ASSALOY YRHCPZW0 User Manual

IC Radio Standards Specification: RSS-210

Models: YRD220-ZW, YRD210-ZW, YRT210-ZW, YRT220-ZW

Certification Exhibit

FCC ID: U4A-YRHZPZW0

IC: 6982A-YRHZPZW0

FCC Rule Part: 15.249

ACS Project Number: 12-0002

Manufacturer: Assa Abloy Inc.

Manual – YRT220-ZW

5015 B.U. Bowman Drive Buford, GA 30518 USA Voice: 770-831-8048 Fax: 770-831-8598

Yale Real Living™ Touchscreen Lever

Installation and Programming Instructions

NOTE TO INSTALLER

FAILURE TO FOLLOW THESE INSTRUCTIONS

COULD RESULT IN DAMAGE TO THE PRODUCT

AND VOID THE FACTORY WARRANTY

This document is available on our website in printed Spanish and French. Go to www.yalerealliving.com.

Este documento está disponible en español en nuestra página de internet. Vaya a www.yalerealliving.com.

Ce document est disponible sur notre site Web dans le français imprimé. Allez à www.yalerealliving.com.

An ASSA ABLOY Group brand

For Technical Assistance call Yale at 1-800-810-WIRE (9473)

Click "Product Information & Documentation" and then "Installation Instructions".

Presione "Información del Producto y Documentación" y luego "Instrucciones de Instalación".

Cliquez sur le "Information sur le produit et Documentation" et puis "Installation Instructions".

P/N AYRT-220-INST-FUL Rev A

TABLE OF CONTENTS

Warnings .........................................................................................................................2

Return Lock to Factory Default ................................................................................3

Introduction .....................................................................................................................3

Installation

Components and Tools .............................................................................................4

Prepare Lock for Installation ................................................................................. 5-6

Install Lock .......................................................................................................... 6-11

Programming

Programming Features-Menus-Keys-Definitions ............................................. 12-13

Operation .......................................................................................................... 14-16

Miscellaneous Information

Hardware Troubleshooting .....................................................................................17

Programming Troubleshooting ...............................................................................18

Installing the Network Module ...............................................................................19

Sample Pin Code Management Sheets ........................................................... 23-24

WARNINGS

Warning: Changes or modifications to this device not expressly approved by Yale Security, Inc.

could void the user's authority to operate the equipment.

IMPORTANT: The accuracy of the door preparation is critical for the proper functioning and

security of this product. Misalignment can cause performance degradation and a lessening of

security.

Finish Care: This lockset is designed to provide the highest standard of product quality and performance. Care should be taken to ensure a long-lasting finish. When cleaning is required use a soft, damp

cloth. Using lacquer thinner, caustic soaps, abrasive cleaners or polishes could damage the coat-

ing and result in tarnishing.

FCC:

FCC ID: U4A-YRHCPZW0 (Z-Wave); U4A-YRHCPZB0 (Zigbee)

Model(s): YRT220-ZW, YRT220-ZB

This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against

harmful interference in a residential installation. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions, may cause harmful

interference to radio communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful Interference to radio or television reception,

which can be determined by turning the equipment off and on, the user is encouraged to try to correct

the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver

is connected.

• Consult the dealer or an experienced radio/TV technician for help.

