Page 1

Associated Equipment Corp.

St

. Louis, MO 63115

314-385-5178 (Outside US)

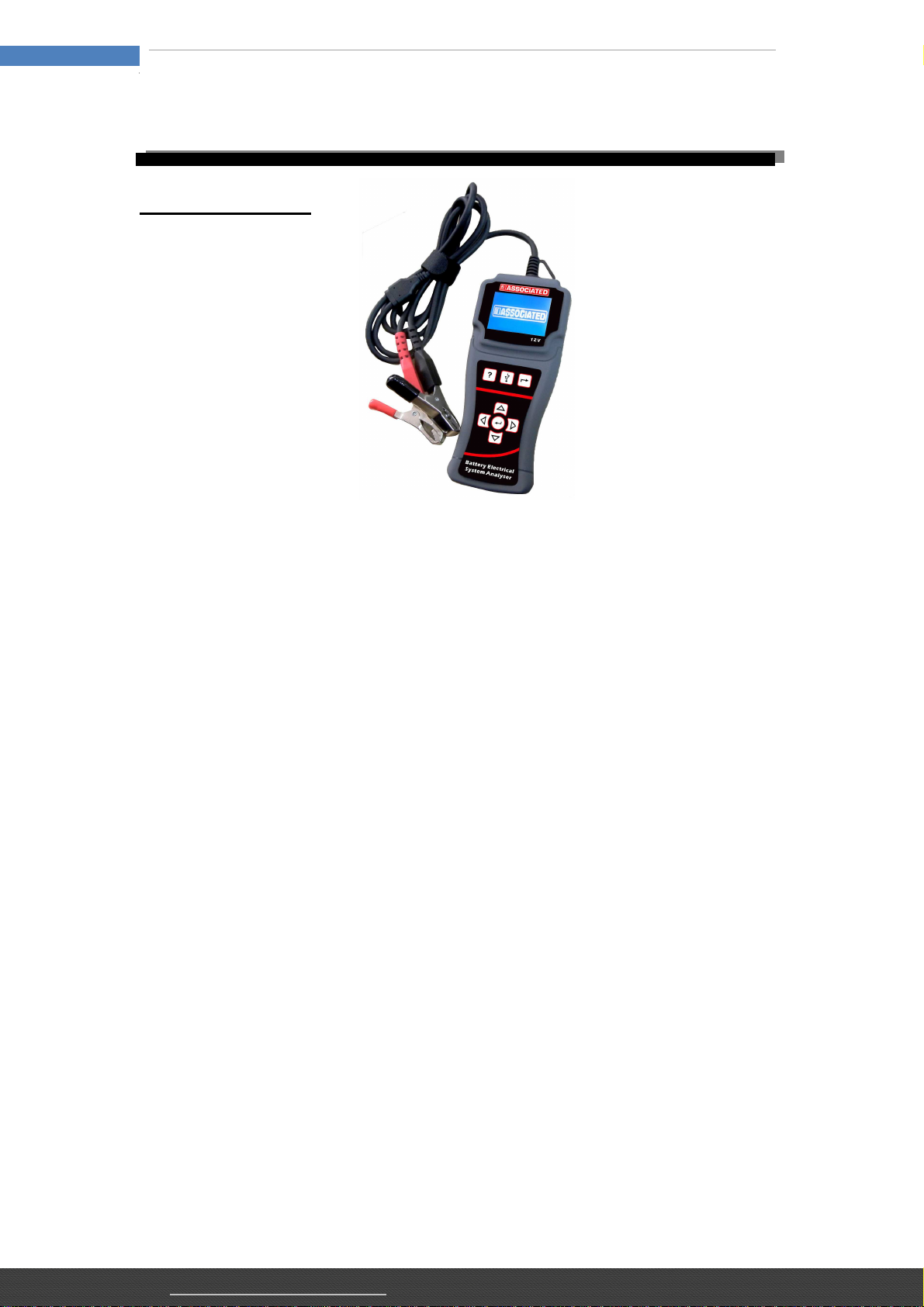

Battery Electrical System Analyzer

Model: 12-1012

User’s Manual

Version 13.08

5043 Farlin Ave. 800-949-1472(US)

Page 2

- 2 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

_______________________________________________________________________________

Table of Contents

1.0 Introduction------------------------------------------------------------------------------------------

1.1 The Product-------------------------------------------------------------------------------------------------------3

1.2 Specifications----------------------------------------------------------------------------------------------------4

2.0 Safety Measures-----------------------------------------------------------------------------------

2.1 Safety Precautions---------------------------------------------------------------------------------------------5

2.2 Other Precautions----------------------------------------------------------------------------------------------7

3.0 Working with Batteries--------------------------------------------------------------------------

8

4.0 The Battery Electrical System Analyser------------------------------------------------------

4.1 MODEL 12-1012------------------------------------------------------------------------------------------------10

4.2 Keypad Functions-------------------------------------------------------------------------------------------- 10

4.3 Functions of Individual Key-------------------------------------------------------------------------------11

5.0 HELP Key-----------------------------------------------------------------------------------------

12

6.0 Battery Test-----------------------------------------------------------------------------------------

6.1 Start Testing ---------------------------------------------------------------------------------------------------14

7.0 Battery Rating Charts-----------------------------------------------------------------------------

7.1 Japanese Industrial Standards (JIS#) Rating Chart-----------------------------------------------24

7.2 DIN & EN Standards Rating Charts---------------------------------------------------------------------26

7.3 YUASA Battery Rating Chart -----------------------------------------------------------------------------28

7.4 Rough CCA Guide------------------------------------------------------------------------------------------- 28

8.0 Grounding Test -----------------------------------------------------------------------------------

8.1 Start Testing----------------------------------------------------------------------------------------------------29

9.0 Starter Test --------------------------------------------------------------------------------------

9.1 Begin Testing---------------------------------------------------------------------------------------------------35

10.0 Alternator Test----------------------------------------------------------------------------------

10.1 Start Testing----------------------------------------------------------------------------------------------------39

No load testing at 3,000 RPM-----------------------------------------------------------------------------39

Testing with load at 2,000 RPM---------------------------------------------------------------------------42

11.0 View Last Test Results-----------------------------------------------------------------------

12.0 Setting Up the PC ready for MODEL 12-1012------------------------------------------

12.1 Installing Driver------------------------------------------------------------------------------------------------47

12.2 Printing Results from normal printer ------------------------------------------------------------------50

12.3 Saving results--------------------------------------------------------------------------------------------------50

34

38

45

47

13.0 Warranty Information----------------------------------------------------------------------------

13.1 Limited Warranty----------------------------------------------------------------------------------------------51

13.2 Limitations of Warranty-------------------------------------------------------------------------------------52

5043 Farlin Ave. 800-949-1472(US)

Page 3

- 3 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

_______________________________________________________________________________

1.0 - Introduction

1.1-The Product:

As we all know battery plays a very important role in a vehicle by providing

power to all the electrical components and also the initial power to get the

engine started. Once the engine runs, the alternator will take over and at the

same time it charges the battery. In order these power systems to perform

efficiently at all times, they need to be checked regularly during service and

maintenance of the vehicle.

For quick and convenient way of checking the condition of these power

systems, this Battery Electrical System Analyzer is designed to perform the

following tasks:

1. Battery Test:

Analyzes the battery condition using microprocessor controlled

testing methods without the need of fully charging it before test.

The unit consumes very little current during testing hence the test

can be repeated numerous times without worry of draining the

battery and its results are highly accurate.

Extremely safe as it does not create any sparks during clamp on and

it takes less than 8 seconds to obtain the full analyzed results of

tested battery.

2. Grounding Test:

Analyzes the condition of the electrical return circuit contact

resistance which was connected to the engine or chassis body from

the battery terminal with results and recommendations display after

test.

5043 Farlin Ave. 800-949-1472(US)

Page 4

- 4 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

_______________________________________________________________________________

3. Starter Test:

Checks the cranking effectiveness of the battery to predict when the

battery will fail to crank a vehicle basing on voltage profiles with

results and recommendations display.

4. Alternator Test:

This test checks the alternator charging condition during load at

2,000 RPM and without load at 3,000 RPM with results and

recommendations display after each test.

This Analyzer is maintenance free and does not require internal batteries.

It powers up when connected to the battery posts during testing or through an

external 12 Volts DC source for later review of the test results.

The operation is fast and simple. When hooked up to the battery posts, the

displayed instructions on the screen will lead you through and a warning tone

to caution you to perform the correct steps. In event that you need assistance,

there is a key. It will display information about each function when selected.

Its result is consistent and repeatable and can be performed numerous times

without heating up the unit. It is very safe as it does not create any sparks

when connected to the battery terminals during testing on the vehicle.

After the test, the results will be stored in its memory and can be reviewed

again later and it is equipped with an USB port to be connected to the PC to

store the results or have it printed out from normal computer printer.

