Page 1

MODEL 6009

OPERATOR'S MANUAL

ASSOCIATED

SAVE THESE INSTRUCTIONS. This manual contains important safety and operating instructions for battery charger you have

1.

purchased. You may need to refer to these instructions at a later date.

2.

CAUTION. To reduce risk of injury, charge only wet cell, lead-acid, automotive type rechargeable batteries. Other types of batteries may

burst causing personal injury and property damage.

3. Do not expose the charger to rain or snow if specifically warned on the unit not to do so.

4. Use of an attachment not recommended or sold by the battery charger manufacturer may result in a risk of fire, electric shock, or injury to

persons.

5. To reduce the risk of damage to the electric plug and cord, pull by the plug rather than the cord when disconnecting the charger.

6. Make sure the cord is located so that it will not be stepped on, tripped over, or otherwise subjected to damage or stress.

7. An extension cord should not be used unless absolutely necessary. Use of a improper extension cord could result in a risk of fire and electric

shock. If an extension cord must be used, make sure:

a. That the pins on the plug of extension cord are the same number, size, and shape as those of the plug on the charger;

b. That the extension cord is properly wired and in good condition; and

c. If the length of the extension cord is less than 25 feet, use a 16AWG cord, If 50 feet- 12AWG, 100 feet-10AWG, 150 feet-8AWG.

8. Do not operate the charger with a damaged cord or plug, replace them immediately.

9. Do not operate the charger if it has received a sharp blow, been dropped, or otherwise damaged in any way; take it to a qualified serviceman.

10. Do not disassemble the charger unless you are qualified to work on electrical products. If not, take it to a qualified serviceman when service or

repair is required. Incorrect reassembly may result in risk of electric shock or fire.

11. To reduce the risk of electric shock, unplug the charger form the outlet before attempting any maintenance or cleaning. Turning off the

controls will not reduce this risk.

WARNING - RISK OF EXPLOSIVE GASES

12.

a. WORKING IN VICINITY OF A LEAD-ACID BATTERY IS DANGEROUS. BATTERIES GENERATE EXPLOSIVE GASES DURING

NORMAL BATTERY OPERATION. FOR THIS REASON IT IS OF UTMOST IMPORTANCE THAT EACH TIME BEFORE USING YOUR

CHARGER, YOU READ THIS MANUAL AND FOLLOW THE INSTRUCTIONS EXACTLY.

b. To reduce the risk of battery explosion, follow these instructions and those published by the battery manufacturer and manufacturer of

13.

14.

15.

any equipment you intend to use in vicinity of the battery. Review cautionary markings on these products and on the engine.

PERSONAL PRECAUTIONS

a. Someone should be within range of your voice or close enough to come to your aid when you work near a lead-acid battery.

b. Have plenty of fresh water and soap nearby in case battery acid contacts skin, clothing, or eyes.

c. Wear complete eye protection, and clothing protection. Avoid touching eyes while working near battery.

d. If battery acid contacts skin or clothing, wash immediately with soap and water. If acid enter eyes, immediately flood eyes with running

cold water for at least 10 minutes and get medical attention immediately.

e. NEVER smoke or allow a spark or flame in vicinity of the battery or engine.

f. Be extra cautious to reduce risk of dropping a metal tool onto the battery. It might spark or short circuit the battery or other electrical parts

that may cause an explosion.

g. Remove personal metal items such as rings, bracelets, necklaces, and watches when working with a lead-acid battery. A lead-acid

battery can produce a short circuit current high enough to weld a ring or the like to metal, causing a severe burn.

h. Use this charger for charging a LEAD-ACID battery only. It is not intended to supply power to a low-voltage electrical system other than

in an automotive application. Do not use this battery charger for charging dry-cell batteries that are commonly used with home

appliances. These batteries may burst and cause injury to persons and damage to property.

i. NEVER charge a frozen battery.

PREPARING TO CHARGE

a. If necessary to remove battery from vehicle to charge, always remove the grounded terminal from the battery first. Make sure all

accessories in the vehicle are off, so as not to cause an arc.

b. Be sure the area around the battery is well ventilated while the battery is being charged. Gas can be forcefully blown away by using a

piece of cardboard or other non-metallic material as a fan.

c. Clean the battery terminals. Be careful to keep corrosion from coming in contact with eyes.

d. Add distilled water in each cell until battery acid reaches level specified by the battery manufacturer. This helps purge excessive gas

from cells. Do not overfill. For a battery without cell caps, carefully follow the manufacturer's recharging instructions.

e. Study all battery manufacturer's specific precautions such as removing or not removing the cell caps while charging and the

recommended rates of charge.

f. Determine voltage of the battery by referring to the car owner's manual and make sure that the output voltage selector switch is set at the

correct voltage. If the charger has adjustable charge rate, charge the battery initially at the lowest rate.

CHARGER LOCATION

a. Locate the charger as far away from the battery as the DC cables permit.

b. Never place the charger directly above the battery being charged; gases from the battery will corrode and damage the charger.

c. Never allow battery acid to drop on the charger when reading the specific gravity or filling battery,

d. Do not operate the charger in a closed-in area, or restrict ventilation in any way.

e. Do not set a battery on top of the charger.

IMPORTANT SAFETY INSTRUCTIONS

1

Page 2

DC CONNECTION PRECAUTIONS

16.

a. Connect and disconnect the DC output clamps only after setting the charger switches to the OFF position and removing the AC cord from

the electric outlet. Never allow the clamps to touch each other.

b. Attach the DC clamps to the battery post and twist or rock back and forth several times to make a good connection. This tends to keep

17.

18.

the clamps from slipping off the terminals and helps to reduce the risk of sparking.

STOP/GO LITE INSTRUCTIONS

When used properly, the STOP/GO LITE will indicate whether clamp connections will be

correct. Connect the positive (red) clamp to the positive (POS, P, +) battery post. Touch the

contact button of the negative (black) clamp to the other battery post. Observe the L.E.D.

lights in the STOP/GO LITE:

GREEN LIGHT: The first connection is correct. Make the second clamp connection per

instructions.

RED LIGHT: The first connection made with the positive clamp to the battery is incorrect.

Attach the positive clamp to the other battery post and retest.

RED AND GREEN LIGHT: The battery charger is turned on. Turn the charger "OFF" and

retest.

NO LIGHT: Check for a shorted or open battery. Clean any corrosion from the clamp jaws

and the battery post and retest. If still no light, use a voltmeter or other means to make certain you have properly identified the polarity of the

battery post. Then attach the clamps per instructions, disregarding the STOP/GO LITE.

FOLLOW THESE STEPS WHEN THE BATTERY IS INSTALLED IN A VEHICLE. A SPARK NEAR THE

BATTERY MAY CAUSE A BATTERY EXPLOSION. TO REDUCE THE RISK OF A SPARK NEAR THE

BATTERY:

a. Read the section "STOP/GO LITE INSTRUCTIONS" before proceeding.

b. Position the AC and DC cords to reduce the risk of damage by the hood, door, or moving engine parts.

c. Stay clear of fan blades, belts, pulleys, and other parts that can cause injury to persons.

d. Check the polarity of the battery post. The POSITIVE (POS, P, +) battery post usually has a larger diameter than the NEGATIVE (NEG,

N, –) post.

e. Determine which post of the battery is grounded (connected) to the chassis. If the negative post is grounded to the chassis (as in most

vehicles), see item "e". If the positive post is grounded to the chassis, see item "f".

f. For negative-grounded vehicles, connect the POSITIVE (RED) clamp from the battery charger to the POSITIVE (POS, P, +) ungrounded

post of the battery. Touch the contact button of the STOP/GO LITE to the NEGATIVE (NEG, N, –) battery post. Interpret the light and

take appropriate action. When the green light is on, connect the NEGATIVE (BLACK) clamp to the vehicle chassis, heavy gauge metal

part of the frame, or engine block, away from the battery. Do not connect to the carburetor, fuel lines, or sheet metal body parts.

g. For positive-grounded vehicles, connect the POSITIVE (RED) clamp from the battery charger to the POSITIVE (POS, P, +) battery post.

Touch the contact button of the STOP/GO LITE to the NEGATIVE (NEG, N, –) battery post. Interpret the light and take appropriate

action. When the green light is on, disconnect the POSITIVE (RED) clamp from the battery. Attach the NEGATIVE (BLACK) clamp to the

NEGATIVE (NEG, N, –) ungrounded post of the battery. Attach the POSITIVE (RED) clamp to the vehicle chassis or engine away from

the battery. Do not connect the clamp to the carburetor, fuel lines, or sheet-metal body parts. Connect to a heavy gauge metal part of the

frame or engine block.

h. When disconnecting the charger, turn the switches to OFF, disconnect the AC cord, remove the clamp from the vehicle chassis, and then

remove the clamp from the battery terminal.

i. See the operating instructions for length of charge information.

19.

FOLLOW THESE STEPS WHEN THE BATTERY IS OUTSIDE THE VEHICLE. A SPARK NEAR THE

BATTERY MAY CAUSE BATTERY EXPLOSION. TO REDUCE THE RISK OF A SPARK NEAR THE

BATTERY:

a. Read section "STOP/GO LITE INSTRUCTIONS" before proceeding.

b. Check the polarity of the battery post. The POSITIVE (POS, P, +) usually has a larger

diameter than the NEGATIVE (NEG, N, –) post.

c. Attach at least a 24 inch long 6-gauge (AWG) insulated battery cable to the NEGATIVE

(NEG, N, –) battery post.

d. Connect the POSITIVE (RED) charger clamp to the POSITIVE (POS, P, +) post of the

battery.

e. Touch the contact button of the STOP/GO LITE to the free end of the battery cable. If the

red light comes on, reverse the connections to the battery and retest. When the green

light come on, position yourself and the free end of the cable as far away from the battery

as possible, then connect the NEGATIVE (BLACK) charger clamp to the free end of

cable.

f. Do not face the battery when making the final connection.

g. When disconnecting the charger, always do so in reverse sequence of connecting procedure, and break the first connection while

standing as far away from the battery as practical.

h. A marine (boat) battery must be removed and charged on shore. To charge it on board requires equipment specially designed for marine

use.

