IC Radio Standards Specification: RSS-210

ACS Report Number: 09-0176 - 15C

Certification Exhibit

FCC ID: U4A-SCYPROX2

IC: 6982A-SCYPROX2

FCC Rule Part: 15.225

Manufacturer: Assa Abloy, Inc.

Model: Bored/Exits, Mortise

Manual – Bored/Exits

5015 B.U. Bowman Drive Buford, GA 30518 USA Voice: 770-831-8048 Fax: 770-831-8598

Installation Instructions

Harmony Series H2

8600, 8800, 8900 Exits

A8029A

06/09

Copyright © 2009, Sargent Manufacturing Company, an ASSA ABLOY Group company.

All rights reserved. Reproduction in whole or in part without the express written

permission of Sargent Manufacturing Company is prohibited.

Table of Contents

Warning ...................................................................................2

1

2

General Description .................................................................3

Hardware Specifications .........................................................3

3

Electronics Specifications .......................................................3

4

H2 8600 Concealed Vertical Rod (CVR) Exit Device ................4

5

6

H2 8800 Rim Exit Device ........................................................11

7

H2 8900 Mortise Exit Device ..................................................17

8

Wiring Diagrams ....................................................................24

9

Mechanical Operational Check .............................................28

10

Electrical Operational Check .................................................28

1

Warning

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) this device

may not cause harmful interference, and (2) this device must accept any interference received, including interference that

may cause undesired operation.

Note: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation.

This equipment generates, uses and can radiate radio frequency energy and if not installed and used in accordance with

the instructions, may cause harmful interference to radio communications. However, there is no guarantee that the interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

• Reorient or relocate the receiving antenna

• Increase the separation between the equipment and receiver

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected

• Consult the dealer or an experienced technician for help

The term “IC:” before the radio certication number only signies that Industry Canada technical specications were

met. This Class B digital apparatus meets all requirements of the Canadian Interference Causing Equipment Regulations.

Operation is subject to the following two conditions: (1) this device may not cause harmful interference, and (2)

this device must accept any interference received, including interference that may cause undesired operation.

Cet appareillage numérique de la classe B répond à toutes les exigences de l’interférence canadienne causant des

règlements d’équipement. L’opération est sujette aux deux conditions suivantes: (1) ce dispositif peut ne pas causer

!

l’interférence nocive, et (2) ce dispositif doit accepter n’importe quelle interférence reçue, y compris l’interférence qui

peut causer l’opération peu désirée.

Copyright © 2009 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

Observe precautions for handling electrostatic sensitive devices.

Warning: Changes or modications to this unit not expressly approved by the party

responsible for compliance could void the user’s authority to operate the equipment.

06/30/09

A8029A • 800-810-WIRE (9473) • www.sargentlock.com 2

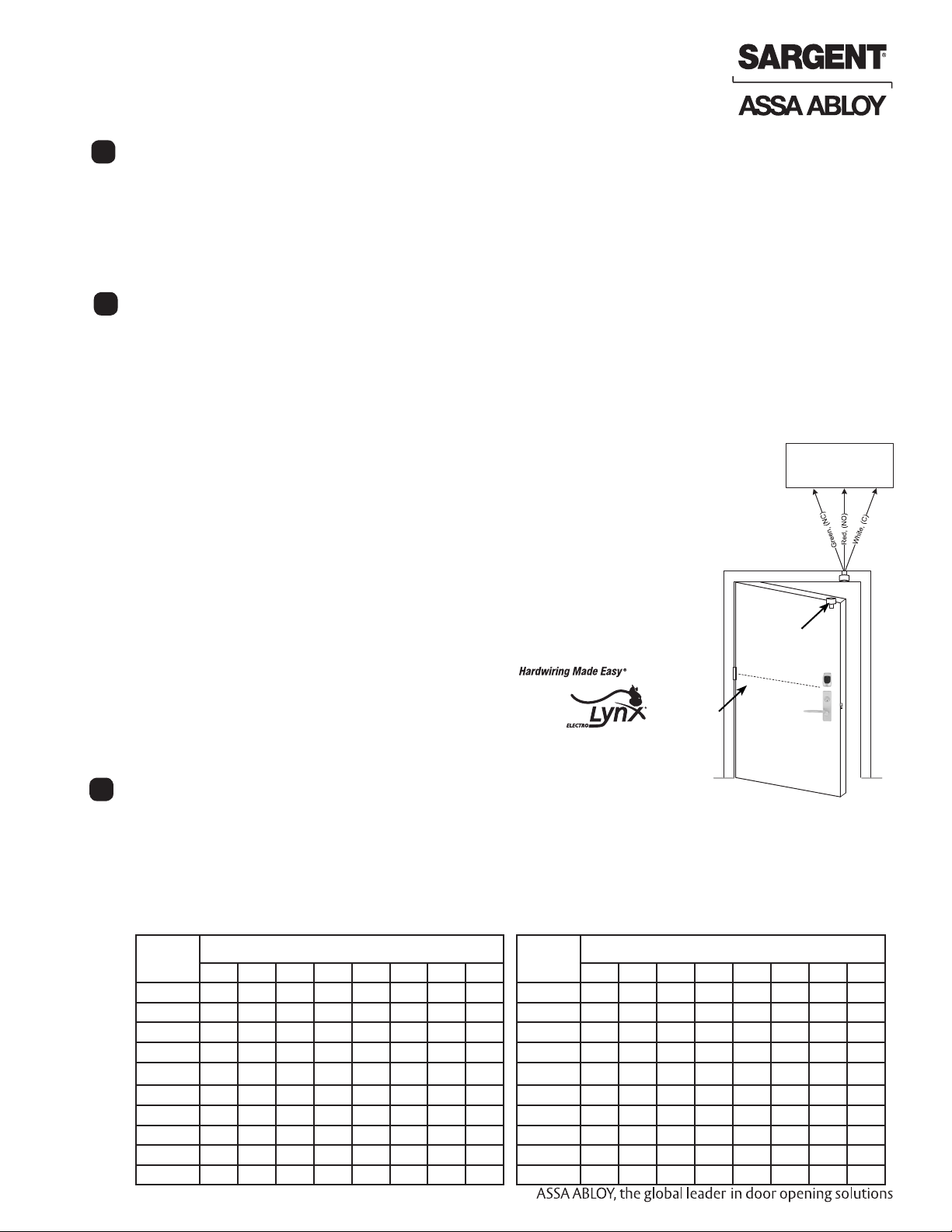

Harmony Series H2 Exit Devices

2

General Description

The SARGENT Harmony H2 series exit devices (8600, 8800, 8900) are designed to interface with existing Wiegand

Electronic Access Control (EAC) panels. The reader requires 12 or 24VDC for power and is compatible with HID

iCLASS® 13.56MHz technology. The Harmony series technology is backed by SARGENT Grade 1 mechanical hardware.

All exits include RX (request to exit) monitoring in the rail and an external Door Position Switch (DPS) for door position

monitoring. Harmony is available as 12VDC or 24VDC solenoid operated ET trim. Weatherseal gaskets are also included

for exterior door applications. The Harmony H2 iCLASS reader provides visual and audible indicators of lock state

(locked/unlocked).

3

Hardware Specifications

All Harmony Exit Devices

• Certied ANSI/BHMA A156.3 Grade 1

• Push bar retracts latch from inside, allowing free egress

• Request-to-Exit (REX) Switch activated by pushing rail

• Outside lever controlled by any 13.56MHz HID

iCLASS Wiegand credential

• Fire rated devices available

• UL Listed

• Exit devices furnished for 1-3/4” doors

• Fail safe or fail secure available

• Door Position Switch (DPS, part #3287) supplied to

allow for monitoring

• 12VDC/24VDC solenoid-operated ET trim

• EAC Panel wiring to door must be shielded with a

drain. Drain terminated at EAC Panel controller

Harmony 8600 Series Concealed Vertical Rod (CVR)

• Cylinder override available for 8600 CVR with 106

Series Auxiliary Control

• The AFF is 41” for Standard Applications; when a 100

Series Auxiliary Control is used, 38” AFF is

recommended to meet local accessibility standards

Harmony 8800 Series Rim

• Cylinder override available

• Accepts all SARGENT rim cylinders (75/76 functions)

• Key retracts latch (75/76 functions)

• Latch – 3/4” throw, stainless steel

Harmony 8900 Series

Mortise

Weigand Access

Control System

• Cylinder override available

• Accepts all

SARGENT mortise

cylinders (75/76 functions)

• Key retracts latch

(75/76 functions)