1.2 Specifications:

Operating Voltage: 9V ~ 15V DC (max)

Analyzing Capacity (Amps): CCA: 100 ~ 1700 EN: 100 ~ 1700

IEC: 100 ~ 1000 DIN: 100 ~ 1000

JIS#: 100 ~ 1700

Battery analyzing time: Less than 8 seconds.

DC Volts Accuracy: ± 2% Reading

Working Temperature: 0ºC (32°F) ~ 50ºC (122°F).

Working Humidity: 10% ~ 80 %

Dimensions: 181 x 110 x 90 mm

5043 Farlin Ave. 800-949-1472(US)

Page 5

- 5 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

_______________________________________________________________________________

2.0 Safety Measures:

For safety reasons, read this manual thoroughly before operating the Tool.

Always refer to and follow the safety instructions and testing procedures

provided by the car or equipment manufacturer. The safety messages

presented below and throughout this user’s manual are reminders to the

operator to exercise extreme care when using this test instrument.

2.1 Safety Precautions:

When the engine is running, it produces carbon

monoxide, a toxic and poisonous gas. Always operate

the vehicle in a well ventilated area. Do not breathe

exhaust gases – they are hazardous that can lead to

death.

To protect your eyes from propellant object such as

caustic liquids, always wear safety eye protection.

Fuel and battery vapors are highly flammable.

DO NOT SMOKE NEAR THE VEHICLE DURING TESTING.

When engine is running, many parts (such as pulleys,

coolant fan, belts, etc) turn at high speed. To avoid

serious injury, always be alert and keep a safe distance

from these parts.

Before starting the engine for testing or trouble

shooting, always make sure the parking brakes is firmly

engaged. Put the transmission in Park (automatic

transmission) and Neutral (manual transmission).

Always block the drive wheels.

Never leave vehicle unattended while testing.

5043 Farlin Ave. 800-949-1472(US)

Page 6

- 6 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

_______________________________________________________________________________

Never lay tools on vehicle battery. You may short the

terminals together causing harm to yourself, the tools or

the battery.

Engine parts become very hot when engine is running.

To prevent severe burns, avoid contact with hot engine

parts.

Do not wear loose clothing or jewelry while working on

engine. Loose clothing can get caught in fan, pulleys,

belts, etc. Jewelry can conduct current and can cause

severe burns if comes in contact between power source

and ground.

When the engine is running, be cautious when working

around the ignition coil, distributor cap, ignition wires

and spark plugs. They are HIGH VOLTAGE components

that can cause electrical Shock.

Always keep a fire extinguisher readily available and

easily accessible in the workshop.

5043 Farlin Ave. 800-949-1472(US)

Page 7

- 7 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

_______________________________________________________________________________

2.2 Other Precautions:

• This battery analyzer is meant for testing of 12 Volts batteries only.

• Its operating voltage is from 9V ~ 15V DC and should not be tested on

24V directly. It will cause damage the unit. For 12V x 2 batteries (in

series or parallel), disconnect the connections and test them

individually.

• Battery that has just been charged by the charger contains surface

charge and it should be discharged by turning ON the Head lights for

3~5 minutes before testing.

• Always attached the analyzer clips on the lead side of the battery

terminal posts during testing so that it has a good contact. This will

provide better and accurate results.

• Do not attach the analyzer clips directly onto the steel bolt that tightened

to the battery terminal posts; this may give inaccurate readings or

inconsistent results. (Note: This also applies to all other battery testing

methods.)

• If the battery terminal posts were oxidized or badly corroded and the

connections were bad, the analyzer will prompt you to check the

connections. In this case, clean the terminal posts and performs testing

directly on the terminal posts it-self.

• During testing on the battery whist it is still in the car, make sure the

engine is OFF.

• Do not store the analyzer near high humidity or temperature area.

Exposing to extreme temperatures will cause damage to the unit.

5043 Farlin Ave. 800-949-1472(US)

Page 8

- 8 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

_______________________________________________________________________________

3.0 Working with Batteries

Lead-acid batteries contain a sulfuric acid electrolyte, which is a highly

corrosive poison and will produce gasses when recharged and explode if

ignited. It can hurt you badly.

When working with batteries, make sure you have plenty of ventilation, remove

your hand jewelry, watch and wear protective eyewear (safety glasses),

clothing, and exercise caution.

Do not allow battery electrolyte to mix with salt water. Even small quantities of

this combination will produce chlorine gas that can KILL you!

Whenever possible, please follow the manufacturer's instructions for testing,

jumping, installing, charging and equalizing batteries.

Never disconnect a battery cable from a vehicle with the engine

running because the battery acts like a filter for the electrical

system.

Unfiltered [pulsating DC] electricity can damage expensive

electronic components, e.g., emissions computer, radio,

charging system, etc.

Turn off all electrical switches and components; turn off the

ignition before disconnecting the battery.

For non-sealed batteries, check the electrolyte level. Make sure it

is covering the plates, and it is not frozen before starting to

recharge (especially during winters).

Do not add distilled water if the electrolyte is covering the top of

the plates because during the recharging process, it will warm

and expand. After recharging has been completed, recheck the

level.

5043 Farlin Ave. 800-949-1472(US)

Page 9

- 9 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

_______________________________________________________________________________

Reinstall the vent caps BEFORE recharging, recharge ONLY in

well-ventilated areas, and wear protective eye ware (safety

goggle).

Do NOT smoke or cause sparks or flames while the battery is

being recharged because batteries give off explosive gasses.

If your battery is an AGM or a sealed flooded type, do NOT

recharge with current ABOVE 12% of the battery's RC rating (or

20% of the ampere-hour rating).

Gel cells should be charged over a 20-hour period and never

over the manufacturer's recommended level or over 14.1 VDC.

Follow the battery and charger manufacturer's procedures for

connecting and disconnecting cables and other steps to minimize

the possibility of an explosion or incorrectly charging the battery.

You should turn the charger OFF before connecting or

disconnecting cables to a battery.

Do not wiggle the cable clamps while the battery is recharging,

because a spark might occur, and this could cause an

explosion. Good ventilation or a fan is recommended to disperse

the gasses created by the recharging process.

If a battery becomes hot, over 110° F (43.3° C), o r violent

gassing or spewing of electrolyte occurs, turn the charger off

temporarily or reduce the charging rate.

When charging the battery in the car with an external MANUAL

charger, make sure that it will not damage the vehicle's electrical

system or components with high voltages.

Even if this is a remote possibility, it is best to disconnect the

vehicle's battery cables from the battery BEFORE connecting the

charger.

5043 Farlin Ave. 800-949-1472(US)

Page 10

- 10 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

6

( + ) post.

to PC.

( -

) post.

_______________________________________________________________________________

4.0 - The Battery Electrical System Analyzer

4.1 – MODEL 12-1012

Black Clamp to

battery negative

Red Clamp to

battery positive

USB port for

connection

Figure 1

4.2 - Keypad Functions:

7

8

4

3

1

2

5

Figure 2

5043 Farlin Ave. 800-949-1472(US)

Page 11

- 11 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

_______________________________________________________________________________

4.3 - Functions of Individual key:

1. Use this key to scroll up to the next item OR when it is in

the keying-in Battery Ratings values mode, press this key

once will increase the value by step of 5 units.

2. Use this key to shift the selection tab to the right item OR

when it is in the keying-in Battery Ratings values mode,

press this key once will increase the value by step of 100

units.

3. Use this key to scroll down to the next item OR when it is in

the keying-in Battery Ratings values mode, press this key

once will decrease the value by step of 5 units.

4. Use this key to shift the selection tab to the left item OR

when it is in the keying-in Battery Ratings values mode,

press this key once will decrease the value by step of 100

units.

5. Press this key will get into the selected function or proceed

to the next step.

6. To EXIT the function, press this key once will return back to

the previous screen.

7. This is the HELP key. Press this key will enter into the help menu

and it will explain the functions of the item you have selected in

detail.

8. Press this key when the Analyzer has connected to the computer

to activate the communication which allows data retrieving and

printing of the Last Tested Results.