2

Page 3

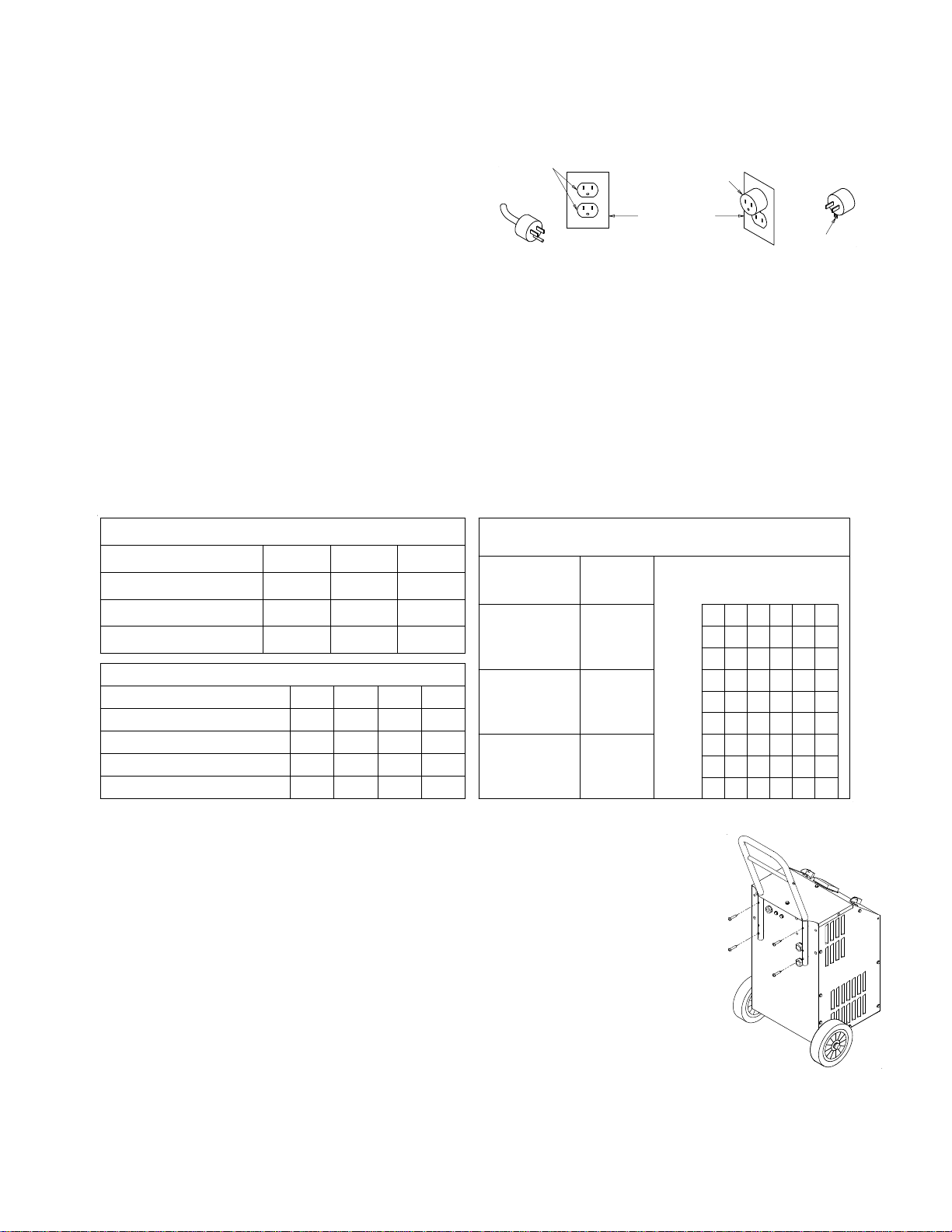

GROUNDING AND AC POWER CORD CONNECTION INSTRUCTIONS

20.

The charger should be grounded to reduce the risk of electric shock. This charger is equipped with an electric cord having an equipment

grounding conductor and a grounding plug. The plug must be plugged into an outlet that is properly installed and grounded in accordance with

all local codes and ordinances.

DANGER. Never alter the AC cord or plug provided - if it will not fit

the outlet, have a proper outlet installed by a qualified electrician.

Improper connection can result in a risk of an electric shock. This

battery charger is for use on a nominal 120-volt circuit, and has a

grounding plug that looks like the plug illustrated in FIGURE (A). A

temporary adapter, which looks like the adapter illustrated in FIGURE

(C), may be used to connect this plug to a two-pole receptacle, as

shown in FIGURE (B), until a properly grounded outlet can be

installed by a qualified electrician.

GROUNDED

OUTLET

GROUNDING METHODS

ADAPTER

COVER OF GROUNDED

OUTLET BOX

(A) (B)

ADAPTER

GROUNDING

MEANS

DANGER. Before using an adapter as illustrated, be certain that the center screw of the outlet plate is grounded. The green-colored rigid

ear or lug extending from the adapter must be connected to a properly grounded outlet - make certain it is grounded. If necessary, replace the

original outlet cover plate screw with a longer screw that will secure the adapter ear or lug to the outlet cover plate and make ground

connection to grounded outlet.

NOTE: USE OF AN ADAPTER IS NOT ALLOWED IN CANADA. IF A GROUNDING TYPE RECEPTACLE IS NOT AVAILABLE, DO NOT

USE THIS APPLIANCE UNTIL THE PROPER OUTLET IS INSTALLED BY A QUALIFIED ELECTRICIAN.

21.

LENGTH OF CHARGE

a. Test the battery for state of charge. Do not charge if it is over 75% charged or the battery is determined to be defective.

b. Set beginning amps charge rate for size of battery and state of charge per charts

c. Charge for length of time per charge,

d. Discontinue charge when the specific gravity of electrolyte reaches 1.260 or above. A temperature compensating hydrometer should be

used for this reading. Discontinue charge if the battery begins to gas excessively or when the temperature of the electrolyte reaches

approximately 120°F. Do not overcharge batteries. Overcharging results in excessive water loss and eventual damage to the battery.

BATTERY SIZE TABLE

BATTERY SIZE

Ampere Hours

Reserve Capacity

Cold Cranking Amps

STATE OF CHARGE TABLE

STATE OF CHARGE

Specific Gravity

Open Circuit Voltage 6V

Open Circuit Voltage 12V

Open Circuit Voltage 24V

SMALL MEDIUM LARGE

40

60

275

60

90

350

80+

100+

400+

25%50%75% DEAD

1.225

1.185

1.140

1.110

6.2

6.05

12.4

24.8

12.1

24.2

5.95

11.9

23.8

5.9

11.8

23.6

BATTERY SIZE %CHARGE

CHARGE RATE Vs. MINUTES CHARGE

0-25

SMALL

MEDIUM

25-50

50-75

0-25

25-50

50-75

A

M

P

E

R

E

S

0-25

LARGE

25-50

50-75

MINUTES

15 30 45 60 75 90

25

30

30

45

15

20

20

30

15

70

45

25

90

60

30

10

50

30

15

55

40

20

10

10

45

25

15

10 10 10

55

35

20

15 15 15

15

ASSEMBLY INSTRUCTIONS

Attach the handle to the charger using the four screws provided.

2025

10

303540

202020

454550

303030

(C

)

55

3

Page 4

OPERATING INSTRUCTIONS

CAUTION: This battery charger must be fully assembled before operating. Failure to do so may result in risk of injury.

USE OF THE INSTRUMENT PANEL:

The MINUTES CHARGE timer has an OFF position, a CONTINUOUS CHARGE position and a timed charge range from 0 to 120 minutes.

a. OFF - Always make sure the timer is in the OFF position before connecting or disconnecting the clamps from the battery. The charger will not

charge with the timer in this position.

b. 0 to 120 MINUTES TIMED CHARGE - The timer will automatically turn the charger off at the end of the pre-set charging time. Turn the timer

past 20 before setting the desired time.

c. CONTINUOUS CHARGE - The timer will not shut the charger OFF while in this position. Extended Charging can be done if the operator is

knowledgeable in determining the proper rate and length of charge and monitors the charging process to prevent overcharging.

TO CHARGE BATTERIES

Make the connections to the battery per the instructions in the previous sections. Determine if the battery is 6 or 12 volts and then set the CHARGE

VOLTAGE switch to 6/12 LOW CHARGE for a 6 or 12 volt battery. If higher rate is desired, set at 12 MED. or 12 HIGH. DO NOT

battery at setting other than 6/12 low.(Damage may occur to the battery.) Turn the timer on and the Ammeter will show the amount of current

delivered to the battery. Length of charge should be per the above chart and instructions.

charge a 6 volt

12 VOLT CRANKING ASSIST

1. Turn off all lights and accessories in the stalled vehicle.

2. Connect the charger to battery per previous instructions.

3. Charge the battery on 12HI for at least five minutes before attempting to start the vehicle.

4. Start the vehicle with the charger connected to the battery. Follow the duty cycle on the unit.

NOTE: Do not crank the engine more than 20 seconds in any five minute period; excessive cranking may overheat and damage the starter.

If the vehicle fails to start, while waiting for the starter to cool, allow the charger to continue to charge the battery. Turn the switch to OFF and

remove the AC power cord from the electric outlet before disconnecting the DC clamps.

CHARGING SULFATED BATTERIES

If your battery has sat in the discharged state for an extended period of time, it can become SULFATED. This usually is seen as a white deposit

near the top of the battery. The sulfate is formed when a battery with low water levels remains discharged for an extended time. Sulfated batteries

exhibit the characteristic of accepting no charge regardless of the rate of charge.

The charging method is two staged. The first stage of attempting to break down the sulfation to allow the battery to accept a charge must be closely

watched to avoid excessive charge rates as the battery begins to charge and overheating. The second stage is a slow charging to restore the

battery to full charge.

READ AND FOLLOW ALL PRECAUTIONS AND WARNINGS IN YOUR INSTRUCTION MANUAL BEFORE ATTEMPTING TO CHARGE

SULFATED BATTERIES. FAILURE TO OBSERVE THESE WARNINGS MAY RESULT IN PROPERTY DAMAGE OR SERIOUS PERSONAL

INJURY OR DEATH.

