Page 1

Page 2

2

:: Introduction

Thank you for purchasing this Team Associated product. This assembly manual contains instructions and tips for building and maintaining your new RC10TC7.2.

Please take a moment to read through this manual to help familiarize yourself with these steps. We are continually changing and improving our designs; therefore,

actual parts may appear slightly different than in the illustrations. New parts will be noted on supplementary sheets located in the appropriate parts bags.

Check each bag for these sheets before you start to build.

:: KIT Features

With the current touring car platforms reaching an even higher plateau of precision and performance, the Engineers behind the doors of Area-51 wasted no time

in ensuring the TC7.2 is up to the level. The RC10TC7.2-FT comes packed full of a host of new components and features necessary to keep you on top.

As the on-road market advances at an ever increasing rate, more is demanded from the chassis’ to accommodate the ultra-competitive racing classes. A successor

to the TC7.1, the TC7.2 maintains the proven suspension geometry, but adds the refinement to chassis balance and flex necessary for today’s racing class. The

centrally mounted IFM motor mount adds several mounting configurations to help fine tune chassis flex to the racing surface, and also has an integral mounting

position for an optional chassis pitch control system (PCS). The TC7.2 also carries an all new aluminum rear gear differential for the ultimate in precision and heat

dissipation, as well as an ultra-light front spool assembly. Along with a list of new features, the RC10TC7.2 FT gives you everything you need to keep you racing

at the highest level. All without sacrificing low part count or affordability. A well-refined racing chassis with success in its heritage, the RC10TC7.2 FT is another

“Champion by Design” from Team Associated!

:: Key Features

• All new ultra-precise rear gear diff for maximum performance

o Aluminum diff case for precision gear alignment and increased heat

dissipation

o Durable composite gear set for minimized mass

o Hard anodized aluminum outdrives for low wear and long life

o Outdrives supported by ball bearings eliminates binding under load

o Lightweight belt pulley with relief holes to help clear debris

• Ultra-light weight front spool with replaceable hardened steel outdrives

o Lightweight aluminum spool hub for efficient power delivery and low

rotational mass

o Hardened steel outdrives for minimum wear and increased durability

o Lightweight belt pulley with relief holes to help clear debris

• One-piece IFM (Inline Flex Mount) motor mount system

o Central mounting to allow free chassis flex in either direction

o Several mounting positions to help further adjust chassis flex characteristics

o One-piece design ensures proper spur/pinion gear alignment

• Updated bearing caps with integral camber link mount for ultra-fine link

length adjustments

o Camber link mount fastens to bearing cap allowing the use of shims to

adjust camber link length for ultra-fine tuning of camber gain

o Symmetric parts on all four corners minimizes spare part count

o Optimized shock tower mounting positions for improved flex characteristics

o Vertical ballstud orientation allows for fine adjustments of roll center height

• Updated floating servo mount

o 7075-T6 aluminum for increased durability

o Servo mounts to chassis center to allow equal chassis flex in both directions

and a tweak free assembly

o Servo mount pins to chassis to eliminate servo shifting under hard impact

o Slotted servo mount design allows fit for almost any servo size

• New battery mounting system for greater adjustability

o Battery position can be set front-back and in-out to help fine tune chassis

mass balance

o Battery tabs for tape free battery installation

o Adjustable to fit dimensional differences between battery manufacturers

• Updated narrow chassis shape with optimized flex characteristics

o 2.25mm graphite laminate with updated profile and symmetric pockets for

optimal chassis flex

:: Items Needed / Other Helpful Items

Your new FT TC7.2 comes unassembled and requires the following items for completion. (refer to catalog section for suggestions):

• 1:10th scale electric motor and electronic speed control • 1:10th scale 190mm polycarbonate touring car body

• 3.7V-7.4V LiPo, 6.6V LiFe, or 4.8V-7.2V NiMh/NiCd battery • Polycarbonate specific paint for body

• Battery charger (suited for, and particular to, one of the batteries mentioned) • Body Scissors (AE Part #1737)

• 2 channel surface transmitter, 2 channel receiver, and steering servo • 1:10th scale rubber (or foam) touring car tires, wheels and inserts

• Silicone Shock Fluid (Refer to catalog for complete listings) • CA Glue (AE Part# 1597)

• Silicone Diff Fluid (Refer to catalog for complete listings) • Thread Lock (AE Part #1596)

• Shock Shaft Pliers (AE Part #1675) • FT Dual Turnbuckle Wrench (AE#1114)

• FT Hex Wrenches (AE Part #1518) • Wire Cutters/ Hobby Knife / Reamer / Hole Punch

• FT Hex/Nut Drivers Set (AE Part #1519) • Soldering Iron

• Calipers or a Precision Ruler • Needle Nose Pliers

Associated Electrics, Inc.

26021 Commercentre Dr.

Lake Forest, CA 92630

http://www.TeamAssociated.com http://www.RC10.com https://twitter.com/Team_Associated https://www.facebook.com/TeamAssociated

o A narrow 84mm wide to minimize chassis dragging at maximum chassis

roll angles

o Chassis incorporates mounting position for 1UP DTC

(Dynamic Toe Control) rear end option

o Chassis ballast mass mounting locations to fine tune mass balance

• PCS (Pitch Control System) option to further adjust chassis flex characteristics

o Motor mount and servo mount incorporate mounting positions for pitch

control brace option

• Fox “short” shocks with genuine Kashima Coating

o “Short” shock lowers overall center of mass allowing for more stability in

high grip conditions

o Ultra-smooth Kashima Hard Coating for minimal friction and extended

wear

o Hard coated shock shafts with polished finish

o Machined piston and bushing sets for the most precise build

o Updated bladder profile for consistent performance

• DCV drive shaft assemblies included for front drive

o DCV (dual CV) drive shafts are double-cardon joints, allowing free rotation

of drive shaft at extreme angles typical of the front drive due to addition of

steering angle to suspension arm angle

o The use of DCV’s results in smooth steering through larger corners by

eliminating the “chatter” typical of standard CV axles

• Ultra-light weight carbon composite suspension components

o Carbon composite material used for the best combination of strength at

minimized mass

o Optimized suspension arm length and shock mounting positions

o Pivot ball on inner hinge pin allows free pin movement at any toe or kickup

angle

o Insert system for precise adjustment of toe and inner pin width

o Independent arm mount design to allow maximum flex through entire

chassis length, resulting in better grip on all track conditions

• Aluminum rear CV bones

o 7075-T6 aluminum with hard coating for ultimate durability and decreased

wear

o Low rotational mass

• 26 precision ball bearings

Customer Service

Tel: 949.544.7500

Fax: 949.544.7501

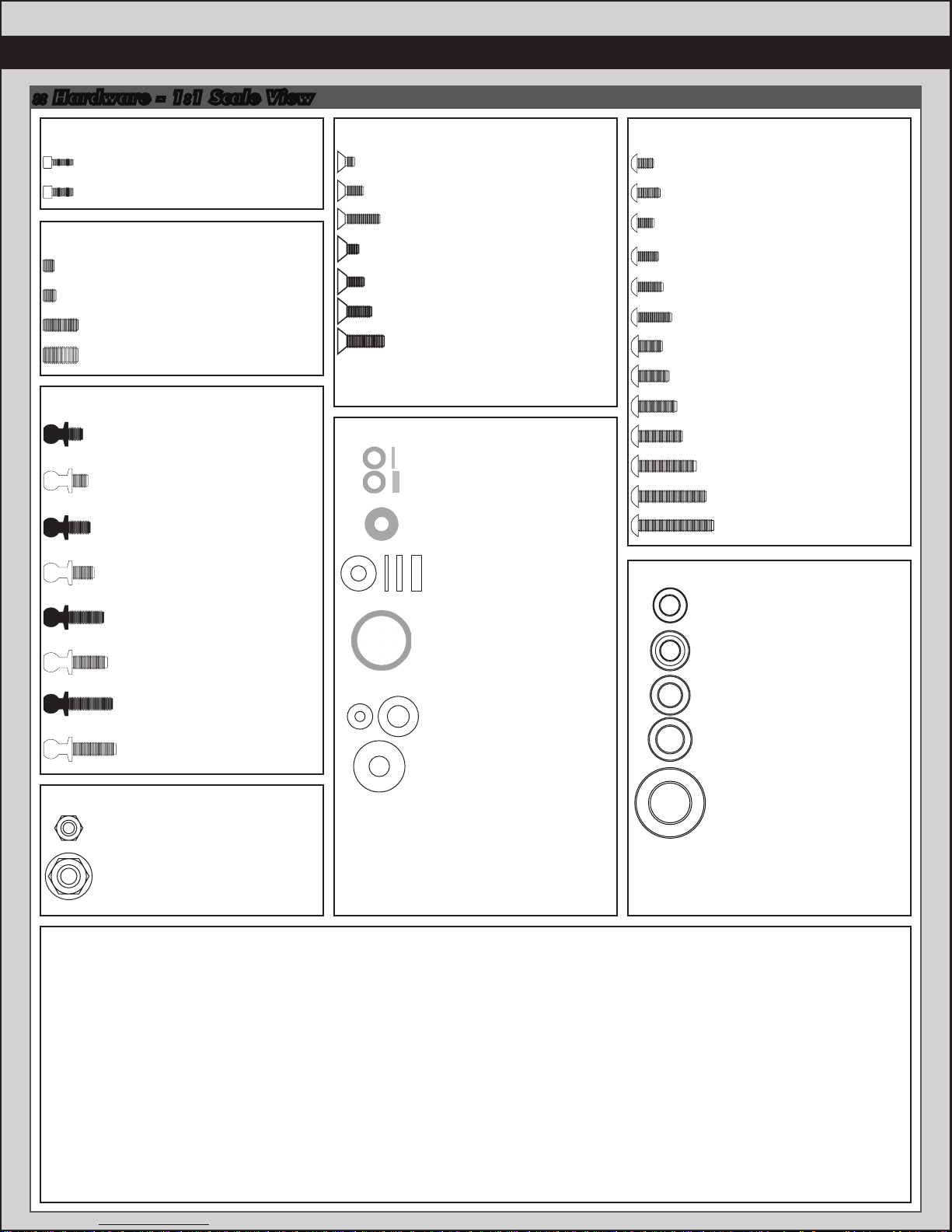

Page 3

3

:: Hardware - 1:1 Scale View

Cap Head (shcs)

Setscrew

Ballstuds

Black 3.25mm short (31390)

Ti Nitride 3.25mm short (31374)

Black 3.25mm long (31391)

Ti Nitride 3.25mm long (31374)

Black 5mm short (31280)

Ti Nitride 5mm short (31288)

Silver 5mm long (31283)

Ti Nitride 5mm long (31291)

Black 8mm short (31281)

Ti Nitride 8mm short (31289)

Silver 8mm long (31284)

Ti Nitride 8mm long (31292)

Black 10mm short (31285)

Ti Nitride 10mm short (31290)

Silver 10mm long (31285)

Ti Nitride 10mm long (31293)

Nuts (lock/plain)

1.6x5mm (91611)

2x5mm (31511)

3x2.5mm (31500)

3x3mm (25225)

3x8mm (4670)

4x8mm (25227)

Flat Head (fhcs)

Shims and Washers

Axle & Diff shim (31782)

Gear Diff Shims (31788)

2.5x4mm (31518)

2.5x6mm (4675)

2.5x10mm (31350)

3x5mm (31540)

3x6mm (31541)

3x8mm (25201)

3x10mm (25202)

Ballstud Washers

(31382 1mm,

31383 2mm)

Washer (7337)

Bulkhead Shim

(31384 0.5mm,

31385 1mm,

31386 2mm)

Button Head (bhcs)

2x4mm (31510)

2x5mm (31511)

2.5x4mm (4673)

2.5x5mm (31519)

2.5x6mm (31520)

2.5x8mm (31521)

3x5mm (31530)

3x6mm (31531)

3x8mm (31532)

3x10mm (25211)

3x12mm (89202)

3x14mm (25187)

3x16mm (89203)

Ball Bearings

4x7mm (31403)

4x8x3mm flanged (31331)

5x8mm (31400)

5x10x4mm (91560)

10x15x4mm (91563)

M3 locknut (31550)

M4 locknut (91148)

Notes:

B

Page 4

4

:: Table of Contents

1....................Cover

2....................Introduction

3....................1:1 Hardware “Fold Out”

4...................Table of Contents

5-6...............Shock Build

(Bag 1)

6-7...............Spool and Differential Build

(Bag 2)

8....................Front DCV/ Rear CVA Build

(Bag 3)

12-16.........Bulkheads, Spur Gear, and

Steering Rack Build

(Bag 6)

16-19.........Caster Blocks /Rear Hubs Build

(Bag 7)

19-23.........Bumper, Anti Roll Bar, and

Electronics Build

(Bag 8)

23-24.........Battery Stop/Final Build

(Bag 9)

24-27.........Tuning Tips / Gear Charts

28-35.........Catalog

9...................Turnbuckles Build

(Bag 4)

9-11.............Suspension Arms Build

(Bag 5)

:: Notes

This symbol indicates a special

note or instruction in the manual.

!

This symbol indicates a Racers Tip.

36................Setup Sheet “Kit Setup”

37.................Setup Sheet “Blank”

38................Back Cover

There is a 1:1 hardware foldout page in the

front of the manual. To check the size of a part,

line up your hardware with the correct drawing

until you find the exact size. Each part in the

foldout has a number assigned to it for ordering

replacement parts.

Associated Electrics, Inc.

