Page 1

Switching amplifier

BS 805

Original

Manual

Strain gauge switching amplifier BS 805.01 / BS 805.11 / BS 805.21

A.S.T. Angewandte SYSTEM-TECHNIK GmbH Dresden

Marschnerstraße 26 01307 Dresden

phone (03 51) 44 55 30 fax (03 51) 44 55 555

www.ast.de vertrieb.dd@ast.de

1

Page 2

Page 3

Manual switching amplifier BS 805

Index of contents

1. Safety Instructions ............................................................................................................................... 1

2. Wiring Diagram ..................................................................................................................................... 2

3. Operating elements .............................................................................................................................. 2

3.1. Adjustments ........................................................................................................................................ 4

3.2. Button .................................................................................................................................................. 4

4. LED- display .......................................................................................................................................... 4

5. Function of key T1 ............................................................................................................................... 5

5.1. Code table ........................................................................................................................................... 5

5.2. Example .............................................................................................................................................. 6

6. Information on Performance-Level PLc in accordance with DIN EN 13849-1 ............................... 6

6.1. Classification of Type Series “Switching Amplifier BS 805” ................................................................ 6

6.2. Error detection in operation with a connected sensor ........................................................................ 6

6.3. Other functions .................................................................................................................................... 7

7. Commissioning .................................................................................................................................... 7

7.1. Mounting ............................................................................................................................................. 7

7.2. Connection .......................................................................................................................................... 7

7.3. Signal settings ..................................................................................................................................... 8

7.4. Control of settings ............................................................................................................................... 9

8. Specification ....................................................................................................................................... 10

