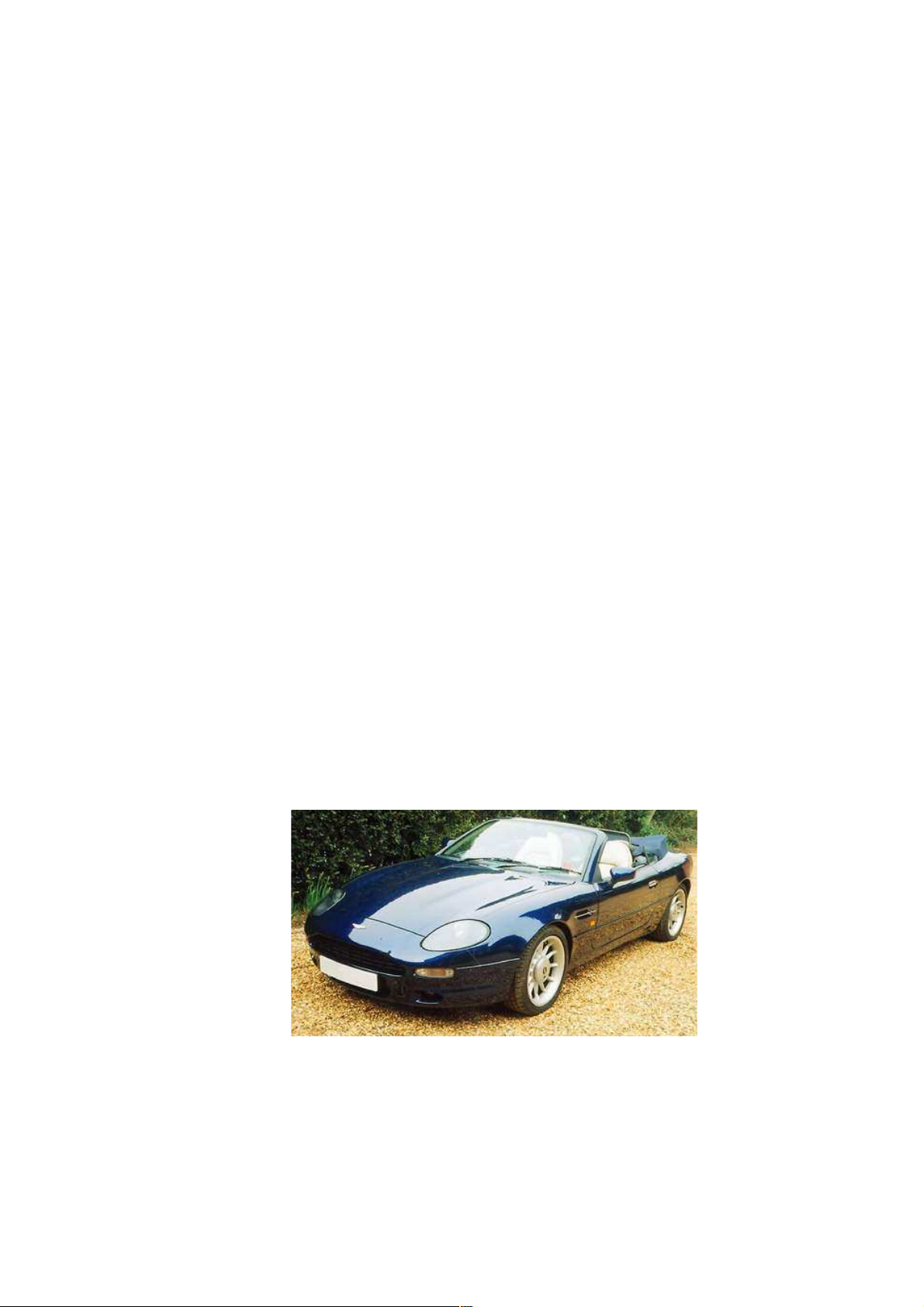

1997 Aston Martin DB7 Volante

Chassis No: SCFAA3117VK 201479

© BYRON INTERNATIONAL

Page 7

7

The Volante soft top version of the DB7 was planned from the beginning and the development of a

dedicated convertible design began once the form of the coupe had been established. But the two

cars were treated as separate entities with no thought of compromise.

“We actually clay modelled the raised roof” recalled Ian Callum in a recent interview, “and I worked

closely with the trimmers at Aston Martin to learn the constraints coming from the hood material

and the folding mechanism, and to ensure that the hood had the correct form. The skills of the

trimmers ensured that the silhouette of the raised roof reflects the purity and elegance that

characterised the rest of the car.”

The end result is that, from the edge of the doors forward, the Volante is virtually identical to the

coupe. However the rear panels are redesigned to produce a shape with a longer boot lid and

stowage space for the hood, though this was not designed to fold out of sight. What was out of

sight was the extra stiffening and the strengthening of the screen surround which delivered some

degree of roll over protection.

To satisfy US type approval, a larger rear bumper was fitted pushing the overall length up by 3

inches. The tailored hood was operated by electric controls and the overall weight of the car raised

a total of 150 kilograms. So in spite of the otherwise unchanged specification (no rear anti roll bar)

slower acceleration and lower top speeds resulted.

The construction of the DB7 was a departure from established Aston Martin practice. Rather than

the traditional hand-made aluminium skin attached to a steel platform, the new car had a steel semimonocoque bodyshell with steel panels together with composite bonnet, sills and boot lid.

The bodies were made in Coventry and then sent to Rolls Royce in Crewe for painting and finally to

the new facility at Bloxham where engines, running gear and interior trims were fitted. The

installation of a new paint plant at Bloxham in 2000 shortened that production process and put

Aston Martin in closer control.

The light alloy, twin camshaft supercharged straight six engine had four valves per cylinder while the

Eaton (Roots type) supercharger ran off a multi grooved flat belt. The engine was designed to run

on unleaded petrol and to meet the emission standards anywhere in the world.

It developed 335bhp at 5600 rpm and driving through a 5 speed Getrag gearbox gave a top speed of

157 mph to go with a sub six second zero to sixty miles per hour.

The resources that Walter Hayes was able to bring to the development of the DB7 made it probably

the best tested and prepared car ever from Aston Martin. Its early announcement and presentation

at Geneva in March 1993 allowed the car to be seen in public during its crucial final development

phase. It meant that a total of 30 prototypes were driven in every condition from the heat of

Arizona to the cold of snow driven Scandinavia.

When originally shown the car was presented with a Targa top – it was more of a removable

sunroof panel with its own carrying case with the main roof structure in place when it was removed.

However, research, of customers’ opinion, showed that good air conditioning was preferred on a

coupe with a genuine soft top requested by the fresh air fanatics.

Inevitably, it was not long before lure of performance and product development saw the first

departure from the standard production car. It was conceived as a plan to develop a single make

racing series and Prodrive, the race and rally specialists were asked to develop two prototypes.

Page 8

8

ASTON MARTIN DB7 VANTAGE

Production dates: March 1999 August 2003

Top Speed: 185 mph

Acceleration: 0 – 60 mph 5.2 secs 0 – 100 mph 11.9 secs

Chassis numbers: SCFAB121 – XK 300001-304458

Length 184 inches (4666mm)

Width 72 inches (1830 mm)

Height 48 inches (1238 mm)

Ground clearance

Track Front 60 inches (1524 mm)

Rear 60.2 inches (1530 mm)

Wheelbase 102 inches (2591 mm)

Turning circle

Dry weight 3,916 pounds (1,780 Kg)

Engine 6.0 litre V12

Capacity 5935 cc

Cylinder bore 89 mm (stroke 79.5 mm)

Compression ratio 10.3:1

Power output 420 bhp @ 6,000 rpm

Fuel Injection: Electronic multi-point sequential with Visteon EEC V

Transistorised engine management

Chassis All steel semi-monocoque with steel panels

Composite bonnet, front wings, sill and boot lid

Transmission Tremex 6 speed gearbox

5 speed ZF Automatic option with traction control

Clutch Hydraulically operated twin plate

Front suspension Independent, unequal length wishbones with anti dive geometry

Ball jointed kingpins

Coils springs over telescopic dampers, anti roll bar

Rear suspension Independent wishbone with drive shaft as upper link

Longitudinal control arms, coil springs over telescopic dampers

Steering Power assisted rack and pinion

Brakes Brembo brake system with Teves anti lock control

Front 14” discs (355mm) Ventilated, cross drilled steel

Back 11.6” discs (295mm) Ventilated

1999 Aston Martin DB7 Vantage Automatic

Chassis No: SCFAB123XYK 300128

© BYRON INTERNATIONAL

Page 9

9

Prodrive took two cars and undertook a weight loss exercise – all electrical controls for windows

and seats were lost as was the glass in the side windows – lightweight aluminium window frames

held acrylic sheets instead. Aluminium radiators were introduced while TWR further enhanced the

engine performance by 50 bhp and a new gearbox and clutch were fitted to absorb the power.

Unfortunately there was insufficient interest in a one make series and the completed cars found their

way to “gentleman racers”.