26021 Commercentre Dr.

Lake Forest, CA 92630

http://www.TeamAssociated.com http://www.RC10.com https://twitter.com/Team_Associated https://www.facebook.com/TeamAssociated

Customer Service

Tel: 949.544.7500

Fax: 949.544.7501

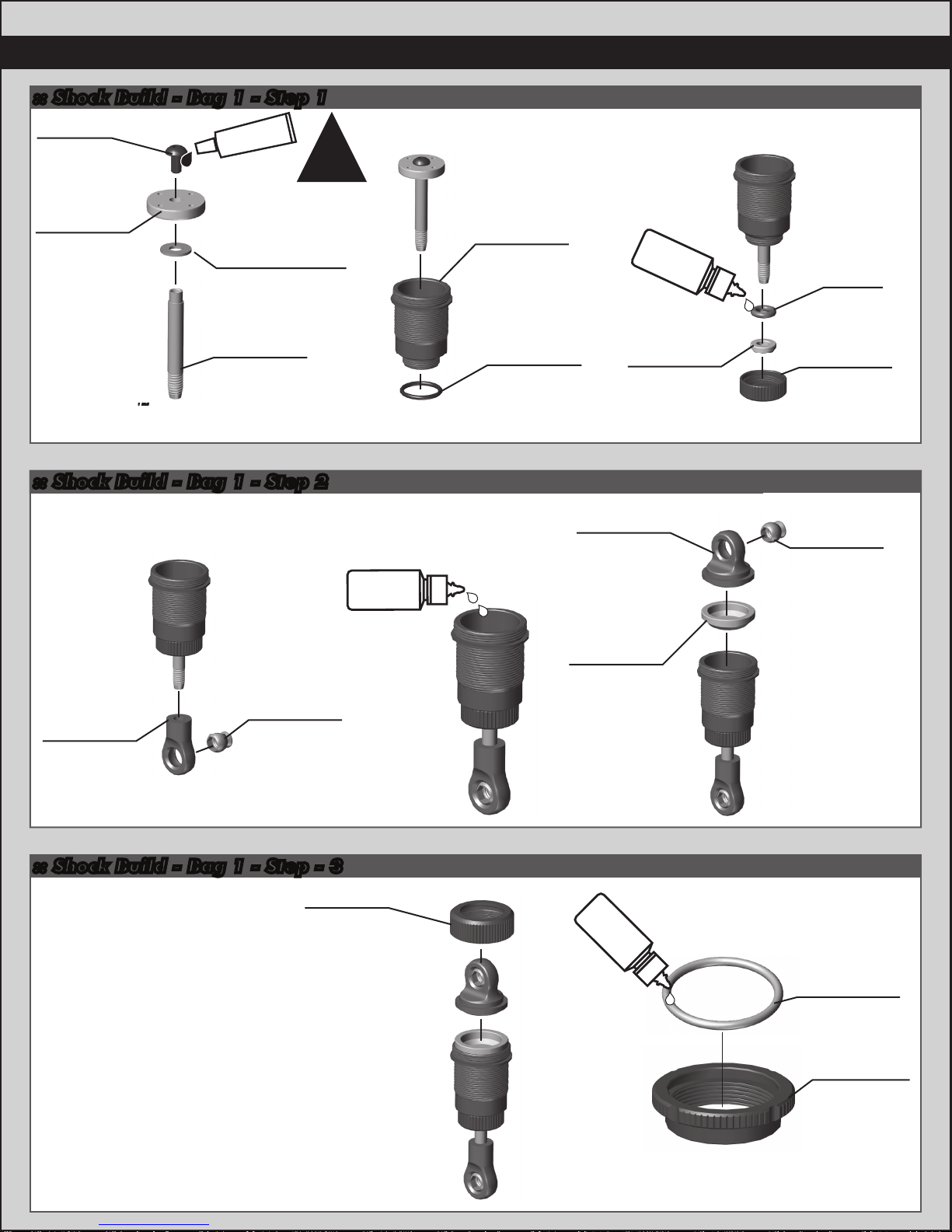

Page 5

7/18

:: Shock Build - Bag 1 - Step 1

5

31510

M2x4mm

#1596

thread lock

bhcs

Thread lock

not included!

31747

TC7.1

shock

piston

(4x1.1)

89278

Steel washer

(2.6x6x0.5mm)

31746

TC7.1

shock shaft

Build four

shock shafts

:: Shock Build - Bag 1 - Step 2

!

Shock fluid

#5429

(35wt)

31745

TC7.1 FT

shock body

(Fox

Kashima

Coat)

31753

TC7.1 shock

bottom cap

o-ring

Shock fluid

(35wt)

shock shaft

bushing

31757

TC7.1

shock cap

#5429

31752

TC7.1

5407

Red

o-rings

31753

TC7.1 shock

bottom cap

4637

FT pivot

balls

4637

31757

TC7.1 shock

FT pivot

balls

eyelet

:: Shock Build - Bag 1 - Step - 3

31756

TC7.1

shock cap

retainer

Bladder Installation

With the shaft extended 25%, place bladder on

the top of the shock body, displacing the extra oil.

While maintaining pressure on the bladder against

the shock body, carefully lift one side of the bladder

to allow any extra oil to escape. Place stock cap on

top of bladder, and secure it by threading the

aluminum cap retainer onto the shock body.

31752

TC7.1

bladder

Shock Fluid

#5429

(35wt)

Build four

shocks

Build four

shock collars

31758

TC7.1 shock

collar o-ring

31758

TC7.1

shock collar

Page 6

6

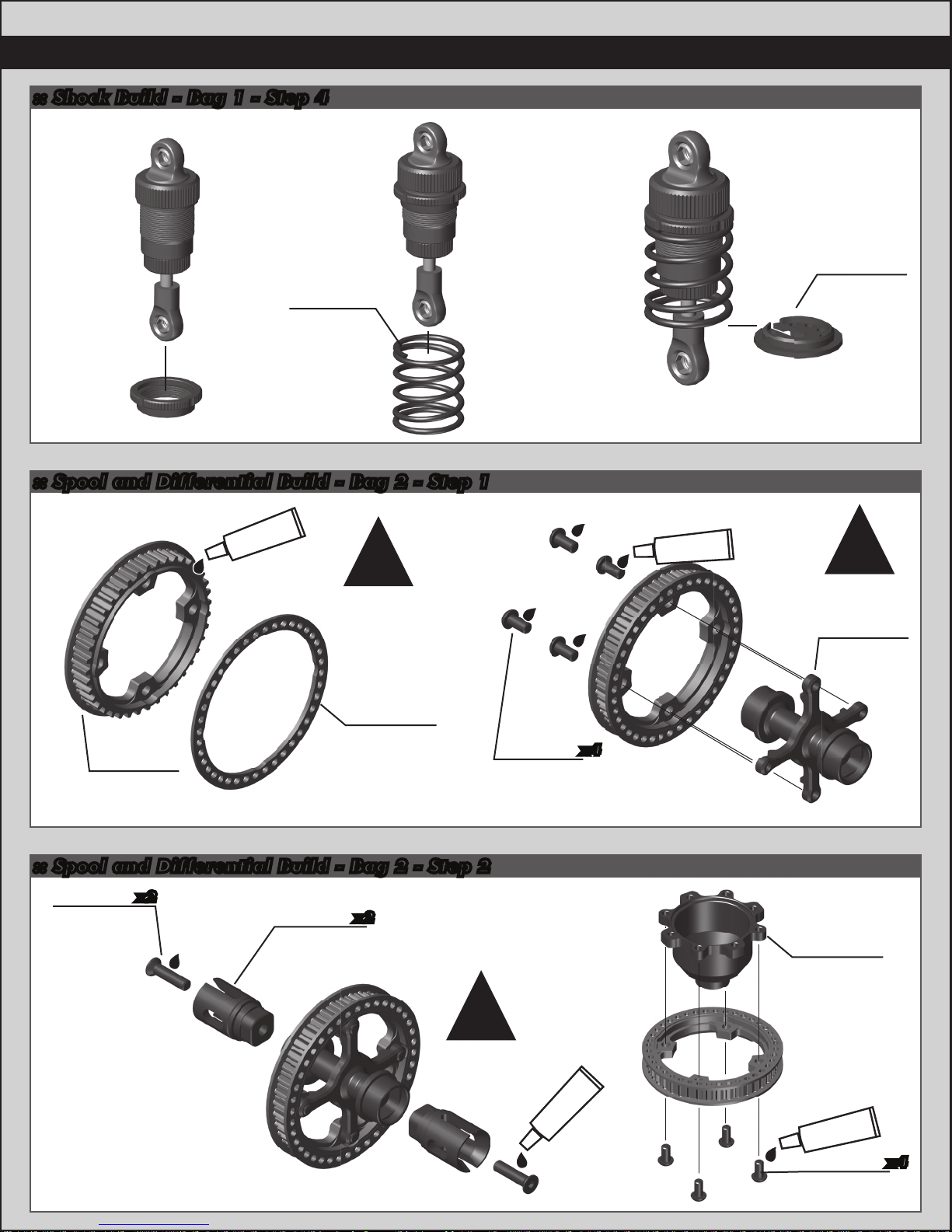

:: Shock Build - Bag 1 - Step 4

31763

TC 20.5mm

Spring,

Blue

(15.8lbs)

:: Spool and Differential Build - Bag 2 - Step 1

Build two!

#1597

ca glue

!

CA glue

not included!

#1596

thread lock

31759

TC7.1 shock

spring cup

Build four

shocks

!

Thread lock

not included!

31788

Spool hub

31786

Diff pulley

31786

Diff pulley

(40T)

flange

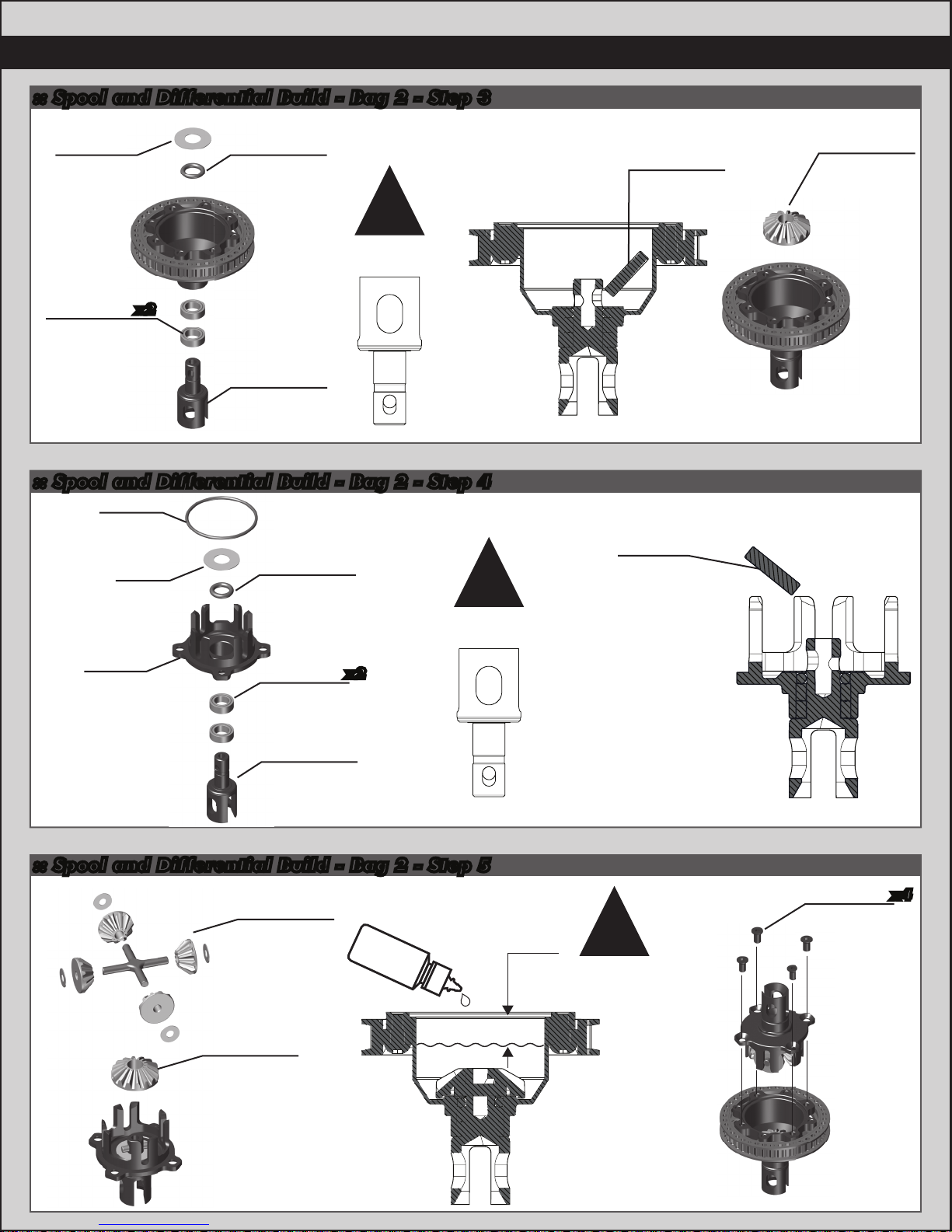

:: Spool and Differential Build - Bag 2 - Step 2

x231350

M2.5x10mm

fhcs

31638

Spool

outdrive,

(steel)

x2

M2.5x5mm

!

Thread lock

not included!

31519

bhcs

#1596

thread lock

x4

31783

Diff case,

Aluminum

#1596

thread lock

31519

M2.5x5mm

bhcs

x4

Page 7

:: Spool and Differential Build - Bag 2 - Step 3

7

31782

Diff shim

31782

Diff outdrive

o-ring

!

Oval hole is for

X-Pin install

8680

M5x8x2.5mm

bhcs

:: Spool and Differential Build - Bag 2 - Step 4

x2

31782

Diff case

o-ring

31782

Diff

shim

31785

TC7.2 diff

outdrive

31782

Diff outdrive

o-ring

!