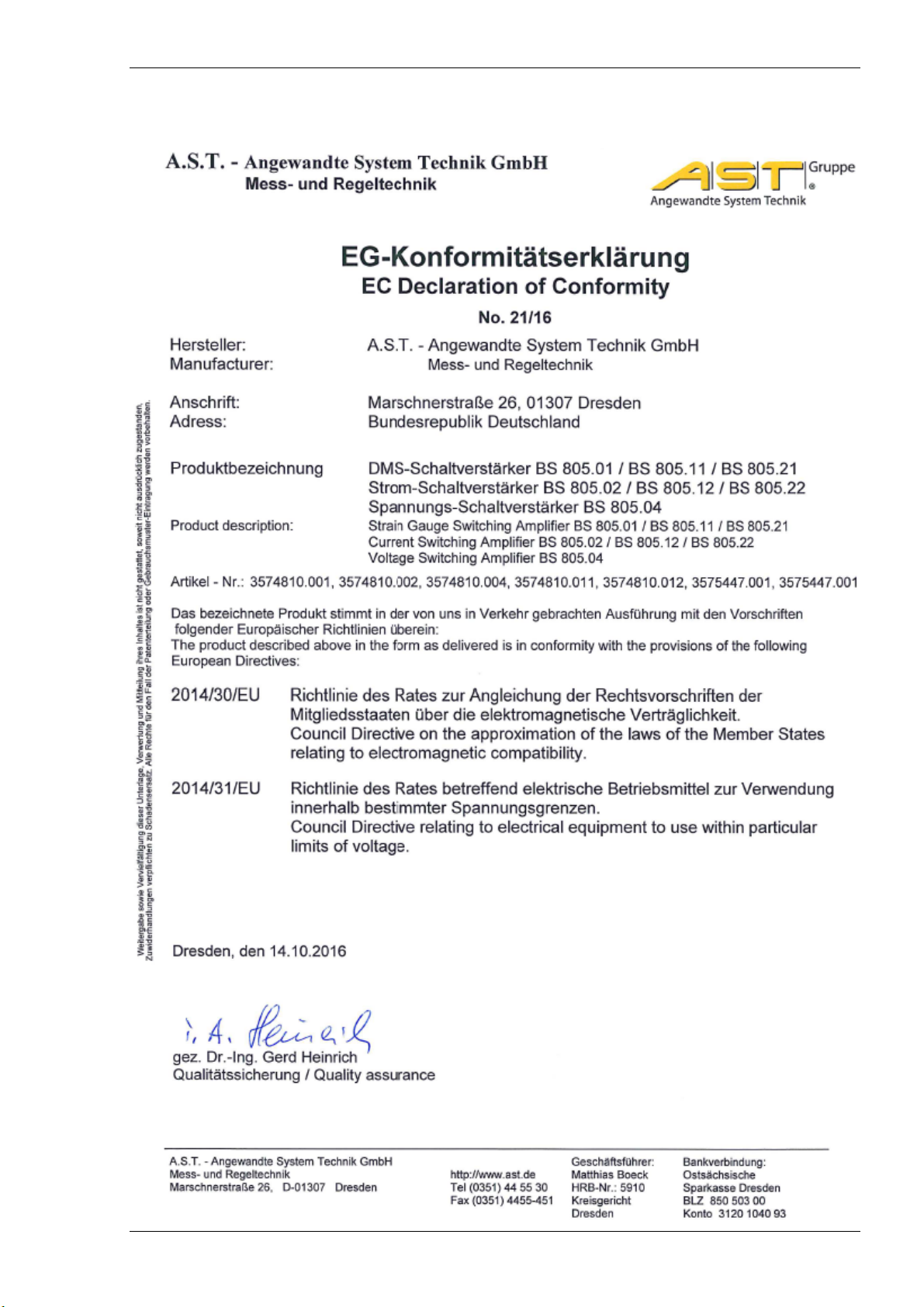

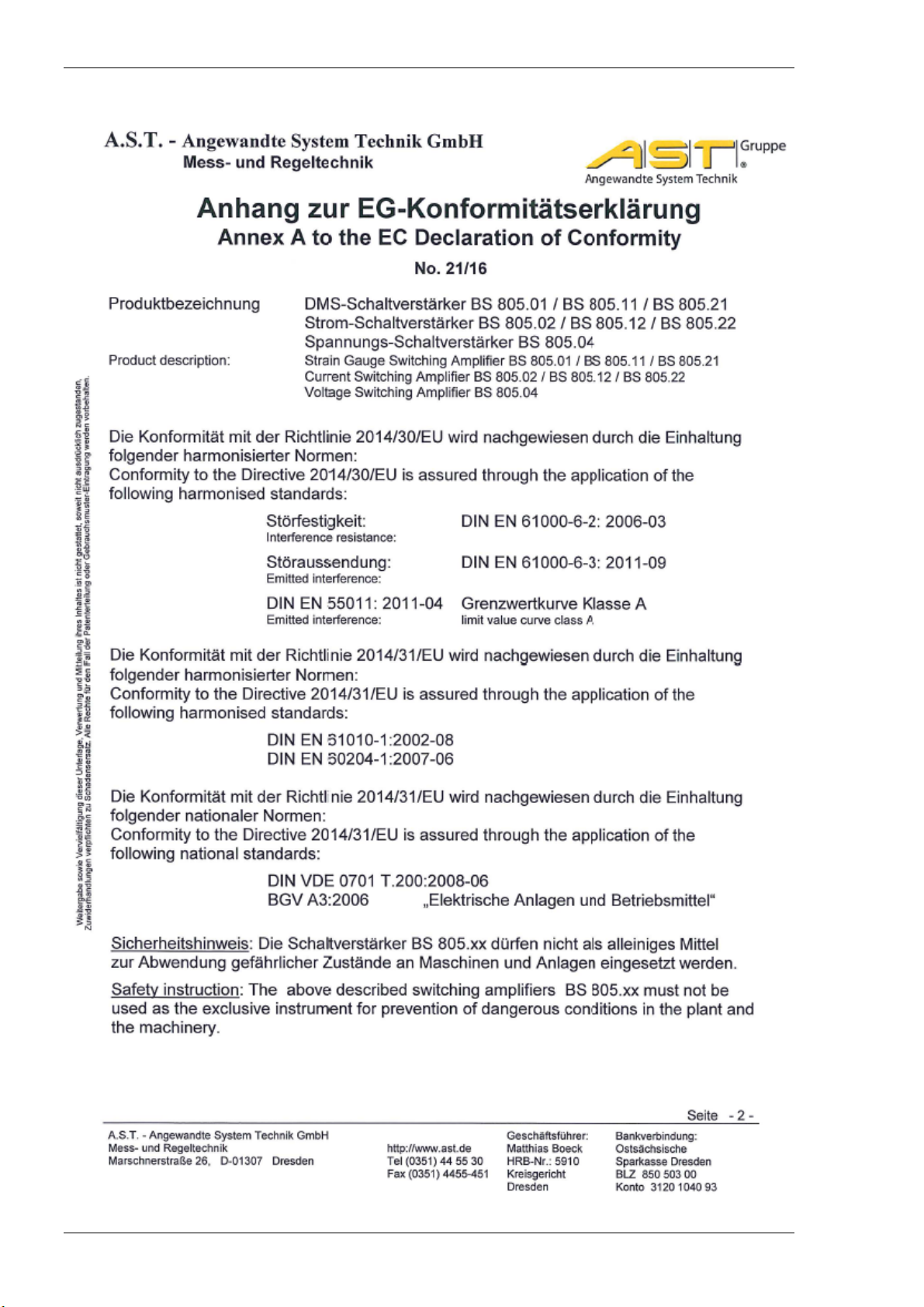

9. EC Declaration of Conformity ........................................................................................................... 11

Subject to technical change 10/2017 1

A.S.T. Angewandte SYSTEM-TECHNIK GmbH Dresden

Page 4

Page 5

Manual switching amplifier BS 805

1. Safety Instructions

ATTENTION!

