Page 1

Weighing Controller

A 810

Manual

Rev. 1.10-22

A.S.T. Angewandte SYSTEM-TECHNIK GmbH Dresden

Marschnerstraße 26 01307 Dresden, Germany

Telefon (03 51) 44 55 30 Telefax (03 51) 44 55 555

www.ast.de

Page 2

Page 3

Thank You!

Thank you for purchase A.S.T. products!

SAFETY PRECAUTION

The integrated circuits used in this equipment are highly immune to noise and RFI when properly installed

in the unit.

The terminal on the rear panel must be grounded directly, not with the AC ground.

Therefore, when shipping please always use original packing (conductive material) for shiping. Remove

equipment from the shopping container and examine the external surfaces of the equipment for physical

damage.

The A 810 should be positioned in a safe area with no combustible gas, the operating temperature is

+14°F to 104°F (-10°C to +40°C), storage temperature -28°F to 185°F (-20°C to +85°C)

Confirm the AC voltage of all equipment before power-up. The A 810 can operate within a -15% to + 10%

voltage variation.

A.S.T. Angewandte SYSTEM-TECHNIK GmbH Dresden Page 1

Page 4

Manual of Weighing Controller A 810

Table of contents

DESCRIPTION...................................................................................................................................................7

1.

1.1. FRONT PANEL ................................................................................................................................................7

1.1.1. Numeric Display....................................................................................................................................7

1.1.2. Unit Display ..........................................................................................................................................7

1.1.3. Status display.........................................................................................................................................7

1.1.4. Keypad...................................................................................................................................................9

1.1.5. Rear Panel...........................................................................................................................................10

1.2. PANEL CUT SIZE ...........................................................................................................................................10

2. CONNECTIONS...............................................................................................................................................11

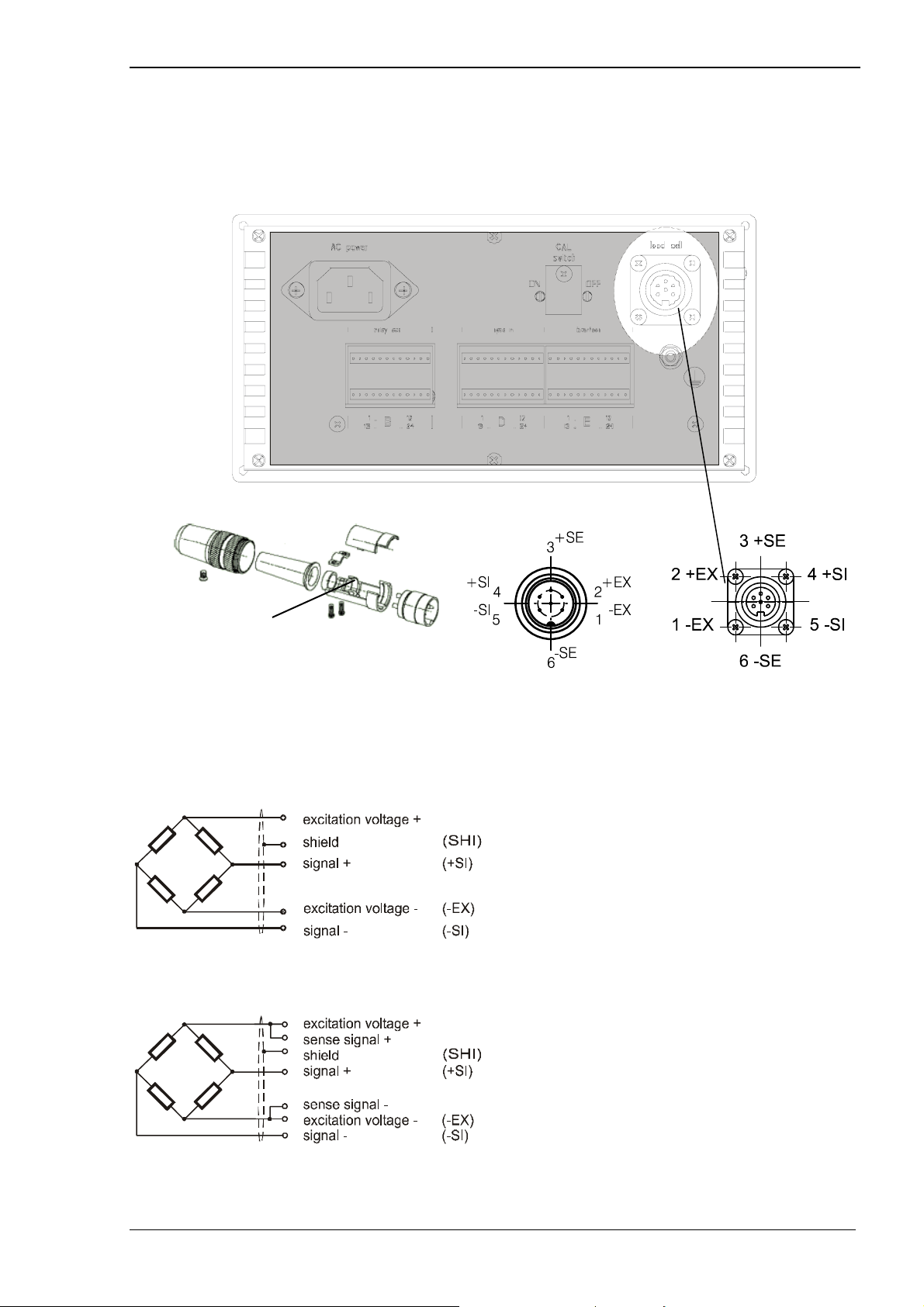

2.1. LOADCELL CONNECTOR...............................................................................................................................11

2.2. PIN- ASSIGNMENT OF CONTROL SIGNAL INPUT / OUTPUT CONNECTOR ......................................................12

2.3. CONTROL INPUT SIGNALS ............................................................................................................................16

2.4. CONTROL OUTPUT SIGNALS.........................................................................................................................19

3. HOW TO GET STARTED...............................................................................................................................21

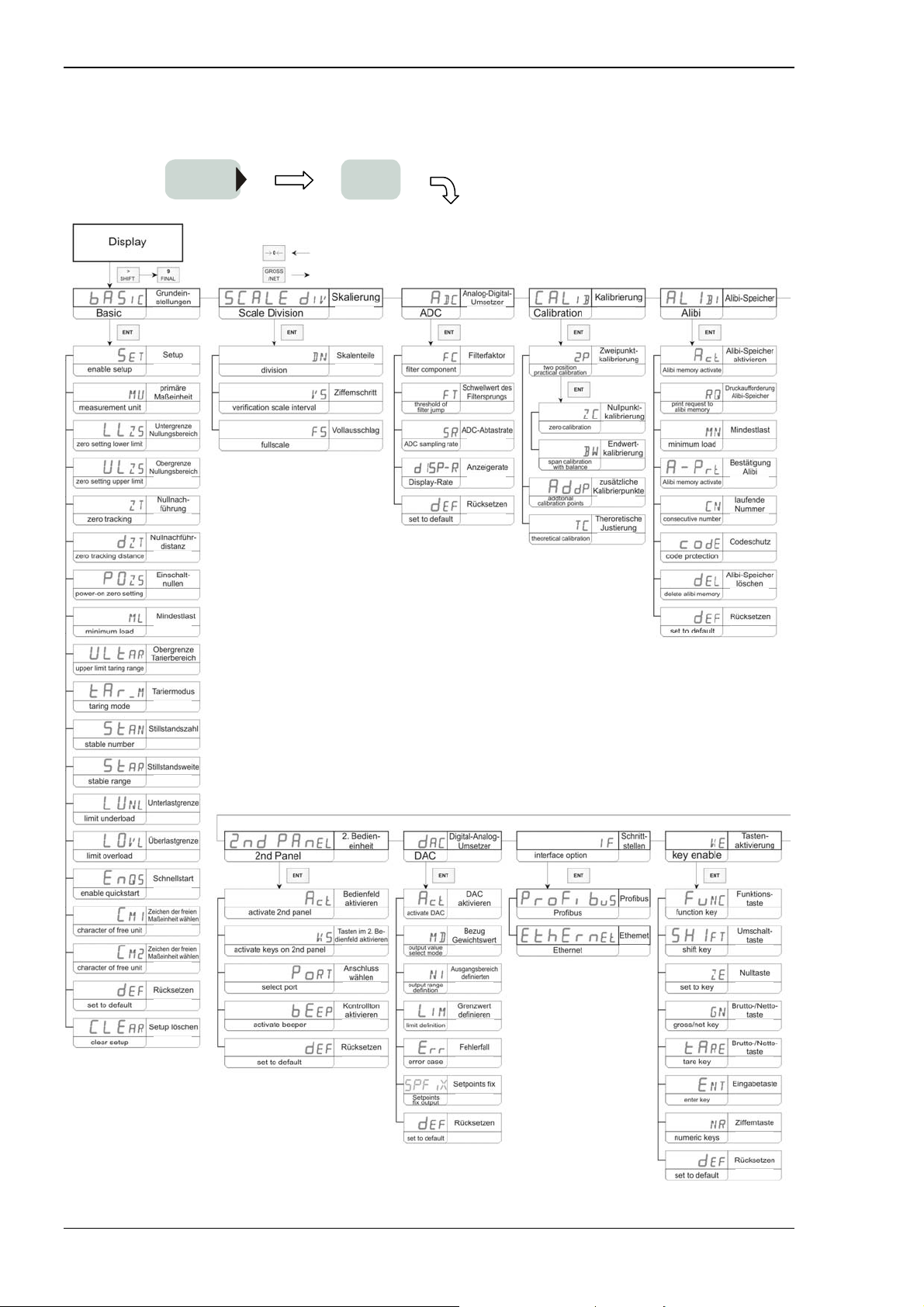

3.1. PARAMETER SETUP SECTION ........................................................................................................................22

3.1.1. Submenu “Basic”................................................................................................................................24

3.1.1.1. Enable Setup “Set”........................................................................................................................................... 24

3.1.1.2. Select primary measurement unit “MU”..........................................................................................................24

3.1.1.3. Range of zero setting lower limit “LLZS”....................................................................................................... 25

3.1.1.4. Range of zero setting upper limit “ULZS”....................................................................................................... 25

3.1.1.5. Zero tracking “ZT” ..........................................................................................................................................25

3.1.1.6. Zero tracking distance “dZT”.......................................................................................................................... 25

3.1.1.7. Power-on zero setting “POZS” ....................................................................................................................... 26

3.1.1.8. Minimum Load “ML”......................................................................................................................................26

3.1.1.9. Upper limit taring range “ULtAR”...................................................................................................................26

3.1.1.10. Taring Mode “tAR_M”................................................................................................................................26

3.1.1.11. Stable number “StAN”............................................................................................................................... 27

3.1.1.12. Stable range “StAR”................................................................................................................................... 27

3.1.1.13. Limit underload “LUNL”........................................................................................................................... 27

3.1.1.14. Limit overload “LOVL”............................................................................................................................. 27

3.1.1.15. Enable quickstart “EnQS”...........................................................................................................................28

3.1.1.16. Select character of free unit “CM1”.............................................................................................................28

3.1.1.17. Select character of free unit “CM2”.............................................................................................................28

3.1.1.18. Set to default “dEF”.....................................................................................................................................29

3.1.1.19. Clear Setup “CLEAR”................................................................................................................................. 29

3.1.2. Submenu “Scale division”...................................................................................................................30

3.1.2.1. Parameter for unit “MU”.................................................................................................................................. 30

3.1.2.1.1. Divisions “DN” ................................................................................................................. ........................ 30

3.1.2.1.2. Verification scale interval “VS”................................................................................................................30

3.1.2.1.3. Fullscale “FS”........................................................................................................................................... 30

3.1.3. Submenu “ADC”.................................................................................................................................32

3.1.3.1. Filter component “FC” .....................................................................................................................................32

3.1.3.2. Threshold of filter jump “FT”.......................................................................................................................... 32

3.1.3.3. ADC sampling rate “SR”.................................................................................................................................32

3.1.3.4. Display Frequency...........................................................................................................................................33

3.1.3.5. Set to default “def”...........................................................................................................................................33

3.1.4. Submenu “Calibration” ......................................................................................................................34

3.1.4.1. Two position practical calibration “2P”........................................................................................................... 34

3.1.4.1.1. Zero calibration “ZC”..............................................................................................................................34

3.1.4.1.2. Span calibration with balance “BW”........................................................................................................ 34

3.1.4.2. Additional calibration points “AddP”..............................................................................................................35

3.1.4.3. Theroretical calibration “TC” .......................................................................................................................... 35

3.1.5. Submenu “Alibi”.................................................................................................................................36

3.1.5.1. Alibi memory activate “Act” ........................................................................................................................... 36

3.1.5.2. Print request to Alibi memory “RQ”................................................................................................................ 36

3.1.5.3. Minimum Load “MN” ..................................................................................................................................... 36

3.1.5.4. Alibi confirmation “A-Prt” ..............................................................................................................................37

3.1.5.5. Consecutive Number “CN”.............................................................................................................................. 37