Oval hole is for

X-Pin install

31782

Diff pin

2x9mm

31782

Diff pin

2x9mm

31782

TC7.2 gear

diff sun

gear

31783

TC7.2

diff cap

8680

M5x8x2.5mm

31785

TC7.2 diff

outdrive

x2

bhcs

:: Spool and Differential Build - Bag 2 - Step 5

31782

TC7.2 diff

gears,

washers,

and crosspin

31782

TC7.2 gear

diff sun

gear

Diff Fluid

#5453

(5,000cst)

5.5mm

Add 2 grams of diff fluid

or approximately 5.5mm

from the top of the cup!

!

31518

M2.5x4mm

fhcs

x4

Page 8

8

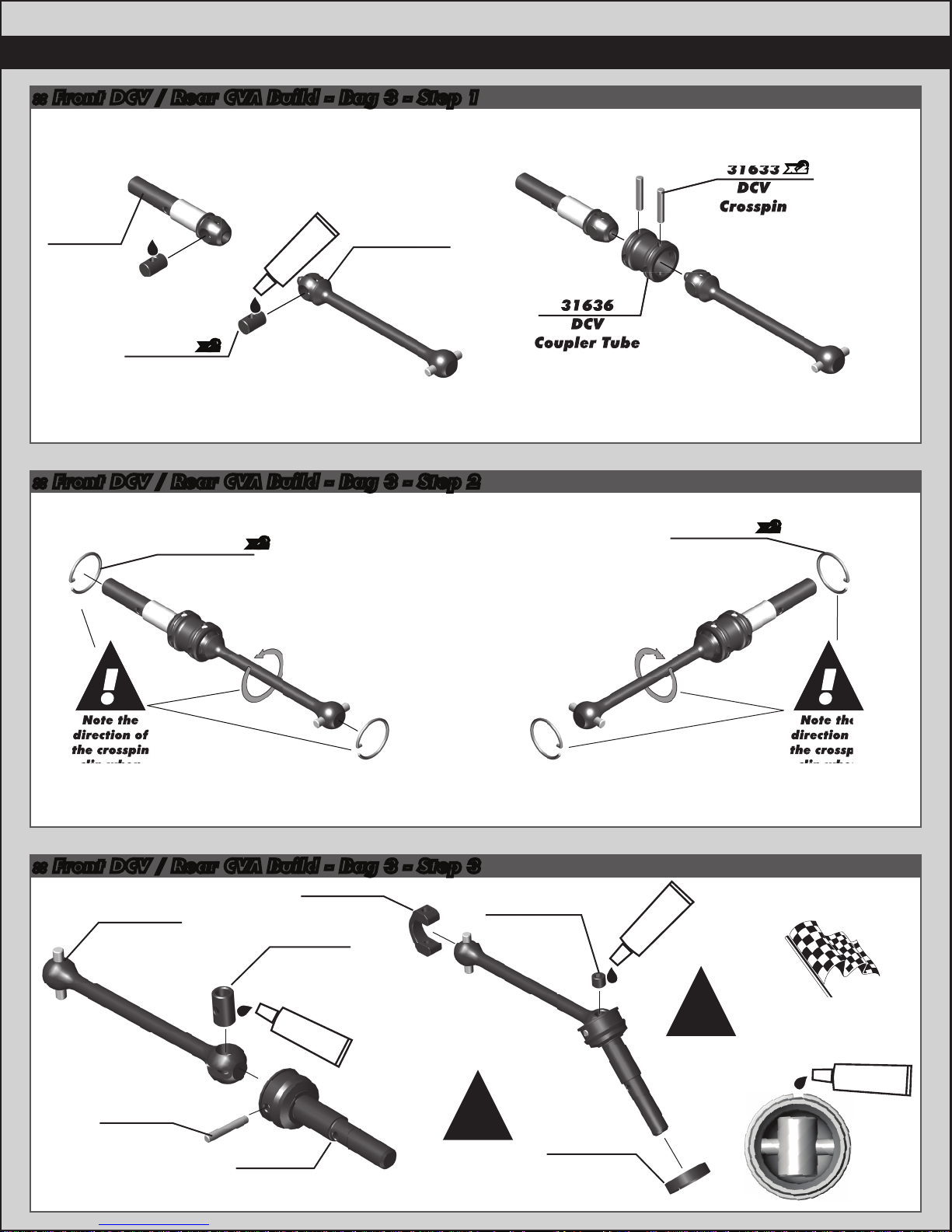

31633

DCV

Crosspin

x2

31636

DCV

Coupler Tube

Note the

direction of

the crosspin

!

Note the

direction of

the crosspin

!

:: Front DCV / Rear CVA Build - Bag 3 - Step 1

31634

DCV Stub

Axle

31633

DCV

Coupler

#6588

black grease

x2

31635

DCV Bone

:: Front DCV / Rear CVA Build - Bag 3 - Step 2

31633

DCV

Crosspin Clip

x2

31636

DCV

Coupler Tube

31633

DCV

Crosspin

Build two DCVs

31633

DCV

Crosspin Clip

x2

x2

! !

Note the

direction of

the crosspin

clip when

installing

:: Front DCV / Rear CVA Build - Bag 3 - Step 3

31796

TC7.2 CVA

bones,

Aluminum

31367

CVA

cross pin

Right Side

TC6.1 CVA

black grease

31369

TC6.1 CVA

axle

31238

CVA blade 31500

31367

coupler

#6588

opposite of the CVA pin.

M3x2.5mm

setscrew

!

Note!

Align the gap in the

pin retainer to be

31237

Retaining

clip

Left Side

#1596

thread lock

!

Thread lock

and CA glue

not included!

Note the

direction of

the crosspin

clip when

installing

Build two DCVs

Build two

CVAs

RACERS TIP!

place a drop of CA glue

on the pin retainer gap.

#1597

CA glue

Page 9

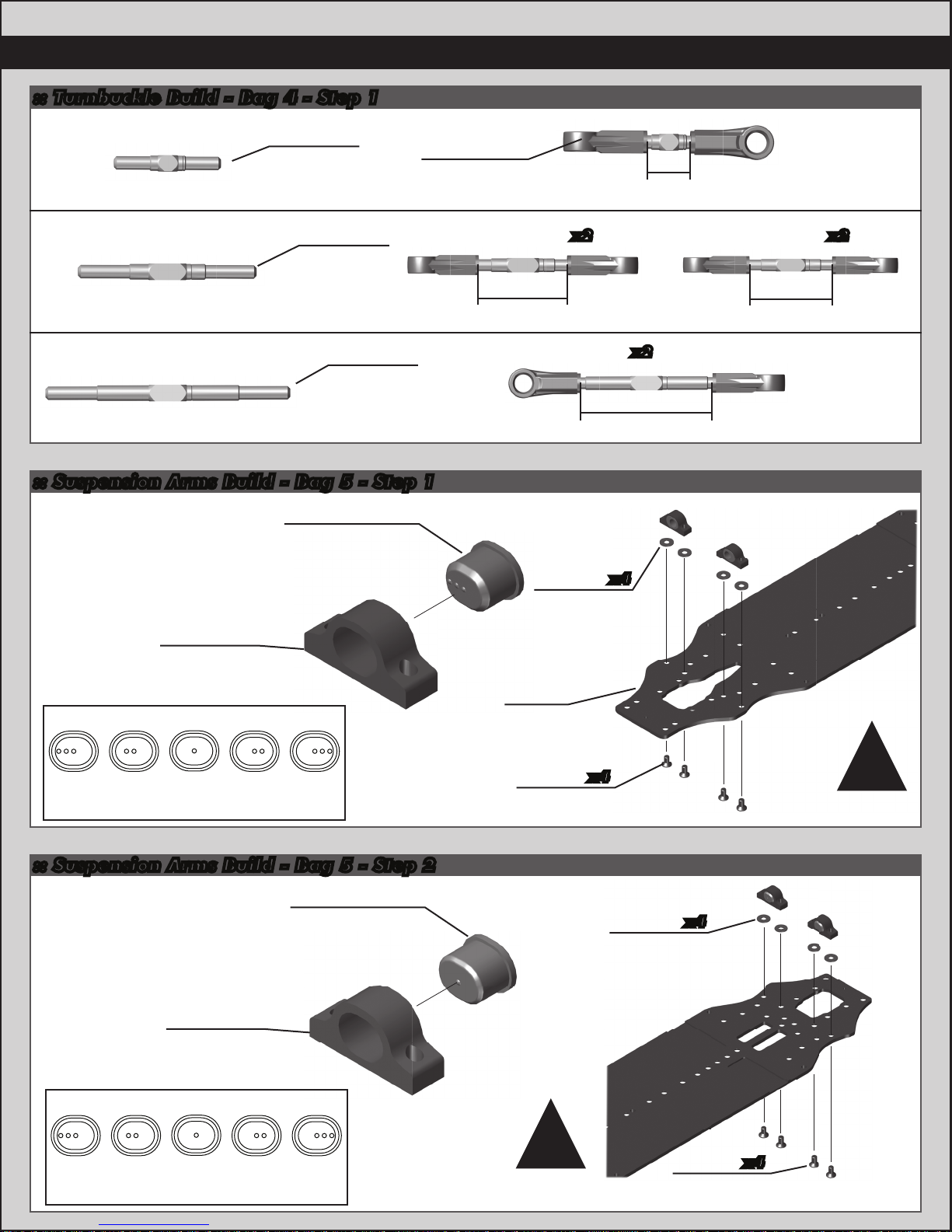

:: Turnbuckle Build - Bag 4 - Step 1

Servo Turnbuckle

6258

3x21mm

turnbuckle

31305

Turnbuckle

eyelet

9

10.15mm

Camber Turnbuckle

6264

3x35mm

turnbuckle

Steering Turnbuckle

91723

3x48mm

turnbuckle

:: Suspension Arms Build - Bag 5 - Step 1

Build two front

inner arm

mounts

TC7.2 Inner

arm mount

Arm Mount Inserts

-3 DOT

-2 DOT

31802

1 DOT

+2 DOT

31620

TC6.2 arm

mount insert

(Front: -3 dot)

+3 DOT

Front Rear

20.50mm

x2 x2

19.00mm

x2

30.15mm

31384

x4

Bulkhead

washers

(0.5mm)

31771

TC7.2

chassis

-1.2 °

-0.6 °

Negative to the inside of vehicle.

Positive to the outside of vehicle.

0 °

+0.6 °

+1.2 °

:: Suspension Arms Build - Bag 5 - Step 2

Build two rear

inner arm

mounts

31802

TC7.2 Inner

arm mount

Arm Mount Inserts

-3 DOT

-1.2 °

-2 DOT

-0.6 °

Negative to the inside of vehicle.

Positive to the outside of vehicle.

1 DOT

0 °

+2 DOT

+0.6 °

31620

TC6.2 arm

mount insert

(Rear: 0 dot)

+3 DOT

+1.2 °

31541

M3x6mm

fhcs

!

Rear of

chassis

x4

31384

Bulkhead

washers

(0.5mm)

x4

31541

M3x6mm

fhcs

!

Front of

chassis

x4

Page 10

10

31801

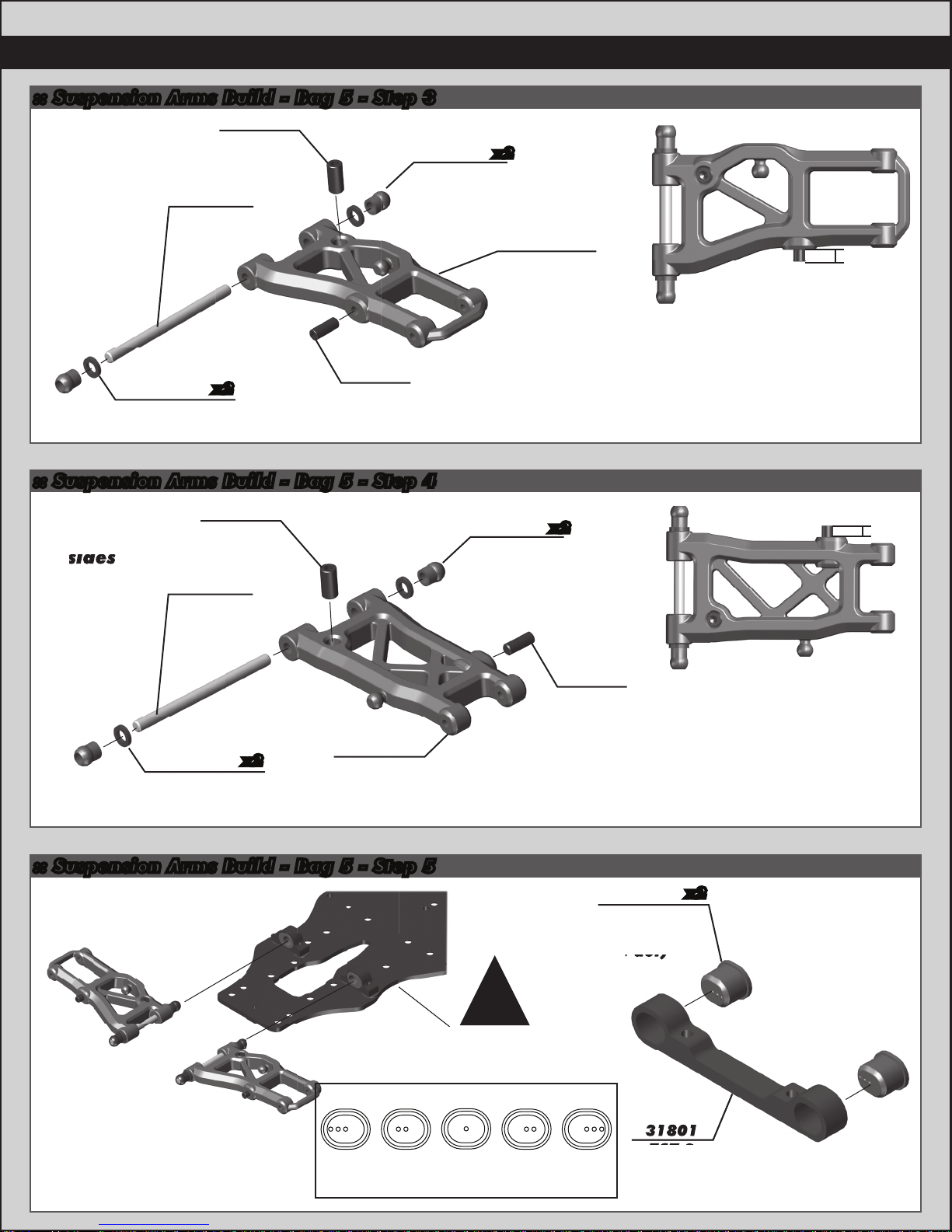

:: Suspension Arms Build - Bag 5 - Step 3

Build left

and right

sides

TC7 Inner

hinge pin

M4x8mm

set screw

31677

25227

hinge pin

ball, Steel

31647

Inner

x2

31673

TC7 Front

suspension

arm

3mm

31382

Ballstud

x2

M3x8mm

set screw

washer, (1mm)