Around 1998 there was collaboration with Alfred Dunhill adding luxury Dunhill items and

accessories to the car and resulted in some 79 cars being marketed. Aston Martin Sales in Mayfair

also instigated a “special”known as the DB7GTS ll with a number of cosmetic feature differences, but

there was still a performance focus at Aston Martin that lead to Project Vantage.

This was a show car that surfaced at the Detroit Motor Show in 1998 and reflected designer Ian

Callum’s desire to put the car, and Aston Martin, back into the muscle car league. Featuring

aluminium extrusions bonded together with carbon fibre mouldings to create a chassis platform and

wheels pushed as far out of the wheel arches as possible – the car made use of V12 power and

added items like a paddle shift gearbox. It was very much a precursor to the 1999 Geneva Motor

Show when Aston Martin launched their new car – the DB7 Vantage.

The only shared item with Project vantage was the V12 engine, but the new model was still a

stunning car. The 48 valve, all alloy 60 degree V12 had been developed by Cosworth and forged in

their foundry. It incorporated the latest Formula 1 technology and had a Visteon engine

management system capable of processing 1.6 million commands per second.

The car, like the original DB7, had been subjected to a rigorous test programme – not for Aston

Martin of the ‘90’s was there to be discoveries about high speed engine problems as they had

experienced in the 1960’s with the DB4. The DB7 Vantage had a high speed durability test running

for 48 hours continuously at 165 mph in hot mid-summer in Southern Europe. The new engine

produced a massive 420 bhp and a performance potential of over 180 mph and there had to be

other areas of development in the car. The Brembo brakes, run through a Teves four channel antilock braking system, had ventilated, cross drilled front discs of 14” diameter.

Special 15 inch alloy wheels were specially developed with 9 inch rims at the rear and 8 inch rims for

the front wheels. Added to that were an advanced traction control system and revised suspension.

New upper and lower wishbones linked a new vertical link at the front while at the rear, there was

an additional transverse link incorporated. The modifications were completed by Bilstein shock

absorbers and uprated springs. To accommodate the V12 engine and the associated 6 speed manual,

5 speed automatic or Touchtronic transmission, the underside of the car had to be redesigned. This

involved an enlarged transmission tunnel and new front end structure with increased strength and

torsional rigidity built into the revised structure.

New cooling requirements meant wider radiator openings and justified the new bright metal grille

while new bumpers and integrated sill design blended in the other subtle external differences. Inside

the car was standard Aston Martin luxury with Connolly hide, Kenwood car stereo and the

introduction of a large red starter button mounted in the centre console.

At missile control, that red starter button would have a large, lockable lever preventing accidental

use, such is the power it unleashes. Press the button and almost primeval forces are set free, the

initial thunder of the engine settling back into a barely perceptible burble. Engage gear, brace your

neck and accelerate – power, beauty and soul.

But buy any DB7 and it will be specified to exactly the demands of its first customer with

personalisation of anything from external colour to choice of accessory

Page 10

10

ASTON MARTIN DB7 VANTAGE GT and GTA

Production dates: 2002

Top Speed: 185 mph

Acceleration: 0 – 60 mph 4.9 secs

Chassis numbers: Within the Vantage Series

Length 184 inches (4666mm)

Width 72 inches (1830 mm)

Height 48 inches (1238 mm)

Ground clearance

Track Front 60 inches (1524 mm)

Rear 60.2 inches (1530 mm)

Wheelbase 102 inches (2591 mm)

Dry weight 3,916 pounds (1,780 Kg)

Engine 6.0 litre V12 – recalibrated for fuel and ignition

Capacity 5935 cc

Cylinder bore 89 mm (stroke 79.5 mm)

Compression ratio 10.3:1

Power output 420 bhp @ 6,000 rpm

Fuel Injection: Electronic multi-point sequential with Visteon EEC V

Transistorised engine management

Chassis All steel semi-monocoque with steel panels

Composite bonnet, front wings, sill and boot lid

Transmission Quickshift gearbox (GT only) reduces shift displacement by

16% - final drive ration 3:77 -> 4:09

5 speed ZF Automatic option with traction control

Clutch AP twin plate race clutch

Front suspension Independent, unequal length wishbones with anti dive geometry

Ball jointed kingpins revised dampers and stiffer bushes

Bump stop lowered

Coils springs over telescopic dampers, anti roll bar

Rear suspension Independent wishbone with drive shaft as upper link

Longitudinal control arms, coil springs over telescopic dampers

Additional brace fitted

Steering Power assisted rack and pinion – improved rack location and

lateral snubber bushes

Brakes Racing style Brembo brake system with Teves anti lock control

Front 14” discs (355mm) Ventilated, cross drilled steel grooved

Back 11.6” discs (295mm) Ventilated & grooved

Exhaust System Active sports system with by pass valves

2003 Aston Martin DB7 Vantage GTA

Chassis No: SCFAB12323K 304176

© BYRON INTERNATIONAL

Page 11

11

In spite of the outstanding performance of the DB7 Vantage, there remained an ethic of continuous

improvement within Aston Martin. Nowhere is that better demonstrated, than in the

announcement, at the Birmingham Motor Show of October 2003, of the DB7 Vantage GT and GTA.

A review of the specification sees evidence of small gains in every area of the car’s performance –

the engine power moved up to 435 bhp and the torque went up by 10 pounds to 410 lb ft. A

redesigned and shorter gear lever (on the GT) gave a quicker gear change and together with a lower

final drive ratio improved the acceleration to get the 0 – 60 mph under 5 seconds. 265/30 tyres on

the rear and 245/35 on the front allowed for the additional performance and the revised exhaust

helped the breathing.

Better suspension, cooling and reduced lift all contributed to additional performance – but Aston

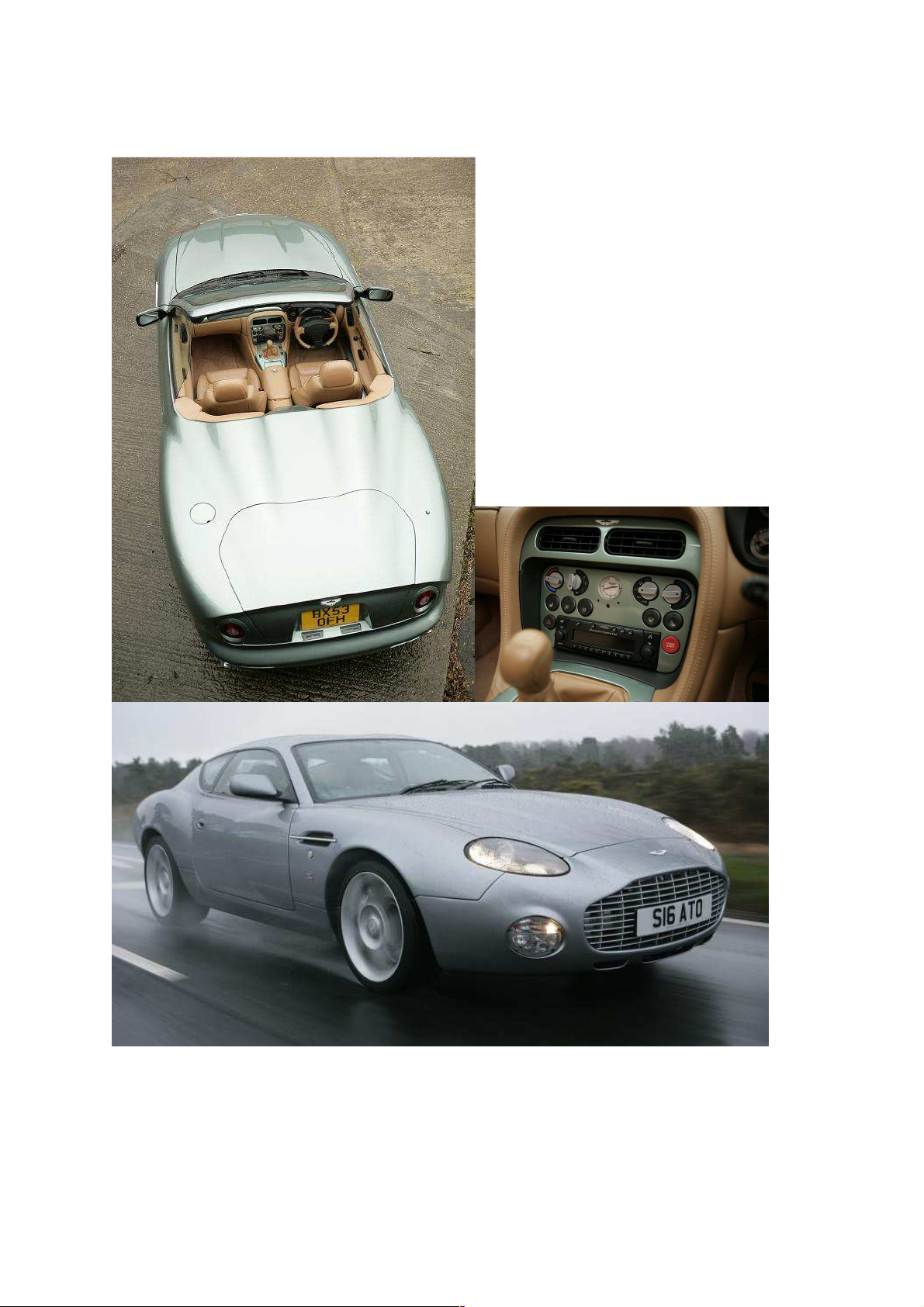

Martin didn’t stop there – in 2002, Henrik Fisker, the new Director of Design at Aston Martin met

with Andrea Zagato, the third generation of his family to be involved in automotive art. The design

of the latest Aston Martin to wear the Zagato badge created in metal in just three months. The car

shared the chassis, windscreen structure and interior design of the DB7 Vantage Volante.

