Page 1

Dust

ACE IilDASTilAL

5043 FARLIN

3r4.385.5178

AVE.

.

PBODUCTS

sT. LOU|S, MO.63115

FAX:

314.385.3254

Gollector

Read inslructions

These dust co leclors are

sale conditions around dusl

and lactories.

hooked

exhausl volumes

duslguch

or Zirconium,

severe explosion

personal

the National Fire Protection

484;

and Metal Dusts,2002 Edilion".

Fire DeDarlment

Not

pressure.

high

Do

can be

Ca.lon musl be in uprighl

shipping

Check

Fead

install,

Retain this rnanualfor

directly onlo lhe dusr creating machine.

as Atuminum, Magnesium, Tantalum,

injury

"Standard for Combustible

designed lo be

Avold ducts sma ler than

pressurc

slatic

not use to collecl hot meral

igniled.

damage and advise carrier immediately

parts

listlor missing or darnaged

inslruclons cafefully before

operate, move, inspect or

carefully betore attempting to assemble, inslall,

Description

desgned to help malntain clean,

creating machines in workshops

The flexible hose incllded

required for dillerent

None

of thes€

designed lo

Collecling lhese materials can result

an(Uor fke resulling in death,

and ertensive

tor assislance.

used on a syslem Gquiring high static

and restricl a r movemenl.

property

Associatlon

dusti

wilh each unit can be

applications,

Dust

Collectors are

collect any reactive metal

damage.

Metals, lMetal Powderc,

Also, contact

3' diameter as they require

plaslic

Unpacking

General

future reference.

position

Satety Information

before opening. Inspect for

parts.

attempling lo assemble,

service

yo!r

Betain insvuctions

page

See

severe

(NFPA)

your

and cloth

il damaged.

dust collectorl

7 for

Titanium

in a

Consult

for NFPA

local

parts

OPERATING INSTRUCTIONS

operate, move, inspecl

for luture reference,

Always disconnect

let motor come to a

movlng

or seruicing.

A WARI{I]{G

not

opeate the collector unless

attacheclj

blower

blin.lness.

or lock

complete stop betore inspecting,

1. Follow

Nalional EleclricalCodes

Associalion

and Health Act

wiring should be

2. l\,,lake sure ihe

requirements

3. Exercise

h€h speed

anolhef on the lop

iingers of

salety

4. THESE DUST

CAN 8E OVERTURNED

ON A CLEAN LEVEL

high speed dust

outlet can cause severe

Guaftls must always be in

trcm

out

all

glasses

oower

local

elecl cal and safetv

(NFPA)

(OSHA).

oower sdurce conlorrns to the

ol

caution when the un t is in

blower wheel nside ihe blower housing

grab

loose

when

COLLECTORS ARETOP HEAVY, AND

or seruice

High voltage electical

cause aeverc injury or death.

lock

or

performed

your

of lhe molor. Both can amputate

out lrom

complete stop belore inspecting,

Hlgh speed rotating equiryent

cause

severc

partcles

eye alamage anal

source an.l let motor

(NEC).

slandards and Occupauonal

All electical conneciions

only by

dusl colleclor motor

clolhing or necklies. Always wear

operaling ihe dusl collector

IF BUMPED OB NOT PLACED

SUBFACE.

PAFITS LIST

&

your

dust cottector!

power

power

source

personal

the filEr bag is

exiting frcm the

moving or

codes. as wett as

National F

qualiJed personnel.

ooeration.There is a

place.

injury. Do

Disconnect

come to a

servicing,

re Proleclion

Safety

can

anc!