:: Suspension Arms Build - Bag 5 - Step 4

4670

Build left

and right

sides

washer, (1mm)

25227

M4x8mm

set screw

31677

TC7 Inner

hinge pin

31382

Ballstud

x2

31674

TC7 Rear

suspension

arm

31647

Inner

hinge pin

ball, Steel

3mm

x2

4670

M3x8mm

set screw

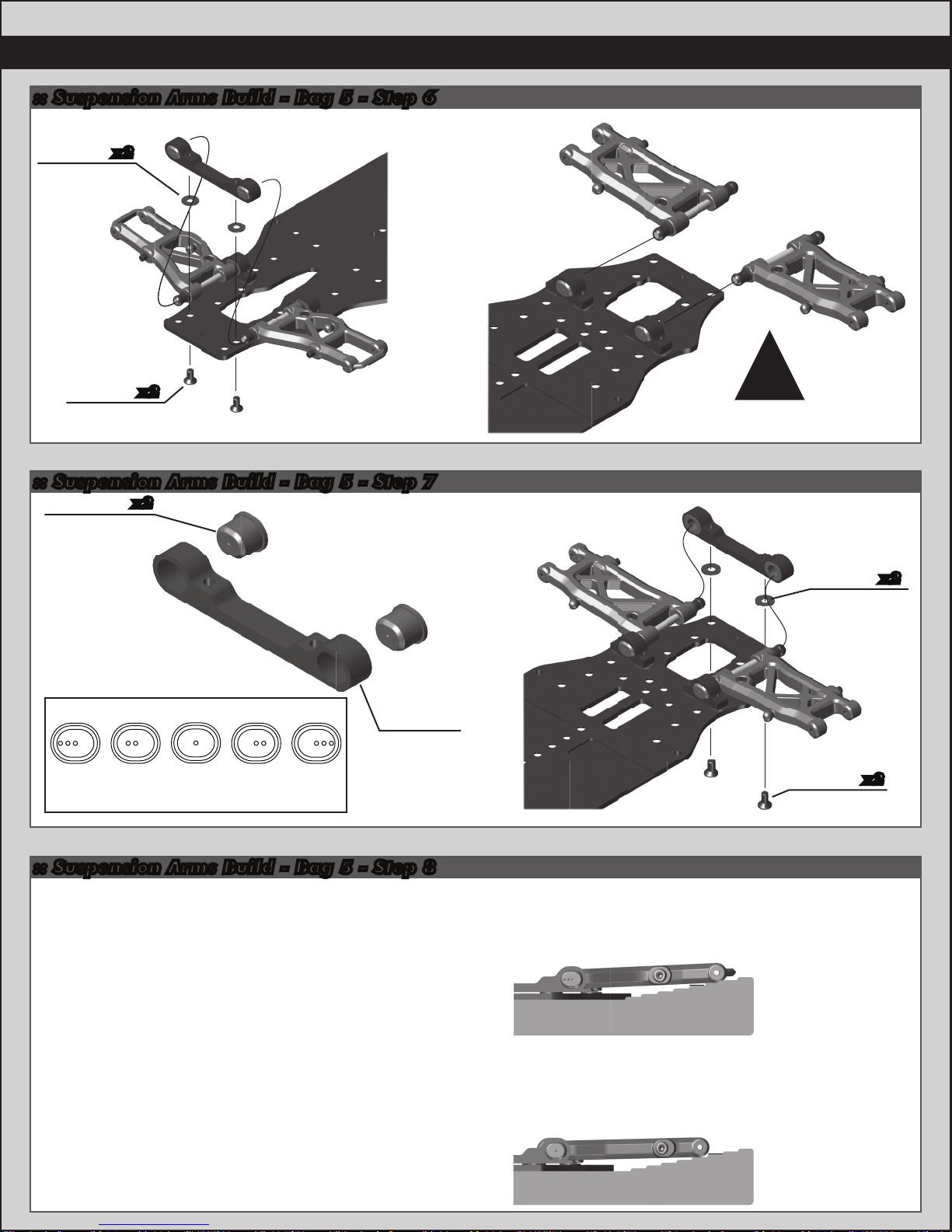

:: Suspension Arms Build - Bag 5 - Step 5

-3 DOT

-1.2 °

!

Front of

chassis

Arm Mount Inserts

-2 DOT

-0.6 °

Negative to the inside of vehicle.

Positive to the outside of vehicle.

1 DOT

0 °

+2 DOT

+0.6 °

31620

x2

TC6.2 arm mount

insert, front

(-3 dot)

+3 DOT

31801

+1.2 °

TC7.2

Outer Arm

Mount

Page 11

:: Suspension Arms Build - Bag 5 - Step 6

11

31384

x2

Bulkhead

washers

(0.5mm)

31541

x2

M3x6mm

fhcs

:: Suspension Arms Build - Bag 5 - Step 7

31620

TC6.2 arm

mount insert ,

rear

(1 dot)

x2

Rear

outer arm

mounts

!

Rear of

chassis

31384

Bulkhead

washers

(0.5mm)

x2

Arm Mount Inserts

-3 DOT

-2 DOT

1 DOT

+2 DOT

+3 DOT

31801

TC7.2

-1.2 °

-0.6 °

Negative to the inside of vehicle.

Positive to the outside of vehicle.

0 °

+0.6 °

+1.2 °

Outer Arm

Mount

:: Suspension Arms Build - Bag 5 - Step 8

Droop:

The standard settings of 6mm front and

5mm rear will work best in most cases.

Droop is measured just underneath the

outer hinge pin as shown in the photos

to the right.

On bumpy or low grip

surfaces, increase the droop (going to a

lower number on the droop gauge), this

will help increase traction and consistency.

Droop adjustments of 0.5mm to 1mm can

be very effective on the track!

Front Droop

Setting: 6mm

5

4

3

2

1

0

Rear Droop

Setting: 5mm

31541

x2

M3x6mm

fhcs

8

7

6

0

8

7

6

5

4

3

2

1

Page 12

12

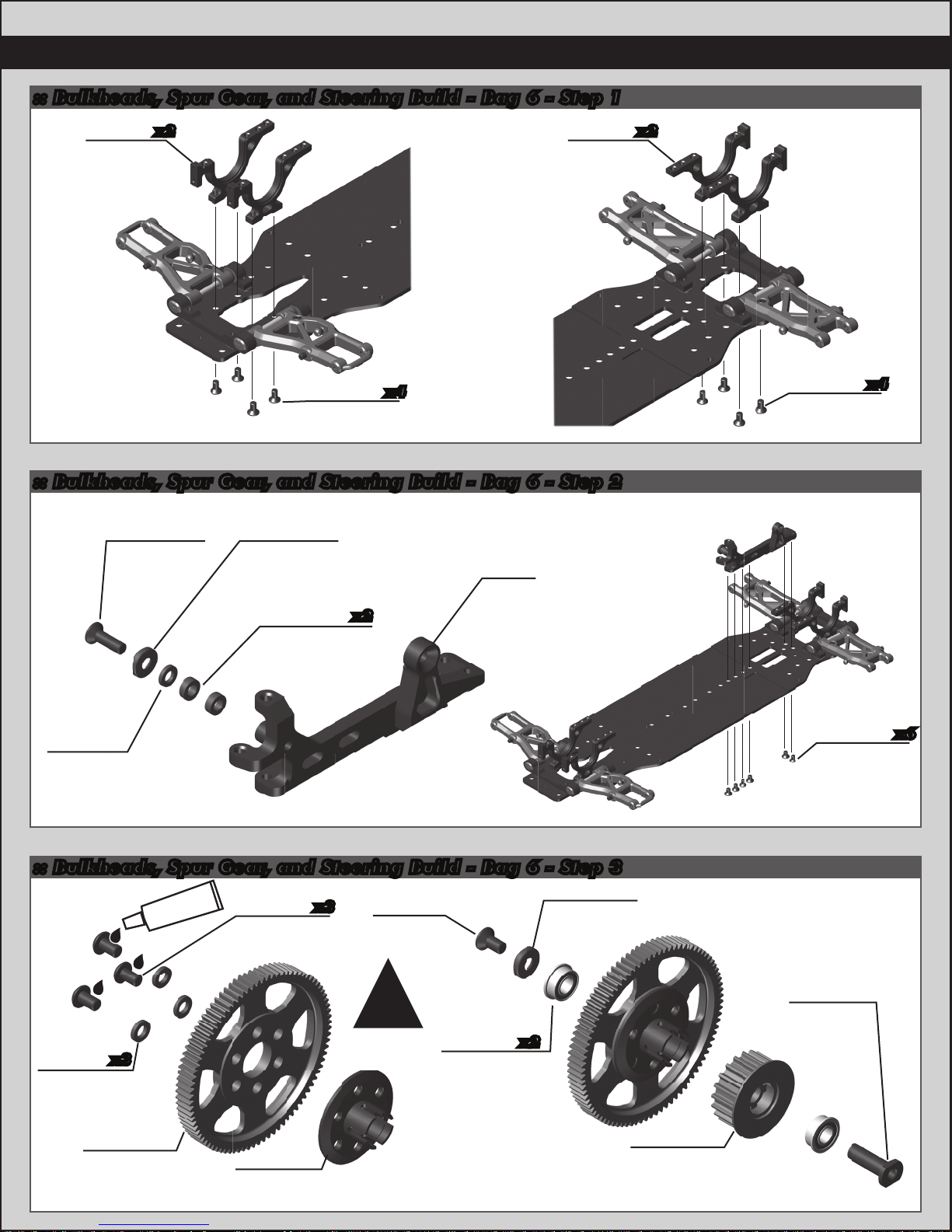

:: Bulkheads, Spur Gear, and Steering Build - Bag 6 - Step 1

31800

TC7.2

Bulkhead

x2 x2

31541

M3x6mm

fhcs

x4

31800

TC7.2

Bulkhead

:: Bulkheads, Spur Gear, and Steering Build - Bag 6 - Step 2

25202

M3x10mm

fhcs

89229

Blue

countersunk

washer

31383

Ballstud

washer,

(2mm)

x2

31790

TC7.2

motor

mount

31541

M3x6mm

fhcs

x4

31382

Ballstud

washer,

(1mm)

:: Bulkheads, Spur Gear, and Steering Build - Bag 6 - Step 3

#1596

thread lock

31530

M3x5mm

bhcs

x3

31541

M3x6mm

fhcs

countersunk

!

31382

Ballstud

washer,

(1mm)

x3

31333

TC6

spur gear

(87T / 48P)

31792

TC7.2 spur

gear hub

Thread lock

not included!

FT bearing

4x8x3mm

flanged

x231731

89229

Blue

washer

31787

TC7.2 spur

pulley

(20T)

31540

M3x5mm

fhcs

31791

TC7.2 spur

gear shaft

x6

Page 13

:: Bulkheads, Spur Gear, and Steering Build - Bag 6 - Step 4

Rear Belt

13

Front Belt

31658

TC7 Front

belt

31659

TC7 Rear

belt

:: Bulkheads, Spur Gear, and Steering Build - Bag 6 - Step 5

Belt Tension

Cam Position

Number

Left Side

161

Mid-Low

Low

Note!

Always use the same

cam position on both

sides of the car.

Mid-High

High

17 32

View from left

side of car

!

Use belt tension

position 9 for

standard setup

on the front.

Right Side

31615

Cam

holder

(mid-low)

x2

31615

Diff

bearing

cam

25202

M3x10mm

fhcs

x2

:: Bulkheads, Spur Gear, and Steering Build - Bag 6 - Step 6

x231782

Diff

shim

x291563

FT bearing

10x15x4mm

Slide belt over

spool pulley!

!

Page 14

14

:: Bulkheads, Spur Gear, and Steering Build - Bag 6 - Step 7

Belt Tension

Cam Position

Number

Left Side

!

Use belt tension

position 8 for

standard setup

on the rear.

Right Side

31615

Diff

bearing

cam

x2

Mid-Low

Low

Note!

Always use the same

cam position on both

sides of the car.

Mid-High

High

161

17 32

View from left

side of car

:: Bulkheads, Spur Gear, and Steering Build - Bag 6 - Step 8

x231782

Diff

shim

31615

Cam

holder

(mid-low)

x2

!

Slide belt over

gear diff pulley!

x291563

FT bearing

10x15x4mm

:: Bulkheads, Spur Gear, and Steering Build - Bag 6 - Step 9

31283

Ballstud,

5mm,

long

31780

TC7.2

camber

link mount

x2

bearing cap

31779

TC7.2

x2

x2

31383

Ballstud

washer,

(2mm)

x4

31382

Ballstud

washer,

(1mm)

31532

M3x8mm

bhcs

31531

M3x6mm

bhcs

x2

x4

x4

Page 15

:: Bulkheads, Spur Gear, and Steering Build - Bag 6 - Step 10

31283

Ballstud,

5mm,

long

x2

31382

Ballstud

washer,

(1mm)

x2

31383

Ballstud

washer,

(2mm)

x4

31531

M3x6mm

bhcs

15

x4

31780

TC7.2

camber

link mount

x2

31779

TC7.2

bearing cap

x2

31532

M3x8mm

bhcs

x4

:: Bulkheads, Spur Gear, and Steering Build - Bag 6 - Step 11

Note!