The roof, with Zagato’s signature “double bubble” and the rear wings were of steel while the rest of

the body panels were of hand formed aluminium. The chassis platform and wheelbase were

shortened by 60mm and the overall length by a total 211mm whilst the front and rear tracks were

widened. The front lighting was DB7 but the wide mouthed “egg box” grille and the pronounced

rear wing shaping was reminiscent of the original DB4GT Zagato. In overall terms the design saved

60lbs of weight.

The interior was special to Zagato with hand stitched aniline leather, dyed not colour coated, and

quilted. The space behind the passenger’s and driver’s seats were devoted to luggage with retaining

straps and nets. Exactly 100 of these cars were built but they were not the only Zagato designed car

produced by Aston on the DB7 Vantage Volante. With the DB7 Vantage Zagato, Aston Martin had

tested the market with an exclusive showing to prospective customers amongst the tailored suits of

Gieves and Hawkes in Savile Row. For the American market – and truthfully the sunshine states –

the DBAR1 was shown to prospective customers in Los Angeles.

Thursday 2nd January 2003, an Aston Martin press release officially announced a concept Zagato

bodied roadster to be built to satisfy a niche in their ever expanding US market place. This unique

car was to be manufactured in a similar manner to the DB7 Zagato but as a roofless open two

seater-sports tourer. Dr Ulrich Bez emphasised that this car was a first for the company particularly

as it was specifically designed for the fair-weather Californian customer who wanted an exclusive

Aston Martin.

With a large and distinctive radiator grille, special multispoke 19” alloy wheels and accentuated rear

wheel arches, it was a hit with prospective buyers. A production run of 100 cars – all but two of

them in left hand drive – sold very quickly with the last of the run being retained by the factory.

As with the Zagato Coupe, the DBAR1 had the Volante base but, unlike the Zagato Coupe, it was

not shortened and it had the power train, suspension and brakes from the Vantage GT. The

Vanquish active sports exhaust was fitted with its bypass valve giving the DBAR1 a distinctive exhaust

note.

The braking was improved with the fitment of GT Brembo disc brakesand uprated Pagid RS 42-1

front pads. This delivered better sustained performance and removed judder and fade under heavy

braking.

Page 12

12

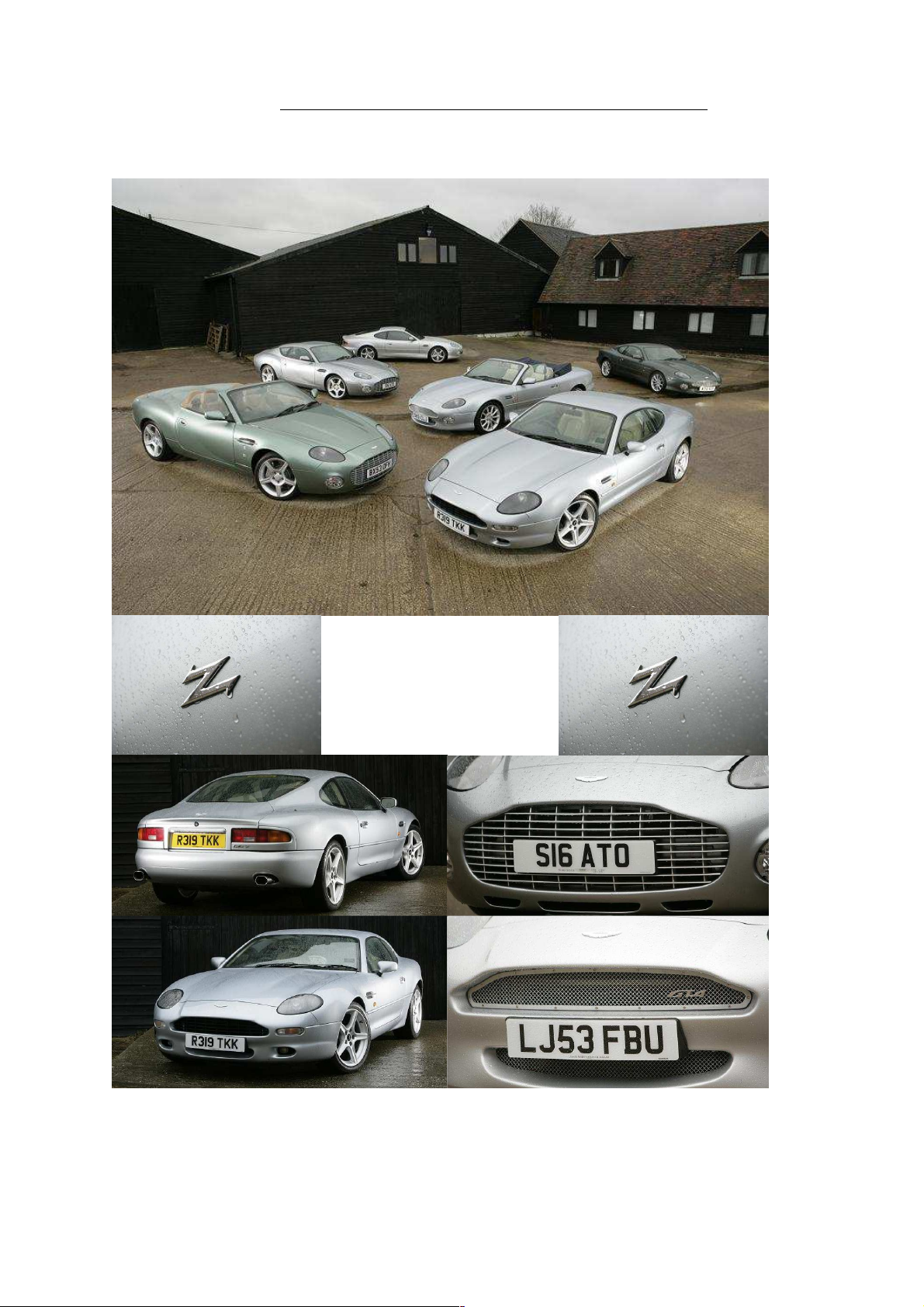

Byron International Customer Cars January 2007

(and 2 courtesy of Aston Martin Lagonda)

Page 13

13

Maybe an Aston

Martin DBAR1

does need a roof!!

Page 14

14

Page 15

15

ASTON MARTIN DB7 VANTAGE ZAGATO

Production dates: 2003

Top Speed: 180 mph

Acceleration: 0 – 60 mph 5.0 secs

Chassis numbers: SCFAE123-3K700001 - 700100

Length 176 inches (4481mm)

Width 72 inches (1830 mm)

Height 48 inches (1238 mm)

Ground clearance

Track Front 65 inches (1536 mm)

Rear 66 inches (1540 mm)

Wheelbase 99.7 inches (2531 mm)

Turning circle

Dry weight 3,836 pounds (1,740 Kg)

Engine 6.0 litre V12 – recalibrated for fuel and ignition

Capacity 5935 cc

Cylinder bore 89 mm (stroke 79.5 mm)

Compression ratio 10.3:1

Power output 420 bhp @ 6,000 rpm

Fuel Injection: Electronic multi-point sequential with Visteon EEC V

Transistorised engine management

Chassis All steel semi-monocoque with steel panels

Composite bonnet, front wings, sill and boot lid

Transmission Six speed manual final drive ratio 3:77 Limited Slip Differential

Touchtronic 5 speed Automatic fitted only to 710016

Clutch AP twin plate 228mm race clutch

Front suspension Independent, double wishbones with anti dive geometry

Coil springs, monotube dampers and anti roll bar

Rear suspension Independent double wishbone with longitudinal control arms,

coil springs over monotube dampers anti roll bar

Steering Power assisted rack and pinion, column tilt and reach adjuster

Brakes Racing style Brembo brake system with Teves anti lock control

Front 14” discs (355mm) Ventilated, cross drilled steel grooved

Back 330mm Ventilated & grooved with 4 piston callipers

Drum handbrake

Exhaust System Active sports system with by pass valves

Wheels and Tyres Lightweight 18” aluminium alloy with 8 “ front rims and 9” rear

245/40 tyres front 265/35 tyres rear.