An ASSA ABLOY Group brand

2

P/N AYRT-220-INST-FUL Rev A

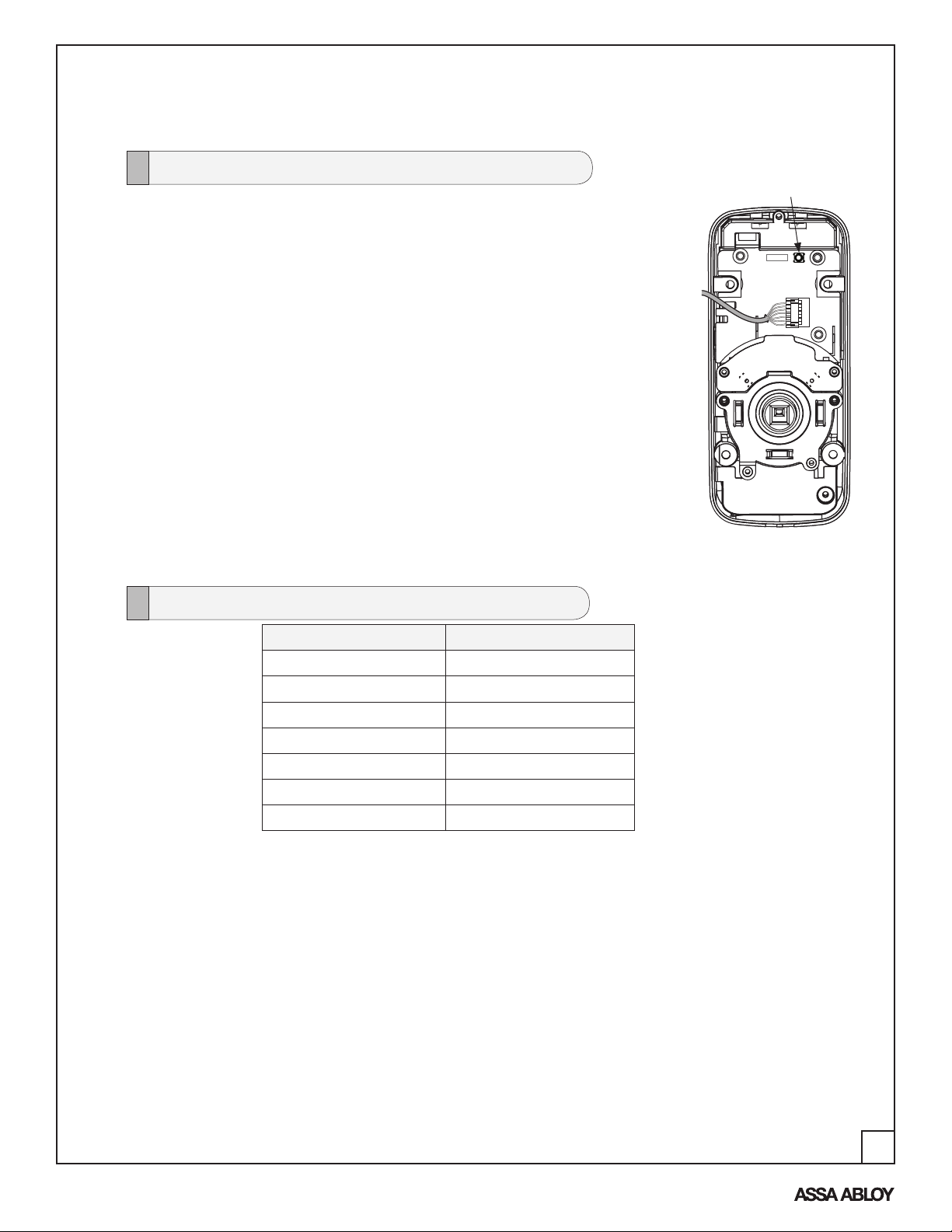

To reset the lock to factory default, see the following:

Reset Lock to Factory Default

Reset Button

The following procedure returns the lock to its factory defaults

by deleting all user codes (including the Master PIN code*) and

returning all programming features to their original default settings

(see below).

1. Remove the batteries and then remove the inside escutcheon

to access the reset button.

2. The reset button (see image at right) is located above the

PCB cable connector.

3. Hold down the reset button for a minimum of 3 seconds and

then reinstall the batteries; once the batteries are properly

installed, release the reset button.

All features (including adjustable settings** (see below) should

now be returned to factory default.

Upon reset, Master Code Registration is the only option available

and must be performed prior to any other programming of the lock.

See "Operation" later in this manual for programming instructions.