Insert 1mm washer

!

between top plate

and motor mount.

31382

Ballstud

washer,

(1mm)

!

Note!

Insert top

plate between

the front belt.

31774

TC7.2

top plate

(2.0mm)

x931530

M3x5mm

bhcs

:: Bulkheads, Spur Gear, and Steering Build - Bag 6 - Step 12

31776

31775

TC7.2 front

shock tower

31532

M3x8mm

bhcs

x2

TC7.2 rear

shock tower

31532

M3x8mm

bhcs

x2

Page 16

16

Note direction

of clip for left &

right side DCV -

refer to page 10

:: Bulkheads, Spur Gear, and Steering Build - Bag 6 - Step 13

31803

TC7.2

steering

rack

31391

3.25mm

ballstud,

long neck

31804

TC7.2

steering

bellcrank

x2

31732

FT Bearing,

4 x 7 x 2.5mm

x4

x3

31732

FT Bearing,

4 x 7 x 2.5mm

x4

31283

Ballstud,

5mm,

long

31382

Ballstud

washer,

(1mm)

x2

:: Bulkheads, Spur Gear, and Steering Build - Bag 6 - Step 14

25211

M3x10mm

bhcs

x2

#1596

thread lock

31803

TC7.2 steering

rack hat

bushing

x2

!

Thread lock

not included!

31794

TC7.2 steering

rack post

x2

31530

M3x5mm

bhcs

x2

:: Caster Blocks and Hubs Build - Bag 7 - Step 1

Build two Build two

31734

5 x 10 x 3,

Bearing

31382

Ballstud

washer,

(1mm)

31679

TC7

steering

blocks

31370

TC6.1

axle crush

tube

31283

Ballstud,

5mm,

(long)

91560

FT bearing

5x10x4mm

!

Note direction

of clip for left &

right side DCV -

refer to page 10

31541

M3x6mm

fhcs

x2

Page 17

:: Caster Blocks and Hubs Build - Bag 7 - Step 2

Build two

!

Do not

overtighten!

M1.6x5mm

91611

shcs

!

17

Use a 1.5mm hex tool tip to poke

through any left over flashing (extra

thin piece of plastic) in the hinge pin

set screw hole on the caster blocks.

31112

1/16” x 5/16”

dowel pins

31670

Clamping

wheel hex

(5mm)

:: Caster Blocks and Hubs Build - Bag 7 - Step 3

Build two

31678

TC7 caster

block,

(4 degree)

31382

Ballstud

washer,

(1mm)

31285

10mm

ballstud

(long)

31680

TC7 king

pin bushing

:: Caster Blocks and Hubs Build - Bag 7 - Step 4

Build two

31680

31382

Ballstud

washer,

(1mm)

TC7 king

pin bushing

25211

M3x10mm

bhcs

31677

TC7 hinge

pin, outer

25225

M3x3

set screw

Page 18

18

Build left

and right

sides

:: Caster Blocks and Hubs Build - Bag 7 - Step 5

!

Orient the notch

to the left throughout

the car. The notch

indicates which end has

the left hand threads!

:: Caster Blocks and Hubs Build - Bag 7 - Step 6

It is important that the turnbuckle eyelets move freely

once snapped on to the ballstud. If the fit is too tight,

the car handling will be inconsistent. To check, grab

!

turnbuckle eyelet with fingers and rotate the cup. If

there is resistance, lightly squeeze ball cup with needle

nose pliers as shown and test again. It is important

that the ball cup be snapped onto the ballstud before

squeezing with needle nose pliers. Be sure to check

and adjust the fit for each ball cup that is installed.

!

Use a 1.5mm hex tool tip to

poke through any left over

flashing (extra thin piece of

plastic) in the hinge pin set

screw hole on the rear hubs.

:: Caster Blocks and Hubs Build - Bag 7 - Step 7

Build left

and right

sides

31681

TC7 rear

hub

carrier

31284

Ballstud

8mm,

(long)

31383

Ballstud

washer,

(2mm)

Build left

and right

sides

31370

TC6.1

axle crush

tube

x291560

FT bearing

5x10x4mm

Page 19

:: Caster Blocks and Hubs Build - Bag 7 - Step 8

Build left

and right

sides

31112

1/16” x 5/16”

dowel pins

!

Do not

overtighten!

91611

Build left

and right

M1.6x5mm

shcs

sides

:: Caster Blocks and Hubs Build - Bag 7 - Step 9

31670

Clamping

wheel hex

(5mm)

31677

TC7 hinge

pin, outer

19

Build left

and right

sides

25225

M3x3

set screw

!

Orient the notch

to the left throughout

the car. The notch

indicates which end has

the left hand threads!

:: Bumper, Anti-Roll Bar, and Electronics Build - Bag 8 - Step 1

31383

Ballstud

washer,

aluminum

(2mm)

x2 x2

31532

M3x8mm

bhcs

x2

Ballstud

washer,

aluminum

(1mm)

31382

31532

M3x8mm

bhcs

x2

Page 20

20

:: Bumper, Anti-Roll Bar, and Electronics Build - Bag 8 - Step 2

4673

M2.5x4mm

bhcs

x3

!

Transponder

not included!

31625

TC6.2 front

body posts

31623

TC6.2

bumper

:: Bumper, Anti-Roll Bar, and Electronics Build - Bag 8 - Step 3

25201

M3x8mm

fhcs

31623

TC6.2

bumper

brace

x3

x2

31797

TC7.2

foam

bumper

25202

M3x10mm

fhcs

x2

:: Bumper, Anti-Roll Bar, and Electronics Build - Bag 8 - Step 4

25201

M3x8mm

fhcs

x2

31532

M3x8mm

bhcs

x2

31625

TC6.2 rear

body posts

x2

Page 21

:: Bumper, Anti-Roll Bar, and Electronics Build - Bag 8 - Step 5

21

31701

TC7 anti-

31701

TC7 anti-

roll bar

coupler

Build four

anti-roll

bar mounts

roll bar

eyelet

31058

Anti roll

bar

ballstud

31305

Turnbuckle

eyelet

Anti Roll Bar

Link Adjust

9.5mm

ment

31500

M3x2.5mm

set screw

31701

TC7 anti-

roll bar

retainer

1.4mm (blue)

1.2mm (white)

:: Bumper, Anti-Roll Bar, and Electronics Build - Bag 8 - Step 6

31500

M3x2.5mm

set screw

Tighten #25225 set

screws just enough

to allow the anti-roll

bar to move freely !

!

25225

M3x3mm

set screw

x2

31703

TC7 Front

anti-roll bar,

31707

TC7 Rear

anti-roll bar,

Anti Roll Bar

Color/Size Chart

Green

White

Gray

Blue

Yellow

1.1mm

1.2mm

1.3mm

1.4mm

1.5mm

!

Shrink the colored

heat shrink tubing to

the anti roll bar!

31511

M2x5mm

shcs

x2

:: Bumper, Anti-Roll Bar, and Electronics Build - Bag 8 - Step 7

31500

M3x2.5mm

set screw

Tighten #25225 set

screws just enough

to allow the anti-roll

bar to move freely !

!

25225

M3x3mm

set screw

31511

M2x5mm

shcs

x2

x2

31701

TC7 anti-

roll bar

mount

31701

TC7 anti-

roll bar

mount

x2

x2

Page 22

22

:: Bumper, Anti-Roll Bar, and Electronics Build - Bag 8 - Step 8

25202

M3x10mm

fhcs

31382

Ballstud

washer,

(1mm)

89229

Blue

countersunk

washer

31793

mount

TC7.2

servo

31383

Ballstud

washer,

(2mm)

31532

M3x8mm

x2

bhcs

!

Servo not

included!

x3

:: Bumper, Anti-Roll Bar, and Electronics Build - Bag 8 - Step 9

31530

M3x5mm

bhcs

x3

31777

TC7.2 servo

mount brace

31285

Ballstud

10mm,

(long)

31383

Ballstud

washer,

(2mm)

31550

FT M3 Locknut,

blue aluminum

31805

TC7.2

servo

mount

(outer)

7337

.250x.125x.015

washer

x3

!

Use screw that was

included with your servo.

Servo not included!

:: Bumper, Anti-Roll Bar, and Electronics Build - Bag 8 - Step 10

!

Install the servo

mount into the

chassis using the

guide posts/tabs.

31540

M3x5mm

fhcs

x2

89007

Servo

horn

89007

Servo

horn ring

Page 23

:: Bumper, Anti-Roll Bar, and Electronics Build - Bag 8 - Step 11

Gearing will depend on the

motor and track size.

Gear charts on pages 26 and 27.

!

Receiver not

included!

!

ESC not

included!

!

Motor, pinion gear, and set screw

are not included!

23

6727

Servo tape

:: Battery Stop, Final Build - Bag 9 - Step 1

31384

Bulkhead

washer,

(0.5 mm)

31386

Bulkhead

31382

Ballstud

washer,

(1mm)

31532

M3x8mm

bhcs

x2

x2

washer,

(2.0 mm)

31795

TC7.2

battery

stop

x2

31385

Bulkhead

washer,

(1.0 mm)

31382

Ballstud

washer,

(1mm)

31778

TC7.2

battery tab

31798

TC7.2 battery

lock, bottom

89229

Blue

countersunk

washer

31541

M3x6mm

fhcs

x2

25202

M3x10mm

!

Motor not

included!

x2

x2

x2

x2

fhcs

:: Battery Stop, Final Build - Bag 9 - Step 2

25201

M3x8mm

fhcs

x2

31531

M3x6mm

bhcs

x2

31798

TC7.2 battery

lock, top

x2

Page 24

24

:: Battery Stop, Final Build - Bag 9 - Step 3

0.5mm

1736

x4

FT body

clips

x4

!

Use these shims to adjust

the battery lock top height

for 0.5mm clearance

above the battery.

91148

M4 flanged

locknut,

knurled

:: Tuning Tips

Tips for Beginners:

Before making any changes to the standard setup, make sure you can get around the track without crashing. Changes to your car

will not be beneficial if you can’t stay on the track. Your goal is consistent laps.

Once you can get around the track consistently, start tuning your car. Make only ONE adjustment at a time, testing it before making

another change. If the result of your adjustment is a faster lap, mark the change on the included setup sheet (make additional

copies of the sheet before writing on it). If your adjustment results in a slower lap, revert back to the previous setup and try another

change. When you are satisfied with your car, fill in the setup sheet thoroughly. Use this as a guide for future racing.

Ride Height:

The standard starting point for ride height is 5.0mm (your local track may have minimum ride height requirements). You can slightly

raise the rear relative to the front to give the car more steering. Raise the car slightly for tracks with large bumps.

Wheelbase:

Lengthening the front will reduce steering, shortening the front will increase steering.

Shortening the rear will increase rear grip, lengthening the rear will decrease rear traction.

Rear Toe-In:

Standard rear toe-in angle for inner hinge pin when using same insert front and rear

is 3°. Standard insert used is 1 dot. Rear toe-in can be adjusted by 0.6° increments at

the inner hinge pin with supplied arm mount inserts (see chart to right).

-3 DOT

-1.2 °

Arm Mount Inserts

-2 DOT

-0.6 °

Negative to the inside of vehicle.

Positive to the outside of vehicle.

1 DOT

0 °

+2 DOT

+0.6 °

+3 DOT

+1.2 °

Ackermann:

Ackermann refers to the relative angle difference

between the front wheels as they are turned to steer

the car. The outside wheel will turn less than the inside

wheel in most conditions. Settings with more

Ackermann will have a bigger difference in wheel

angle, causing the outside wheel to turn less. Likewise,

settings with less Ackermann will cause the outside

wheel to turn more.

Increasing the Ackermann will smooth out the steering

and is used most often on high traction surfaces such

as carpet. This is a result of the reduced outside wheel

angle. Settings with reduced Ackermann will help to

increase corner entry steering, and are typically used

when running a spool in the front.

A

B

Steering Block Steering Rack

Steering

Block

Position

B

B

B

A

A

A

Steering

Rack

Shims

2mm

1mm

0mm

2mm

1mm

0mm

Less Ackermann

STD

More Ackermann

The chart to the right lists the different Ackermann

options.

Page 25

:: Tuning Tips

Droop:

The standard settings of 6mm front and 5mm

rear will work best in most cases. Droop is

measured just underneath the outer hinge pin

as shown in the photos to the right.

On bumpy or low grip surfaces, increase the

droop (going to a lower number on the droop

gauge), this will help increase traction and

consistency.

Droop adjustments of 0.5mm to 1mm can be

very effective on the track!

Front Droop

Setting: 6mm

4

3

2

1

0

25

Rear Droop

Setting: 5mm

5

0

4

3

2

1

8

7

6

8

7

6

5

Anti-Roll Bar:

Anti-roll bars are only effective during roll (when the chassis leans from side to side when cornering).

Because of this they isolate a change in the suspensions spring rate in the corners only, and can be a very useful

tuning option.

Anti-roll bars stiffen the spring rate of the suspension during roll movements when cornering. The larger the

roll bar wire, the stiffer the spring rate will be in roll. The chart on the right shows the available anti-roll bar

sizes (as well as their corresponding colors) from the softest on the top, to the stiffest on the bottom.

The standard setup with a blue front anti-roll bar (1.4mm) and a white rear anti-roll bar (1.2mm), is a balanced starting point.