To recharge a sulfated battery:

1. Attach the battery clamps as described in the instruction manual.

2. Always use the chargers lowest rate when turning the charger on. Set the charger to the chargers highest rate for the voltage of the battery

being charged.

CAUTION: NEVER CHARGE A BATTERY AT VOLTAGES RATES ABOVE THAT OF THE BATTERY.

3. The battery will show little or no amperage at the start of the charging process. This will continue until the sulfation begins to break down.

CAUTION: AS THE SULFATION BREAKS DOWN, THE AMPERAGE MAY RAPIDLY RISE. CONSTANT

ATTENTION MUST BE OBSERVED TO PREVENT SERIOUS OVERHEATING OF THE BATTERY.

4. Lower the charge rate to the lowest rate for the voltage of battery being charged.

5. Charge the battery at this low rate until the electrolyte reaches the fully charged state as described in the tables in your instruction manual.

This may take as long as two or three days.

NOTE: SOME BATTERIES MAY BE SO BADLY SULFATED THEY CAN NOT BE RESTORED TO A NORMAL OPERATING CONDITION,

REGARDLESS OF THE RATE OF CHARGE OR THE LENGTH OF TIME THE CHARGE IS APPLIED. IF THE BATTERY CANNOT BE

RESTORED TO A FULLY CHARGED CONDITION BY A SLOW CHARGING, IT SHOULD BE REPLACED.

4

Page 5

R

TIMER

456

WHITE

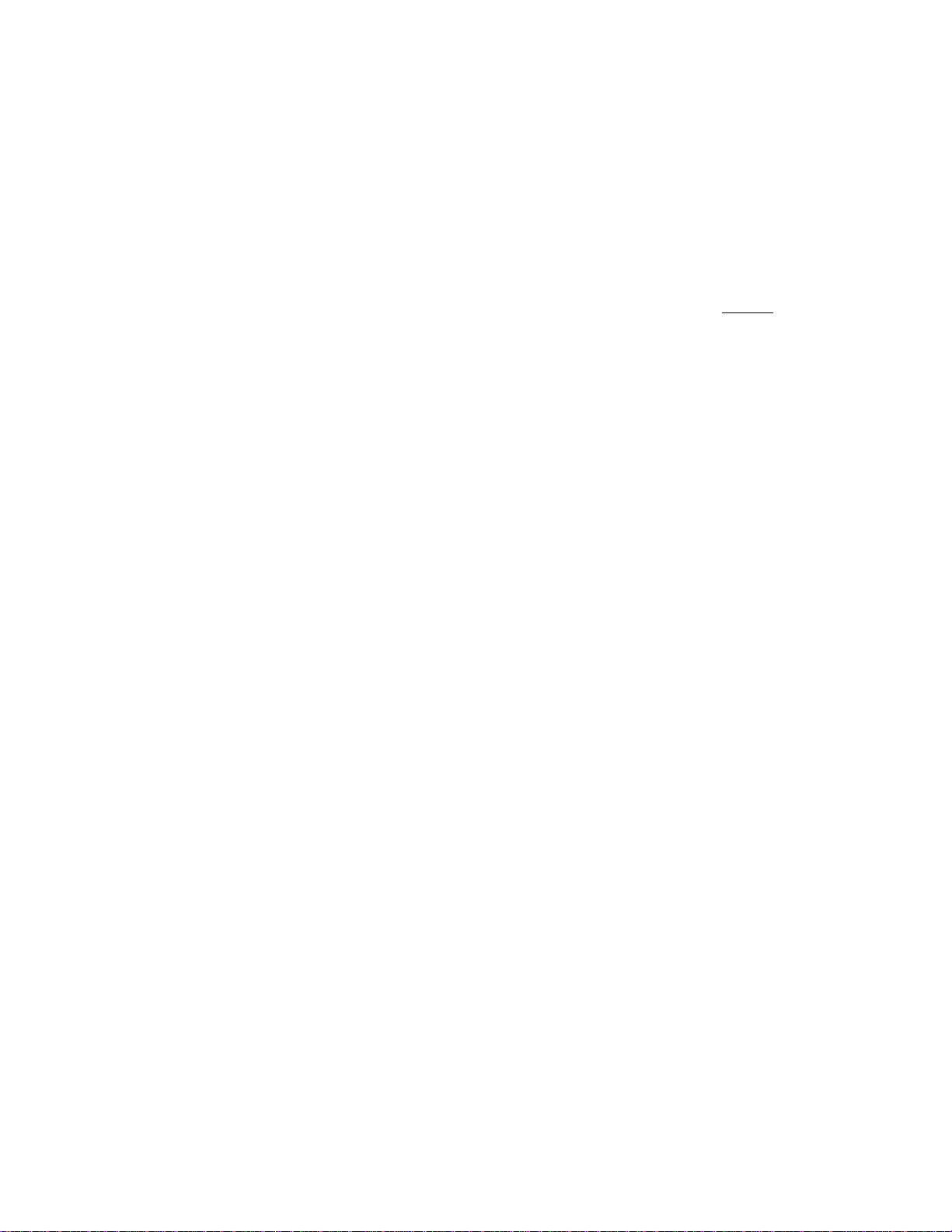

WIRING DIAGRAM

VOLTS

CHARGE

SWITCH

6

1

2

4

8

ORANGE

BROWN

VIOLET

GRAY

AMMETER

RESISTOR

BLACK

YELLOW

2

1

BLACK

3

WHITE

GREEN

BLACK

YELLOW

AC CIRCUIT

PROBE

BLACK

WHITE

BREAKER

FAN

"STOP/GO LIGHT"

YELLOW

TRANSFORMER

NEGATIVE

(BLACK)

JAW GUIDE

RECTIFIER

DC

CIRCUIT

BREAKE

POSITIVE

(RED)

MODEL 6009 PARTS LIST

Item

Description Part No.

1 Front leg ................................................... 605671

2 Wheels w/nuts (2)..................................... 611157

10

4

12

3

19

22

13

23

16

21

6

5

11

9

8

17

18

14

7

15

3 Handle ...................................................... 605213

4 Stop/Go Lite.............................................. 604579

5 Fan Blade .................................................610189

6 Fan Motor .................................................610190

7 Rectifier .................................................... 610364

8 Timer ........................................................ 611245

9 Amps Meter ..............................................605204

10 AC Cord.................................................... 611248

11 Switch w/knob (1)...................................... 611187

12 DC Cable Set............................................ 610855

13 DC Circuit Breaker (1) .............................. 610536

14 Axle w/nuts ............................................... 610052

15 Transformer .............................................. 610819

16 AC Breaker ............................................... 603597

17 Clamps ......................................................... 6202

18 Jaw Kit (repairs 1 clamp) ..........................610970

19 Clamp Bar................................................. 610517

2

20

20 Base ......................................................... 610054

21 Pointer Knob ............................................. 603147

22 Back Panel ............................................... 610977

1

24

23 Right Side Panel ....................................... 611032

24 Front Panel ............................................... 611250

Not shown

Top Panel .................................................611011

Left Side Panel ......................................... 611031

MAINTENANCE INSTRUCTIONS

Worn clamps and jaws should be replaced. Worn parts can lead to poor connections and present a safety hazard. See parts list for part number of

jaw and clamp kits. Any Maintenance or repair of this unit that involves disassembly of the cabinet should be done only by a qualified serviceman.

Incorrect reassembly may result in a risk of electric shock when the unit is subsequently used.

5

Page 6

MODÈLE 6009

MANUEL D'UTILISATION

INSTRUCTIONS DE SÉCURITÉ IMPORTANTES

CONSERVER CES INSTRUCTIONS. Le présent manuel contient des instructions de sécurité et d'utilisation importantes pour

1.

l'utilisation du chargeur de batterie que vous avez acheté et qui pourront se révéler utiles ultérieurement.

2.

AVERTISSEMENT - Afin de réduire le risque de blessures, ne charger que des batteries au plomb rechargeables (6 cellules peu importe

l'ampèrage). Tout autre type de batterie peut exploser, causant des blessures corporelles et des dégâts matériels.

3. Ne pas exposer le chargeur à la pluie ou à la neige.

4. L'utilisation d'un accessoire non recommandé ou non vendu par le fabricant du chargeur de batterie peut être la cause d'incendies,

d'électrocutions ou de blessures corporelles.

5. Afin de réduire les risques de dommages à la fiche électrique ou au cordon d'alimentation, débrancher le chargeur en tirant sur la fiche et non

sur le cordon.

6. S'assurer que le cordon d'alimentation est placé de sorte qu'il ne puisse être écrasé, accroché ou soumis à toute autre forme de dommages

ou de contraintes.

7. N'utiliser de rallonge électrique que si absolument nécessaire. L'utilisation d'une rallonge inadéquate peut être la cause d'incendies ou

d'électrocutions. Si l'utilisation d'une rallonge est absolument nécessaire, s'assurer que:

a. les tiges de la fiche de la rallonge sont des mêmes dimension, forme et nombre que celles de la fiche du cordon d'alimentation;

b. la rallonge électrique est en bon état et que son câblage est adéquat; et

c. Si le longueur du cordon prolongateur est moins de 25 pieds, utilisez un cordon - 16AWG, 50 pieds - 12AWG, 100 pieds - 10AWG, 150

8. Ne pas faire fonctionner le chargeur si le cordon ou la fiche ont été endommagés - les remplacer immédiatement.

9. Ne pas faire fonctionner le chargeur s'il a été heurté violemment, échappé ou endommagé de quelque façon que ce soit; l'apporter à un

10. Ne pas démonter le chargeur; l'apporter à un technicien qualifié lorsqu'on doit en effectuer l'entretien ou la réparation. Un remontage

11. Pour réduire les risques d'électrocutions, débrancher le chargeur avant d'entreprendre tout type d'entretien ou de nettoyage. Le fait d'arrêter

12.

13.

14.

pieds - 8AWG.

technicien qualifié.

inadéquat peut être la cause d'électrocutions ou d'incendies.

les commandes ne réduit pas ces risques.