Inside Escutcheon

Factory Default Settings

Master Code Registration required

Auto Re-lock Enabled

One Touch Re-Lock Enabled

Auto Re-lock Time **30 Seconds

Wrong Code Entry Limit **5 Times

Shutdown Time **60 Seconds

**Adjustable only when using Network Module

Settings Factory Default

Audio Enabled

An ASSA ABLOY Group brand

3

P/N AYRT-220-INST-FUL Rev A

Industry Canada:

Canadian ID: 6982A-YRHCPZW0 (Z-Wave); 6982A-YRHCPZB0 (Zigbee)

Model(s): YRT220-ZW, YRT220-ZB

This Class B digital apparatus meets all requirements of the Canadian Interference Causing Equipment

Regulations. Operation is subject to the following two conditions: (1) this device may not cause harmful

interference, and (2) this device must accept any interference received, including interference that may

cause undesired operation.

Cet appareillage numérique de la classe B répond à toutes les exigences de l’interférence canadienne

causant des règlements d’équipement. L’opération est sujette aux deux conditions suivantes: (1) ce

dispositif peut ne pas causer l’interférence nocive, et (2) ce dispositif doit accepter n’importe quelle

interférence reçue, y compris l’interférence qui peut causer l’opération peu désirée.

For the U4A-YRHCPZB0 and 6982A-YRHCPZB0, the following statement applies:

“This equipment complies with FCC/IC radiation exposure limits set forth for an uncontrolled

environment. This equipment should be installed and operated with minimum distance 20cm between

the radiator and your body. This transmitter must not be co-located or operating in conjunction with any

other antenna or transmitter.”

Section 7.1.2 of RSS-GEN Under Industry Canada regulations, this radio transmitter may only operate

using an antenna of a type and maximum (or lesser) gain approved for the transmitter by Industry

Canada. To reduce potential radio interference to other users, the antenna type and its gain should be

so chosen that the equivalent isotropically radiated power (e.i.r.p.) is not more than that necessary for

successful communication.

En vertu des règlements d'Industrie Canada, cet émetteur radio ne peut fonctionner avec une antenne

d'un type et un maximum (ou moins) approuvés pour gagner de l'émetteur par Industrie Canada. Pour

réduire le risque d'interférence aux autres utilisateurs, le type d'antenne et son gain doivent être choisies

de façon que la puissance isotrope rayonnée équivalente (PIRE) ne dépasse pas ce qui est nécessaire

pour une communication réussie.

Section 7.1.3 of RSS-GEN This Device complies with Industry Canada License-exempt RSS standard(s).

Operation is subject to the following two conditions: 1) this device may not cause interference, and 2)

this device must accept any interference, including interference that may cause undesired operation of

the device.

Cet appareil est conforme avec Industrie Canada RSS standard exemptes de licence(s). Son

fonctionnement est soumis aux deux conditions suivantes: 1) ce dispositif ne peut causer des

interférences, et 2) cet appareil doit accepter toute interférence, y compris les interférences qui peuvent

causer un mauvais fonctionnement du dispositif.

INTRODUCTION

The Yale Real Living™ Stand-alone Touchscreen Deadbolt Lock combines a robust lockset with a

contemporary electronic aesthetic.

Users benefit from an interactive touchscreen that makes day-to-day access effortless, as well as

offering voice-guided programming for simple updates to user information in the event of staffing

changes or security breaches. Yale Real Living™ is engineered for quick and easy installation and

fits in place of a standard deadbolt lock door prep (ANSI/BHMA A156.115).

If this is an RF-enabled network lock, it needs to be located within 50 - 100 feet of another network

controller. That distance is influenced by objects between the lock and the controller and may be

expanded depending on proximity to other RF network devices. Also, if the lock is connected to a

network controller, it is recommended that it is programmed through the centralized user interface

(PC or hand-held device) to ensure communication between the lock and the controller unit.

