Page 1

TM

Technology

by AST

TM

Bond

K

rystal

AST2000 Hydrogen Pressure Sensor

316L Stainless Steel, Media Isolated Pressure Sensor for Hydrogen Applications

Overview

The AST2000 series is now available for hydrogen pressure sensing

applications. Tested to a variety of hydrogen and automotive standards,

the AST2000 series combines the best mechanical design for hydrogen

measurement with high performance digital compensation.

Benets

l One piece design

l All 316L wetted material for optimal compatibility

l No oil-lled cavities leave no chance of containment

l Non-welded diaphragm eliminates leak paths and weak points

l Digitally compensated

l Krystal Bond™ Technology

Applications*

l PEM Fuel Cells l Hydrogen Storage

l Hydrogen Filling Stations l Test Stands

l Back Up Power

* Lean more about Hydrogen pressure measurement (Hydrogen Applications)

Environmental Data

Approvals

l EC79 (applicable to table below)

l CE EN61326 (all models)

TUV

Approval

Files

07-01820/1-TUV 20 Bar (2MPa) 600 Bar

EC79 20 Bar (2MPa) 600 Bar

EC79 350 Bar (35MPa) 2800 Bar

EC79 700 Bar (70MPa) 2800 Bar

Pressure

Range

Burst

Pressure

Temperature

Operating -40 to 85°C (-40 to 185°F)

Storage -40 to 125°C (-40 to 250°F)

Thermal Limits

Compensated Range -10 to 60°C (14 to 140°F)

Thermal Error +/- 2% of FS

Other

Shock 100G, 11 msec, 1/2 sine

Vibration 20G peak, 20 to 2400 Hz.

EMI/RFI Protection: Yes

Rating: IPX6K

Performance @ 25°C (77°F)

Accuracy* < ±0.5% BFSL

Electrical Data

Output 0.5-4.5V ratiometric**

Excitation 5VDC regulated

Stability (1 year) ±0.25% FS, typical

Output Impedance <100 Ohms, Nominal

Current Consumption: <10mA

Over range Protection 2X Rated Pressure

Bandwidth -(3dB): DC to 3kHz

Output Noise: <2mV RMS

Pressure Cycles > 100 Million

Zero Offset +/-0.5% of FS

Span Tolerance +/-0.5% of FS

* Accuracy includes non-linearity, hysteresis & non-repeatability

Output Load: 10K Ohms, Min.

Reverse Polarity Protection Yes

**4-20mA and 1-5V outputs available, contact factory

American Sensor Technologies • 450 Clark Dr., Mt. Olive, NJ 07828 • phone (973) 448-1901 • fax (973) 448-1905 • email: info@astsensors.com

Page 2

TM

Ordering Information

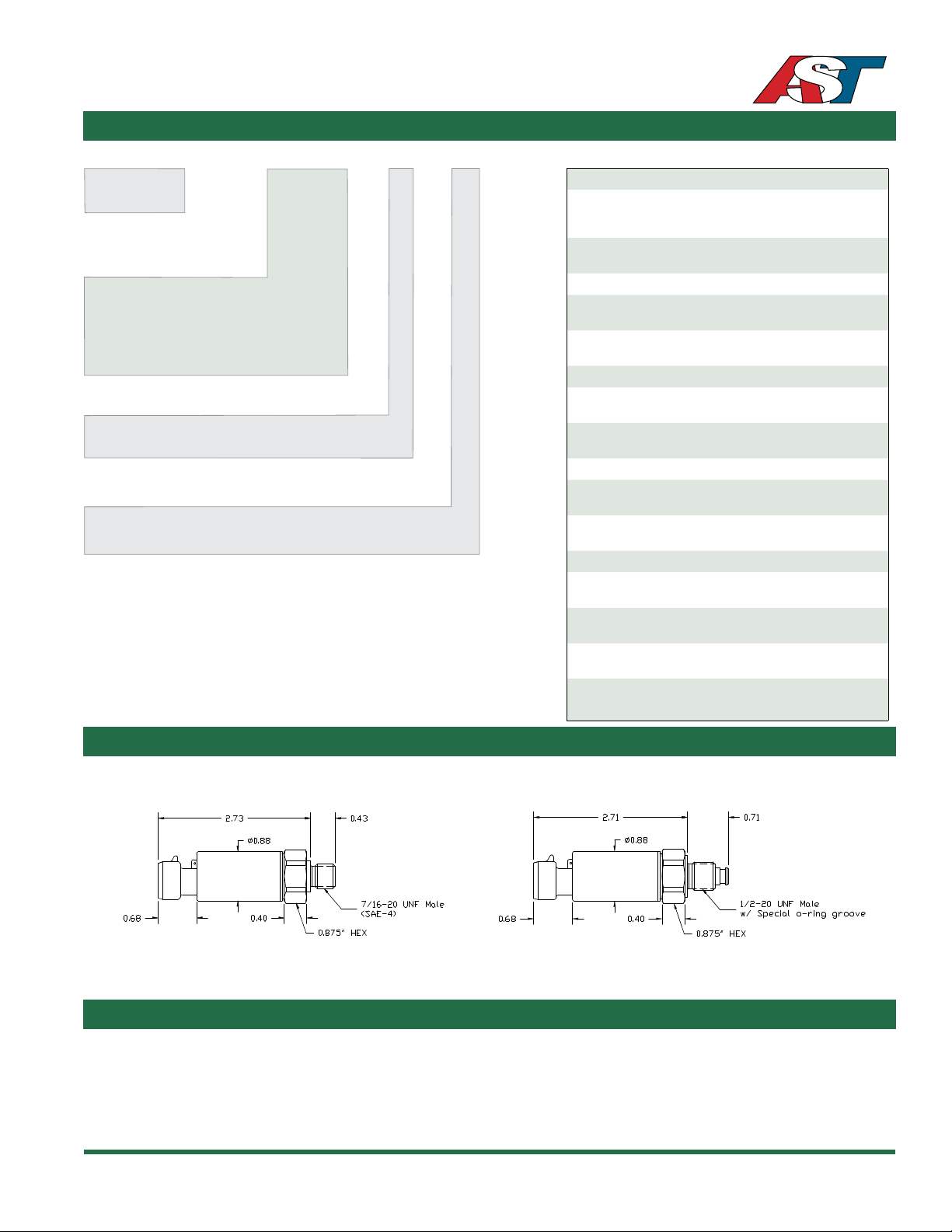

AST2000 F 00500 B 1 F 1 000

Series

Pressure Ports

F= 7/16-20 UNF Male [SAE 4]

M= 3/8-24 UNF Male [SAE 3]

X= Special (see option code 487)

Pressure Range

00020= 20 Bar

00448= 448 Bar

00500= 500 Bar

00700= 700 Bar

00900= 900 Bar

Pressure Unit

B= Bar

Output

1 = 0.5-4.5V ratiometric [5VDC supply]

Electrical

F= Packard Metripack 150

Wetted Material

1= 316L

Options

000= No Options

384= High Accuracy

487= 1/2-20 UNF Stud for high pressure H

+

storage

2

+

3/8-24 UNF Male [SAE 3] is only available for 20 bar and 448 bar

Test Performed

The tests preformed are marked as "X" in the following table. The test

conditions, parameters, and details are described in the Annex 1. (Test

Report) to Technical Report No. KS1011296 dated 2011-01-04.

No. Type of Test EU 406/2010

Remark

Annex IV

1 General Requirements Part 3 Sect. 2 X

2 Technical

Part 3 Sect. 3 X

Requirements

3 Hydrogen

Part 3 Sect. 4.1.1 X

Compatibility Test

4 Ageing Test* Part 3 Sect. 4.1.2 X

5 Ozone Compatibility

Test**

6 Corrosion Resistance

Part 3 Sect. 4.1.3 Not

Applicable

Part 3 Sect. 4.2.1 X

Test

7 Endurance Test Part 3 Sect. 4.2.2 X

8 Hydraulic Pressure

Part 3 Sect. 4.2.3 X

Cycle Test

9 Internal Leakage Test Part 3 Sect. 4.2.4 Not

Applicable

10 External Leakage Test Part 3 Sect. 4.2.5 X

11 Isolation Resistance

ECE R110 Rev. 1 X

Testing

12 EMC Compatibility

ECE R110 Rev. 1 X

Testing

13 Review of Information

Documentation

* Test applies only for non-metallic materials ** Test applies only to elastomer

materials where either a sealing surface is exposed directly to air or if used as a

flexible fuel line cover.

EU 406/2010 Annex

II Part 1

X

Dimensional Data

Warranty

Workmanship - AST, Inc. pressure transmitters have a limited one-year warranty to the original purchaser. AST, Inc. will replace or repair,

free of charge, any defective transmitter. This warranty does not apply to any units that have been modied; misused, neglected or installed

where the application exceeds published ratings. AST’s sensors are made with pride in New Jersey, USA. If in the area please feel free to

stop by for a visit!

Installation/Applications - The purchaser is responsible for media compatibility, functional adequacy, and correct installation of the transmitter.

www.astsensors.com

© 2012 American Sensor Technologies Inc. AST2000-H2 12/18/12.

All specications subject to change without notice.

Loading...

Loading...