5043 Farlin Ave. 800-949-1472(US)

Page 12

- 12 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

Select Test

_______________________________________________________________________________

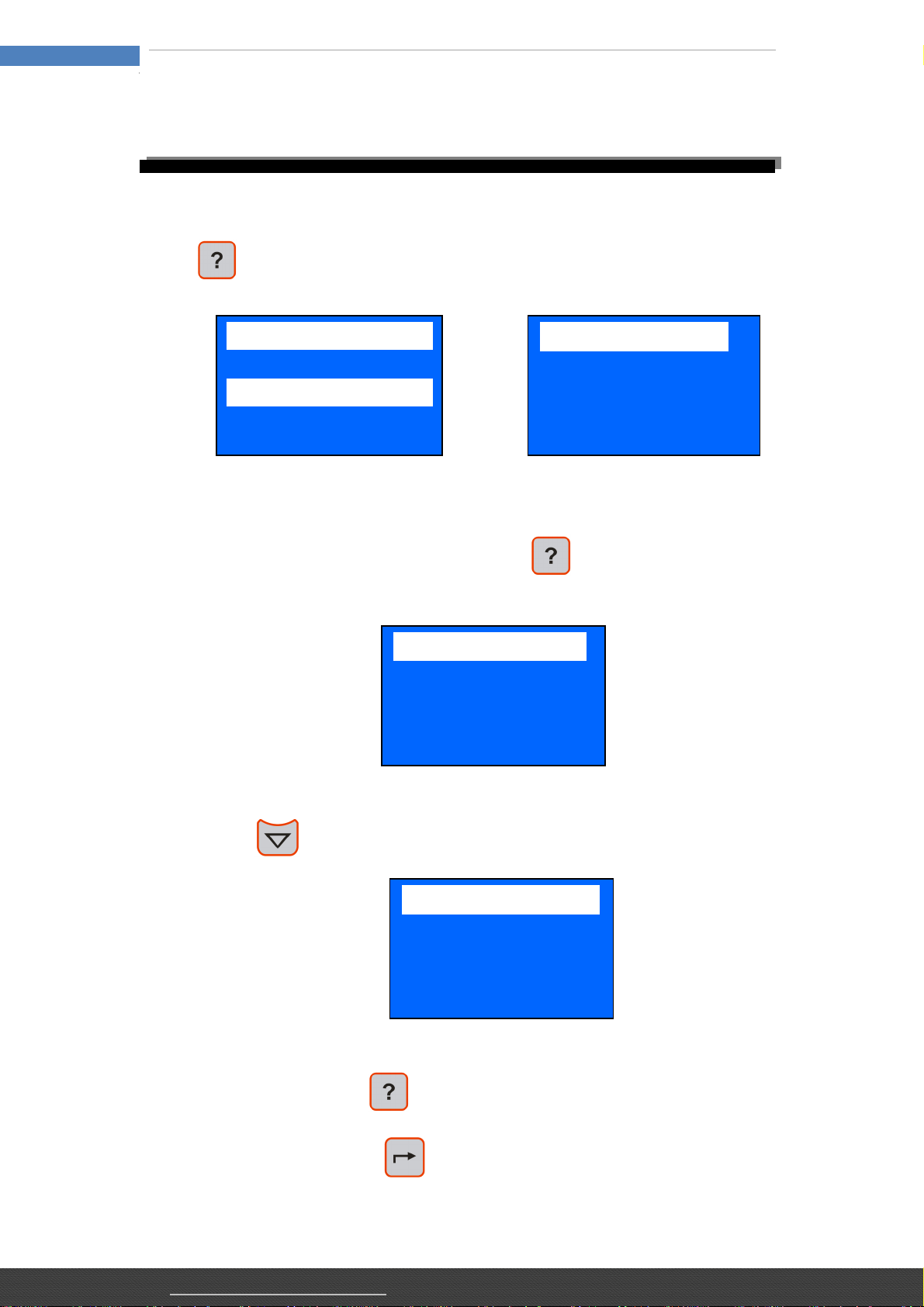

5.0 – Help Key

This selection helps you to familiarize with the usage of the MODEL 12-1012 as well

as explaining the various test functions and its results. To get into this function, just

press key at any one of the functions displayed on the menu screens as

shown below (Fig.3 and Fig 4):

EXIT

For Example:

If help is needed on “Battery Test”, then press key on this item and the

display will change to as shown (Fig 5).

Pressing the key will scroll down to the next item “Results” (Fig 6) and so

forth until it reaches “Life”.

To see the help text, press key again on the selected item and it will display

on the screen.

If you need to quit, just press key will go back to the main menu (Fig. 4)

New: ClearMemory

Continue Test...

LastTest Results

Figure 3

How to operate

Results

Voltage

CCA

Figure 5

Results

Voltage

CCA

Life

Figure 6

Battery Test

Grounding Test

Starter Test

Alternator Test

Figure 4

5043 Farlin Ave. 800-949-1472(US)

Page 13

- 13 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

_______________________________________________________________________________

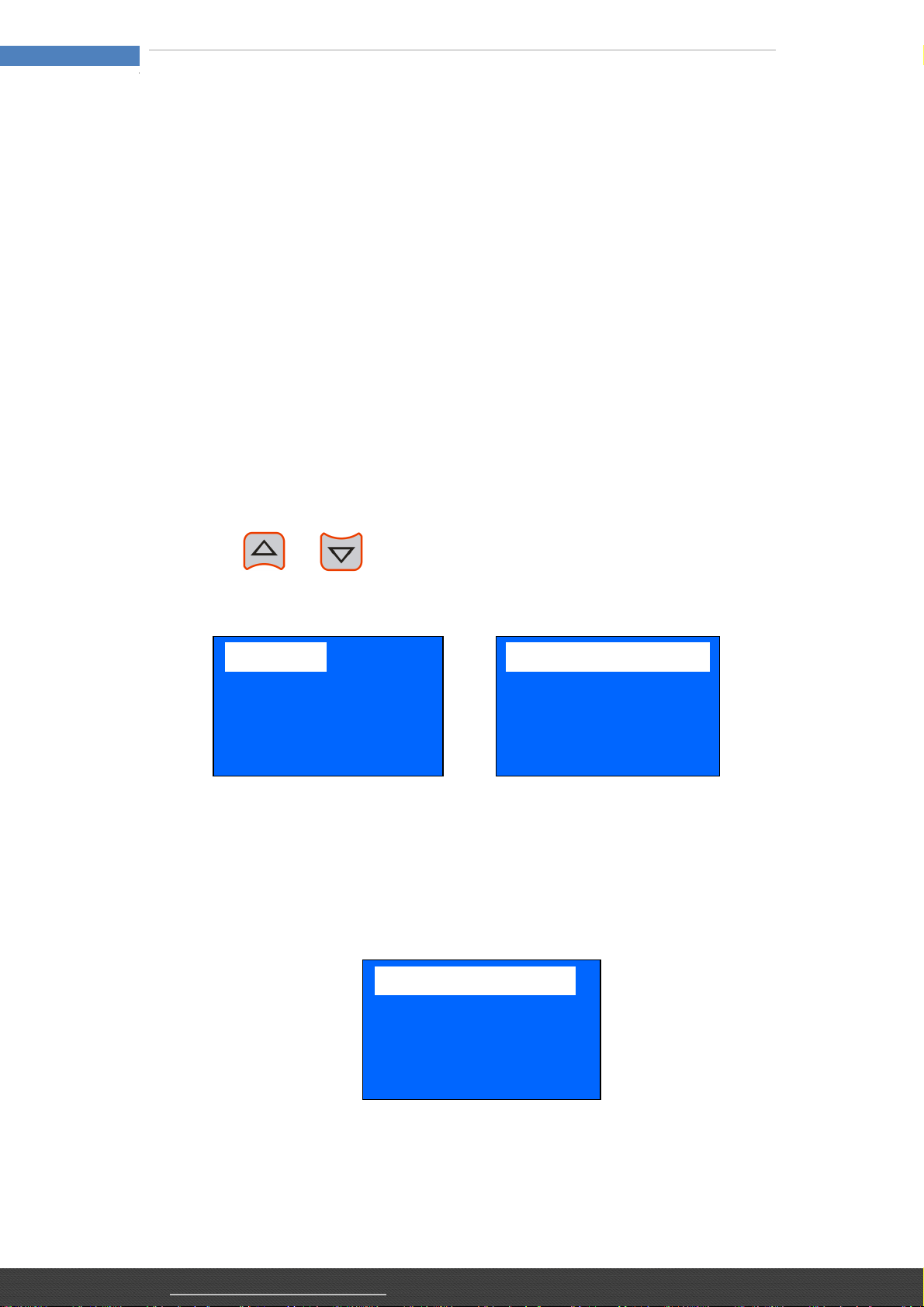

Let say if you need help on “How to operate”, press key in this selection

will get into the display as shown below:

Press key will scroll down to the next page to continue reading the text

(Fig. 8 and Fig 9) below.

Clips to Battery [+]

and [-]posts

Check battery

Rating [CCA,EN

If you wish to continue help on rest of the item like “Results, Voltage, CCA, Life”,

press key anytime will go back to the main menus (Fig. 5).

Here just select the item you want with key and then press key will

enter into the display screen with the explanation text.

To exit press key twice will go back to the main menu for you to begin testing.

(Fig.4)

Figure 8 Figure 9

Operation:Engine

Must be OFF.

Locate battery.

Clamp Tester.

Figure 7

DIN,JIS# & IEC]

and key the

value into the

Tester

5043 Farlin Ave. 800-949-1472(US)

Page 14

- 14 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

Select Test

_______________________________________________________________________________

6.0 - Battery Test

6.1 – Start Testing

Performing Battery Test whilst it is still in the car:

Vehicle that was running has to have its engine OFF first and then switch ON

the headlights for 30 seconds to remove the surface charge. After the

headlights had switched OFF, let the battery rest for at least 1 minute to

recover before testing commences.

The car engine and all other accessory loads must be OFF during test in order

to have accurate results. When attaching the analyzer clips, make sure that the

battery posts were not oxidized or badly corroded. Clean them first before

clamping to it. Do not clamp onto the steel bolts directly which may give

inaccurate and inconsistent results.