• Latch – 3/4” throw,

anti-friction, brass

McKinney

Electronic

Transfer

Hinge

3287 Door

Position Switch

Harmony Series H2

4

Electronics Specifications

12VDC System

• Reader Draw = 125mA

• 12VDC Solenoid Draw = 500mA

• Total Current Draw = 625mA

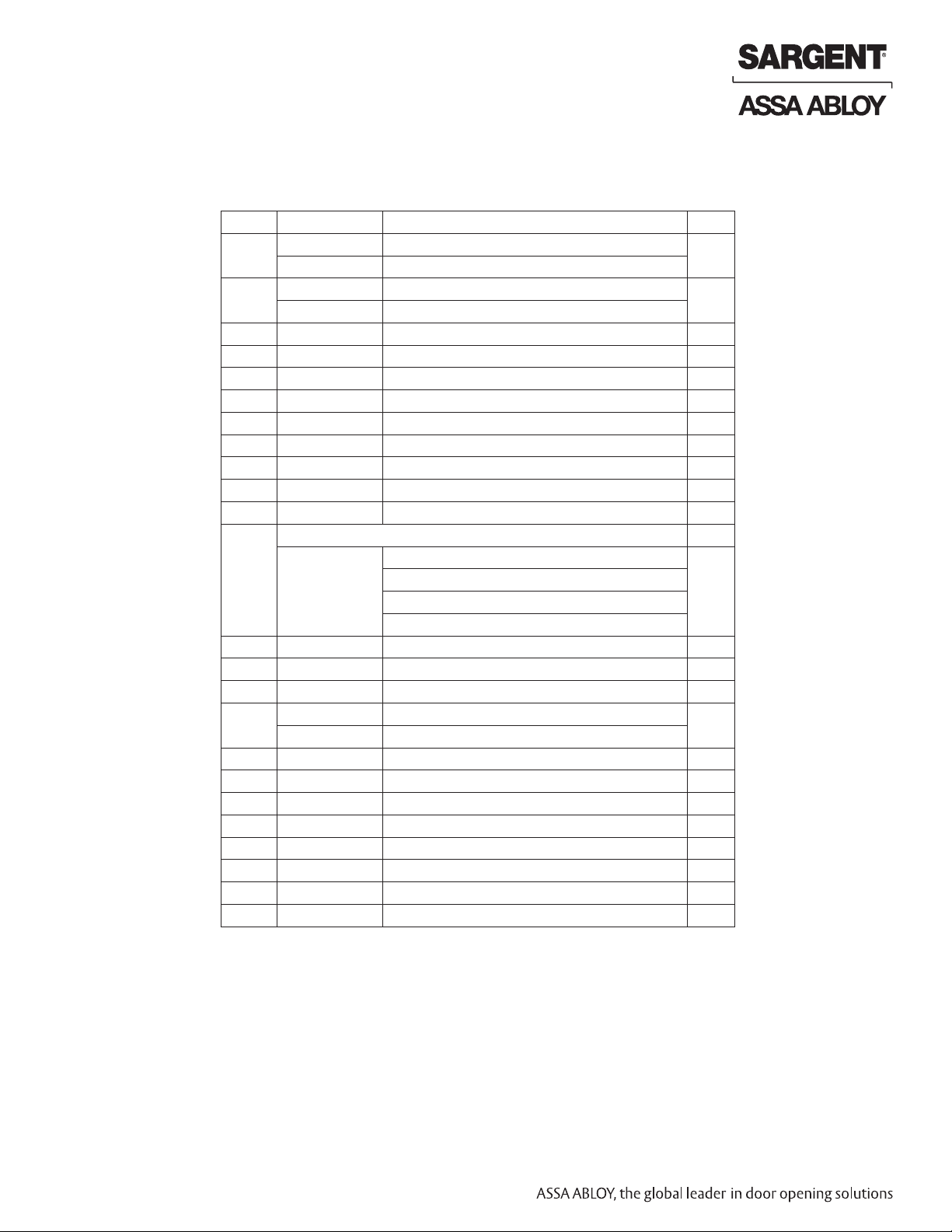

Wire Gauge Charts

Total

One-Way

Length of

Wire Run (ft)

1/4A 1/2A 3/4A 1A 1-1/4A 1-1/2A 2A 3A

100 20 18 16 14 14 12 12 10

150 18 16 14 12 12 12 10 —

200 16 14 12 12 10 10 — —

250 16 14 12 10 10 10 — —

300 16 12 12 10 10 — — —

400 14 12 10 — — — — —

500 14 10 10 — — — — —

750 12 10 — — — — — —

1,000 10 — — — — — — —

1,500 10 — — — — — — —

A8029A • 800-810-WIRE (9473) • www.sargentlock.com 3

Load Current @ 12VDC

24VDC System

• Reader Draw = 125mA

• 24VDC Solenoid Draw = 250mA

• Total Current Draw = 375mA

Total

One-Way

Length of

Wire Run (ft)

1/4A 1/2A 3/4A 1A 1-1/4A 1-1/2A 2A 3A

100 24 20 18 18 16 16 14 12

150 22 18 16 16 14 14 12 10

200 20 18 16 14 14 12 12 10

250 18 16 14 14 12 12 12 10

300 18 16 14 12 12 12 10 —

400 18 14 12 12 10 10 — —

500 16 14 12 10 10 — — —

750 14 12 10 10 — — — —

1,000 14 10 10 — — — — —

1,500 12 10 — — — — — —

Load Current @ 24VDC

Copyright © 2009 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

06/30/09

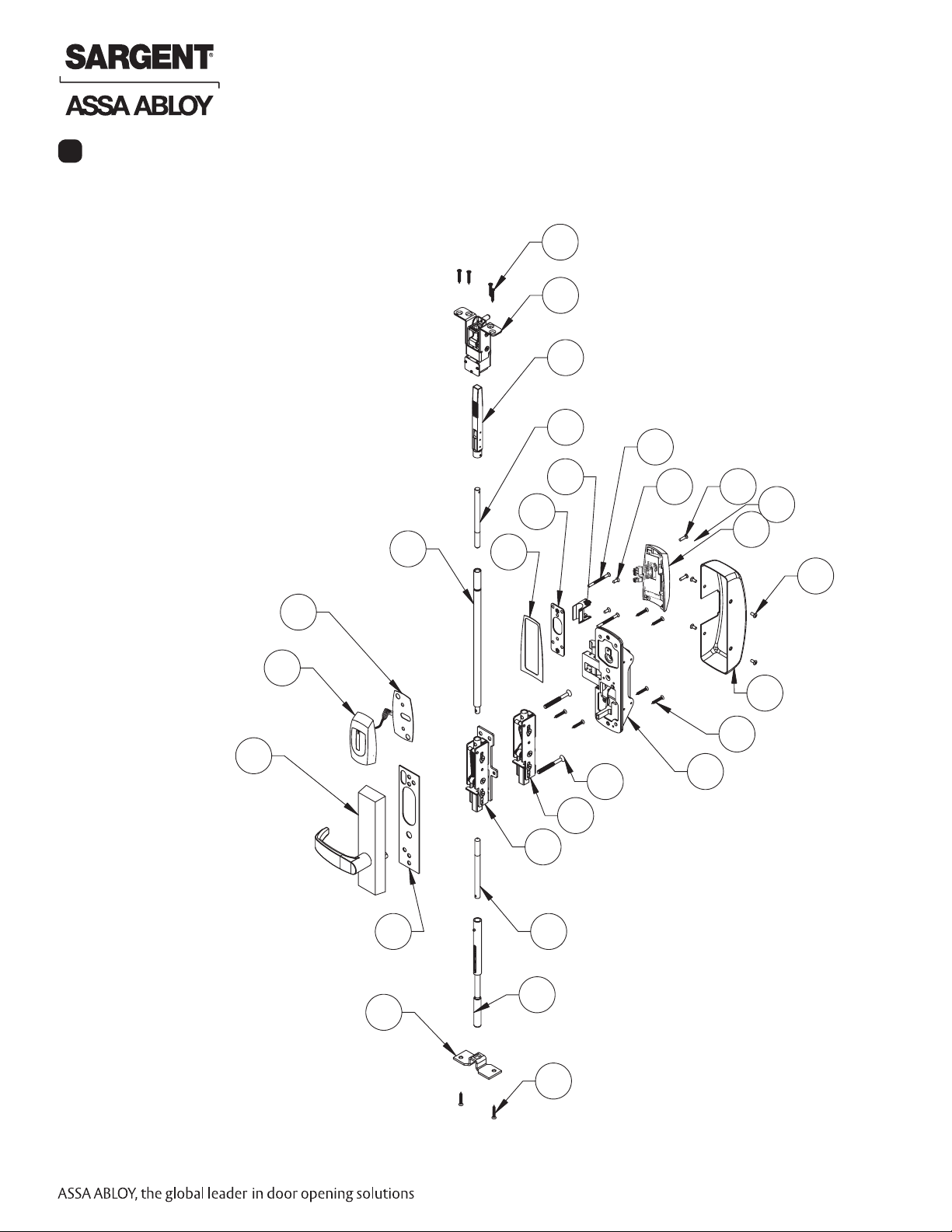

Installation Instructions For Harmony Series H2 8600

5

Concealed Vertical Rod (CVR) Exit Device

Harmony Series H2 8600 Exits

Parts Breakdown

Tools Required

• Phillips screw driver (standard size)

• Flat blade screw driver (standard)

5

4

1

2

2

2

9

8

7

3

6

99

10A

10

10

16

15

11

12

18

Copyright © 2009 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

06/30/09

1

1

13B

13A

17

17

1

A8029A • 800-810-WIRE (9473) • www.sargentlock.com4

14

Harmony Series H2 8600 Exits

Parts Breakdown For Harmony Series H2 8600 (Continued)

Shipment Contents

ITEM PART # Description Req.