P/N AYRT-220-INST-FUL Rev A

An ASSA ABLOY Group brand

4

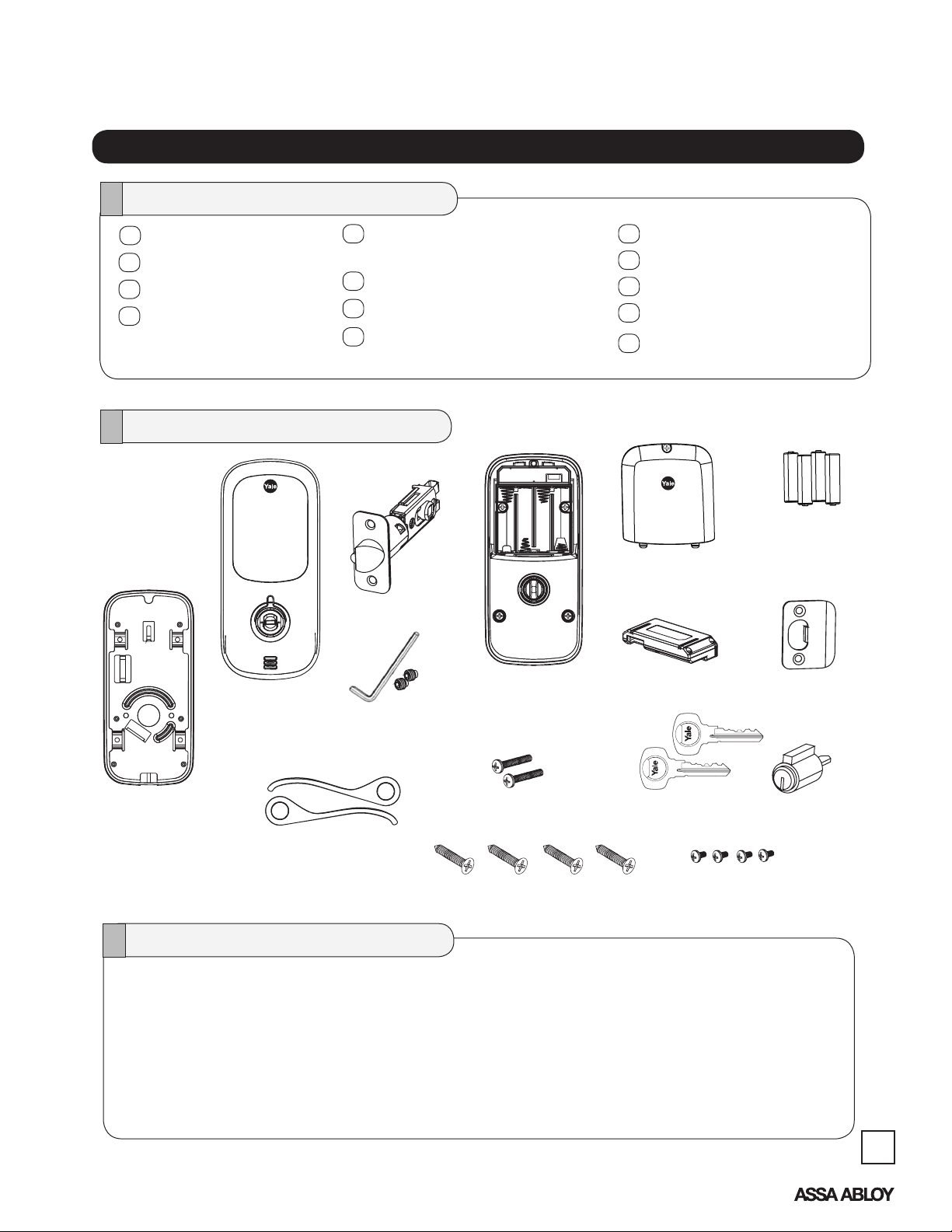

Included in the box. . .