ATTENTION!

Any non-compliance with these safety precautions may result in severe damage to property and health!.

ATTENTION!

These Operating Instructions explain the installation, bringing into service, and operation of the type BS

805.0x amplifier. It is assumed that every action is taken by qualified staff only who have adequate

knowledge in the fields of measuring and control engineering.

The equipment must be installed and attached under adherence to of the current DIN and VDE

standards.

The type BS 805.01 Strain-Gauge amplifier has been designed to the purpose of amplifying the output

signals of sensors with metal-foil strain gauges, preferably force transducers.

The type BS 805.02 has been designed to the purpose of amplifying the output signals of sensors with

standard signal 4-20mA, preferably force transducers.

Any other application is regarded contrary to intended usage.

The BS 805.0x may not be used as exclusive means for the prevention of dangerous conditions at

machines and plants.

Make sure that any erroneous setting or malfunction of the unit or its break-down cannot cause damage

or be a risk to the staff or other persons.

Subject to technical change 10/2017 Page 1 of 12

A.S.T. Angewandte SYSTEM-TECHNIK GmbH Dresden

Page 6

Manual switching amplifier BS 805

V

2

V

2

6

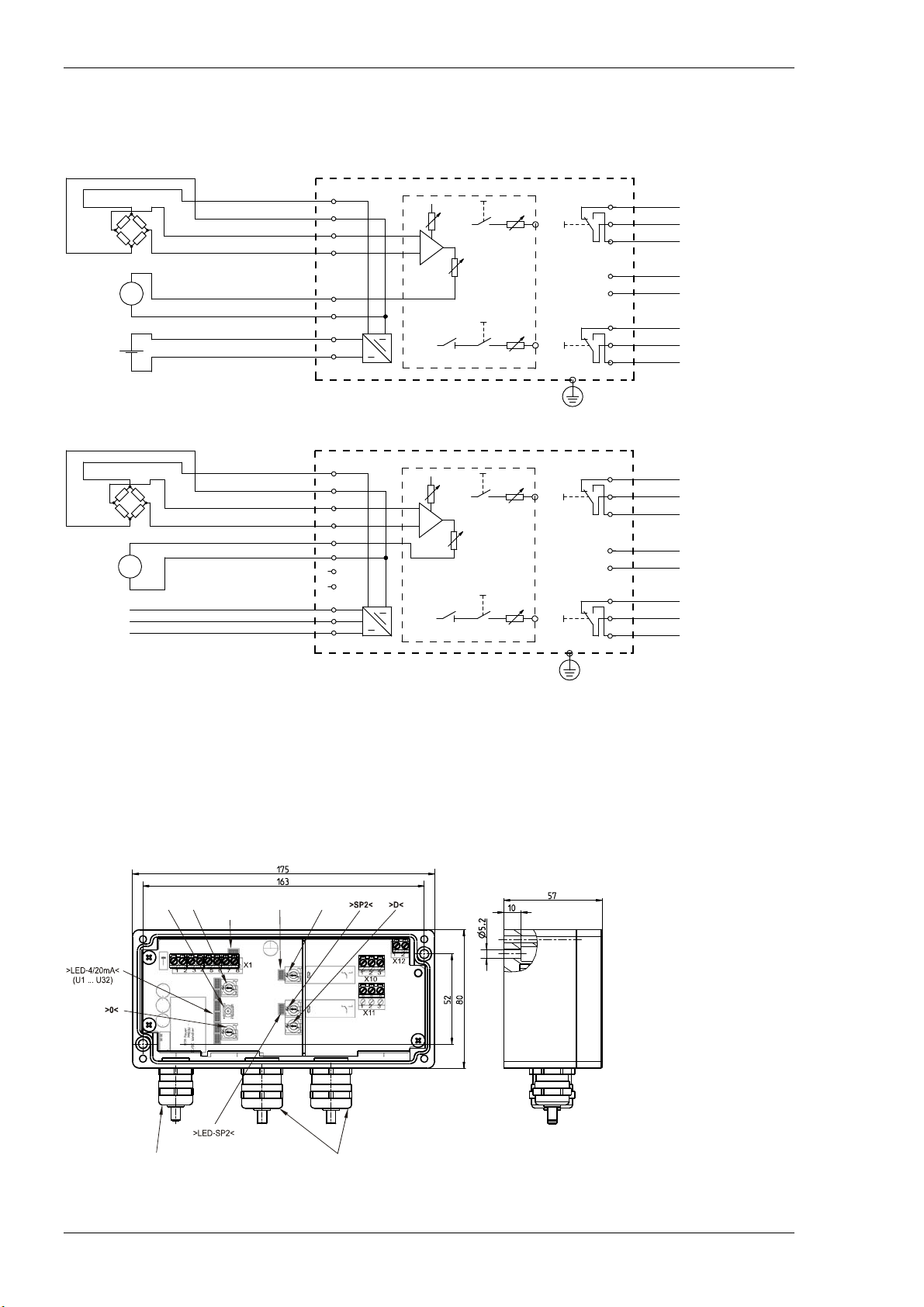

2. Wiring Diagram

BS 805.01 / BS 805.21

Force transducer

-X1

+SI+EX

-SI-EX

Standard signal output

A

Power supply

+EX

-EX

+SI

4-20mA

0mA

10-30VDC

GND

-SI

1

2

3

4

5

6

7

8

µC

-X10

SP1

T1

0

T1

?t

1

SP2

1

1NC1

2COM1

3NO1

-X12

1PE1

2PE2

-X11

1NC2

2COM

3NO2

BS 805.11

Force transduce r

-X1

+SI+EX

-SI-EX

A

Standard signal output

Power supply 230VAC

+EX

-EX

+SI

-SI

4-20mA

0mA

L

N

PE

-X5

1

2

3

4

5

6

7

8

1

2

3

3. Operating elements

BS 805.01 Strain gauge switching amplifier

Supply voltage 10…30VDC / case IP65 – die cast

µC T1

0

T1?t

SP1

SP2

-X10

1NC1

1

1

2COM1

3NO1

-X12

1PE1

2PE2

-X11

1NC2

2COM

3NO2

>V<>T1<

Cable gland M16

D = 5 … 10mm

>LED-i.O.<

(U78)