1 68-3577 Chassis Wood Door (WD) Screw Pack 1

68-3905 Chassis Metal Door (MD) Screw Pack (not shown)

2 68-7057 WD 8600 Top Assembly 1

68-7060 MD/AD 8600 Top Assembly (not shown)

3 94-0212 Aux Control Rod Adapter 1

4 52-4038 Outside Harmony Escutcheon Assembly 1

5 52-0792 Outside Harmony Gasket 1

6 52-0793 Inside Harmony Gasket 1

7 52-5219 Harmony Inside Escutcheon Mounting Plate 1

8 52-0801 Wire Guide 1

9 52-5236 Screw Pack (Escutcheon) 1

10 68-1581 Inside Harmony Escutcheon 1

10A 52-4036 H2 Controller Assembly 1

11 *Harmony Trim is Ordered as "N1"

12 52-0263 ET Trim Gasket 1

13A 68-3859 WD Inner Case Assembly 1

13B 68-5067 MD/AD Inner Case Assembly 1

14 68-7241 8600 Chassis LHRB 1

68-7242 8600 Chassis RHRB (not shown)

15 68-0407 Chassis Cover 1

16 68-3905 Screw Pack (Rail and Chassis Cover) 1

17 68-0888 MD/WD Bottom Case Assembly 1

17 68-0037 AD Bottom Case Assembly 1

18 3287 DPS Door Position Switch (not shown) 1

19 A8029 Installation Instructions (not shown) 1

20 4621 MD/AD Door Manufacturer Template (not shown) 1

21 4622 Wood Door Manufacturer Template (not shown) 1

N1-773-4 ETL12V Fail Safe 1

N1-773-4 ETL 24V Fail Safe

N1-774-4 ETL12V Fail Secure

N1-774-4 ETL 24V Fail Secure

How to Specify ET Trim

How to order without an exit device.

Specify: 7 for 700 Series ET, Function, Sufx, Lever, Finish and handing (e.g., 775-8 ETL x 26D x RHRB).

Note: Sufx requirements are based on type of device to be used:

• -8 sufx is required for 8800, 8500, NB8700, PP, PR and SP8700 devices, except with these functions: 04, 10, 16, 40 and 44.

• -6 sufx is required for all PP, PR, SP, LP, LR and LS devices.

• -4 sufx is required for all 8400, WD, MD and AD 8600 devices.

• No sufx is necessary for all 8900, 8300, 8700 with bottom rod and 8800, 8500, NB8700, PP, PR & SP8700 devices

with these functions: 04, 10, 16, 40 and 44.

A8029A • 800-810-WIRE (9473) • www.sargentlock.com 5

Copyright © 2009 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

06/30/09

Harmony Series H2 8600 Exits

Step #1 – Prepare Door

A. Verify Hand and Bevel of Door

• Check hand of door. Exit Device may be handed.

• Door should be tted and hung.

• Verify box label for size of exit device, function and hand.

B. Door Preparation

Prepare door according to appropriate template. If necessary,

refer to website, www.intelligentopenings.com:

• Metal door (MD/AD): A7002

- Templates: 4621 and 4445

• Wood door (WD): A3937

- Templates: 4622 and 4431

Note: Instruction examples show wood door installation.

For metal/aluminum doors, route cables inside door.

Left Hand

Reverse

LHR

Inside

Outside

Fig. 1A

Wood Door Shown

Right Hand

Reverse

RHR

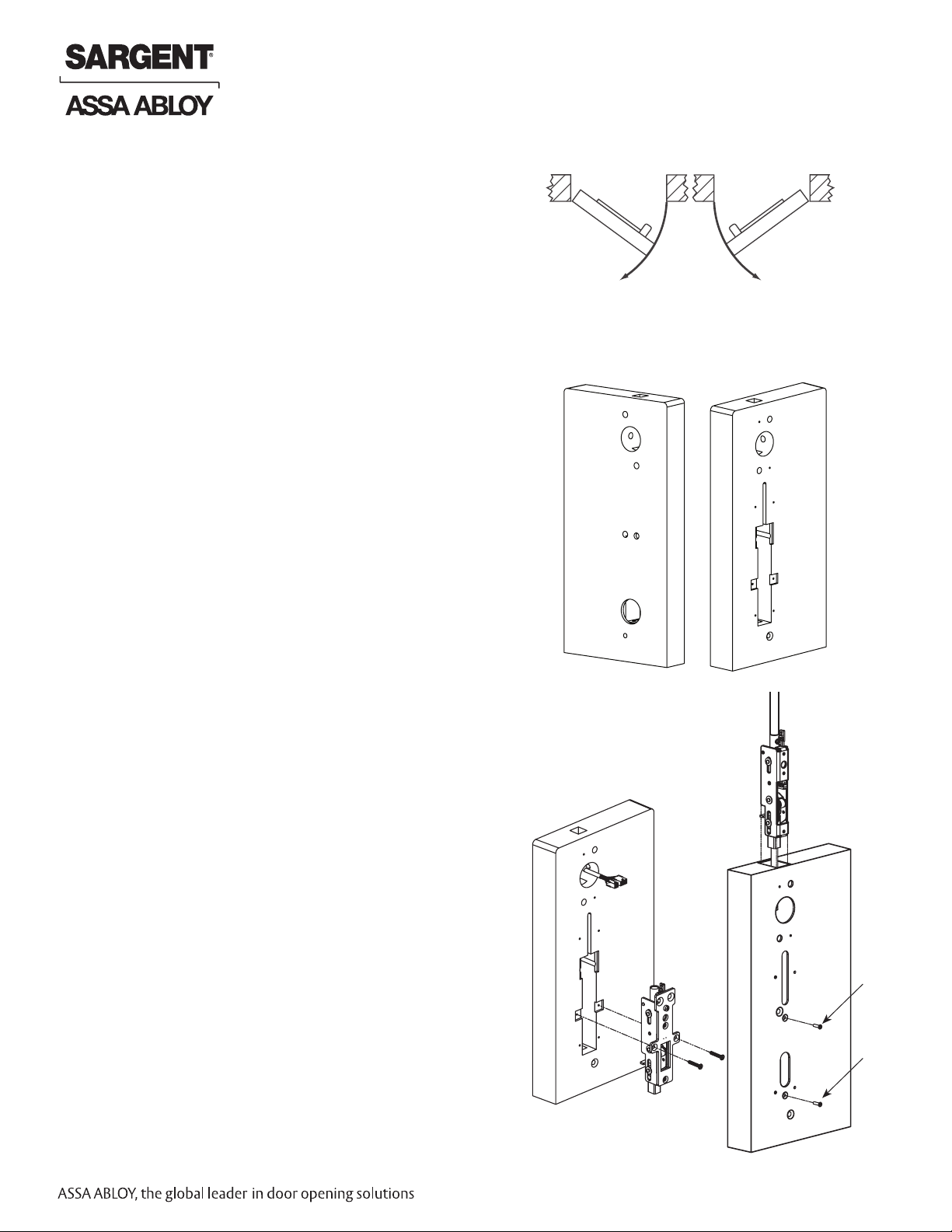

Step #2 - Inner Case Assembly Installation

A. Wood Door (WD)

Install the inner case assembly with (2) #12 x 1” Phillips

athead screw (Fig. 2A).

B. Metal Door (MD/AD)

1. Assemble rods to inner case.

2. Slide rod assembly into door and secure with #10-24 x 3/8”

screw for top inner case assembly and #10-24 x 1/2” screw

for bottom inner case assembly (Fig. 2B).

Copyright © 2009 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

Fig. 1B

#10-24 x 3/8”

#10-24 x 1/2”

Fig. 2A

Fig. 2B

06/30/09

A8029A • 800-810-WIRE (9473) • www.sargentlock.com6

Harmony Series H2 8600 Exits

8600 Installation Instructions (Continued)

Step #3 – Install Outside Exit Trim (ET) and Chassis

A. Outside Trim

1. For exterior applications, use ET gasket (52-0263)

to seal ET escutcheon and outside door surface (Fig. 3A).

2. Route ET wire harness through inner chassis

assembly:

- For wood doors: Route wire harness in cutout.

- For metal doors: Route wire harness through

access hole.

3. Mount ET trim to inner chassis assembly using

(2) # 1/2 -20 x 2-3/8” at head machine screws.

ET spindle engages inside the inner chassis

assembly (Fig. 3B).