Testing on stand-alone batteries:

Clean the battery posts with a wire brush prior testing. For side - post batteries,

install stud adaptors. Do not use steel bolts for better results.

1. Attach the Analyzer clips onto the battery terminal posts [Red to (+) and

Black to (-)] the unit will power up and lights up the LCD display screen

as shown (Fig.10).

2. It will run through a self-test and when completed it displays the Main

Menu as shown: (Fig. 11)

Figure 10

New: ClearMemory

Continue Test...

LastTest Results

Figure 11

5043 Farlin Ave. 800-949-1472(US)

Page 15

- 15 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

_______________________________________________________________________________

Here, it will let you select your choice from the Menu:

New: Clear Memory

Selecting this item will allow the tester to clear the last tested results

stored in its memory and begin a new test.

Continue… Test

Selecting this item will allow you to continue the last test on the same

car from where you had stopped.

For example:

If you had done Battery Test and later you wish to do Alternator Test

or Grounding Test on the same car, just select this item and it will

update the results after each test in its memory so that it can be review

later or to be printed out from the printer.

Last Test Results

Here it will let you review the test results of the last tested car. The

results stored will always depends on the tests that you had done.

Use or keys to scroll for the pages during viewing.

Examples:

3. After you have made your choice, selecting “New: Clear Memory” or

RESULTS: Good

12.40V 419 CCA

Int.R: 6.43mΩ

LIFE: 76%

Figure 12

“Continue…Test” will proceed to the display below: (Fig. 14)

ENGINE GROUND

Results: OK

Resistance is

within limits.

Figure 13

Battery Test

Grounding Test

Starter Test

Alternator Test

Figure 14

5043 Farlin Ave. 800-949-1472(US)

Page 16

- 16 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

_______________________________________________________________________________

4. Pressing key once will scroll down to the next item if there is a

need to select it.

5. As an example (Fig.14) the selected item was on “Battery Test” and it is

being highlighted.

6. Press key will proceed to do the battery testing and if it has

detected any surface charge on the battery, it will start to remove and a

message is shown (Fig. 15) below.

7. If the surface charge is too great for the analyzer to handle, it will prompt

you with the instructions as shown: (Fig. 16) below.

8. Wait until the surface charge removal had completed, the analyzer will

advise as follows: (Fig.17) and then press key.

Removing Surface

Charge...

Please Wait!

Figure 15

Turn ign.key ON.

Headlights ON to

remove Surface

Charge...

Figure 16

Surface Charge

now removed. Key

& headlights OFF

Then press Enter

Figure 17

5043 Farlin Ave. 800-949-1472(US)

Page 17

- 17 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

Select Input

_______________________________________________________________________________

9. If there is no surface charge present, then it will straight away enter into

“Select Rating” menu screen as shown in Fig. 18

SANS DIN

CCA JIS#

EN Unknown

Figure 18

10. Before selecting the ratings ‘CCA, EN, IEC, DIN and JIS #’ from the

menu, check the battery specification value. This value can be checked

on the battery labels as some of the examples shown below:

5043 Farlin Ave. 800-949-1472(US)

Page 18

- 18 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

_______________________________________________________________________________

If it is selected under JIS # (Japanese Industrial Standard) then the

display will prompt you as shown (Fig.19) below.

Refer to the battery model (example: 80D26L or NX110-5L) on the

Cold Cranking Amps (CCA) Table list supplied separately or from this

manual on page 24 & 25 (See example Fig.20 below.)

Press key and the display will show: (Fig.21) below:

JIS# to CCA:

See user manual

for conversion

Enter to proceed

Figure 19

Figure 20

Input Value

Set 500 CCA⊳

Enter to start..

Figure 21

5043 Farlin Ave. 800-949-1472(US)

Page 19

- 19 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

_______________________________________________________________________________

11. Referring to the Table list (Fig.20) basing on 80D26L, check the battery

type: WET, MF, Sealed MF or Closed MF (CMF) as each category has

different CCA ratings. For instance, if the battery is a Sealed MF (CMF)

then it is rated at 630 CCA.

Note: WET - Wet Cell Type

MF - Maintenance Free Type

SMF - Closed or Sealed Maintenance Free

12. To enter the value 630, press key will increase the original value

of 500 (Fig.21) by step of 100 units to 600. Likewise use key to

increase the last two digits (00) to 30 by step of 5 units for each pressing.

(Fig. 22)

13. Once the CCA rating of the battery is confirmed, press key will

start the testing process. Refer to the display below (Fig. 23).

Input Value

Set 630 CCA⊳

Enter to start..

Figure 22

Analysing...

Please Wait!

ıııııııııııııııı

Figure 23

5043 Farlin Ave. 800-949-1472(US)

Page 20

- 20 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

1

3

_______________________________________________________________________________

14. For less than 5 seconds, the results of the testing will be displayed on

the LCD screen. (Fig. 24)

2

4

5

RESULTS: Good

12.40V 419 CCA

Int.R: 6.43mΩ

LIFE: 76%

Figure 24

Interpretations of the above results:

1. RESULTS: Good

A very straight forward display of the final results basing on the

evaluation of the tested condition. ‘Good’ indicates the battery

in good condition. ‘Replace’ indicates that the battery needs to be

replaced. If not, the battery will fail anytime without any warning.

2. Voltage : 12.40V

This indicates the tested battery voltage (12.46V). It depends

on the state of charge on the battery:

100% fully charged - 13.20V

90% charged - 12.90V

75% charged - 12.45V

3. CCA (Cold Cranking Amps): 419 CCA

CCA ratings has been used here, therefore the tested result is

in 406 CCA. If other rating (DIN or JIS, or IEC, or EN) were

selected, it will base on the respective rating to calculate and show

the results in that selected rating.

Please take Note:

This output value (406 CCA) is related to the actual power

available in the battery in relation to that battery's rating (630

CCA). On average, a new battery's CCA as measured by this

tester will read 10-15 % higher than its stated rating.

As the battery ages, the CCA number measured by this tester

5043 Farlin Ave. 800-949-1472(US)

Page 21

- 21 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

_______________________________________________________________________________

will decrease so it reads near its rating. While this value is not

the same as a CCA test, it is the best available measurement for

showing a battery's current condition in relation to its rating.

From the above example, a 630 CCA rated battery measuring

406 CCA available power does not mean that the battery would

pass a CCA test at 406 CCA. The available power reading shows

that the battery is not able to perform up to its rated ability (630

CCA).

In comparison to another battery when fully charged, the 630

CCA battery measuring 406 CCA is no stronger than a 400 CCA

battery showing 400 CCA available power when fully charged.

The available power number is meant for comparison to its own

rating. In fact, in this example the 630 CCA battery is failing to

perform to its rating, while the 400 CCA battery is still working.

Basing on SAE, CCA test is a manufacturing process control

test applicable only on new, fully charged batteries. It does not

produce an actual value, but is a PASS / FAIL test.

It measures the discharge load, in amps, that a battery can

supply for 30 seconds at 0°F/-18°C while maintainin g a voltage

of 1.2 volts per cell (7.2 volts per battery) or higher.

Thus, the CCA test shows the minimum power requirement for

the battery as rated, which means a battery rated at 400 CCA

must measure 7.2 volts or above for 30 seconds when a load of

400 amps is applied at 0°F/ -18°C.

The above methods also hold for DIN, IEC, JIS, EN basing on its

individual ratings.

4. Int. R (Internal Resistance): 6.43mΩΩΩΩ

In normal condition, the internal resistance should fall between

2.0 mΩ ~ 15.0 mΩ. As a matter of fact, the higher the battery

CCA readings obtained the lower the internal resistance should

be.

5. LIFE: 76 %

This is an indication of the battery life expectancy in percentage. If

the life falls below 45 %, the RESULT will display “Replace” and it

is time to change to a new battery.

5043 Farlin Ave. 800-949-1472(US)

Page 22

- 22 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

_______________________________________________________________________________

Explanation of the following terms used as shown on the LCD display:

• CCA (Cold Cranking Amps) – most commonly used Standard.

CCA is a rating used in the battery industry to rate a battery’s ability to

start an engine in cold temperatures. This rating is the number of

amperes that a new fully charged battery can delivery at 0°F (-18°C) for

30 seconds, while maintaining a voltage of at least 7.2 Volts for a 12V

battery.

The bigger the CCA will have the greater starting power of the battery.

• IEC (International Electro-technical Commission) Standard.

IEC amperes rating require that at 0°F (-18°C), the number of amperes

that the 12V battery can deliver while maintaining a voltage of at least of

8.4 Volts for 60 seconds during cranking.

• EN (European Norms) Standard

EN amperes rating require that at 0°F (-18°C), the number of ampere

that the 12V battery can deliver while maintaining a voltage of at least

6.0 Volts for 180 seconds during cranking.

• JIS# (Japanese Industrial Standard)

JIS # amperes’ rating is based on Ampere Hours and is calculated using

20 hours rating. In this manual, it is using CCA ratings reference table

list provided basing on the JIS model number (See page 24 & 25).