INSTALLATION

COMPONENTS AND TOOLS

Installation Instructions

Template

Latch Bolt

Strike Plate

Parts Illustrations

Outside

Escutcheon

Inside Mounting Plate

(with gasket)

Inside Escutcheon

Outside Escutcheon

(2) Screw Packs (see below)

Latch

Allen Wrench

(2) Hex Set Screws

(Pack 1)

Inside

Escutcheon

Keys

Cylinder

Battery Cover

Allen Wrench

4 AA Alkaline Batteries

Battery Cover

Network Module

(Optional)

Keys

4 AA Alkaline

Batteries

Latch bolt

Strike

Inside Mounting Plate

with Gasket

(back of Inside Escutcheon)

Tools Needed

Door Prep

2-1/8" (54mm) hole saw

1" (26mm) boring bit

7/64" (2.5mm) drill bit

Chisel & hammer

An ASSA ABLOY Group brand

Outside & Inside Lever

Handles

(2) Inside Mounting Plate Screws

(Pack 1)

(2) Latch & (2) Strike Plate Mounting

Screws (Pack 2)

Lock Installation

#2 Phillips screw driver

Allen wrench (3mm) - provided

Cylinder

(4) Inside Escutcheon

Mounting Screws

(Pack 1)

5

P/N AYRT-220-INST-FUL Rev A

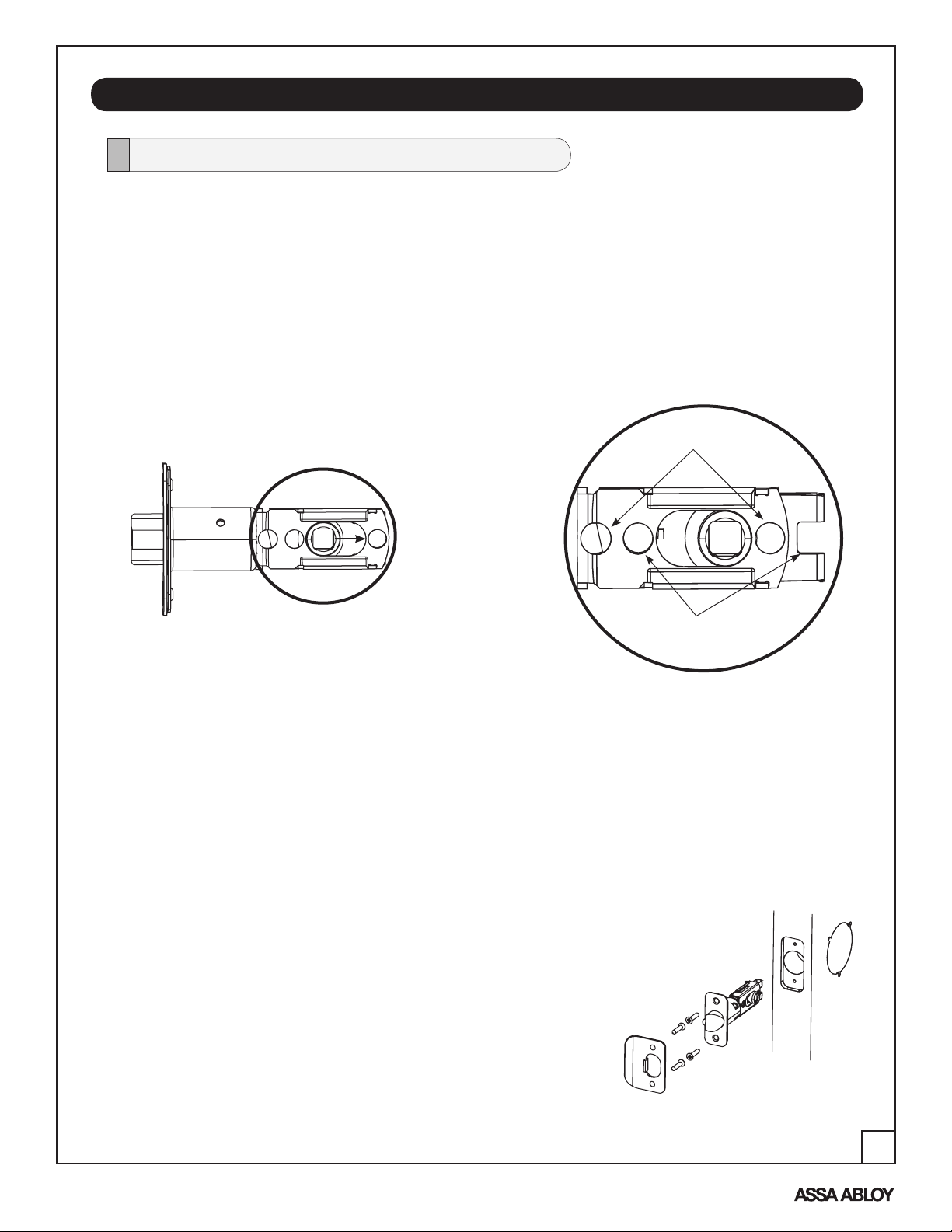

INSTALL LOCK

Install Latch

The lock is packed representative of how it will install on the door.

Before installing the lock on the door:

A. Remove the latch (Fig. 1) and strike plate from the packaging.

NOTE: Latch ships with backset in 2-3/8" position (Fig. 1).

Backset is the measurement from door edge to center

of 2-1/8" diameter hole (see template supplied with lock).

If required, pull to extend to 2-3/4" backset position (Detail 1A).

NOTE: Different holes are used for (2) through bolts depending on backset (see Detail 1A).

2-3/8" through bolt posts

Figure 1

2-3/4" through bolt posts

Detail 1A

NOTE: Make sure door has been prepped according to specifications in template included

with lock.

NOTE: The latch bolt (and strike) can be installed in only one of two ways -

with the bevel (slope) of latch facing out or facing in while standing

outside of the door.

If the door opens in, the bevel will face the outside; if the doors opens out, the

bevel will face in.

The strike plate is installed according to the orientation of the latch bolt. See

Figures 1 & 2 for an example of a RH door that opens in.

NOTE: Both latch face and strike plate have adhesive-backed covers to

prevent marring and should be removed upon installation.

B. Install latch bolt in door.

1. Attach with two (2) M4 x 25.4mm screws supplied.

C. Install strike on the door frame, using two (2) M4 x 25mm

screws supplied, making sure to allow for the latch to be

centered in the strike.