Gasket

#10-24 x 3/8”

Fig. 3A

B. Chassis

1. Position chassis carefully onto the inner chassis assembly from the

inside of the door. Be careful not to pinch wire harness.

2. Fasten the chassis to door using (4) #12 x 1” Phillips

athead screws (Fig. 3C).

Fig. 3C

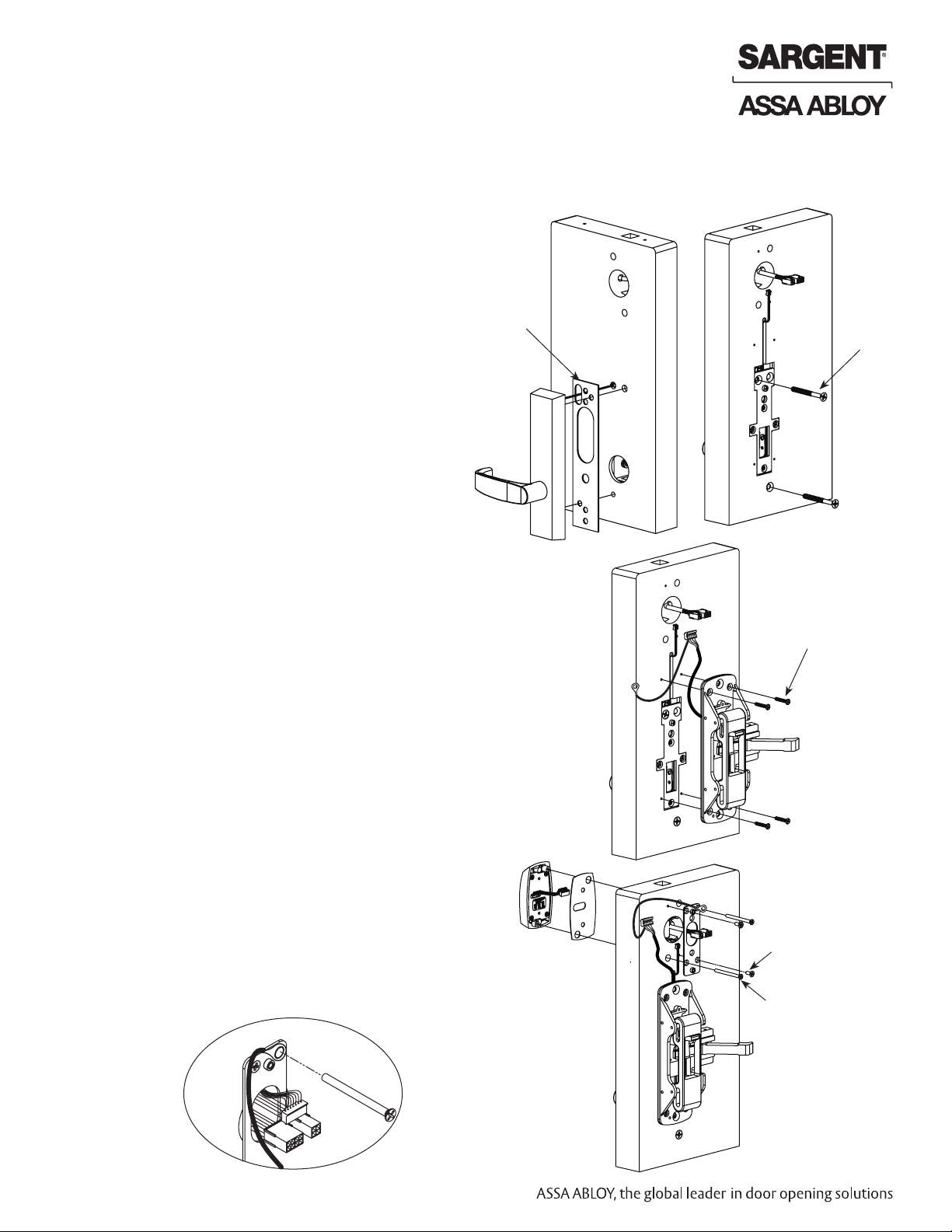

Step #4 – Attach Ground Wire and Install Outside

Escutcheon and Inside Mounting Plate

1. Connect pin 5 green/yellow ground wire ring terminal

to top right screw (Fig. 4A and 4B).

2. Secure the mounting plate with (2) #8 x 1/2”

self-tapping screws (Fig. 4A).

3. Feed the reader cable connector located

on the back of the outside escutcheon

from the outside of door through door.

4. Securely tighten the outside escutcheon with

through-bolts using (2) #8-32 x 2” Phillips at

head screws through the mounting plate.

Fig. 3B

(4) #12 x 1” Phillips

Flathead Screws

Fig. 3B

#8-32 X 1/2”

#8-32 X 2”

Fig. 4B

A8029A • 800-810-WIRE (9473) • www.sargentlock.com 7

Fig. 4A

Inside of Door

Copyright © 2009 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

06/30/09

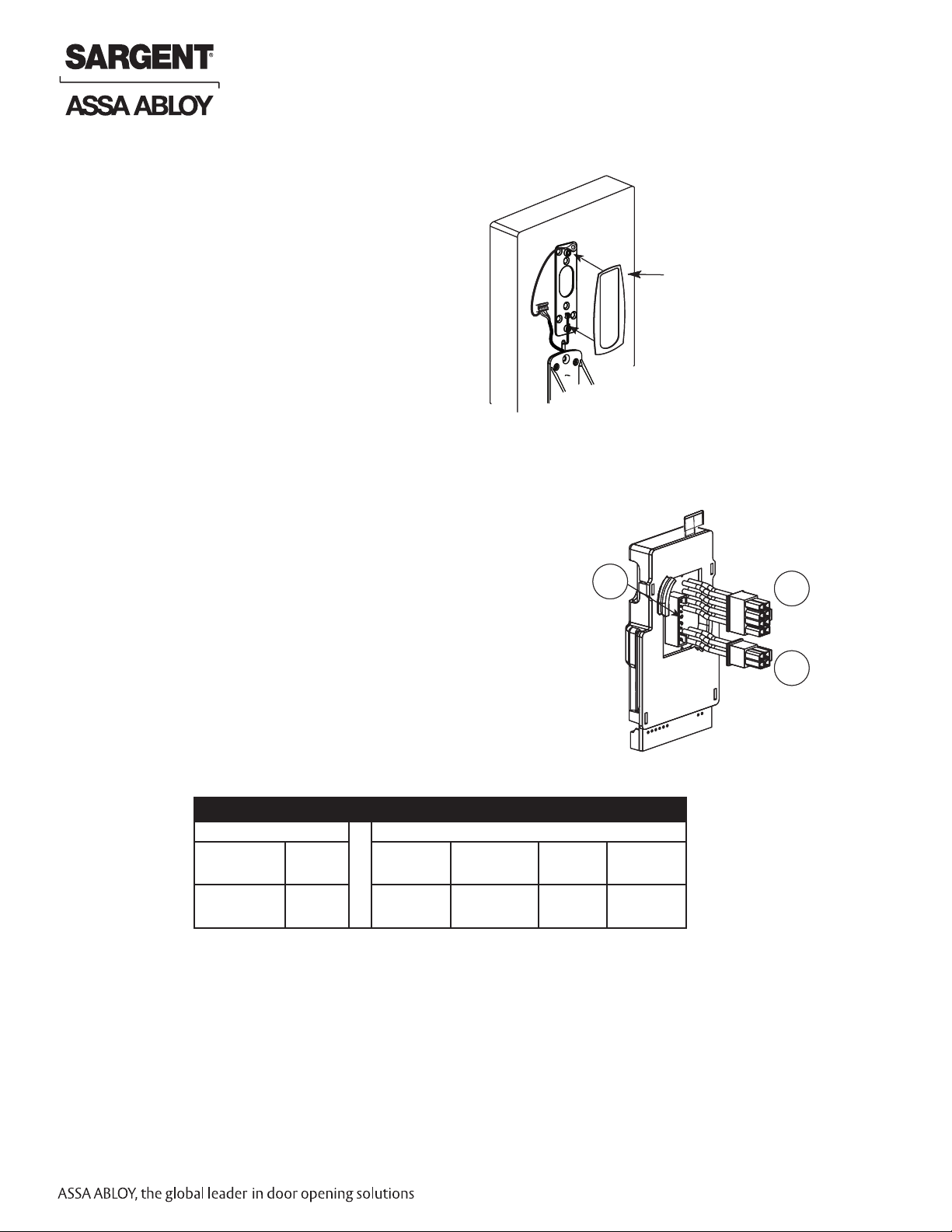

Step #5 – Install Gasket

Add Gasket (if necessary):

Remember the inside gasket must be used

Inside of Door

Inside of Door

when installing in an outdoor application.

Remove backing and place gasket

on door (Fig. 5A).

Step #6 – Connect ElectroLynx

1. Connect P5 (7 Pin Connector) from reader board

to J5 on interior escutcheon PCB assembly (Fig. 6A).