• DIN (Deutsches Institut für Normung)

German Institute for Standardization.

Basing on DIN , the rating requires that at 0°F (-18°C), the 12V battery is

able to deliver the number of amperes while maintaining a voltage of at

least of 9.0 Volts for 30 seconds and 8.0 Volts for 150 seconds during

cranking.

• Unknown

If you are not sure which ratings (CCA, EN, IEC, JIS or DIN) that the

battery is based on then choose this setting. It will show the battery’s

Voltage, CCA and the Internal Resistance (mΩ) only. This selection can

also be used to test 12V - Deep Cycle Batteries.

5043 Farlin Ave. 800-949-1472(US)

Page 23

- 23 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

_______________________________________________________________________________

An example of the results display is shown below: (Fig.25)

To determine the condition of the tested Deep Cycle Batteries, refer the

Voltage reading (should not fall below 12.6V when fully charged) and

the Internal Resistance [Int.R] (should not more 15mΩ) readings.

Batteries that had been left idle for long periods can still be tested with

this analyzer. To perform the test, just clamp the analyzer clips onto the

battery terminals and it will display the screen (Fig.26) as shown if its

voltage falls below the normal 12 volts and a buzzing sound is heard.

Press key to continue and the display will show: (Fig.27)

RESULTS:

12.40V 419 CCA

Int.R: 6.43mΩ

Figure 25

Voltage too low!

Press Enter to

continue..

Figure 26

Input Value

Set 500 CCA⊳

Enter to start..

Figure 27

5043 Farlin Ave. 800-949-1472(US)

Page 24

- 24 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

CMF

CMF

26A17R

34B17L

26A17L

34B19R

26A19R

34B19L

26A19L

34B19RS

28A19R

34B19LS

28A19L

36B20R

32A19R

36B20L

32A19L

36B20RS

26A17R

36B20LS

26B17L

38B20R

28B17R

38B20RS

28B17L

38B20L

28B19R

38B20LS

28B19L

40B20L

32B20R

40B20R

32B20L

42B20L

32C24R

42B20RS

32C24L

42B20LS

34B17R

46B24L

_______________________________________________________________________________

Check the battery ratings and enter it as described in step 10 and 11

(page 17~19) and the results will show as an example below: (Fig. 28)

RESULTS:

09.76V 38 CCA

Int.R: 70.09mΩ

LIFE:Charge>Test

Figure 28

You will notice that there is no indication of message (Good or Replace)

on the RESULTS instead on LIFE; it indicates “Charge > Test”. It means

that the battery has to be fully charged and repeat the test again.

15. Pressing the key at any moment will exit and return back to the

previous screen.

7.0 – Battery Ratings Charts

7.1 Japanese Industrial Standard (JIS#) CCA Ratings

Battery Model (JIS#)

NEW

OLD

200

200

12N24-4 200 220 264

12N24-3 200 220 264

NT50-N24 250

NT50-N24L 250

NX60-N24 270 295

NX60-N24L 270 295

200

200

245

245

NS40S 245

NS40LS 245

NS40 270

NS40L 270

N40 240 325 400

N40L 240 325 400

280

CCA Rating

WET

MF

SMF

Battery Model (JIS#)

NEW

OLD

280

NS40ZA 270 325 400

NS40ZAL 270 325 400

NS40ZAS 270 325 400

NS40ZALS 270 325 400

NS40Z 275 300 360

NS40ZL 275 300 360

NS40ZS 275 300 360

NS40ZLS 275 300 360

NX60-N24 330 340 410

NT60-N24S 330 340 410

NX60-24L 330 340 410

NX60-24LS 330 340 410

330

330

330

330

330

NS60L 325 360 420

CCA Rating

WET

MF

SMF

5043 Farlin Ave. 800-949-1472(US)

Page 25

- 25 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

CMF

CMF

46B24R

75D31L

46B24RS

80D23R

46B24LS

80D23L

46B26R

80D26R

46B26L

80D26L

46B26RS

85B60K

46B26LS

85BR60K

48D26R

95D31R

48D26L

95D31L

50B24L

95E41R

50B24R

95E41L

50D20R

105E41R

50D20L

105E41L

50D23R

105F51R

50D23L

105F51

50D26R

115E41R

50D26L

115E41L

55B24R

115F51R

55B24L

115F51L

55B24RS

130E41R

55B24LS

130E41L

55D23R

130F51R

55D23L

130F51L

55D26L

145F51R

55D26R

145F51L

60D23R

145G51R

60D23L

150F51R

65D23R

150F51L

65D23L

165G51R

65D26R

165G51L

65D26R

170F51R

65D31R

170F51L

65D31L

180G51R

70D23R

180G51L

70D23L

195G51R

75D23R

195G51L

75D23L

190H52R

75D26R

190H52L

75D26L

245H52R

75D31R

245H52L

_______________________________________________________________________________

Battery Model (JIS#)

NEW

OLD

NS60 325 369 420

NS60S 325 360 420

NS60LS 325 360 420

NS60 360

360

360

360

N50 280 360 420

N50L 280 360 420

NT80-S6L 390

NT80-S6 390

310 380 480

310 380 480

85BR60K 500

85B60K 500

50D20R 370

50D20L 370

NX100-S6 435 420 500

NX100-S6L 435 420 500

NT80-S6S 430 420 500

NT80-S6LS 430 420 500

355 480 500

355 480 500

N50ZL 350 440 525

N50Z 350 440 525

520

520

420 540 580

420 540 580

NS70 415 520 625

NS70L 415 520 625

N70 390 520 630

N70L 390 520 630

35-60 490 540 580

25-60 490 540 580

500 520 580

500 520 580

F100-5 490

F100-5L 490

N70Z 450 540 735

CCA Ratings Battery Model (JIS#)

WET MF

SMF

NEW

OLD

N70ZL 450 540 725

580

580

NX110-5 580 580 630

NX110-5L 580 580 630

500

500

NX120-7 620 660 850

NX120-7L 620 660 850

N100 515 640 770

N100L 515 640 770

N100Z 580 720 880

N100ZL 580 720 880

N100Z 580

N100ZL 580

NS120 650 800 960

NS120L 650 800 960

N120 650 800 960

N120L 650 800 960

NX200-10 800

NX200-10L 800

800

800

NS150 780 920

NS150L 780 920

N150 780 900 1100

NT200-12 640

NT200-12L 640

NS200 935 980

NS200L 935 980

NX250-12 1045

NX250-12L 1045

NT250-15 1090

NT250-15L 1090

NX300-51 1145

NX300-51L 1145

N200 925 1100 1300

N200L 925 1100 1300

NX400-20 1530 1250

NX400-20L 1530 1250

CCA Ratings

WET MF

SMF

5043 Farlin Ave. 800-949-1472(US)

Page 26

- 26 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

Battery

Amps

Battery

Amps

DIN

EN

DIN

EN

52805

55057

52815

55068

53517

55069

53520

55218

53521

55414

53522

55415

53621

55421

53624

55422

53625

55423

53638

55427

53646

5542

8

53653

55457

53836

55529

53890

55530

54038

55531

54039

55545

54232

55548

54312

55552

54313

55559

54317

55559L

54324

55563

54434

55564

54437

55565

54449

55565L

54459

55566

54459L

55567

54464

55811

54465

56012

54466

56048

54469

56049

54519

56068

54523

56069

54524

56073

54533

56077

54537

56091

54545

56092

54551

56111

54577

56216

54578

56218

54579

56219

54580

56220

54584

56225

54590

56311

54612

56312

54801

56318

54827

56322

55040

56323

55041

56420

55042

56530

55044

56618

55046

56619

55048

56620

55056

56633

_______________________________________________________________________________

7.2 DIN & EN Standards Rating Chart

Model No.

180 240

180 240

175 300

150 240

150 240

150 240

175 300

175 300

175 300

175 300

175 300

175 300

175 300

175 300

175 300

175 300

175 300

210 360

220 330

210 360

220 330

210 360

210 360

210 360

210 360

210 360

220 330

210 360

210 360

210 360

210 360

220 300

220 300

210 360

190 300

190 300

220 300

220 300

220 300

220 300

220 300

220 300

210 330

210 360

190 300

240 360

265 450

220 360

220 360

265 450

300 510

300 540

320 540

Model No.