3.1.5.6. Code protection “code”.................................................................................................................................... 37

3.1.5.7. Delete Alibi memory “dEL”............................................................................................................................ 37

3.1.5.8. Set to default ”dEF”......................................................................................................................................... 38

Page 2 A.S.T. Angewandte SYSTEM-TECHNIK GmbH Dresden

Page 5

Manual of Weighing Controller A 810

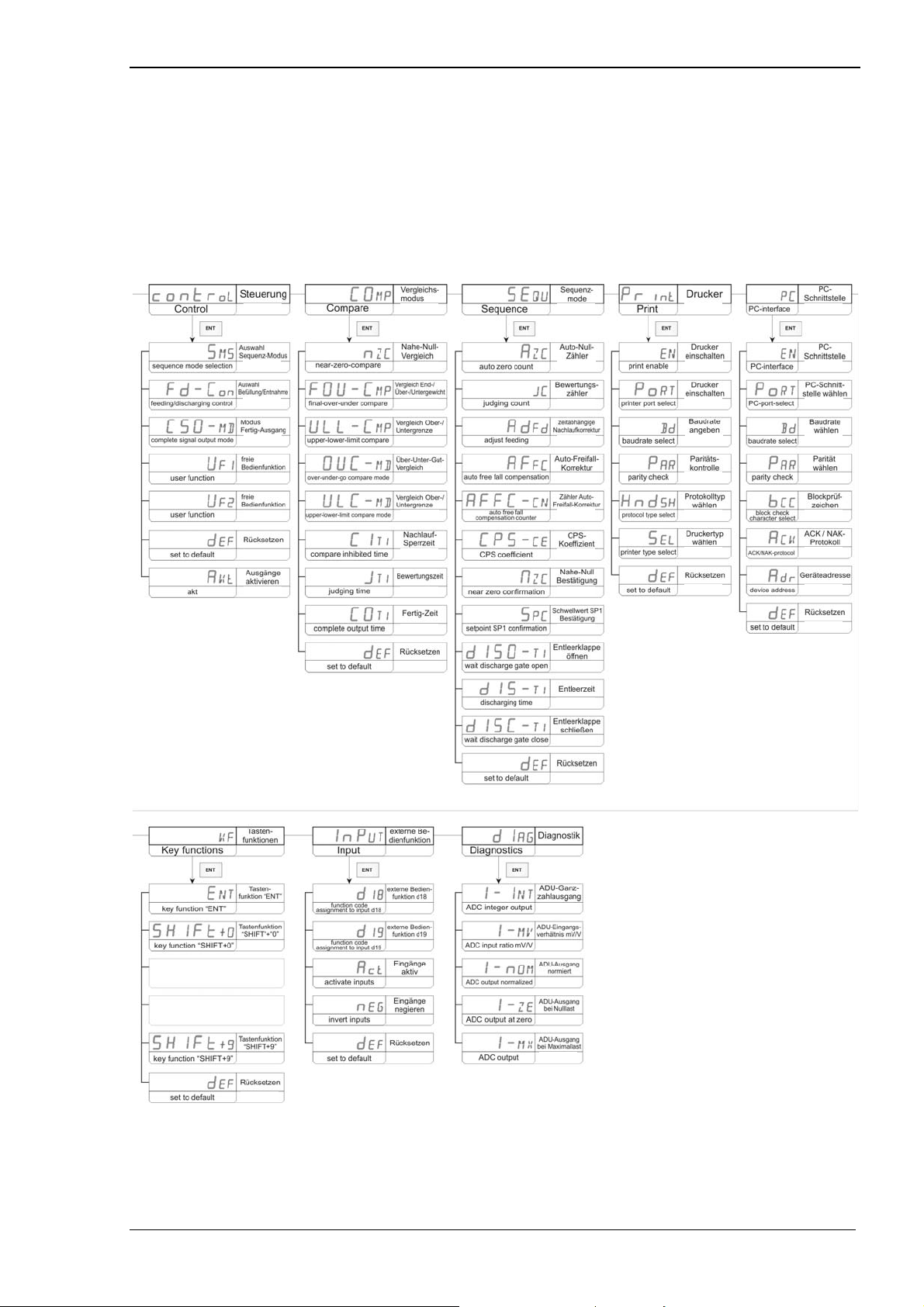

3.1.6.

Submenu “Control”.............................................................................................................................39

3.1.6.1. Sequence mode selection “SMS”.....................................................................................................................39

3.1.6.2. Feeding / Discharging control “Fd-Con”..........................................................................................................39

3.1.6.3. Complete signal output mode “CSO-MD”.......................................................................................................39

3.1.6.4. User function “UF1” ........................................................................................................................................40

3.1.6.5. User function “UF2” ........................................................................................................................................40

3.1.6.6. Set to default “dEF” .........................................................................................................................................40

3.1.7. Submenu comparison mode “COMP”................................................................................................41

3.1.7.1. Near-Zero-Compare “nZC”..............................................................................................................................41

3.1.7.2. Final-Over-Under-Compare “FOU-CMP”.......................................................................................................41

3.1.7.3. Upper-Lower-Limit-Compare “ULL-CMP” ....................................................................................................41

3.1.7.4. Over-under-go-compare mode “OUC-MD”.....................................................................................................42

3.1.7.5. Upper-lower-limit-compare mode “ULC-MD”................................................................................................42

3.1.7.6. Compare inhibited time “CITI” ........................................................................................................................42

3.1.7.7. Judging time “JTI” ...........................................................................................................................................42

3.1.7.8. Complete output time “COTI” .........................................................................................................................43

3.1.7.9. Set to default “dEF” .........................................................................................................................................43

3.1.8. Submenu “SEQU”...............................................................................................................................44

3.1.8.1. Auto Zero Count “AZC”..................................................................................................................................44

3.1.8.2. Judging count “JC”...........................................................................................................................................44

3.1.8.3. Adjust feeding “AdFd”.....................................................................................................................................44

3.1.8.4. Auto free fall compensation “AFFC”...............................................................................................................45

3.1.8.5. Auto free fall compensation counter ”AFFC-CN”...........................................................................................45

3.1.8.6. CPS coefficient “CPS-CE”...............................................................................................................................45

3.1.8.7. Near zero confirmation “NZC” ........................................................................................................................45

3.1.8.8. Setpoint SP1 confirmation “SPC”....................................................................................................................46

3.1.8.9. Wait discharge gate open “dISO-TI”................................................................................................................46

3.1.8.10. Discharging time “dIS-TI”...........................................................................................................................46

3.1.8.11. Wait discharge gate close “dISC-TI”...........................................................................................................46

3.1.8.12. Set to default “dEF”.....................................................................................................................................47

3.1.9. Submenu “Print”.................................................................................................................................48

3.1.9.1. Printer enable “EN”..........................................................................................................................................48

3.1.9.2. Printer port select “PoRT”................................................................................................................................48

3.1.9.3. Baudrate select “Bd”........................................................................................................................................48

3.1.9.4. Parity check “PAR”..........................................................................................................................................48

3.1.9.5. Protocol typ select “HndSH”............................................................................................................................49

3.1.9.6. Printer type select “SEL” .................................................................................................................................49

3.1.9.7. Set to default “dEF” .........................................................................................................................................49

3.1.10. Submenu PC-Interface “PC”..............................................................................................................50

3.1.10.1. PC-Interface “EN”.......................................................................................................................................50

3.1.10.2. PC-Port-select “PoRT” ................................................................................................................................50

3.1.10.3. Baudrate select “Bd”....................................................................................................................................50

3.1.10.4. Parity select “PAR”......................................................................................................................................50

3.1.10.5. Block check character select “bCC” ............................................................................................................51

3.1.10.6. ACK / NAK-Protocol “ACK”......................................................................................................................51

3.1.10.7. Device address “Adr” ..................................................................................................................................51

3.1.10.8. Set to default “dEF”.....................................................................................................................................51

3.1.11. Submenu “2nd Panel”.........................................................................................................................52

3.1.11.1. Activate 2nd Panel “Act”.............................................................................................................................52

3.1.11.2. Activate keys on 2nd panel “KS....................................................................................................................52

3.1.11.3. Select “Port” ................................................................................................................................................52

3.1.11.4. Activate beeper “bEEP”...............................................................................................................................52

3.1.11.5. Set to default “dEF”.....................................................................................................................................53

3.1.12. Submenu “dAC”..................................................................................................................................54

3.1.12.1. Activate DAC “Act”....................................................................................................................................54

3.1.12.2. Output value select mode “MD”..................................................................................................................54

3.1.12.3. Output range definition “NI”.......................................................................................................................54

3.1.12.4. Limit definition “LIM”................................................................................................................................55

3.1.12.5. Error case “Err” ...........................................................................................................................................55

3.1.12.6. constant analog output “SPFix”...................................................................................................................55

3.1.12.7. Set to default “dEF”.....................................................................................................................................55

3.1.13. Submenu Interface option “IF”...........................................................................................................57

3.1.13.1. Submenu “Profibus“ ...................................................................................................................................57

3.1.13.1.1. Profibus activate “Act“............................................................................................................................57

3.1.13.1.2. PB-address select “Pb-ADR”..................................................................................................................57

3.1.13.1.3. Set to default “def”..................................................................................................................................57

3.1.13.2. Submenu “Ethernet“ ....................................................................................................................................58

3.1.13.2.1. Ethernet activate “Act“............................................................................................................................58

3.1.13.2.2. TCP/IP-address “IP_ADR“..................................................................................................................... 58

3.1.13.2.3. Subnetmask “Net_M“..............................................................................................................................58

A.S.T. Angewandte SYSTEM-TECHNIK GmbH Dresden Seite 3

Page 6

Manual of Weighing Controller A 810

3.1.13.2.4. Gateway “Gate_W“.................................................................................................................................59

3.1.13.2.5. Set to default “def”..................................................................................................................................59

3.1.14. Submenu Key enable “KE”.................................................................................................................60

3.1.14.1. Function – Key “Func”................................................................................................................................ 60

3.1.14.2. Shift – Key “SHIFT”................................................................................................................................... 60

3.1.14.3. Set – Zero – Key “ZE” ................................................................................................................................ 60

3.1.14.4. Gross / Net – Key “GN”.............................................................................................................................. 60

3.1.14.5. Tare – Key “TA”................................................................................................................ ......................... 61

3.1.14.6. Enter – Key “ENT”......................................................................................................................................61

3.1.14.7. Numeric – Keys “NR”................................................................................................................................. 61

3.1.14.8. Set to default “dEF”.....................................................................................................................................61

3.1.15. Submenu key functions “KF”..............................................................................................................62

3.1.15.1. Key Function “ENT”................................................................................................................................... 62

3.1.15.2. Key Function “Shift+0”...............................................................................................................................62

3.1.15.3. Key Function “Shift+9”...............................................................................................................................62

3.1.15.4. Set to default “dEF”.....................................................................................................................................62

3.1.16. Submenu “Input”.................................................................................................................................64

3.1.16.1. Function code assignment to input D° 18....................................................................................................64

3.1.16.2. Function code assignment to input D° 19....................................................................................................64

3.1.16.3. Activate inputs “Act”...................................................................................................................................64

3.1.16.4. Invert inputs “neg”.......................................................................................................................................64

3.1.16.5. Set to default “dEF”.....................................................................................................................................65

Submenu “Diagnostics”......................................................................................................................................66

3.1.16.6. ADC – Integer output “I - INT”.................................................................................................................66

3.1.16.7. ADC – input ratio mv/V “I – MV”.............................................................................................................. 66

3.1.16.8. ADC – output normalized “I – nOM........................................................................................................... 66

3.1.16.9. ADC – ouput at zero “I – ZE”..................................................................................................................66

3.1.16.10. ADC – output “I – MX”..............................................................................................................................66

3.2. COMBINATION OF “FUNC” AND ANY NUMERIC KEY .....................................................................................67

3.2.1. Reduced setup (0)................................................................................................................................67

3.2.2. Show actaul code (1)...........................................................................................................................67

3.2.3. Activate code / edit codesets (2)..........................................................................................................67

3.2.3.1. Code selection..................................................................................................................................................67

3.2.3.2. Code source select............................................................................................................................................ 67

3.2.3.2.1. Parameter set of code N° 0........................................................................................................................ 68

3.2.3.2.2. Parameter “FINAL” of code N° 0............................................................................................................. 68

3.2.3.2.3. Parameter “Compensation” of code N° 0.................................................................................................. 68

3.2.3.2.4. Constant analog output “CPS out”............................................................................................................ 68

3.2.3.2.5. Parameter “Set Point 2” of code N° 0.......................................................................................................68

3.2.3.2.6. Constant analog output “SP2 out”............................................................................................................. 69

3.2.3.2.7. Parameter “Set Point 1” of code N° 0......................................................................................................69

3.2.3.2.8. Constant analog output “SP1 out”............................................................................................................. 69

3.2.3.2.9. Parameter “Over” of code N° 0................................................................................................................. 70

3.2.3.2.10. Parameter “Under” of code N° 0.............................................................................................................70

3.2.3.2.11. Parameter “Upper” of code N° 0.............................................................................................................70

3.2.3.2.12. Parameter “Lower” of code N° 0................................................................................................. ........... 70

3.2.3.2.13. Parameter “Near Zero” of code N° 0......................................................................................................71

3.2.3.2.14. Parameter “AFFL” of code N° 0............................................................................................................. 71

3.2.3.2.15. Parameter “CFTI” of code N° 0............................................................................................................ 71

3.2.3.3. Parameter set of code N° 1............................................................................................................................... 71

3.2.3.4. Parameter set of code N° 9............................................................................................................................... 71

3.2.4. Show accumulation total sum (3) ........................................................................................................72

3.2.5. Show accumulation count (4)..............................................................................................................72

3.2.6. Clear active accumulated sum (5).......................................................................................................72

3.2.7. Clear all codesets (6)...........................................................................................................................73

3.2.8. Set date and time (7)............................................................................................................................73

3.2.9. Edit Consecutive number (8)...............................................................................................................74

3.2.10. Show higher resolution (9) ..................................................................................................................74

4. SERIAL INTERFACES ...................................................................................................................................75

4.1. MODES OF OPERATION OF THE SERIAL INTERFACES ....................................................................................75

4.2. EXCHANGE OF A CHARACTER ......................................................................................................................75

4.2.1. Data Exchange Parameters.................................................................................................................75

4.2.2. Character Coding................................................................................................................................75

4.2.3. Electrical Implementation of the Serial Interfaces..............................................................................75

4.2.4. Physical Protocol (Handshake)...........................................................................................................76

4.2.5. Logical Devices...................................................................................................................................76

Page 4 A.S.T. Angewandte SYSTEM-TECHNIK GmbH Dresden

Page 7

Manual of Weighing Controller A 810

4.3.