Page 16

16

2004 Aston Martin DB7

Zagato

Chassis No:

SCFAE12343K700052

© BYRON INTERNATIONAL

Page 17

17

ASTON MARTIN DBAR1

Production dates: 2003

Top Speed: 185 mph

Acceleration: 0 – 60 mph 4.9 secs

Chassis numbers: SCFAD423-3K 800001 - 800099

Length 184 inches (4666mm)

Width 72 inches (1830 mm)

Height 48 inches (1238 mm)

Ground clearance

Track Front 60 inches (1524 mm)

Rear 60.2 inches (1530 mm)

Wheelbase 102 inches (2591 mm)

Turning circle

Dry weight

Engine 6.0 litre V12 – recalibrated for fuel and ignition

Capacity 5935 cc

Cylinder bore 89 mm (stroke 79.5 mm)

Compression ratio 10.3:1

Power output 420 bhp @ 6,000 rpm

Fuel Injection: Electronic multi-point sequential with Visteon EEC V

Transistorised engine management

Chassis All steel semi-monocoque with steel panels

Composite bonnet, front wings, sill and boot lid

Transmission Quickshift gearbox (GT only) reduces shift displacement by

16% - final drive ration 3:77 -> 4:09

5 speed ZF Automatic option with traction control

Clutch AP twin plate race clutch

Front suspension Independent, unequal length wishbones with anti dive geometry

Ball jointed kingpins revised dampers and stiffer bushes

Bump stop lowered

Coils springs over telescopic dampers, anti roll bar

Rear suspension Independent wishbone with drive shaft as upper link

Longitudinal control arms, coil springs over telescopic dampers

Additional brace fitted

Steering Power assisted rack and pinion – improved rack location and

lateral snubber bushes

Brakes Racing style Brembo brake system with Teves anti lock control

Front 14” discs (355mm) Ventilated, cross drilled steel grooved

Back 11.6” discs (295mm) Ventilated & grooved

Exhaust System Active sports system with by pass valves

2003 Aston Martin DB AR1

Chassis No: SCFAB26313K800025

© BYRON INTERNATIONAL

Page 18

18

ASTON MARTIN V12 VANQUISH

Production dates: Summer 2001

Top Speed: 306 kph (190 mph)

Acceleration: 0 – 60 mph 4.7 secs

Chassis numbers: SCFAC133341B 500001 -

Length 184 inches (4665mm)

Width 75.71 inches (1923 mm)

Height 51.89 inches (1318 mm)

Ground clearance

Track Front

Rear

Wheelbase 106 inches (2690 mm)

Turning circle

Dry weight

Engine 6.0 litre V12

Capacity 5935 cc

Cylinder bore 89 mm (stroke 79.5 mm)

Compression ratio 10.5:1

Power output 460 bhp @ 6,500 rpm

Fuel Injection: Electronic multi-point sequential with Visteon twin PTEC

engine management

Chassis Advanced aluminium/carbon composite construction

Transmission Six speed manual gearbox with ASM/SSM electro-hydraulic

Control system. SCP/CAN interface to engine management

Limited slip differential 3.69:1

Clutch

Front suspension Independent aluminium double wishbones,coil springs,

monotube damper and anti roll bar

Rear suspension Independent aluminium double wishbones,coil springs,

monotube damper and anti roll bar

Steering Power assisted rack and pinion

Brakes Teves anti lock control

Front 355mm Ventilated, cross drilled steel grooved 4 piston

caliper

Back 330mm Ventilated & grooved 4 piston calliper, separate

handbrake calliper

Electronic brake/engine intervention traction control system

Exhaust System Active sports system with by pass valves

2002 Aston Martin Vanquish

Chassis No: SCFAC133X2B500201

© BYRON INTERNATIONAL

Page 19

19

Ian Callum continued his design themes on to the hugely anticipated Vanquish – such was the

anticipation, that at the eventual launch of the car at Geneva in 2001, there was already a quote of a

12 month waiting list.

Inevitably, the body design retained a strong “family “ likeness to the DB7, looking like a bigger,

more muscular version of the Vantage – under the skin, it was a very different car. For a start, it

was being built at the newly refurbished factory at Newport Pagnell but most importantly, it had an

advanced aluminium/carbon composite chassis – making a strong, safe and rigid design, especially

suited for low volume production.

The main substructure of the car including the floor and the front and rear bulkheads had been

developed in conjunction with Lotus Engineering. It was formed of extruded aluminium sections

bonded and riveted around a carbon fibre central transmission tunnel. The inner body side sections

formed a single composite piece with carbon fibre windscreen pillars that were bonded to the main

substructure to form a single entity – a high strength safety cell.

Ahead of this passenger cell, a steel, aluminium and carbon fibre subframe carried the front

suspension and the engine/transmission. The distinctive Aston Martin mesh air intake was in fact a

stressed member providing additional protection and accommodating radiators for the engine,

transmission and air conditioning. A simple flat surface was developed for the underbody, enabling

air to be channelled into a venture section at the rear to aid aerodynamics.

Similarly, together with extruded aluminium side impact beams in the doors, the composite floor,

parcel shelf and side rails of the luggage area provided additional deformable crash protection.

For Aston Martin, the biggest change was the structure of the outer skin – in the past, panels had

been hand moulded by craftsmen out of individual sheets. The Vanquish body was made from

“super-plastic-formed and pressed aluminium – essentially shaped over a mould. It didn’t mean the

end of craftsmen – their skills were still needed for fixing the body to the central structure and the

fit and finish of every car.

A new 6 litre 450 bhp engine filled the under bonnet with sophisticated fuel and ignition management

through the Visteon twin PTEC engine management system. Transmission was through a six speed

gearbox. There was a paddle control system for the driver to drive manually but there was also an

automatic mode.....and a winter mode, and a sports mode.......the car was built to be the last word in

luxury motoring.

The performance of the car was targeted at 190 mph and a 0 – 60 well under 5 seconds, the

suspension was all new with front and rear forged aluminium wishbones, coil springs, telescopic

dampers and aluminium uprights with anti roll bars.

The waisted aluminium body sides and prominent rear wings covered massive 10J x 19” wheels with

Yokohama tyres that were needed to cope with the additional power that was delivered through a

limited slip differential with electronic traction control. The car could be specified in 2 seater or 2 +

2. leather from Connolly, carpets by Wilton and a dazzling array of extras and sensors that

controlled everything from lights to tyre pressures and wipers.

The final mark of approval for the car was a return of Aston Martin to a starring role in the new

James Bond film, Die Another Day. Rockets firing from the grille, machine guns out of the bonnet as

well as other devices, put Aston Martin and especially the Vanquish on very public display.

Page 20

20

ASTON MARTIN V12 VANQUISH ‘S’

Production dates: Summer 2004

Top Speed: 331 kph (200 mph +)

Acceleration: 0 – 60 mph 4.7 secs

Chassis numbers: In range of V12 Vanquish

Length 184 inches (4665mm)

Width 75.71 inches (1923 mm)

Height 51.89 inches (1318 mm)

Ground clearance

Track Front

Rear

Wheelbase 106 inches (2690 mm)

Turning circle

Dry weight

Engine 6.0 litre V12

Capacity 5935 cc

Cylinder bore 89 mm (stroke 79.5 mm) – new hot forged connecting rods

Compression ratio 10.5:1

Power output 520 bhp @ 7,000 rpm

Fuel Injection: Electronic multi-point sequential with Visteon twin PTEC

engine management remapped

Chassis Advanced aluminium/carbon composite construction

Transmission Six speed manual gearbox with ASM/SSM electro-hydraulic

Control system. SCP/CAN interface to engine management

Limited slip differential 3.69:1

Clutch

Front suspension Independent aluminium double wishbones,coil springs,

monotube damper and anti roll bar

Rear suspension Independent aluminium double wishbones,coil springs,

monotube damper and anti roll bar

Steering Power assisted rack and pinion

Brakes Teves anti lock control

Front 378mm Ventilated, cross drilled steel grooved 6 piston

caliper

Back 330mm Ventilated & grooved (2mm thicker than standard

Vanquish)4 piston calliper, separate handbrake calliper

Electronic brake/engine intervention traction control system

High performance brake pads

Exhaust System Active sports system with by pass valves

Aston Martin V12 Vanquish 2 + 2 Configuration

Chassis No: SCFAC13333B500557

© BYRON INTERNATIONAL

Page 21

21

The Aston Martin V12 Vanquish had established a clear position as flagship for the range. It had

replaced the old V8’s and worked successfully with its “little brother” the DB7.

However, at the Frankfurt Show in 2004, the DB7 was replaced with the all new Aston Martin DB9

and journalists and customers alike were saying, “Why buy the Vanquish when the DB9 has it all?”

Aston Martin’s riposte came a couple of weeks later in Paris where they showed what they called

“The fastest production car ever produced by Aston Martin” – the Vanquish S.

The simple “S” on the boot lid was obvious, as was the high mounted stop lamp – less obvious was

the subtle redesign that helped airflow and contributed to a reduction in the drag co-efficient to a

Cd of 0.32. Other styling and aerodynamic changes saw a more rounded, open appearance of the

grille for better cooling and a front splitter to improve stability.

Under the bonnet, new cylinder heads with fully machined inlet ports and combustion chambers

improved the airflow in the engine while revised engine mapping and new fuel injectors helped

increase the power output. The power increased to 520 bhp at 7,000 rpm and new, hot forged

connecting rods helped cope with the increased pressures in the engine.

To handle this extra performance, Aston Martin made a few other changes. The Sports Dynamics

package that had been offered as an option on other models, became a standard feature of the

Vanquish ‘S’. It gave improvements in the suspension and steering with stiffer springs and shorter

steering arms. The brakes were also upgraded significantly.