can

and

and

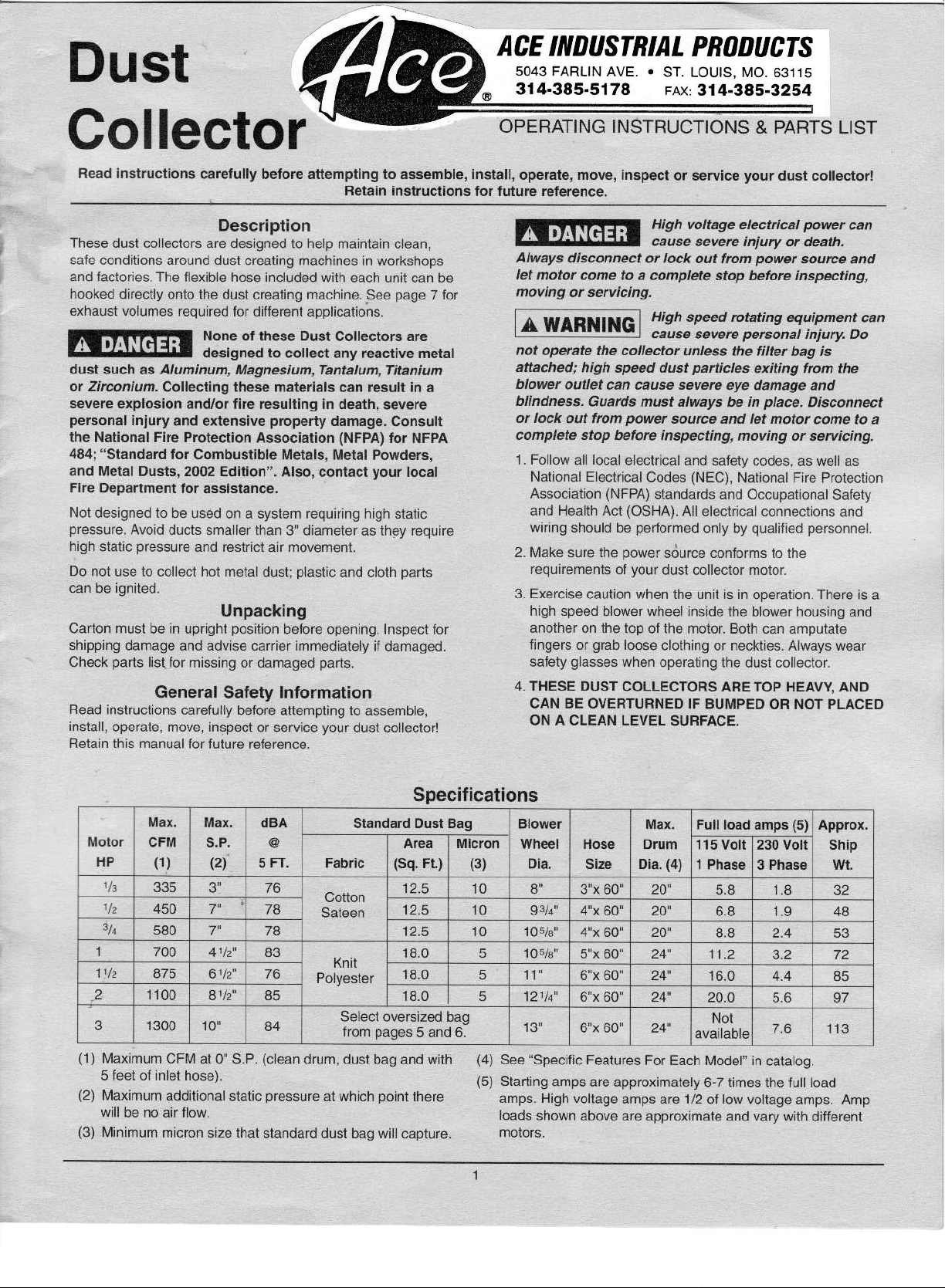

CFM

HP

2 1 100

3 1300 10'

(ll

I\,laximum CFM

5 Jeel of nlel hose).

l\,4aximum addilional

t2)

(3)

lvlinimum

0)

335

450

580

700

475 61/,' 76

micron

Max.

s.P.

\2)

3 76

7 7A

A1l2'

al0' S.P.

static

that

size

Specifications

dBA

@

FT.

5

7A 12.5

83

a4

(c

ean drum, dust

pressure

slandad dust bag wittcaplure,

Slandard Dusl Bag

Fab

Cotlon

Saleen

Knil

Selecl oversized bag

lrom

ai which

(sq.

c

12.5

12.5 10 10

18_0 5

18.0

18.0

5 and 6.

Pages

bag and with

point

there

Fl.)

Blower

Micron

(3)

10 8'

10

5 ll 6x60 24'

5 121/a 6x60 24',

(4)

(5)

DIa.

3"x 60' 20'

4"x 60' 20'

5/s'

4'x 60' 20'

5x60'

13',

See Speclfic Features

Slarting

amps. High vollage

loads shown above

6"x 60' 24',

amps are approximately

Max.

Drum

(4)

Dia.

Full load amps

115 Voll

I Phase

5.8 1.8 32

6.8 1.9 4a

8.8 2.4 53

16.0 85

(5)

230 Voll

3 Phase

20.o 5.6 97

Nol

avallable

For Each l\,,lodel" in

6-7 times the lullload

amps are 1/2

are approxlmale and vary wilh

of

low

1.6

catalog.