>LED-SP1<

>SP1<

Cable gland M20

… 12mm

D =

Page 2 of 12 Subject to technical change 10/2017

A.S.T. Angewandte SYSTEM-TECHNIK GmbH Dresden

Page 7

Manual switching amplifier BS 805

m

m

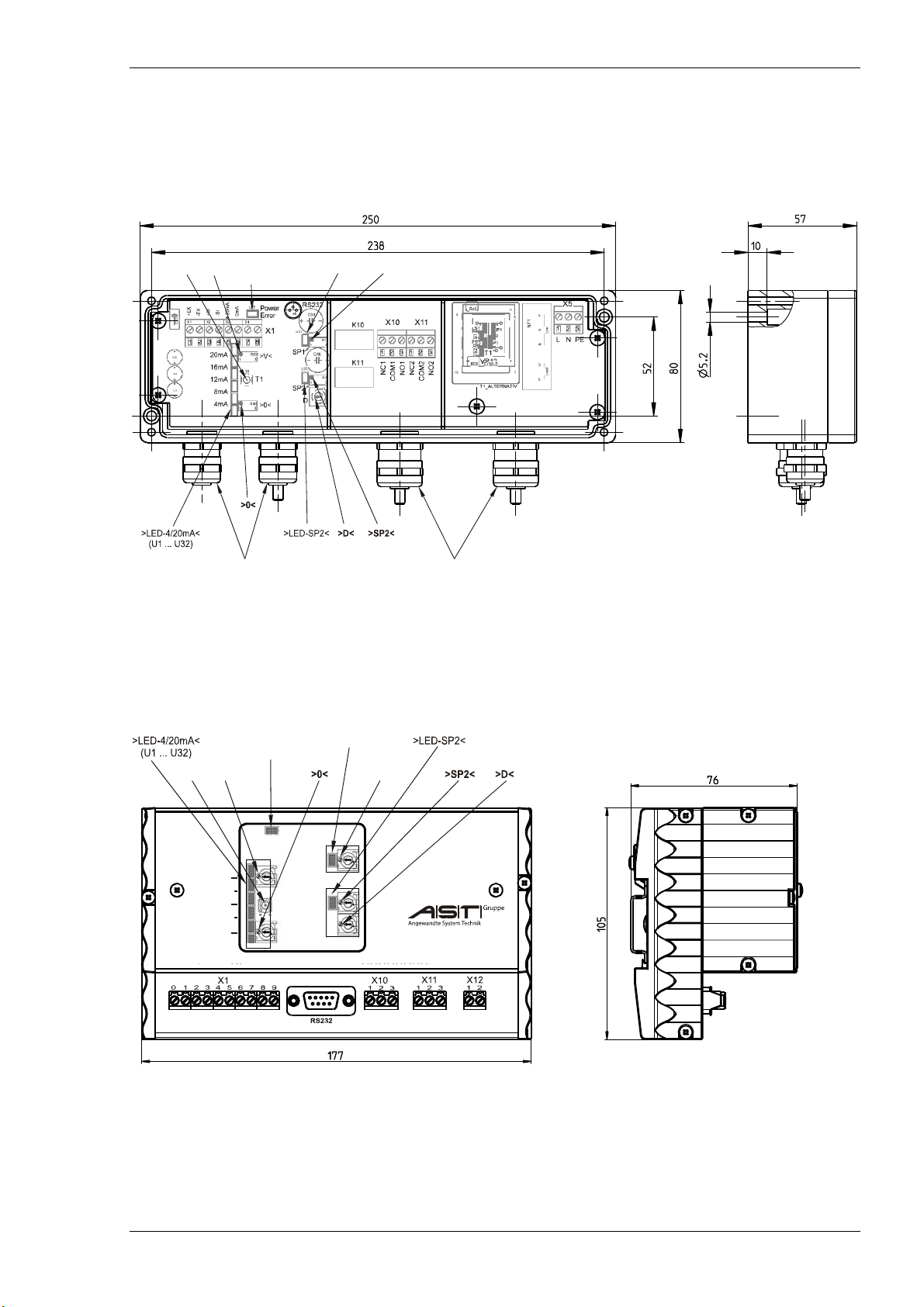

BS 805.11 Strain gauge switching amplifier

Supply voltage 230VAC /case IP65 – die cast

>V<>T1<

>LED-i.O.<

(U78)

Setup

>LED-SP1<

>SP1<

Cable gland M16

D = 5 … 10m

Cable gland M20

D = 6 … 12m

BS 805.21 Strain gauge switching amplifier

Supply voltage 10…30VDC / case IP40 – DIN rail

>V<

>0<

SH

+EX

Power

T1

-EX

>V<>T1<

+SI

20

mA

4

-SI

4-20

>LED-i.O.<

(U78)

-

+

24V

mA

0mA

SH

>LED-SP1<

>SP1<

SP1

SP2

>D<

NC1

COM1

Schaltverstärker

BS 805

NC2

NO1

NO2

PE

COM2

PE

Subject to technical change. 10/2017 Page 3 of 12

A.S.T. Angewandte SYSTEM-TECHNIK GmbH Dresden

Page 8

Manual switching amplifier BS 805

3.1. Adjustments

Switch Function

>V< 16 mA - characteristic value setting 0,8 … 2,5mV/V

>0< 4mA - setting to zero point -0,5 … +0,5mV/V

SP1 Switching point setting/ switching range 4....20mA

SP2 Switching point setting/ switching range 4....20mA

D Switching delay for SP2 0 ... 5sec.

Strain gauge switching amplifier

BS 805.01

BS 805.11

BS 805.21

3.2. Button

Switch

T1 Additionally function see Point 5

Function

4. LED- display

LED Normal operations Error (flashing display)

U1 <4mA incorrect code enter

U2 4mA < I < 8mA

U4 8mA < I < 12mA -

U8 12mA < I < 16mA U16 16mA < I < 20mA U32 20mA < I U78 Ready for operation break or short in sensor wire

U21 SP1 current on U22 SP2 current on -

blinks once Current level exceeded through +EX

for BS805.y1 bridge resistance < 300

for BS805.y1 sensor current > 40mA

blinks twice Current level not attained through +EX

Only for BS805.y1 bridge resistance > 1000

blinks 3 times Input signal exceeded

for BS805.y1 bridge signal = > +2.5mV

blinks 4 times Input signal not attained

for BS805.y1 bridge signal < -2.5mV/V

blinks 5 times Bridge median voltage exceeded

only for BS805.y1 (–SI zu –EX >2.2V)

blinks 6 times Bridge median voltage not attained

only for BS805.y1(–SI zu –EX <1.2V)