AVERTISSEMENT - DANGER DÛ AUX GAZ EXPLOSIFS

a. IL EST DANGEREUX DE TRAVAILLER PRÈS D'UNE BATTERIE AU PLOMB EN RAISON DES GAZ EXPLOSIFS PRODUITS LORS

DU FONCTIONNEMENT NORMAL DE LA BATTERIE. POUR CETTE RAISON, IL EST DE LA PLUS HAUTE IMPORTANCE DE LIRE

SOIGNEUSEMENT ET D'OBSERVER LES INSTRUCTIONS DU PRÉSENT MANUEL AVANT TOUTE UTILISATION DU CHARGEUR.

b. Pour réduire les risques d'explosion de la batterie, suivre les présentes instructions et celles du fabricant de la batterie ou de tout autre

équipement devant être utilisé près d'une batterie. Revoir les avertissements indiqués sur ces produits et sur le moteur.

PRÉCAUTIONS PERSONNELLES

a. S'assurer que quelqu'un est à portée de voix ou suffisamment près pour prêter assistance lorsqu'on travaille près d'une batterie au

plomb.

b. Avoir à la portée de la main une réserve suffisante d'eau fraîche et du savon au cas où l'acide de la batterie entrerait en contact avec la

peau, les vêtements ou les yeux.

c. Porter des lunettes de sécurité et des vêtements de protection. Éviter de se toucher les yeux lorsqu'on travaillé à proximité d'une

batterie.

d. Si la peau ou les vêtements entrent en contact avec l'acide de la batterie, les laver immédiatement à l'eau et au savon. Si l'acide pénètre

dans les yeux, les rincer immédiatement à l'eau courante froide pendant au moins 10 minutes et appeler immédiatement un médecin.

e. NE JAMAIS fumer ni provoquer d'étincelles ou flammes à proximité de la batterie ou du moteur.

f. Faire bien attention de ne pas échapper d'outil métallique sur la batterie. Cela pourrait provoquer une étincelle ou encore court-circuiter

la batterie ou d'autres pièces électriques pouvant provoquer une explosion.

g. Enlever tout objet métallique personnel comme les bagues, bracelets, colliers et montres avant de travailler avec une batterie au plomb.

h. N'utiliser le chargeur que pour recharger une batterie AU PLOMB. lln'est pas conçu pour alimenter les systèmes électriques à faible

tension autres que ceux s'appliquant aux automobiles. Ne pas utiliser le chargeur pour recharger des piles sèches normalement utilisées

pour les appareils électroménagers. Ces piles peuvent exploser et causer des blessures et des dommages matériels.

i. NE JAMAIS charger une batterie gelée.

PRÉPARATION DE LA CHARGE

a. S'il est nécessaire de retirer la batterie du véhicule pour la charger, toujours retirer en premier la borne mise à la masse. S'assurer que

tous les accessoires dans le véhicule sont arrêtés afin de pas causer d'arc.

b. S'assurer de la bonne ventilation des lieux lors de la charge de la batterie. On peut dissiper les gaz en utilisant comme éventail un

morceau de carton ou un article non métallique

c. Nettoyer les bornes de la batterie. Faire bien attention que les yeux n'entrent pas en contact avec les matières corrodées.

d. Ajouter de l'eau distillée dans chacune des cellules de la batterie, jusqu'à ce que le niveau d'acide dans la batterie atteigne celui qui est

spécifié par le fabricant. Cela facilite la purge de gaz excédentaires des cellules. Ne pas dépasser le niveau spécifié. Suivre

attentivement les instructions de charge du fabricant pour les batteries qui n'ont pas de bouchons de cellules.

e. Étudier toutes les précautions spécifiques du fabricant de la batterie tels celles qui concernent le retrait ou non des bouchons de cellules

lors de la charge, ou encore le régime de charge recommandé.

f. Déterminer la tension de la batterie en se référant au manuel du véhicule et s'assurer que le sélecteur de tension de sortie du chargeur

est réglé à la bonne tension. Si le chargeur offre un régime de charge réglable, charger initialement la batterie au régime de charge le

plus faible.

6

Page 7

EMPLACEMENT DU CHARGEUR

15.

a. Installer le chargeur aussi loin de la batterie que les câbles c.c. le permettent.

b. Ne jamais placer le chargeur directement au-dessus d'une batterie pendant la charge; les gaz s'échappant de la batterie peuvent

corroder et endommager le chargeur.

c. Ne jamais laisser l'acide de la batterie s'égoutter sur le chargeur pendant la lecture de densité ou le remplissage de la batterie.

d. Ne pas utiliser le chargeur dans une endroit fermé ou mal ventilé en aucune circonstance.

e. Ne pas placer la batterie sur le chargeur.

16.

PRÉCAUTIONS RELATIVES AUX CONNEXIONS c.c.

a. Brancher et débrancher les pinces de sortie c.c. seulement après avoir mis tous les interrupteurs du chargeur à la position d'arrêt et

débranché le cordon d'alimentation c.a. de la prise de courant. Ne jamais les pinces se toucher.

b. Brancher les pinces aux bornes de la batterie puis faire pivoter ou basculer la pince d'avant en arrière plusieurs fois pour obtenir une bon

17.

18.

contact afin d'empêcher les pinces de plisser de même que pour réduire le risque d'étincelles.

INSTRUCTIONS RELATIVES AU VOYANT ARRÊT/MARCHE

Lors d'une utilisation correcte, le voyant ARRÊT/MARCHE indiquera le bon branchement des

pinces. Brancher la pince positive (ROUGE) à la borne positive (POS, P, +) de la batterie.

Mettre le bouton de contact de la pince négative (NOIRE) en contact avec l'autre borne de la

batterie. Observer les voyants DEL au voyant ARRÊT/MARCHE.

VOYANT VERT: La première connexion est bonne. Brancher la deuxième pince selon les

instructions.

VOYANT ROUGE: La première connexion est mauvaise. Débrancher la pince positive rouge,

la brancher à l'autre borne de la batterie et refaire l'essai.

VOYANT ROUGE ET VERT: Le chargeur de batterie est en marche. Le mettre sur "O" et

refaire un essai.

AUCUN VOYANT NE S'ALLUME: Vérifier s'il y a un court circuit ou un circuit ouvert à la

batterie. Enlever toute corrosion déposée sur les mâchoires des pinces et sur les bornes de

la batterie. Refaire un essai. Si aucun voyant ne s'allume, utiliser un voltmètre ou autre

moyen de mesure afin de s'assurer de la correcte identification des polarités des bornes de la

batterie. Brancher ensuite les pinces selon les instructions sans faire attention au voyant

ARRÊT/MARCHE.

RESPECTER LES ÉTAPES SUIVANTES LORSQUE LA BATTERIE SE TROUVE À L'INTÉRIEUR DU

VÉHICULE. UNE ÉTINCELLE À PROXIMITÉ DE LA BATTERIE PEUT LA FAIRE EXPLOSER. POUR

RÉDUIRE LE RISQUE D'ÉTINCELLES PRÈS DE LA BATTERIE, IL FAUT :

a. et c.a. de façon à réduire les risques de dommages pouvant être causés par le capot, les portières, ou des

Positionner les cordons c.c.

pièces mobiles du moteur.

b. Se tenir à distance des pales de ventilateur, courroies, poulies et autres pièces pouvant causer des blessures corporelles.

c. ornes de la batterie. En général, la borne positive (POS, P, +) a un diamètre plus grand que celui de la borne

Vérifier la polarité des b

négative (NEG, N, –).

d. u châssis (comme dans la

Déterminer quelle borne est mise à la masse (reliée au châssis). Si la borne négative est mise à la masse a

plupart des véhicules) voir l'article (e). Si la borne positive est mise à la masse au châssis, voir l'article (f).

e.

Pour un véhicule avec masse au négatif, brancher la pince positive (ROUGE) du chargeur à la borne positive (POS, P, +) non mise à la

masse de la batterie. Connecter le bouton de contact du Stop/Go lite à la borne négative (NEG, N, –). Observer la lumière et prendre de

mesures appropriées. Quand la lumière verte s'allume, attacher la pince NEGATIVE (NOIRE) au châssis de la voiture ou au bloc m

à distance de la batterie. Jamais brancher la pince au carburateur, au conduites

mince. Brancher à une pièce métallique épaisse du châssis ou au bloc moteur.

f.

Pour un véhicule avec masse au positif, brancher la pince POSITIVE (ROUGE) du chargeur à la borne POSITIVE (POS, P, +) de la

batterie. Connecter le bouton de contact du Stop/Go lite à la borne négative (NEG, N, –). Observer la lumière et prendre de mesures

appropriées. Quand la lumière verte s'allume, déconnecter la pince positive (ROUGE). Attacher la pince NEGATIVE (NOIR) à la b

masse NÉGATIVE (NEG, N, –) de la batterie. Attacher la pince POSITIVE (ROUGE) au châssis de la voiture ou au bloc moteur à

distance de la batterie. Jamais brancher la pince au carburateur, au con

Brancher à une pièce métallique épaisse du châssis ou au bloc moteur.

Pour débrancher le chargeur, mettre les interrupteurs sur "O" (off), débrancher le cordon

g. d'alimentation c.a., débrancher la pince du

châssis du véhicule, puis débrancher la pince de la borne de la batterie, dans cet ordre

h

. Pour toute information relative au temps de charge, voir les instructions d'utilisations.

19.

RESPECTER LES ÉTAPES SUIVANTES LORSQUE LA BATTERIE SE TROUVE À L'EXTÉRIEUR DU

d'essence ou aux pièces du châssis faites de tôle

duites d'essence ou aux pièces du châssis faites de tôle mince.

VÉHICULE. UNE ÉTINCELLE À PROXIMITÉ DE LA BATTERIE PEUT LA F

RÉDUIRE LE RISQUE D'ÉTINCELLES PRÈS DE LA BATTERIE, IL FAUT:

a. positive (POS, P, +) a un

Vérifier la polarité des bornes de la batterie. En général, la borne

diamètre plus grand que celui de la borne négative (NEG, N, –).

b. e la batterie un câble pour batterie isolé de calibre 6

Relier à la borne négative (NEG, N, –) d

(AWG) d'au moins 24 pouces de long.

c. la pince positive (ROUGE) du chargeur à la borne positive (POS, P, +) de la

Brancher

batterie.

d. du câble puis brancher la pince

Se tenir à distance de la batterie et dégager l'extrémité

négative (NOIRE) du chargeur à l'extrémité du câble.

e. Ne pas faire face à la batterie pour effectuer le dernier branchement.

f. nverse les étapes relatives au branchement et débrancher la première connexion tout en se

Pour débrancher le chargeur, suivre en sens i

tenant aussi loin que possible de la batterie.