320 540

220 390

220 390

255 420

265 450

265 450

265 450

265 450

300 510

300 510

300 510

265 450

220 360

255 420

255 420

255 420

255 420

255 420

255 420

255 420

255 420

255 420

255 420

255 420

265 450

255 420

360 540

230 420

250 390

250 390

250 390

250 390

250 390

300 510

360 540

300 510

300 540

300 510

300 510

300 510

280 510

300 510

300 510

300 510

300 510

300 510

300 510

300 510

300 510

300 510

300 510

300 510

300 510

5043 Farlin Ave. 800-949-1472(US)

Page 27

- 27 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

Battery

Amps

Battery

Amps

DIN

EN

DIN

EN

56638

60026

56641

60038

55647

60044

56821

60527

56820

60528

56828

61017

57024

61018

57029

61023

57113

61047

57114

61048

57217

62034

57218

62038

57219

62045

57220

62529

57230

63013

57412

63545

57412L

63549

5

7413

64020

57512

64028

57513

64035

57531

64036

58424

64317

58513

64318

58514

64323

58515

65513

58521

65514

58522

65515

58527

67043

58811

67045

58815

68021

58820

68032

58821

68034

58827

68040

58833

70027

58838

7

0029

59017

70036

59018

70038

59040

71014

59215

71015

59218

72512

59219

73011

59226

88038

59514

88046

5951

8

88056

59519

88066

59615

88156

59616

88074

60018

88092

60019

_______________________________________________________________________________

Model No.

300 510

300 510

300 510

315 540

315 540

315 540

315 540

315 540

400 680

400 680

420 720

420 720

420 720

420 720

380 640

400 680

400 680

400 680

350 570

350 570

350 570

450 760

320 540

320 540

450 760

320 540

320 540

395 640

440 720

395 640

395 640

395 640

400 640

400 680

400 680

360 600

360 600

360 600

450 760

290 480

290 480

450 760

320 540

395 640

395 640

360 600

360 600

250 410

250 410

Model No.

440 720

500 760

500 760

410 680

410 680

400 680

400 680

450 760

450 760

450 760

420 680

420 680

420 680

450 760

470 680

420 680

420 680

325 550

520 760

520 760

460 760

540 900

540 900

540 900

540 900

570 900

570 900

600 1000

600 1000

570 950

600 1000

600 1000

570 950

630 1050

630 1050

570 950

630 1050

700 1150

700 1150

680 1150

740 1200

175 300

210 360

265 450

300 510

320 540

400 680

400 680

5043 Farlin Ave. 800-949-1472(US)

Page 28

- 28 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

Battery

Battery

24-500

75A-72

34-6MF

75-660

34-60

78A-72

34-610MF

78-710

34-710

GR40R

-MF

35-580

GR40R

-

CMF

41-580

GTH40

55D23R

GTH40L

58-6MF

GTH40S

58-60

GT50L

58-530

GTH55DL

65-70

GTH60L

65-730

GTH60DL

65-900

GTH75DL

74-60

GTH75DR

75-6MF

GR96R

-MF

75-72

GR96R

-

CMF

_______________________________________________________________________________

7.3 YUASA Battery Rating Chart

Model No.

CCA

500

500

525

610

710

580

580

522

530

525

530

700

730

850

525

615

500

Model No.

CCA

630

660

670

710

700

820

277

276

275

356

356

325

325

520

521

500

580

7.4 Rough CCA Guide

Given below is a rough CCA ratings guide for any unknown battery model

basing on the capacity of the vehicle:

Vehicle Capacity Approximate Battery CCA Rating

1200 ~ 1600 cc 350 CCA

1600 ~ 2000 cc 500 CCA

2000 ~ 3000 cc 650 CCA

3000 cc and above 750 CCA

M. Benz over 3000 cc 760 CCA

5043 Farlin Ave. 800-949-1472(US)

Page 29

- 29 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

Select Test

_______________________________________________________________________________

8.0 – Grounding Test

The engine body and the vehicle chassis are always connected to the battery

negative terminal to provide the electrical return path (grounding) for all the

electrical components. Due to the surrounding environmental effect, the

surface contacts of these joints or connections of these circuits will subject to

oxidation and corrosion in a matter of time rendering them to have high

resistance in it. One typical example is the connection at the battery

terminals where oxidation and corrosion takes place very often. If these

contacts were no good then it will pose a lot of electrical problems to the

vehicle.

To check the grounding condition, this Analyser will measure the resistance

from the engine body contact to the battery terminal then it will display the

results and the recommendations.

8.1 – Start Testing

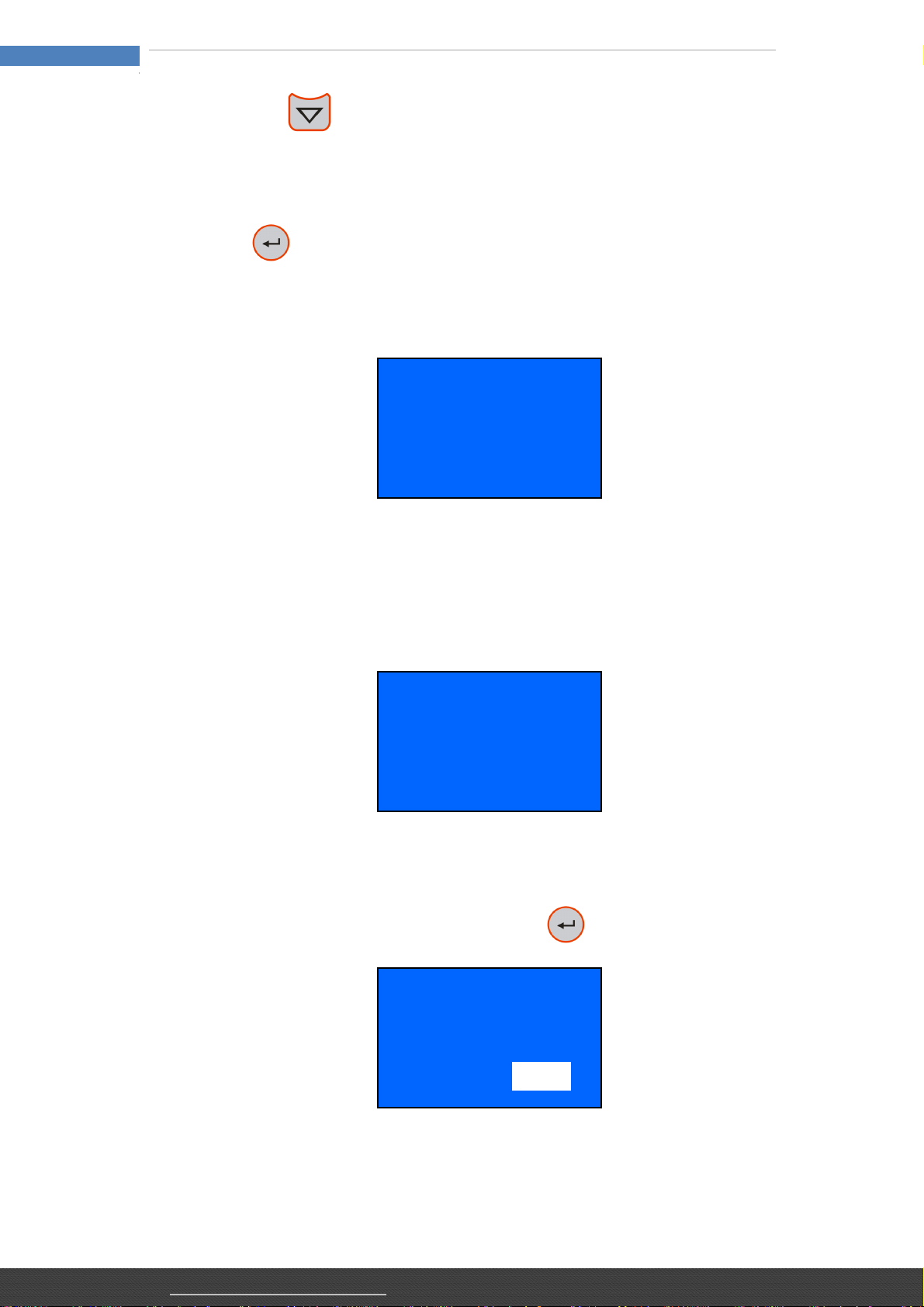

1. Make sure that the engine is switched OFF. Attach the clips onto the

battery terminal posts and the analyzer will power up and lights up the

LCD display screen as shown (Fig.29).

2. It will run through a self-test and when completed it displays the Main

Menu as shown: (Fig. 30)

New: ClearMemory

Continue Test...

LastTest Results

Figure 29

Figure 30

5043 Farlin Ave. 800-949-1472(US)

Page 30

- 30 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

_______________________________________________________________________________

3. After you have made your choice, selecting “New: Clear Memory” or

“Continue…Test” will proceed to the display below: (Fig. 31)

4. Pressing key once will scroll down to the ‘Grounding Test’

(Fig.32)

5. Press key will proceed to the display as follows: (Fig. 33)

6. Now transfer the BLACK tester clip from the battery [-] terminal to a

suitable position on the engine or chassis body leaving the RED clip still

attached to the battery [+] terminal.

Battery Test

Grounding Test

Starter Test

Alternator Test

Figure 31

Battery test

Grounding Test

Starter Test

Alternator Test

Figure 32

Red clip to Batt

[+],Black clip

To Engine body.