The diameter of the front pads was increased by 21% from 355mm to 378 mm which not only

increased the swept area but also allowed a 33% increase in thermal capacity meaning more heat

dissipation and less fade. Six piston callipers improved the operation of these larger brakes and the

use of floating discs gave a consistency of feel to the driver. The rear discs were the same diameter

as the standard Vanquish at 330mm but they were 2mm thicker which delivered a 21% increase in

thermal capacity. The final tweak to the brakes was a new pedal assembly to reduce travel and

improve feel.

Internally, Bridge of Weir leather replaced the Connolly hide in a cabin that mixed traditional Aston

Martin finish with contemporary metal interior fittings and finishes.

Having made the statement that this was the fastest production Aston Martin ever, the company

took a very responsible attitude to customers who purchased the Vanquish S. They were all eligible

for a Performance Driving Course at Millbrook in the UK, Lommel in Belgium or Romeo in Michigan.

With the Vanquish S no longer able to be sold in the US market, production of the Vanquish was no

longer viable and in February 2007, Aston Martin announced the last 40 cars would be Vanquish S

Ultimate Edition models. Only available in 2 + 2 format, these cars were finished in a unique colour

– Ultimate Black – and had semi-aniline leather seating with coarse stitching and a leather headlining.

In addition there were chrome interior highlights and each car came with personalised sill plaques

noting the owner’s name and the limited edition number of the car.

Although the Vanquish had been designed with the structural rigidity for easy conversion to a

Volante, Aston Martin did not produce one. However, with the backing of Aston Martin, Zagato

produced a Vanquish Roadster and displayed it on the stand at the 2004 Geneva Motor Show.

Unlike past offerings, Zagato did not create an entirely new look for the car with changes restricted

to the clever hood design and a rounding of the rear lights. In spite of customer interest, the display

model was the only one made.

Page 22

22

ASTON MARTIN DB9

Production dates: 2004

Top Speed: 306 kph (190 mph)

Acceleration: 0 – 60 mph 4.7 secs

Chassis numbers: SCFA01A4G A00001 -

Length 184 ½ inches (4697mm)

Width 73 inches (1875 mm)

Height 51 inches (1318 mm)

Ground clearance

Track Front 61¾ inches (1568mm)

Rear 61½ inches (1562mm)

Wheelbase 107 inches (2740 mm)

Turning circle

Dry weight 3762 lbs (1710 Kg) Manual

3872 lbs (1760 Kg) Automatic

Engine 6.0 litre V12

Capacity 5935 cc

Cylinder bore 89 mm (stroke 79.5 mm)

Compression ratio 10.3:1

Power output 450 bhp @ 6,000 rpm

Fuel Injection: Electronic multi-point sequential with Visteon EEC V

engine management system

Chassis Advanced aluminium/carbon composite construction

Transmission Graziano six speed manual transaxle

Touchtronic 2 shift-by-wire Graziano automatic

Limited slip differential

Clutch Hydraulically operated twin plate

Front suspension Independent double wishbones with anti dive geometry,

coil springs over telescopic dampers, anti roll bar. Ball jointed

king pins

Rear suspension Independent double wishbones, longitudinal control arms, coil

Springs over telescopic dampers controlled by an anti roll bar

Steering ZF rack and pinion, Servotronic speed sensitive power

assistance – column tilt and reach adjustment

Brakes Conti Teves stability control system with ABS, EBD (brake

Distribution), TC (traction control), EBA (brake assist) and

DSC (dynamic stability control)

Front: 355mm Ventilated, grooved 4 piston Brembo monobloc

calipers

Back: 330mm Ventilated 4 piston calliper, separate

handbrake calliper

2005 Aston Martin DB9 Coupe

Chassis No: SCFAC01A75GA02124

© BYRON INTERNATIONAL

Page 23

23

Launched at the Frankfurt Motor Show in September 2003, the DB9 was a huge step forward for

Aston Martin. Yes, it replaced the DB 7 but it was more than a successor, it was a move to a new

technological car manufacturing base. Ian Callum had moved to Jaguar and, in contrast with past

practice, 120 product designers using computer aided design and engineering (CAD/CAE) put a huge

raft of technological advances into the new car.

The factory at Bloxham had closed and the DB9 was the first product from the company’s new

purpose built facility at Gaydon. It was the first car built on Aston Martin’s VH (vertical/horizontal)

platform with its tub constructed from stamped aluminium sheets, cast aluminium joints and

aluminium extrusions bonded together with advanced adhesives and self- piercing rivets.

On to this light, immensely strong structure, the aluminium roof, bonnet and rear wings were

bonded together with the composite front wings. The resulting bodyshell was twice as rigid as the

DB7 but 25% lighter. The adhesive application at Gaydon involved another first for Aston Martin – a

robot they call James Bonder. In spite of this innovation, handcraftsmanship was still dominant and

every car took around 200 hours to build.

The strength and rigidity of the new car was tested at Volvo’s Safety Centre in Sweden. This was

part of an extensive development and testing programme for the car where 93 prototypes were

proven in the deserts of the USA, Arctic conditions and at test tracks at Lommel in Belgium and

Nardo in Italy.

The new car was stretched by 2 inches in length and 4 ½ inches in wheelbase compared with the

DB7 and a stunning design feature were the so called “swan wing” doors. This was a feature that

allowed the doors to open and swing up at a 12 degree angle allowing easier access but, more

importantly , stopping damage to the doors from high kerbs.

The engine was the third generation of the V12 unit first seen on Project Vantage but it was quite

different to the unit seen on the DB7 Vantage. With revised intake and exhaust system, new

manifolds, crankshafts and cams all managed by an upgraded engine management system. Most

controversially, and as a major departure from past Aston Martin practice, the engine production

was moved to Germany. Officially opened on 28th October 2004, the Aston Martin Engine Plant

(AMEP) was located within Ford’s Niehl engine plant near Cologne. It was a 12,500 square metre

facility dedicated to Aston Martin with all engine testing completed during assembly and V8 and V12

units being built concurrently. One tradition that was maintained from Newport Pagnell was that

each engine was built by one technician.

In the car, the engine linked with the rear-mounted ZF 6 speed drive-by-wire automatic transmission

by a cast aluminium torque tube and carbon fibre propshaft, which endowed the DB 9 with an

almost perfect 50:50 weight distribution. That had helped John Miles, the chassis designer, to finetune the chassis. Forged aluminium wishbones with aluminium dampers and anti roll bars front and

rear together with other performance enhancements like the ventilated and grooved disc brakes

with electronic brake assist, electronic braking distribution, traction control and dynamic stability

control.

Inside the cabin, seats by Recaro were clothed in Bridge of Weir leather while wood, including

walnut, mahogany and bamboo were used only in the centre console and, optionally on the door

cappings and were designed to look structural rather than just a veneer. Driver control included a

Formula 1 type “paddle” gear shift while the “organic electroluminescent display” was said to be

easier to read than traditional LCD screens while the dials included an anti-clockwise swinging

tachometer. A Linn audio system specially designed for the DB 9 was standard fitment but an option

list allowed customers to personalise their purchase.

Every feature of the car was uniquely Aston Martin.

Page 24

24

ASTON MARTIN DB9 VOLANTE

Production dates: 2004

Top Speed: 306 kph (190 mph)

Acceleration: 0 – 60 mph 5.0 secs

Chassis numbers: SCFAC02A75G4 B02349 -

Length 185 inches (4710mm)

Width 74 inches (1875 mm)

Height 53 inches (1318 mm)

Ground clearance

Track Front 61¾ inches (1568mm)

Rear 61½ inches (1562mm)

Wheelbase 108 inches (2740 mm)

Turning circle

Dry weight 3770 lbs (1710 Kg) Manual

3968 lbs (1800 Kg) Automatic

Engine 6.0 litre V12

Capacity 5935 cc

Cylinder bore 89 mm (stroke 79.5 mm)

Compression ratio 10.3:1

Power output 450 bhp @ 6,000 rpm

Fuel Injection: Electronic multi-point sequential with Visteon EEC V

engine management system

Chassis Advanced aluminium/carbon composite construction

Transmission Graziano six speed manual transaxle

Touchtronic 2 shift-by-wire Graziano automatic

Limited slip differential

Clutch Hydraulically operated twin plate

Front suspension Independent double wishbones with anti dive geometry,

coil springs over telescopic dampers, anti roll bar. Ball jointed

king pins

Rear suspension Independent double wishbones, longitudinal control arms, coil

Springs over telescopic dampers controlled by an anti roll bar

Steering ZF rack and pinion, Servotronic speed sensitive power

assistance – column tilt and reach adjustment

Brakes Conti Teves stability control system with ABS, EBD (brake

Distribution), TC (traction control), EBA (brake assist) and

DSC (dynamic stability control)

Front: 355mm Ventilated, grooved 4 piston Brembo monobloc

calipers

Back: 330mm Ventilated 4 piston calliper, separate

handbrake calliper

Page 25

25

Although launched at Detroit in 2004, the Aston Martin DB9 Volante was shown well ahead of

schedule and it wasn’t until the first half of 2005 that the first cars were delivered to the public.