.

AIRE EXPLOSER. POUR

oteur

orne

7

Page 8

g. Les batteries pour bateaux doivent être démontées et chargées à terre. La charge à bord d'un bateau exige un instrument mis au point

spécialement pour applications maritimes.

NOTA: NE PAS UTILISER COMME CHARGEUR POUR APPLICATIONS MARITIMES

20.

INSTRUCTIONS DE MISE À LA TERRE ET DE CONNEXION DU CORDON C.A.

Le chargeur doit être mis à la masse afin de réduire le risque d'électrocution. Le chargeur est muni d'un cordon électrique pourvu d'un

conducteur de mise à la terre de l'équipement et d'une fiche avec la terre. La fiche doit être branchée dans une prise adéquatement installée

et mise à la terre conformément aux règlements et codes en vigueur.

DANGER. Ne jamais modifier le cordon

d'alimentation c.a. ni la fiche fournis pour les adapter

à la prise; faire installer une prise adéquate par un

électricien qualifié. Une connexion inadéquate peut

être cause d'électrocution. Le chargeur doit être

utilisé sur un circuit d'une valeur nominale de 120

volts et possède une fiche avec la terre similaire à

celle de la FIGURE A. Un adaptateur temporaire,

similaire à celui de la FIGURE C, peut être utilisé pour brancher cette fiche à une prise bipolaire, tel que montré à la FIGURE B, jusqu'à ce

qu'une prise avec terre adéquate soit installée par une électricien qualifié.

Prise avec terre

Adaptateur

Plaquecouvercle

de la boite de

prise de courant

avec terre

(A) (B)

Adaptateur

Dispositif de mise

a la terre

DANGER. Avant d'utiliser un adaptateur, tel qu'illustré, s'assurer que la vis centrale de la plaque-couvercle de la prise est mise à la terre.

L'oreille rigide verte de la patte faisant saillie de l'adaptateur doit être branchée à une prise de courant mise à la terre adéquatement -

s'assurer que l'oreille est mise à la masse. Si nécessaire, remplacer la vis originale de la plaque-couvercle de la prise par une vis plus longue

qui saura bien retenir la patte de l'adaptateur à la plaque-couvercle et assurer la connexion de terre à la prise avec terre.

L'UTILISATION D'UN ADAPTATEUR EST INTERDITE AU CANADA. SI UNE PRISE DE COURANT AVEC MISE À

LA TERRE N'EST PAS DISPONIBLE EN FAIRE INSTALLER UNE PAR UN ÉLECTRICIEN QUALIFIÉ AVANT

D'UTILISER CET APPAREIL.

21.

PÉRIODE DE CHARGE

a. Utiliser un voltmètre ou un densimètre à compensation thermique pour déterminer l'état de charge de la batterie. Ne pas charger une

batterie déjà chargée à plus de 75% ou défectueuse. Voir le tableau ÉTAT DE LA CHARGE.

b. Déterminer la taille de la batterie (Petite, Moyenne ou Grande), voir tableau TAILLE DE LA BATTERIE.

c. Se référer au tableau RÉGIME DE CHARGE PAR RAPPORT AU TEMPS DE CHARGE, pour déterminer le temps de charge

recommandé pour la batterie, selon sa taille, son état de charge et l'ampérage de charge.

d. Interrompe la charge quand la densité de l'électrolyte atteint 1.260 ou plus. La lecture doit être effectuée au moyen d'un densimètre à

compensation thermique. Interrompe la charge se la batterie commence à émettre une quantité excessive de gaz ou lorsque la

température de l'électrolyte atteint environ 50°C. Ne pas surcharger la batterie.

TABLEAU-TAILLE DE LA BATTERIE

TAILLE DE LA BATTERIE

Ampères-Heures (Ah) 60

Capacité de réserve (A)

Courant de démarrage

à froid (A)

TABLEAU-ETAT DE CHARGE

ÉTAT DE CHARGE

Densité

Tension à vide (6V)

Tension à vide (12V )

Tension à vide (24V )

PETITE MOYENNE GRANDE

80+

100+

400+

HORS

TENSION

1.110

5.9

11.8

23.6

275

1.225

6.2

12.4

24.8

40

1.185

6.05

12.1

24.2

90

350

25%50%75%

1.140

5.95

11.9

23.8

60

RÉGIME DE CHARGE/PAR RAPPORT AU TEMPS DE CHARGE

TAILLE DE

LA BATTERIE

PETITE

MOYENNE

GRANDE

% DE

CHARGE

0-25

25-50

50-75

0-25

25-50

50-75

0-25

25-50

50-75

A

M

P

E

R

E

S

TEMPS (MINUTES)

15 30 45 60 75 90

45

30

30

25

30

20

20

15

15

70

45

25

90

60

30

10

10

10

50

45

30

25

10 10 10

15

15

55

55

40

35

15 15 15

20

20

15

(C)

2025

10

55

303540

202020

454550

303030

8

Page 9

INSTRUCTIONS D'ASSEMBLAGE

Attacher la poignée au chargeur en utilisant les quatre vis fournis.

INSTRUCTIONS D'OPERATION

ATTENTION: Cet chargeur de batterie doit être complètement assemblé avant l'utilisation. Faillira à l'attention

peut conduire aux risques de blessure.

UTILISATION DU PANNEAU DE BORD:

Le compte minutes TEMPS DE CHARGE possède une position éteinte, une position charge continus et un temps de

charge étalé de 0 à 120 minutes.

a. ETEINT - Toujours être sure que le compte minutes est sur la position éteinte avant de brancher ou de

débrancher les pinces hors de la batterie. Le chargeur ne chargera pas tant que le compte minutes est dans

cette position.

b. DE 0 À 120 MINUTES DE CHARGE - Le compte minutes éteindra automatiquement éteindre le chargeur à la

fin du temps sélectionné. Tourner le compte minutes à travers 20 avant le sélection du temps désiré.

c. CHARGE CONTINUS - Cette position est utilisée pour des chargements lents ou en parallèles, le compte

minutes n'eteindra pas le chargeur dans cette position. Ne pas utiliser cette position pour la charge rapide.

POUR CHARGER LA BATTERIE

Faire des connections à la batterie en suivant les instructions dans la section précédant. Déterminer si la batterie est à 6 ou 12 volts. Établir la

charge voltage à 6/12 faible charge pour les batteries de 6 ou 12 volts. Si une régime supérieure de charge est nécessaire, établir à 12 moyenne ou

12 grande. Ne jamais charger la batterie de 6 volts par l'établissement d'autre que 6/12 faible. (Si non les risques de dommage à la batterie peuvent

se produire.)Tourner le compteur en position de fonctionnement et l'ampèremètre indiquera la quantité d'électricité chargée à la batterie. Le période

de charge sera fixé par le précédent tableau ainsi que les instructions dans cet manuel l'opération.

AIDE A LA MANIVELLE (12 VOLTS)

Éteindre toutes les lumières ainsi que tous les installations électriques dans la voiture. Connecter le chargeur de batteries en suivant les

instructions précédentes. Charger la batterie sur 12 Hi pour au moins 5 minutes avant de démarrer la voiture. Mettre l'interrupteur sur la position 12

CHARGE/SURVOLTEUR. Démarrer la voiture avec le chargeur branché à la voiture. Surveiller le cycle de travail du chargeur.

Note: Ne pas tourner le contact de démarreur plus de 20 secondes pour chaque période de 5 minutes; l'abuse ment du démarrage peut,

surchauffer et fait dommage le démarreur. Si le voiture ne se démarre pas, laisser le démarreur se refroidir tout en laissant le chargeur charge la

batterie. Tourner l'interrupteur en position ETEINTE et enlever les cordons d'alimentation du courant électrique hors de la prise avant de

débrancher les pinces.

CHARGER UNE BATTERIE SULFATEE.

Si la batterie a été déchargée pour une longue période, il se peut qu'elle devienne SULFATEE. Cela peut se voir par un dépôt blanc en haut de la

batterie. Le sulfate se forme lorsqu'une batterie a un faible taux un eau est reste déchargée pendant une longue période. Les batteries sulfatées

ont la caractéristiques de ne pas se charger indifféremment du taux de charge.

La méthode de chargement a deux étapes. La première est d'essayee de retirer le sulfate pour permettre a la batterie de se charger. Cela doit etre

surveiller prudemment pour éviter un surchauffe ment ainsi qu'un débit trop important. La deuxième étape est de charger doucement pour charger

complètement la batterie.

LIRE ET SUIVRE TOUTES LES PRECAUTIONS DANS LE MANUAL D'INSTRUCTION AVANT D'ESSAYER DE CHARGER UNE BATTERIE

SULFATEE. FAILLIR A FAIRE ATTENTION PEUT DETRUIRE CE QUE VOUS AVEZ, OU VOUS BLESSEZ OU BIEN VOUS TUEZ.

POUR RECHARGER UNE BATTERIE SULFATEE.

1. Attacher les serre joints comme indique sur le manuel d'instruction.

2. Toujours utiliser le débit le plus faible du chargeur quand le chargeur est mis en route. Mettre le chargeur sur le plus fort debit pour le voltage

quand la batterie se charge.

ATTENTION: NE JAMAIS CHARGER LA BATTERIE A UN DEBIT DE VOLTAGE PLUS FORT QUE CELUI DE LA BATTERIE.

3. La batterie montera peut ou aucun ampérage au début du char gage. Cela continuera jusqu'a ce que le sulfate commence a se casser.

ATTENTION: AU FURE ET A MEUSURE QUE LE SULFATE SE CASSE, L'AMPERAGE PEUT S'ACCROITE RAPIDEMENT. UNE

ATTENTION CONSTANTE DOIT ETRE PORTER POUR EVITER QUE LA BATTERIE NE CHAUFFE.