Page 4 of 12 Subject to technical change 10/2017

A.S.T. Angewandte SYSTEM-TECHNIK GmbH Dresden

Page 9

Manual switching amplifier BS 805

5. Function of key T1

5.1. Code table

Element Function Code

Relay 1 Normal from

appointed SP1

current less

Inverse from

appointed SP1

current on

Hysterese 0,0mA 230

Hysterese 0,1mA 231

Hysterese 0,5mA 232

Hysterese 1,0mA 233

Hysterese 2,0mA 234

Relay 2 Normal from

appointed SP2

current less

Inverse from

appointed SP2

current on

Hysterese 0,0mA 240

Hysterese 0,1mA 241

Hysterese 0,5mA 242

Hysterese 1,0mA 243

Hysterese 2,0mA 244

Mandatory security

SP1

Relay 1 and Relay 2 Reset at normal 255

Constant current 4,0 311

(mA) 12,0 312

20,0 313

+ 0,2 344

+ 0,5 343

+ 1,0 331

+ 2,0 332

+ 3,0 333

+ 4,0 334

+ 5,0 335

- 0,2 341

- 0,5 342

- 1,0 321

- 2,0 322

- 3,0 323

- 4,0 324

- 5,0 325

Example 16,8=12,0+5,0-0,2 “312”+”335

Current to reset Back to measuring

Subject to technical change. 10/2017 Page 5 of 12

A.S.T. Angewandte SYSTEM-TECHNIK GmbH Dresden

Switching attitude

SP1, SP2: normal,

adjustment SP1: to

2mA over SP2,

fault: SP1 and SP2

current less and

output signal 2mA

mode

211

212

221

222

251

”+”341”

355 or

voltage

supply 10–

30VDC to

break

Element Function Code

Basic setting

(only BS 805.01 )

Setup-protection on 421

off 425

Strain gauge input tension and

Negative 412

Positive 415

Test signal on 422

off 423

>V< - limit stop left ∆16mA = ∆2,0mV/V 431

∆16mA = ∆1,5mV/V 432

∆16mA = ∆1,0mV/V 433

∆16mA = ∆2,5mV/V 435

>V< - limit stop right ∆16mA = ∆0,5mV/V 441

∆16mA = ∆1,0mV/V 442

∆16mA = ∆1,5mV/V 443

∆16mA = ∆0,83mV/V 445

>0< - adjusting range - 1,00 ... 0,00mV/V 451

- 0,75 ... +0,25mV/V 452

- 0,25 ... +0,75mV/V 453

0,00 ... +1,00mV/V 454

- 0,50 ... +0,50mV/V 455

SP1: normal / without

hysteresis

SP2: normal / without

hysteresis

Strain gauge input

positive

Zero point -/+ 0,5

mV/V

compression:

12mA=0mV/V

555

411

Page 10

Manual switching amplifier BS 805

R

d

e

5.2. Example

sequence Operation for Code 341 LED-display

1.

3-times press >T1<

>U2-U4-U8< light

2. Wait approx. 2 sec Light off

3.

4-times press >T1<

>U2-U4-U8-U16< light

4. Wait approx. 2 sec Light off

5.

1-times press>T1<

>U2< light

6. end LED >U16< flashing approx. 2 sec

6. Information on Performance-Level PLc in accordance with DIN EN 13849-1

6.1. Classification of Type Series “Switching Amplifier BS 805”

The Switching Amplifier BS805 can be classified in the Performance-Level PLc in accordance with the set of

standards governing Safety Relevant Control Systems DIN EN 13849-1.

This then covers hazards as shown in the hazard graphs below recommended for safety-relevant control systems in

conjunction with the Performance-Level PLc and SK1 Category.

Severity of injury (S)

S1 Slight injury (usually temporary)

S2 Severe injury (usually irreversible),

including death

Frequency and/or duration of exposure to

hazard (F)

F1 ... Seldom to quite often and/or short

duration of exposure

F2 ... Frequent to permanent and/or short

duration of exposure

Possibility of preventing the hazard (P)

P1 ... Possible under certain conditions

P2 ... Hardly possible

Starting

point for

assessing

risk

reduction

equire

Low

risk

performanc

level PL

a

P

1

F

S

1

F

2

1

P

2

b

P

1

P

2

c

P

F

1

S

2

F

2

1

P

2

d

P

1

P

2

e

High

risk

6.2. Error detection in operation with a connected sensor

The Switching Amplifier BS805 identifies the following errors:

Sensor monitoring

- Wire breakage, also on single core of sensor cable.

- Short circuit on any number of cores of sensor cable.

- “Unsafe” connection of individual cores.