PRINTERS .....................................................................................................................................................76

4.4. REMOTE DISPLAY UNITS..............................................................................................................................76

4.4.1. A810 Remote Display Units.................................................................................................................76

4.4.2. Foreign Remote Display Units ............................................................................................................77

4.5. PC / SPC......................................................................................................................................................77

4.5.1. Acknowledgement Protocol.................................................................................................................77

4.5.2. Structure of a Data Frame...................................................................................................................77

4.5.3. Remote Control Commands.................................................................................................................77

4.5.3.1. Keyboard Commands.......................................................................................................................................78

4.5.3.2. Commands for Weighing Operations...............................................................................................................79

4.5.3.3. Commands for Printer Output ..........................................................................................................................82

4.5.3.4. Commands for Data Protocol...........................................................................................................................84

4.5.3.5. Miscellaneous Command .................................................................................................................................85

4.5.4. Behaviour in case of trouble................................................................................................................86

4.6. EXAMPLES OF COMMUNICATION INTERFACES .............................................................................................87

4.6.1. RS-485 Interface..................................................................................................................................87

4.6.2. RS-232 Interface..................................................................................................................................88

4.7. TABLES OF SERIAL INTERFACES....................................................................................................................89

4.7.1. Commands of the PC Interface............................................................................................................89

4.7.2. Code-Table A810 Keyboard................................................................................................................90

5. SPECIFICATIONS...........................................................................................................................................91

5.1. INTERFACE ...................................................................................................................................................92

5.2. FEATURES / BASIC FUNCTIONS .....................................................................................................................92

5.3. CALIBRATION LOCK.....................................................................................................................................93

6. APPLICATION NOTES...................................................................................................................................94

6.1. CALIBRATION PROCEDURE ...........................................................................................................................94

6.2. THEORETICAL CALIBRATION ........................................................................................................................96

6.3. SIMPLE COMPARISON MODE – FEEDING WEIGHING E.G. 1...........................................................................97

6.4. SIMPLE COMPARISON MODE – FEEDING WEIGHING E.G. 2...........................................................................99

6.5. SIMPLE COMPARISON MODE – DISCHARGING WEIGHING ..........................................................................101

6.6. SEQUENCE MODE.......................................................................................................................................103

6.7. SEQUENCE MODE WITHOUT JUDGEMENT ...................................................................................................105

6.8. SEQUENCE MODE WITH ADJUST FEEDING ..................................................................................................106

6.9. AUTO FREE FALL COMPENSATION .............................................................................................................107

7. APPENDIX ......................................................................................................................................................108

7.1. ASCII-TABLE.............................................................................................................................................108

7.2. SURVEY OF OPERATING FUNCTIONS ..........................................................................................................109

7.3. DESCRIPTION OF STATES OF ERROR ...........................................................................................................112

A.S.T. Angewandte SYSTEM-TECHNIK GmbH Dresden Seite 5

Page 8

Manual of Weighing Controller A 810

0 History

1.10.22 (May 11): signal output B21 used in sequence-mode; generation of Err109 due to

missing confirmation signal at input pins D18 or D19 (with user function

“230” associated); detailed description of signal input D18/19 at page 65;

change of picture “PC-Interface” at page 88; new parameter “SPFix” in

menu “DAC” for constant analog output at setpoints SP1, SP2 and CPS

1.10-21 (November 10): Interface: USB as option

1.10-20 (September 10): graphics of frontdesign and rear-panel changed due to constructive

reasons

1.10-19 (January 10): due to change of processor, sample rate of 400/s is selectable

(Firmware-Version V.32)

1.10-18 (June 09): due to Firmware-Update to V.31 default parameter dISP-R changed

(faster display rate)

1.10-17 (June 09): due to Firmware-Update to V.30 parameter dISP-R added (display rate

selectable)

1.10-16 (May 08): description Err 129 added

1.10-15 (March 08): refresh rate of I/O added

1.10-14 (January 08): additional operating functions added

1.10-13 (November 07): description of “dAC” changed

Page 6 A.S.T. Angewandte SYSTEM-TECHNIK GmbH Dresden

Page 9

Manual of Weighing Controller A 810

1. Description

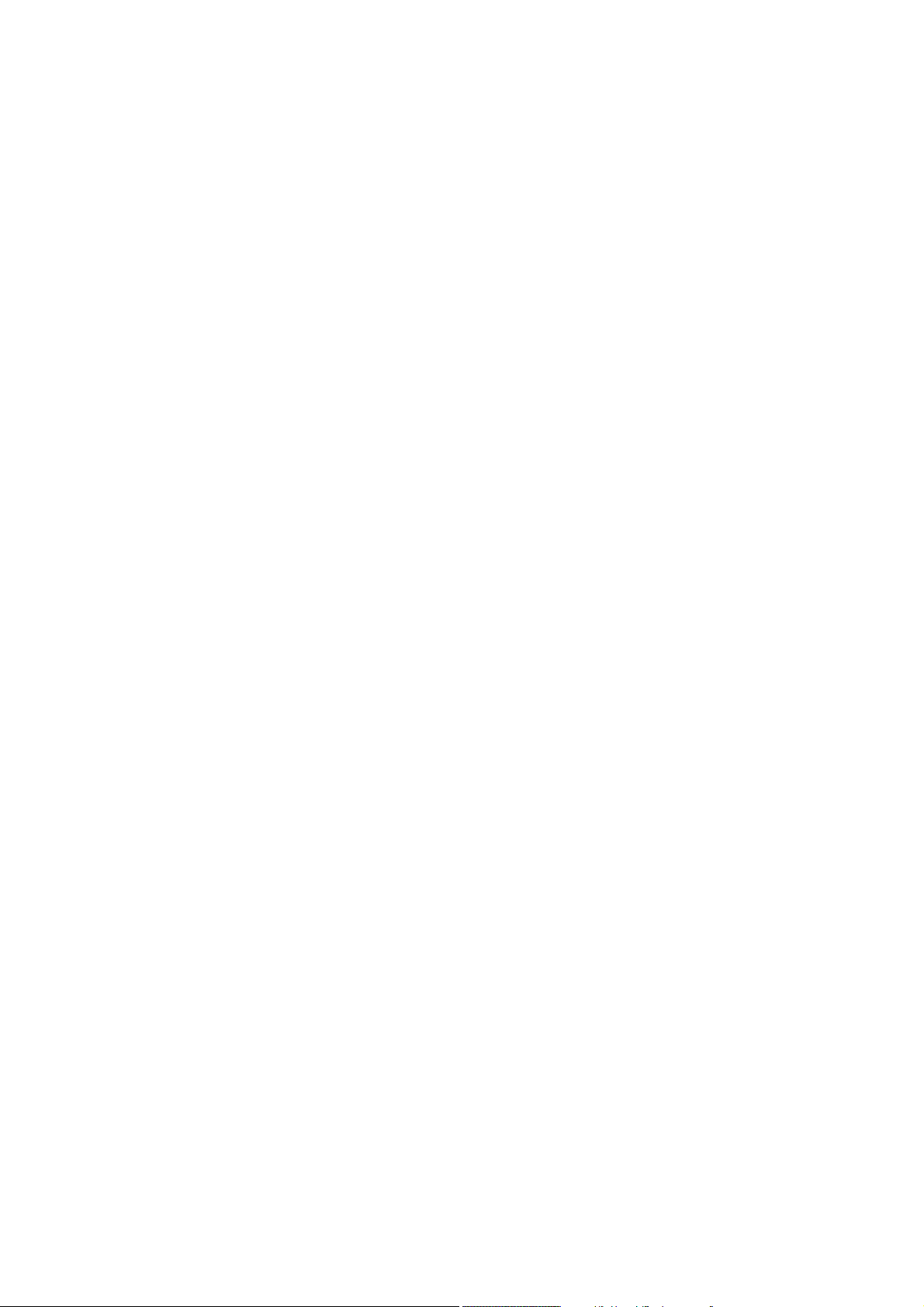

1.1. Front Panel

Numeric display

Unit display

Status display

SP3

KEY ZT ZALM TARE NET GROSS 0

HOLD LO LIM LO GO HI HI LIM NZ

1

UPPER

6

LOWER

SP2 SP1 STAB

23

OVER NEAR Z

78

UNDER FINAL

SP1

9

CPS

Keypad

54

SP2

0

USER

0

TAR E ENT

GROSS

/NET

SHIFTFUNC

The front panel contains a 7 digit numeric display, a two digit alphanumeric display, a multiple status

display and 16 key membrane pad.

Legal-for-trade weighing parameter information is available in a separate window (Descriptive marking).

1.1.1. Numeric Display

The seven digit large size display allows showing a six digit weighing value and an additional plus / minus

character. This display is used for weighing values like Gross, Net, Tare, accumulation values and setup

values as well as Error messages.

1.1.2. Unit Display

This two digit unit display is used for units in weighing mode and for alphanumeric information in setting

mode.

1.1.3. Status display

SP3 : Turns on, if the weighing value has reached “FINAL” – “CPS” and the desired output

signal at the rear panel is active on.

SP2 : Turns on, if the weighing value has reached “FINAL” - “SetPoint2” and the desired

output signal at the rear panel is active on.

SP1 : Turns on, if the weighing value has reached “FINAL” - “SetPoint1” and the desired

output signal at the rear panel is active on.

KEY : Turns on, if the calibration lock is enabled.

ZT : Turns on, if zero tracking is in operation.

ZALM : Starts flashing if zero drift exceeds the Digital Zero limit.

A.S.T. Angewandte SYSTEM-TECHNIK GmbH Dresden Seite 7

Page 10

Manual of Weighing Controller A 810

0

STAB

: Turns on, if weighing value is stable.

: Turns on, if Tare weight is displayed.

TARE : “TARE” turns on, if Tare subtraction is active and Tare has a content.

NET : Turns on, if Net weight is displayed.

GROSS : Turns on, if Gross weight is displayed.

HI LIM : Turns on, if upper limit has been reached and the desired output signal at the rear panel

is active on.

HI : Turns on, if “weighing_value” > “FINAL” + “OVER”.

GO : Turns on, if ”FINAL” - “UNDER” ≤ “weighing_value” ≤ “FINAL” + “OVER”.

LO : Turns on, if “weighing_value” < “FINAL” - “UNDER”.

LO LIM : Turns on, if lower limit has been reached and the desired output signal at the rear panel

is active on.

HOLD : Turns on, if weighing display is held.

NZ : Turns on, if “weighing_value” ≤ “Near_Zero”.

: Turns on, if weighing value is at +1/4 scale division.

: Turns on, if weighing value is at centre zero.

: Turns on, if weighing value is at -1/4 scale division.