4. Baisser le taux de charge au plus faible taux de charge pour le voltage de la batterie qui est entrain de se charger.

5. Charger la batterie a ce faible taux jusqu'a ce que l'electrolyte soit complètement charge comme décrit dans les tableau du manuel d'intruction.

Cela peut pendre de 2 a 3 jours.

NOTE: QUELQUES BATTERIES SONT TELLEMENT SULFATEES QU'ELLES NE PEUVENT ETRE REMISES EN CONDITION D'OPERATION,

INDIFFERENT DU TAUX DE CHARGE OU DE LA DUREE DE CHARGE. SI LA BATTERIE NE PEUT ETRE COMPLETEMENT RECHARGER

PAR CHARGEMENT LENT, ELLE DEVRA ETRE REMPLACEE.

9

Page 10

R

TIMER

456

WHITE

SCHÉMA DE CÂBLAGE

VOLTS

CHARGE

SWITCH

1

6

2

4

8

ORANGE

BROWN

VIOLET

GRAY

AMMETER

RESISTOR

BLACK

YELLOW

2

1

BLACK

3

WHITE

GREEN

BLACK

YELLOW

AC CIRCUIT

PROBE

BLACK

WHITE

BREAKER

FAN

"STOP/GO LIGHT"

YELLOW

TRANSFORMER

NEGATIVE

(BLACK)

JAW GUIDE

RECTIFIER

DC

CIRCUIT

BREAKE

POSITIVE

(RED)

MODÉLE 6009 LISTE DES PIÈCES DE RECHANGE

Pièces Description Numéro de Pièce

1 Pied avant ...........................................................605671

2 Roue avec écrous ...............................................611157

3 Poignée............................................................... 605213

4 Voyant Arrét/Marrche.......................................... 604579

5 Pale de ventilateur ..............................................610189

6 Moteur de ventilateur ..........................................610190

7 Redresseur.......................................................... 610364

8 Minuterie ............................................................. 611245

9 Indicateur de courant de charge .........................605204

10 Cordon D’alimentation C.A.................................. 611248

11 Interrupteur avec bouton..................................... 611187

12 Jeu de cables c.c ................................................610855

13 Disjoncteur c.c..................................................... 610536

14 Axe Aveć Écrous................................................. 610052

15 Transformateur.................................................... 610819

16 Disjoncteur pour AC............................................ 603597

17 Pinces (1 paure avec mâchoires)............................ 6202

18 Jeu de mâchoires (1 pince)................................. 610970

19 Barre de Bride..................................................... 610517

20 Base.................................................................... 610054

21 Bouton................................................................. 603147

22 Bouton-Minuterue................................................ 610930

23 Panneau latéral cóté droit ...................................611032

24 Panneau avant.................................................... 611250

Masqué\

10

4

12

3

19

22

13

23

16

21

6

5

11

9

8

17

18

14

7

15

2

20

1

24

Panneau Supérior ............................................... 611011

Panneau latéral, côté gauche .............................611031

INSTRUCTIONS D'ENTRETIEN

Les pinces, les rallonges ou les câbles usés doivent être remplacés. Des pièces usées peuvent causer une mauvaise connexion et par là même poser un

danger pour l'utilisateur. Voir la liste des pièces de rechange pour les numéros de pièce. Tout entretien ou toute réparation de l'appareil nécessitent le

démontage du boîtier doit être effectué par un technicien qualifié.

10

Page 11

MODELO 6009

MANUAL DEL OPERADOR

MEDIDAS IMPORTANTES DE SEGURIDAD

GUARDE ESTAS INSTRUCCIONES. Este manual contiene importantes medidas de seguridad y operatividad para el cargador de

1.

baterías que usted ha comprado. Puede necesitar acudir a ellas en algún momento.

2.

PRECAUCIÓN. Para reducir el riesgo de peligro, cargue solo baterías de automóviles con celdas y ácido de plomo. Otras baterías pueden

arder causando daños.

3. No exponga el cargador a la lluvia o nieve si la unidad no lo especifica como posible.

4. El uso de una conexión no recomendada por el fabricante del cargador de baterias puede causar riesgo de fuego, shock eléctrico o daño a

personas.

5. Para reducir el riesgo de dañar el enchufe y el cable, al desconectarlos tire del enchufe, no del cable.

6. Asegúrese de que el cable esté colocado de manera que no cause peligro de tropiezos.

7. Una extensión no debe ser usada a no ser que sea absolutamente necesario. El uso de la extensión incorrecta puede causar peligro de fuego o

shock eléctrico. Si usa una extensión, asegúrese de que:

a. Las terminales de la extensión son del mismo número, tamaño, talla y forma que las del enchufe del cargador.

b. La extensión está bien conectada y en buenas condiciones eléctricas.

c. Si la longitud de la extensión es menor que 25 pies, use un cable de 16 AWG. Si es menor que 50 pies, 12 AWG, 100 pies, 10 AWG, 150 pies,

8. No opere el cargador con el enchufe o el cable dañado, cámbielo inmediatamente.

9. No opere el cagador si ha recibido un golpe fuerte, se ha caído, o ha sido dañado de cualquier otra forma, llévelo a un servicio cualificado cuando

10. No desmonte el cagador a no ser que esté cualificado para trabajar con equipos eléctricos. Si no, llévelo a un servicio cualificado cuando la unidad

11. Para reducir el riesgo de shock eléctrico, desenchufe el cargador antes de limpiarlo o hacerle cualquier tipo de reparación. Apagando los controles

12.

13.

14.

8 AWG.

la nidad lo necesite. Un ensamblaje incorrecto puede causar riesgo de fuego o shock eléctrico.

lo necesite. Un ensamblaje incorrecto puede causar riesgo de fuego o shock eléctrico.

este riesgo no se eliminará.

PRECAUCIÓN. RIESGO DE GASES EXPLOSIVOS

a. TRABAJAR EN LA PROXIMIDAD DE BATERÍAS DE ÁCIDO DE PLOMO ES PELIGROSO. LAS BATERÍAS GENERAN GASES

EXPLOSIVOS DURANTE SU FUNCIONAMIENTO NORMAL. POR ESTA RAZÓN, ES DE MUCHA IMPORTANCIA LEER ESTE MANUAL

ANTES DE USAR EL CARGADOR.

b. Para reducir el riesgo de una explosión de la batería, siga estas insrtucciones y las publicadas por el fabricante de la batería y el fabricante de

cualquier equipo que vaya a utilizar cerca de la batería. Revise las marcas de precaución de estos productos, y del motor.

PRECAUCIONES PERSONALES

a. Al trabajar con baterías de ácido de plomo, ha de tener a alguien que pueda acudir en su ayuda en caso necesario.

b. Tenga suficiente agua fresca cerca por si el ácido llegase a su piel, ropa u ojos.

c. Lleve protección en los ojos y en la ropa. Evite tocarse los ojos cuando trabaje cerca de la batería.

d. Si el ácido llegase a su piel o a su ropa, lávese inmediatamente con agua y jabón. Si el ácido llega a sus ojos, aclárese con agua al menos

durante diez minutos y consiga atención médica.

e. NUNCA fume o permita una chispa cerca de la batería o del motor.

f. Sea extremadamente cuidadoso de no dejar caer un instrumento metálico en la batería. Puede producir una chispa o un cortocircuíto en la

batería o en otra parte del sistema eléctrico.

g. Quítese todo tipo de metal como anillos, pulseras, relojes, etc cuando trabaje con baterías de ácido de plomo. Una batería de ácido de plomo

puede producir un cortocircuíto con corriente lo suficientemente alta para fundir un anillo causando quemaduras graves.

h. Use este cargador solo para cargar baterías de ácido de plomo. Este cargador no está destinado para dar potencia a sistemas eléctricos de

bajo voltaje.

i. Nunca carga una batería congelada.

PREPARANDO PARA CARGAR

a. Si fuese necesario sacar la batería del vehículo para cargarla siempre quite la terminal a tierra primero. Asegúrese que todos los accesorios

del vehículo están apagados para no causar un arco.

b. Asegúrese de que el área alrededor de la batería está ventilada mientras la batería se está cargando. Usando un cartón u otro elemento que

funcione como ventilador podemos quitar el gas que la batería desprende.

c. Limpie las terminales de la batería. Tenga cuidado de que la corrosión no llegue a sus ojos.

d. Añada agua destilada en cada celda hasta que el ácido de la batería llegue a los niveles especificados por el fabricante. Esto ayuda a purgar

el excesivo gas de las celdas. No sobre llene. Para una batería sin celdas, siga las instrucciones de carga del fabricante.

e. Estudie todas las intrucciones del fabricante de la batería como quitar o no las tapas de las celdas mientras cargamos y los rangos de carga

recomendados.

f. Determine el voltage de la batería acudiendo al manual del automóvil y asegúrese de que el selector de salida de voltage está marcando el

voltaje adecuado. Si el cargador tiene rango de carga ajustable, carge la batería inicialmente con el rango más bajo.

11

Page 12

COLOCACIÓN DEL CARGADOR

15.

a. Coloque el cargador tan lejos de la batería como los cables de corriente directa lo permitan.

b. Nunca coloque el cargador directamente por encima de la batería a cargar; los gases dañarán el cargador.

c. Nunca permita que el ácido de la batería pueda caer en el cargador cuando se lee la gravedad específica o al rellenar la batería.

d. No opere en cargador en un área cerrada o con ventilación restringida.

e. No coloque la batería encima del cargador.

16.

PRECUACIONES DE LA CONEXIÓN DC

a. Conecte y desconecte las pinzas de salida DC solo después de poner los interruptores en posición OFF y de quitar los cables AC de la

terminal eléctrica.

b. Conecte las pinzas a la terminal de la batería, ajústelas varias veces para asegurar una buena conexión. Esto previene que las pinzas se

17.

18.

suelten y reduce el riesgo de chispas.

INSTRUCCIONES DE LA LUZ STOP/GO

Cuando es usada correctamente la luz stop/go indica cuando las conexiones de las pinzas

son correctas. Conecte la pinza positiva (roja) a la terminal positiva (POS,+). Toque con el

botón de contacto de la pinza negativa la otra terminal de la batería. Observe las luces LED:

LUZ VERDE: Primera conexión correcta. Haga la segunda conexión.