Internal monitoring

- Failure of operating voltage

- Failure of sensor power supply

The BS 805 is responding to an error with:

- Relay SP1 and SP2 fall (to drop out)

- LED U78 blinking

- Output signal is 2mA

Page 6 of 12 Subject to technical change 10/2017

A.S.T. Angewandte SYSTEM-TECHNIK GmbH Dresden

Page 11

Manual switching amplifier BS 805

6.3. Other functions

In the event of a software error occurring, the inherent processor watchdog will repeatedly attempt to restart the

Switching Amplifier BS805, this involving constant opening/closing of the relays SP1 and SP2.

Zero drifts on the internal amplifier are cyclically corrected.

The function of the Switching Amplifier BS805 is not impaired by errors occurring on downstream devices.

Coercive fusing of relay SP2 can be set by means of key code ‘251’ as follows: SP1 lies 0…2mA above SP2.

Accordingly, SP1 monitors SP2 (the latter normally being set with a time lag) and is immediately de-energised

whenever a short and high load peak occurs

7. Commissioning

7.1. Mounting

The BS 805.01 and BS 805.11 appliances are intended to be wall-mounted using two M5 screws. The drilling patterns

for BS 805.01 (163 x 52) and BS 805.11 (238x52) will be found under 3.

Appliances BS 805.21 are designed for mounting on a standard rail.

7.2. Connection

Excitation voltage + + EX

Excitation voltage - -EX

Signal + + SI

Signal - - SI

Analogue Output 4…20mA

Analogue Output 0 mA

Shield SHI

Power supply 10-30VDC

Power supply GND

230VAC L

N

PE

PE

PE

Rel. 1 NC

Com

NO

Rel. 2 NC

Com

NO

BS 805.01 BS 805.11 BS 805.21

X1/1

X1/2

X1/3

X1/4

X1/5

X1/6

cable gland cable gland X1/0

X1/9

X1/7 - X1/7

X1/8 - X1/8

- X5/1 -

- X5/2 -

- X5/3 X12/1

X12/2

X10/1

X10/2

X10/3

X11/1

X11/2

X11/3

The cables for the sensor, the supply voltage and the signal output are to the strip_X1: to attach. Protective

conductors of the discharges for the switching signals are to be attached absolutely to the strip_X12: PE

Standard contacting of cable shield to contact clip

cable jacket and shield dismantle

cut around the cable jacket 15mm behind the end, do not remove however yet

pass through the cable

cable jacket removal

draw back the cable until the connection between cable shield and contact clip is existent

tighten

Contacting of cable shield with thin cables without cable sheath:

cable jacket dismantle

roll up the shield over the cable jacket approx.15 - 20 mm

pass through the cable until the connection between cable shield and contact clip is existent

tighten

Subject to technical change. 10/2017 Page 7 of 12

A.S.T. Angewandte SYSTEM-TECHNIK GmbH Dresden

Page 12

Manual switching amplifier BS 805

7.3. Signal settings

With the aid of an ammeter and/or LED corresponding to Section 4, the zero point is set by means of the >0<

adjuster, the load value for sensor loading being set using the >V< adjuster.

Setting the zero point with the >0< adjuster

- De-charge the sensor.

- The zero point 4mA is correctly set at the very point where the red LED just about lights up.

- Output current below 4mA: Turn >0< adjuster clockwise,

- Red LED remains on: Extend zeroing range in minus

direction applying functions 452 or 451

Setting the load value using the >V< adjuster

- Charge the sensor.

- The load value, e.g. 20mA is correctly at the point where the red LED does not yet light up.

- Output current below 20mA: Turn >0< adjuster

clockwise,

- Red LED remains off: Extend zeroing range with

functions 44x

Whenever the appliance detects an error (refer to point 4 LED display, LED U78) an output current of 2mA is always

generated and the red LED >U1< lights up.

A note can be made of the test signal (Code No.: Switch-on 422, Switch-off 423) for documentation purposes later on.

For this purpose de-charge the sensor, measure the output signal and connect the test signal by means of function

422. Now measure the output signal and switch the test signal back off again by means of function 423. A note is

made of the difference between the output signals which can then be reviewed when checks are carried out at a later

point.

Setting the switching points >SP1< and >SP2<

Setting of the switching points with the aid of the rotary potentiometers SP1 and SP2 governing the relays takes place

applying the corresponding test loads or, if proceeding from a computed current signal, by means of the constantcurrent settings (Code No. 311 to 355).

The switching action of the relays needs to be set as required using key >T1< (Code No. 211 to 255).

After being connected, the sensor is charged with a test load. If the test load cannot be attained or no constant setting

is possible, an alternative in lieu of this is to set a constant current applying the functions 31x

Page 8 of 12 Subject to technical change 10/2017

A.S.T. Angewandte SYSTEM-TECHNIK GmbH Dresden

- Output current exceeds 4mA: Turn >0< adjuster counter clockwise,

- Green LED remains on: Extend zeroing range in plus

direction applying functions 453 or 454

- Output current exceeds 20mA: Turn >V< adjuster

counter-clockwise,

- Red LED remains on: Extend zeroing range with

functions 43x

Page 13

Manual switching amplifier BS 805

Example

- Cut-off point 1 14mA is intended to switch >SP1<:

- Call function 312 and function 332 (output current now 12mA + 2mA = 14mA)

- Turn >SP1< adjuster clockwise up to the very point where relay 1 just about switches over.

- Cut-off point 2 8mA is intended to switch >SP2<:

- Call function 334 (output current now 14mA + 4mA = 18mA)

- Turn >SP2< adjuster clockwise up to the very point where relay 2 just about switches over.

- Switch to measuring mode applying function 355.

When geared to the standard setting, the relay de-energises as soon as the switching point is attained. The function

2x2 reverses the switching action and allows the relay to energise when the switching point is attained.

7.4. Control of settings

The signal and switching attitude of the BS 805,01 are to be proven at the latest for the delivery of the plant to the

operator at material load cycles.

Protect the setup adjustments with key >T1< (Code-Nr. locking-421 and unlocking-425).

Subject to technical change. 10/2017 Page 9 of 12

A.S.T. Angewandte SYSTEM-TECHNIK GmbH Dresden

Page 14

Manual switching amplifier BS 805

8. Specification

BS 805.01

BS 805.11

BS 805.21

Input

Input signal range

Resistance of strain-gauge bridge

Excitation voltage for sensor

Input resistance

Output

Output signal

Display

Zero point range >0< 4mA

Full load range >V< 20mA

Constant current adjustable

Max. load resistor

Output Relays >SP1< / Relays >SP2<

Switching point adjustable

Switching hysteresis adjustable with >T1<

Switching delay >D< during overstepping

Switching voltage / switching current

Normal / Invers with. >T1<

Accuracy

Reproducibility the settings

Linear error plus hysteresis

Temperature effect full load 20mA

Temperature effect zero 4mA

Power supply

- - Nominal voltage

- - Current consumption

Environmental conditions

Operating temperature range °C -25 ... +60

storage temperature range

Noise immunity

Emitted interference

Oscillating resistance DIN EN 60068-2-6

Shock resistance DIN EN 60068-2-27/-29

Construction

Dimensions (B x H x T)

Environmental protection

admissible conductor cross-section

protective earthing

1) Setting adjustable – 1mV/V to +1mV/V – via key functions 45x.

2) Setting adjustable – 0.5mV/V to 2.5mV/V – via key functions 43x und 44x.

V

mA

mA

mA

mA

Sec

%v. E.

%v. E.

%v.E./10K

%v.E./10K

A

°C -40 ... +70

mm

EN 60529

2

mm

IP65 for BS805.01 and BS805.11/ IP40 for BS805.21

LED-display for Switching status

(10 ... 30)VDC

see measurements in drawings

-2.5 ... +2.4mV/V

350 … 1000

6 LED – display on 4mA-Steps

+/- 0.5mV/V

0.8 ... 2.5mV/V

2 ... 22

0.05 – 0.1 – 0.5 – 1 – 2

250V / 6A

- adjustable -

LED-display for stand by

for BS805.01 and BS805.21/

230VAC for BS805.11

max. 0,3A

DIN EN 61000-6-2

DIN EN 55011-B

Aluminum-die cast

0.14 ... 1.5

Protection class 1

ca. 4

-

4 - 20

300

4 ... 22

0 ... 5

0.5

0.2

0.2

0.2

1)

2)

Page 10 of 12 Subject to technical change 10/2017

A.S.T. Angewandte SYSTEM-TECHNIK GmbH Dresden

Page 15

Manual switching amplifier BS 805

9. EC Declaration of Conformity

Subject to technical change. 10/2017 Page 11 of 12

A.S.T. Angewandte SYSTEM-TECHNIK GmbH Dresden

Page 16

Manual switching amplifier BS 805

Page 12 of 12 Subject to technical change 10/2017

A.S.T. Angewandte SYSTEM-TECHNIK GmbH Dresden

Loading...

Loading...