Featuring taut aluminium and composite panels, the DB9 Volante was designed by Henrik Fisker. As

a departure from Aston Martin tradition, it had no soft tonneau cover, instead the folded roof fitted

neatly into the body under a hard, flush fitting panel. One push of the button and the hood raised or

lowered in just 17 seconds.

The design and operation of the roof was possible because the fabric was light, durable material,

which allowed for effective stowage meaning no loss of practicality in the car. The rear seats

remained unobstructed and the boot space was the same as for the coupe.

The DB9 Volante was conceived at the very start of the model’s production and the structural

rigidity of the design made it an ideal and practical convertible. Safety was addressed as well because

the car had tilt sensors that detected potential rollover accidents deploying twin hoops from the seat

headrests to protect the occupants.

Performance motoring remained at the centre of Aston Martin’s philosophy and in July 2006, it

announced an optional Sports Pack for the DB9. The package featured new, lighter 5 spoke alloy

wheels and a revised suspension package that included new spring rates, front anti roll bar and

dampers. This reduced the ride height by 6mm and a composite undertray was repaled with a load

bearing aluminium panel which added structural stiffness. The Sports Pack could be specified from

new or could also be retro-fitted.

The focus on performance and rumours of a return to racing had been fuelled as early as 2002 by

the appointment of Jeremy Main as Director of Product Development and Motorsport. On arriving

at the company, he conducted a Motorsport feasibility study and upon analysis, it was agreed to

establish a separate Motorsport division in partnership with Prodrive.

Prodrive had a strong reputation in world championship motorsport – their Chairman, David

Richards was a Rally World Champion co-driver, while his company had taken Subaru to Rally

World Championships for drivers and manufacturers.

Worldwide interest in sports car racing at this time was rising and new regulations were drafted by

Automobile Club de l’Ouest, who run Le Mans. This would allow production based cars to compete

in the 24 hour race on equal terms.

At the launch, David Richards said “At Aston Martin Racing, we will take care of all racing activity for

Aston Martin for the next five years. The first venture in this is to build the DB 9 race car.”

The DBR9 was officially unveiled to the press on 4th November 2004 at Gaydon. Finished in Aston

Racing Green with a yellow nose cone, it had the number 59 to commemorate the 1959 Aston

Martin Le Mans victory. Dr Bez, Chief Executive, said “The DBR9 is the first step in our return to

Motorsport. I know that our customers and enthusiasts alike are looking forward to seeing Aston

Martin racing again at an international level.”

Page 26

26

THE NEW

ASTON MARTIN DB9

Production dates: 2013 -

Top Speed: 295 kph (183 mph)

Acceleration: 0 – 62 mph 4.2 secs

Chassis numbers:

Length 4720mm

Width 2061 mm with mirrors

Height 1282 mm

Ground clearance

Track Front

Rear

Wheelbase 2740 mm

Turning circle

Dry weight 1785 kg

Engine 6.0 litre V12

Capacity 5935 cc

Cylinder bore

Compression ratio 10.9:1

Power output 510 bhp @ 6,500 rpm

Fuel Injection: Sequential electronic fuel injection system with SCP/Can

Interface to engine management control system

Chassis Extruded aluminium bonded monocoque

Transmission Rear mid-mounted ‘Touchtronic 2’ six-speed transmission with

electronic shift-by-wire control system

Limited slip differential

Final Drive Ratio Manual: 3.46:1

Alloy torque tube with carbon fibre prop shaft

Front suspension Independent with double aluminium wishbones.

Anti dive geometry. Coil springs, monotube

dampers, anti roll bar.

Rear suspension Independent with double aluminium wishbones.

Coil springs, monotube dampers, anti roll bar

Steering Rack and pinion –

power-assisted steering, 3.0

turns lock-to-lock

Brakes Stability control system with ABS, EBD (brake

distribution), TC (traction control), EBA (brake

assist) and DSC (dynamic stability control)

Front: 398mm Ceramic six piston calipers

Back: 360mm Ceramic four piston calipers

Exhaust System Fully catalysed stainless steel lightweight sports exhaust system with

active bypass valves

Page 27

27

Launched to acclaim in 2003 at the Frankfurt Motor Show DB9 was the first car to be produced at Aston

Martin's Gaydon Headquarters. Powered by a V12 engine, the 'DB' name skipped '8' to avoid the perception

that the car incorporated a V8 engine. This was also the first Aston Martin to be developed on the VH

(Vertical / Horizontal) Platform which underpins all Gaydon produced cars. This advanced engineering

platform allowed for unparalleled production flexibility and engineering excellence.

In replacing that original car, Aston Martin set out to build the best DB9 they had ever produced. It is

powered by the all-new AM11 engine, the most powerful in DB9's history. Its 6.0-litre capacity delivering 517

PS, a 0-62 mph time of just 4.6 secs and 620 Nm of torque – a significant 10% increase on the previous model.

AM11 had also been specifically engineered to give an extra 40 Nm of torque between 0 and 4000 rpm,

meaning impressive improvements at both high and low engine speeds and additional power at higher revs.

Technology integrated from our GT race car programme such as CNC-machined combustion chambers and

hollow cam shafts mean AM11 is also as advanced as it is powerful.

Revolutionary Carbon Ceramic Matrix brakes made their DB9 debut. Larger than an equivalent steel brake

but an impressive 12kg lighter, they reduce fade through better heat dissipation and improved performance

through silicon-injected carbon fibre. Reduced rotational inertia and a lower un-sprung mass deliver razor

sharp handling with a level of driver feel never reached before on DB9.

This latest DB9 introduced a new suspension system, Gen4. Aston Martin engineers delivered breakthrough

technology with a state-of-the-art three stage Adaptive Damping System (ADS). ‘Normal’ ‘Sport’ and ‘Track’

modes allow the driver to tailor the New DB9 to their personal preference with instant adjustments to

conditions, road surface and speed.

Push the Sport button - made of real glass - and the New DB9’s powertrain response is transformed. The

suspension stiffens, the steering is more direct, the throttle sharpens, the gear shift points are quicker and the

control valves open to generate a louder exhaust note.

All of this technology is clothed in a two door coupe body with a 2 + 2 seating configuration, unsurprisingly

the extruded bonded aluminium body structure follows Aston Martin VH architecture with aluminium,

magnesium alloy and composite body. Side protection comes from extruded aluminium door side impact

beams while single bi-xenon headlamps light the way and are complemented by LED side, rear and direction

indicator lamps.

20 inch 5 spoke cast alloy silver painted wheels come specified with Pirelli P Zero tyres – 245/35ZR20’s on

the front and 295/30ZR20’s to the rear.

Inevitably, the list of standard equipment for the new DB9 marks the car down as a true luxury car, but in this

day and age, combining luxury with performance is not enough – people want identify the car as “my Aston”,

so Aston Martin provide a huge range of optional features to allow for that personalisation – the full

specifications are shown overleaf.

Page 28

28

THE NEW ASTON MARTIN DB9

STANDARD EQUIPMENT 2013.

•

Full-grain leather interior

•

Walnut facia trim with graphite centre console finish and iridium silver surround

•

Leather sports steering wheel

•

Electrically adjustable sports seats with side airbags

•

Memory seats & exterior mirrors (three positions)

•

Dual-stage driver/front passenger front airbags

•

Powerfold exterior heated mirrors

•

Heated front seats (sports seats only)

•

Heated rear screen

•

Automatic temperature control

•

Organic Electroluminescent (OEL) displays

•

Trip computer

•

Cruise control

•

Bluetooth® telephone preparation1

•

Satellite navigation1,2

•

Auto-dimming interior rear-view mirror1

•

Auto-dimming interior rear-view mirror with garage door opener (USA and Canada only) 1

•

Satellite radio system (USA only) 1

•

Front and rear parking sensors

•

Tyre pressure monitoring system1

•

Alarm and immobiliser

•

Remote-control central door locking and boot release

•

Glass ECU

•

Tracking device1,3 (UK only)

•

LED map-reading lights

•

Boot-mounted umbrella

•

Lamy pen and pen holder

•

700-watt Aston Martin Premium audio system with Dolby® Pro Logic II® including six-CD

autochanger

•

Integrated Apple iPod®,4 connector

•

USB Connector with Waveform Audio Format (WAF), Windows Media Audio (WMA) and MPEG

(MP3) audio file compatibility

•

3.5 mm auxiliary input socket

Page 29

29

THE NEW ASTON MARTIN DB9

OPTIONAL EQUIPMENT 2013.