LUZ ROJA: La primera conexión es incorrecta, conecte la terminal positiva a la otra terminal

de la batería.

LUZ ROJA Y VERDE: El cargador de baterías está encendido. Apáguelo.

SIN LUZ: Revise la batería. Limpie la corrosión de las pinzas, mordazas y terminales de la

batería. Repita la prueba. Si todavía no se encendiera la luz, use un voltímetro u otro medio

para asegurarse de que ha indentificado correctamente la polaridad de las terminales de la

batería. Entonces conecte las pinzas sin hacer caso de la luz Stop/Go.

SIGA ESTOS PASOS CUANDO LA BATERÍA ESTE INSTALADA EN EL VEHÍCULO. UNA CHISPA CERCA

PUEDE CAUSAR UNA EXPLOSIÓN DE LA BATERÍA. PARA REDUCIR EL RIESGO DE UNA CHISPA CERCA

DE LA BATERÍA:

a. Lea la sección INSTRUCCIONES DE LA LUZ STOP/GO antes de seguir.

b. Coloque los cables AC y DC de forma que no causen ningún peligro.

c. Permanezca alejado de ventiladores, correas etc que pueden dañar al operador.

d. Revise la polaridad de las terminales de la batería, la terminal positiva es normalmente de mayor diámetro que la negativa.

e. Determine qué terminal de la batería está conectada a tierra por el chasis. Si la terminal negativa está conectada a tierra por el chasis

(como en la mayoría de los vehículos), pase al punto f. Si la terminal positiva está conectada a tierra por el chasis, pase al punto g.

f. Para un vehículo con conexión a tierra negativa, conecte la pinza positiva (roja) del cargador de baterías a la terminal no a tierra Positiva

(POS, P, +) de la batería. Conecte el botón de contacto Stop/Go a la terminal Negativa de la batería. Interprete la luz y realice lo

conveniente. Cuando la luz verde se enciende, conecte la pinza negativa (negra) al chasis del vehículo, o parte pesada de metal. No

conecte la pinza al carburador o a los tubos de combustible.

g. Para vehículos con terminal a tierra positiva, conecte la pinza positiva (roja) del cargador de baterías a la terminal positiva (POS, P, +) de

la batería. Conecte la luz Stop/Go a la terminal negativa (NEG, N, –) no a tierra de la batería. Conecte la pinza Positiva (roja) al chasis

del vehículo. No conecte la pinza al carburador o tubos de combustible.

h. Cuando desconecte el cargador, apague los iterruptores, desconecte los cables AC, quite la pinza del chasis del vehículo y después

quite las pinzas de la terminal de la batería.

i. Vea las instrucciones de operación para las instrucciones de la duración de la carga.

SIGA ESTOS PASOS CUANDO LA BATERÍA ESTA FUERA DEL VEHÍCULO. UNA CHISPA CERCA DE LA

19.

BATERÍA PUEDE CAUSAR EXPLOSIÓN DE LA BATERÍA. PARA REDUCIR EL RIESGO DE UNA CHISPA

CERCA DE LA BATERÍA:

a. Lea la sección "instrucciones de la luz Stop/Go" antes de empezar.

b. Compruebe la polaridad de los postes de la batería. El polo positivo (POS, P, +) tiene

normalmente un diámetro más ancho que el negativo (Neg, N, –).

c. Conecte un cable de por lo menos 24" de largo y 6AWG de diámetro aislado al polo negativo

de la batería (Neg, N, –).

d. Conecte la pinza roja positiva del cargador al polo positivo (POS, P, +) de la batería.

e. Conecte el botón Stop/Go al final del cable de la batería. Si se enciende la luz roja, cambie la

conexión. Compruebe de nuevo. Cuando se enciende la luz verde, póngase tan lejos de la

batería como le sea posible-Entonces conecte la pinza negra negativa del cargador al final del

cable.

f. No se ponga de cara a la batería cuando haga a la conexión final.

g. Cuando desconecte el cargador, hágalo siempre en el orden inverso al prodedimiento de conexión, y rompa la primera conexión

mientras permanece tan lejos de la batería como le sea práctico.

h. Una batería marina (barco) puede quitarse y cargarse en el almacén. Para cargarse a bordo se requiere un equipo especial, diseñado

para uso marino.

12

Page 13

20.

INSTRUCCIONES DE CONEXIÓN DEL CABLE AC A TIERRA

El cargador debería estar en tierra para reducir el riesgo de shock eléctrico. El cargador está equipado con un cable eléctrico que tiene un

conductor y un enchufe de tierra. El enchufe debe ser conectado en una terminal que esté adecuadamente instalada de acuerdo con las normas

locales.

PELIGRO. Nunca altere el cable AC o el enchufe-Si no se

ajusta, necesita ser instalado por un electricista profesional.

Conexiones incorrectas pueden causar riesgo de shock eléctrico.

El cargador de la batería es para uso de circuítos de 120 voltios y

tiene un enchufe de tierra como aparace en la FIGURA A. Un

adaptador temporal como aparace en la FIGURA C, puede usarse

para conectar el enchufe a un receptáculo de dos polos, como se

muestra en la FIGURA B, hasta que una terminal de tierra

adecuada pueda ser instalada por un electricista cualificado.

TERMINAL DE TIERRA

(

TOMA DE CORRIENTE)

PATILLA VERDE PARA LA CONEXION A LA TERMINAL DETIERRA

METODOS DE ENSAMBLAJE A TIERRA

ADAPTADOR

CUBIERTA DE

LA TERMINAL

(A)

DE TIERRA

(B)

ADAPTADOR

PELIGRO. Antes de usar el adaptador, asegúrese de que el tornillo del centro de la teminal está en tierra. La reja de color verde del enchufe

que sale del adaptodor, debe ser conectada a una terminal a tierra adecuada-Asegúrese de que está en tierra. Si es necesario, cambie el tornillo

original del plato de la terminal por un tornillo más largo, que asegurará la oreja del adaptador a la terminal y hará la conexión a tierra con la

terminal a tierra.

21.

DURACIÓN DE LA CARGA

a. Mida la batería para ver el estado de carga. No cargue si está cargada más del 75% o si es defectuosa.

b. Coloque el rango de carga de amperaje según el tamaño de la batería y el estado de carga de la misma.

c. Marque los minutos de carga y empiece la carga de amperios.

d. Desconecte la carga cuando la gravedad específica del electrolito alcanza 1.260 o superior. Un hidrómetro compensador de la temperatura

debería usarse para esta lectura. Desconecte la carga si la batería empieza a liberar gases excesivamente o cuando la termperatura del

electrolito alcanza 120 grados F. No sobrecargue las baterías. La sobrecarga causará una excesiva pérdida de agua y dañará la misma.

TABLA DEL TAMAÑO DE LA BATERIA

TAMAÑO DE LA BATERIA

Amperios de cranking frio

TABLA DEL ESTADO DE CARGA

ESTADO DE CARGA

Gravidad Especifica

Voltage del circuito abíerto 6V

Voltage del circuito abíerto 12V

Voltage del circuito abíerto 24V

40 80+60Horas de Amperaje

60

275

75%

1.225

12.4

24.8

MEDIANAPEQUEÑA

90Capacidad de reserva

350

50%

1.185

6.056.2

12.1

GRANDE

100+

400+

25%

MUERTA

1.140 1.110

5.95

11.9

23.824.2

5.9

11.8

23.6

TAMAÑO DE

LA BATERIA

PEQUEÑA

MEDIANA

GRANDE

RELACION ENTRE LA CAPACIDAD

Y LOS MINUTOS DE CARGA

% DE

MINUTOS

CARGA

0-25

25-50

50-75

0-25

25-50

50-75

0-25

25-50

50-75

45

30

A

M

15

P

70

E

R

45

E

25

S

90

60

30

30

20

10

50

30

15

55

40

20

30

20

10

45

25

15

55

35

20

251525 20

15

55

10

40 35 30

20 20 20

50 45 45

30 30 30

INSTRUCCIONES DE ENSAMBLAJE

Conecte el mango a la parte de atrás del cargador usando los cuatros tornillos provistos.

907560453015

10

101010

151515

(C

)

13

Page 14

INSTRUCCIONES DE OPERACIÓN

PRECAUCIÓN. El cargador de batería debe estar totalmente ensamblado antes de ser utilizado. Si no, podría haber riesgo de daños personales.

UTILIZACIÓN DEL PANEL DE INSTRUMENTOS

El cromómetro de TIEMPO DE CARGA tiene una posición de OFF, una posición de CARGA CONTINUA y un rango de CARGA PROGRAMABLE de 0 a

120 minutos.

a. APAGADO "OFF" - Asegúrese siempre de que el cronómetro se encuentre en la posición de OFF antes de conectar o desconectar las pinzas a la

batería. El cargador no cargará con el cronómetro en esta posición.

b. CARGA CONTINUA "CONTINUOUS CHA RGE" - Esta posición se utiliza para una carga lenta o para carga en paralelo, el cronómetro no apagará

el cargador mientras este en esta posición. No utilice esta posición para una carga rápida.

c. RANGO DE CARGA PROGRAMABLE de 0 a 120 minutos - El cargador se apagará automáticamente al final del tiempo de carga preestablecido.

Gire el cronómetro pasado los 20 minutos antes de poner el tiempo decaído.

PARA CARGAR BATERÍAS

Efectúe las conexiones a la batería siguiendo las instrucciones de las secciones anteriores. Determine si la batería es de 6 ó de 12 voltios. Ponga el

interruptor “CHARGE VOLTAGE” en la posición “6/12 LOW CHARGE” para una batería de 6 ó 12 voltios. Sí una carga mas alta es deciada, ponga el

interruptor en “12 MED” ó “12 HIGH”. NO

el cronómetro y el medidor de corriente mostrara la cantidad de corriente enviada a la batería. La duración de la carga debe ser determinada usando la

tabla provista.

ARRANQUE RÁPIDO

Apague todas las luces y accesorios del vehículo.

Conecte el cargador a la batería siguiendo las instrucciones anteriores.

Cargue la batería por 5 minutos en la posición “12 HI” antes de intentar arrancar el vehículo.

Ponga el interruptor en la posición “12 CRANK ASSIST”.