Then press Enter

Figure 33

5043 Farlin Ave. 800-949-1472(US)

Page 31

- 31 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

_______________________________________________________________________________

7. Press key again and it will starts analyzing (Fig. 34)

8. Once it has finished analyzing, it will prompt you with an instruction

(Fig. 35) stating that you have should unclamp the Black tester clip from

the engine or chassis body and transfer to the battery negative [-]

terminal within 20 seconds time limit if not the testing procedure has to

be repeated again as the gathered data will be lost.

Analysing...

Please Wait!

ıııııııııııııııı

Figure 34

9. Once the Black clip is clamped onto the battery [-] terminal, the

Analyzer display will light up as shown. (Fig. 36)

Now clamp the

Black clip to

battery [-] post

20sec time limit

Figure 35

GROUNDING TEST:

Press Enter to

continue.

Figure 36

5043 Farlin Ave. 800-949-1472(US)

Page 32

- 32 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

ENGINE GROUND

_______________________________________________________________________________

10. Now you need to press key to proceed and the display will show

as follows (Figure 37).

10. If the measured resistance reading is within limits, then it will display

as follows (Fig. 38)

11. If the measured resistance reading has gone beyond the limits, then it

will display the screen as follows (Fig. 39).

Analysing...

Please Wait!

ıııııııııııııııı

Figure 37

ENGINE GROUND

Results: OK

Resistance is

within limits.

Figure 38

Results: HIGH

Clean contacts

And check cables

Figure 39

5043 Farlin Ave. 800-949-1472(US)

Page 33

- 33 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

_______________________________________________________________________________

Note:

The above indicates that the ground contact from the engine body

to the battery is bad. Check for rusted or corroded point of

contacts. If found, dismantle it for cleaning or replace before fixing

back. Repeat the test again after fixing.

Another thing is that if you suspect that the result is in question,

you may conduct the test with the Black clip clamp at different

location.

12. If you did not follow the right procedures during the testing, it will

display the results as follows (Fig. 40) below:

ENGINE GROUND

Not detected...

Try again follow

right procedure

Figure 40

13. To exit the program, pressing the key at any moment will exit

and return back to the main menu screen (Fig.30).

5043 Farlin Ave. 800-949-1472(US)

Page 34

- 34 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

_______________________________________________________________________________

9.0 – Starter Test

This test actually checks the cranking effectiveness of the battery and

also can predicts when the battery will fail to crank a vehicle.

This Analyzer is designed to address the weakness of conventional

testers with its cranking power measurements. Simply connect the

analyzer to the battery in the vehicle and start the engine!

To understand the working principle of the tests, let’s look at the wave

form displays taken during the cranking tests with an oscilloscope.

Figure (A) above shows the voltage profile of a healthy battery during

the cranking of an engine. The graph starts off at the battery's nominal

voltage, and a voltage drop is detected when the vehicle is cranked.

The voltage recovers to the battery's nominal voltage and eventually

rises to approximately 14.4 V when the alternator starts charging the

battery.

For Figure (B) where a typical 2 year-old battery, you noticed the

difference in the voltage drop which indicates that it is weaker but still

usable.

Whereas Figure (C) represents a very weak battery that can barely

crank a car and is due to fail in the very near future.

As voltage profiles can indicate the relative ability of the tested battery in

starting an engine, so there is no need for knowledge on the starter

motor requirement or the battery's rating and size.

MODEL 12-1012 will capture the highest voltage drop and calculate the

final results which should not be lower than 9.6V average during

cranking and computes the result after the test.

5043 Farlin Ave. 800-949-1472(US)

Page 35

- 35 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

Select Test

_______________________________________________________________________________

9.1– Begin Testing

1. With engine OFF, place the vehicle transmission in NEUTRAL for

Manual and PARK for Automatic then apply the parking brake.

2. Connect the analyzer to the battery terminals and the display will light

up as shown (Fig 41).

3. After you have made your choice, selecting either “New: Clear Memory”

or “Continue…Test” will proceed to the display below: (Fig. 42)

4. From the main MENU, select ‘Starter Test’ by scrolling down using

New: ClearMemory

Continue Test...

LastTest Results

Figure 41

Battery Test

Grounding Test

Starter Test

Alternator Test

Figure 42

key. (Fig.43)

Battery Test

Grounding Test

Starter Test

Alternator Test

Figure 43

5043 Farlin Ave. 800-949-1472(US)

Page 36

- 36 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

_______________________________________________________________________________

2. Press key to continue and the display will show: (Fig.44)

3. Switch the ignition key to ON and start cranking the engine until it

starts. Immediately after that press key and the results will

Voltage: 12.65V

Crank engine now

until it starts.

Then press Enter

Figure 44

show as follows (Figure 45):

4. If the voltage drop is too great during the cranking, the tested results

will display as follows (Figure 46) and will prompt you to check the

starter system.

CRANKING TEST

MinVolts: 10.26V

VoltDrop: Normal

Results: OK

Figure 45

MinVolts: 9.56V

VoltDrop: HIGH

Chk Starter Sys

Battery has aged

Figure 46

5043 Farlin Ave. 800-949-1472(US)

Page 37

- 37 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

_______________________________________________________________________________

5. During cranking when it detects that there is no drop in voltage, it will

display the following screen (Figure 47).

CRANKING TEST

Not detected...

Check connection

and test again.

Figure 47

6. Pressing the key at any moment will exit and return back to

the previous screen.

5043 Farlin Ave. 800-949-1472(US)

Page 38

- 38 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

_______________________________________________________________________________

10.0 – Alternator Test

An alternator is the device used to produce the electricity the car needs to

run and to keep the battery charged. The alternator uses the principle of

electromagnetic induction to produce voltage and current. The four main

parts of the alternator are the Rotor, Stator, Diode Pack, Voltage Regulator

and an Ammeter or Indicator Light to inform the driver of any problems. All

of these parts must be in good working order for the alternator to do its job.

The Rotor is a coil of wire wound around an iron core. The Rotor rotates as

the alternator shaft rotates and current passes through brushes. The Rotor

winding passes the Field current. This causes the Rotor to produce a

magnetic field. So basically the Rotor is a rotating electro magnet.

The Stator is a set of three windings fixed to the case of the alternator and

these windings are static i.e. they don’t rotate. As the Rotor rotates its

magnetic field “cuts” each Stator winding in turn, this induces a current in

each winding. The outputs from the Stator windings are 120 degrees apart

and are alternating current (AC).

But vehicles run on DC current, so we need something that will convert the

AC current to DC current. This is the job of the diode pack. A diode is an

electrical one-way check valve that will let current flow in only one direction.

The typical diode pack uses four diodes to accomplish this. AC current is

feed in on one side of the diode pack and DC current comes out the other

side. The diode pack here will rectify the alternating 3 phases from the

Stators and combine them into a single Direct Current which also works

the dash ammeter or indicator light.

Now that we have a DC current that the vehicle can use, we need a way to

control that current. That is the job of the voltage regulator. As the name

implies, it regulates the voltage going to the battery. It does this by turning

current to the field (stator) terminal of the alternator on and off.

If the battery voltage goes below 13.5 volts, the voltage regulator sends

current to the field terminal and allows the alternator to start charging.

Current will then flow into the battery and bring it up to full charge.

5043 Farlin Ave. 800-949-1472(US)

Page 39

- 39 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

_______________________________________________________________________________

If the voltage goes above 15.0 volts, the voltage regulator shuts off the

current to the field terminal and keeps the battery from overcharging and

cooking itself. This is how the voltage regulator controls the alternator

output.

When you first start your vehicle, the alternator needs some current to start

working. The voltage regulator supplies this current from the battery to the

field (stator) terminal of the alternator to get it started.

The state of charge of the battery controls amperage output of the

alternator. When the battery has a full charge, the electro-motive force of

the voltage lowers the amperage to almost zero. As the battery charge

wears down, the electro-motive force is not enough to stop the amperage,

so it flows into the battery and charges it again.

10.1 – Start Testing

This test is to check the MAX and MIN charging voltages output of the

alternator at 3000 RPM without load and 2000 RPM with all loads ON. With

this test you can determine the alternator’s condition when in reference with

the vehicle’s Service Manual.

No load testing at 3,000 RPM

1. With engine OFF, place the vehicle transmission in NEUTRAL for

Manual and PARK for Automatic and apply the parking brake.

2. Attach the Analyzer clips onto the battery terminal posts and it will

power up and lights up the LCD display screen as shown (Fig.48)

Figure 48

5043 Farlin Ave. 800-949-1472(US)

Page 40

- 40 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

_______________________________________________________________________________

3. It will run through a self-test and when completed it displays the Main

Menu as shown: (Fig. 49)

4. After you have made your choice, selecting either “New: Clear Memory”

or “Continue…Test” will proceed to the display below: (Fig. 50)

Pressing key to scroll down to the ‘Alternator Test’ (Fig.51)

5. Press key to continue and the display will show: (Fig.52)

Select Test

New: ClearMemory

Continue Test...