vo tage amps. Amp

Ship

72

differcnt

Page 2

Ooeratino lnstruclions and Parts IVanual

Assembly

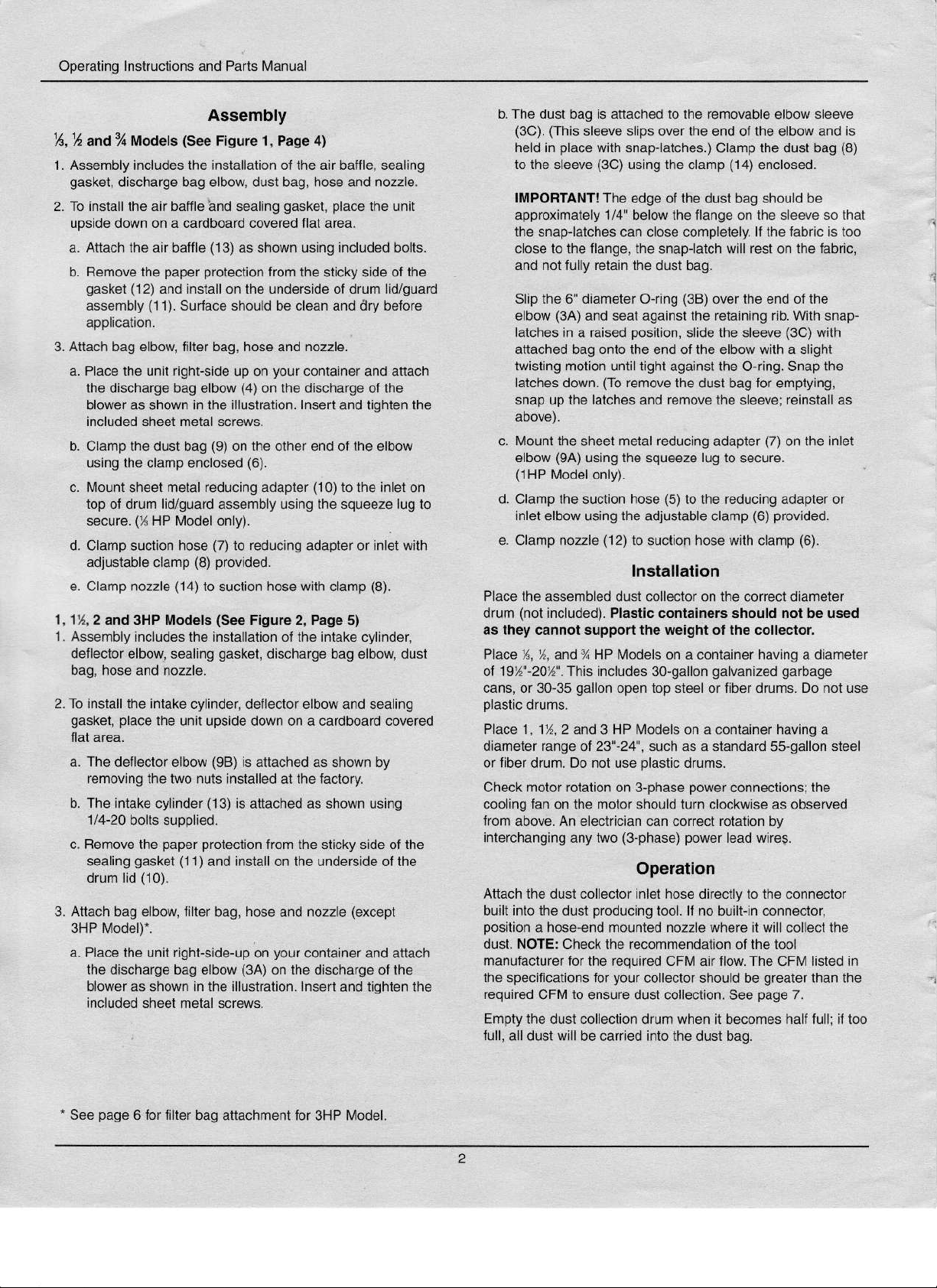

%, % and % Models

1. Assembly includes lhe lnslallation oi the a r ballle, sealng

gaskel,

2. To install the air bafile irnd sealing

upside down on a cardboard covered tlal area.

a. Atiach lhe air balfle

b. Remove the

3. Attach bag elbow, filier bag, hose and nozzle.

a. Place the unil right-side

b. CLamp

c. I\lo!nt

d. Clamp suclion hose

e. Clamp nozzle

'1,

1x, 2 and 3HP Models

1. Assembly

deflector elbow, sealing

bag, hose and nozzle.

2.To insiallthe intake

gaskel, place

a. The

b.

c. Bemove lhe

3. Allach bag elbow, I lter

3HP lVodel)'.

a. Place the unit right-slde-up

discharge bag elbow, dust bag, hose and nozzle.

gaskel (12)

assembly

the discharge bag

blower as

included sheet rnetal screws.

the

using the clamp enclosed

sheel

iop

ol drum

secure.

adjustable clarnp

rcmoving the two nuts nslalled

The nrake

1/4-20

sealing

drum lld

lhe discharce bag elbow

bower as shown in the illustration.Inserl

lncluded

(x

delleclor e bow

bolls supplied.

gaskel (11)

(See

Flgure 1, Page 4)

gaskel, place

(13)

as shown using included bots.

paper protection

and install on lhe underside of drum ld/guard

Sudace should be clean and dry belofe

{11).

elbow

in lhe illuslration. Insert and lighten lhe

shown

dust bag

lid/guard

HP [4odelon]y).

ncludes the insrallation ol lhe intake cylinder,

lhe

cyLinde' {13) is dhaLhed as shown Lsirg

paper proieciion

(10).

sheel melal screws.

(9)

melal reducing

assernbly using

(7)10

(8) provided.

(14)to

suction

(See

gaskel,

cylinder, delleclor elbow and sealing

unit upside do\,!n on a cardboard covered

(98)

and install on lhe unders de of lhe

bag,

from

the siicky s de of

yoLrr

up on

(4)

the

on

(6).

reducing

Figure 2, Page

is allached as shown by

hose

on

(3A)

conta

the discharge ol lhe

on

other end of

adapler

discharge bag elbow, dusl

from the slicky side of the

(10)

lhe

adapter or

hose wilh

al lhe laclory,

nozzle

and

your

container and atlach

lhe

on

discharge of lhe

ihe unit

ner

and attach

lhe

elbow

to lhe inlel

squeeze

inlet wth

(8).

camp

5)

(excepl

ilghlen ihe

and

the

lug lo

on

b. The dusl

(3C). (This

place

held in

to lhe sleev€

IMPORTANT!The

approxirnately 1/4'below

the snap-lalches

close to

and not fully rerain rhe dusl

Slip th€ 6 diameler O-ring

(3A)

elbow

latches ln a aised

attached bag onlo the end of the elbow wlh a slight

lwisling morion

latches down.

snap up lhe lalches and remove ihe

c. l,lounl lhe

(9A)

elbow

(1HP

N4odelonly).

d.

Clamp lhe suclion

nlet elbow

e. Clamp nozzle

atlached lo lhe rernovable

bag s

sleeve s ips

wilh snap'atches.) Clarnp lhe dusl bag

(3C)

using lhe clamp

edge of lhe dust bag should be

can close complelely.

flange, the

the

and seat againsl lhe retainrng r b. Wilh snap

posilion,

unliltghl aga

(To

remove lhe

meial reduc ng

sheel

using rhe squeeze lug to

hose

the

using

(12)to

lhe

over

snap-latch

i5)

adjustable clamp

suclion hose wllh clamp

end of the elbow

flange

lhe

will rest

bag.

(38)

over the end of the

slide the sleeve

nsl

lhe oling. snap the

dusl bag lor ernptying,

adapler

to the reducing adapler or

elbow sleeve

(14)

enclosed.

lhe

on

seeve so

lt lhe iabrlc is too

ihe iabric,

on

(3C)wilh

seeve;reinsta

(7)

on

secure.

(6) provided.

(6).

the inlet

and is

(8)

that

las

lnstallation

Pace lhe assembled dusi collector on rhe

(not

drum

included). Plastic conlainers should nol be used

as lhey cannot support th€ weight ol lhe colleclor.

Pace X, l, and t1 HP Models on a conlainer having a diameter

ol 19[''201'-This includes 3o-gallon

cans, or 30 35

gallon

open iop sieel or liber drums. Do nol use

galvanized garbage

Place 1, 114, 2 and 3 HP Models on a conlainer having a

diameter €nge of 23" 24', such as a standard 55-gallon sle€l

liber

or

drum. Do not use

Check motor rotation on 3-phase

plastic

drums.

power

connections;lhe

cooling lan on the molor should tum clockwrse as observed

ifom

above. An electrician can coffect rolanon b?

interchanging

any two

(3-phase)

power

lead wlres.

correct

diameter

Operation

Attach ihe dusi collector inlel hose direcly to ihe conneclor

built inlo the dust

poslion

a hose end mounled nozzle where t wil collecl lhe

dusl. NOTE: Check lhe recommendaion of lhe loo

manufaclurer for

lhe specifications lor

required

CFI!'lto ensure dusl collection, See

Empty the

lull,

all dlst

producing

lool. lf no built- n conneclor,

the required CF[,4 air llowThe CFM lisled in

your

collector should be

greater

page

7.

than the

dusl collection drum when it becomes haf fult if too

wl I

be carried into the dust bag.

See

'

page

6lor liler

bag attachment for 3HP lvodel.

Page 3

Operaling Inslructions

and Parls l.lanual

Est mate 2 CFM reduclion ln

CFM reduction for each

conveyance oi wood dusl requires a minimum

FP[4 in

3500

CFIV must not

this arr velocily.

lhe hose or duct; higher lor heav]er

reduced

be

air llow lof each loot ol duct; 15

90'curved bend. Pneumaiic

below the level requlred

Maintenance

High voltage

cause severe iniury

clisconnect

come to

A WARIIIiIG

Disconnect

come to

of lock out ,rom

a complete stop belore inspecting,

High spee.l

cause severe

of lock out trom

a complete stop belore inspecting,

MOTOR

The

bearings on the electricalmoror

for lile,

so they need no lubrication

clean

as excessive dul may

more lhan

A

CAUTIOI{

BLOWEF WHEEL AND

The cast alumrnum

psi

50

air lo blow off excessive

Wear

at hose tor

STEEL COMPONENTS

blower wheeland steelcomponents are

mainlenance free and shou

during the ife oi the unit-

electical

or death. Always

tmwer source and let motor

rctating equlpment can

perconal

power

source ancl let motor

lubrlcaled

are

durlng use. Keep lhe motor

prevenl proper

coo

dirl.

prctectlon

eye

while using an

cleaning-

d nol require any maintenance

air veloclly ol

materiats.

provide

lo

powet

can

moving ol

injury

moving or

and seaed

ing,

use no

lf a vibralion should

damage to lhe blower wheel.

lurned

OFF and LOCKED

develop it may indicate excessive wear

In this case, with the motor

OUI inspect the blower whee. lf

any damaged or excessivey worn

A WASI{[{G

blower wheel. The

speecl anr! high

sevete

FILTER

Perlodca

Beplace

A

could leacl to

clamage or blinclness.

It lhe inieior surlace

notceable

be cleaned. Disconnecl molor

Remove

dislodge

ihe bag may

cycle,

anolher labric type may

Do nol wash

coating;genlly

perconal

(DO

BAG

ly check the filler

lhe bag il worn or damaged

CAUTIOI{

rcspitation

drop-ofl in air ilow

ihe bag and lurn inside

sudace dusl. ll l\e

be washed. Wa3h using

ine

and

dry. lf the bag becomes

fet labric filler bags which

r nse lhe coal ng with

Do not opercte the

with a damagecl ot severcly wom

wheel may disinEgrcte

speecl fragrnenls may cause

ancl

prcperty

injury

NOT BEMOVE

for

bag

Do not operate with

clamaged lilEr

(brcathing) prouems

ol lhe bag becomes didy and

deveops, lhe bag may need to

or lock out lrom

oul. Use low

dusl ls lodged below the surface,

be needed.

or

areas are noted, replace

alust collector

at opeating

death or

clamage.

WHILE UNIT IS RUNNING)

worn or damaged areas.

areas are lound.

a won or

bag as escaping clu6t

ancuot eye

a

power

source.

pressure

a cold wdle .

dirty aga n very

have a sudace

water

aif to

gertle

quickly,

SYMPTOM

unit w ll nol

'Tighlen wheel

POSSIBLE CAUSE(S)

operate. 1. {mproper

2. Blowef wheel loose.

2. Suclion hose too long.

3. Dusl bag dirty.

NOT REMOVE WHILE

{DO

IS

RUNNING)

set screws to 165 inch-pounds

Troubleshooting

electrical connecl on.

UNIT

Chart

CORRECTIVE ACTION

1.

Turn

power

OFF - asslrre

unil

instruclions. Check and replace luse

clrcuit breaker as needed but do not

oversize tor the circuit.

2. Turn

1. Turn unil OFF

unil OFF. Dsconnect

unit over

and tighlen

& spin wheel by hand. Beposilion

sel screws il necessary.'

whee rciation as il

Place

2.

3.

unit coser to dusl

Clean

dusl bag. Wash collon or kn t filrer

bags in

slandard washer, line dry. Do not

wash nternally

rinse coating wlth

and observe motor cooling

coated felt bags;gently

clear water. Replace bag

power

stops. Rewire correcly

source and

is wired

or

cord.Turn

per

Page 4

Operating Instructions and Parls l,lanual

Fig.

1

12

13

3A

3B

al>.

ttffit

6--

NOTE

Palt #38, *4

rnusi be n

posilon

and

+9

at

ReDlacement Parts List for

Motor, 1 Phase.

115/208-230Volt. 60 Hz.

Motort 1 Phase'TErc

I15/208-230 Volt, 60 Hz.

Molor,3 Phase. TEFC

230/460 Volt, 60 Hz.

Molor, 1 Phase EYP

1l!430

Molor, 3 Phase, EXP

V_o11,q!!!

230/460 Volt.

Swrch.115v.

Housing, Blower

34,38 & 3C, See nole

Glard D

Clamp, Hose & Nozz

qes.q!'-s-t

Feducer Inel(1

Ld/ lnlel Guard Assemb

Nozzle, Square

Cord & Pluq, r r5V

Bolt

3/8-16 x 1/2 Hex Head

ODP

60 Hz.

& Guard

scha

e

(9!e!

3 HP

On

1/3. 1/2

3/a

and

HP Models

Part Number lor Mcdel

1/3HP

37753

371Q4 37154 37207

37102

37105

37754

37152

3lAHP

37761

(1X2)

372193

372009

31623

3i

013

1?99?

31069

51078

51014

51078

t?p92

31069

51078

NOTES:

(1)

lic udes

(grounded)plug

on 115 Volt 1 Phase

cord

372193

at correcl

sides oi slamped sleel

ho!s1.9 wfth an ABS

mounred. Thsw lon

b€ sod as an assembry

On y discharge

(38)

store lems

8lool.od.

p!g

and swtch

(-IEFC

can be

price

purchased

avarlab e

ror rse

noto4

when

y

quard

Boll.

l/4 20 x 3/4 Hex Head

Hei

Nul, r/4 20

Boll, 1/4-20 x 1/2" Hex Head

nearesr moror repa r

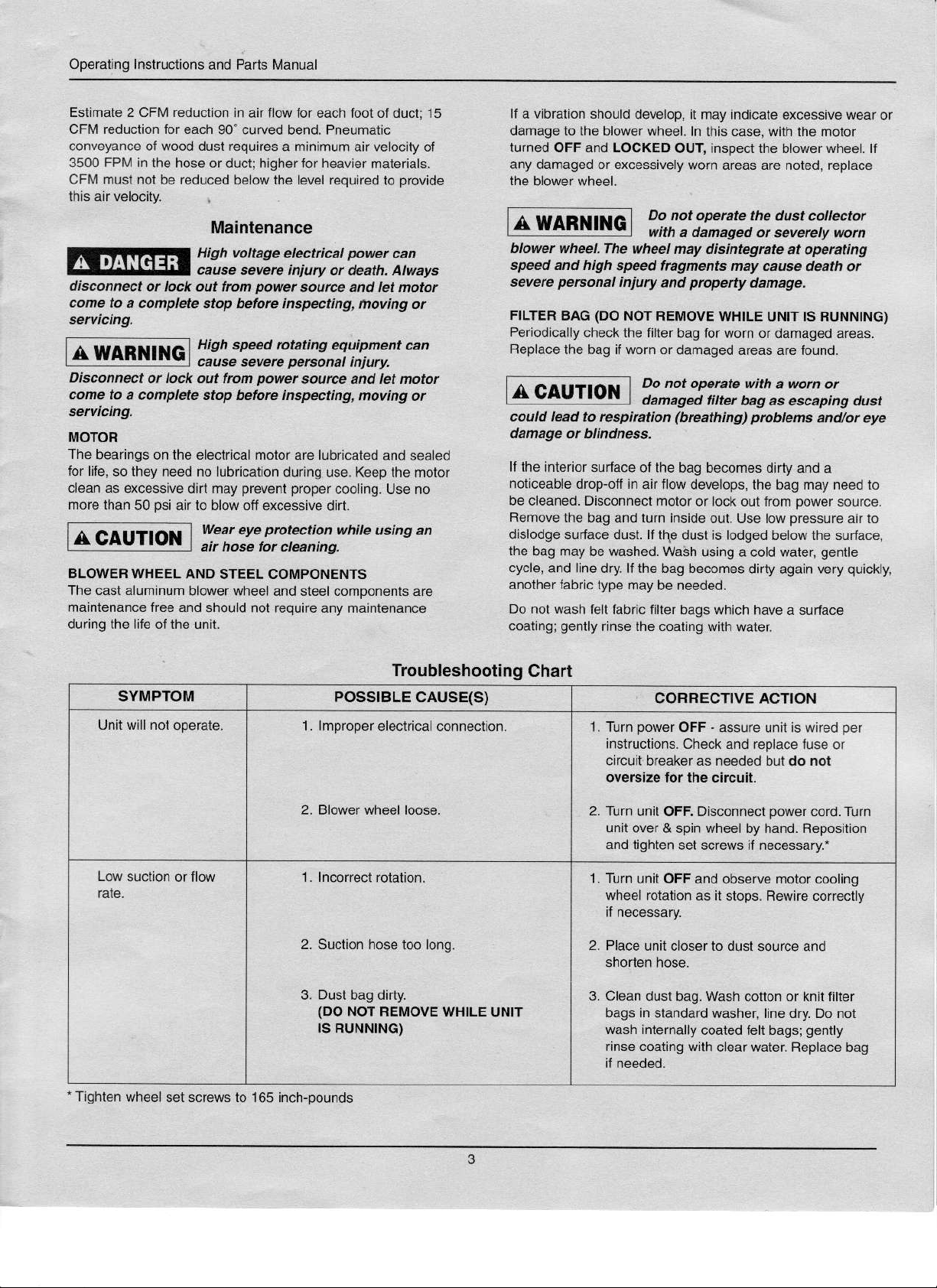

Page 5

Operating

Inslructions

and Parts Manual

Fig.2

Ref.

No.

2A-zC

28

3

5

6

7

I

9A&98

10

11

12

14

16

'17

otv.

2

2

1

6

t--\-----f

ll

98

Replacement

Parts List

Description

Molor,

1 Phase,

115/208-230

Motor,3

230/460 Voll,

llotor,

1 Phase, EXP

115/230 Voll.

Molor,

3 Phase, EXP

230/460 VoltHolsing,

(24.,

28 & 2C.

Gua'd,

Discharoe

Snap lalch

(3A,

38 &3C)

Clamp. Hose

Reducer, Inlel

aaq,

Dlst

Elbow, Inlet

Lid, Drum

Gasket. Lid

Cylinder, lnlahe

Ciamo,

Cord Sel. 115V.

Swilch. 115V.

Bol1.3/8-16 r 1/2'Hex

Dust Aao

TEFC

Volt.

60

Phase,

TEFC

60 Hz

60 Hz.

60 Hz

Blower

& cuard

See note 2)

lonlv)

elbow assembly

& Nozzle

(1HP

(srandard)

& Defleclor

Onlv

Onlv

\

Hz.

onlv)

Head

-t

'..--l

-

a'"

for 1, 11/2,

1HP

37755

(1)

37254

37252

3725462

34029DC

29318

5126402

5530602

31625

31016

51110

25071

12061

12060

31070

51016

51074

31244

I

I

2A

28

2 and

Part

11/rHP

37301

37304

37302

37305

34029DC

29318

5126402

5500702

31626

31244

25071

12061

r2060

31070

51417

51074

31244

:-

E=__----

11

---+ +;"E

3Hp Models

Number

for Model

2HP

373719

37353

37354

34029DC

29318

5126402

5501002

31626

31244

25071

12061

1?060

31070

51017

51474

31244

3A

3B

.-q.

3HP

374155

34029DC

29318

5510304

31626

31244

12061

12060

31070

51017

51074

NOTE

Parl #28, #3

posiiion

be rn

and #8 musl

3

NOTES

(l)

ncrudes I iool

(srounded)

on 115 Volt.

(2)

P/N inc udes

housing kift

moLrted. This

be sold as an assenbly

Ony discharge

(28)

cai be

Standard hadware

ilems

avaiable loca ly.

nea6$ moror

at

all times.

plu9

1 Phase,

Oothsides

an ABS

pu,chased

repatr

cord,

ror

use

wrl only

guard

slore

12

18

18

6 Boli,

Boll,

He, Nut,1/4-20

t/4-20 x 3/4'

1/4-20 r l

Hex Head

Hex Head

Page 6

Page 7

Exhaust Volumes Required

for

Ditterent Applications

(1)

WOODWORKING

Equipment

Krife Lengrh

'

Sander, Bell

(Horizonlal)

Sander, Disc

Saw, Badial Hood

Saw, Swing Blade

Planer,

Single Knile Length

(r)

The exhausl vollme

American

\ACGIH@),

P.a.rbes, 1gth

sion. Consult nranua tor more

Conlacl lhem

(2)

CFMs

velocity should nol

dusifrom setling in ducl work

Conference oi Governmentar Industriat

lntlustriai ventitation:

requlred

Bell Widlh

D sc Diameref = Up to 12'

Drum Sudace

(in

square nchet 201 to 400

Blade Width

pod

From

Diarneter = Up lo 20

Blade Diameter

(CFlVl)

Editiof. Copyighl 1986. Beprnred

al www.acgih.org

are mnimums

be less lhan 3500 FP[,4 to

Min. CFM

Required

Size

=

Up to 6^

6+ to 12'

12+'

to 20'

ovet 20'

=

Upto 6

6+' to I'

9+ ro 14

12+

to iB

18+'lo 26'

=

Up to 200

401

to 700

701 lo 1400

=

ro

Up

2'

2+" lo 3'

3+ lo 4'

behind b ade

on b ade

=

Vaieiv with

=

requircmenls shown

A Manual ot Fecannnenoeo

detailed recommendaiions.

pereach

glard

Total=

over 20'

lJp to 16'

16+

to 24'

ovet 24

dado

Up to 20'

20+' lo 26'

equipmenl lype. Duci

prevent

1240l3J

1100

1350 {3)

=

=

=

1100

trom

arc

Hygienisls

wilh

wood

Q\

350

440

550

800

(3)

790

(3)

900

350

450

550

350

550

785

(3)

700

(3)

s00

430

70

500

350

440

350

440

550

550

785

the

permis-

Equipmenl

Bufiing,

Bufiing,

Gfindlng Wheel

Grinding wh€el

Abbreviations

CFI\,,|= Cubic leet ol

FP[,4 = Feet

sflm = Surface leet

(3)

(4)

(5)

Belt Bell Widlh

Wheel

used in charts:

per

minute

Feqlires 2 nozzes

bolh nozzles or hoods.

For all melalworkng

3500 FPM

heavy

The wheel hood

considered a

for light g nding or b!fiing

grinding

good

METALWORKING

Size

=

Up to 3'

3+ lo5

5+ lo

7+'lo 9'

9+ to

11+ lo J3

3

5

6

1

\5)

\5)

,3'

per

air

minute

per

minute

or hoods. CF[/is shown

applications, ducl velociiy should

or bltiing

should cover al leasl 75%

enclosure.

prevenl

lo

1/2

2

3

5

6

1.1/2'

2"

5'

and at least 4500 FPIVI IoT

seltling in dlciwork.

Min, CFM

Required

{4)

220

300

7'

390

500

11'

610

740

300

500

610

740

1040

220

220

390

500

610

880

1200

220

390

610

740

880

1200

are totatCF|M for

be at

oi the wheei 10 be

least

These dusl m lectols wllgiv€

ps,

ch

Iine dust and metalshav

centralsyslem

llom machne

I Addth€'CFM

yolr

s

2 Now,

geater

models

required, you

oryornl

pul

3. lllhe untwl be n

metalducl ifsiead

hose is aboirl 2

applcalions These are

to machne. To selecl the

BEOUIBED" lor

t0,41cFlv

select the Duslcolieclor modelfrom

lhan

on Page t have a Max.

-pFdrosh-

iag lrom or rle

REourBED.

your

TOTAL

wi I need more

ofInesrw i daloe !l

ar a ine'<,Fe nolps b d o 7

a lixed nslalalion'at duclworkshoutd

olliexble hose. The

4 I mes lhai of smmlh wa I

How

To Select The Proper

you

excellenl resrlts in

ngs, theyare noldesigned

portable

propersize

each machineperlhe above chart. Th

FEOU

CFM

than one unit ora larger

IRED n step 1 . ll none

greaferlhan your

CFM

pressure

co lectirg wood

to work in targe

uritsthatcan be moved

DustColleclor 6eihe

Page l wilh a'lvtax

TOTAL

'centratsyslem'

\odL,rcolecro' <onlv

c'.qht/.