Page 8 A.S.T. Angewandte SYSTEM-TECHNIK GmbH Dresden

Page 11

Manual of Weighing Controller A 810

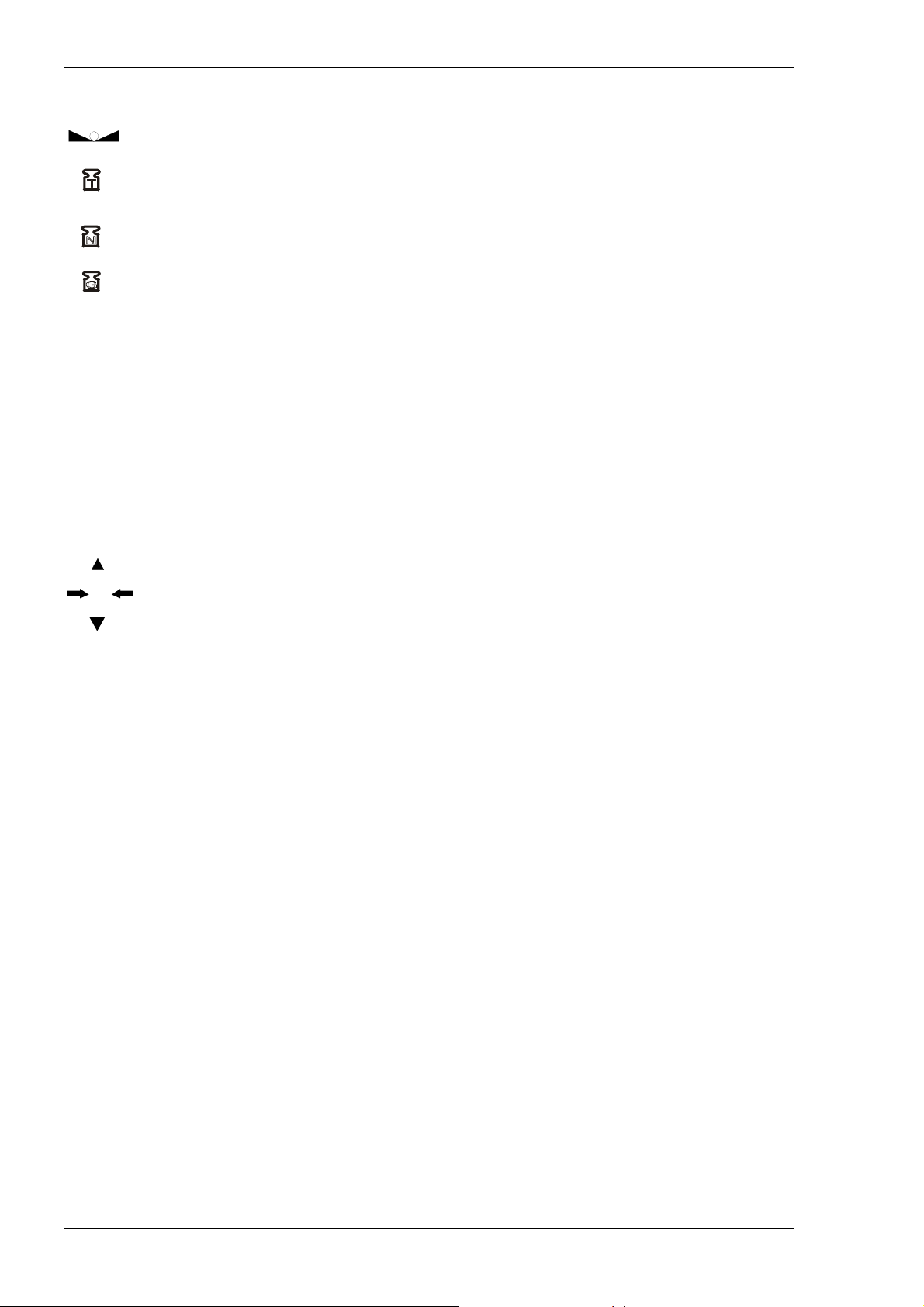

1.1.4. Keypad

Display in weighing mode Display in setup mode

FUNC

Entry in setting modes according

followed key inputs

(see page 67)

Shifting active cursor position one

position to the left

SHIFT

Entry into code display modes

according followed key inputs

Shifting active cursor position one

position to the right

if pressed the weighing value is

0

zeroed, the Gross weight becomes

Zero. Only available when “ZALM”

is inactive.

Æ one step up in navigation at the

present level

Æ incrementing the value of active

(flashing) character position

Æ toggle between on / off display

GROSS

/NET

if pressed the weighing value display

toggled between Gross and Net

indicated by the

or sign

Æ one step down in navigation at the

present level

Æ decrementing the value of active

(flashing) character position

Æ toggle between on / off display

if pressed the Tare weight will be

subtract, Net weight becomes Zero

TAR E

(ESC)

and “TARE” -sign switches on;

SHIFT

to clear Tare weight press

6

LOWER

then

Signs

Press

.

are illuminated.

TAR E

for 2 sec and tare weight

and

Æ if pressed in setup mode the

present action is terminated and the

setting goes one level up;

Æ in first setting level this key

terminates the setup mode and

returns the display to weighing mode

is cleared.

ENT

Default: Print;

User defined action selectable.

(Refer to 3.1.15.1)

Confirms the present setting.

Changed Parameter will be stored.

1

UPPER

…..

direct display and setting of values of

the presently selected code

9

CPS

A.S.T. Angewandte SYSTEM-TECHNIK GmbH Dresden Page 9

Page 12

Manual of Weighing Controller A 810

1.1.5. Rear Panel

AC Power Input Connector

1

AC input is labeled with the standard AC voltage of the country in

which the unit was purchased.

Available voltage is: 115 or 230 V AC

Confirm the correct voltage on your A810. AC frequency is 48 to 62 Hz

and voltage supply -15 to +10%

2

Output Connector

Interface Connector for RS232, TTY, RS485

3

Load cell connector Refer to Page 11 – Loadcell Connector

4

Calibration lock

5

Control signal Input/ Refer to Page 12 - PIN- Assignment of Control Signal Input / Output

Connector

1.2. Panel cut size

Page 10 A.S.T. Angewandte SYSTEM-TECHNIK GmbH Dresden

Page 13

Manual of Weighing Controller A 810

2. Connections

2.1. Loadcell Connector

Shield

4 wire standard:

Frontview

(+EX)

6 WIRE FOR REMOTE SENSING:

(+EX)

(+SE)

(-SE)

A.S.T. Angewandte SYSTEM-TECHNIK GmbH Dresden Page 11

Page 14

Manual of Weighing Controller A 810

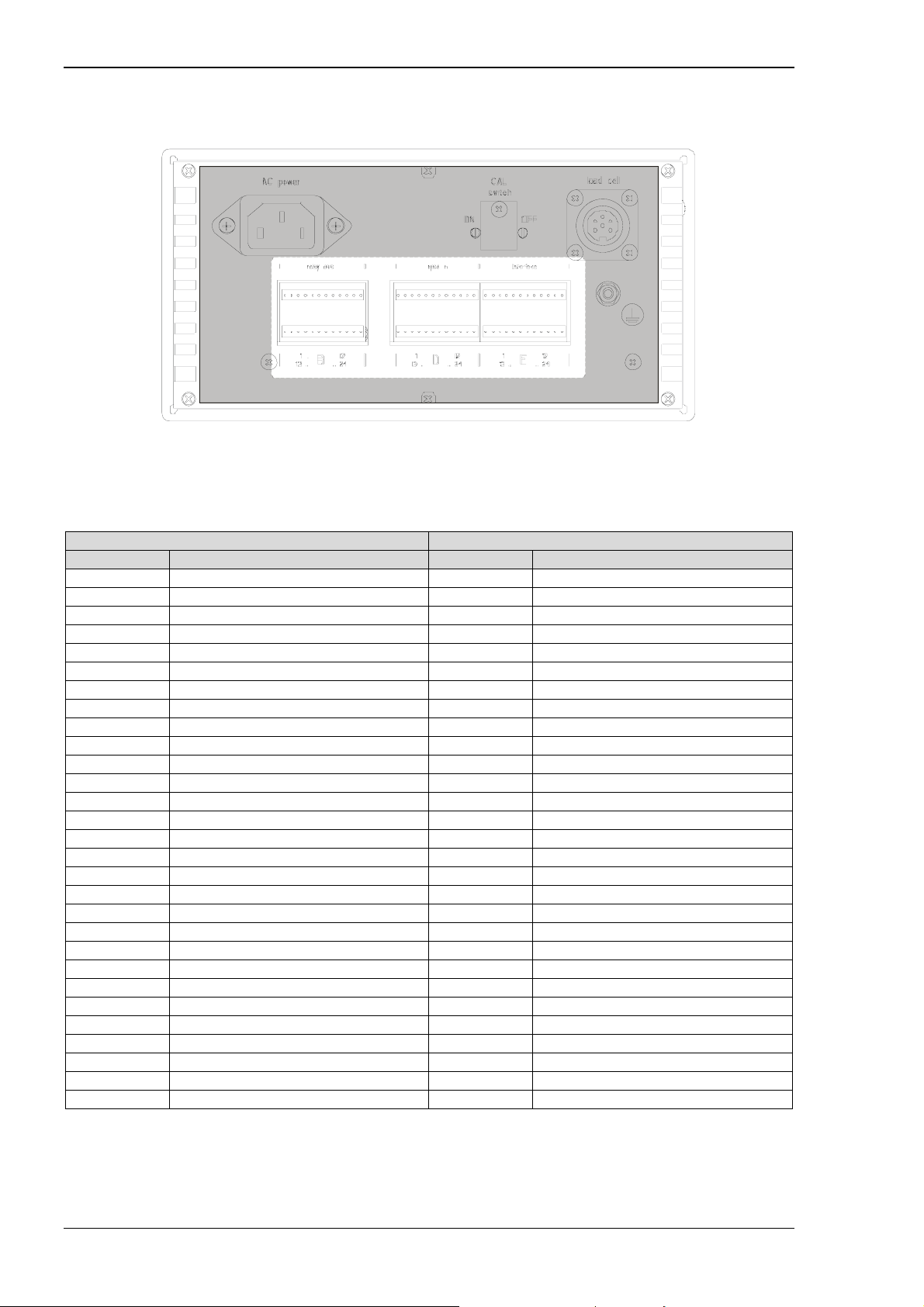

2.2. PIN- Assignment of Control Signal Input / Output Connector

Connector A: Power

B: Control- Output- Signals

D: Control- Input- Signals

E: RS232, RS485, TTY- Interface, 4...20mA norm output

Connector B / Output-Signals Connector D / Input-Signals

PIN Signal PIN Signal

B13 COM *2 D3 COM *2

B1 SP1 D4 G/N

B2 SP2 D5 D/Z ON

B3 SP3/ CPS D6 Tare subtraction ON

B4 near zero D7 Tare subtraction OFF

B14 COM *2 D12 COM *2

B5 under D8 Hold or Judgment

B6 over D9 Feed/ Discharge

B7 lower limit D10 start *1

B8 upper limit D11 stop *1

B15 COM *2 D24 COM *2

B9 stable D16 start accumulation

B10 discharge D17 clear accumulation sum

B11 go D18 user defined function

B12 complete D19 user defined function

B16 COM *2 D15 COM *2

B21 sequence active *1 D20 Code No. 8

B22 run D21 Code No. 4

B23 sequence error D22 Code No. 2

B24 weight error D23 Code No. 1

B17 GND, extern I/O D1

B18 GND, extern I/O D2

B19 +24V, extern I/O D13

B20 +24V, extern I/O D14

*1 are effective in sequence mode

*2 COM- terminals are not connected internally

Page 12 A.S.T. Angewandte SYSTEM-TECHNIK GmbH Dresden

Page 15

Manual of Weighing Controller A 810

Connector E Description Remarks

E1 RxD5+ TTY (Port 4)

E2 RxD5- TTY (Port 4)

E3 TxD5+ TTY (Port 4)

E4 TxD5- TTY (Port 4)

E5 GND RS232

E6 GND RS232

E7 TxD2 RS232 (Port 1)

E8 RxD2 RS232 (Port 1)

E9 R(A) RS485 (Port0)

E10 R(B) RS485 (Port0)

E11 D(Z) RS485 (Port0)

E12 D(Y) RS485 (Port0)

E13 GND_24

E14 P24

E15 U-OUT DAC (0…10V)

E16 I-OUT DAC (0…20mA)

E17 GND_24 DAC

E18 AUTO_SENSOR

E19 RxD3 RS232 (Port 2)

E20 TxD3 RS232 (Port 2)

E21 R(A) RS485 (Port0)

E22 R(B) - Rt RS485 (Port0)

E23 D(Z) RS485 (Port0)

E24 D(Y) - Rt RS485 (Port0)

Please refer to section 4.6 “Examples of Communication Interfaces” at page 87 for a detailed description

of interfaces.