Changing the size of the front or rear anti-roll bars can help to make the chassis more consistent through the corner. Decreasing the

size of the front anti-roll bars will help to increase mid-corner steering, but will tend to be less stable in sweepers. This is a

typical setup for smaller tracks with tighter turns. Increasing the size of the front anti-roll bars will give more stability in the

sweepers, and is better for larger tracks with high speed corners. Increasing the size of the rear ant-roll bars will help add stability

into and through the corner in high traction conditions, but can make the car inconsistent in low traction, or bumpy, surfaces.

Belt Tension:

When altering the differential height, you will need

to adjust the tension of the belt. The following chart

shows suggested starting positions.

TighterLooser

Left Side

Front

Note! Charts show left side cam positions from the left side of the car. Match right side cam position to left side cam position.

Tighter Looser

Cam Position

Mid-Low

Low

Left Side

Front

Mid-High

High

Belt Tension

Number

161

17 32

View from left

side of car

Anti Roll Bar

Color/Size Chart

High

Mid

Low

High

Mid

Low

1.1mm

1.2mm

1.3mm

1.4mm

1.5mm

Pos.

31

28

Pos.

18

20

Green

White

Gray

Blue

Yellow

Height

Mid-High

Front

Height

Mid-High

Rear

8

5

7

9

Motor Gearing:

The gear charts on the following page show final drive ratio numbers for the TC7.2. Refer to motor manufacturer’s suggested gear

ratio for starting point. You may need to adjust the gearing according to your track size.

The following formula’s can also be helpful in determining final drive ratios and pinion size.

TC7.2 Internal Ratio = 2.0

# of Teeth on Pinion

Final Drive Ratio

Final Drive Ratio = (# of Teeth Spur) x (Internal Ratio)

# of Teeth on Pinion = (# of Teeth on Spur) x (Internal Ratio)

Page 26

26

:: Gear Chart 48 Pitch

!

the gear charts

Blank spaces in

fit in the vehicle.

Gear fitment will

ratio that will not

designates a gear

also depend on the

motor brand.

77 78 79 80 81 82 83 84 85 86 87

15 -- -- -- -- -- -- -- -- -- -- 11.60

16 -- -- -- -- -- -- -- -- -- 10.75 10.88

17 -- -- -- -- -- -- -- -- 10.00 10.12 10.24

18 -- -- -- -- -- -- -- 9.33 9.44 9.56 9.67

19 -- -- -- -- -- -- 8.74 8.84 8.95 9.05 9.16

20 -- -- -- -- -- 8.20 8.30 8.40 8.50 8.60 8.70

21 -- -- -- -- 7.71 7.81 7.90 8.00 8.10 8.19 8.29

22 -- -- -- 7.27 7.36 7.45 7.55 7.64 7.73 7.82 7.91

23 -- -- 6.87 6.96 7.04 7.13 7.22 7.30 7.39 7.48 7.57

24 -- 6.50 6.58 6.67 6.75 6.83 6.92 7.00 7.08 7.17 7.25

25 6.16 6.24 6.32 6.40 6.48 6.56 6.64 6.72 6.80 6.88 6.96

26 5.92 6.00 6.08 6.15 6.23 6.31 6.38 6.46 6.54 6.62 6.69

27 5.70 5.78 5.85 5.93 6.00 6.07 6.15 6.22 6.30 6.37 6.44

28 5.50 5.57 5.64 5.71 5.79 5.86 5.93 6.00 6.07 6.14 6.21

66 67 68 69 70 71 72 73 74 75 76

26 -- -- -- -- -- -- -- -- -- -- 5.85

27 -- -- -- -- -- -- -- -- -- 5.56 5.63

28 -- -- -- -- -- -- -- -- 5.29 5.36 5.43

29 -- -- -- -- -- -- -- 5.03 5.10 5.17 5.24

30 -- -- -- -- -- -- 4.80 4.87 4.93 5.00 5.07

31 -- -- -- -- -- 4.58 4.65 4.71 4.77 4.84 4.90

32 -- -- -- -- 4.38 4.44 4.50 4.56 4.63 4.69 4.75

33 -- -- -- 4.18 4.24 4.30 4.36 4.42 4.48 4.55 4.61

34 -- -- 4.00 4.06 4.12 4.18 4.24 4.29 4.35 4.41 4.47

35 -- 3.83 3.89 3.94 4.00 4.06 4.11 4.17 4.23 4.29 4.34

36 3.67 3.72 3.78 3.83 3.89 3.94 4.00 4.06 4.11 4.17 4.22

37 3.57 3.62 3.68 3.73 3.78 3.84 3.89 3.95 4.00 4.05 4.11

38 3.47 3.53 3.58 3.63 3.68 3.74 3.79 3.84 3.89 3.95 4.00

39 3.38 3.44 3.49 3.54 3.59 3.64 3.69 3.74 3.79 3.85 3.90

40 3.30 3.35 3.40 3.45 3.50 3.55 3.60 3.65 3.70 3.75 --

41 3.22 3.27 3.32 3.37 3.41 3.46 3.51 3.56 3.61 -- --

42 3.14 3.19 3.24 3.29 3.33 3.38 3.43 3.48 -- -- --

43 3.07 3.12 3.16 3.21 3.26 3.30 3.35 -- -- -- --

44 3.00 3.05 3.09 3.14 3.18 3.23 -- -- -- -- --

45 2.93 2.98 3.02 3.07 3.11 -- -- -- -- -- --

46 2.87 2.91 2.96 3.00 -- -- -- -- -- -- --

47 2.81 2.85 2.89 -- -- -- -- -- -- -- --

29 5.31 5.38 5.45 5.52 5.59 5.66 5.72 5.79 5.86 5.93 --

30 5.13 5.20 5.27 5.33 5.40 5.47 5.53 5.60 5.67 -- --

31 4.97 5.03 5.10 5.16 5.23 5.29 5.35 5.42 -- -- --

32 4.81 4.88 4.94 5.00 5.06 5.13 5.19 -- -- -- --

33 4.67 4.73 4.79 4.85 4.91 4.97 -- -- -- -- --

34 4.53 4.59 4.65 4.71 4.76 -- -- -- -- -- --

35 4.40 4.46 4.51 4.57 -- -- -- -- -- -- --

36 4.28 4.33 4.39 -- -- -- -- -- -- -- --

37 4.16 4.22 -- -- -- -- -- -- -- -- --

38 4.05 -- -- -- -- -- -- -- -- -- --

48 2.75 -- -- -- -- -- -- -- -- -- --

Page 27

:: Gear Chart 64 Pitch

!

27

the gear charts

Blank spaces in

fit in the vehicle.

Gear fitment will

ratio that will not

designates a gear

also depend on the

motor brand.

102 103 104 105 106 107 108 109 110 111 112 113 114 115

19 -- -- -- -- -- -- -- -- -- -- -- -- -- 12.11

20 -- -- -- -- -- -- -- -- -- -- -- -- 11.40 11.50

21 -- -- -- -- -- -- -- -- -- -- -- 10.76 10.86 10.95

22 -- -- -- -- -- -- -- -- -- -- 10.18 10.27 10.36 10.45

23 -- -- -- -- -- -- -- -- -- 9.65 9.74 9.83 9.91 10.00

24 -- -- -- -- -- -- -- -- 9.17 9.25 9.33 9.42 9.50 9.58

25 -- -- -- -- -- -- -- 8.72 8.80 8.88 8.96 9.04 9.12 9.20

26 -- -- -- -- -- -- 8.31 8.38 8.46 8.54 8.62 8.69 8.77 8.85

27 -- -- -- -- -- 7.93 8.00 8.07 8.15 8.22 8.30 8.37 8.44 8.52

28 -- -- -- -- 7.57 7.64 7.71 7.79 7.86 7.93 8.00 8.07 8.14 8.21

29 -- -- -- 7.24 7.31 7.38 7.45 7.52 7.59 7.66 7.72 7.79 7.86 7.93

30 -- -- 6.93 7.00 7.07 7.13 7.20 7.27 7.33 7.40 7.47 7.53 7.60 7.67

31 -- 6.65 6.71 6.77 6.84 6.90 6.97 7.03 7.10 7.16 7.23 7.29 7.35 7.42

32 6.38 6.44 6.50 6.56 6.63 6.69 6.75 6.81 6.88 6.94 7.00 7.06 7.13 7.19

33 6.18 6.24 6.30 6.36 6.42 6.48 6.55 6.61 6.67 6.73 6.79 6.85 6.91 6.97

34 6.00 6.06 6.12 6.18 6.24 6.29 6.35 6.41 6.47 6.53 6.59 6.65 6.71 6.76

35 5.83 5.89 5.94 6.00 6.06 6.11 6.17 6.23 6.29 6.34 6.40 6.46 6.51 6.57

36 5.67 5.72 5.78 5.83 5.89 5.94 6.00 6.06 6.11 6.17 6.22 6.28 6.33 6.39

37 5.51 5.57 5.62 5.68 5.73 5.78 5.84 5.89 5.95 6.00 6.05 6.11 6.16 6.22

38 5.37 5.42 5.47 5.53 5.58 5.63 5.68 5.74 5.79 5.84 5.89 5.95 6.00 6.05

39 5.23 5.28 5.33 5.38 5.44 5.49 5.54 5.59 5.64 5.69 5.74 5.79 5.85 5.90

40 5.10 5.15 5.20 5.25 5.30 5.35 5.40 5.45 5.50 5.55 5.60 5.65 5.70 --

41 4.98 5.02 5.07 5.12 5.17 5.22 5.27 5.32 5.37 5.41 5.46 5.51 -- --

42 4.86 4.90 4.95 5.00 5.05 5.10 5.14 5.19 5.24 5.29 5.33 -- -- --

43 4.74 4.79 4.84 4.88 4.93 4.98 5.02 5.07 5.12 5.16 -- -- -- --

44 4.64 4.68 4.73 4.77 4.82 4.86 4.91 4.95 5.00 -- -- -- -- --

45 4.53 4.58 4.62 4.67 4.71 4.76 4.80 4.84 -- -- -- -- -- --

46 4.43 4.48 4.52 4.57 4.61 4.65 4.70 -- -- -- -- -- -- --

47 4.34 4.38 4.43 4.47 4.51 4.55 -- -- -- -- -- -- -- --

48 4.25 4.29 4.33 4.38 4.42 -- -- -- -- -- -- -- -- --

49 4.16 4.20 4.24 4.29 -- -- -- -- -- -- -- -- -- --

50 4.08 4.12 4.16 -- -- -- -- -- -- -- -- -- -- --

51 4.00 4.04 -- -- -- -- -- -- -- -- -- -- -- --

52 3.92 -- -- -- -- -- -- -- -- -- -- -- -- --

88 89 90 91 92 93 94 95 96 97 98 99 100 101

34 -- -- -- -- -- -- -- -- -- -- -- -- -- 5.94

35 -- -- -- -- -- -- -- -- -- -- -- -- 5.71 5.77

36 -- -- -- -- -- -- -- -- -- -- -- 5.50 5.56 5.61

37 -- -- -- -- -- -- -- -- -- -- 5.30 5.35 5.41 5.46

38 -- -- -- -- -- -- -- -- -- 5.11 5.16 5.21 5.26 5.32

39 -- -- -- -- -- -- -- -- 4.92 4.97 5.03 5.08 5.13 5.18

40 -- -- -- -- -- -- -- 4.75 4.80 4.85 4.90 4.95 5.00 5.05

41 -- -- -- -- -- -- 4.59 4.63 4.68 4.73 4.78 4.83 4.88 4.93

42 -- -- -- -- -- 4.43 4.48 4.52 4.57 4.62 4.67 4.71 4.76 4.81

43 -- -- -- -- 4.28 4.33 4.37 4.42 4.47 4.51 4.56 4.60 4.65 4.70

44 -- -- -- 4.14 4.18 4.23 4.27 4.32 4.36 4.41 4.45 4.50 4.55 4.59

45 -- -- 4.00 4.04 4.09 4.13 4.18 4.22 4.27 4.31 4.36 4.40 4.44 4.49

46 -- 3.87 3.91 3.96 4.00 4.04 4.09 4.13 4.17 4.22 4.26 4.30 4.35 4.39

47 3.74 3.79 3.83 3.87 3.91 3.96 4.00 4.04 4.09 4.13 4.17 4.21 4.26 4.30

48 3.67 3.71 3.75 3.79 3.83 3.88 3.92 3.96 4.00 4.04 4.08 4.13 4.17 4.21

49 3.59 3.63 3.67 3.71 3.76 3.80 3.84 3.88 3.92 3.96 4.00 4.04 4.08 4.12

50 3.52 3.56 3.60 3.64 3.68 3.72 3.76 3.80 3.84 3.88 3.92 3.96 4.00 4.04

51 3.45 3.49 3.53 3.57 3.61 3.65 3.69 3.73 3.76 3.80 3.84 3.88 3.92 3.96

52 3.38 3.42 3.46 3.50 3.54 3.58 3.62 3.65 3.69 3.73 3.77 3.81 3.85 3.88

53 3.32 3.36 3.40 3.43 3.47 3.51 3.55 3.58 3.62 3.66 3.70 3.74 3.77 3.81

54 3.26 3.30 3.33 3.37 3.41 3.44 3.48 3.52 3.56 3.59 3.63 3.67 3.70 3.74

55 3.20 3.24 3.27 3.31 3.35 3.38 3.42 3.45 3.49 3.53 3.56 3.60 3.64 --

56 3.14 3.18 3.21 3.25 3.29 3.32 3.36 3.39 3.43 3.46 3.50 3.54 -- --

57 3.09 3.12 3.16 3.19 3.23 3.26 3.30 3.33 3.37 3.40 3.44 -- -- --

58 3.03 3.07 3.10 3.14 3.17 3.21 3.24 3.28 3.31 3.34 -- -- -- --

59 2.98 3.02 3.05 3.08 3.12 3.15 3.19 3.22 3.25 -- -- -- -- --

60 2.93 2.97 3.00 3.03 3.07 3.10 3.13 3.17 -- -- -- -- -- --

61 2.89 2.92 2.95 2.98 3.02 3.05 3.08 -- -- -- -- -- -- --

62 2.84 2.87 2.90 2.94 2.97 3.00 -- -- -- -- -- -- -- --

63 2.79 2.83 2.86 2.89 2.92 -- -- -- -- -- -- -- -- --

64 2.75 2.78 2.81 2.84 -- -- -- -- -- -- -- -- -- --

65 2.71 2.74 2.77 -- -- -- -- -- -- -- -- -- -- --

66 2.67 2.70 -- -- -- -- -- -- -- -- -- -- -- --

67 2.63 -- -- -- -- -- -- -- -- -- -- -- -- --

Page 28

28

:: Shocks :: CVAs

4637

5407

31510

31745

31746

31752

31753

31756

31757

31758

31759

31760

89278

FT Pivot Balls

Red O-Rings

M2 x 4mm BHCS

TC7.1 Shock Body (Fox Kashima Coat)

TC7.1 Shock Shaft

TC7.1 Shock Rebuild Kit

TC7.1 Shock Bottom Cap

TC7.1 Shock Cap Retainer

TC7.1 Shock Eyelet Set

TC7.1 Shock Collar

TC7.1 Shock Spring Cup

TC7.1 Shock Kit (Fox Kashima Coat)

Washers, M2.6 x 6mm

:: Springs

31761

31762

31763

31764

TC 20.5mm Spring (White), 13.8lbs

TC 20.5mm Spring, (Gray), 14.8lbs

TC 20.5mm Spring, (Blue), 15.8lbs - Kit

TC 20.5mm Spring, (Yellow), 16.8lbs

:: Pistons

31747

31748

TC7.1 Shock Piston (4x1.1)

FT TC7.1 Shock Piston (4x1.1G)

:: FT Parts

31751

91493

PSD (Position Sensitive Damping)

shock system

FT Low Friction X-Rings

Pr.

8

8

10

2

2

1

2

2

2

2

2

2

20

Pr.

Pr.

Pr.

Pr.

4

4

31756

8

31237

31238

31367

31369

31500

31796

:: DCVs

31632

31633

31634

31635

31636

CVA Pin Retaining Clip

CVA Bone Blade

TC6.1 CVA Rebuild Kit

TC6.1 Stub Axle

M3 x 2.5mm Set Screw

TC7.2 CVA Bone

31238

31796

DCV Kit

DCV Rebuild Kit

DCV Stub Axles

DCV Bones

DCV Coupler Tubes

2

8

1

Pr.

6

Pr.

31367

31500

31369

31237

Pr.

1

2

2

2

31633

31510

31758

31747

31752

89278

31763

31745

31746

31759

4637

31757

:: Shock Fluid

5420

5421

5422

5423

5424

5425

5426

5427

5428

5429

5430

5431

5432

5433

5434

5435

5436

5437

5438

10 Weight Silicone Shock Fluid

20 Weight Silicone Shock Fluid

30 Weight Silicone Shock Fluid

40 Weight Silicone Shock Fluid

22.5 Weight Silicone Shock Fluid

80 Weight Silicone Shock Fluid

27.5 Weight Silicone Shock Fluid

15 Weight Silicone Shock Fluid

25 Weight Silicone Shock Fluid

35 Weight Silicone Shock Fluid

45 Weight Silicone Shock Fluid

55 Weight Silicone Shock Fluid

32.5 Weight Silicone Shock Fluid

37.5 Weight Silicone Shock Fluid

42.5 Weight Silicone Shock Fluid

50 Weight Silicone Shock Fluid

60 Weight Silicone Shock Fluid

70 Weight Silicone Shock Fluid

47.5 Weight Silicone Shock Fluid

31757

5407

31752

31753

31753

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

2oz.

4637

31635

31633

31633

:: Anti-Roll Bars

25225

31058

31305

31500

31511

31701

31703

31707

25225

31511

M3 x 3mm Set Screw

Roll Bar Ballstuds, blue

Turnbuckle Eyelets

M3 x 2.5mm Set Screw

M2 x 5mm SHCS

TC7 Anti-Roll Bar Mount Set

TC7 Front Anti-Roll Bar,

1.3mm (gray), 1.4mm (blue), 1.5mm (yellow)

TC7 Rear Anti-Roll Bar,

1.1mm (green), 1.2mm (white), 1.3mm (gray)

31500

25225

31636

31703

31707

31701

31634

10

2

14

10

10

1

1 ea.

1 ea.

31500

31701

31058

31305

Page 29

:: Front Spool

31350

31519

31615

31638

31782

31786

31788

91563

M2.5 x 10mm FHCS

M2.5 x 5mm BHCS

TC6.2 Diff Bearing Cam Set

Spool Outdrives, Steel

TC7.2 Diff Rebuild Kit

TC7.2 Diff Pulley

TC7.2 Spool Hub

FT Bearing 10 x 15 x 4mm

10

29

6

1

2

1

1

1

4

91563

31350

31782

31638

31519

31786

31615

:: Rear Gear Differential

5450

5451

5452

5444

5453

5446

5454

5465

8680

31518

31615

31782

31783

31785

31786

91563

Silicone Diff Fluid 1,000CST

Silicone Diff Fluid 2,000CST

Silicone Diff Fluid 3,000CST - Kit

Silicone Diff Fluid 4,000CST

Silicone Diff Fluid 5,000CST

Silicone Diff Fluid 6,000CST

Silicone Diff Fluid 7,000CST

Silicone Diff Fluid 1,000,000CST

FT Bearing 5 x 8 x 2.5mm

M2.5 x 4mm FHCS

TC6.2 Diff Bearing Cam Set

TC7.2 Diff Rebuild Kit

TC7.2 Diff Case

TC7.2 Diff Outdrive

TC7.2 Diff Pulley

FT Bearing 10 x 15 x 4mm

10

31519

31786

31788

1

1

1

1

1

1

1

1

4

1

1

1

2

1

4

91563

31782

31782

31615

31782

8680

31783

31518

31785

31519

31782

31782

8680

31519

31518

31785

31782

31350

31786

31783

91563

31638

31786

31782

31782

91563

31782

31783

31782

31782

:: Spur Gear Assembly

25202

31382

31530

31541

31731

31787

31791

31792

89229

M3 x 10mm FHCS

Ballstud Washer 5.5x1.0mm

M3 x 5mm BHCS

M3 x 6mm FHCS

FT 4x8x3mm Flanged Bearing

TC7.2 Spur Pulley & Diff X-Pin

TC7.2 Spur Gear Shaft

TC7.2 Spur Gear Hub

Blue Countersunk Washers

:: Spur Gears

3921

3922

3923

3924

3994

4462

4615

31332

31333

31334

31335

Spur Gear (69T/48P)

Spur Gear (72T/48P)

Spur Gear (75T/48P)

Spur Gear (66T/48P)

Spur Gear (73T/48P)

Spur Gear (100T/64P)

Spur Gear (96T/64P)

Spur Gear (80T/48P)

Spur Gear (87T/48P)

Spur Gear (106T/64P)

Spur Gear (115T/64P)

20

10

10

10

10

4

1

1

1

1

1

1

1

1

1

1

1

1

1

1

31541

89229

31530

31731

31333

31382

31787

31792

31791

31731

25202

Page 30

30

:: Steering Bellcrank and Servo Mounts

7337

25202

25211

31283

31285

31382

31383

31530

31532

31540

31541

31550

31732

31777

31793

31794

31803

31804

31805

89007

89229

.250” x.125” x.015” Washer

M3 x 10mm FHCS

M3 x 10mm BHCS

5mm Ballstud, long

Ballstuds, long, 10mm

Ballstud Washer 5.5 x 1.0mm

Ballstud Washer 5.5 x 2.0mm

M3 x 5mm BHCS

M3 x 8mm BHCS

M3x5mm FHCS

M3 x 6mm FHCS

FT M3 Locknut, blue aluminum

FT 4x7x2.5mm Bearing

TC7.2 Servo Mount Brace

TC7.2 Servo Mount

TC7.2 Steering Bellcrank Post

TC7.2 Steering Rack

TC7.2 Steering Bellcrank

TC7.2 Servo Mount (outer)

Steering Servo Horn & Ring

Blue Countersunk Washers

:: Front Bumper

1736

4673

25201

25202

31623

31625

31797

FT Body Clips, short

M2.5 x 4mm BHCS

M3 x 8mm FHCS

M3 x 10mm FHCS

TC6.2 Bumper Set

TC6.2 Body Post Set

TC7.2 Foam Bumper

6

10

10

10

1

1

1

4

10

10

10

10

10

10

10

10

10

10

6

4

1

1

2

1

2

1

1

10

31383

31285

31732

31732

31382

31283

25211

31803

31803

31550

89007

31391

31382

31530

31732

31804

31732

31794

31541

1736

25201

89229

31625

31530

25202

31382

31383

7337

31532

31540

31532

31777

31530

31793

31805

7337

1736

:: Front and Rear Shock Towers

1736

4637

31283

31382

31383

31531

31532

31541

31625

31775

31776

31779

31780

31800

FT Body Clips, short

FT Pivot Balls

Ballstuds, long, 5mm

Ballstud Washer 5.5 x 1.0mm

Ballstud Washer 5.5 x 2.0mm

M3 x 6mm BHCS

M3 x 8mm BHCS

M3 x 6mm FHCS

TC6.2 Body Post Set

TC7.2 Shock Tower, Front

TC7.2 Shock Tower, Rear

TC7.2 Bearing Cap

TC7.2 Camber Link Mount

TC7.2 Bulkhead

10

10

10

10

10

10

6

8

1

1

1

2

2

2

31531

31779

31383

31623

31797

31541

31283

31382

31800

4637

31780

31532

31383

31532

31382

31532

4637

1736

31776

4673

25202

31532

31775

31383

31625

31532

31625

31623

4637

31532

25201

1736

31625

31382

Page 31

:: Front Bulkhead

4637

4670

25211

25225

25227

31112

31283

31285

31370

31382

31647

31670

31673

31677

31678

31679

31680

31734

91148

91560

91611

FT Pivot Balls

M3 x 8mm Set Screw

M3 x 10mm BHCS

M3 x 3mm Set Screw

M4 x 8mm Setscrew

1/16” x 5/16” Dowel Pins

Ballstuds, long, 5mm

Ballstuds, long, 10mm

TC6.1 Axle Crush Tubes

Ballstud Washer 5.5 x 1.0mm

FT Steel Inner Hinge Pin Balls

TC7 Wheel Hex, 5mm

TC7 Front Suspension Arm

TC7 Hinge Pin Set

TC7 Caster Block, 4 deg

TC7 Steering Block

TC7 King Pin Bushing

FT Bearing 5 x 10 x 3mm

M4 Locknut, w/flange and knurl

FT Bearing 5 x 10 x 4mm

M1.6 x 5mm SHCS

8

10

10

10

10

8

10

10

4

10

1

2

Pr.

1

Pr.

Pr.

2

4

8

4

4

31680

31678

31680

31285

31382

(1mm)

31734

25225

31382

(1mm)

31382

(1mm)

31647

31679

25227

4637

31370

31

31382

(1mm)

31647

31677

31677

31673

4670

91560

31670

:: Rear Bulkhead

4637

4670

25225

25227

31112

31284

31370

31382

31383

31647

31670

31674

31677

31681

91148

91560

91611

FT Pivot Balls

M3 x 8mm Set Screw

M3 x 3mm Set Screw

M4 x 8mm Setscrew

1/16” x 5/16” Dowel Pins

8mm Ballstud, long

TC6.1 Axle Crush Tubes

Ballstud Washer 5.5 x 1.0mm

Ballstud Washer 5.5 x 2.0mm

FT Steel Inner Hinge Pin Balls

TC7 Wheel Hex, 5mm

TC7 Rear Suspension Arm

TC7 Hinge Pin Set

TC7 Hub, 0 deg.

M4 Locknut, w/flange and knurl

FT Bearing 5 x 10 x 4mm

M1.6 x 5mm SHCS

8

10

10

10

8

10

4

10

10

1

2

Pr.

1

Pr.

8

4

4

31382

(1mm)

25211

31382

31283

25227

91560

31286

(1mm)

31112

31681

31647

91611

31284

31383

(2mm)

91148

91560

31370

31112

31670

25225

91611

91148

4637

4670

31647

31677

31674

31677

Page 32

32

31305

31305

31305

:: Motor Mount / Battery Mount

25201

25202

31382

31383

31384

31385

31386

31531

31532

31540

31541

31778

31790

31795

31798

89229

M3x8mm FHCS

M3x10mm FHCS

Ballstud Washer 5.5 x 1.0mm

Ballstud Washer 5.5 x 2.0mm

Bulkhead Washer 7.8 x 0.5mm

Bulkhead Washer 7.8 x 1.0mm

Bulkhead Washer 7.8 x 2.0mm

M3x6mm BHCS

M3x8mm BHCS

M3x5mm FHCS

M3x6mm FHCS

TC7.2 Battery Tab

TC7.2 Motor Mount

TC7.2 Battery Stop

TC7.2 Battery Lock Set

Blue Countersunk Washers

10

10

10

10

10

10

10

10

10

10

10

1

1

2

1

10

31532

25202

31382

31382

89229

31383

31790

31382

89229

31541

31531

31798

31798

31384

31385

31386

31795

31778

:: Chassis / Top Plate / Belts / Turnbuckles / Arm Mounts

6258

6264

31305

31382

31384

31530

31541

31620

31658

31659

31771

31774

31801

31802

91723

Steel Turnbuckle, 3x21mm

Steel Turnbuckle, 3x35mm

Turnbuckle Eyelets

Ballstud Washer 5.5 x 1.0mm

Bulkhead Washer 7.8 x 0.5mm

M3 x 5mm BHCS

M3 x 6mm FHCS

TC6.2 Arm Mount Insert Set

TC7 Front Belt

TC7 Rear Belt

TC7.2 Chassis, Graphite

TC7.2 Top Plate, 2.0mm

TC7.2 Arm Mount, Outer

TC7.2 Arm Mount, Inner

Turnbuckle, 3x48mm

2

2

14

10

10

10

10

1

1

1

1

1

2

4

2

31620

31384

31801

31541

31530

31802

31541

31540

31384

31530

25202

25201

31530

31774

31382

31659

31305 31305

6258

31305 31305

6264

31305 31305

91723

31658

31771

Page 33

33

:: Pinions

1335

1336

1337

1338

1339

1340

1341

1342

1343

1344

1345

1346

1347

1348

1349

1350

1351

1352

1353

17T 48P Aluminum Pinion Gear

18T 48P Aluminum Pinion Gear

19T 48P Aluminum Pinion Gear

20T 48P Aluminum Pinion Gear

21T 48P Aluminum Pinion Gear

22T 48P Aluminum Pinion Gear

23T 48P Aluminum Pinion Gear

24T 48P Aluminum Pinion Gear

25T 48P Aluminum Pinion Gear

26T 48P Aluminum Pinion Gear

27T 48P Aluminum Pinion Gear

28T 48P Aluminum Pinion Gear

29T 48P Aluminum Pinion Gear

30T 48P Aluminum Pinion Gear

31T 48P Aluminum Pinion Gear

32T 48P Aluminum Pinion Gear

33T 48P Aluminum Pinion Gear

34T 48P Aluminum Pinion Gear

35T 48P Aluminum Pinion Gear

:: Factory Team and Option Parts

1401

1402

1404

1405

1418

1735

1736

25391

31280

31281

31282

31283

31284

31285

31288

31290

31291

31293

31296

31381

31382

31383

31384

31385

31386

31550

31551

31629

31630

31638

31639

31640

31641

31646

31649

31661

31662

31671

31672

31733

31734

31772

31773

31781

31799

31806

31807

31808

91493

FT Titanium Turnbuckle 33mm

FT Titanium Turnbuckle 35mm

FT Titanium Turnbuckle 45mm

FT Titanium Turnbuckle 48mm

FT Titanium Turnbuckle 21mm

FT Blue Body Clip, long

FT Blue Body Clip, short

FT 4mm Locknuts, blue

5mm Ballstud, short

8mm Ballstud, short

10mm Ballstud, short

5mm Ballstud, long

8mm Ballstud, long

10mm Ballstud, long

Ti Nitride Ballstuds 5mm, short

Ti Nitride Ballstuds 10mm, short

Ti Nitride Ballstuds 5mm, long

Ti Nitride Ballstuds 10mm, long

TC6 Ballast Weight

Ballstud Washers, 5.5x0.5 mm, blue aluminum

Ballstud Washers, 5.5x1.0 mm, blue aluminum

Ballstud Washers, 5.5x2.0 mm, blue aluminum

Bulkhead Washers, 7.8x0.5 mm, blue aluminum

Bulkhead Washers, 7.8x1.0 mm, blue aluminum

Bulkhead Washers, 7.8x2.0 mm, blue aluminum

M3 Aluminum Lock Nut, blue

M4 Aluminum Flange Lock Nut, blue

TC6.2 Arm Mount Shims, Graphite (outer)

TC6.2 Arm Mount Shims, Graphite (inner)

TC6.2 Spool Outdrive, Steel

TC6.2 Belt Tensioner Kit

TC6.2 Fan Mount Set

TC6.2 30mm Cooling Fan

TC7.1 Suspension Arm Shims, 0.2mm

TC7.1 FT Bumper Brace, Graphite

TC7.1 FT Brass Arm Mounts, outer

TC7.1 FT Brass Arm Mounts, inner

TC7 Wheel Hex, 4mm

TC7 Wheel Hex Spacer Set

TC7.1 FT Bearing Kit

Bearing, 5 x 10 x 3, metal (used with #31632)

TC7.2 Chassis, Aluminum

TC7.2 Top Plate, 1.6mm

TC7.2 Diff Kit

TC7.2 Adjustable Body Post Set

TC7.2 Camber Link Mount Shims (graphite)

TC7.2 Battery Stop (tape version)

TC7.2 Arm Mount (front inner)

FT Low Friction X-Rings

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

2

2

2

2

4

6

10

6

6

6

6

6

6

2

2

2

2

1

10

10

10

10

10

10

6

6

4ea.

2ea.

1

1

1

1

1

1

2

2

2

1

1

2

1

1

1

1

4ea.

2

1

8

:: Lubes & Adhesives / Misc.

1105

1596

1597

5450

5451

5452

5444

5453

5446

5447

5454

5455

5456

5457

5458

5448

5459

5461

5463

5465

6588

6591

6636

6727

9787

FT Green Slime Shock Lube

FT Locking Adhesive

FT Tire Adhesive, Medium

Silicone Diff Fluid 1,000CST

Silicone Diff Fluid 2,000CST

Silicone Diff Fluid 3,000CST

Silicone Diff Fluid 4,000CST

Silicone Diff Fluid 5,000CST

Silicone Diff Fluid 6,000CST

Silicone Diff Fluid 15,000CST

Silicone Diff Fluid 7,000CST

Silicone Diff Fluid 10,000CST

Silicone Diff Fluid 20,000CST

Silicone Diff Fluid 30,000CST

Silicone Diff Fluid 60,000CST

Silicone Diff Fluid 80,000CST

Silicone Diff Fluid 100,000CST

Silicone Diff Fluid 200,000CST

Silicone Diff Fluid 500,000CST

Silicone Diff Fluid 1,000,000CST

Black Grease - 4cc

S.Diff Lube - 4cc

Silicone Grease - 4cc

Servo Tape

Chassis Protective Sheet

:: Decals

726

31810

Reedy 2016 Sticker Sheet

TC7.2 Decal Sheet

:: Reedy Batteries

302

304

305

27313

27315

27317

27320

27321

AA Alkaline 1.5V (4)

LiPo Pro TX/RX Battery 1600mAh 7.4V Flat

LiFe Pro TX/RX Battery 1300mAh 6.6V Flat

LiPo Pro TX/RX 2400mAh 7.4V Flat

LiFe Pro TX/RX 1600mAh 6.6V Flat

Wolfpack HV LiPo 50C 5100mAh 7.6V Stick

Zappers SG HV-LiPo 7.6V 8200mAh 110C Stick

Zappers SG HV-LiPo 7.6V 6000mAh 110C LP Stick

:: Reedy Chargers / Accessories

27200

27200CN

27200EU

27200UK

611

996

997

27201

27220

27221

27222

27223

27224

27225

27226

27227

27228

27229

1216-C2 Dual AC/DC

Competition Battery Charger

1216-C2 Dual AC/DC

Competition Battery Charger - CHN Plug

1216-C2 Dual AC/DC

Competition Battery Charger - EURO Plug

1216-C2 Dual AC/DC

Competition Battery Charger - UK Plug

Charge Harness 2S Standard Pack 5mm

5.0mm 1S-2S Balance Charge lead w/SP Clip

4.0mm 1S-2S Balance Charge lead w/SP Clip

324-S AC LiPo/LiFe Compact Balance Charger

7-in-1 Universal Charge Lead (4mm)

T-plug Charge Lead (4mm)

XH 2-6S Balance Board (4mm)

RX Charger Lead FUT (4mm)

US to IEC 320 C5 angle 1M AC Power Cord

US to IEC 320 C5 angle .5M AC Power Cord

EU to IEC 320 C5 angle 1M AC Power Cord

UK to IEC 320 C5 angle 1M AC Power Cord

AU to IEC 320 C5 angle 1M AC Power Cord

CN to IEC 320 C5 angle 1M AC Power Cord

CHARGERS

CHARGING ACCESSORIES

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1596

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Page 34

34

:: Reedy Motors / Spare Parts / Accessories

256

257

258

259

260

261

262

263

264

265

266

287

293

294

297

907

27401

27402

27403

271

272

273

274

275

276

277

279

280

281

282

283

286

295

296

27414

27415

27416

27417

27418

27419

27420

27421

27423

978

979

980

981

982

994

995

Sonic 540-M3 10.5

Sonic 540-M3 9.5

Sonic 540-M3 8.5

Sonic 540-M3 8.0

Sonic 540-M3 7.5

Sonic 540-M3 7.0

Sonic 540-M3 6.5

Sonic 540-M3 6.0

Sonic 540-M3 5.5

Sonic 540-M3 5.0

Sonic 540-M3 4.5

Sonic 540-M3 25.5 ROAR Spec

Sonic 540 FT 17.5 Fixed Timing

Sonic 540 FT 13.5 Fixed Timing

Sonic 540 FT 21.5 Fixed Timing

540-SL4 3300kV 4-pole Sensorless

S-Plus 21.5 Spec

S-Plus 17.5 Spec

S-Plus 13.5 Spec

SPARE PARTS/ACCESSORIES

Sonic 540-M3 Spec Rotor 12.0 x 7.25 x 25.3

Sonic 540-M3 Spec Rotor 12.2 x 7.25 x 25.3

Sonic 540-M3 Spec Rotor 12.5 x 7.25 x 25.3

Sonic 540-M3 Mod Rotor 12.3 x 5.0 x 25.3

Sonic 540-M3 Mod Rotor 12.5 x 5.0 x 25.3

Sonic 540-M3 Mod Rotor 13.0 x 5.0 x 25.3

Sonic 540-M3 Stainless Steel Bearing Set

Sonic 540-M3 Sensor Assembly

Sonic 540-M3 Rotor Spacer Set

Sonic 540-M3 Case Screws w/Insulator

Sonic 540-M3 Motor Mounting Plate 1S

Sonic 540-M3 Motor Mounting Plate

540-M3/S-Plus Spec Rotor 12.3 x 7.25 x 25.3

Sonic 540-FT Spec Rotor 12.0 x 7.25 x 25.3

Sonic 540-M3 Mod Rotor 12.0 x 5.0 x 24.2

540-M3/S-Plus Spec Rotor 12.5 x 7.15 x 24.2

540-M3/S-Plus Spec Rotor 12.3 x 7.15 x 24.2

540-M3/S-Plus Spec Rotor 12.0 x 7.15 x 24.2

S-Plus Screw Set

540-M3/S-Plus Lightweight Sensor Board

S-Plus Front Plate

540-M3/S-Plus Aluminum Case Screw Set

540-M3/S-Plus Aluminum Timing Screw Set

30mm Motor Fan w/195mm extension

Flat Sensor Wire 70mm

Flat Sensor Wire 110mm

Flat Sensor Wire 150mm

Flat Sensor Wire 200mm

Flat Sensor Wire 270mm

Flat Sensor Wire 125mm

Flat Sensor Wire 175mm

MOTORS

SENSOR WIRES

:: Reedy Servos & Accessories

27108

27109

27124

27125

27126

27127

RS0806 Digital HV Hi-Speed LP Competition Servo

RT1408 Digital HV Hi-Speed LP Competition Servo

RS0806 LP Case Set

RS0806 LP Gear Set

RT1408 LP Case Set

RT1408 LP Gear Set

:: Reedy ESC’s and Accessories

1

256C

1

258C

1

259C

1

260C

1

261C

1

262C

1

285C

1

287C

1

27002

1

27003

1

27004

1

27005

1

27006

1

29180

1

29185

1

29193

1

1

1

27024

27026

27027

1

27028

1

27029

1

27030

1

27031

1

29182

1

29184

1

29186

1

29194

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

:: Reedy Accessories

1

643

644

645

1

646

1

647

1

648

1

650

1

654

1

655

1

656

658

659

747

748

790

1

1

1

1

1

1

791

792

793

794

795

27304

Blackbox 1000Z+/540-M3 10.5 Combo

Blackbox 1000Z+/540-M3 8.5 Combo

Blackbox 1000Z+/540-M3 8.0 Combo

Blackbox 1000Z+/540-M3 7.5 Combo

Blackbox 1000Z+/540-M3 7.0 Combo

Blackbox 1000Z+/540-M3 6.5 Combo

Blackbox 800Z/540-M3 10.5 SS Combo

Blackbox 800Z/540-M3 25.5 ROAR Combo

Blackbox 800Z 2S Zero-Timing Competition ESC

Blackbox 1000Z+ 2S Competition ESC

Blackbox 510R Competition ESC

Blackbox 510R Comp. ESC w/PROgrammer2

Blackbox 600Z 2S Zero-Timing Competition ESC

SC800-BL Brushless ESC

SC600-BL Brushless ESC

SC550 Brushed ESC

Blackbox Pro Capacitor Unit

Blackbox 1000Z+ Fan w/Screws

Blackbox PROgrammer2

Blackbox 30x30x7mm Fan w/screws

Blackbox Pro Modified Capacitor Unit

Blackbox ESC/Programmer2 Connection Wire

Blackbox 510R 30x30x10mm Fan w/screws

SC800-BL Fan

SC800-BL/SC1000-BL/SC1000-DB/SC600-BL Switch

SC600-BL Fan

SC550 Bridge Plug

Low Profile Bullet Plug 4mm x 14mm (2)

Low Profile Bullet Plug 4mm x 14mm (10)

Low Profile Bullet Plug 5mm x 14mm (2)

Low Profile Bullet Plug 5mm x 14mm (10)

Silicone Wire 12AWG-Black (1m)

Silicone Wire 14AWG-Black (1m)

Shrink Tubing - 15pcs 4.5mm x 20mm

4.0mm Bullet Plugs (2M, 2F)

4.0mm Bullet Plugs (2M, 10F)

4.0mm Bullet Plugs (10F)

4.0mm Bullet Plugs (10M)

4.0mm Bullet Plugs (30M)

Silicone Wire 12AWG-Black (30m)

Silicone Wire 14AWG-Black (30m)