drop thmugh i exible

pipe

DO NOT use any

cFM'

or the

CFM

be sheel

Size Dust

PVC or

caused by high velocity

The Dusl

preieraby

and

5

s

Use as iew

90'ebow

6

llthedusl

insla I

sl de

seclion

colleclorto

dusl col eclor

Iyptal/y

model2HP Modelwl workwlh

3HP Mode willwor*

valuesare

6 above)

'ro1e

Collector

plaslic pipe.lt

Colreclorsholld be localed ascloselothe machne

erbows as

sequallo approxmalery l0ieetotstraighl,

col€clorwil be used on morelhan

gale

ol ducl when us ng anolher machire.

pu

I ffom on y one machine

perlormance.

r/rHP

a 1

basedon havingdampersat

and a Iducl work is smooth wal,

ca, deliver a severe st.tic

passlnglhrcugh

dust

fo more lhan 10leel away

possible

danrpe6 in lhe

Model w I work

with up to 75-85 totat leet

yowducnrofi.

in

ducr at eac, mach ne 10

at a time and lhus increase the

w th up lo 20 lolat leel ol dLcl work

uplo30tota leel

each machine connection

etectric shock

it.

The loss through one

smoollr wat

one machne,

"close

This wl allow lhe d!s1

ol duct

ot ducl wod( These

sheet meta

aspossible

you

sholld

ofl' lhal

work

and a

pipe.

(as

a

if

Page 8

Operating lnstruclions and Parts lvanual

Limited Warranty

The seller wafrunts

againsi defecls of maierialand workmanship

norma use and service for a

monlhs lrom daie of shiomenl or hvelve

fiom

date of inslallation. which ever occurs fnst. Th s

warranly

any

and tear, accidenl,

negligence or alteralion.This

systems or malerials nol

Expenses incurrcd by Buye(s) in repaifing

any d€fective

aulhorized in wril ng and signed

Seller

The obligalion ol lhe Selier undef lhis warranty

limited lo

allowing credil al Se lels oplions. THISWABRANTY lS

EXPRESSLY IN LIEU

EXPRESSED

WARRANTIES OF MEBCHANTABILITY AND

FOR USE AND

LIABILITIES OFTHE SELLEB. THE BUYEB

ACKNOWLEDGES THAT NO OTHER

REPRESENTATIONS WEBE MADETO HIM OF

RELIED

OR FUNCTION

The Se er shal not

ndlrecl or consequenlial

else by redson of any o<s

propedy

products

prope y

producl.

manufaclured bV

ihe same warranly

manufaclurer lhereol.

does

parl

lhereol

repalring or replacing FO.B. Se leas

UPON HIM WITH BESPECTTOTHE OUALITY

or mate alprocessed by Buye(s)wilh the

or on account ol lhe character or

material processed

or

producls

On

oroducts

not

apply lo any of Sellels

which has been subjecl lo ordinary wear

abuse, misuse, overloading,

produci

IMPLIED

OR

ALL

OF

OFTHE PRODUCT HEREIN SOLD.

be

furnished by Seller, bul

olhers. such as molors. Seller exiends

as Seller

ol ils own rnanulacture

under

period

ol eighleen

(12)

wa(anty does nol cover

of sellels

will not be allowed

OF ALL OTHER WARRANTIES

INCLUDINGTHE

OTHER OBLIGATIONS AND

iable lor

damages

or

manulacture.

an ollicer

by

any specia, direct,

to Auye(s)

ary daTage

by Buye(s)wilh the

received

from the

(18)

monlhs

prcducls

or replacing

where

except

of the

shall be

plani,

FITNESS

or anyone

o ant

quality

ol any

or

or

Hlgh voftage electrical

cauae severe injury or cEath, Always

disconnect or lock

come to a complete

A WARI{IlIG

opeaE the co ector untess

high speed dust

can cause severc eye damage

must always be in

powef

source an.! let motor come

betore inspecting, moving or seruicing-

metal dust

Titanium or Zirconium.

resull in a sever€ explosion

severe

Consult the National Fire Proiecrion

for

NFPA 484;"Slandard tor

Powders,

your

All Dusl

lhe

blower housing.These

Bemoval

liabilily. DO NOT

PLACE.

such as 4/uminum, Magnesium, Tantalum,

personal

and Metal Dusls,2002 Edition". Also,

local Fire Deparlment for assistance.

Colleclorc have a salety

guards

ol

from

out

stop betore inspecting, moving or

High speed rctating equipment can

cause severc

particles

place.

None of these Dust

designed to collecl any reaclive

iniury and

Salety

for any reason voids warranly and

OPEBATEWITHOUT ALL GUARDS lN

oower source ancl let motor

personal

the t ter bag is attached;

exiting trom the blowet outlet

and blinclness, Guards

Disconnect

Collecting these materials can

ancUor tire resulting in death,

exlensive

Combuslible l\rlelals, Metal

or lock out tfom

to a complete stop

property

Association

Guards

guard

on the discharge ol

guards

are lor

powet

injury. Do not

Collectors are

damage.

(NFPA)

contact

your

safety.

can

1M-11/04,

AOV

ACE IIIDUSTilAL

5043 FARLIN

314.385-5178

AVE.

.

PRODUCTS

sT. LOU|S, t\to.

FAX:

314.385-3254

63115

Loading...

Loading...