external ground

optocoupler

external sypply

optocoupler

A.S.T. Angewandte SYSTEM-TECHNIK GmbH Dresden Page 13

Page 16

Manual of Weighing Controller A 810

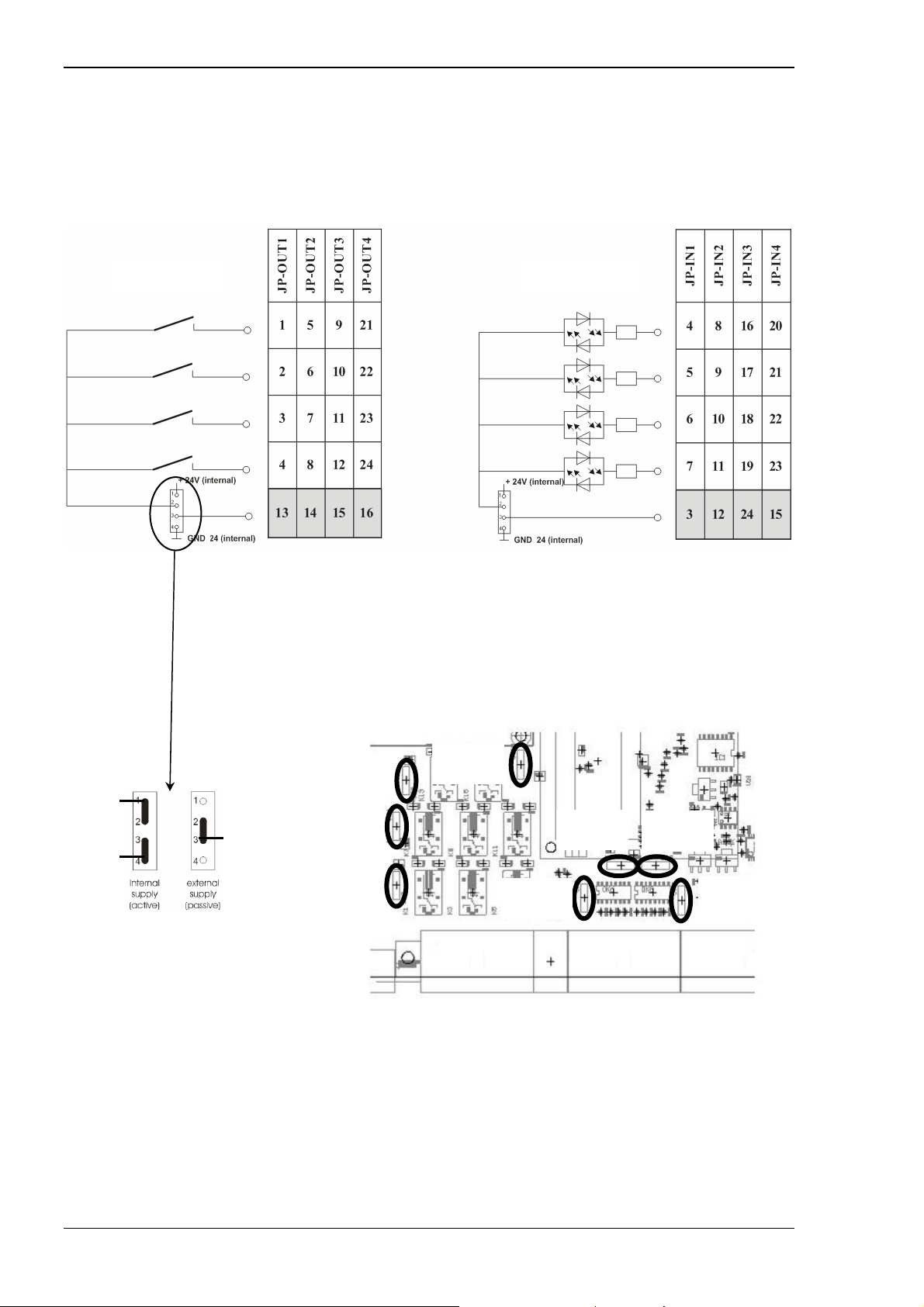

Relay outputs (connector B) and Opto inputs (connector D) can either be with power (active) or neutral

(passiv) depending on interal jumper position on mainboard. Both Input and Output connectors are

separated into four groups. Each group contains four signals with dedicated COM. By setting each

individual jumper’s position to decide each group whether the I/O are with power or neutral.

Connector B Connector D

COM COM

Fig. 1 Internal schematic of Relay Output (B) and Opto Input (D)

I/Os are I/Os are

with power neutral

+24V

COM

JP- OUT3

(B9-12)

JP- OUT2

(B5-8)

JP-OUT4

(B21-24)

Gnd

JP-OUT1

(B1-4)

JP-IN4

(D20-23)

Fig. 2 Jumper setting

JP-IN1

(D4-7)

JP-IN2

(D8-11)

JP-IN3

(D16-19)

B D E

Fig. 3 Jumper positions on mainboard

Page 14 A.S.T. Angewandte SYSTEM-TECHNIK GmbH Dresden

Page 17

Manual of Weighing Controller A 810

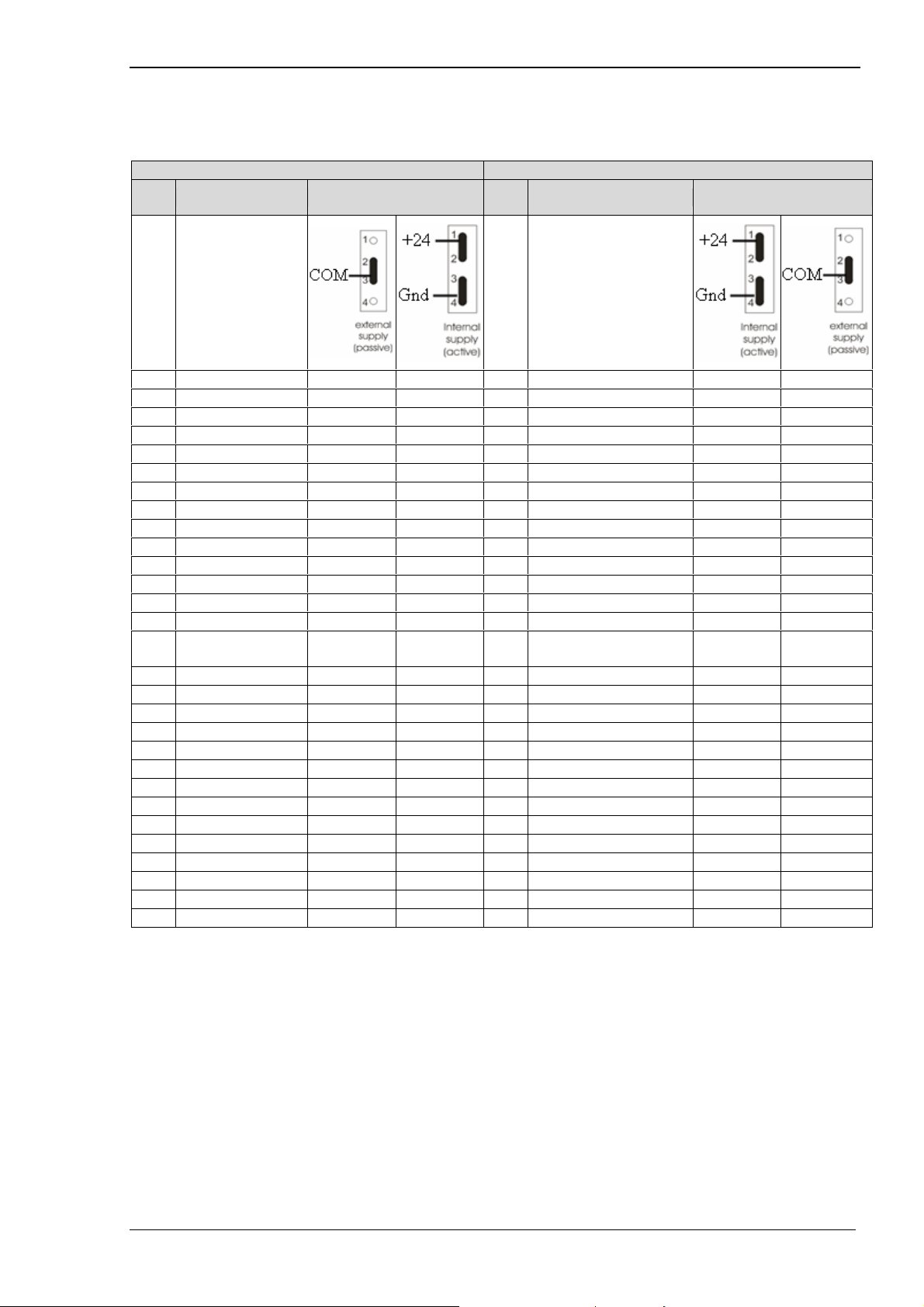

Jumper-Positions:

Connector B / Output-Signals Connector D / Input-Signals

PIN Signal Polarity (JP-OUT1…4) PIN Signal Polarity (JP-IN1…4)

B13 COM none *2 - D3 COM - none *2

B1 SP1 none + D4 G/N + none

B2 SP2 none + D5 D/Z ON + none

B3 SP3/ CPS none + D6 Tare subtraction ON + none

B4 near zero none + D7 Tare subtraction OFF + none

B14 COM none *2 - D12 COM - none *2

B5 under none + D8 Hold or Judgment + none

B6 over none + D9 Feed/ Discharge + none

B7 lower limit none + D10 start *1 + none

B8 upper limit none + D11 stop *1 + none

B15 COM none *2 - D24 COM - none *2

B9 stable none + D16 start accumulation + none

B10 discharge none + D17

B11 go none + D18 user defined function + none

B12 complete none + D19 user defined function + none

B16 COM none *2 - D15 COM - none *2

B21 Sequence active None *1 + D20 Code No. 8 + none

B22 run none + D21 Code No. 4 + none

B23 sequence error none + D22 Code No. 2 + none

B24 weight error none + D23 Code No. 1 + none

B17 GND, extern I/O - - D1 not used none none

B18 GND, extern I/O - - D2 not used none none

B19 +24V, extern I/O + + D13 not used none none

B20 +24V, extern I/O + + D14 not used none none

default default

*1 are effective in sequence mode

*2 COM- terminals are not connected internally

clear accumulation

sum

+ none

A.S.T. Angewandte SYSTEM-TECHNIK GmbH Dresden Page 15

Page 18

Manual of Weighing Controller A 810

2.3. Control Input Signals

- Gross / Net (G/N) (pin D4)

(edge triggered)

Display value is switched between Gross and Net by pressing key or by changing input

D4.

When input signal is shorted to COM (OFFÆON) Net weight is displayed.

When input signal is opened to COM (ONÆOFF) Gross weight is displayed.

Pressing dedicated key will always toggle between Net and Gross, independent of input signal.

- Digital Zero (DZ) (pin D5)

(edge triggered)

The Gross weight is set to zero by pressing key or by shorten input D5 to COM

(OFFÆON).

When “ZALM” is illuminated, Digital Zero Regulation Value is exceeded and no setting to zero can

be done. Refer to 3.1.1.3 and 3.1.1.4 at page 25 for zero settings.

- Tare substraction (TARE) (pin D6)

(edge triggered)

The Net weight is set to zero by pressing key or by shorten input D6 to COM (OFFÆON).

Taring depends on its mode (3.1.1.10 at page 26) and its limit (3.1.1.9 at page 26).

- Tare Reset (TARE long press, when is illuminated )

(pin D7)

(edge triggered)

The Net weight is brought to Gross weight by pressing key and then key.

6

LOWER

After that is illuminated. Reset Taring weight by pressing for longer then 1s or by

shorten input D7 to COM (OFFÆON).

- Hold or Judgement (pin D8)

(level triggered)

The weighing value is hold by shorten input D8 to COM (OFFÆON) and “HOLD” is illuminated.

Over/Go/Under (3.1.7.4 at page 42) and Upper/Lower (3.1.7.5 at page 42) Limit have to be both

set to “0”.

At other settings the input switches to “Judgement”.

Over/Go/Under comparison mode (“OUC-MD”, 3.1.7.4 at page 42):

0: compare always

1: compare when judging input is ON

2: compare when complete output is ON

3: compare when complete output is ON

and weight will be hold during that time

Note: “Hold mode” is only available in Simple Comparison mode.

Page 16 A.S.T. Angewandte SYSTEM-TECHNIK GmbH Dresden

Page 19

Manual of Weighing Controller A 810

- Feed/ Discharge (pin D9)

(level triggered)

Feed or Discharge is accessed by shorten(Discharge) or open (Feed) input D9 to COM.

“Fd-Con” (3.1.6.2 in submenu “control” at page 39 has to be “2”).

0: feeding

1: discharge

2: external control

During Dischrage mode, “Upper/ Lower Limits” has to be compared with Gross weight (“ULLCMD” 3.1.7.3 set to “0”) and “Final/Over/Under” has to be ompared with Net weight (“FOU-CMD”

3.1.7.2 set to “1”).

Note: “Discharge mode” is only available in Simple Comparison mode.

- Start (pin D10)

(edge triggered)

During “Sequence mode” shorten input D10 to COM will start sequence cycle.

- Stop (pin D11)

(edge triggered, level triggered)

During “Sequence mode” shorten input D11 to COM will stop sequence cycle or clears sequence

errors.

Refer to 6.6 “Sequence mode” at page 103 for more detail.

- Start accumulation (pin D16)

(edge triggered)

Accumulation is done when shorten input D16 to COM (OFFÆON) and at rising edge of

“Complete output” signal. FOUC-MD (3.1.7.2 at page 41) has to be set to 0 (gross) or 1 (net).

“Func” + “3”: shows sum of accumulated weight

“Func” + “4”: shows counter of accumulated weight cycles

- Clear accumulation (pin D17)

(edge triggered)

Accumulation Counter and weight value is cleared when shorten input D17 to COM (OFFÆON)

for more than 3 seconds. For confirmation “del Acc” will be displayed.

- User Function I (pin D18)

(edge triggered)

This user defined function is activated when shorten input D18 to COM (OFFÆON).

Refer to 3.1.16.1 at page 64.

A.S.T. Angewandte SYSTEM-TECHNIK GmbH Dresden Page 17

Page 20

Manual of Weighing Controller A 810

- User Function II (pin D19)

(edge triggered)

This user defined function is activated when shorten input D19 to COM (OFFÆON).

Refer to 3.1.16.2 at page 64.

- Code selection (pins D20-23)

(level triggered)

This binary input select active codeset when inputs are shortened to COM. “External Code”

(3.2.3.2 at page 67) has to be “ON”.

Any selected codeset greater than 9 will generate “Err110”.

D23 is low-bit and D20 is high-bit.

Example: binary presentation

Selection of codeset 5: shorten D23 to COM (code N°1); 1

open D22 to COM (code N°2); 0

shorten D21 to COM (code N°4); 1

open D20 to COM (code N°8); 0

Page 18 A.S.T. Angewandte SYSTEM-TECHNIK GmbH Dresden

Page 21

Manual of Weighing Controller A 810

2.4. Control Output Signals

- Setpoint1 (SP1) (Pin B1)

(low-activ)

Will set „ON“, if setpoint1 SP1 (3.2.3.2.7, p.69) of active codeset has been exceeded.

- Setpoint 2 (SP2) (Pin B2)

(low-activ)

Will set „ON“, when setpoint2 SP2 (3.2.3.2.5, p.68) of active codeset has been exceeded.

- Setpoint3/ Compensationpoint (SP3/CPS) (Pin B3)

(low-activ)

Will set „ON“, when setpoint3 SP3/CPS (3.2.3.2.3, p.68) of active codeset has been exceeded.

- Near Zero (NZ) (Pin B4)

(low-activ )

Will set „ON“, when actual weight has gone below Near Zero value (3.2.3.2.13, p.71) of active

codeset.

- Under (LO>) (Pin B5)

(Low-aktiv)

Will set „ON“, when actual weight has gone below Final-UNDER value (3.2.3.2.10, p.70) of active

codeset.

- Over (<HI) (Pin B6)

(low-activ)

Will set „ON“, when actual weight has exceeded Final+OVER value (3.2.3.2.9, p.70) of active

codeset.

- Lower Limit (LO LIM) (Pin B7)

(low-activ)

Will set „ON“, when actual weight has gone below Lower Limit value (3.2.3.2.12, p.70) of active

codeset.

- Upper Limit (HI LIM) (Pin B8)

(low-activ)

Will set „ON“, when actual weight has exceeded Upper Limit value (3.2.3.2.11, p.70) of active

codeset.

A.S.T. Angewandte SYSTEM-TECHNIK GmbH Dresden Page 19

Page 22

Manual of Weighing Controller A 810

- Stable (STAB) (Pin B9)

(low-activ)

Will set „ON“, when actual weight matches stable conditions.

Parameter that affect that condition are:

Stable number “StAN”, 3.1.1.11, p.27;

Stable range “StAR”, 3.1.1.12, p.27;

ADC sampling rate “SR”, 3.1.3.3, p.32;

Filter component “FC”, 3.1.3.1, p.32;

Threshold of filter jump “FT”, 3.1.3.2, p.32;

- Discharge (Pin B10)

(low-activ)

Will set „ON“, when “Complete”-signal is set in sequence-mode. Duration of that signal is set via

Discharging time “dIS-TI” (p.46).

- Go (GO) (Pin B11)

(low-activ)

Will set „ON“, when actual weight is between threshold underweight UN (3.2.3.2.10, p.70) and

overweight OV (3.2.3.2.9, p.70) of active codeset.

- Complete (Pin B12)

(low-activ)

Will set „ON“, when conditions under Complete signal output mode “CSO-MD” (3.1.6.3, p.39) are

fulfilled. Duration of that signal is set via Complete output time “COTI” (p.43).

- Sequence active (Pin B21)

(low-active)

Will set “ON”, when “Start”-signal is activated. Will set “OFF”, when “Complete”-signal is finished

or an error is reset.

- Run (Pin B22)

(low-activ)

Will set „ON“, when A810 is ready for operation.

- Sequence error (Pin B23)

(low-activ)

Will set „ON“, when an error during a weighing cycle has occurred. Observation via Near zero

confirmation “NZC” (p.45) and Setpoint SP1 confirmation “SPC” (p.46) possible.

- Weight error (Pin B24)

(low-activ)

Will set „ON“, when an error of A810 or load cell has occured. Refer to „Description of States of

Error“ at page 112.

Page 20 A.S.T. Angewandte SYSTEM-TECHNIK GmbH Dresden

Page 23

Manual of Weighing Controller A 810

3. How to get started

At delivery the A810 is preset on default parameters (comply with legal-for-trade) to operate as a simple

scale provided the resolution is set and the calibration has been carried out.

The following section explains how to setup the instrument according the required function by using the

front panel keypad and display.

As an option a sophisticated Windows® based setup program is available to make the adjustment easier

and faster. Via PC-Programm all parameter can be saved for backup in a separate file, the print image is

changable and A810 can send weighing- and status-strings to PC via commands (see separate

information).