Arranque el vehículo con el cargador conectado a la batería. Siga el ciclo de trabajo de la unidad.

NOTA: No intente arrancar el motor durante más de 20 segundos en períodos de 5 minutos. Una insistencia excesiva puede sobrecalentar o dañar el

motor de arranque. Si el vehículo no arranca, mientras espera que el motor de arranque se enfríe, deje que el cargador siga cargando la batería.

Ponga el interruptor en la posición de “OFF” y desconecte el cable de la toma de corriente antes de desconectar las pinzas.

CARGANDO BATERÍAS SULFATADAS

Si su batería ha estado descargada por un periodo extendido de tiempo, puede estar sulfatada. Esto usualmente se ve como depósitos blancos cerca

de la parte de arriba de la batería. El sulfato se forma cuando una batería con niveles bajos de agua se queda descargada por un tiempo extendido.

Las baterías sulfatadas tienen la característica de no aceptar carga, sin importar la medida de esta que se aplique.

El método de carga tiene dos estapas. La primera estapa es intentar descomponer el sulfato para permitir que la batería acepte la carga. Tiene que

hacerse con cuidado para evitar una medida de carga excesiva cuando la batería empieza a cargarse y que se sobrecaliente. La segunda estapa es un

cargamiento despacio para permitir a la batería que se cargue completamente.

LEA Y SIGA TODAS LOS PRECAUCIONES Y AVISOS EN SU MANUAL DE INSTRUCCIONES ANTES DE INTENTAR CARGAR LAS BATERÍAS

SULFATADAS. NO CUMPLIR ESTOS AVISOS PUEDE RESULTAR EN DAÑOS DE COMPAÑÍA, SERIOS DAÑOS PERSONALES O INCLUSO LA

MUERTE.

Para recargar una batería sulfatada:

1. Sujete las pinzas de la batería como está explicado en el manual de instrucciones.

2 Use siempre la medida más baja del cargardor cuando lo encienda. Ponga el cargardor en la medida más alta para el voltaje del cargardor que

está siendo cargado.

AVISO: NUNCA CARGUE UNA BATERÍA A UN VOLTAGE SUPERIOR AL DE LA BATERÍA EN SÍ.

3. La batería mostrará poco o no amperaje al comienzo del proceso de carga.

AVISO: MIENTRAS EL SULFATO SE DESCOMPONE, LOS AMPERIOS PUEDEN AUMENTAR RÁPIDAMENTE. SE NECESITA ATENCIÓN

CONSTANTE PARA PREVENIR EL SOBRECALIENTAMIENTO DE LA BATERÍA.

4. Baje la medida de carga a la medida más baja para los voltios de la batería que está cargando.

5. Cargue la batería a la medida más baja hasta que el electrolito llegue al estado de carga completa como está explicado en las tablas de su manual

de instrucciones. Esto puede llegar a durar dos o tres días.

NOTA: ALGUNAS BATERÍAS PUEDE ESTAR TAN SULFATADAS QUE NO PUEDEN REPARARSE Y VOLVER A UNA CONDICIÓN DE OPERACIÓN

NORMAL, SIN IMPORTAR LA MEDIDA DE CARGA O LONGITUD DE TIEMPO QUE SE APLIQUE. SI LA BATERÍA NO PUEDE SER REPARADA Y

VOLVER A UNA CONDICIÓN DE CARGA COMPLETA MEDIANTE UNA CARGA LENTA, DEBE SER REEMPLAZADA.

cargue una batería de 6 voltios en otra posición que no sea “6/12 LOW” (La batería podria dañarse). Encienda

14

Page 15

CRONOMETRO

R

456

BLANCO

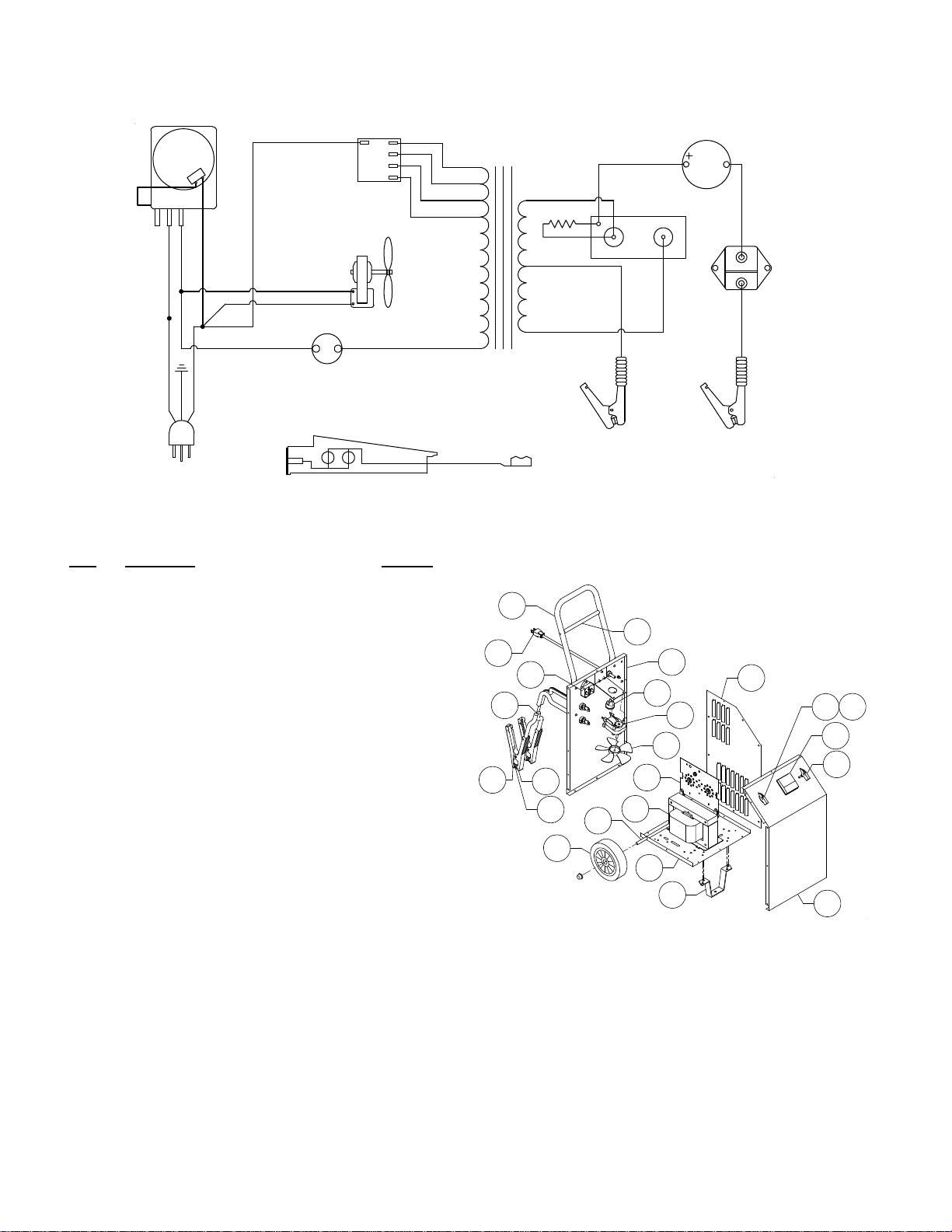

DIAGRAMA DE CABLES

VOLTS

CHARGE

SWITCH

1

6

2

4

8

NARRANJA

CHOCOLATE

VIOLETA

GRIS

AMPERIMETRO

RESISTENCIA

NEGRO

1

NEGRO

AMARRILLO

2

NEGRO

3

BLANCO

VERDE

BOTON DE ALERTA

AMARRILLO

VENTILADOR

NEGRO

BLANCO

CIRCUITO

PROTECTOR

"LAMPARA INDICADORA"

AMARILLO

TRANSFORM ADOR

NEG

(NOIR)

TENAZA

GUIA

RECTIFICADOR

POS.

(ROJO)

CIRCUITO

PROTECTO

MODELO 6009 LISTA DE PARTES

Articulo Description N Pieza

1 Pata Frontal .............................................. 605671

2 Ruedas con tuercas (2) ............................ 611157

3 Mango....................................................... 605213

4 Luz Stop/Go.............................................. 604579

5 Hélice del Ventilador................................. 610189

6 Motor del Ventilador.................................. 610190

7 Rectificador............................................... 610364

8 Cronómetro............................................... 611245

9 Medidor del Amperaje .............................. 605204

10 Cable AC .................................................. 611248

11 Interruptor con se amador ........................ 611187

12 Set De Cables DC .................................... 610855

13 Circuito Protector DC (1) .......................... 610536

14 Barre Con Tuercas ................................... 610052

15 Transformador .......................................... 610819

16 Circuito Protector AC ................................ 603597

17 Pinzas........................................................... 6202

18 Set De Mordazas (repara una pinza)........ 610970

19 Barra de Presilla ....................................... 610517

20 Base ......................................................... 610054

21 Pomo ........................................................ 603147

22 Panel Tracero ........................................... 610977

10

4

12

3

19

22

13

23

16

21

6

5

11

9

8

17

18

14

7

15

2

20

1

24

23 Panel Derecho .......................................... 611032

24 Panel Frontal ............................................ 611250

No se muestra

Panel Superior.......................................... 611011

Panel Izquierdo......................................... 611031

INSTRUCCIONES DE MANTENIMIENTO

Pinzas y mordazas deterioradas deben ser reemplazadas. Las partes deterioradas causan malas conexiones y pueden ser un peligro para su

seguridad. Vea la lista de piezas para el número de kits de pinzas y mordazas. Cualquier mantenimiento y reparación de esta unidad que necesite

el desmonte de la caja debe ser realizado sólo por un servicio cualificado. El montaje incorrecto puede llevar a un shock eléctrico cuando se use la

unidad.

15

Page 16

NOTES:

W2053 027-0587 Rev. 20120127

ASSOCIATED EQUIPMENT CORPORATION

5043 FARLIN AVE. ST. LOUIS, MISSOURI 63115

Tel. (314) 385-5178 Fax. (314) 385-3254

www.associatedequip.com

16

Loading...

Loading...