An ASSA ABLOY Group brand

(4) M4 x 25.4mm

Flat Head

Combination Screws

P/N AYRT-220-INST-FUL Rev A

Figure 2

6

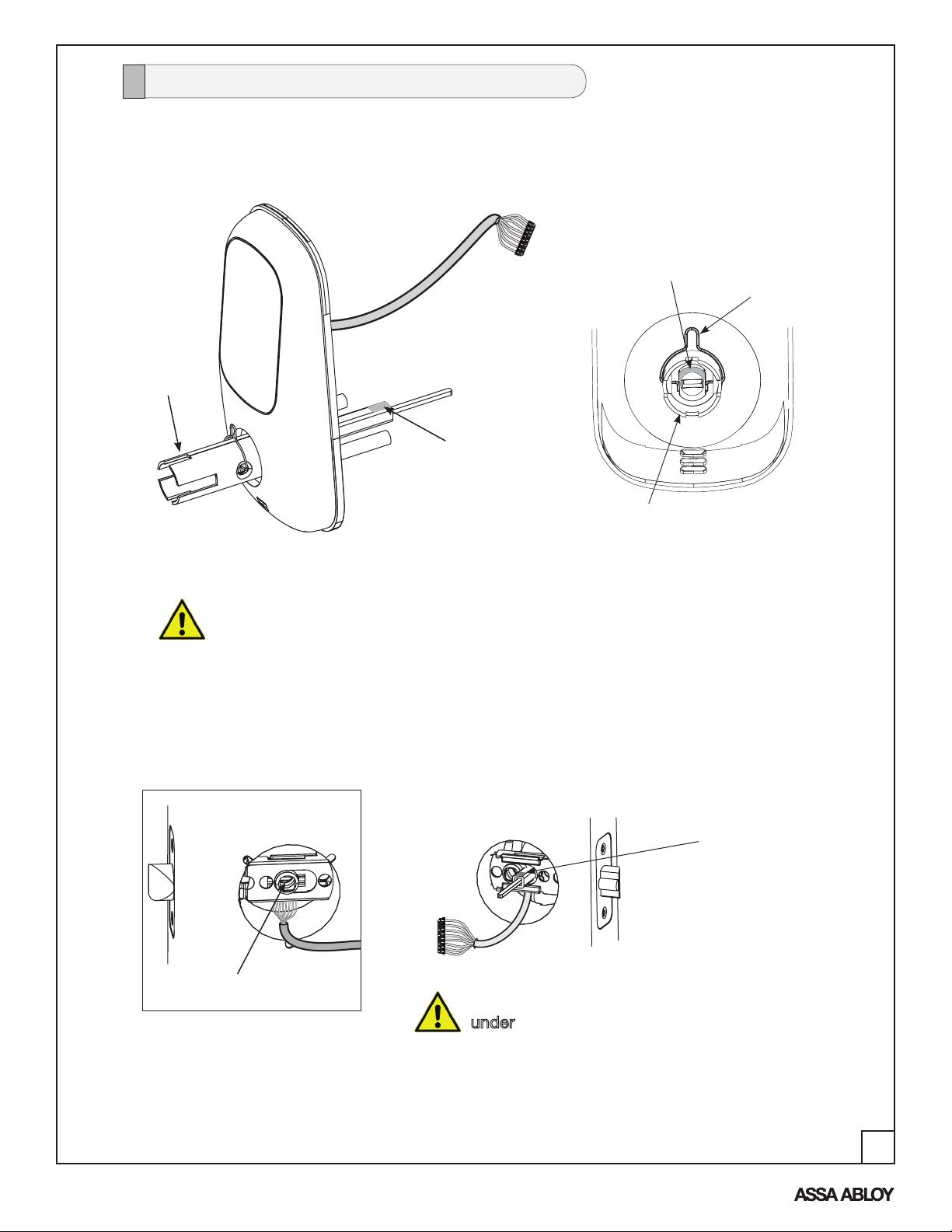

Install Outside Escutcheon

NOTE: The "tops" of both the square drive tube and the hub (in the shank) are marked to

indicate their orientation for proper installation (Figures A & B).

NOTE: RED marking

indicates "top" of hub

Clip

Shank

Square

Drive Tube

is marked

(WHITE) to

indicate

"top"

Figure A Figure B

Outside Escutcheon

(with gasket)

Shank

Do not remove clip from Outside Escutcheon shank until correct handing has

been determined and Outside Lever Handle is to be installed.

(See page 9)

1. From outside of door, position the outside escutcheon by first routing the cable

through 2-1/8" diameter hole and under the latch (Fig. 3A & B), then insert

posts* and tailpiece into the latch.

Tailpiece

Outside of Door

Figure 1A

Inside of Door

Figure 1B

NOTE: Cable goes

under latch (Fig. 1A & 1B).

"Top" of Drive Tube

(marked WHITE)

*Posts are inserted in holes according to

backset adjustment. (Refer back to Detail 1A

under "Install Lock")