A.S.T. Angewandte SYSTEM-TECHNIK GmbH Dresden Page 21

Page 24

Manual of Weighing Controller A 810

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

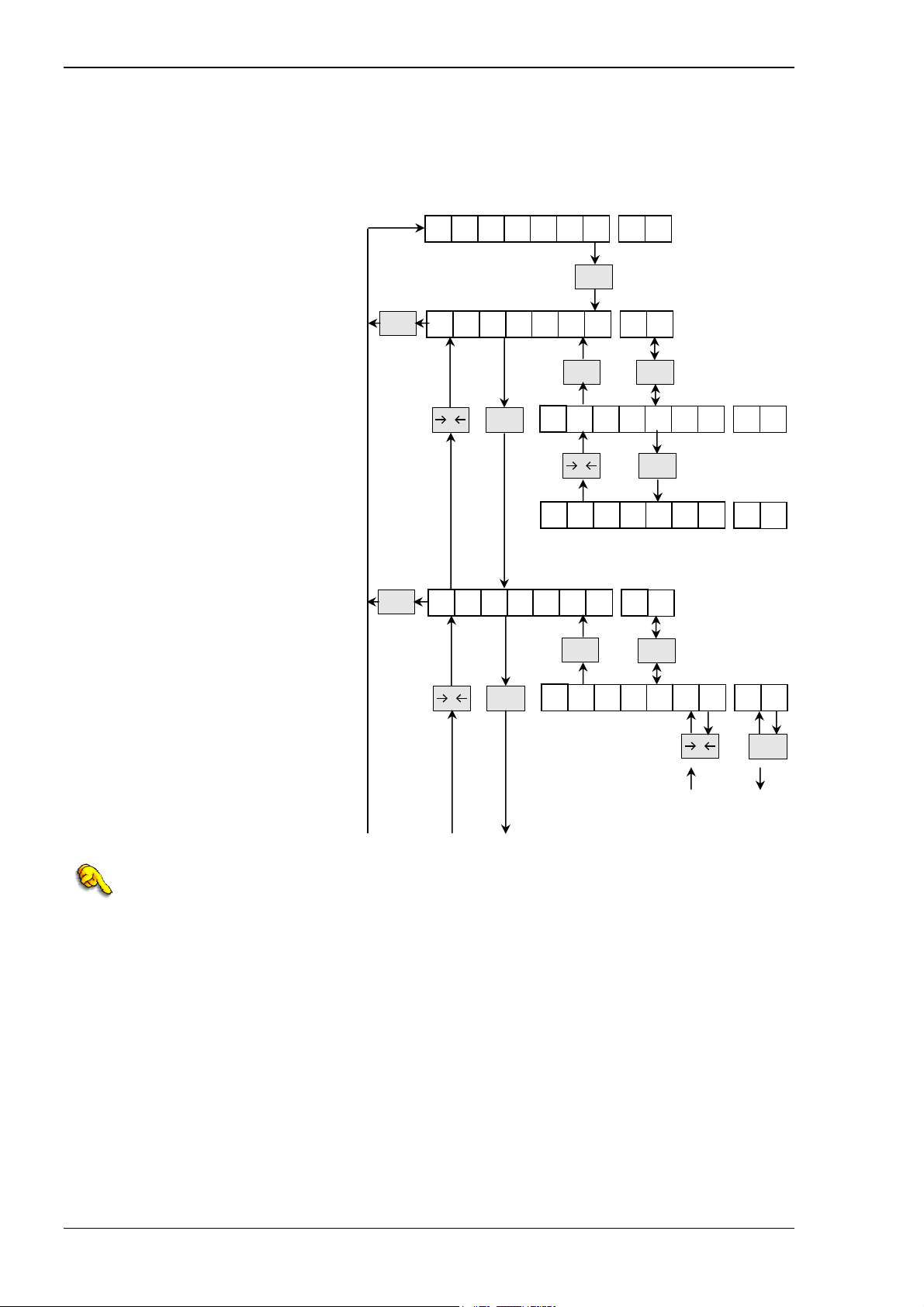

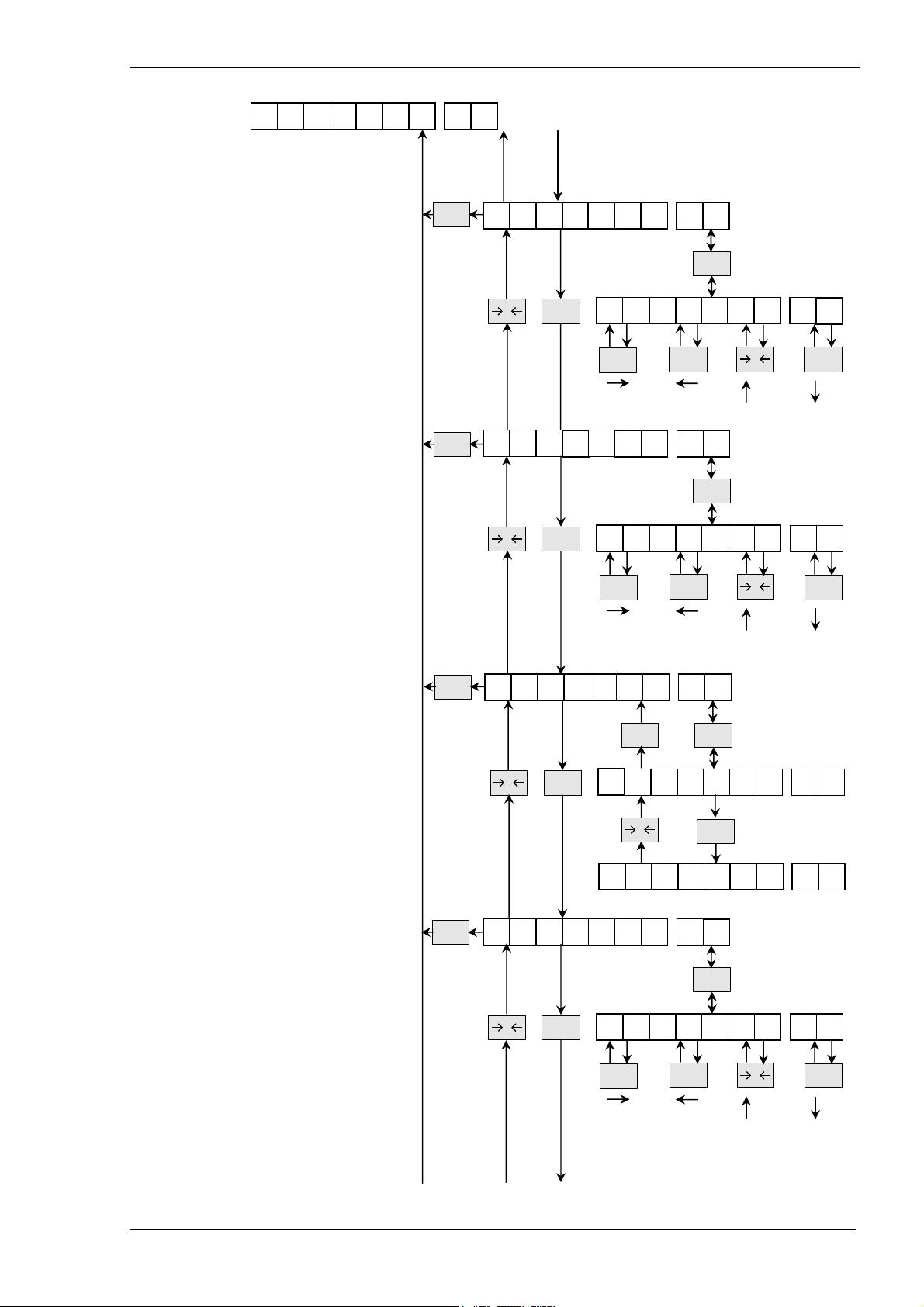

3.1. Parameter setup section

To enter into the parameter setup please press

SHIFT

9

CPS

. 24

. 30

. 32

. 24

. 24

. 25

. 25

. 25

. 25

. 30

. 30

. 30

. 32

. 32

. 33

. 33

. 34

. 35

. 35

. 36

. 36

. 34

. 36

. 34

. 37

. 37

. 26

. 37

. 26

. 38

. 26

. 26

. 27

. 27

. 27

. 28

. 28

. 28

. 29

. 29

. 52

. 52

. 52

. 52

. 52

. 53

. 54

. 54

. 54

. 54

. 55

. 55

S. 57

S. 57

S. 58

. 60

. 60

. 60

. 60

. 61

. 55

. 61

. 55

. 61

. 61

Page 22 A.S.T. Angewandte SYSTEM-TECHNIK GmbH Dresden

Page 25

Manual of Weighing Controller A 810

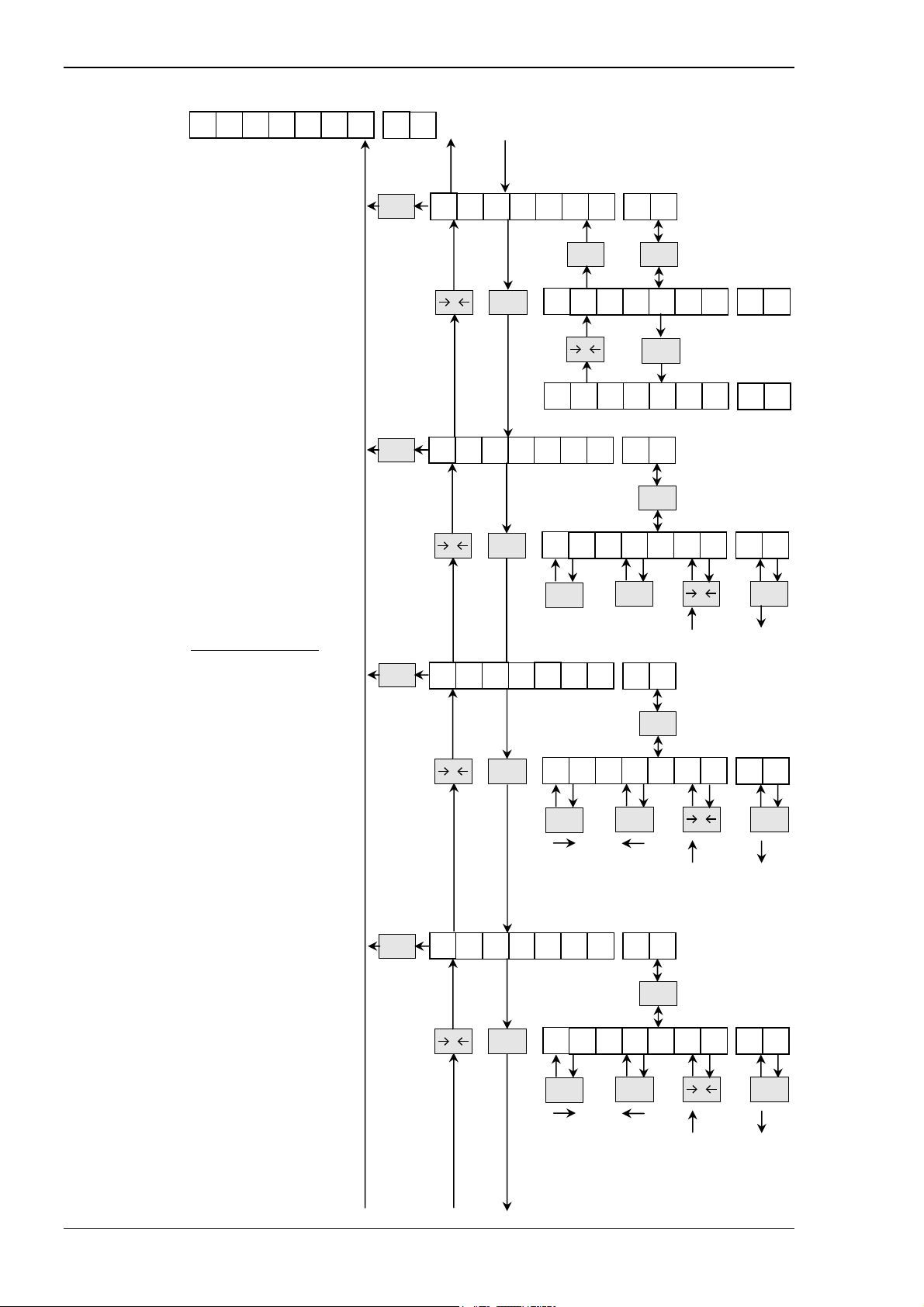

p

p

p

p

p

p

p

p

p

p

p

p

p

p

3

p

p

p

5

p

p

5

p

p

p

6

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

. 62

. 62

. 62

. 62

. 62

. 39

. 39

. 39

. 39

. 40

. 40

. 40

. 40

. 41

. 42

. 42

. 42

. 42

. 43

. 4

. 64

. 64

. 64

. 64

. 64

. 66

. 66

. 66

. 66

. 66

. 66

. 46

. 44

. 44

. 4

. 45

. 4

. 46

. 4

. 47

. 48

. 48

. 48

. 48

. 48

. 49

. 49

. 49

. 50

. 50

. 50

. 50

. 50

. 51

. 51

. 51

. 51

A.S.T. Angewandte SYSTEM-TECHNIK GmbH Dresden Page 23

Page 26

Manual of Weighing Controller A 810

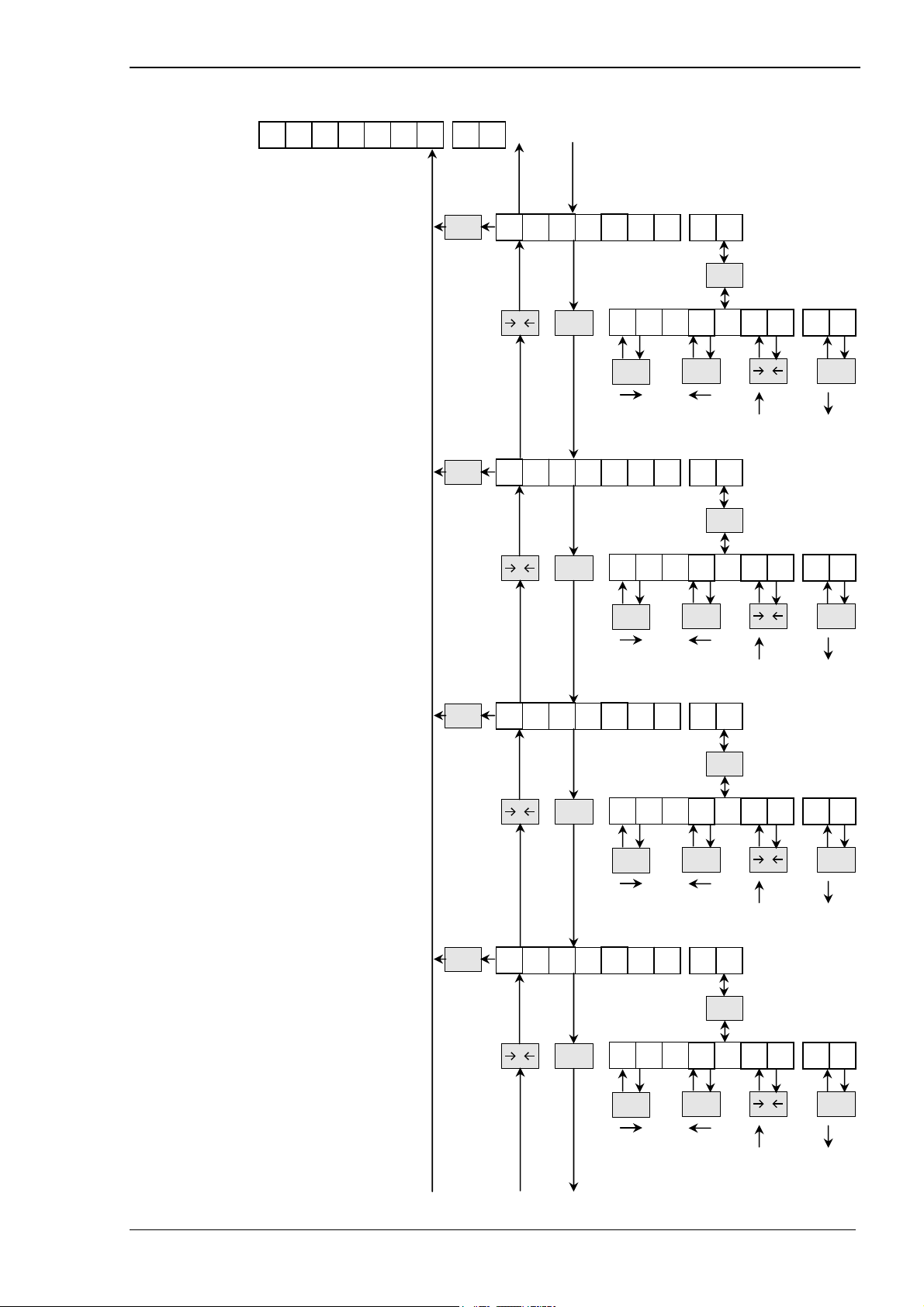

3.1.1. Submenu “Basic”

This menu contains the basic adjustments affecting the ability of the scale to be approved for calibration.

The adjustment might be carried out before calibration.

3.1.1.1. Enable Setup “Set”

Alternative decision to enable access

to a reduced setup section via function

call 108.

When ON, only parameters that not affect

legal-for-trade settings are available.

When OFF function call has no affect.

default setting: off

Refer to 5.3 at page 93 for locked menus.

TAR E

GROSS

0

/NET

b A S

ENT

S

TAR E

o

F F

0

o

n

I

E

C

T

ENT

GROSS

/NET

S

E

T

S

E

T

3.1.1.2. Select primary

measurement unit

TAR E

M

U

“MU”

Select one of the units

KG, To, Gr, Lb, oz, N, KN and FU (free unit)

as primary unit.

This unit is used for scale settings and

calibration.

default setting: KG

The Weighing Controller A810 will be calibrated with this unit and after each restart this unit is shown.

Note: Free Unit “FU” is scaled and calibrated as “KG”. Setting appropriate chars for “FU” is done in

“basic” menu 3.1.1.16 and 3.1.1.17 at page 28.

GROSS

0

/NET

TAR E

ENT

0

scroll between active

units

K

GROSS

G

/NET

Page 24 A.S.T. Angewandte SYSTEM-TECHNIK GmbH Dresden

Page 27

Manual of Weighing Controller A 810

3.1.1.3. Range of zero setting

lower limit “LLZS”

The lower limit of zero setting range

can be adjusted between 0 … –20%

of full scale.

default setting: 1

3.1.1.4. Range of zero setting

b

A S

TAR E

TAR E

I

C

0

GROSS

/NET

L L

>

SHIFT

cursor

right

U L

Z

FUNC

cursor

left

Z

S

ENT

S

+1

incr. decr.

0

value

0

GROSS

/NET

1

-1

upper limit “ULZS”

FUNC

cursor

left

Z

Z

ENT

T

ENT

GROSS

/NET

T

+1

incr. decr.

0

value

0

GROSS

/NET

Z

Z

3

-1

T

T

The upper limit of zero setting range

is adjustable between 0 … 20% of FS

and indicates in which range the zero

setting function is operating.

default setting: 3

3.1.1.5. Zero tracking “ZT”

This toggle decision enables or disables

the zero tracking option.

default setting: off

3.1.1.6. Zero tracking

TAR E

TAR E

GROSS

0

/NET

cursor

GROSS

0

/NET

>

SHIFT

right

TAR E

o

F F

0

o n

d

distance “dZT”

FUNC

cursor

left

ENT

0

0

value

GROSS

/NET

0

+1

incr. decr.

5

-1

Set in terms of number of divisions

(tenth of division per second) in the

range of 0…100.

Weight deviations within the

selected window that have been stable

for more than one second is tracked off.