•

Volante body style

•

20-inch five-spoke alloy graphite painted wheels with diamond-turned finish

•

20-inch ten-spoke alloy Liquid Silver painted wheels

•

20-inch ten-spoke alloy silver painted wheels with diamond-turned finish

•

20-inch ten-spoke alloy graphite painted wheels with diamond-turned finish

•

20-inch ten-spoke alloy Satin Black painted wheels with diamond-turned finish

•

Alternative brake caliper finish – black, red, and yellow

•

Exterior Carbon Fibre Pack (comprising front splitter, rear diffuser, mirror cap, mirror arm and

graphitic tailpipe finish)

•

2+0 Seating (Coupe only)

•

Lightweight seats with six-way electrical adjustment (must be ordered in conjunction with 2+0 seating

configuration, not available with heated seats feature)

•

Optional facia trims - Piano Black, bamboo, tamo ash, mahogany

•

Black Alcantara Steering Wheel

•

Matching wood door trim (not available with B&O BeoSound audio system options)

•

Personalised sill plaques

•

1000-watt Bang & Olufsen BeoSound audio system with ICEpower technology

•

Auto-dimming interior rear-view mirror1

•

Auto-dimming interior rear-view mirror with garage door opener 1

•

Alarm upgrade (volumetric and tilt sensor)

•

Satellite radio system (Canada only) (excludes subscription)1

•

Tracking device (UK category five)1,3

•

First-aid kit

•

Trinket tray

•

Satellite radio system1

•

Second Glass ECU

•

Rear Parking Assist Camera

•

Interior Carbon Fibre Pack (comprising facia trim, gearshift paddles and door pulls)

•

DB9 logo or Aston Martin wings embroidery on front seat headrests

•

Leather headlining

•

Smokers’ kit

•

Contemporary Pack (comprising contemporary paint, contemporary leather, contemporary carpet,

leather headlining, contrast stitching)

Page 30

30

ASTON MARTIN DBR9

Production dates: 2004

Top Speed: 322+ kph (200+ mph)

Acceleration: 0 – 60 mph 4 secs 0 – 100 mph 9 secs

Chassis numbers: DBR9/101 -

Length 187 inches (4767mm)

Width 77 ½ inches (1978 mm)

Height 52 ½ inches (1318 mm)

Ground clearance

Track Front 61¾ inches (1568mm)

Rear 61½ inches (1562mm)

Wheelbase 108 inches (2740 mm)

Turning circle

Dry weight 2420 lbs (1100 Kg) Manual

Engine 6.0 litre V12

Capacity 5935 cc

Cylinder bore 89 mm (stroke 79.5 mm)

Compression ratio

Power output 600 bhp @ 7,000 rpm

Fuel Injection: Electronic multi-point sequential with Visteon twin

PTEC engine management and fuel system. Pi Data system

Pectel engine ECU

Chassis Advanced aluminium/carbon composite construction

Transmission X-trac six speed sequential transaxle. Limited slip differential

Clutch Hydraulically operated twin plate

Front suspension Independent aluminium double wishbones, adjustable Koni

Dampers and Eibach springs

Rear suspension Independent aluminium double wishbones, adjustable Koni

Dampers and Eibach springs

Steering Power assisted rack and pinion

Brakes Front: Servo assisted 330 mm carbon discs with Brembo

six piston callipers.

Back: Servo assisted 330 mm carbon discs with Brembo

six piston callipers.

Page 31

31

The Aston Martin DBR9 was built within GTI (formerly GTS) regulations as specified by the FIA

(Federation International d’Automobile) the motorsport world governing body. Styled using

Computational Fluid Dynamics to optimise aerodynamics, the body followed the profile of the DB9

from the wheels upwards but it was shorter and wider. The aluminium roof was taken straight from

the road car but other panels were carbon-fibre composite including a flat underbody and large rear

wing. A steel roll cage, designed by Aston Racing, completed the body.

It all sat on bespoke aluminium double wishbone suspension with Koni dampers and Eibach springs

with OZ Racing forged magnesium alloy wheels and lightweight 330mm carbon disc brakes with

Brembo six piston callipers.

The cockpit, as stipulated in the FIA rules, retained the dimensions of the road car and featured a

carbon composite dashboard and lightweight racing seat. The car weighed 480 kilograms less than

the DB9 and delivered a power to weight ratio of 550 bhp per ton.

The DBR9’s engine was based on exactly the same aluminium block and cylinder head as the DB9

V12 but was modified to deliver over 600 bhp at a rev limited 8,000 rpm. It had a dry sump, double

overhead camshafts , four valves per cylinder and two 31.2mm air restrictors. The X-trac

transmission was mounted on the rear axle.

The commercial objectives at the start of the project were to produce Works cars and Customer

cars. The Works teams were established on a franchise basis with a franchise reputedly costing

£2,750,000 over three years. The Customer cars were targeted at private racers and collectors and

had a target price of £475,000.

Two Aston Martin Works teams were established to compete in the GTI category in the 2005

international sports car racing season including the FIA GT Championship and the American Le Mans

Series (ALMS). Both teams, with three drivers apiece, were run independently with full factory

support.

The opening race of the ALMS series, on 19th March 2005, was the Sebring 12 Hours and it saw

Aston Martin’s official return to racing. David Brabham, driving car number 57 took the flag and a

class win in GTI – an amazing result on the new car’s competitive debut. Next on 15th April, it was

to Silverstone for the Tourist Trophy, the scene of Aston Martin victories in 1958 and 1959.

The two DBR9’s started first and second on the grid and finished in the same order – Aston Martin’s

name on the Tourist Trophy again! With these two amazing results, anticipation was high going to

Le Mans especially when the Aston Martins qualified first and second in class. Sadly, after swapping

lead placings, with just one and a half hours to go, both cars suffered problems – one with fuel loss

out on the track whilst the other made it to the pits with radiator problems. That car was sent out

10 minutes from the end to claim a well merited third in class and that set the tone for the rest of

the season.

At Spa the cars proved their reliability by finishing in fifth and sixth place and at Laguna Seca they

lead before a stop and go penalty pushed them down the field. The season started in a better way

than it finished, but in the context of a development year, 2005 was a huge success.

It also established a clear platform for an expansion of the product through a customer version of

the car, designated the DBRS9.

Page 32

32

ASTON MARTIN DBRS9

Production dates: 2006

Top Speed: 322+ kph (200+ mph)

Acceleration: 0 – 60 mph 4 secs 0 – 100 mph 9 secs

Chassis numbers: DBRS9/1-

Length 4687 mm

Width 1979 mm

Height 1318 mm

Ground clearance

Track Front 1568mm

Rear 1562mm

Wheelbase 2741mm

Turning circle

Dry weight 2420 lbs (1100 Kg) Manual

Engine 6.0 litre V12

Capacity 5935 cc

Cylinder bore 89 mm (stroke 79.5 mm)

Compression ratio

Power output 550 bhp @ 7,000 rpm

Fuel Injection: Electronic multi-point sequential with Visteon twin

PTEC engine management and fuel system. Pi Data system

Pectel engine ECU

Chassis Advanced aluminium/carbon composite construction

Transmission Six speed manual(H pattern with syncromesh)

Option of six speed sequential / transaxle

Clutch Hydraulically operated twin plate

Front suspension Independent aluminium double wishbones rose jointed

adjustable Koni Dampers uprated springs

Rear suspension Independent aluminium double wishbones rose jointed

adjustable Koni Dampers uprated springs

Steering Power assisted rack and pinion

Brakes Front: Servo assisted 330 mm carbon discs with Brembo

six piston callipers.

Back: Servo assisted 330 mm carbon discs with Brembo

six piston callipers.

Page 33

33

As originally planned, Aston Martin Racing unveiled the DBRS9 in 2006. It is designed as a

competition car for club and national race series and it creates a bridge for teams and drivers

looking towards international GT racing.

The DBRS9 is based on the DB 9 road car but shares features with the full GTI specification DBR9.

It uses the road cars bonded aluminium chassis fitted with the DBR9 roll cage. All the body panels,

apart from the roof, have been replaced with carbon composite materials with the same materials

being used on the interior trim, with the side and rear window glass has been replaced with

polycarbonate. This means a weight saving of 480 kilograms compared with the DB9.

Aston Martin have tuned the V12 engine increasing the power by nearly 20% to 550 bhp which, with

the reduced weight, means a power to weight ratio of 430 bhp per tonne. The standard

transmission is an H pattern, fully syncromesh gearbox with shorter competition ratios. There is an

option to upgrade this to a fully sequential racing gearbox. The car’s ride has been lowered and the

double wishbone suspension has been rose jointed and fitted with two-way adjustable Koni dampers

and stiffened competition springs.

Aston Martin Racing have been focussed on performance, but not at the expense of practicality. The

seat and steering are easily adjustable and there is even the option of a passenger seat for

demonstration purposes. Removable body panels, a modular chassis and a comprehensive package

of spares simplify service and maintenance.

When the DBRS9 was launched, David Richards, on behalf of Aston Martin Racing, said “The

DBRS9 opens GT Racing up to more enthusiasts and with its levels of performance will offer aspiring

racing drivers the experience of a GT racing car without the complexity associated with running a

full GTI car.”

The cars are built to order at Banbury with prices starting at £175,000 plus taxes and spare packages

and the project has proved successful with teams competing in the French, Belgian, British and Open

GT Championships.

Typical are Barwell Motorsport of Great Bookham in Surrey, running 3 cars in the 2007 British GT

Championship, they scored five race wins and nineteen podiums netting them the Team

Championship as well as second and third places in the Drivers’ Championship.

Aston Martin Racing has restored the racing pedigree of the marque with the DBR9 and the

DBRS9. Dr Ulrich Bez, Chairman and Chief Executive of Aston Martin said at the launch of the

DBRS9 “It reinforces the DB9’s performance potential and inherent racing qualities.”

And it is a strategy that Aston Martin have continued to pursue as in January 2008 it was announced

that for the first time, Aston Martin Racing is designing this car to run on either standard race fuel or

E85 bio-ethanol (where regulations allow). In 2007, Aston Martin Racing successfully converted a

standard DBRS9 to run on E85.

Aston Martin Racing also revealed the first impressions of its new GT2 racing car. Known as the

Vantage GT2, the new car is based on the V8 engined Aston Martin Vantage road car.

The new Vantage GT2 completed Aston Martin’s product portfolio for 2008 with competitive cars

now available in every category. The new car will mean Aston Martin is the only manufacturer to

offer cars in every GT racing category: GT1 – DBR9; GT2 - Vantage GT2; GT3 – DBRS9; GT4 –

Vantage N24.

Page 34

34

ASTON MARTIN V8 Vantage

Production dates: 2005 -

Top Speed: 282 kph (175 mph)

Acceleration: 0 – 60 mph 4.9 secs

Chassis numbers: SCFBB03B869 C00001-

Length 172 ½ inches (4382mm)

Width 73 ½ inches (1866 mm) without mirrors

Height 53.5 inches (1265 mm)

Ground clearance

Track Front 61¾ inches (1568mm)

Rear 61½ inches (1562mm)

Wheelbase 102.4 inches (2600 mm)

Turning circle

Dry weight 3461 lbs (1570 Kg)

Engine 4.3 litre V8 Dry Sump

Capacity 4281 cc

Cylinder bore 89 mm (stroke 86 mm)

Compression ratio

Power output 380 bhp @ 7,300 rpm

Fuel Injection: Sequential electronic fuel injection system with SCP/Can

Interface to engine management control system

Chassis Extruded aluminium bonded monocoque

Transmission Graziano six speed manual

or Sportshift transaxle Limited slip differential

Clutch Hydraulically operated twin plate

Front suspension Independent double aluminium wishbones. Ball jointed king pins

coil springs over aluminium telescopic dampers, anti roll bar.

Rear suspension Independent double aluminium wishbones.

coil springs over aluminium telescopic dampers, anti roll bar

Steering Rack and pinion – column tilt and reach adjustment

Brakes Stability control system with ABS, EBD (brake

distribution), TC (traction control), EBA (brake assist) and

DSC (dynamic stability control)

Front: 355mm Ventilated, grooved 4 piston Brembo monobloc

calipers

Back: 330mm Ventilated 4 piston calliper, separate

handbrake calliper

Exhaust System Active sports system with by pass valves

2006 Aston Martin Vantage V8 Coupe

Chassis No: SCFBA03B96GC01936

© BYRON INTERNATIONAL

Page 35

35

The development of the Aston Martin V8 Vantage was conducted almost totally in public view – not

for this car the disguised panels and secrecy normally reserved for new models. From Autocar’s

introduction to a “Baby V8” to compare with a Porsche 911 through a concept car on display at the

Detroit Motor Show in 2003 up to the unveiling of the V8 Vantage Concept Car at Geneva in 2005,

the V8 Vantage was very much public property.

It took Aston Martin into uncharted territory with target production levels of 2,500- 3,000 units per

annum and a more affordable car for a younger customer. The engine was a return to roots as it

took Aston Martin back to a V8 – although based on a Jaguar unit, most of its internal parts were

unique to Aston Martin with the unit built alongside the V12 in the Cologne engine plant. Also

returning to roots was the lubrication system for the new engine – back in 1928, Aston Martin had

pioneered the “dry sump” system where the oil is carried in a separate tank rather than in the

bottom section of the engine. As an aid to design, it reduced the overall height of the engine

allowing it to sit lower bringing the centre of gravity down and improving the handling.

To allow the engine to be set as near to the middle of the car as possible, the six speed gearbox and

the final drive to the back axle were included in a single casing at the rear of the car delivering

virtually 50:50 weight distribution.

The chassis platform of the car follows the V/H (Vertical/Horizontal) Platform Strategy and was

made form an assembly of extruded and moulded aluminium alloy sections riveted together and

further strengthened by use of composite materials. The body design by Aston Martin’s Design

Director, Henrik Fisker, again took Aston Martin back to the days of the DB2 and DB2/4. By

restricting the car to a 2 seater, the luggage area could be maximised and, like its predecessor,

access was through an opening rear hatch.

Such was the space in the luggage area that it was designed to take a golf bag laying across the car as

well as other bags. The driver and passenger, cosseted in the normal levels of Aston Martin luxury

with Bridge of Weir leather and a huge range of options, are protected from the luggage by a builtin-wall.

2006 saw the launch of two derivative models of the V8 Vantage in the twin traditions of Aston

Martin – performance and luxury. In June, a V8 Vantage was entered into the ADAC Nurburgring

24 Hours. With a crew that included Aston Martin’s Chairman and CEO, Dr Ulrich Bez, the car

achieved a creditable 24th place and was then driven back to Gaydon. In commemoration of this, the

V8 Vantage N24 was launched offering a car that was largely production standard with an FIA roll

cage, larger bag fuel tank, built in air jacks and lightweight wheels

Out went air conditioning, air bags, electric windows and side/rear glass. Weight saving took the

car’s weight to 2932 pounds while tuning the engine and suspension scaled the acceleration down to

a 0-60 sprint time of 4.3 seconds while the top speed was limited to 175 mph.

Later that year, came the luxury with the launch of the V8 Vantage Roadster – like the DBAR1, the

Roadster name was used with Volante retained for Aston Martin’s 4 seater convertibles. The

operating mechanism and design for the soft top was shared with the DB9 Volante meaning that the

same purity of line could be retained at the rear along with maximum visibility. The luxury of the

interior matched the coupe and, in a very similar fashion to the DBAR1, the Bridge of Weir leather

interior trim carried on to twin rear pods behind the driver and passenger.

After criticism over the rigidity of the DB9 Volante, additional engineering was applied to the

standard V/H structural architecture to ensure coupe levels of chassis rigidity – and it has proved

worthwhile.

Page 36

36

ASTON MARTIN V8 Vantage Roadster

Production dates: 2006 -

Top Speed: 282 kph (175 mph)

Acceleration: 0 – 60 mph 4.9 secs

Chassis numbers: SCFBB03B869 C00001-

Length 172 ½ inches (4382mm)

Width 73 ½ inches (1866 mm) without mirrors

Height 49.4 inches (1255 mm)

Ground clearance

Track Front 61¾ inches (1568mm)

Rear 61½ inches (1562mm)

Wheelbase 102.4 inches (2600 mm)

Turning circle

Dry weight 3770 lbs (1710 Kg)

Engine 4.3 litre V8 Dry Sump

Capacity 4281 cc

Cylinder bore 89 mm (stroke 86 mm)

Compression ratio

Power output 380 bhp @ 7,300 rpm

Fuel Injection: Sequential electronic fuel injection system with SCP/Can

Interface to engine management control system

Chassis Extruded aluminium bonded monocoque

Transmission Graziano six speed manual

or Sportshift transaxle Limited slip differential

Clutch Hydraulically operated twin plate

Front suspension Independent double aluminium wishbones. Ball jointed king pins

coil springs over aluminium telescopic dampers, anti roll bar.

Rear suspension Independent double aluminium wishbones.

coil springs over aluminium telescopic dampers, anti roll bar

Steering Rack and pinion – column tilt and reach adjustment

Brakes Stability control system with ABS, EBD (brake

distribution), TC (traction control), EBA (brake assist) and

DSC (dynamic stability control)

Front: 355mm Ventilated, grooved 4 piston Brembo monobloc

calipers

Back: 330mm Ventilated 4 piston calliper, separate

handbrake calliper

Exhaust System Active sports system with by pass valves

Page 37

37

ASTON MARTIN V8 Vantage N24

Production dates: 2006 -

Top Speed: 282 kph (175 mph)

Acceleration: 0 – 60 mph 4.3 secs

Chassis numbers: As V8 Vantage

Length 172 ½ inches (4382mm)

Width 73 ½ inches (1866 mm) without mirrors

Height 49.4 inches (1255 mm)

Ground clearance

Track Front 61¾ inches (1568mm)

Rear 61½ inches (1562mm)

Wheelbase 102.4 inches (2600 mm)

Turning circle

Dry weight 2932 lbs (1330 Kg)

Engine 4.3 litre V8 Dry Sump

Capacity 4281 cc

Cylinder bore 89 mm (stroke 86 mm)

Compression ratio

Power output 410 bhp @ 7,500 rpm

Fuel Injection: Sequential electronic fuel injection system with SCP/Can

Recalibrated engine management control system

Chassis Extruded aluminium bonded monocoque

Transmission Graziano six speed manual

Clutch Valeo twin plate ceramic with lightweight flywheel

Front suspension Independent double aluminium wishbones.

coil springs over aluminium monotube dampers, anti roll bar.

Rear suspension Independent double aluminium wishbones.

coil springs over aluminium monotube dampers, anti roll bar

Steering Rack and pinion – column tilt and reach adjustment

Brakes Stability control system with ABS, EBD (brake

distribution), TC (traction control), EBA (brake assist) and

DSC (dynamic stability control)