2. Connect ElectroLynx harness (4 and 8-pin) from door harness

to ElectroLynx harness on interior PCB assembly (Fig. 6A).

NOTES:

Neatly fold the wires onto themselves and into the remaining

space to prevent pinching wires when mounting escutcheon.

Do not tuck extra mortise lock body wires back inside the lock

body cylinder hole.

Connectors go on only one way.

Do not offset connector and be sure they are completely seated.

Harmony Series H2 8600 Exits

Gasket required

Gasket required

for exterior door

for exterior door

applications.

applications.

Fig. 5A

Fig. 5A

From Reader

From Reader

Board P5 to J5

Board P5 to J5

J5

J5

Fig. 6A

Fig. 6A

J1

J1

To ElectroLynx

To ElectroLynx

Harness

Harness

J2

J2

PCB Layout - Wire Assignments - ElectroLynx Assembly (Molex)

J2 J1

1-Violet Lock DC Neg

(Solenoid, neg)

2-Gray, Lock DC Pos

(Solenoid, pos)

Copyright © 2009 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

06/30/09

3 - Pink

NOT USED

4-Tan

NOT USED

1- Black

PWR NEG

2-Red

PWR POS

3-White

Wiegand DATA 1

4-Green

Wiegand DATA 0

5-Orange

RX (N/O)

6-Blue

RX (COM)

7-Brown

EGND

8-Yellow

LED

A8029A • 800-810-WIRE (9473) • www.sargentlock.com8

Harmony Series H2 8600 Exits

Step #7 – Position Outside Wires

Please follow these steps prior to installing

inside escutcheon to prevent any damage

caused by pinching wires:

1. Once wires are arranged, position piece

at a rotated angle against the door, under

earth ground wire.

2. Press piece against door unwhile turning

clockwise (Fig. 7A).

3. Twist into place, perpendicular with door (Fig. 7B).

Rotate Clockwise

Rotate Clockwise

Inside of Door

Inside of Door

Fig. 7A

Fig. 7A

Step #8 – Attach Connectors (Exterior PCB Assembly)

1. Connect P3 (2-pin connector) from lock body

to J3 on module (Fig. 8A).

2. Connect P4 (6-pin connector) from lock body

to J4 on module (Fig. 8A).

Fig. 7B

Fig. 7B

A8029A • 800-810-WIRE (9473) • www.sargentlock.com 9

From Lock

From Lock

Body P3 to J3

Body P3 to J3

Fig. 8A

Fig. 8A

J4 J3

J4 J3

From Lock

From Lock

Body P4 to J4

Body P4 to J4

Copyright © 2009 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

06/30/09

Step #9 – Install Inside Escutcheon

1. Position inside gasket and escutcheon against door.

Verify that no wires are being pinched.

2. Mount inside escutcheon assembly to plate using

(2) #8-32 x 5/8" Phillips at head undercut

machine screws.

Step #10 – Install Rail Assembly

1. Retrieve harness from end of rail. Harness has limited travel

and can be damaged.

2. Attach harness to female connector on chassis.

3. Install rail and screws per exit device instructions.

Note: This view shows rim exit device version.

Harmony Series H2 8600 Exits

Inside of Door

(2) #8-32 x 5/8” Phillips

Flat Head Under-cut

Machine Screws

Fig. 9A

Fig. 10A

Step #11 - Concealed Door Position Switch Instructions (3287)

Use SARGENT 3287 Concealed Door Position Switch with this

Harmony H2 series product:

1. Install the 3287 Concealed Door Position Switch described in SARGENT

document A7448B.

2. Wire the 3287 Concealed Door Position Switch to the EAC door position Input.

3. Connect the common wire of the switch to the common input terminal of the EAC;

and the normally open wire of the switch to the normally open input

termnial of the EAC.

Lock is 12VDC.

Optional 24VDC

lock is available.

McKinney

QC12 Hinge

Wiegand Access

Control System

3287 Door

Position Switch

Harmony Series H2

(Others)

Copyright © 2009 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

>> Continue to Section 9 for Wiring Diagrams to wire Device to EAC Panel. <<

06/30/09

Fig. 11A

A8029A • 800-810-WIRE (9473) • www.sargentlock.com10

Harmony Series H2 8800 Exits

7

Installation Instructions For Harmony Series H2 8800 Rim Exit Device

Parts Breakdown

Left Hand Reverse Door Shown

Tools Required

• Phillips screw driver (standard size)

• Flat blade screw driver (standard)

6

6A

5

5

4

3

2

1

15

10

12

13

14

5

6

7

8

9

9

9

9

10

11

A8029A • 800-810-WIRE (9473) • www.sargentlock.com 11

Copyright © 2009 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

06/30/09

Parts Breakdown For Harmony Series H2 8800 (Continued)

Shipment Contents

ITEM PART # Description Req.

1 52-4038 Outside Harmony Escutcheon Assembly 1

2 52-0792 Outside Weather Gasket 1

3 52-0793 Inside Weather Gasket 1

4 52-5219 Harmony Inside Escutcheon Mounting Plate 1

5 52-5236 Screw Pack (Escutcheon) 1

6 68-1581 Inside Escutcheon Assembly 1

6A 52-4036 H2 Controller Assembly 1

7 68-3905 Screw Pack (Rail and Chassis Cover) 1

8 68-0406 Chassis Cover 1

9 68-3922 Screw Pack (Chassis) 1

10 13-0074 Cylinder Connecting Screws 2

11 68-7255 8800 Chassis Assembly (Standard)

12 13-0086 Cylinder back Plate Used with non-Sargent Cylinders) 1

13 52-0263 ET Trim Gasket 1

14 *Harmony Trim is Ordered as "N1" 1

15 -- Reference Harmony Series Catalog for Available Cylinders 1

16 3287 DPS Door Position Switch (not shown) 1

17 A8029 Installation Instructions (not shown) 1

18 A7883 Field Template (not shown) 1

19 4615 Manufacturer Template (not shown) 1

68-7256 8800 Chassis Assembly (12-)

68-5836 8800 Chassis Assembly (GL)

68-5837 8800 Chassis Assembly (12-, GL)

N1-773-ET 12V Fail Safe Without Cylinder

N1-773-ET 24V Fail Safe Without Cylinder

N1-774-ET 12V Fail Secure Without Cylinder

N1-774-ET 24V Fail Secure Without Cylinder

N1-775-ET 12V Fail Safe Without Cylinder

N1-775-ET 24V Fail Safe Without Cylinder

N1-776-ET 12V Fail Secure Without Cylinder

N1-776-ET 24V Fail Secure Without Cylinder

Harmony Series H2 8800 Exits

1

How to Specify ET Trim

How to order without an exit device.

Specify: 7 for 700 Series ET, Function, Sufx, Lever, Finish and handing (e.g., 775-8 ETL x 26D x RHRB).

Note: Sufx requirements are based on type of device to be used:

• -8 sufx is required for 8800, 8500, NB8700, PP, PR and SP8700 devices, except with these functions: 04, 10, 16, 40 and 44.

• -6 sufx is required for all PP, PR, SP, LP, LR and LS devices.

• -4 sufx is required for all 8400, WD, MD and AD 8600 devices.

Copyright © 2009 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

06/30/09

• No sufx is necessary for all 8900, 8300, 8700 with bottom rod and 8800, 8500, NB8700, PP, PR & SP8700 devices

with these functions: 04, 10, 16, 40 and 44.

A8029A • 800-810-WIRE (9473) • www.sargentlock.com12

Harmony Series H2 8800 Exits

Step #1 – Door Preparation

A. Verify Hand and Bevel of Door

• Check hand of door. Exit Device may be handed.

• Door should be tted and hung.

• Verify box label for size of exit device, function and hand.

B. Door Preparation

Prepare door according to appropriate template. If necessary,

refer to website, www.intelligentopenings.com:

• Field prep template: A7883

• Manufacturer template: 4615

• Reference exit device templates: 4415, and 4530

Note: Instruction examples show wood door

installation. For metal doors, route cables inside door.

Left Hand

Reverse

LHR

Inside

Outside

Fig. 1A

Wood Door Shown

Right Hand

Reverse

RHR

Step #2 – Outside Trim (Exit Trim, ET) Installation

1. For exterior applications, use ET gasket (52-0263) to seal between

ET escutcheon and outside door surface (Fig. 2B).

2. Route ET wire harness in cutout for wood doors

and through access hole for metal doors (Fig. 2A).

3. Hold ET control onto door.

Fig. 2B Detail

ET Gasket

ET Control

Fig. 1B

Wire Harness

Fig. 2A

Copyright © 2009 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

A8029A • 800-810-WIRE (9473) • www.sargentlock.com 13

06/30/09

8800 Installation Instructions (Continued)

Harmony Series H2 8800 Exits

Step #3 – Mounting Chassis

1. Position chassis carefully, not to pinch wire harness.

2. ET spindle will engage the lower hub of chassis.

3. Cylinder tailpiece should engage upper hub of the chassis.

4. Though bolt chassis to ET with (2) 1/4 -20 x 2-3/8” at head

machine screws.

5. Using (4) #10 wood screws or #10-24 machine screws fasten

chassis to door.

Step #4 – Cylinder Installation

1. Position cylinder in ET control.

2. For non-Sargent cylinder ONLY:

Secure cylinder with cylinder

backplate using

(2) #12-24 x 1-7/8” screws.

3. Make sure ET harness is clear of

cylinder and cylinder tailpiece.

Cylinder

#12-24 X 1-7/8” Screws

Exit Chassis

Fig. 3A

Inside of Door

#12 x 1” Phillips Flat

Head Wood Screw

1/4 -20 x 2-3/8” Flat

Head Machine Screw

Fig. 4A

Step #5 – Outside Escutcheon and Inside

Mounting Plate and Ground Wire Installation

1. Connect pin 5 green/yellow ground wire ring terminal to

top right screw (Fig. 5A and 5B).

1. Secure the mounting plate with (2) self-tapping screws (#8 x 1/2”).

2. Feed the reader cable connector located on the back of the outside

escutcheon from the outside of door through door.

3. Securely tighten the outside escutcheon with (2) through-bolts

(#8-32 x 2”) Phillips at head screws through the mounting plate.

Copyright © 2009 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

Fig. 5B

06/30/09

A8029A • 800-810-WIRE (9473) • www.sargentlock.com14

Inside of Door

Outside Gasket

Inside of Door

#8-32 x 2” Phillips

Flat Head Screws

Fig. 5A

#8 x 1/2” Self-

Taping Screws

Harmony Series H2 8800 Exits

Step #6 – Install Gasket

Add Gasket (if necessary):

Remember the inside gasket must be used

when installing in an outdoor application.

Remove backing and place gasket

on door (Fig. 6A).

Step #7 – Connect ElectroLynx

1. Connect P5 (7 Pin Connector) from reader board

to J5 on interior escutcheon PCB assembly (Fig. 7A).

2. Connect ElectroLynx harness (4 and 8-pin) from door harness

to ElectroLynx harness on interior PCB assembly (Fig. 7A).

NOTES:

Neatly fold the wires onto themselves and into the remaining

space to prevent pinching wires when mounting escutcheon.

Do not tuck extra mortise lock body wires back inside the lock

body cylinder hole.

Connectors go on only one way.

Do not offset connector and be sure they are completely seated.

Fig. 6A

From Reader

Board P5 to J5

J5

Gasket required

for exterior door

applications.

Inside of Door

Fig. 7A

J1

To ElectroLynx

Harness

J2

PCB Layout - Wire Assignments - ElectroLynx Assembly (Molex)

J2 J1

1-Violet Lock DC Neg

(Solenoid, neg)

2-Gray, Lock DC Pos

(Solenoid, pos)

3 - Pink

NOT USED

4-Tan

NOT USED

1- Black

PWR NEG

2-Red

PWR POS

3-White

Wiegand DATA 1

4-Green

Wiegand DATA 0

Step #8 – Outside Escutcheon and Wire Positioning

Please follow these steps prior to installing inside escutcheon

assembly to prevent any damage caused by pinching wires:

1. Align the ElectroLynx® connectors (8 and 4-pin) to one side of

the wire guide inside of the door prep. The reader connections

and excess wire are arranged on the other.

2. Connect the ElectroLynx® connectors (8 and 4-pin) and

establish their position inside of the door prep on

the proper side of the wire guide (Fig. 8A).

3. Neatly route the remaining wires onto themselves and into

the remaining space to prevent pinching wires when

mounting the escutcheon (Fig. 8B).

5-Orange

RX (N/O)

6-Blue

RX (COM)

Rotate Clockwise

7-Brown

EGND

8-Yellow

LED

Outside of Door

A8029A • 800-810-WIRE (9473) • www.sargentlock.com 15

Fig. 8A

Fig. 8B

Copyright © 2009 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

06/30/09

Step #9 – Connector Attachment

(Exterior PCB Assembly)

1. Connect P3 (2-pin connector) from lock body

to J3 on module (Fig. 9A).

2. Connect P4 (6-pin connector) from lock body

to J4 on module (Fig. 9A).

Harmony Series H2 8800 Exits

Body P3 to J3

Step #10 – Installation of Inside Escutcheon

1. Position inside gasket and escutcheon against door. Verify that no

wires are being pinched.

2. Mount inside escutcheon assembly to plate using (2) #8-32 x 5/8"

Phillips at head undercut machine screws.

From Lock

Fig. 9A

Inside of Door

J4 J3

From Lock

Body P4 to J4

(2) #8-32 x 5/8” Phillips

Flat Head Under-cut

Machine Screws

Copyright © 2009 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

06/30/09

Fig. 10A

A8029A • 800-810-WIRE (9473) • www.sargentlock.com16

Step #11 – Installation of Rail Assembly

1. Retrieve harness from end of rail. Harness has limited travel

and can be damaged.

2. Attach harness to female connector on chassis.

3. Install rail and screws per exit device instructions.

Note: This view shows rim exit device version

Fig. 11A

Step #12 - Concealed Door Position Switch (3287) Instructions

Use SARGENT 3287 Concealed Door Position Switch with this

Harmony H2 series product:

1. Install the 3287 Concealed Door Position Switch described in SARGENT

document A7448B.

2. Wire the 3287 Concealed Door Position Switch to the EAC door position Input.

3. Connect the common wire of the switch to the common input terminal of the EAC;

and the normally open wire of the switch to the normally open input

termnial of the EAC.

Lock is 12VDC.

Optional 24VDC

lock is available.

McKinney

QC12 Hinge

Wiegand Access

Control System

3287 Door

Position Switch

Harmony Series H2

(Others)

Fig. 12A

>> Continue to Section 9 for Wiring Diagrams to wire Device to EAC Panel. <<

A8029A • 800-810-WIRE (9473) • www.sargentlock.com 17

Copyright © 2009 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

06/30/09

Harmony Series H2 8900 Exits

8

Installation Instructions For Harmony Series H2 8900 Mortise Exit Device

Parts Breakdown

Left Hand Reverse Door Shown

Tools Required

• Phillips screw driver (standard size)

• Flat blade screw driver (standard)

5

6

6

6A

5

4

3

2

1

7

8

9

10

11

13

12

14

Copyright © 2009 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

06/30/09

15

16

A8029A • 800-810-WIRE (9473) • www.sargentlock.com18

Harmony Series H2 8900 Exits

Parts Breakdown For Harmony Series H2 8900 (Continued)

Shipment Contents

ITEM PART # Description Req.

1 52-4038 Outside Harmony Escutcheon Assembly 1

2 52-0792 Outside Harmony Gasket 1

3 52-0793 Inside Harmony Gasket 1

4 52-5219 Harmony Inside Escutcheon Mounting Plate 1

5 52-5236 Screw Pack (Escutcheon) 1

6 68-1581 Inside Harmony Escutcheon Assembly 1

6A 52-4036 H2 Controller Assembly 1

7 68-3905 Screw Pack (Rail and Chassis Cover) 1

8 68-0407 Chassis Cover 1

9 68-3922 Screw Pack (Chassis) 1

10 68-7253 8900 Chassis Assembly LHRB 1

68-5754 8900 Chassis Assembly RHRB 1

11 52-0263 ET Trim Gasket 1

12 *Harmony Trim is Ordered as "N1"

N1-773-ET 12V Fail Safe Without Cylinder 1

N1-773-ET 24V Fail Safe Without Cylinder

N1-774-ET 12V Fail Secure Without Cylinder

N1-774-ET 24V Fail Secure Without Cylinder

N1-773-ET 12V Fail Safe With Cylinder

N1-773-ET 24V Fail Safe With Cylinder

N1-774-ET 12V Fail Secure With Cylinder

N1-774-ET 24V Fail Secure With Cylinder

13 -- Reference Harmony Series Catalog for Available Cylinders 1

14 915 8900 Lock Body Assembly LHRB 1

915 8900 Lock Body Assembly RHRB

15 99-2628 Screw Pack (Mortise Lock) 1

16 99-0131TAB Strike Pack (Specify Bevel and Lip Length) 1

17 A8029 Instruction Sheet (not shown) 1

18 A7948 Field Prep Template (not shown) 1

19 4613 Manufacturer Template (not shown) 1

How to Specify ET Trim

How to order without an exit device.

Specify: 7 for 700 Series ET, Function, Sufx, Lever, Finish and handing (e.g., 775-8 ETL x 26D x RHRB).

Note: Sufx requirements are based on type of device to be used:

• -8 sufx is required for 8800, 8500, NB8700, PP, PR and SP8700 devices, except with these functions: 04, 10, 16, 40 and 44.

• -6 sufx is required for all PP, PR, SP, LP, LR and LS devices.

• -4 sufx is required for all 8400, WD, MD and AD 8600 devices.

• No sufx is necessary for all 8900, 8300, 8700 with bottom rod and 8800, 8500, NB8700, PP, PR & SP8700 devices

with these functions: 04, 10, 16, 40 and 44.

A8029A • 800-810-WIRE (9473) • www.sargentlock.com 19

Copyright © 2009 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

06/30/09

Harmony Series H2 8900 Exits

Step #1 – Door Preparation

A. Verify Hand and Bevel of Door

• Check hand of door. Exit Device may be handed.

• Door should be tted and hung.

• Verify box label for size of exit device, function and hand.

B. Door Preparation

Prepare door according to appropriate template. If necessary,

refer to website, www.intelligentopenings.com:

• Field prep template: A7948 (ships with product)

• Door manufacturer templates: 4613, 4290, and 4314.

Note: Instruction examples show wood door installation.

For metal doors, route cables inside door.

Left Hand

Reverse

LHR

Inside

Outside

Fig. 1A

Wood Door Shown

Right Hand

Reverse

RHR

Step #2 – Mortise Lock and Outside Exit Trim (ET) Installation

1. Slide mortise lock into pocket and securely fasten with (2) at head screws (Fig. 2A).

2. Route “ET” harness through wire cutout on inside of door.

3. For exterior applications, use gasket (52-0263)

to seal between ET escutcheon and

outside door surface (Fig. 2B Detail).

4. Place ET control on door with spindle

engaging the mortise lock.

Wire

ET

Copyright © 2009 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

Mortise

Fig. 1B

Fig. 2B Detail

Gasket

ET

06/30/09

Fig. 2A

(2) Flat Head Wood Screws

A8029A • 800-810-WIRE (9473) • www.sargentlock.com20

Harmony Series H2 8900 Exits

8900 Installation Instructions (Continued)

Step #3 – Cylinder Installation

For devices without cylinders, skip this section.

1. Back cylinder set screw out slightly (Fig. 3A).

2. Insert cylinder through “ET” control and thread into

mortise lock until cylinder is ush with “ET”.

Keyway must be vertical and SARGENT

Position Sargent Logo at top of cylinder (Fig. 3B).

3. Tighten cylinder set screw.

SARGENT

SARGENT

Correct Incorrect

Fig. 3B Detail

Step #4 – Chassis to Door Installation

1. Route ET wire harness along track cutout for wood doors

and access hole for metal doors (Fig. 4A).

2. Temporarily attach chassis to rail, then lock push rail down

using hex or cylinder key or by holding push rail in the

depressed position on 8900 exit device (Fig. 4B).

3. Position chassis and rail on door so that lever

arm is under rear section of mortise lock lever

then lift up until latch bolt is completely

retracted. With chassis in this position and

rail horizontal, mark location of chassis

mounting holes (Fig. 4C). Drill holes for screws.

4. Release push rail and disassemble chassis

from rail. Mount chassis on door.

Do not pinch harness wires.

5. Fasten exit chassis to door using

(4) #10 wood screws or #10-24 x 3/4”

machine screws.

6. Using (2) 1/4-20 x 2-3/8” at head screws,

attach “ET” to chassis.

Chassis

Depress arm into rail opening

and slide rail onto chassis.

Push Rail

Cylinder

Fig. 4A

Latchbolt

ET Control

Exit Chassis

Inside of Door

Fig. 3A

ElectroLynx Connectors

Wire Harness

(4) #10 Wood Screws

or #10-24 Machine Screws

Chassis

Cylinder Set Screw

(2) 1/4-20 x 2-3/8” Flat

Head Machine Screws

(to secure ET)

Lock Down Screw

Attach to chassis with (2) #8-32 x 3/8”

Phillips Truss Head Machine Screws

Rail Assembly

Fig. 4B

A8029A • 800-810-WIRE (9473) • www.sargentlock.com 21

Lever

Lever Arm

Fig. 4C

Copyright © 2009 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

06/30/09

Harmony Series H2 8900 Exits

Outside Gasket

Step #5 – Outside Escutcheon and Inside

Mounting Plate and Ground Wire Installation

1. Connect pin 5 green/yellow ground wire ring terminal to

top right screw (Fig. 5A and 5B).

1. Secure the mounting plate with (2) self-tapping screws (#8 x 1/2”).

2. Feed the reader cable connector located on the back of the outside

escutcheon from the outside of door through door.

3. Securely tighten the outside escutcheon with (2) through-bolts

(#8-32 x 2”) Phillips at head screws through the mounting plate.

Inside of Door

Fig. 5B

Step #6 – Install Gasket

Add Gasket (if necessary):

Remember the inside gasket must be used when installing in an

outdoor application.

Remove backing and place gasket on door (Fig. 6A).

Inside of Door

Fig. 5A

#8-32 x 2” Phillips

Flat Head Screws

#8 x 1/2” SelfTaping Screws

Gasket required

for exterior door

applications.

Step #7 – Connect ElectroLynx

1. Connect P5 (7 Pin Connector) from reader board

to J5 on interior escutcheon PCB assembly (Fig. 7A).

2. Connect ElectroLynx harness (4 and 8-pin) from door harness

to ElectroLynx harness on interior PCB assembly (Fig. 7A).

NOTES:

Neatly fold the wires onto themselves and into the remaining

space to prevent pinching wires when mounting escutcheon.

Do not tuck extra mortise lock body wires back inside the lock

body cylinder hole.

Connectors go on only one way.

Do not offset connector and be sure they are completely seated.

PCB Layout - Wire Assignments - ElectroLynx Assembly (Molex)

J2 J1

1-Violet Lock DC Neg

(Solenoid, neg)

Copyright © 2009 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

2-Gray, Lock DC Pos

(Solenoid, pos)

3 - Pink

NOT USED

4-Tan

NOT USED

1- Black

PWR GND

2-Red

PWR POS

3-White

Wiegand DATA 1

4-Green

Wiegand DATA 0

From Reader

Board P5 to J5

J5

5-Orange

RX (N/O)

6-Blue

RX (COM)

7-Brown

EGND

8-Yellow

LED

Fig. 6A

Fig. 7A

J1

To ElectroLynx

Harness

J2

06/30/09

A8029A • 800-810-WIRE (9473) • www.sargentlock.com22

Harmony Series H2 8900 Exits

Step #8 – Outside Escutcheon and Wire Positioning

Please follow these steps prior to installing inside escutcheon

assembly to prevent any damage caused by pinching wires:

1. Align the ElectroLynx® connectors (8 and 4-pin) to one side

of the wire guide inside of the door prep. The reader

connections and excess wire are arranged on the other.

2. Connect the ElectroLynx® connectors (8 and 4-pin) and

establish their position inside of the door prep on

the proper side of the wire guide (Fig. 8A).

3. Neatly route the remaining wires onto themselves and into

the remaining space to prevent pinching wires when

mounting the escutcheon (Fig.8B).

Outside of Door

Rotate Clockwise

Step #9 – Connector Attachment

(Exterior PCB Assembly)

1. Connect P3 (2-pin connector) from lock body

to J3 on module (Fig. 9A).

2. Connect P4 (6-pin connector) from lock body

to J4 on module (Fig. 9A).

Fig. 8A

From Lock

Body P3 to J3

Fig. 9A

J4 J3

Fig. 8B

From Lock

Body P4 to J4

A8029A • 800-810-WIRE (9473) • www.sargentlock.com 23

Copyright © 2009 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

06/30/09

Harmony Series H2 8900 Exits

Step #10 – Installation of Inside Escutcheon

1. Position inside gasket and escutcheon against door. Verify that no

wires are being pinched.

2. Mount inside escutcheon assembly to plate using (2) #8-32 x 5/8"

Phillips at head undercut machine screws.

Step #11 – Installation of Rail Assembly

1. Retrieve harness from end of rail. Harness has limited travel

and can be damaged.

2. Attach harness to female connector on chassis.

3. Install rail and screws per exit device instructions.

Note: This view shows rim exit device version

Inside of Door

Fig. 10A

(2) #8-32 x 5/8” Phillips

Flat Head Under-cut

Machine Screws

>> Continue to Section 9 for Wiring Diagrams to wire Device to EAC Panel. <<

Step #12 - Concealed Door Position Switch (3287) Instructions

Use SARGENT 3287 Concealed Door Position Switch with this

Harmony H2 series product:

1. Install the 3287 Concealed Door Position Switch described in SARGENT

document A7448B.

2. Wire the 3287 Concealed Door Position Switch to the EAC door position Input.

3. Connect the common wire of the switch to the common input terminal of the EAC;

and the normally open wire of the switch to the normally open input

termnial of the EAC.

Copyright © 2009 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

Fig. 11A

Lock is 12VDC.

Optional 24VDC

lock is available.

QC12 Hinge

McKinney

Wiegand Access

Control System

3287 Door

Position Switch

Harmony Series H2

(Others)

06/30/09

Fig. 12A

A8029A • 800-810-WIRE (9473) • www.sargentlock.com24

Harmony Series H2 Exit Devices

8

Wiring Diagrams

Product 8 PIN CONNECTOR 4 PIN CONNECTOR

1-Black 2-Red 3-White 4-Green 5-Orange 6-Blue 7-Brown 8-Yellow 9-Violet 10-Gray 11-Pink 12-Tan

ACCESS CONTROL DEVICES: Harmony H2 Exits, ElectroLynx wire Color / Function assignments

12/24VDC

(Reader)

SARGENT -

HARMONY

SERIES,

H2 Exits

NEG POS DATA_1 DATA_0 NO COM EGND REF.

*Diagrams on following pages

WIE-

GAND

WIE-

GAND

RX RX EGND LED 12 OR 24 VDC

*DIA-

GRAMS

(LOCK RELAY)

NEG POS N/A N/A

DPS

(NC)

DPS

(COM)

Reader LED Configuration

The Harmony Series reader can be congured for (3) modes of LED operation.

HID Programming cards are supported to congure the behavior for LED

color activity. Call 1-800-WIRE for details.

PIN 8 (Yellow – LED)

PIN 6 (Blue – RX COM)

PIN 4 (Green – Data 0)

PIN 2 (Red – Reader POS)

Mode 1:

• Red LED ‘ON’ when powered.

• Presenting a 13.56MHz credential causes LED to ‘FLICKER’

green and return to red state.

• Reference *Diagram #1 as a function of power

requirement (12VDC or 24VDC).

Note: LED wire is unconnected.

Mode 2:

• Green LED “ON” when powered.

• No Flicker after presenting valid 13.56MHz credential.

• Reference *Diagram #2 as a function of power

requirement (12VDC or 24VDC).

Note: LED wire must be connected to circuit GROUND of the

system’s power supply.

PIN 1 (Black – Reader NEG)

PIN 3 (White – Data 1)

PIN 5 (Orange – RX N/O)

PIN 7 (Brown)

PIN 4 (Not Used)

PIN 2 (Gray – Lock POS)

PIN 1 (Violet – Lock NEG)

PIN 3 (Not Used)

Mode 3:

• EAC Panel controls LED operation.

• Reference *Diagram #3 as a function of power requirement (12VDC or 24VDC).

Note: Control of LED is a function of the EAC panel equipment (ie. relay) to toggle between green and red.

Note: When LED wire is tied directly into EAC panel relay, no AC signals should be applied on wire or door reader

performance will be interfered (*Diagram #3).

A8029A • 800-810-WIRE (9473) • www.sargentlock.com 25

Copyright © 2009 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

06/30/09

Harmony Series H2 Exit Devices

Typical Harmony Exit Application Diagram (12/24VDC Lock)

DIAGRAM #1 – MODE 1: RED LED ‘ON’ WHEN POWERED

12/24VDC SYSTEM

• Reader Draw = 125mA

• 12VDC Solenoid Draw = 500mA

• 12VDC Total Current Draw = 625mA

• 24VDC Solenoid Draw = 250mA

• 24VDC Total Current Draw = 375mA

Black (Hot)

White (Neutral)

Green (Gnd)

H N G

12/24VDC

- +

DATA 1

DATA 0

RX (NO Option)

RX (COM)

DPS

DPS

Green (NC)

3287 Door

Position Switch

White (C)

H2 Harmony Exit

12 Conductor

ElectroLynx Harness

From McKinney

QC12 Electric Hinge

From McKinney

READER NEG - Black, 1

READER POS - Red, 2

DATA 1 - White, 3

DATA 0 - Green, 4

RX (NO) - Orange, 5

RX (COM) - Blue, 6

*EGND - Brown, 7

LED - Yellow, 8

LOCK NEG - Violet, 9

LOCK POS - Gray, 10

120 VAC

Input

Power Supply

(By Others)

Not Used

Harmony Series H2

Requires 12 or 24 VDC

Electronic Access

Control Panel

(By Others)

Use (NC) for Fail

Safe Operation

Lock Relay

(NO) Fail Secure

Operation

*IMPORTANT: Pin 7 must be tied to earth ground in the access control panel.

Failure to follow proper ESD safe grounding procedures could lead to equipment failure.

Copyright © 2009 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

06/30/09

A8029A • 800-810-WIRE (9473) • www.sargentlock.com26

Harmony Series H2 Exit Devices

Typical Harmony Exit Application Diagram (12/24VDC Lock)

DIAGRAM #2 – MODE 2: GREEN LED ‘ON’ WHEN POWERED

12/24VDC SYSTEM

• Reader Draw = 125mA

• 12VDC Solenoid Draw = 500mA

• 12VDC Total Current Draw = 625mA

• 24VDC Solenoid Draw = 250mA

• 24VDC Total Current Draw = 375mA

Green (NC)

3287 Door

Position Switch

White (C)

H2 Harmony Exit

12 Conductor

ElectroLynx Harness

From McKinney

QC12 Electric Hinge

From McKinney

READER NEG - Black, 1

READER POS - Red, 2

DATA 1 - White, 3

DATA 0 - Green, 4

RX (NO) - Orange, 5

RX (COM) - Blue, 6

*EGND - Brown, 7

LED - Yellow, 8

LOCK NEG - Violet, 9

LOCK POS - Gray, 10

DPS (NC) - Pink, 11

DPS (COM) - Tan, 12

120 VAC

Input

Power Supply

(By Others)

Black (Hot)

White (Neutral)

H N G

12/24VDC

- +

Green (Gnd)

DATA 1

DATA 0

RX (NO Option)

RX (COM)

DPS

DPS

Harmony Series H2

Requires 12 or 24 VDC

Electronic Access

Control Panel

(By Others)

Use (NC) for Fail

Safe Operation

Lock Relay

(NO) Fail Secure

Operation

A8029A • 800-810-WIRE (9473) • www.sargentlock.com 27

*IMPORTANT: Pin 7 must be tied to earth ground in the access control panel.

Failure to follow proper ESD safe grounding procedures could lead to equipment failure.

Copyright © 2009 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

06/30/09

Harmony Series H2 Exit Devices

Typical Harmony Exit Application Diagram (12/24VDC Lock)

DIAGRAM #3 – MODE 3: EAC PANEL CONFIGURABLE

12/24VDC SYSTEM

• Reader Draw = 125mA

• 12VDC Solenoid Draw = 500mA

• 12VDC Total Current Draw = 625mA

• 24VDC Solenoid Draw = 250mA

• 24VDC Total Current Draw = 375mA

Black (Hot)

White (Neutral)

Green (Gnd)

H N G

12/24DC

- +

Green (NC)

Position Switch

White (C)

3287 Door

12 Conductor

ElectroLynx Harness

From McKinney

120 VAC

Input

Power Supply

(By Others)

Harmony Series H2

Requires 12 or 24 VDC

H2 Harmony Exit

QC12 Electric Hinge

From McKinney

READER NEG - Black, 1

READER POS - Red, 2

DATA 1 - White, 3

DATA 0 - Green, 4

RX (NO) - Orange, 5

RX (COM) - Blue, 6

*EGND - Brown, 7

LED - Yellow, 8

LOCK NEG - Violet, 9

LOCK POS - Gray, 10

*IMPORTANT: Pin 7 must be tied to earth ground in the access control panel.

Failure to follow proper ESD safe grounding procedures could lead to equipment failure.

DATA 1

DATA 0

RX (NO Option)

RX (COM)

LED

DPS

DPS

Electronic Access

Control Panel

(By Others)

Use (NC) for Fail

Safe Operation

Lock Relay

(NO) Fail Secure

Operation

Copyright © 2009 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

06/30/09

A8029A • 800-810-WIRE (9473) • www.sargentlock.com28

10

Mechanical Operational Check

For devices without cylinders, go to step 3.

1. For devices with cylinders, insert key into cylinder and rotate.

2. The key will retract the latch and rods, the key should rotate freely.

3. Depress inside rail to retract latch and rods.

.

11

Electrical Operational Check

Note: Once electrical wiring has been successfully

completed according to proper application, follow the

following step:

1. Turn power ON.

2. Verify LED located on reader is ON - red or green,

depending on reader conguration (see reader

LED conguration).

3. Present credential and verify LED and

sounder activity.

4. Verify valid card read at EAC Panel.

5. Verify system operation functions; i.e., when

credential is presented to reader that the

door unlocks.

SARGENT

100 Sargent Drive

New Haven, CT 06511 USA

800-481-8464 • www.sargentlock.com

Founded in the early 1800s, SARGENT® is a market leader in locksets, cylinders, door closers, exit devices,

electro-mechanical products and access control systems for new construction, renovation, and replacement applications.

The company’s customer base includes commercial construction, institutional, and industrial markets.

Copyright © 2009, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproduction in whole or in part without the express written permission of Sargent Manufacturing Company is prohibited.

ASSA ABLOY is the global leader in door opening solutions, dedicated to

satisfying end-user needs for security, safety and convenience.

A8029A-06/30/09

Loading...

Loading...