Please note: zero tracking should be off

for most set point filling operations to

prevent tracking off any product trickle at

the start of the filling process.

default setting: 5 (0.5 divisions per second)

A.S.T. Angewandte SYSTEM-TECHNIK GmbH Dresden Page 25

GROSS

0

/NET

>

SHIFT

cursor

right

Page 28

Manual of Weighing Controller A 810

b

A S

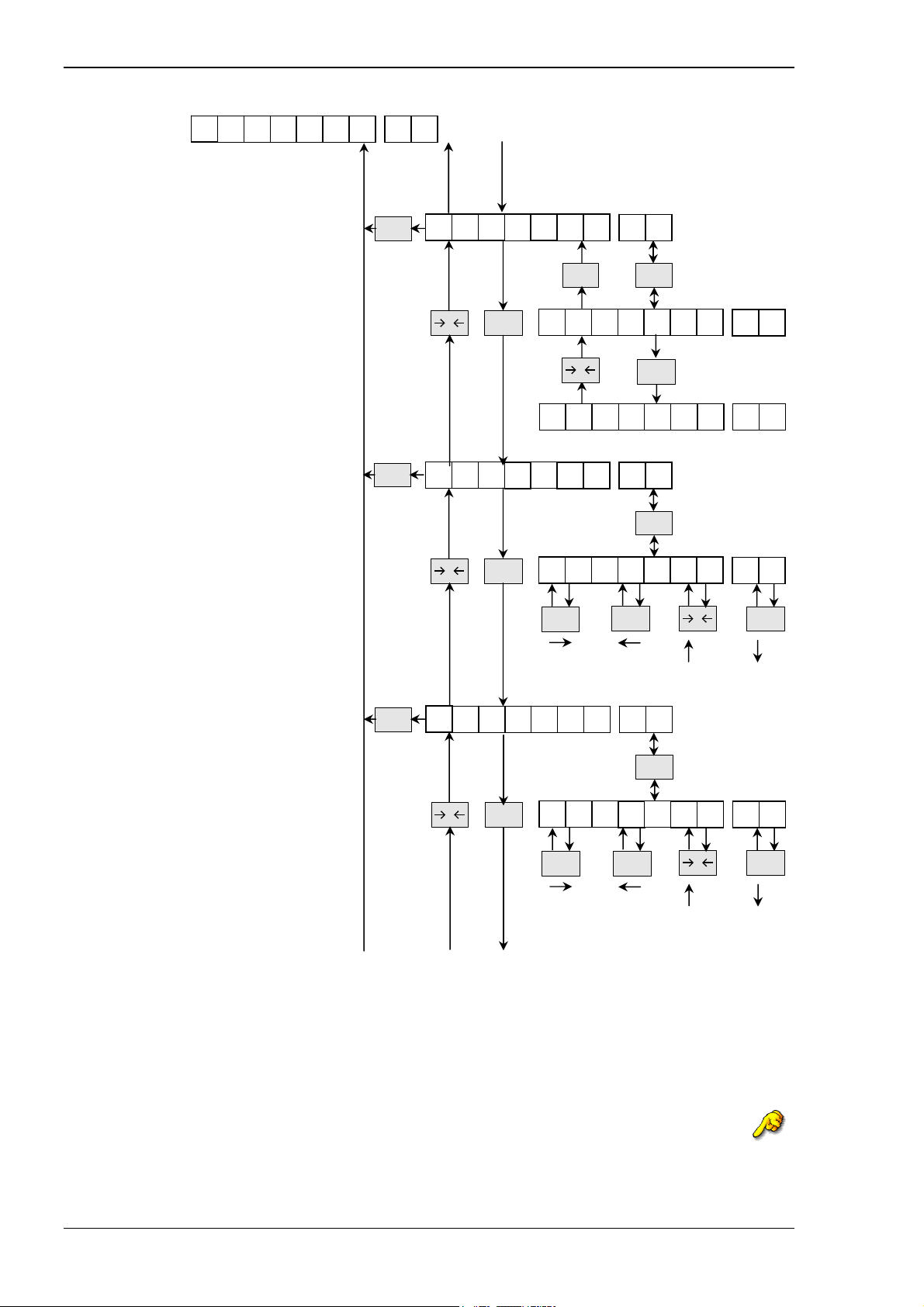

3.1.1.7. Power-on zero

setting “POZS”

This toggle decision enables or

disables the power-on zero setting

option. Range is selected at 3.1.1.3

(Lower Limit) and 3.1.1.4 (Upper Limit)

previous page.

default setting: off

3.1.1.8. Minimum Load “ML”

Set in terms of divisions in the range of

0 … 250.

This value indicates the trigger for the

print out.

default setting: 20

Æ If enabled and other settings are default

printing is possible when weight >2kg

is on load cell (20(ML)*300kg(FS)

3000(DN)

=2kg)

3.1.1.9. Upper limit taring

range “ULtAR”

Set in terms of percentage of full scale

in the range of 0 … 100%.

It indicates the weight above zero up to

which an enabled tare option is operating.

default setting: 100

3.1.1.10. Taring Mode “tAR_M”

This mode selection defines the action

after the tare command.

Set in terms of numbers in the range from

0, 1 or 2.

mode 0 tare always;

mode 1 tare only when stable;

mode 2 if stable Æ tare

not stable Æ tare if stable

is reached

default setting: 2

I

TAR E

TAR E

TAR E

TAR E

C

0

0

0

0

GROSS

/NET

GROSS

/NET

GROSS

/NET

GROSS

/NET

U

t A R

o

o

>

SHIFT

L t

>

SHIFT

cursor

right

>

SHIFT

cursor

right

P O

TAR E

F F

0

n

Z

M

FUNC

A R

FUNC

cursor

left

FUNC

cursor

left

S

ENT

GROSS

/NET

L

ENT

ENT

M

ENT

P O

P O

incr. decr.

incr. decr.

0 2

0

+1

value

1

0

+1

value

Z S

Z

0

0

+1

value

incr. decr.

0

GROSS

/NET

-1

0

GROSS

/NET

-1

2

GROSS

/NET

-1

S

Page 26 A.S.T. Angewandte SYSTEM-TECHNIK GmbH Dresden

Page 29

Manual of Weighing Controller A 810

3.1.1.11. Stable number “StAN”

Set in terms of numbers in the range

between values from 10 … 250.

This value defines the number of

averaged ADC values taken into account

for testing the stable condition.

A higher number provides a safer stable

condition but it also extends the minimum

time necessary to recognize the stable

condition after a load has been changed.

default setting: 50

3.1.1.12. Stable range “StAR”

Set in terms of tenth of a division in the

range of 1 to 255.

This value defines the range of tolerance

a weighing sample has match in order to

meet the stable condition.

A higher value provides a safer and

faster stable condition.

default setting: 10

3.1.1.13. Limit underload “LUNL”

Set in terms of divisions in the range of

0 to 1000.

This value defines the number of divisions

below zero that have to be indicated

before the underload message has been

generated.

default setting: 9

3.1.1.14. Limit overload “LOVL”

Set in terms of divisions in the range of

0 to 1000.

This value defines the number of divisions

above FS (max.) that have to be indicated

before the overload message has been

generated.

default setting: 9

A.S.T. Angewandte SYSTEM-TECHNIK GmbH Dresden Page 27

b

A S

I

TAR E

TAR E

TAR E

TAR E

C

0

0

0

0

GROSS

/NET

GROSS

/NET

GROSS

/NET

GROSS

/NET

S t

>

SHIFT

cursor

right

S t

>

SHIFT

cursor

right

L U

>

SHIFT

cursor

right

L O

>

SHIFT

cursor

right

A

FUNC

cursor

left

A

FUNC

cursor

left

N

FUNC

cursor

left

V

FUNC

cursor

left

ENT

ENT

ENT

ENT

N

R

L

0

L

0

0 0

0 0

0

5

value

0

value

GROSS

1

GROSS

0

+1

incr. decr.

0

+1

incr. decr.

0

0

+1

incr. decr.

GROSS

value

0

0

+1

incr. decr.

GROSS

value

0

/NET

-1

0

/NET

-1

9

/NET

-1

9

/NET

-1

Page 30

Manual Weighing Controller A 810

3.1.1.15. Enable quickstart

b A S

I

TAR E

C

E n

“EnQS”

This toggled decision defines whether the

Power-on self test of the display is a full

version (OFF) or just limited to a short

segment test (ON).

default setting: off

3.1.1.16. Select character of

TAR E

GROSS

0

/NET

TAR E

o

o n

free unit “CM1”

Sets the character at left of the unit.

Refer to appendix 7.1 ASCII-table

at page 108.

default setting: 32 (means “space”)

3.1.1.17. Select character of

TAR E

GROSS

0

/NET

>

SHIFT

cursor

right

free unit “CM2”

Sets the character at right of the unit.

Refer to appendix 7.1 ASCII-table

at page 108.

default setting: 32 (means “space”)

Example:

Desired measurement unit is “kp”.

- enable free unit “FU” by setting it “ON” (3.1.1.2) then

- left character is “k” Æ in submenu “CU1” select “107” and press key “ENT” then

- right character is “p” Æ in submenu “CU2” select “112” and press key “ENT”

Refer to 7.1 ASCII-Table at page 108 for assigning numbers to characters.

GROSS

0

/NET

>

SHIFT

cursor

right

Q

S

ENT

F F

0

C

C

cursor

GROSS

M 1

ENT

FUNC

left

M

/NET

2

ENT

FUNC

cursor

left

E n

E n

+1

incr. decr.

+1

incr. decr.

0

0

0

value

0

value

Q

Q

3 2

3

S

S

GROSS

/NET

-1

2

GROSS

/NET

-1

Page 28 A.S.T. Angewandte SYSTEM-TECHNIK GmbH Dresden

Page 31

Manual of Weighing Controller A 810

3.1.1.18. Set to default “dEF”

Toggled decision to set all parameters

of the “BASIC” sub menu to the default

values when ON.

default setting: off

3.1.1.19. Clear Setup “CLEAR”

Toggled decision to set all parameters

of the whole Setup menu to the default

values when ON.

default setting: off

Note: When clearing Setup-Parameter even calibration is lost. For backup reasons use Windows® Program before clearing.

b

A S

TAR E

TAR E

I

C

GROSS

0

/NET

C L E

d

TAR E

o

F F

0

o

n d

TAR E

o

F F C L E

0

o

n

E F

ENT

GROSS

/NET

A

R

ENT

GROSS

/NET

C

d

L E

E F

E

F

A

R

A R

A.S.T. Angewandte SYSTEM-TECHNIK GmbH Dresden Page 29

Page 32

Manual Weighing Controller A 810

3.1.2. Submenu “Scale division”

This menu is used to setup parameters for the selected unit “MU” 3.1.1.2 at page 24. Each used unit

needs to be defined, the full scale interval (Dn) and the verification scale interval (VS).

See 6.1”Calibration procedure” at page 94 for more detail.

3.1.2.1. Parameter for unit “MU”

TAR E

TAR E

TAR E

d

0

I

GROSS

0

/NET

GROSS

/NET

V

ENT

preset values:

100, 200, 300,

500, 600, 800,

1000, 1200,

1500, 1600,

2000, 2400,

2500, 3000,

4000, 5000,

6000, 8000,

10000, 12000,

15000, 20000,

25000, 30000

0

+1

TAR E

0

+1

TAR E

TAR E

3 0 0 0

GROSS

/NET

-1

when Dn = 0

>

SHIFT

cursor

right

ENT

GROSS

/NET

ENT

3

D

N

ENT

0 0 3 0

FUNC

cursor

left

V

S

preset values:

1; 2; 3; 4; 5

times multiple of 10

-1

F

S

0

0. 1

D

0

ENT

0

value

incr. decr.

0. 1

k

S

C A L E

3.1.2.1.1. Divisions “DN”

Confirming this menu by pressing

ENT

the operator reach the

section of preset values like 100,

200, 300, 500, … 30000.

If the preset value 0 is selected by

pressing an input box will

ENT

be opend to enter a free FS-value

in range between 100 … 100000.

Pressing continues the input

ENT

and returns one level up.

default setting: 3000

3.1.2.1.2. Verification scale

interval “VS”

Confirming this menu by pressing

the operator reaches the

ENT

section of preset division size

values like 0,0001 … 100.

This division size indicates the

count-by value and decimal point.

default setting: 0,1

Note: 1VS = 1e (OIML)

3.1.2.1.3. Fullscale “FS”

This option is used for checking the

value for full scale (FS) and the value

for verification scale interval (VS) have

been entered correctly. The display will

read out fullscale + 1 VS.

In case of default settings the display will

show “300,1kg”

N

0 0

GROSS

/NET

G

-

Page 30 A.S.T. Angewandte SYSTEM-TECHNIK GmbH Dresden

Page 33

Manual of Weighing Controller A 810

Examples:

I.)

Desired: Fullscale 100kg

Resolution 0.01kg

Menu

- Stability settings are done according to operators environment.

- set “MU” to “kg” 3.1.1.2

- “Dn” = 100kg / 0.01kg = 10000

set “Dn” to 10000 Æ A810 is legal-for-trade 3.1.2.1.1

- set “VS” = 0.01 3.1.2.1.2

- for confirmation of correctly set parameters: “FS” shows 100.01kg 3.1.2.1.3

II.)

Desired: Fullscale 30t

Resolution 0.002t

Menu

- Stability settings are done according to operators environment.

- set “MU” to “t” 3.1.1.2

- “Dn” = 30t / 0.002t = 15000

set “Dn” to 15000 Æ A810 is not legal-for-trade 3.1.2.1.1

- set “VS” = 0.002 3.1.2.1.2

- for confirmation of correctly set parameters: “FS” shows 30.002t 3.1.2.1.3

A.S.T. Angewandte SYSTEM-TECHNIK GmbH Dresden Page 31

Page 34

Manual Weighing Controller A 810

3.1.3. Submenu “ADC”

This menu is used to select the ADC and filter characteristics of the data acquisition. Analogue