An ASSA ABLOY Group brand

7

P/N AYRT-220-INST-FUL Rev A

Install Outside Escutcheon

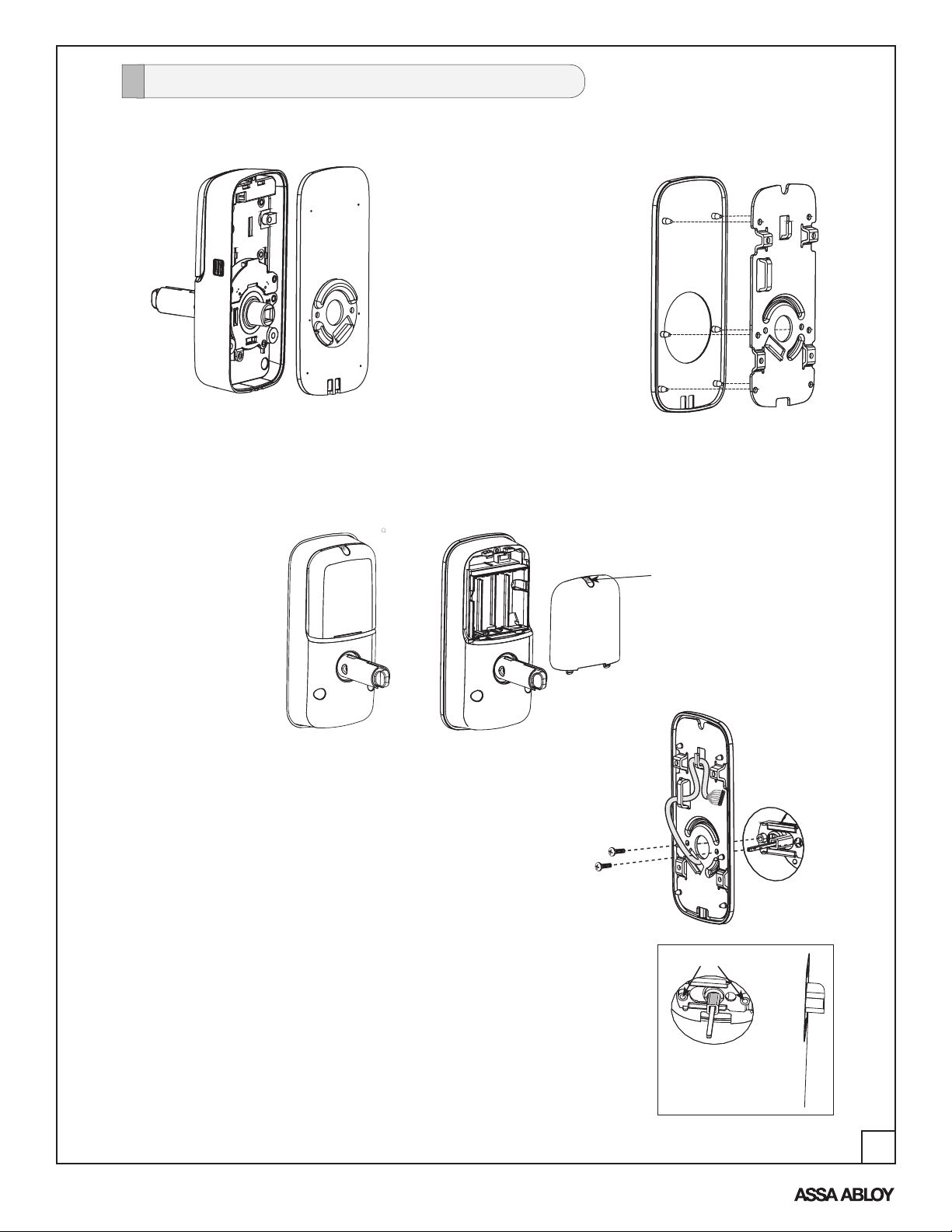

2. Remove the inside mounting plate (with gasket) from

the back (door side) of the inside escutcheon (Fig. 2A).

A. Ensure that gasket on

inside mounting plate

is properly fitted (Fig. 2B).

Figure 2A

Inside Escutcheon & Mounting Plate

(with gasket)

Figure 2B

3. Remove the battery cover from the back of the inside escutcheon (Fig. 3) by loosening

the captive Phillips head screw.

Screw

Battery Cover

Figure 3

Inside of Door

4. Holding the outside escutcheon flush to the door,

position the inside mounting plate by routing the

cable/connector through the mounting plate's 1/2"

rectangular hole below center hole (Fig. 4A).

5. Secure both assemblies by inserting (2) M4 x 25mm

pan head machine screws through the mounting

plate and into the slightly extended through posts of

Figure 4A

the outside escutcheon (Fig. 4B).

Ensure that outside escutcheon is vertically aligned.

Through posts here

Tighten securely with a #2 Phillips screwdriver.

Do not over-tighten.

6. Finish routing the cable and connector through the left

upper slot, then behind center rib as shown in Fig. 4A.

An ASSA ABLOY Group brand

Figure 4B

8

P/N AYRT-220-INST-FUL Rev A

Loading...

Loading...