LastTest Results

Figure 49

Battery Test

Grounding Test

Starter Test

Alternator Test

Figure 50

Battery Test

Grounding Test

Starter Test

Alternator Test

Figure 51

Starter Engine and

keeps it running

Then press Enter

Figure 52

5043 Farlin Ave. 800-949-1472(US)

Page 41

- 41 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

Charging Volts

at 3,000 RPM

3000RPM

13.96V

_______________________________________________________________________________

Start the engine and then press key again and the screen will

prompt you as shown below (Fig. 53).

Make sure that all loads (lights, air-condition, etc) are OFF.

Rev engine up to

3,000 rpm Enter

Continue this

rpm for 10 sec.

Figure 53

Rev the engine up to 3,000 ~ 3,500 RPM by referring to the dashboard

meter, then press key and maintain it for about 10 seconds and

release the pedal. The maximum and minimum voltages values will be

captured.

After that press key again and it show as below (Fig 54.)

No load Test

Captured Volts

readings

With the captured readings, analysis can done by referring to the limits

as indicated that MAX voltage should not exceed 15.0V (max.

voltage at 3,000 RPM) and MIN voltage should be more than 13.3V

(min voltage during idling speed).

Max 14.07V <15.0V

Min 13.55V >13.3V

Enter to proceed

Figure 54

Average

Normal Charging

Volts range

5043 Farlin Ave. 800-949-1472(US)

Page 42

- 42 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

_______________________________________________________________________________

6. Press key will show the results of the test (Figure 55):

7. If either minimum or maximum charging volts are not within the voltage

range limits then it will display one of the screen as below (Figures 56 &

57) and it will prompt you to check the charging system for the fault.

NO LOAD TEST

MinCharge: 12.96V

Results: LOW

Check Belt/Alt

Testing with load at 2,000 RPM

As more electrical accessories, such as lights, heater, air condition, car

stereos, etc. were used; the electro-motive force decreases and this will

allow more amperage from the alternator to flow into the battery to

compensate for the added load. This test is to check the alternator’s

behavior during loading.

8. Continue from the previous test (either Fig. 55, 56 or 57); proceed to

the next step by pressing key will enter to the display as follows.

(Fig.58)

Figure 56 Figure 57

NO LOAD TEST

ChrgVolts: 13.96V

Results: GOOD

Enter to proceed

Figure 55

NO LOAD TEST

MaxCharge: 15.0V

Results: High

Check Regulator

Switch ON all

The Electrical

Loads, then

press Enter

Figure 58

5043 Farlin Ave. 800-949-1472(US)

Page 43

- 43 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

Charging volts.

at 2,000 RPM

_______________________________________________________________________________

Now, switch ON all loads (Head Lights, Radio, Air-condition, Heater, etc)

and press enter key will display: (Fig.59)

Make sure that all electrical loads (lights, air-condition, etc) are ON.

Rev the engine up to 2,000 ~ 2,500 RPM by referring to the dashboard

meter, then press key and maintain it for about 10 seconds and

Rev engine up to

2,000 rpm Enter

Continue this

rpm for 10 sec.

Figure 59

release the pedal. The maximum and minimum voltages values will be

captured.

After that press key again and it show as below (Fig 60.)

Loading Test

Captured Volts

readings

With the captured readings, analysis can done by referring to the limits as

indicated that MAX voltage should exceed 13.5V (max. voltage at 2,000

RPM) and MIN voltage should be more than 12.5V (min voltage during

idling speed).

9. Press key will proceed to show the results of the test:

2000RPM 13.89V

Max 13.96V >13.5V

Min 13.76V >12.5V

Enter to proceed

Figure 60

LOAD TEST

ChrgVolts: 13.96V

Results: GOOD

Average

Normal

Charging range

Figure 61

5043 Farlin Ave. 800-949-1472(US)

Page 44

- 44 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

_______________________________________________________________________________

If either minimum or maximum charging volts are not within the voltage

range limits then it will display one of the screen as below (Figures 62& 63)

and it will prompt you to check the alternator system for the fault.

LOAD TEST

MinCharge: 12.45V

Results: LOW

Check Belt/Alt

10. To exit the program, pressing the key at any moment will exit and

return back to the previous screen.

Figure 62 Figure 63

LOAD TEST

MaxCharge: 13.36V

Results: LOW

Check Belt/Alt

5043 Farlin Ave. 800-949-1472(US)

Page 45

- 45 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

Select Test

PC

_______________________________________________________________________________

11.0 – View Last Test Results

To view the results of the last test, the MODEL 12-1012 has to be connected to

an external power source by either clamping its clips directly to a 12Volt car

battery or connected to a PC via the USB port.

1. Once power up, the wakeup screen will display as follows:

Figure 64

Figure 65

2. It will run through a self-test and when completed it displays the Main

Menu as shown: (Fig. 66)

New: ClearMemory

Continue Test...

LastTest Results

Figure 66

Clamp MODEL 12-1012

to a 12V Battery if it is

not connected to a PC

for viewing Last Test

Results.

5043 Farlin Ave. 800-949-1472(US)

Page 46

- 46 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

Select Test

_______________________________________________________________________________

3. Pressing key once will scroll down to the ‘Last Test Results’

Fig. 67 below.

4. Press key will proceed to display the last test results depending

the type of test you had performed earlier. (Fig. 68)

5. To view the next page, press or key to get to the page you

want.

Some examples below are: (Figs. 69, 70, 71 & 72)

CRANKING TEST

MinVolts: 10.26V

VoltDrop: Normal

Results: OK

Figure 69 Figure 70

NO LOAD TEST

ChrgVolts: 13.96V

Results: GOOD

Enter to proceed

Figure 71 Figure 72

New: ClearMemory

Continue Test...

LastTest Results

Figure 67

RESULTS: Good

12.40V 419 CCA

Int.R: 6.43mΩ

LIFE: 76%

Figure 68

ENGINE GROUND

Results: OK

Resistance is

within limits.

LOAD TEST

MaxCharge: 13.36V

Results: LOW

Check Belt/Alt

5043 Farlin Ave. 800-949-1472(US)

Page 47

- 47 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

_______________________________________________________________________________

12.0 –Setting up the PC ready for MODEL 12-1012

12.1 - Installing Driver.

Important Note:

Before you start to install the driver, please do not plug the Analyzer into the

computer’s USB port or else the installation will fail and the computer cannot

detect the proper driver when it is connected.

If you have made the above error and wish to install the driver the second time,

you need to uninstall the previously installed driver first before starting to

reinstall again. This time make sure that the Analyzer is not plugged in.

Step 1. You can install the driver from the CD provided or download it

from our website:

http://associatedequip.com/downloads/12-1012-15_Drivers.zip

First click to open the folder:

You will find the following files:

Step 2. Double click on the icon . The installation will start

automatically. Typical example below is for Windows 7 operating

system.

5043 Farlin Ave. 800-949-1472(US)

Page 48

- 48 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

_______________________________________________________________________________

As instructed, click [Next>] tab the program will continue to install

the driver on the computer. Once it had finished, it will prompt

you as shown below. Click [Finish] tab to complete the

installation.

Step 3. Next open this folder again:

Look for the program icon (see below).

Then double click it. The software will start to install and will

prompt with the display below:

Click “OK” tab to continue the installation and the software will be

successfully installed.

5043 Farlin Ave. 800-949-1472(US)

Page 49

- 49 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

_______________________________________________________________________________

Step 4. Now plug the Analyzer into any one of the PC USB ports.

Step 5. On the PC, go to desktop display and look for icon.

Left click on this icon to open the program and the display page

will show as below:

It will automatically

detect the COM Port.

If you find that this field

is blank, close the

program, unplug the

analyzer cable and

then plug back again.

Repeat Step 5 to open

the program. The

COM Port(s) will now

appear in the drop

down menu.

Click here to select your

preferred language from the

list of languages shown.

Click here to put your Company

name and address.

Step 6. Now press the communication key on the Analyzer to log

onto the computer; To confirm whether there is communication;

click on [Get Data From Analyser] tab and the Last Test Result

will appear. See example below:

You can type in

the particulars

here and then

click [Add to Test

Report] tab to be

included in the

test report which

will be stored

and printed out if

you wish.

If there is no communication, a message text box will appear

(see below).

5043 Farlin Ave. 800-949-1472(US)

Page 50

- 50 -

Model 12-1012 Users’ Manual Version 13.08

Associated Equipment Corp.

St. Louis, MO 63115

314-385-5178 (Outside US)

_______________________________________________________________________________

In this case, unplug the Analyzer from PC and repeat Step 4 to

Step 6. If problem persist, then select an alternate COMPORT

individually from the dropdown list and click [Get Data From

Analyser] tab to see whether the Last Test Result will appear

(as displayed in Step 6).

If the above fails again, then try plugging the Analyzer to the PC’s

another USB port and repeating Step 4 to 6 again.

12.2 Printing Results from normal printer:

While on this page, if you wish to print out the results, make sure that

your printer is connected to the computer. Click on [PRINT] tab and a

text box will appear. Select the right printer and click [Print] tab to print.

Select the

printer which is

connected to

your computer

here.

12.3 Saving Results: